display MITSUBISHI GALANT 1989 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 447 of 1273

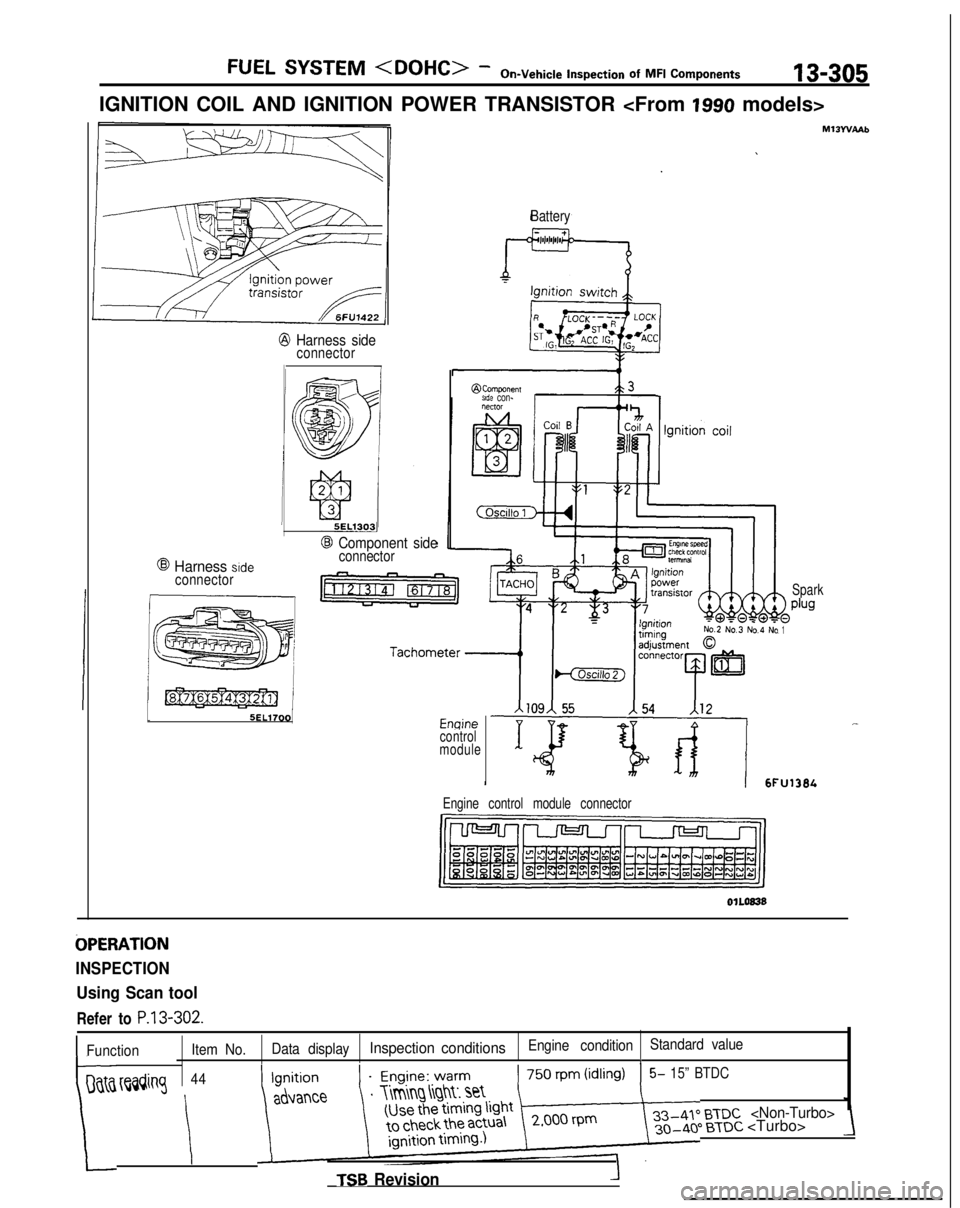

FUEL SYSTEM

of MFI

Components13-305

IGNITION COIL AND IGNITION POWER TRANSISTOR

Ml3WAAb

@ Harness sideconnector

@ Harness sideconnector

5EL13031

@ Component sideconnector

15EL1700

Battery

@CompmntStde con-

control

module

a

Spark

PlUGI .-

'. 1

Enoine

Engine control module connector

OPERATION

INSPECTION

Using Scan tool

Refer to P.13-302.

cm

i

Function Item No.

