display MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 219 of 1273

FUEL SYSTEM

IGNITION SWITCH-ST

>

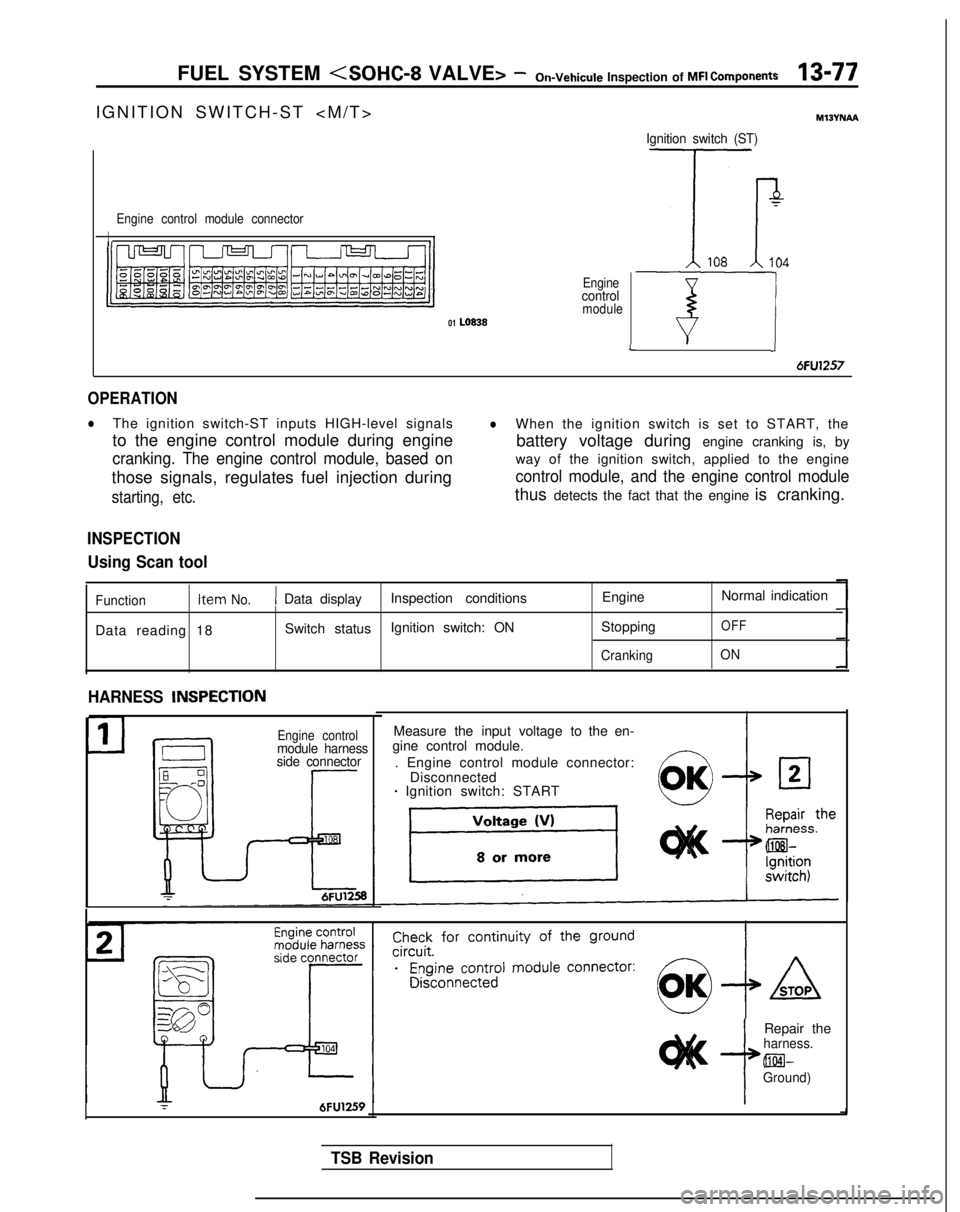

Engine control module connector

II

Enginecontrolmodule01 LO838

Ignition switch (ST)

7

Tr108104

T-7JL

6FU1257

OPERATION

lThe ignition switch-ST inputs HIGH-level signalslWhen the ignition switch is set to START, the

to the engine control module during engine battery voltage during engine cranking is, by

cranking. The engine control module, based onway of the ignition switch, applied to the engine

those signals, regulates fuel injection during

control module, and the engine control module

starting, etc.thus detects the fact that the engine is cranking.

INSPECTION

Using Scan tool

Function Item No.1 Data display

Inspection conditions EngineNormal indication

Data reading 18 Switch status

Ignition switch: ON

Stopping

OFF

CrankingON

HARNESS INSPECTlON

Engine controlmodule harness

side connector

Measure the input voltage to the en-

gine control module.

. Engine control module connector: Disconnected

- Ignition switch: START

r6FU1259i

Repair theharness. @El-

Ground)

