display MITSUBISHI GALANT 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 300 of 1273

On-Vehicle Inspection of MFI

13-158FUEL SYSTEM (SOHC-16 VALVE> - Components

OPERATION

aThe throttle position sensor converts the throttle position opening into a voltage and inputs it to the

engine control module, which

then controls

the

fuel injection, based on the input signal.

l The

5V power in the engine control module is

supplied to the throttle position sensor. It flows

through the resistor in the sensor and is then

grounded in the engine control module.

lAs the throttle valve shaft rotates from the idle position to wide open position, the resistancebetween the variable resistor terminal of the

throttle position sensor and the ground terminal increases. As a result, the voltage at the throttle

position sensor variable resistance terminal also

increases.

INSPECTION

Using Scan Tool TROUBLESHOOTING HINTS

Hint 1: The throttle position sensor signal is more important in the control of automatic trans-

axle than in the engine control. Shifting

shock and other troubles will be caused if

this sensor is faulty.

Hint 2: If the output voltage of the throttle position

sensor is out of specification, adjust the

sensor and check the voltage again.

If there is an evidence of disturbed fixed SAS

setting, adjust the fixed SAS.

Function item No.Data displayCheck conditionThrottle valve Standard value

Data14Sensor Ignition

switch: ON At idle position 300 - 1000 mV

readingvoltage

Open slowlyIncreases with valve

opening

Open widely 4,500

- 5,500 mV

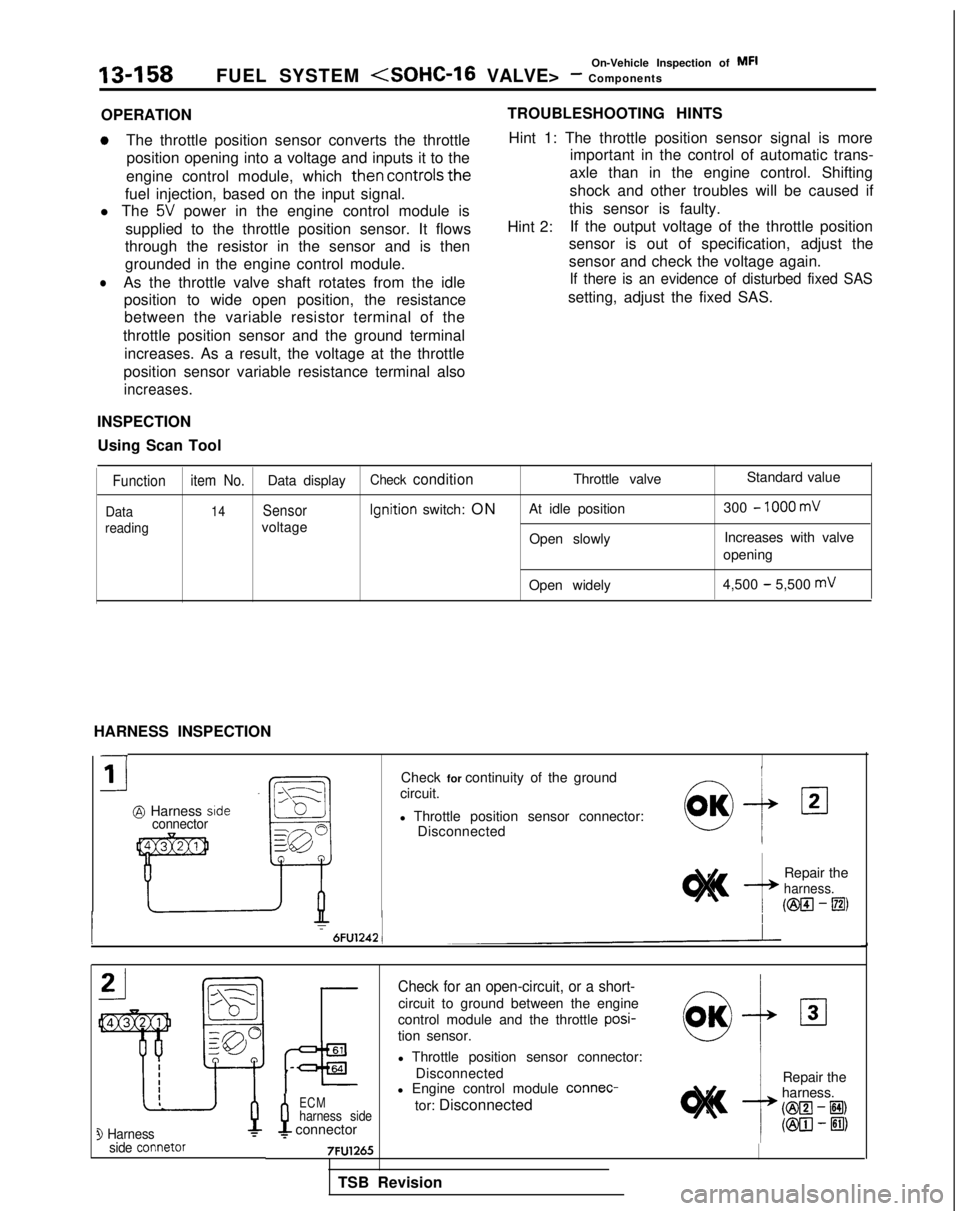

HARNESS INSPECTION

-

i1

@ Harness sideconnector

Check for continuity of the ground

circuit.

l Throttle position sensor connector: Disconnected

Repair the

harness.

(ml-m

3 Harnessside connetor

P

ECMharness sidef connector

Check for an open-circuit, or a short-

circuit to ground between the engine

control module and the throttle posi-

tion sensor.

l Throttle position sensor connector:

Disconnected

l Engine control module connec-

tor: Disconnected Repair the

harness. @El

- El)

(@III-ElII

TSB Revision

Page 305 of 1273

FUEL SYSTEM

INSPECTION

Using Scan Tool

Function

( Item No.

Data reading

/ 5

5

l-

+

L

Data display

IAC valve

position step

TCheck condition

l Engine coolant tem- perature: 85 to

95°C

(185 to 203’F)l Lights, electric cool- ing fan, accesso-

ries: OFF

l Transaxle: Neutral

(P range for A/T)

l Closed throttle posi-

tion switch: ON

l Engine: At idle

(Compressor clutch

to be operating in case air conditioning

switch is ON) Load state

Air conditioning switch:

OFF

Air conditioning switch:

Turn from OFF to ON l Air conditioning switch: OFF

l Selector lever: Shift to

D range

,,,,,,,,,I

Increase from 3-40 I

step

NfOTE

In a new vehicle [driven approximately 500 km (300 miles) or less], th\

e IAC valve position sometimes exceeds the

standard value by approximately 20 steps.

Caution

When shifting the selector lever to the

D range, apply brake to prevent the vehicle from moving forward.

