display MITSUBISHI GALANT 1989 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 409 of 1273

FUEL SYSTEM

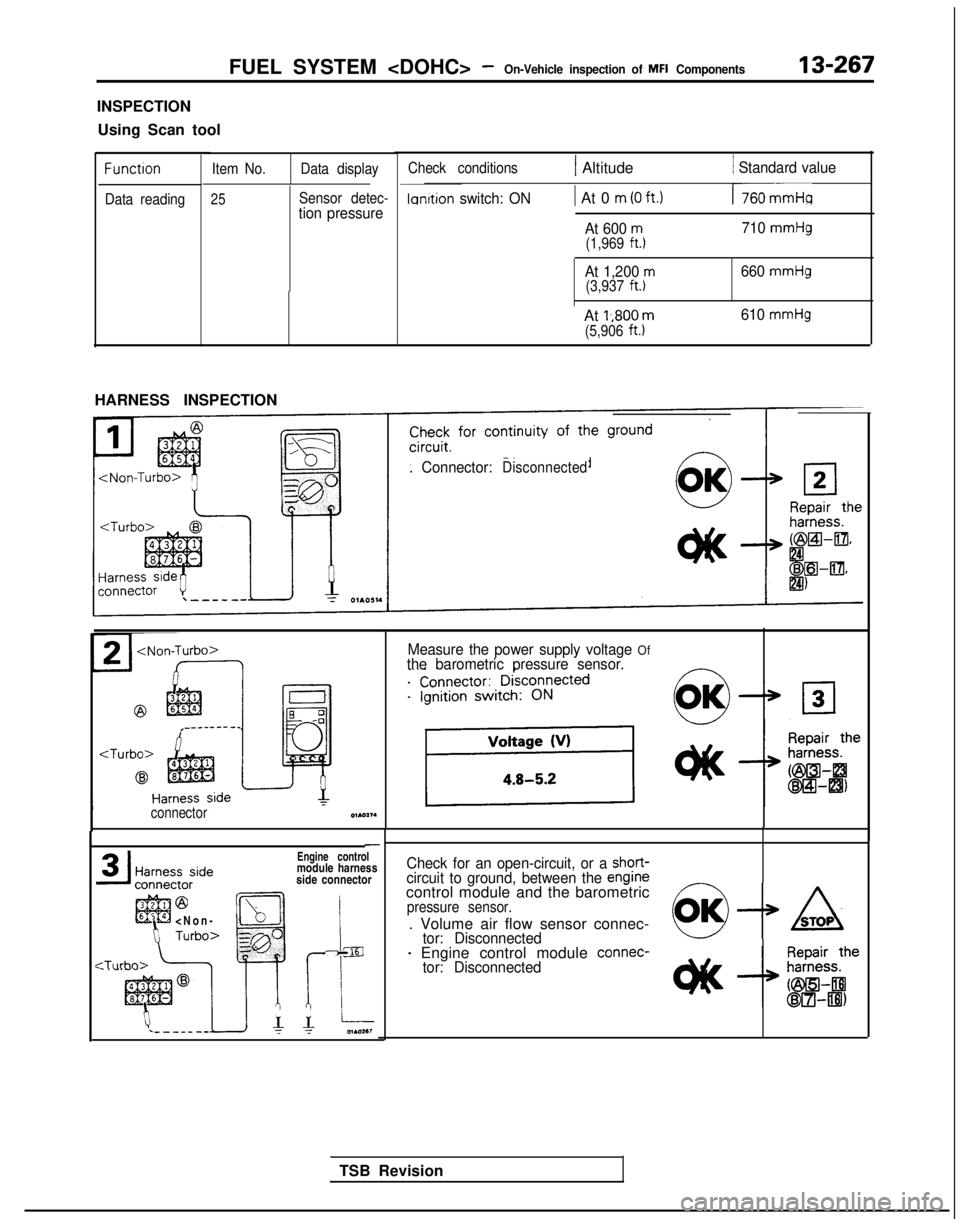

INSPECTION

Using Scan tool

Function Item No.

Data display

Data reading

25Sensor detec-tion pressure

HARNESS INSPECTION

Check conditions1 Altitude1 Standard value

lanltion switch: ON1 At 0 m (0 ft.)LrnmmHq

At 600 m(1,969 ft.)710 mmHg

At 1,200 m660 mmHg(3,937 ft.)

At I:800

m610 mmHg

(5,906 ft.)

. Connector:Disconnected

Measure the power supply voltage Ofthe barometric pressure sensor.

connector

TSB Revision

-Engine controlmodule harness

side connector

6%

Check for an open-circuit, or a shqrt-circuit to ground, between the enginecontrol module and the barometricpressure sensor.

. Volume air flow sensor connec-tor: Disconnected@--/LA

- Engine control module connec-tor: Disconnected

Page 411 of 1273

1 V-L “IVILI.,. ““I ,“Ivn-ven,c,e lnsprcrlorl 91

l”lb-l b”mp”nerlrrI” L””