TSB Revision

Page 221 of 1273

FUEL SYSTEM

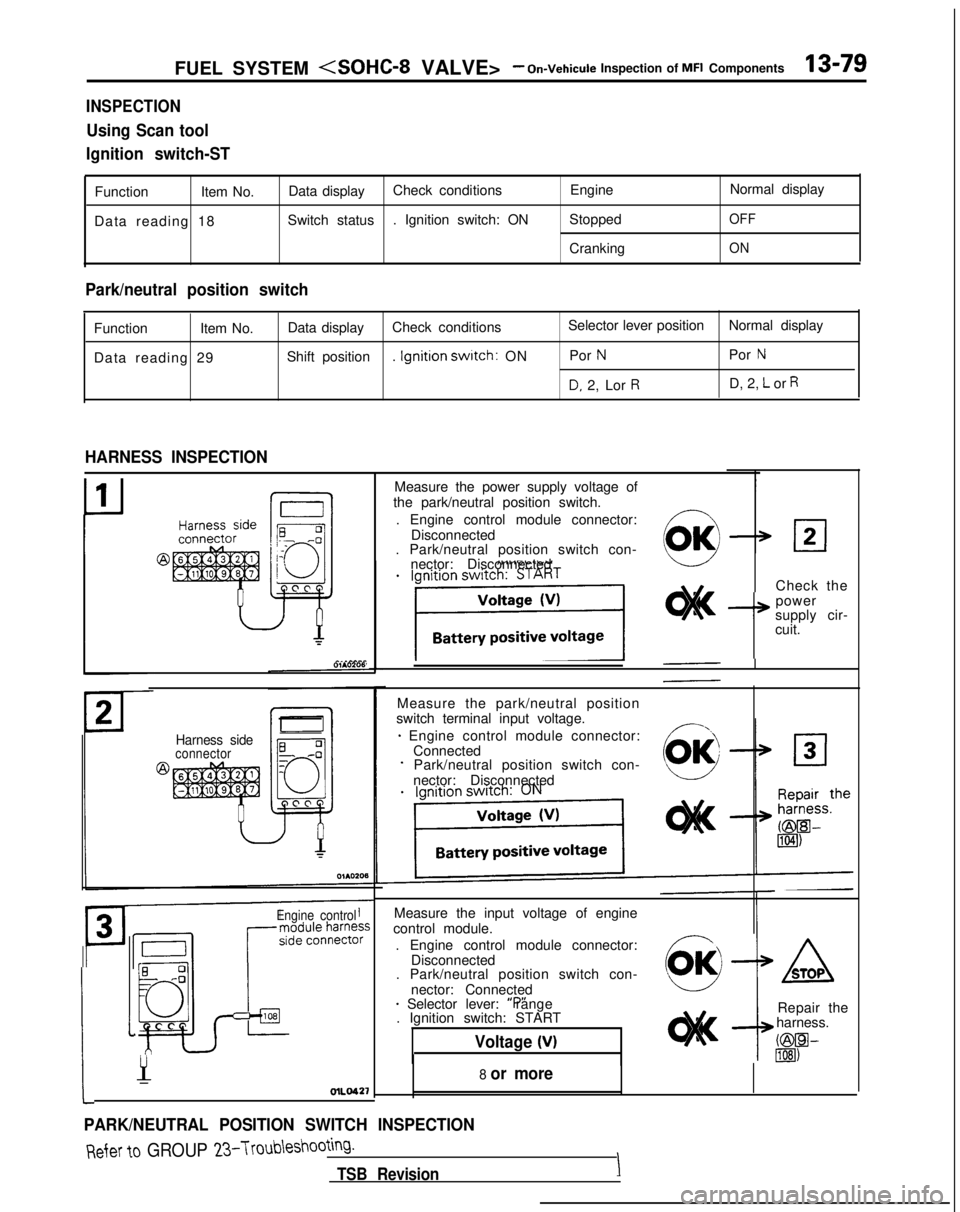

INSPECTION

Using Scan tool

Ignition switch-ST

Function Item No.Data display Check conditions

EngineNormal display

Data reading 18 Switch status

. Ignition switch: ON Stopped

OFF

CrankingON

Park/neutral position switch

Function

Item No.Data display

Check conditions Selector lever position

Normal display

Data reading 29 Shift position

. Ignition

swatch: ON Por NPor N

D, 2, Lor RD, 2, L or R

HARNESS INSPECTION

Harness sideconnector

Engine control

Measure the input voltage of engine

control module.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Connected

* Selector lever: “P” range

. Ignition switch: START

Voltage (V)

:

1

Y-OlLO42’f

PARK/NEUTRAL POSITION SWITCH INSPECTION

Measure the power supply voltage of

the park/neutral position switch.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Disconnected

Check the

I+

power

supply cir-

cuit.

Measure the park/neutral position

switch terminal input voltage.

* Engine control module connector: ConnectedPark/neutral position switch con-

nector: Disconnected

8 or more

ASTOP

Repair the

harness.

C@W lIEI)

Refer to GROUP 23-Troubleshooting.