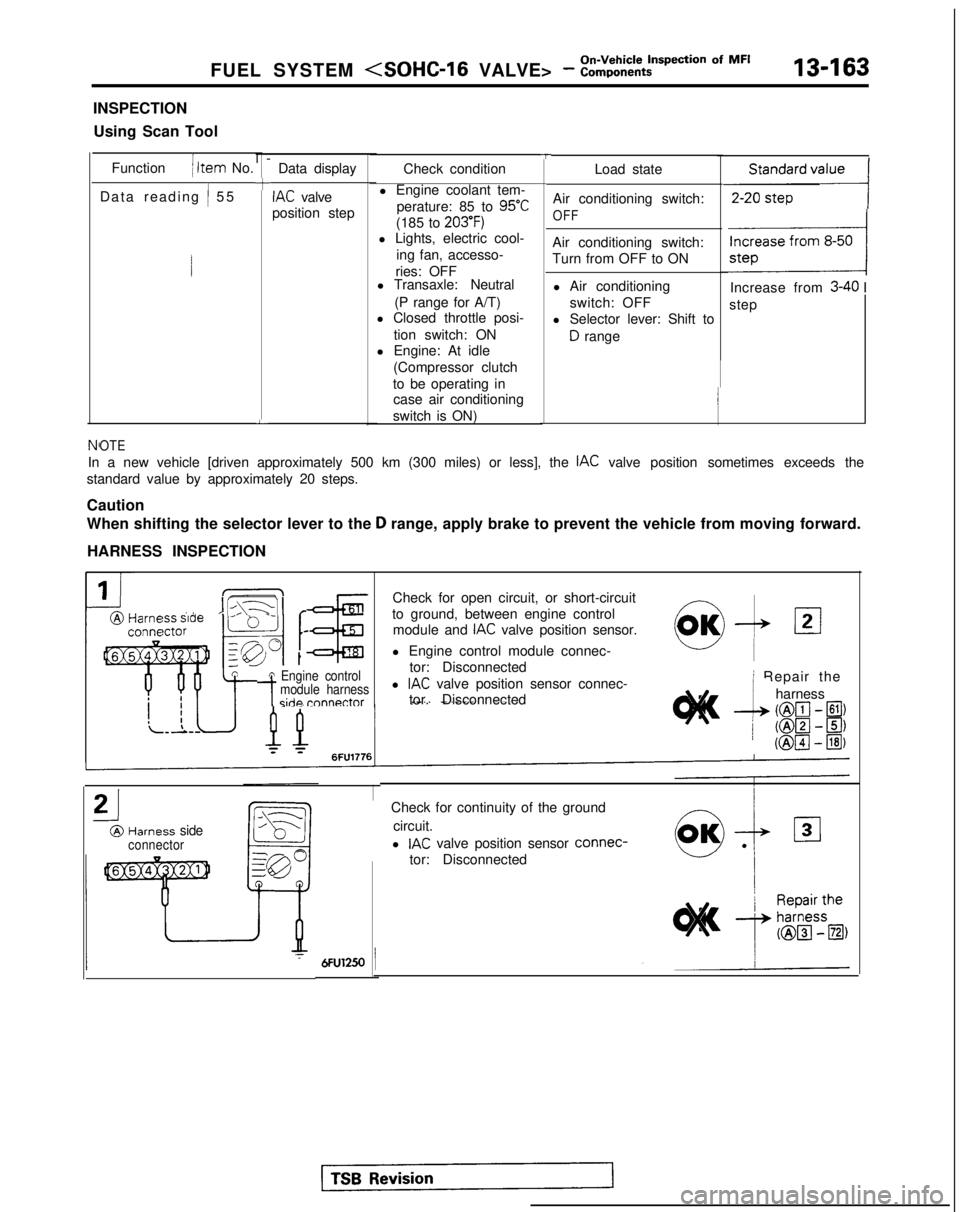

HARNESS INSPECTION

IIL\-11 r@Harm ” ’ -conna

tA Engine control

-tmodule harnessside rnnnnctor

Check for open circuit, or short-circuit

to ground, between engine control module and

IAC valve position sensor.

l Engine control module connec- tor: Disconnected

l

IAC valve position sensor connec-

tor. Disconnected

21

@Harness sideconnector

0,OK-& 121

i Repair the

--L

harness

(@lcl- El)

/ ml-~) (@pJ

- @I)

Check for continuity of the ground

circuit.