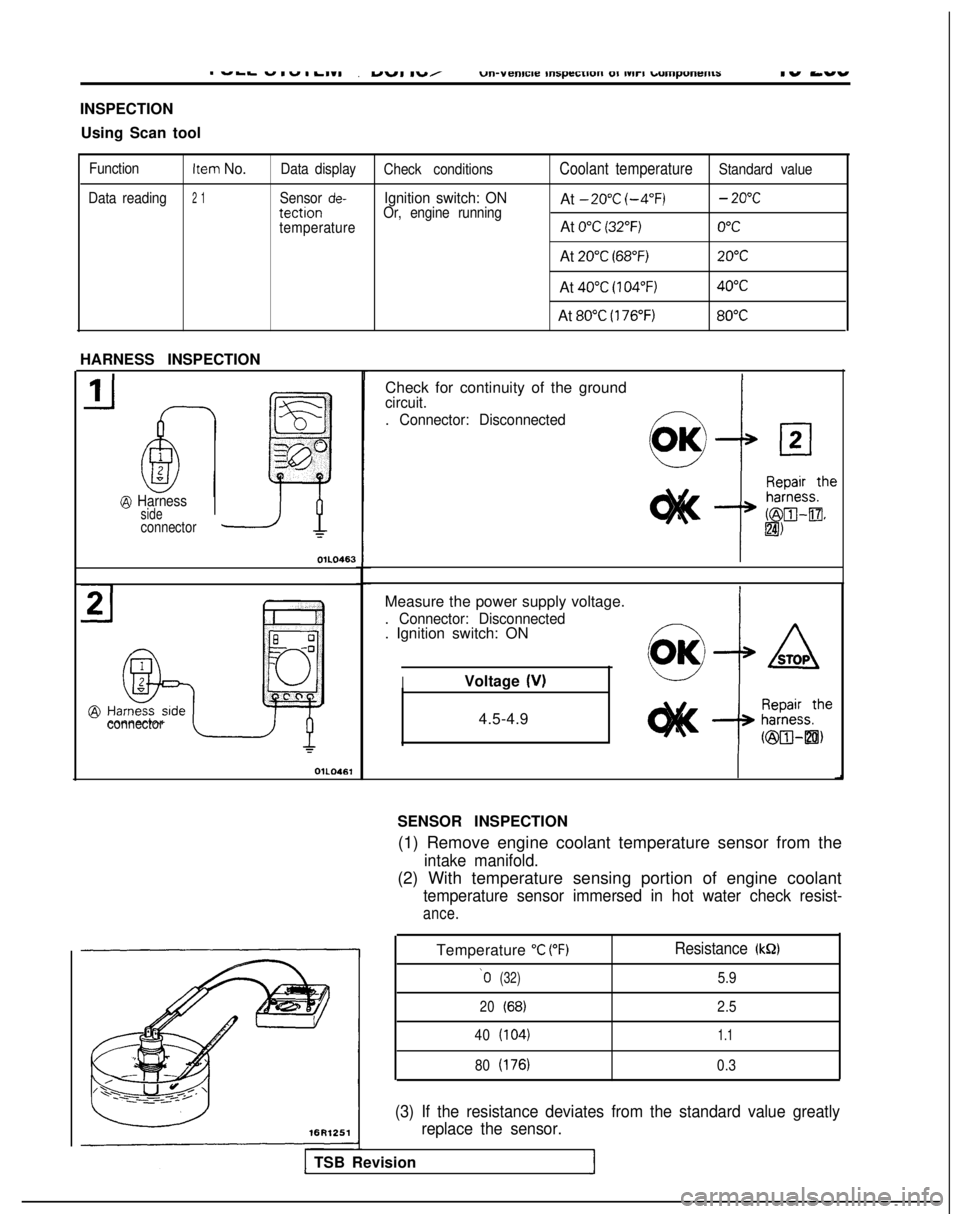

INSPECTION

Using Scan tool

FunctionItem No.Data display Check conditionsCoolant temperatureStandard value

Data reading

2 1Sensor de-Ignition switch: ONAt -20°C

(-4°F)- 20°CtectionOr, engine running

temperatureAt 0°C (32°F)0°C

At 20°C (68°F)20°C

At 40°C (104°F)40°C

At 80°C (176°F)80°C

HARNESS INSPECTION

@ Harnesssideconnector

OlL0463

connector

OlL0461

Check for continuity of the groundcircuit.

. Connector: Disconnected

Measure the power supply voltage.

. Connector: Disconnected. Ignition switch: ON

IVoltage (V)

4.5-4.9

SENSOR INSPECTION (1) Remove engine coolant temperature sensor from the

intake manifold.

(2) With temperature sensing portion of engine coolant

temperature sensor immersed in hot water check resist-

ance.

Temperature “C V’F)Resistance (kQ)

‘0(32)5.9

20(68)2.5

40

(104)1.1

80(176)0.3

(3) If the resistance deviates from the standard value greatly replace the sensor.

TSB Revision

Page 413 of 1273

FUEL SYSTEM

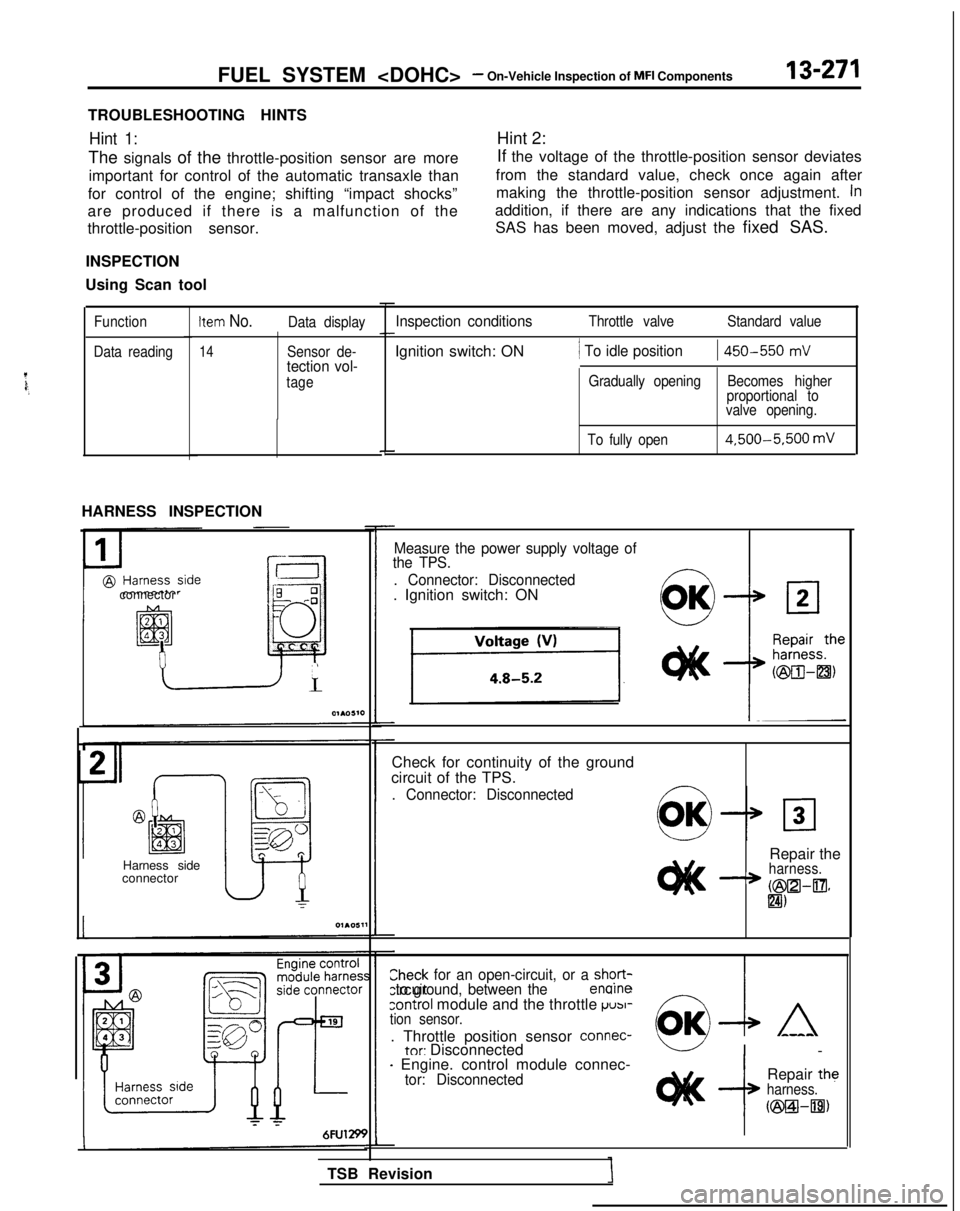

TROUBLESHOOTING HINTS

Hint 1:

The signals of the throttle-position sensor are more

important for control of the automatic transaxle than

for control of the engine; shifting “impact shocks”

are produced if there is a malfunction of the

throttle-position sensor.