TSB RevisionI

Page 224 of 1273

13-82 FUEL SYSTEM

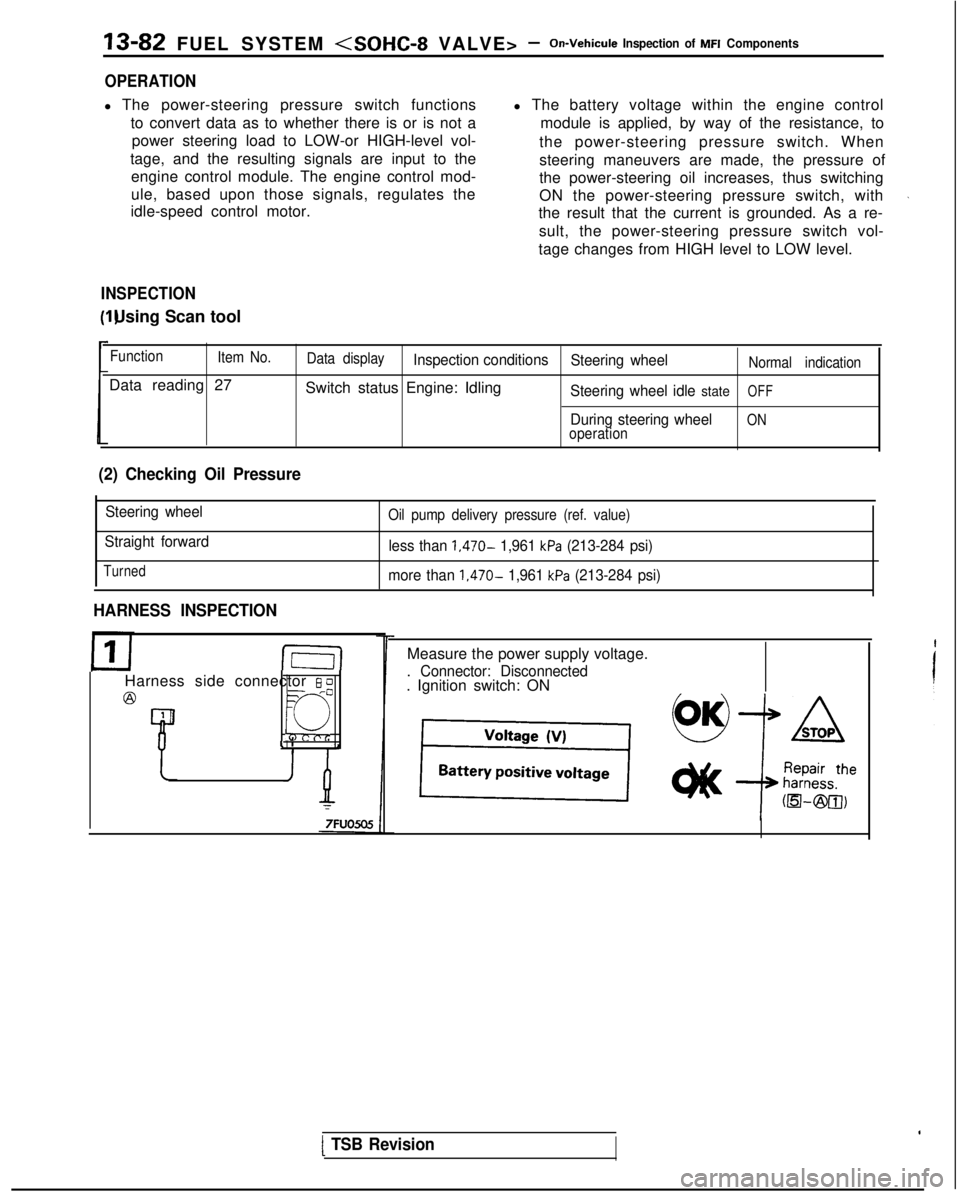

OPERATION

l The power-steering pressure switch functions

to convert data as to whether there is or is not apower steering load to LOW-or HIGH-level vol-

tage, and the resulting signals are input to the engine control module. The engine control mod-

ule, based upon those signals, regulates the

idle-speed control motor. l The battery voltage within the engine control

module is applied, by way of the resistance, to

the power-steering pressure switch. When

steering maneuvers are made, the pressure of

the power-steering oil increases, thus switching

ON the power-steering pressure switch, with

the result that the current is grounded. As a re-

sult, the power-steering pressure switch vol-

tage changes from HIGH level to LOW level.

INSPECTION I) Using Scan tool

Function

Item No.

Data reading 27

Data displayInspection conditions Steering wheelNormal indication

Switch status Engine: IdlingSteering wheel idle stateOFF

During steering wheelONoperation

(2) Checking Oil Pressure

Steering wheel

Straight forward

Turned

Oil pump delivery pressure (ref. value)

less than 1,470- 1,961 kPa (213-284 psi)

more than

1,470- 1,961 kPa (213-284 psi)

HARNESS INSPECTION

I-E-I

Harness side connector 6 0

@=- -0

Q

4 1

Measure the power supply voltage.

. Connector: Disconnected. Ignition switch: ON

[ TSB Revision

Page 226 of 1273

13-84 FUEL SYSTEM

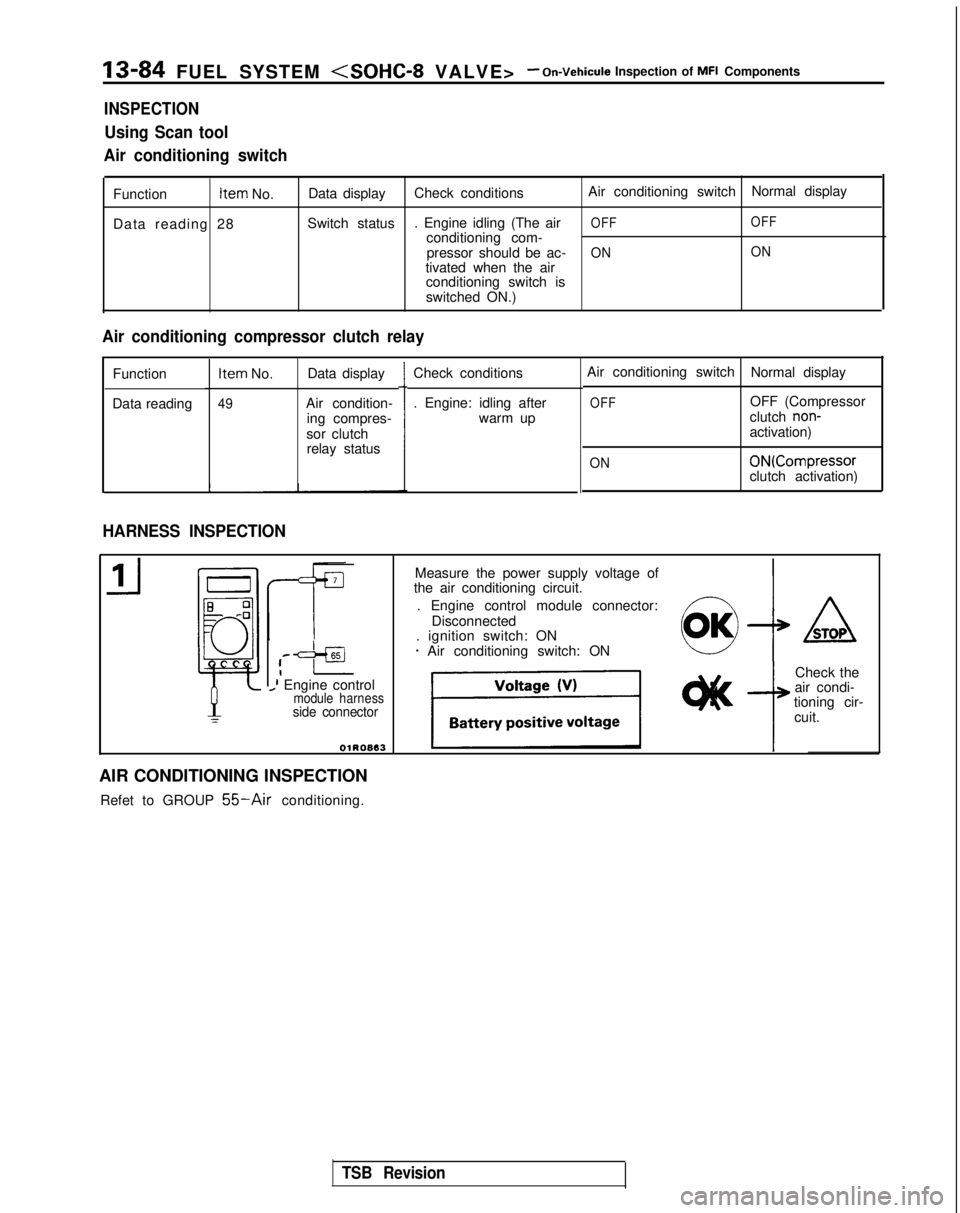

INSPECTION

Using Scan tool

Air conditioning switch

Function Item

No.