l

IAC valve position sensor connec-

tor: Disconnected

Page 311 of 1273

FUEL SYSTEM (SOHC-16 VALVE> - :::%%t:nspection Of MF’13-169

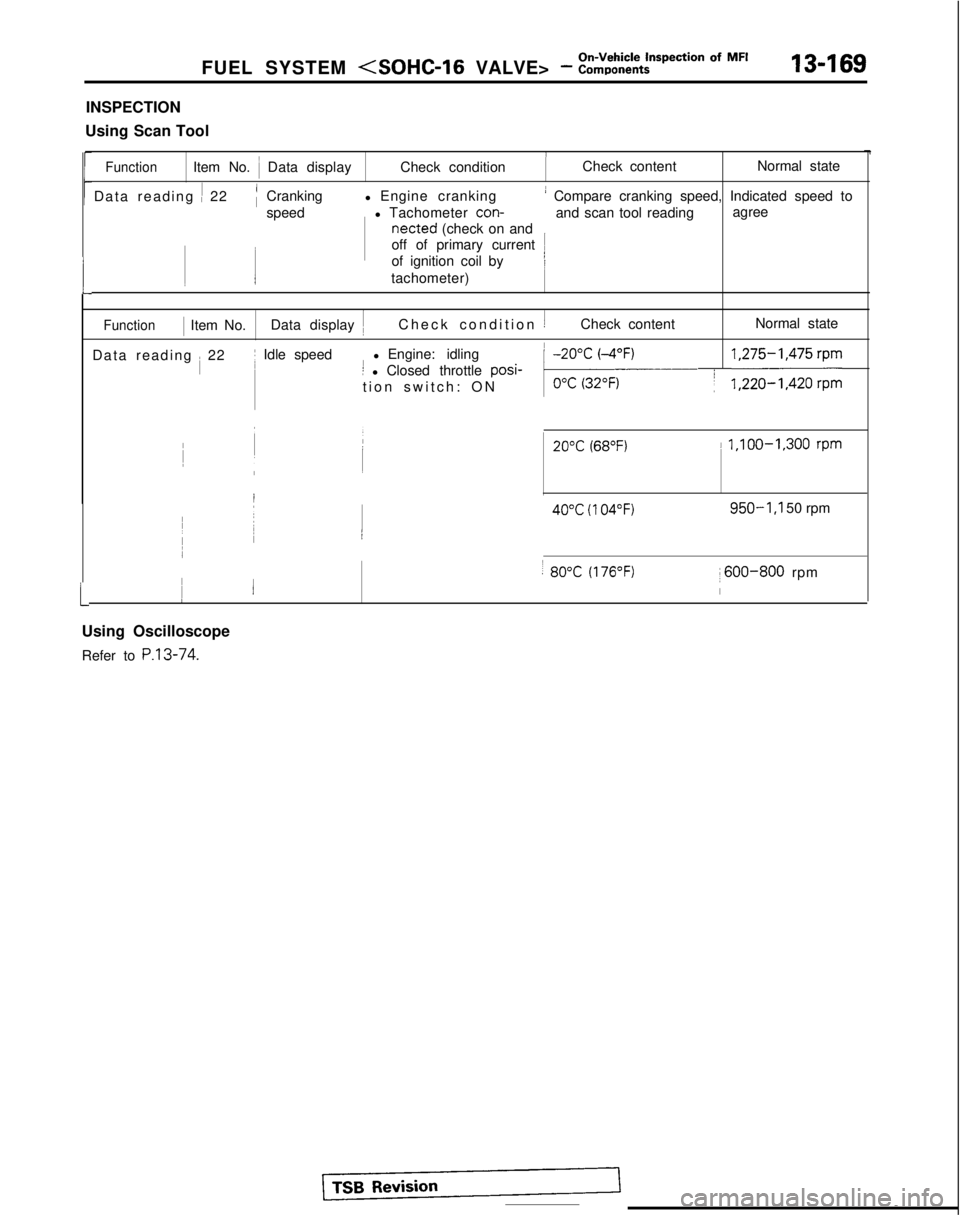

INSPECTION

Using Scan Tool

i

t

/FunctionItem No. i Data display Check condition Check content

Normal state

Data reading

) 22( Cranking l Engine cranking

speed l Tachometer con-’ Compare cranking speed, Indicated speed to

and scan tool reading agree

netted (check on and ~

I

off of primary current 1

of ignition coil by1

tachometer)

Function 1

Item No. Data display ICheck condition !Check content Normal state

Data reading

i 22 ~

Idle speed l Engine: idling! l Closed throttle posi-

tion switch: ONp i ;;:;;:::;;:;;;

20°C (68°F)1 l,lOO-1,300 rpm

40°C

(I

04°F)950-I ,I 50 rpm

: 80°C (176°F) ~

600-800 rpm

I

Using Oscilloscope

Refer to P.13-74.