INSPECTION

Using Scan tool Hint 2:

If the voltage of the throttle-position sensor deviates

from the standard value, check once again after making the throttle-position sensor adjustment.

in

addition, if there are any indications that the fixedSAS has been moved, adjust the fixed SAS.

Function

Data readingItem No.Data display

14Sensor de-tection vol-

tage

HARNESS INSPECTION

connector

Harness side

connector

Inspection conditionsThrottle valve Standard value

Ignition switch: ON/ To idle position1 450-550

mV

Gradually opening Becomes higher

proportional to

valve opening.

To fully open 4,500-5,500

mV

Measure the power supply voltage of

the TPS.

. Connector: Disconnected

. Ignition switch: ON

Check for continuity of the ground

circuit of the TPS.

. Connector: Disconnected

Repair theharness.

+ K25xz.l-~~IZI)

LZheck for an open-circuit, or a shqrt-Yrcuit to ground, between the er-.--control module and the throttle ~USI-tion sensor.

. Throttle position sensor connec-tnr: Disconnected I

-

- Engine. control module connec-tor: DisconnectedRepair theharness.

u23Bl-m)

TSB Revision

Page 417 of 1273

FUEL SYSTEM

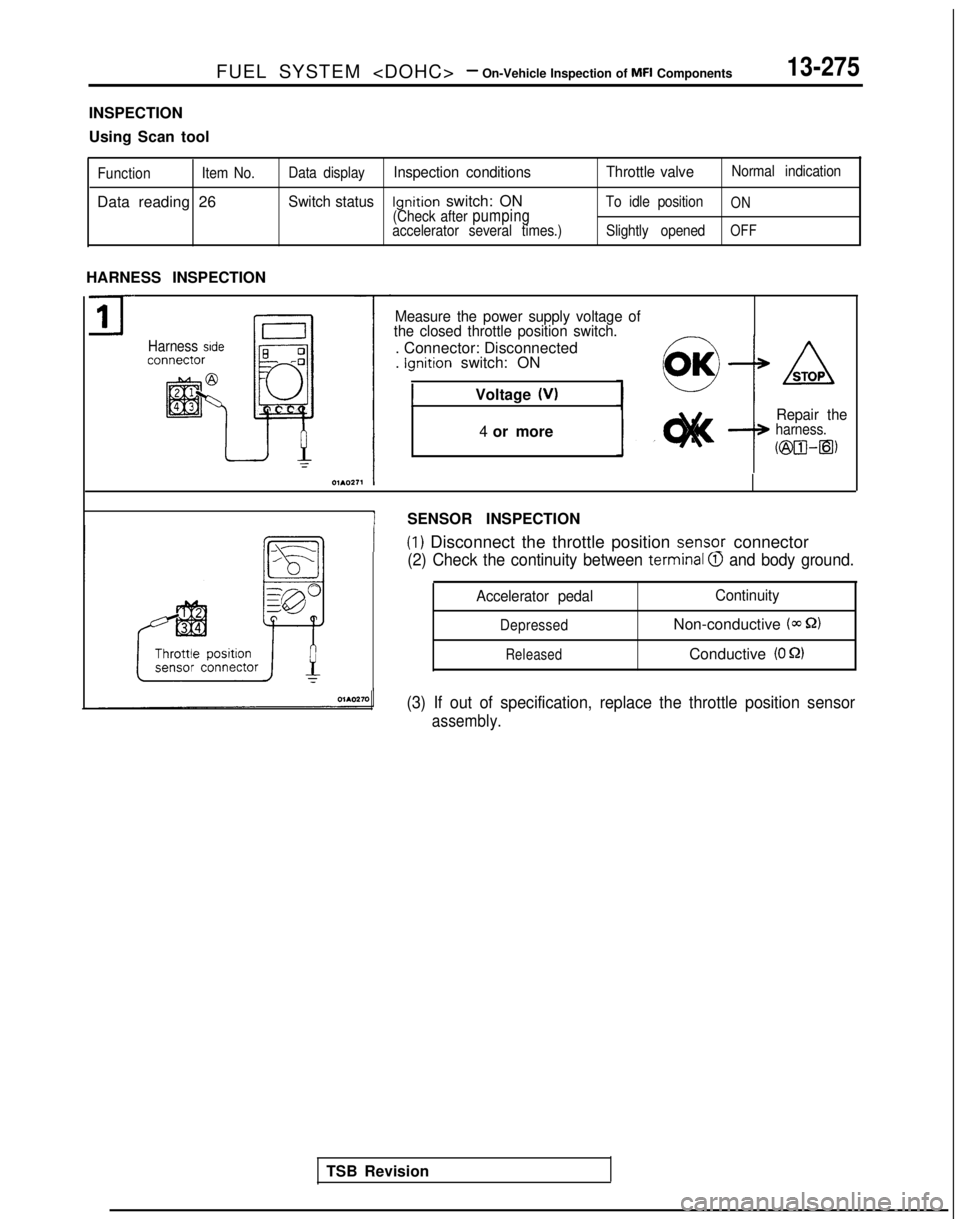

INSPECTION

Using Scan tool

Function

Item No.

Data reading 26

Data displayInspection conditions Throttle valveNormal indication

Switch statusIgnition switch: ONTo idle positionON(Check after pumpingaccelerator several times.)

Slightly openedOFF

HARNESS INSPECTION

71

-

Harness side

Measure the power supply voltage of

the closed throttle position switch.

-. Connector: Disconnected

. Ignition switch: ON

1Voltage (VI

4 or more

ASTOP

Repair theharness.

~@a-Q)

ISENSOR INSPECTION

I(1) Disconnect the throttle position senso_r connector

(2) Check the continuity between terminal QI and body ground.

TSB Revision

Accelerator pedal Continuity

DepressedNon-conductive (m S2)

ReleasedConductive (0 52)

(3) If out of specification, replace the throttle position sensor

assembly.