Data reading 28 Data display

Check conditions Air conditioning switch

Normal display

Switch status . Engine idling (The air

OFF OFFconditioning com-

pressor should be ac-ON ONtivated when the air

conditioning switch is

switched ON.)

Air conditioning compressor clutch relay

Function

Data reading Item

No. Data display

49Air condition-

ing compres-

sor clutch relay status Check conditions

. Engine: idling after

warm up

HARNESS INSPECTION

Air conditioning switch Normal display

OFFOFF (Compressor

clutch non-activation)

ON ON(Compressor

clutch activation)

,--=+aI_I Engine controlmodule harnessside connector

OlROB13

Measure the power supply voltage of

the air conditioning circuit.

. Engine control module connector: Disconnected

. ignition switch: ON

* Air conditioning switch: ON4

ASTOP

Check the

air condi-

tioning cir-

cuit.

AIR CONDITIONING INSPECTION Refet to GROUP

55-Air conditioning.

TSB Revision

Page 228 of 1273

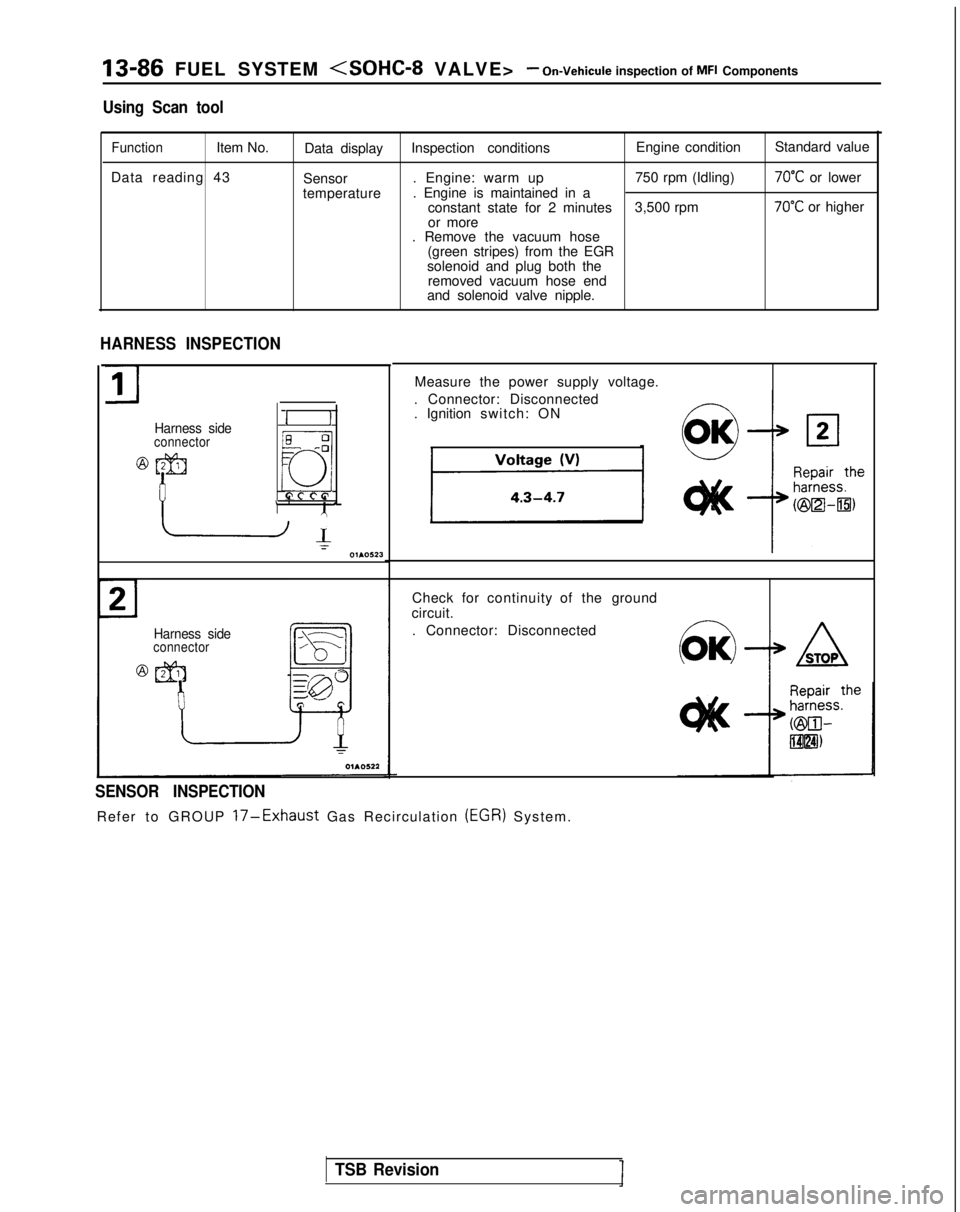

13-86 FUEL SYSTEM

Using Scan tool

FunctionItem No.Data display Inspection conditions Engine condition

Standard value

Data reading 43 Sensor. Engine: warm up

750 rpm (Idling)

70°C or lower

temperature . Engine is maintained in a

constant state for 2 minutes 3,500 rpm

70°C or higher

or more

. Remove the vacuum hose

(green stripes) from the EGR

solenoid and plug both the removed vacuum hose end

and solenoid valve nipple.

HARNESS INSPECTION

Harness sideconnector

@qqJ

I

II

EL -:

f7

Q,

L *A’

-1I01.0523

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Harness sideconnector

Check for continuity of the ground

circuit.

. Connector: Disconnected

SENSOR INSPECTION

Refer to GROUP 17-Exhaust Gas Recirculation (EGR)

System.