Data displayInspection conditionsEngine condition Standard valueI

reading445- 15” BTDC

BTDC

TSB Revision

Page 477 of 1273

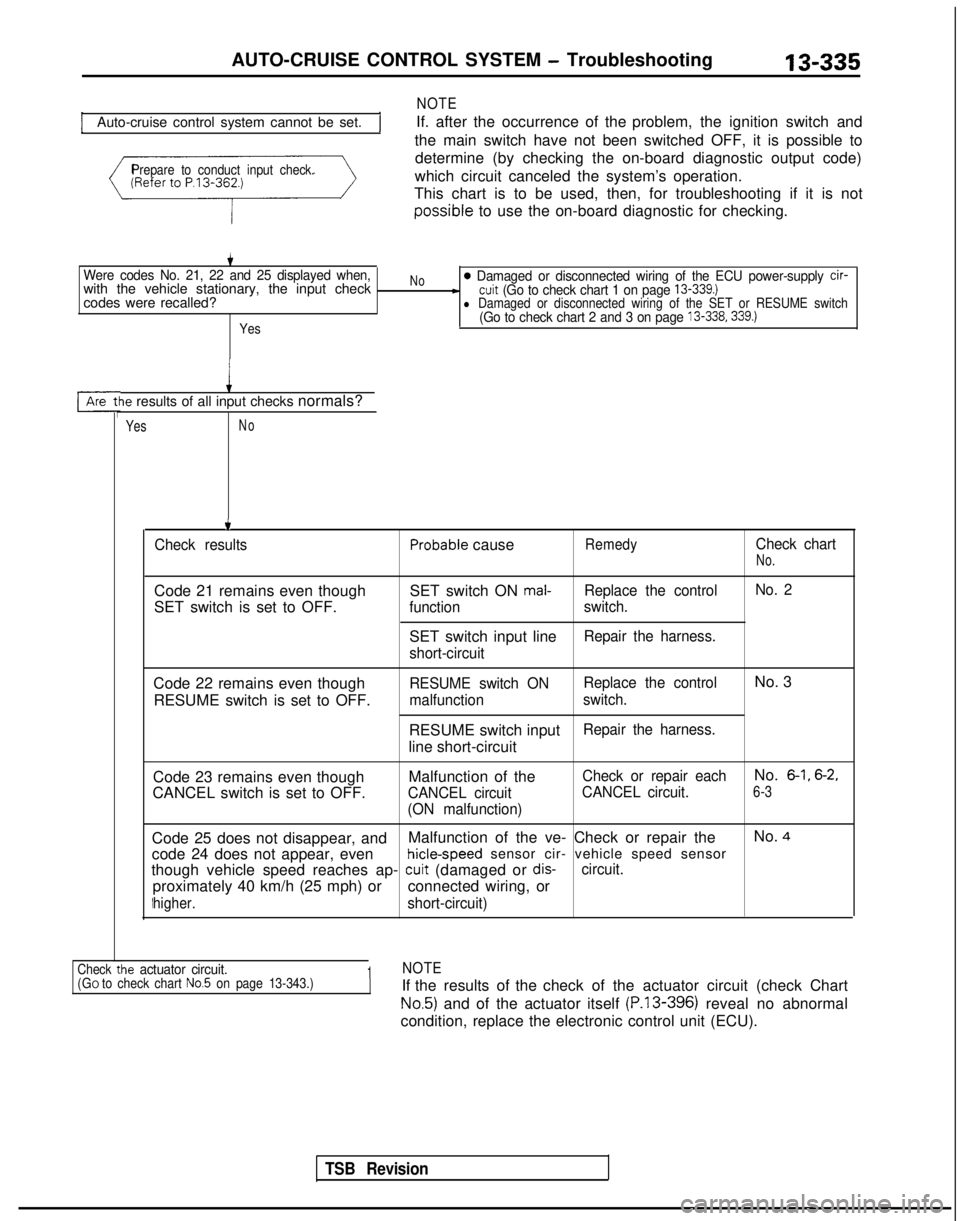

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

Auto-cruise control system cannot be set.