Page 428 of 1273

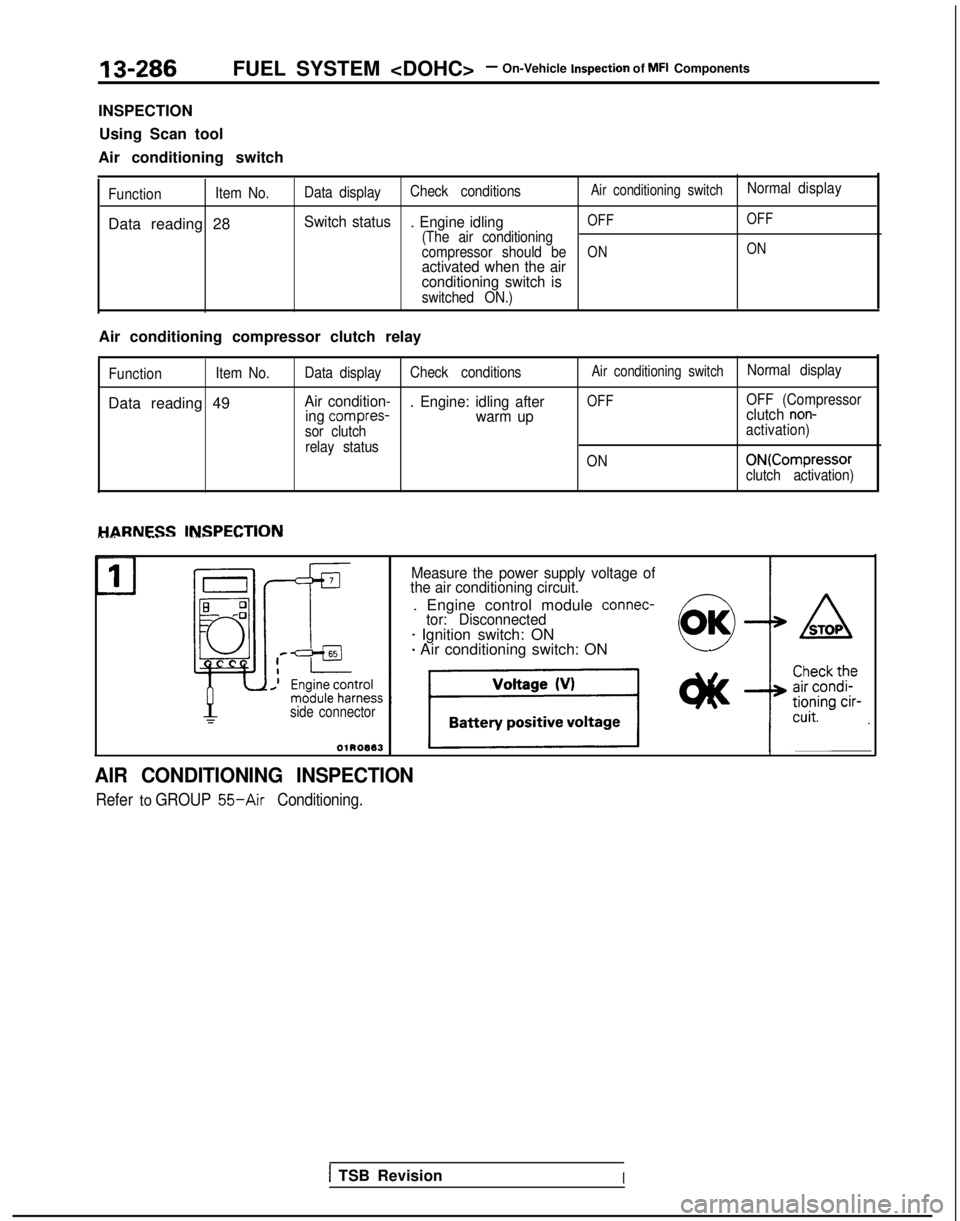

13-286FUEL SYSTEM

INSPECTION Using Scan tool

Air conditioning switch

Function Item No.

Data reading 28

Data displayCheck conditionsAir conditioning switchNormal

display

Switch status

. Engine idlingOFF OFF

(The air conditioning

compressor should beONONactivated when the air

conditioning switch is

switched ON.)

Air conditioning compressor clutch relay

Function

Item No.

Data reading 49

Data display

Check conditionsAir conditioning switchNormal display

Air condition-

. Engine: idling afterOFFOFF (Compressor

ing compres-warm up clutch non-

sor clutch

activation)

relay status ON

ONKompressorclutch activation)

HARNESS INSPECTION________ --- -__-. -- ~~-

Measure the power supply voltage of

the air conditioning circuit.

. Engine control module connec-tor: Disconnected- Ignition switch: ON+ Air conditioning switch: ON

side connector

AIR CONDITIONING INSPECTION

Refer to GROUP 55-Air Conditioning.