Page 319 of 1273

On-Vehicle Inspection of MFI

FUEL SYSTEM (SOHC-16 VALVE> - Components13-177

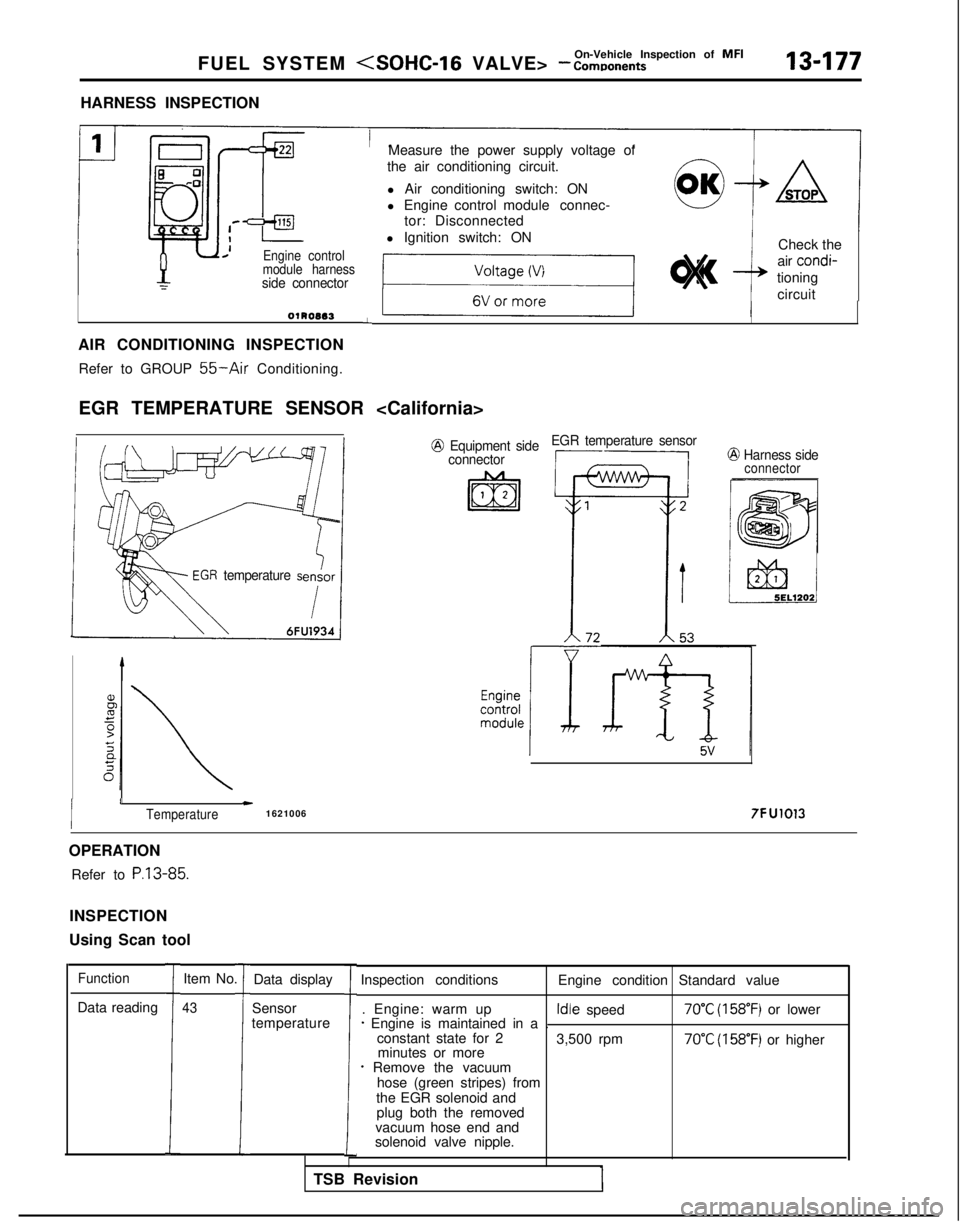

HARNESS INSPECTION

Y

Engine control

module harness

-;side connector

01noee3

AIR CONDITIONING INSPECTION

Refer to GROUP

55-Air Conditioning. Measure the power supply voltage of

the air conditioning circuit.

I

l Air conditioning switch: ON

l Engine control module connec- tor: Disconnected

l Ignition switch: ON

EGR TEMPERATURE SENSOR

GR temperature s

@ Equipment side connector

Check the

air condi-

tioning circuit

EGR temperature sensor71@ Harness sideconnector

i

I*Temperature16210067FU1013

OPERATION

Refer to P.13-85.

INSPECTION

Using Scan tool

Function

Data reading

I

Item No

43

I

Data display

Sensor

temperature

I

Inspection conditions Engine condition Standard value

. Engine: warm up

* Engine is maintained in a . Idle

speed 7o’C (158°F) or lower

constant state for 2 minutes or more 3,500 rpm

70°C (158°F) or higher

* Remove the vacuum

hose (green stripes) from

the EGR solenoid and plug both the removed

vacuum hose end and

solenoid valve nipple.

TSB Revision

Page 324 of 1273

13-182FUEL SYSTEM

INSPECTION

Using Scan Tool

Function1 Item

No. ’Data display 1Check conditionI Coolant temperature Standard value

IData reading / 41Drive trme

*’ 1Engine: Cranking0°C (32°F) *2Approx. 20 ms

j: 20°C (68°F)Approx. 40 ms 80°C

(176°F)/ Approx. 9.8 ms

Data reading