-w

STOP

TSB Revision

Page 230 of 1273

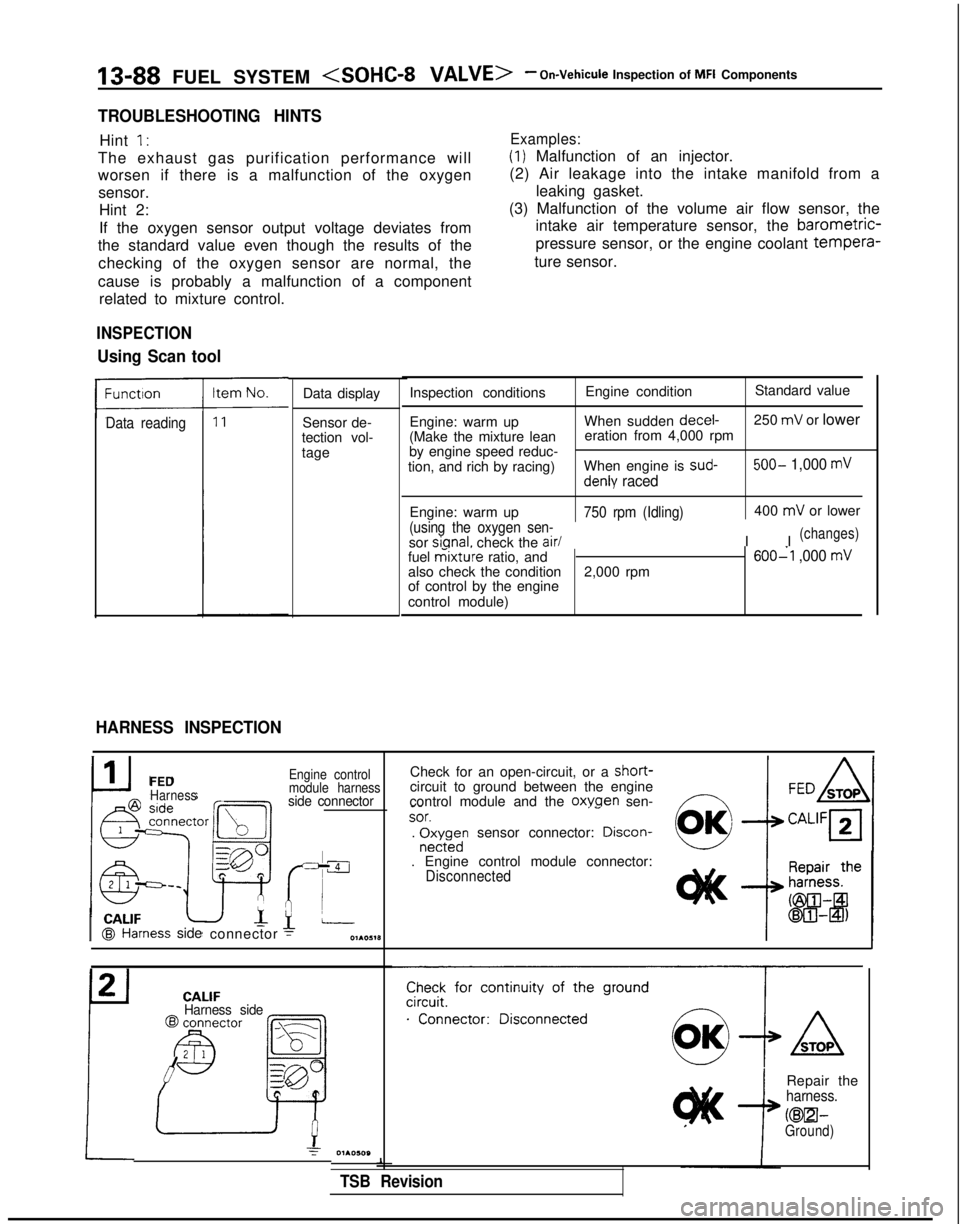

13-88 FUEL SYSTEM

TROUBLESHOOTING HINTS

Hint I’

The exhaust gas purification performance will

Examples:

(1) Malfunction of an injector.

worsen if there is a malfunction of the oxygen sensor. Hint 2:

If the oxygen sensor output voltage deviates from

the standard value even though the results of the

checking of the oxygen sensor are normal, the

cause is probably a malfunction of a component related to mixture control. (2) Air leakage into the intake manifold from a

leaking gasket.

(3) Malfunction of the volume air flow sensor, the intake air temperature sensor, the barometric-

pressure sensor, or the engine coolant tempera-

ture sensor.

Data reading

INSPECTION

Using Scan tool

HARNESS INSPECTION

Data display

Sensor de-

tection vol-

tage Inspection conditions

Engine conditionStandard value

Engine: warm up When sudden decel-

250

mV or lower

(Make the mixture lean eration from 4,000 rpm

by engine speed reduc-

tion, and rich by racing) When engine is sud-

500- 1,000 mV

denly raced

Engine: warm up750 rpm (Idling)

(using the oxygen sen-

sor sianal.

check the air/

400

mV or lower

I I

(changes)

fuel mixture ratio, and600-l ,000 mValso check the condition 2,000 rpm

of control by the engine

control module)

I CALIF@I Hal

FEDHarness

ness

side

connector

Engine control

module harness

side connector

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the oxwen sen-f7 _-

~~SOT.‘-. r$;rdn sensor connector: Drscon-

. Engine control module connector:Disconnected CALIF

Harness side

Check for continuity of the ground

.“‘..“...;;”

Repair theharness.

KEEI-Ground)