1 TSB RevisionI

Page 431 of 1273

FUEL SYSTEM

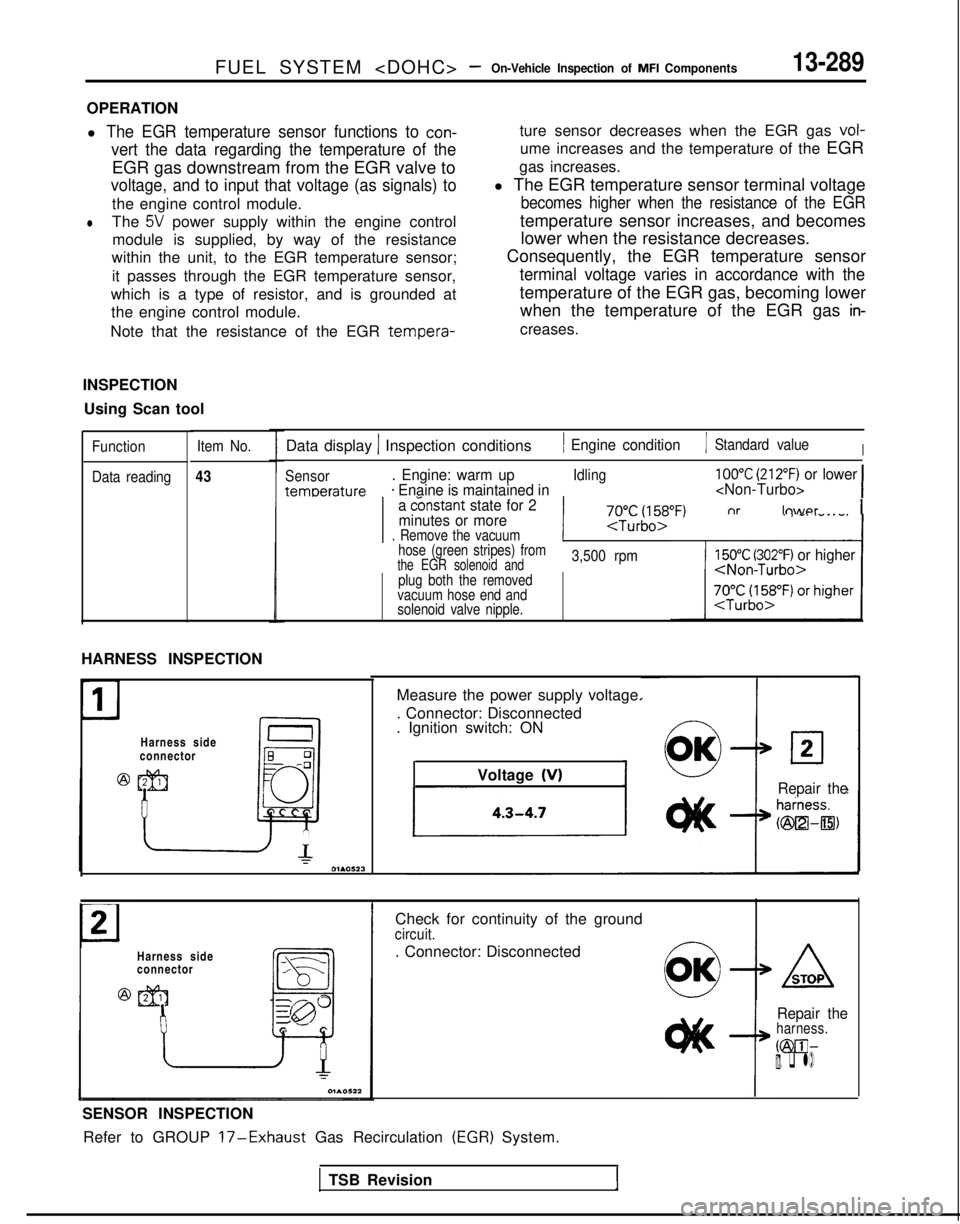

OPERATION

l The EGR temperature sensor functions to con-

vert the data regarding the temperature of the

EGR gas downstream from the EGR valve to

voltage, and to input that voltage (as signals) to

the engine control module.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the EGR temperature sensor;

it passes through the EGR temperature sensor,

which is a type of resistor, and is grounded at the engine control module.

Note that the resistance of the EGR tempera-

ture sensor decreases when the EGR gas vol-

ume increases and the temperature of the EGR

gas increases.

l The EGR temperature sensor terminal voltage

becomes higher when the resistance of the EGR

temperature sensor increases, and becomes lower when the resistance decreases.

Consequently, the EGR temperature sensor

terminal voltage varies in accordance with the

temperature of the EGR gas, becoming lower when the temperature of the EGR gas

in-

creases.

INSPECTION Using Scan tool

Function Item No.

Data reading

43

Data display 1 Inspection conditions1 Engine condition1 Standard valueI

Sensor. Engine: warm upIdling100°C (212°F) or lower

temoerature* Enaine is maintained in

minutes or more

. Remove the vacuum

11 7J$lfifiF~ nr lower 1

hose (green stripes) fromthe EGR solenoid and3,500 rpm150°C (302°F) or higher/hlnn-Turbo>plug both the removed

vacuum hose end and

solenoid valve nipple.

HARNESS INSPECTION

Harness side

connector Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Voltage

(V)Repair the

Harness side

connector Check for continuity of the ground

circuit.

. Connector: Disconnected

SENSOR INSPECTION Refer to GROUP

l7-Exhaust Gas Recirculation (EGR) System.

Repair theharness.

@El-IIll. q l)