NOTE

If. after the occurrence of the problem, the ignition switch and

the main switch have not been switched OFF, it is possible to

Prepare to conduct input check.determine (by checking the on-board diagnostic output code)

which circuit canceled the system’s operation.

This chart is to be used, then, for troubleshooting if it is not possible

to use the on-board diagnostic for checking.

Were codes No. 21, 22 and 25 displayed when,with the vehicle stationary, the input check

codes were recalled?

Yes

No0 Damaged or disconnected wiring of the ECU power-supply cir--cuit (Go to check chart 1 on page 13-339.)l Damaged or disconnected wiring of the SET or RESUME switch(Go to check chart 2 and 3 on page 13-338.339.)

le results of all input checks normals?

YesNo

.t

TSB Revision

.

Check resultsProbable causeRemedyCheck chart

No.

Code 21 remains even though

SET switch is set to OFF. SET switch ON mal-Replace the control

No. 2

function switch.

SET switch input lineRepair the harness.

short-circuit

Code 22 remains even though RESUME switch is set to OFF.RESUME switch ON Replace the controlNo. 3

malfunction

switch.

RESUME switch inputRepair the harness.

line short-circuit

Code 23 remains even though

CANCEL switch is set to OFF. Malfunction of the

CANCEL circuit

(ON malfunction) Check or repair each

No. 6-1, 6-2,

CANCEL circuit.6-3

Code 25 does not disappear, and

Malfunction of the ve- Check or repair the No. 4

code 24 does not appear, even hicle-speed

sensor cir- vehicle speed sensor

though vehicle speed reaches ap-

cuit (damaged or dis-circuit.

proximately 40 km/h (25 mph) or connected wiring, or

higher.short-circuit)

ie actuator circuit.1NOTECheck tl(GO to check chart No.5 on page 13-343.)If the results of the check of the actuator circuit (check Chart

No.5) and of the actuator itself (P.13-396) reveal no abnormal

condition, replace the electronic control unit (ECU).