1

TSB Revision

Page 233 of 1273

FUEL SYSTEM

Inspection of MFI Components13-91

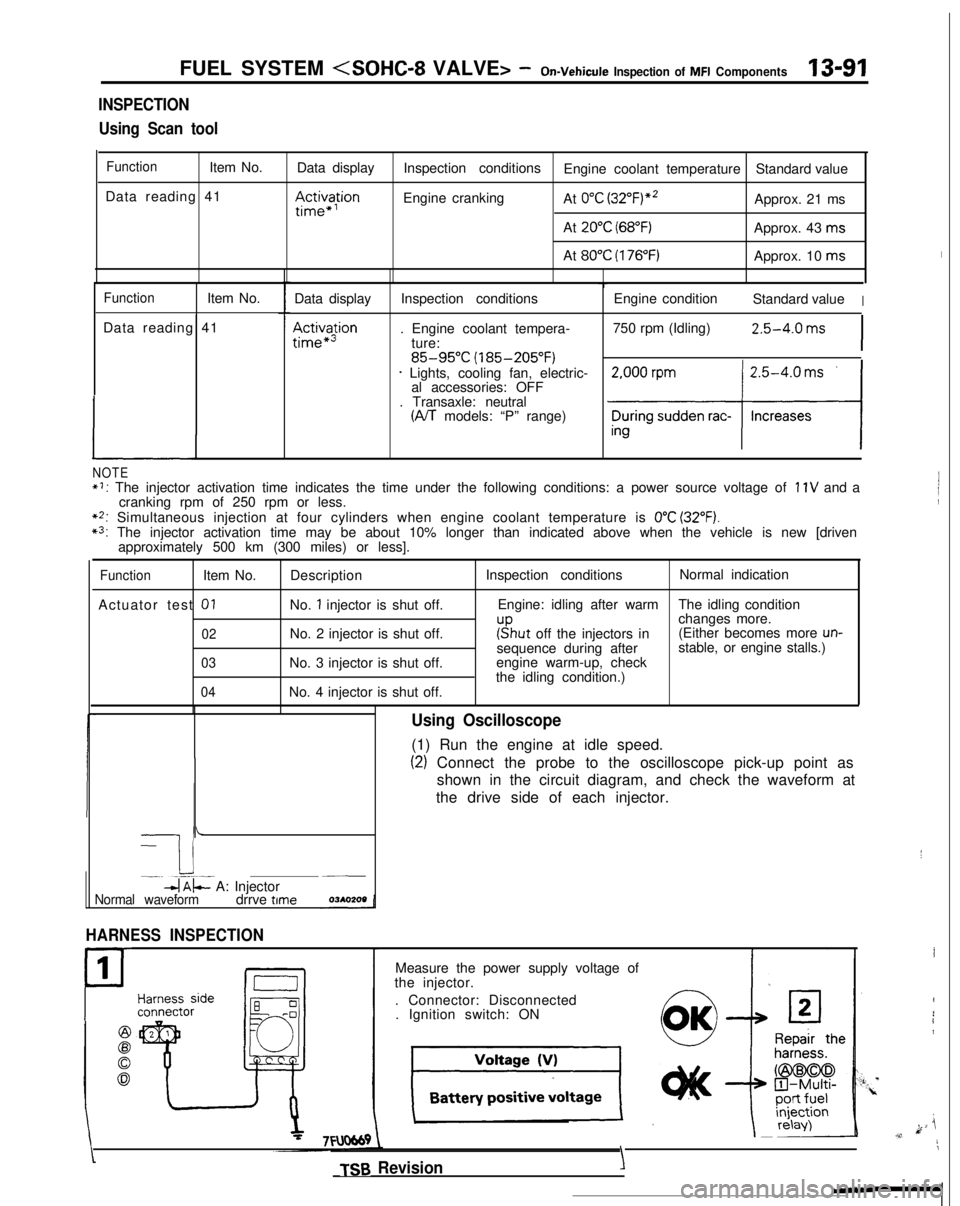

INSPECTION

Using Scan tool

FunctionItem No. Data display

Data reading 41

III~~~ion

Inspection conditions Engine coolant temperature Standard value

Engine cranking At

0°C (3~2°F)“~Approx. 21 ms

At

20°C (68°F)Approx. 43 ms

At

80°C (176°F)Approx. 10 ms

FunctionItem No.

Data reading 41

L

Data display

Ac&a$ion

Inspection conditions

. Engine coolant tempera- ture:

85-95°C (185-205°F)* Lights, cooling fan, electric-al accessories: OFF

. Transaxle: neutral

(A/T models: “P” range) Engine condition

Standard value

I

750 rpm (Idling)2.5-4.0 ms

I

NOTE*I: The injector activation time indicates the time under the following con\

ditions: a power source voltage of 11V and a

cranking rpm of 250 rpm or less.

**: Simultaneous injection at four cylinders when engine coolant temperatur\

e is 0°C (32°F).*3: The injector activation time may be about 10% longer than indicated abo\

ve when the vehicle is new [driven approximately 500 km (300 miles) or less].

FunctionItem No.

Actuator test

01

02

03

04

Description

No.

1 injector is shut off.

No. 2 injector is shut off.

No. 3 injector is shut off.

No. 4 injector is shut off. Inspection conditions

Normal indication

Engine: idling after warm The idling condition

changes more.

r”sput off the injectors in(Either becomes more un-sequence during after stable, or engine stalls.)

engine warm-up, check

the idling condition.)

-

I i-. --.-~-db$- A: Injector~__

Normal waveformdrrve time

HARNESS INSPECTION

1

P

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

Measure the power supply voltage of

the injector.

. Connector: Disconnected. Ignition switch: ON

TSB Revision

I

I

4

i1

k ji,v,11

\

YIY’.