TSB Revision

Page 433 of 1273

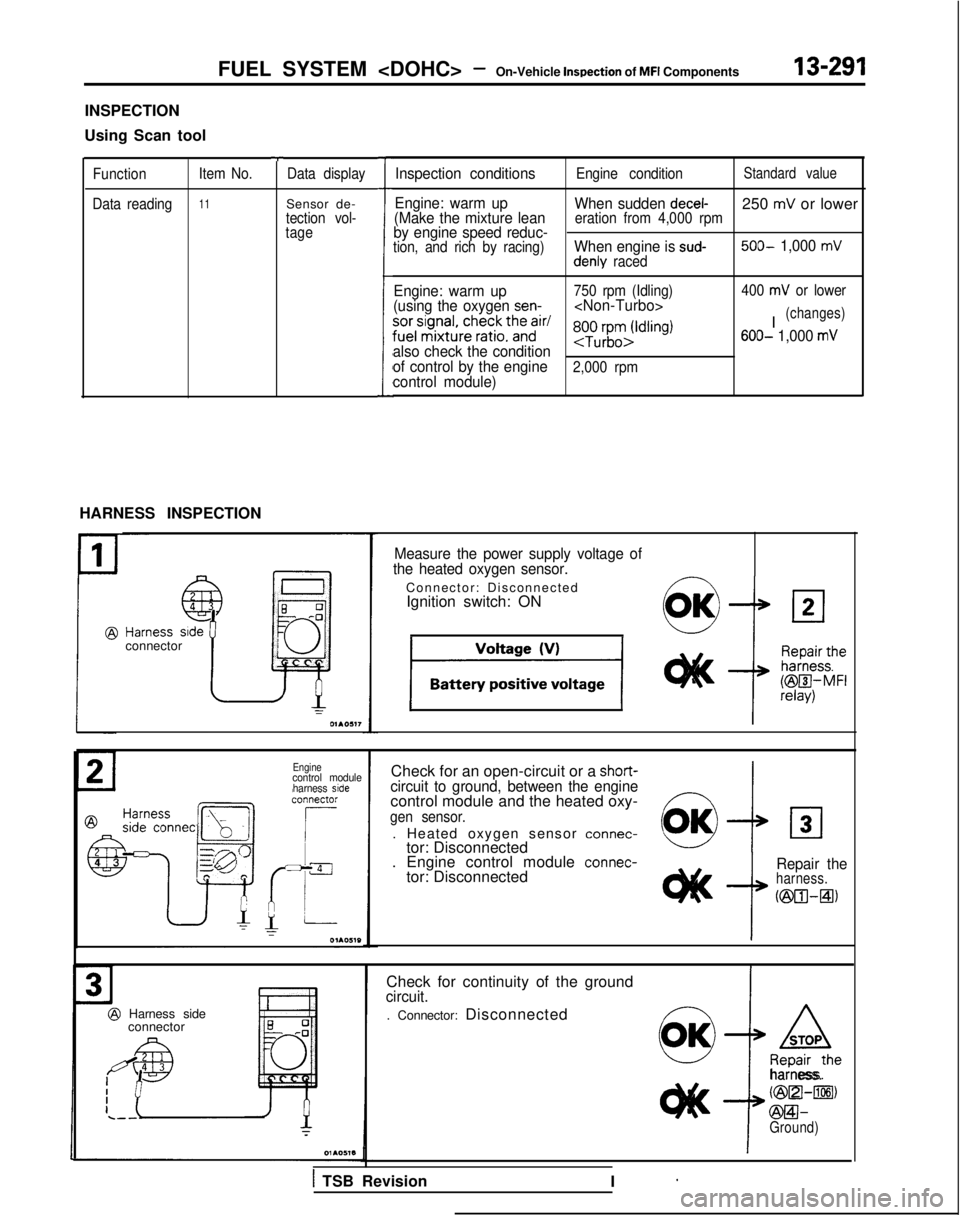

FUEL SYSTEM

INSPECTION

Using Scan tool

Function

Data reading Item No.

11

HARNESS INSPECTION

T

Data display

Sensor de-tection vol-

tage

L

Inspection conditionsEngine conditionStandard value

Engine: warm up When sudden decel-250 mV or lower(Make the mixture leaneration from 4,000 rpmby engine speed reduc-tion, and rich by racing)When engine is sud- 500- 1,000 mVdenly raced