Page 493 of 1273

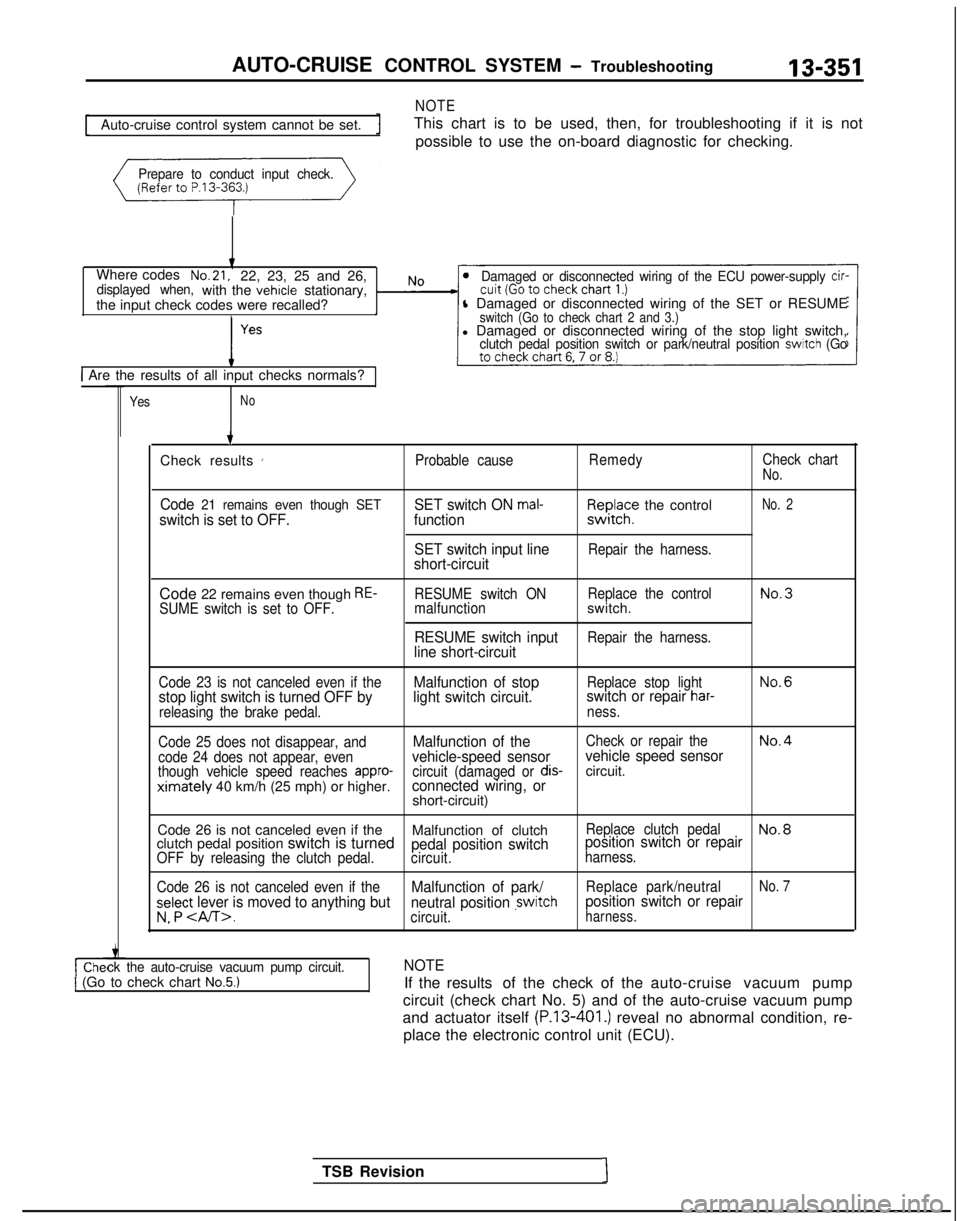

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

NOTE

13-351

Auto-cruise control system cannot be set.

This chart is to be used, then, for troubleshooting if it is not

possible to use the on-board diagnostic for checking.

Prepare to conduct input check.

Where codesNo.21,22, 23, 25 and 26,displayed when,with the vehicle stationary,

the input check codes were recalled?Damaged or disconnected wiring of the ECU power-supply cir-

l Damaged or disconnected wiring of the SET or RESUMEswitch (Go to check chart 2 and 3.)l Damaged or disconnected wiring of the stop light switch,clutch pedal position switch or park/neutral position switch (Go

1 Are the results of all input checks normals?

YesNo

ck the auto-cruise vacuum pump circuit.1 (Go to check chart No.5.)

TSB Revision1 7

Check results

’Probable cause RemedyCheck chartNo.

Code 21 remains even though SETswitch is set to OFF. SET switch ON mal-function

SET switch input line

short-circuitF,I~JI;? the control

Repair the harness.

No. 2

Code 22 remains even though RE-SUME switch is set to OFF. RESUME switch ON

Replace the controlNo.3malfunctionswitch.

RESUME switch inputRepair the harness.line short-circuit

Code 23 is not canceled even if theMalfunction of stopReplace stop lightNo.6

stop light switch is turned OFF by light switch circuit.switch or repair har-

releasing the brake pedal.

ness.

Code 25 does not disappear, and

Malfunction of theCheck or repair theNo.4

code 24 does not appear, evenvehicle-speed sensor vehicle speed sensorthough vehicle speed reaches appro-circuit (damaged or dis-circuit.ximately 40 km/h (25 mph) or higher.connected wiring, orshort-circuit)

Code 26 is not canceled even if the Malfunction of clutch

Replace clutch pedalNo.8clutch pedal position switch is turnedpedal position switchposition switch or repairOFF by releasing the clutch pedal.

circuit.harness.