NOTE Item

No.

41 i

Data display 1

Check condition

IEngine state 1Standard value

Drive time

*3l Engine coolant temperature: 85 to

95°C (185 to 203°F)

l Lights, electric cooling fan, accesso-ries: OFF

l Transaxle: Neutral

(P range for AIT) Idle

speed

1 2.2-3.4 ms

*‘:The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

*2:When engine coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

*3:When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer

Function Item No

.

Drive content Check condition Normal state

Actuator test

01No. 1 injector shut off Engine: Idling afterI Idle state to change further

0

2

No. 2 injector shut off

- warm-up

(becoming less stable or

(Shut off the injectors in stalling)

03li No. 3 injector shut off sequence during after-engine warm-up, check1

I04No. 4 injector shut off

the idling condition)

-k

Imp

4 AL A: Inje,t,r--m--m-Normal waveformdrive time03*0209

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

1

TSB Revision 1

Using Oscilloscope

Page 328 of 1273

13-186On-Vehicle Inspection of MFI

FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

-Distributor(built inignition coiland Ignitionpower

transistor)

Equrpment srdeconnector8”

Engine control module connector Spark

plug

Iynitron coil ‘r ,

lgnitron switch (IG,)

Distributor/,@)f1

9 Harness side

connector

4

lgnrtion timingadjustment

connector

7FU0653

Engine control module 9FUOO35

OPERATION Refer to

P.13-96.