Engine: warm up750 rpm (Idling)(using the oxygen sen-

~~~,s~~~r~hr~~i~t~~~ir’ 6JO;K~~ldling)

also check the condition

of control by the engine

2,000 rpmcontrol module)

400 mV or lower

I(changes) 600-

1,000 mV

connector

Enginecontrol module

harness side

@ ZTE-mector -La

@ El

4 3

-l

g;

@ Harness side

connector

Measure the power supply voltage of

the heated oxygen sensor.

Connector: Disconnected Ignition switch: ON

I II

Check for an open-circuit or a short-circuit to ground, between the enginecontrol module and the heated oxy-gen sensor.

. Heated oxygen sensor connec-

tor: Disconnected103

. Engine control module connec-tor: Disconnected

i

Repair theharness.

Nzm+l)

Check for continuity of the groundcircuit.

. Connector: Disconnected

@fR&eharness.

t

C@rzI-m,

@El-Ground)

1 TSB Revision I ’

Page 438 of 1273

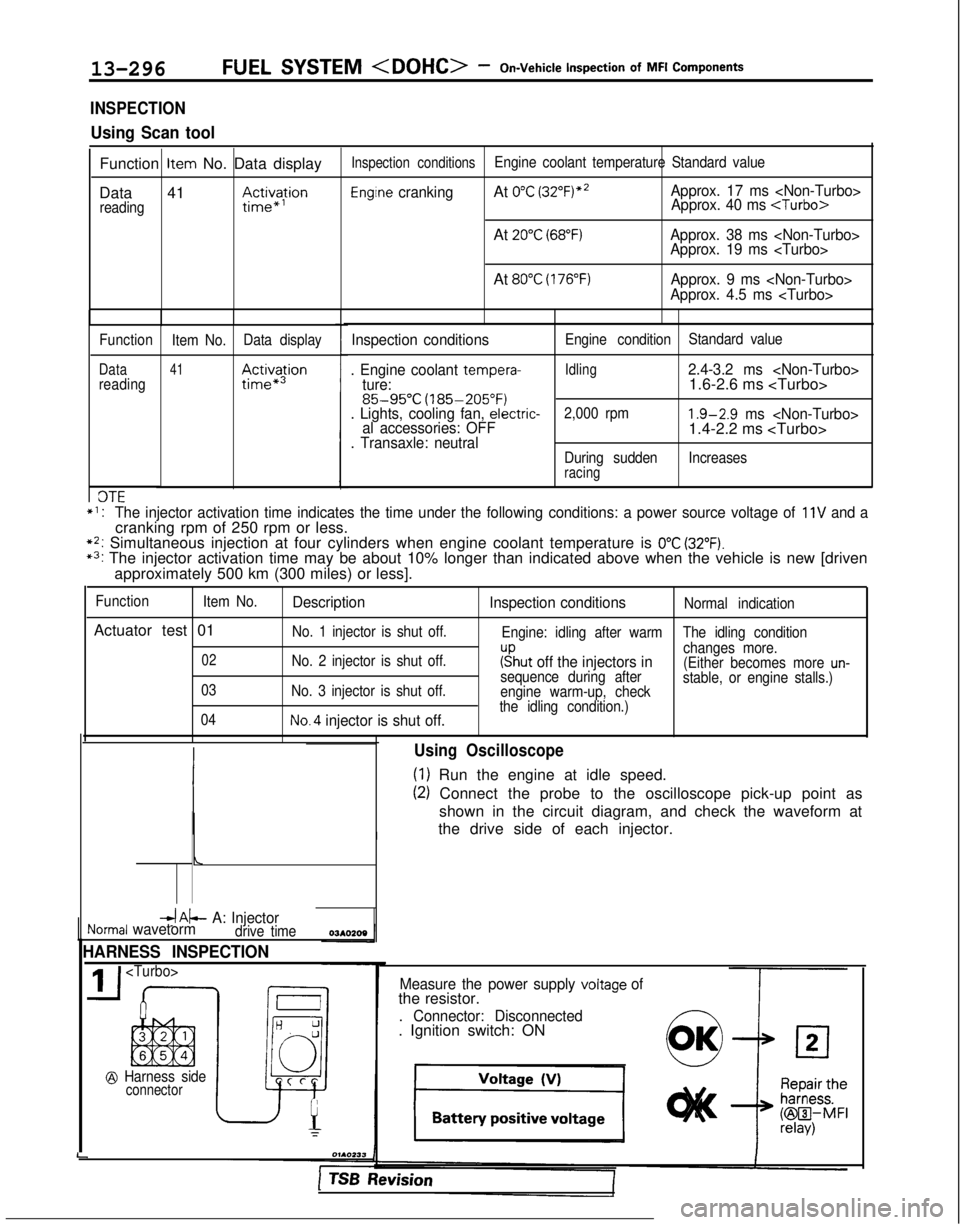

13-296FUEL SYSTEM

Inspection

of

MFI

Components

INSPECTION

Using Scan tool

Function Item No. Data displayInspection conditionsEngine coolant temperature Standard value1

Data 41;ctJ$onEngine crankingAt 0°C (32”F)*2Approx. 17 ms

readingApprox. 40 ms

At 20°C (68°F)Approx. 38 ms

Approx. 19 ms

At 80°C (176°F)Approx. 9 ms

Approx. 4.5 ms

Function

Datareading

3TE Item No.

41

Data display

$ctX$on

Inspection conditionsEngine condition

Standard value

. Engine coolant tempera-Idling2.4-3.2 ms

ture:1.6-2.6 ms

(185-205°F)

. Lights, cooling fan, electric- 2,000 rpm1.9-2.9

ms

al accessories: OFF1.4-2.2 ms

+l:The injector activation time indicates the time under the following cond\

itions: a power source voltage of 11V and acranking rpm of 250 rpm or less.*2: Simultaneous injection at four cylinders when engine coolant temperatur\

e is 0°C (32°F).*3: The injector activation time may be about 10% longer than indicated abo\

ve when the vehicle is new [driven

approximately 500 km (300 miles) or less].

Function Item No.Description Inspection conditionsNormal indication

Actuator test 01No. 1 injector is shut off.

Engine: idling after warmThe idling condition

02No. 2 injector is shut off.?!hut off the injectors inchanges more.

(Either becomes more un-

03

No. 3 injector is shut off.

04

No.4 injector is shut off.

sequence during after

engine warm-up, check

the idling condition.) stable, or engine stalls.)

,d&- A: InjectorNormal wavetormdrive time

HARNESS INSPECTION

@ Harness sideconnector

I

L

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

Measure the power supply voltage ofthe resistor.

. Connector: Disconnected. Ignition switch: ON

1 TSB hevision

Page 441 of 1273

FUEL SYSTEM

MFI Components13-299

OPERATION

l The amount of air taken in during idling is

regulated by the opening and closing of the

servo valve located in the air passage that

bypasses the throttle valve.

l The servo valve is opened or closed by the

activation of the stepper motor (incorporated

within the idle air control motor) in the forward

or reverse direction.

TROUBLESHOOTING HINTS

Hint 1: If the number of stepper motor steps increases to

IOO- 120 steps or decreases

to 0 step, the cause may be presumed to be a malfunction of the stepper motor or

damaged or disconnected wiring of the

harness.

Hint 2: If the number of stepper motor steps

deviates from the standard value even

though the results of the checking of the

harness of the idle air control motor and of

the comoonent

itself indicate no abnormal