Page 238 of 1273

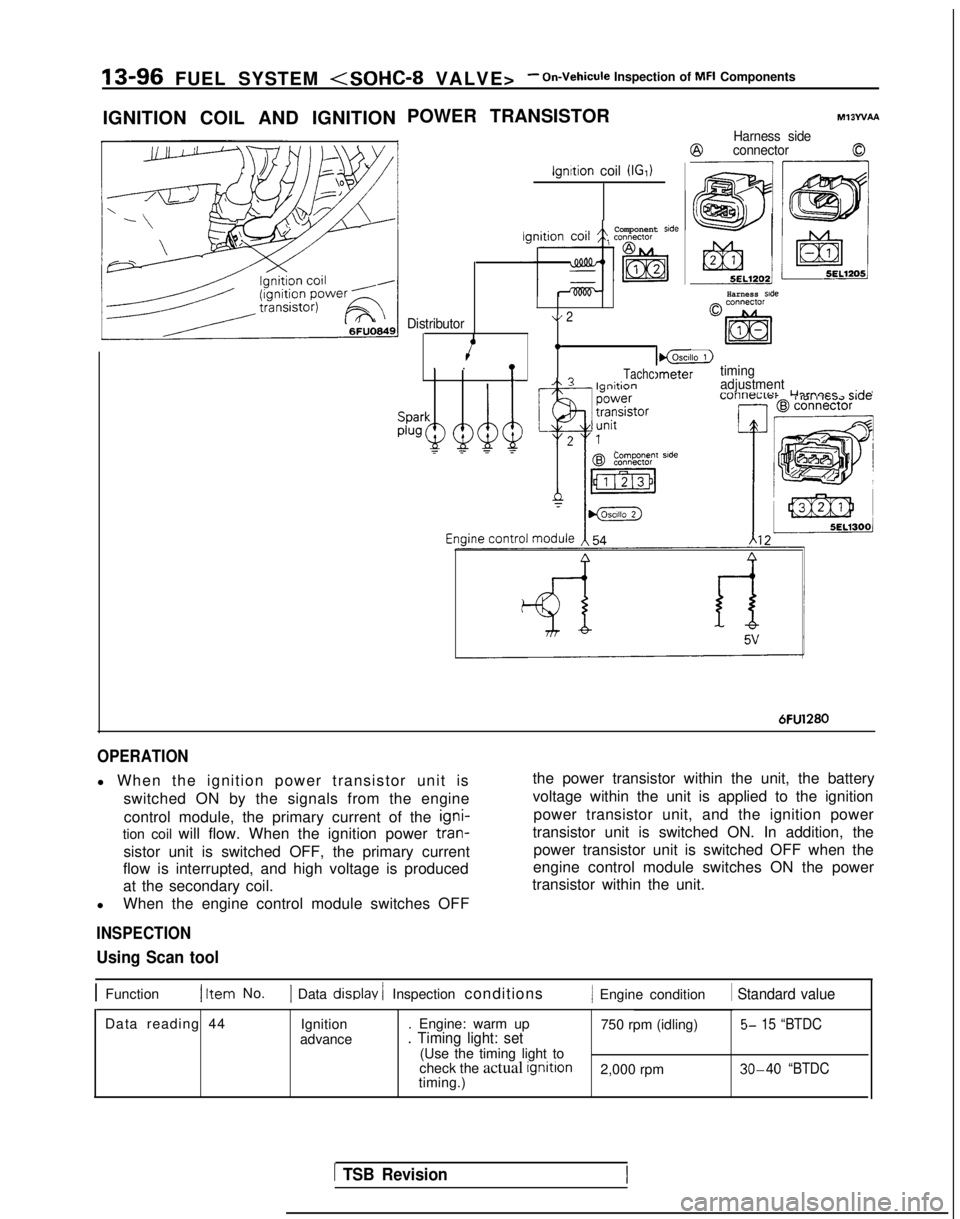

13-96 FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

ignition coil (IGI)

Ml3WAA

Harness side

@connector0

Harness side

Component side

Distributor\/ 2

4.I_lgnltion. .!

I@LZ)

TachcImetertimingA? I--:*:^^adjustment-_

Lllrnacr

r;rlnI 101 i IG.72 Jl”F

Componenr side

6FU1280

OPERATION

l When the ignition power transistor unit is

switched ON by the signals from the engine

control module, the primary current of the igni-

tion coil will flow. When the ignition power tran-

sistor unit is switched OFF, the primary current

flow is interrupted, and high voltage is produced

at the secondary coil.

l When the engine control module switches OFF

INSPECTION

the power transistor within the unit, the battery

voltage within the unit is applied to the ignition

power transistor unit, and the ignition power

transistor unit is switched ON. In addition, the power transistor unit is switched OFF when the

engine control module switches ON the power

transistor within the unit.

Using Scan tool

1 Function1 Item No.1 Data display / Inspection conditions/ Engine condition 1 Standard value

Data reading 44

Ignition

advance . Engine: warm up

750 rpm (idling)5- 15 “BTDC. Timing light: set(Use the timing light to

check the actual ignition

2,000 rpm 30-40 “BTDCtiming.)

1 TSB Revision

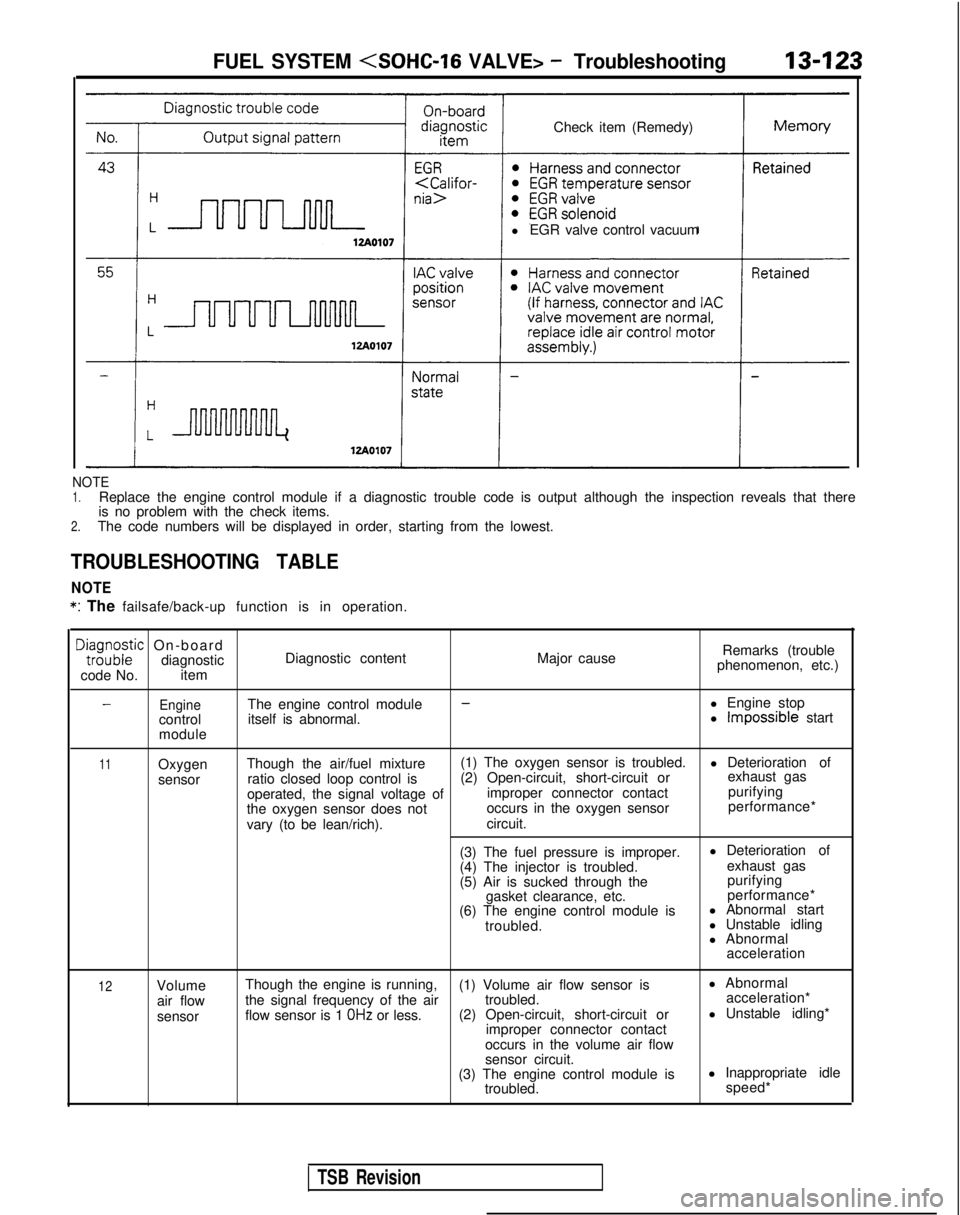

Page 265 of 1273

Check item (Remedy)

l EGR valve control vacuumFUEL SYSTEM

NOTE1.Replace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there

is no problem with the check items.