Code 26 is not canceled even if the

Malfunction of park/Replace park/neutralNo. 7

select lever is moved to anything but neutral position ,switchposition switch or repair

v. P .circuit.harness.

NOTE

If the results of the check of the auto-cruise vacuum pump

circuit (check chart No. 5) and of the auto-cruise vacuum pump

and actuator itself

(P.13-401.) reveal no abnormal condition, re-

place the electronic control unit (ECU).

Page 503 of 1273

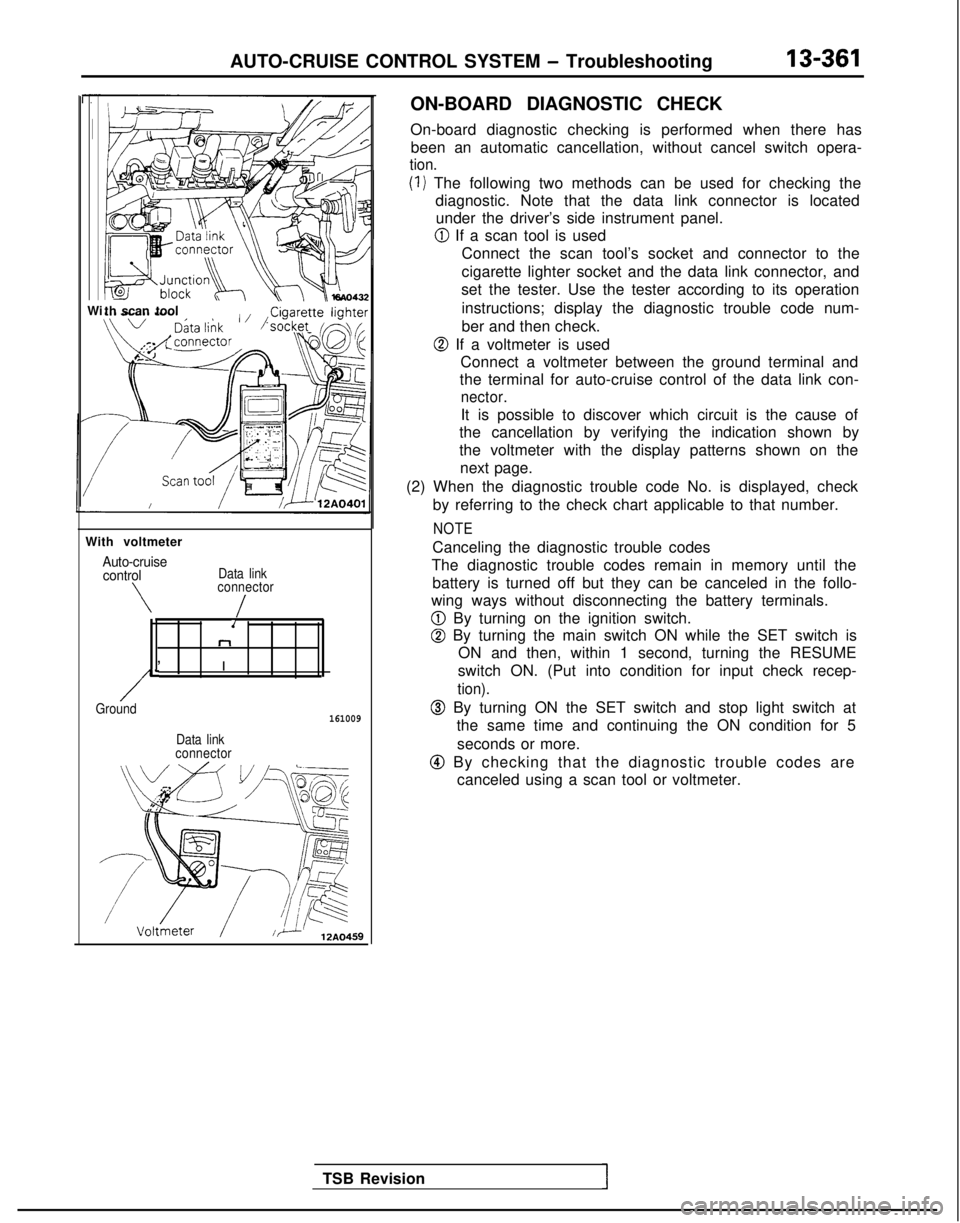

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting13-361

Wi

thscan tool

With voltmeter

Auto-cruise control

\

Data link

connector

III

n

,

/r-I

/Ground161009

Data link

connector

TSB Revision ON-BOARD DIAGNOSTIC CHECK

On-board diagnostic checking is performed when there has

been an automatic cancellation, without cancel switch opera-

tion.

(1) The following two methods can be used for checking the diagnostic. Note that the data link connector is locatedunder the driver’s side instrument panel.

@ If a scan tool is used

Connect the scan tool’s socket and connector to the

cigarette lighter socket and the data link connector, and

set the tester. Use the tester according to its operation

instructions; display the diagnostic trouble code num-

ber and then check.

@ If a voltmeter is used Connect a voltmeter between the ground terminal and

the terminal for auto-cruise control of the data link con-

nector.

It is possible to discover which circuit is the cause of

the cancellation by verifying the indication shown by

the voltmeter with the display patterns shown on the

next page.

(2) When the diagnostic trouble code No. is displayed, check by referring to the check chart applicable to that number.

NOTE

Canceling the diagnostic trouble codes

The diagnostic trouble codes remain in memory until the battery is turned off but they can be canceled in the follo-

wing ways without disconnecting the battery terminals.

@ By turning on the ignition switch.

@ By turning the main switch ON while the SET switch is ON and then, within 1 second, turning the RESUME

switch ON. (Put into condition for input check recep-

tion).

@ By turning ON the SET switch and stop light switch at the same time and continuing the ON condition for 5

seconds or more.

@I By checking that the diagnostic trouble codes are canceled using a scan tool or voltmeter.