condition, the cause may be presumed to be one of the following.

INSPECTION

Using Scan tool

lBattery power supply is supplied, by way of the

multiport fuel injection relay, to the coil of the

stepper motor. The engine control module

switches ON the power transistors (located

within the engine control module) in sequential

order, and, when current flows to the stepper motor coil, the stepper motor is activated in the

forward or reverse direction.

(1) Improper adjustment of the standard

idling speed.

(2) Deposits adhered to the throttle valve.

(3) Leakage of air into the intake manifold

from a gasket gap, etc.

(4) Incomplete close contact of the EGRvalve seat.

(5) Incomplete combustion within the

cylinder.

(Malfunction of the spark plugs, the

ignition coil, the iniectors,

the

com- pression

pressure, etc.)

FunctionItem No.Data display Check conditions Load conditionsStandard value

Data reading 45Steppermotor steps. Engine coolant tempera-

. Air conditioning

4-14Step

ture:switch: OFF

(185-205°F)

. Lights, electrical cooling

:$b::pfan and accessories: OFF

. Transaxle: neutral

. Closed throttle switch: ON

- Air conditioning 20-60 Step

switch: ON

(The compressor clutchshould be activated when

the air conditioning switch;J-;;o~P

is switched ON.)* Engine: idling

1;:!,1;:!,

/!-I\/!-I\

f$&$:”f$&$:”

! ,‘,! ,‘,

4);4);

;jj\(Q(j!jGZ-);jj\(Q(j!jGZ-)

lili

q#Q~Hq#Q~HF]F]

ii 2 L J 2 L ~ -0SClllO 4ii 2 L J 2 L ~ -0SClllO 4

NOTE

When the vehicle is new (driven approximately 500 km (300 miles) or l\

ess) the number of steps may be about

30 steps greater than the standard value indicated above.

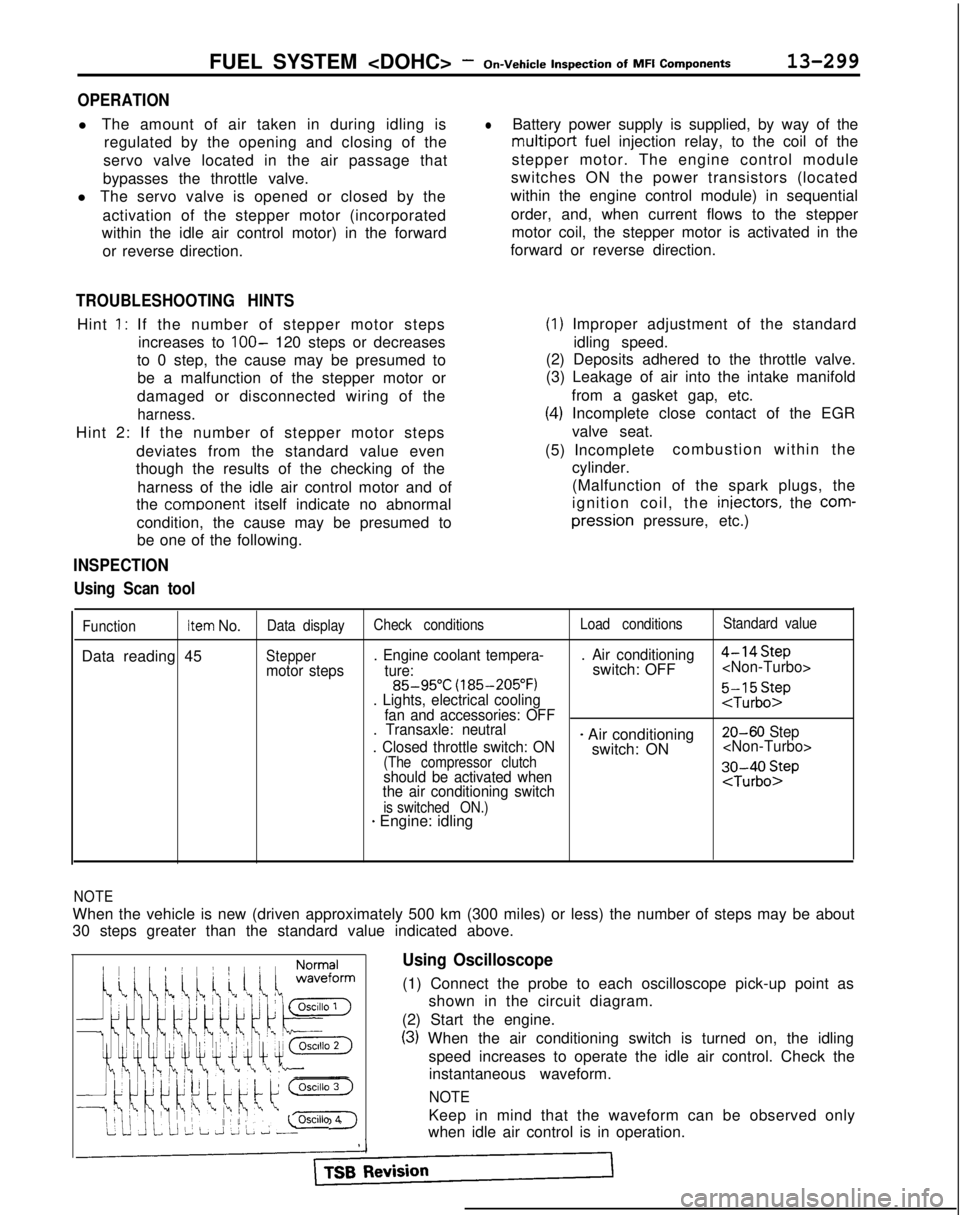

Using Oscilloscope

(1) Connect the probe to each oscilloscope pick-up point as

shown in the circuit diagram.

(2) Start the engine.

(3) When the air conditioning switch is turned on, the idling speed increases to operate the idle air control. Check theinstantaneous waveform.

NOTE

Keep in mind that the waveform can be observed only

when idle air control is in operation.

Page 445 of 1273

r

FUEL SYSTEM

of

MFI Components13-303

INSPECTION

Using Scan tool

Function Item No.

Data reading 44

Data displayInspection conditionsEngine condition Standard value

Ignition

advance

. Engine: warm

. Timing light: set750 rpm (idling)5-15” BTDC

(Use the timing light to

check the actual ignition 2,000 rpm32 - 4 1 “BTDCtiming.)

Oscillo 1

Normal waveform

Oscilio 2

!

1ov --

-

ovNormal waveform

HARNESS INSPECTION

Harness side

connectorE 0-0

J

El0

connectorI

lEnginecontrol

module

harness

sideconnector

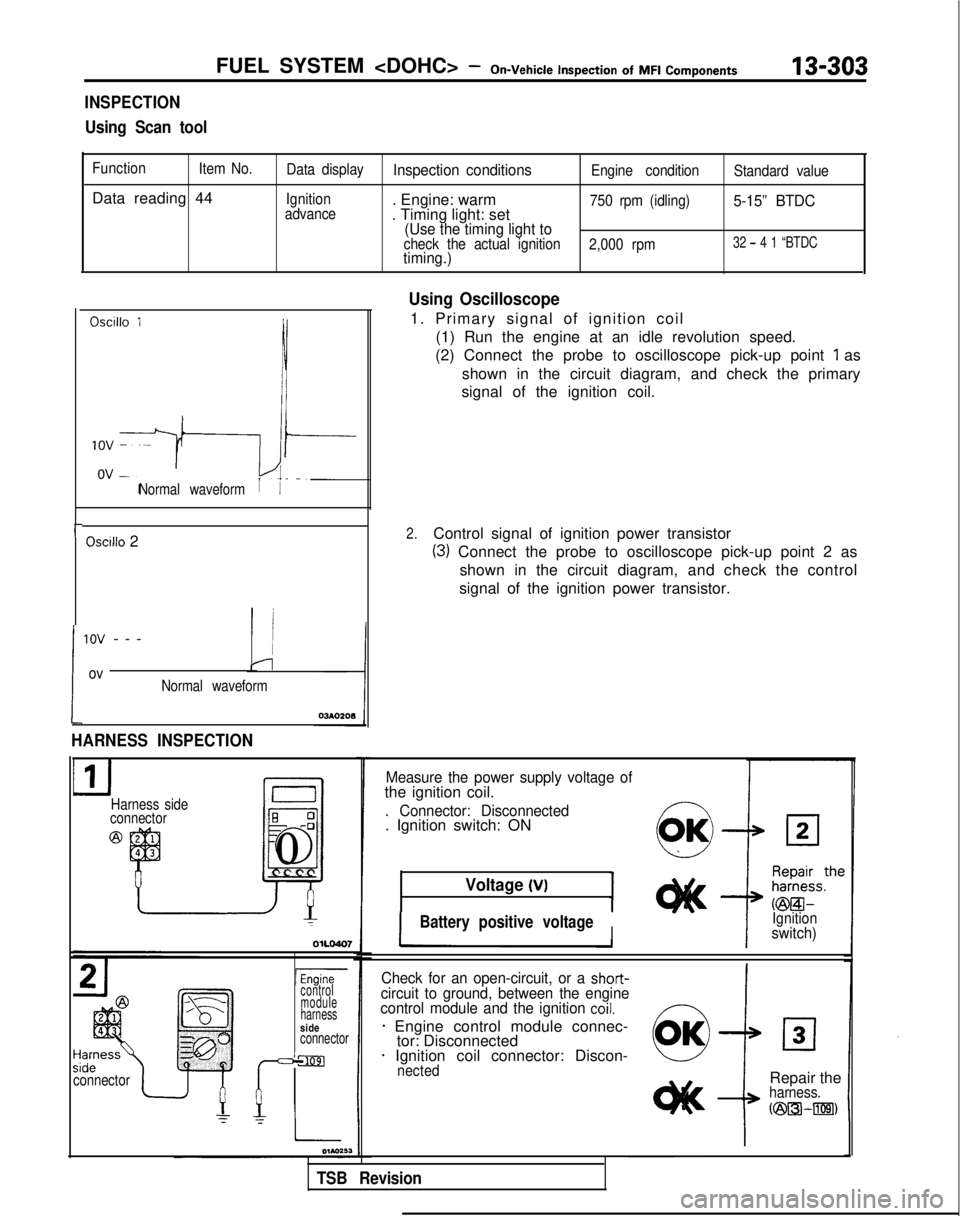

Using Oscilloscope

1. Primary signal of ignition coil

(1) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point

1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2.Control signal of ignition power transistor

(3) Connect the probe to oscilloscope pick-up point 2 as

shown in the circuit diagram, and check the control

signal of the ignition power transistor.

Measure the power supply voltage ofthe ignition coil.

. Connector: Disconnected. Ignition switch: ON

Voltage (VI

IBattery positive voltageIIIgnitionswitch)

Check for an open-circuit, or a

short-circuit to ground, between the engine

control module and the ignition coil.

* Engine control module connec- tor: Disconnected

* Ignition coil connector: Discon-nected

i

Repair theharness.

N23l3k-m)

TSB Revision