INSPECTION Using

Scan Tool

Function

/ Item No.

Data reading

i 44 Data display

iCheck condition jEngine state

Standard value_.-___-- -

-

Ignition

advance

l Engine: Warming up Idle speed

0- 13 “BTDC

l Timing light: Set (set

timing light to check

actual ignition timing)

/--

-

2,000 rpm 19-39 “BTDC

1 TSB Revision1

Page 397 of 1273

FUEL SYSTEM

COMPONENTS INSPECTION PROCEDURE-

Using Scan ToolMlsYsAGa

Refer to P.13-41.

POWER SUPPLY AND IGNITION SWITCH-IG

zT=f?Qjkeinjection relay

contrc! qcdule ,6A04,,-

----_OFF/ (IN

t5

’ i

4

-

‘OWE;uppl-

Ignition switch [IG,]

Component

side

connect<

763 66.----

1 6FU1331, )r

Ml3YcAB

Harness

@ side connector

01 LO838

OPERATION

l While the ignition switch is ON, battery power

supply is supplied to the engine control module,

injectors, volume air flow sensor, etc.

l When the ignition switch is switched ON, cur-

rent flows from the ignition switch, via the mul-

tiport

fuel injection relay coil to ground.

INSPECTION

Using Scan tool As a result, the

multiport fuel injection relay

switch is switched ON, and power is supplied,

by way of the multiport fuel injection relay

switch, from the battery to the engine control

module.

Function

Data reading Item No.

Data display Check conditionsStandard value

16

Engine control module power- Ignition switch: O

N

Battery positive voltage

supply voltage

TSB Revision I

Page 404 of 1273

13-262FUEL SYSTEM

INSPECTION

Using Scan tool

1 Data 12reading

L

Data displayInspection conditions

Sensor de-. Engine coolanttection airtemperature: 85-95°Cvolume (fre-(185-205°F)quency) .Lights, cooling fan, elec-trical accessories: OFF. Transaxle: neutral (PJTmodels: “P” range)

Engine condition

Idling

2,000 rpm

Racing

Standard value 25-50

Hz

60-90 Hz

Frequency increases as

racing rpm increases.

NOTEThe volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new

[driven approximately 500 km(300 miles) or less].

i

Regular waveform03AO203

HARNESS INSPECTION Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the osilloscope

pick-up point as

shown in the circuit diagram, and check the wave form.

Measure the terminal voltage.

. Connector: Disconnected

. Ignition switch: ON

connectorOlMaa

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Harness side

connectorthe multiport fueinjection relay.