2.The code numbers will be displayed in order, starting from the lowest.

TROUBLESHOOTING TABLE

NOTE *:

The failsafe/back-up function is in operation.

DE;;;zic On-board

diagnostic

code No. item Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

EngineThe engine control module--l Engine stop

control itself is abnormal. l Impossible start

module

11Oxygen

sensor Though the air/fuel mixture

(1) The oxygen sensor is troubled.

l Deterioration of

ratio closed loop control is (2) Open-circuit, short-circuit or exhaust gas

operated, the signal voltage of improper connector contact purifying

the oxygen sensor does not occurs in the oxygen sensor performance*

vary (to be lean/rich). circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal

acceleration

12Volume

air flow

sensor Though the engine is running,

(1) Volume air flow sensor is l Abnormal

the signal frequency of the air troubled. acceleration*

flow sensor is 1

OHz or less. (2) Open-circuit, short-circuit or l Unstable idling*

improper connector contact

occurs in the volume air flow

sensor circuit.

(3) The engine control module is l Inappropriate idle

troubled. speed*

TSB Revision

Page 292 of 1273

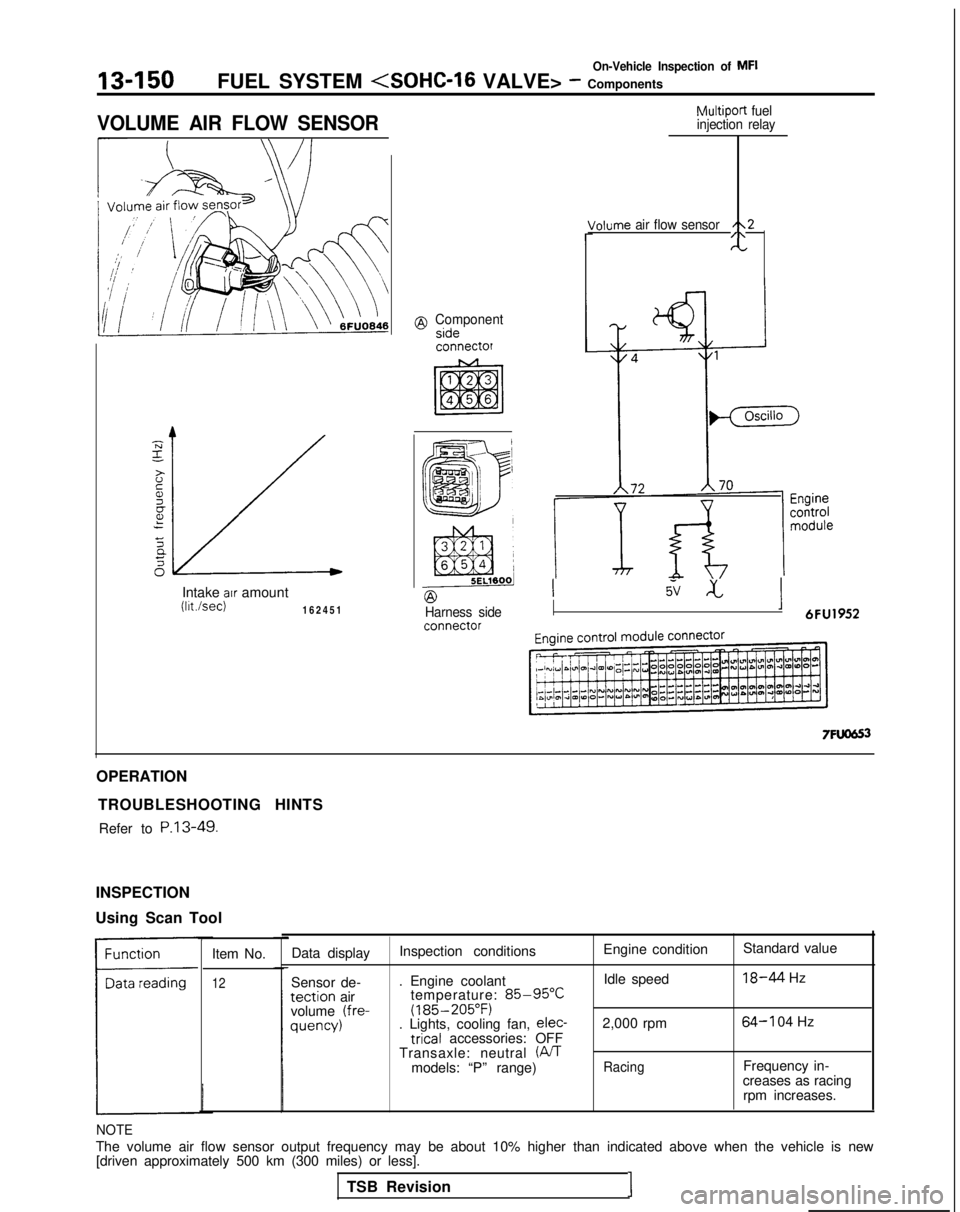

On-Vehicle Inspection of MFI

13450FUEL SYSTEM

VOLUME AIR FLOW SENSOR

Intake air amountWsec)16245

1

@ Componentsideconnectof

Multiport

fuel

injection relay

/ohme air flow sensor/\2/\-

@Harness side

Isv xI 6FU1952

OPERATION TROUBLESHOOTING HINTSRefer to

P.13-49.

INSPECTION

Using Scan Tool

Item No.

12

Data displayInspection conditions Engine condition

Standard value

Sensor de- . Engine coolant Idle speed

18-44 Hz

tection airtemperature: 85-95°C

volume (fre- (185-205°F)

quency)

. Lights, cooling fan, elec-

2,000 rpm64-l 04 Hz tricaI

accessories: OFF

Transaxle: neutral

(PJTmodels: “P” range)RacingFrequency in-

creases as racing rpm increases.

NOTE

The volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new[driven approximately 500 km (300 miles) or less].

TSB Revision

1