TSB Revision

Page 406 of 1273

13-264FUEL SYSTEM

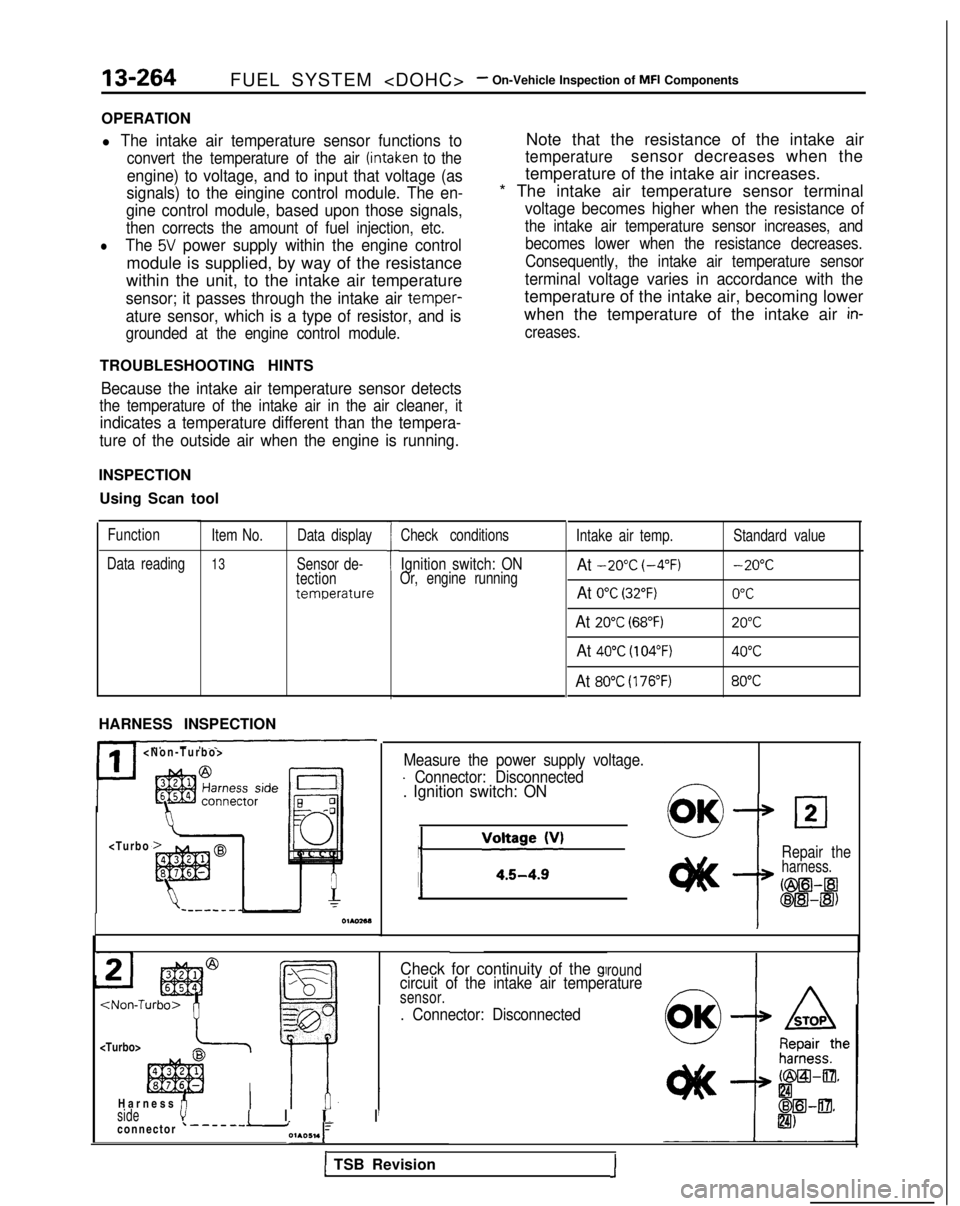

OPERATION

l The intake air temperature sensor functions to

convert the temperature of the air (intaken to the

engine) to voltage, and to input that voltage (as

signals) to the eingine control module. The en-

gine control module, based upon those signals,

then corrects the amount of fuel injection, etc.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the intake air temperature

sensor; it passes through the intake air temper-

ature sensor, which is a type of resistor, and is

grounded at the engine control module.

Note that the resistance of the intake air

temperaturesensor decreases when the

temperature of the intake air increases.

* The intake air temperature sensor terminal

voltage becomes higher when the resistance of

the intake air temperature sensor increases, and becomes lower when the resistance decreases.

Consequently, the intake air temperature sensor

terminal voltage varies in accordance with the

temperature of the intake air, becoming lower

when the temperature of the intake air

in-

creases.

TROUBLESHOOTING HINTS

Because the intake air temperature sensor detects

the temperature of the intake air in the air cleaner, it

indicates a temperature different than the tempera-

ture of the outside air when the engine is running.

INSPECTION

Using Scan tool

Function

Data reading Item No.

13

Data display

Sensor de-

tection

temperature

HARNESS INSPECTION

II

I

Check conditions

Ignition switch: ONOr, engine running

Intake air temp.At -20°C (-4°F)

At 0°C (32°F)

At 20°C (68°F)

At 40°C (104°F)

At 80°C (176°F)

Standard value -20°C

0°C

20°C

40°C

80°C

Measure the power supply voltage.

- Connector: Disconnected. Ignition switch: ON

j

/‘“:;~~~v’0OKLl2

Repair theharness.

Cm--a

oE!l-@)

Check for continuity of the glroundcircuit of the intake air temperaturesensor.

. Connector: Disconnected

I

sidevI I 1~ I

I

Harness fi

connector ‘-------i01A051.1

1 TSB Revision1

Page 408 of 1273

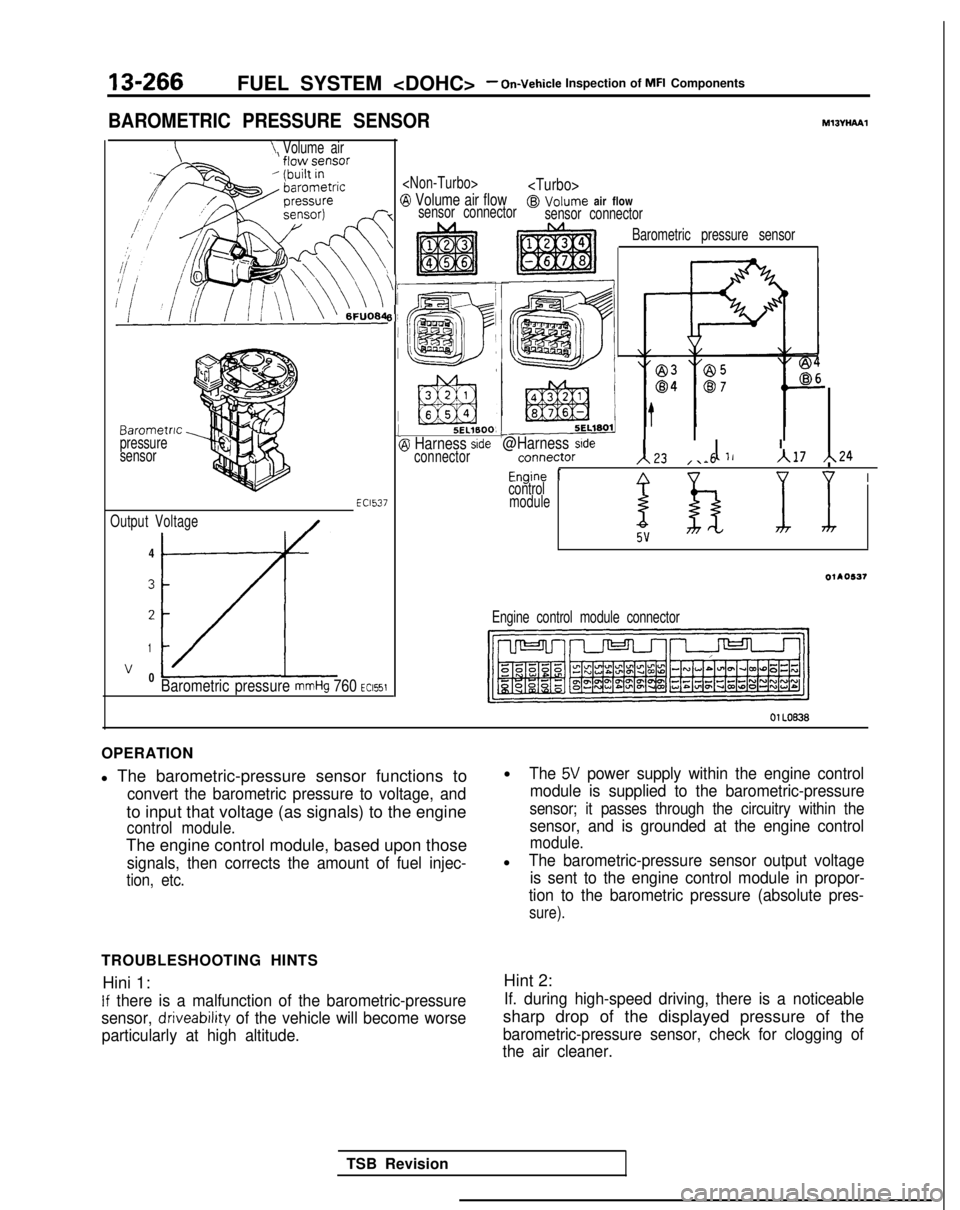

13-266FUEL SYSTEM

BAROMETRIC PRESSURE SENSORMl3VHPYPl

\ Volume air

Barometric

pressure

sensor

Output Voltage

/-4

3

2

1

v 0LzLBarometric pressure mmHg 760 ~~1551

EC1537

(

7

\

‘i

6!

I

I1(

5EL1600, L-@I Harness sideconnector@Harness sidernnn~rtnr131 11, I ’““, ,. Iv-.-.,\L4 ,\-5A17 h24

Fnnine 1Anv uI

Barometric pressure sensor

-“J -control

module

I

OllO537

Engine control module connector

01 LOB38

OPERATION

l The barometric-pressure sensor functions to

convert the barometric pressure to voltage, and

to input that voltage (as signals) to the engine

control module.

The engine control module, based upon those

signals, then corrects the amount of fuel injec-

tion, etc.

TROUBLESHOOTING HINTS Hini 1:

If there is a malfunction of the barometric-pressure

sensor,

driveability of the vehicle will become worse

particularly at high altitude.

lThe 5V power supply within the engine control

module is supplied to the barometric-pressure

sensor; it passes through the circuitry within the

sensor, and is grounded at the engine control

module.

lThe barometric-pressure sensor output voltage is sent to the engine control module in propor-

tion to the barometric pressure (absolute pres-

sure).

Hint 2:

If. during high-speed driving, there is a noticeable

sharp drop of the displayed pressure of the

barometric-pressure sensor, check for clogging of

the air cleaner.

TSB Revision