Page 504 of 1273

13-362AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

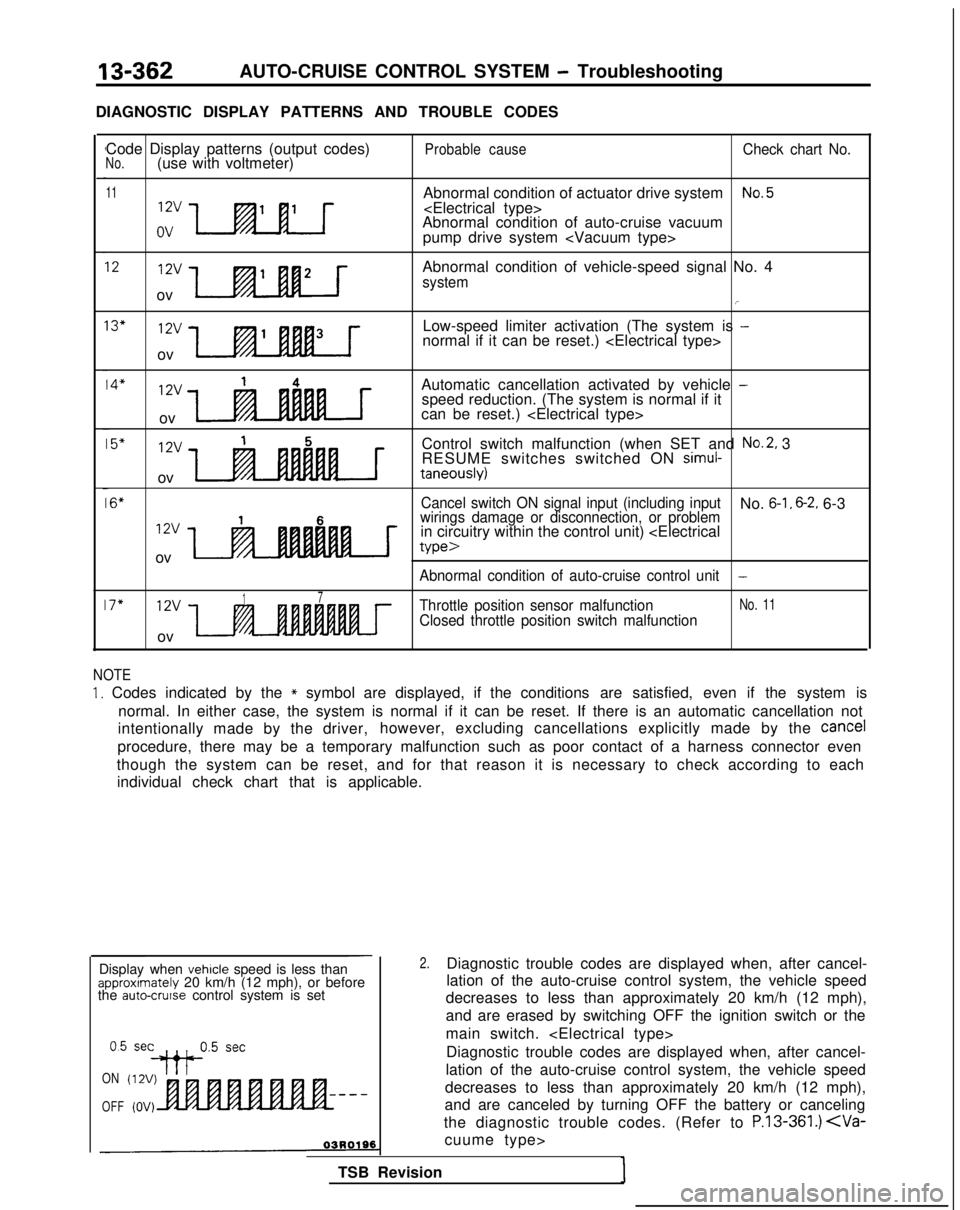

DIAGNOSTIC DISPLAY PATTERNS AND TROUBLE CODES Code Display patterns (output codes)

No.(use with voltmeter)

11

xJa-.tu

Probable causeCheck chart No.

Abnormal condition of actuator drive systemNo.5

Abnormal condition of auto-cruise vacuum

pump drive system

1212vAbnormal condition of vehicle-speed signal No. 4systemov/

13"12vLow-speed limiter activation (The system is -normal if it can be reset.)

ov

14*12v14Automatic cancellation activated by vehicle -speed reduction. (The system is normal if it

ov can be reset.)

15"12v15Control switch malfunction (when SET and No.2, 3

RESUME switches switched ON simul-

ovtaneously)

16"Cancel switch ON signal input (including inputNo. 6-1, 6-2. 6-3

12v16wirings damage or disconnection, or problemin circuitry within the control unit)

we>

Abnormal condition of auto-cruise control unit-

17"12v17Throttle position sensor malfunctionNo. 11

Closed throttle position switch malfunction

ov

NOTE

1. Codes indicated by the * symbol are displayed, if the conditions are satisfied, even if the system is

normal. In either case, the system is normal if it can be reset. If ther\

e is an automatic cancellation not

intentionally made by the driver, however, excluding cancellations explicitly made by the

cancel

procedure, there may be a temporary malfunction such as poor contact of \

a harness connector even

though the system can be reset, and for that reason it is necessary to c\

heck according to each individual check chart that is applicable.

ON

OFF

-

Display when vehicle speed is less thanapproximately 20 km/h (12 mph), or before

the auto-cruise control system is set

0.5 set

++P5 setDiagnostic trouble codes are displayed when, after cancel-

lation of the auto-cruise control system, the vehicle speed

decreases to less than approximately 20 km/h (12 mph),

and are canceled by turning OFF the battery or canceling

the diagnostic trouble codes. (Refer to

P.13-361.)

TSB Revision

2.Diagnostic trouble codes are displayed when, after cancel-

lation of the auto-cruise control system, the vehicle speed

decreases to less than approximately 20 km/h (12 mph),

and are erased by switching OFF the ignition switch or the

main switch.

Page 505 of 1273

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting13-363

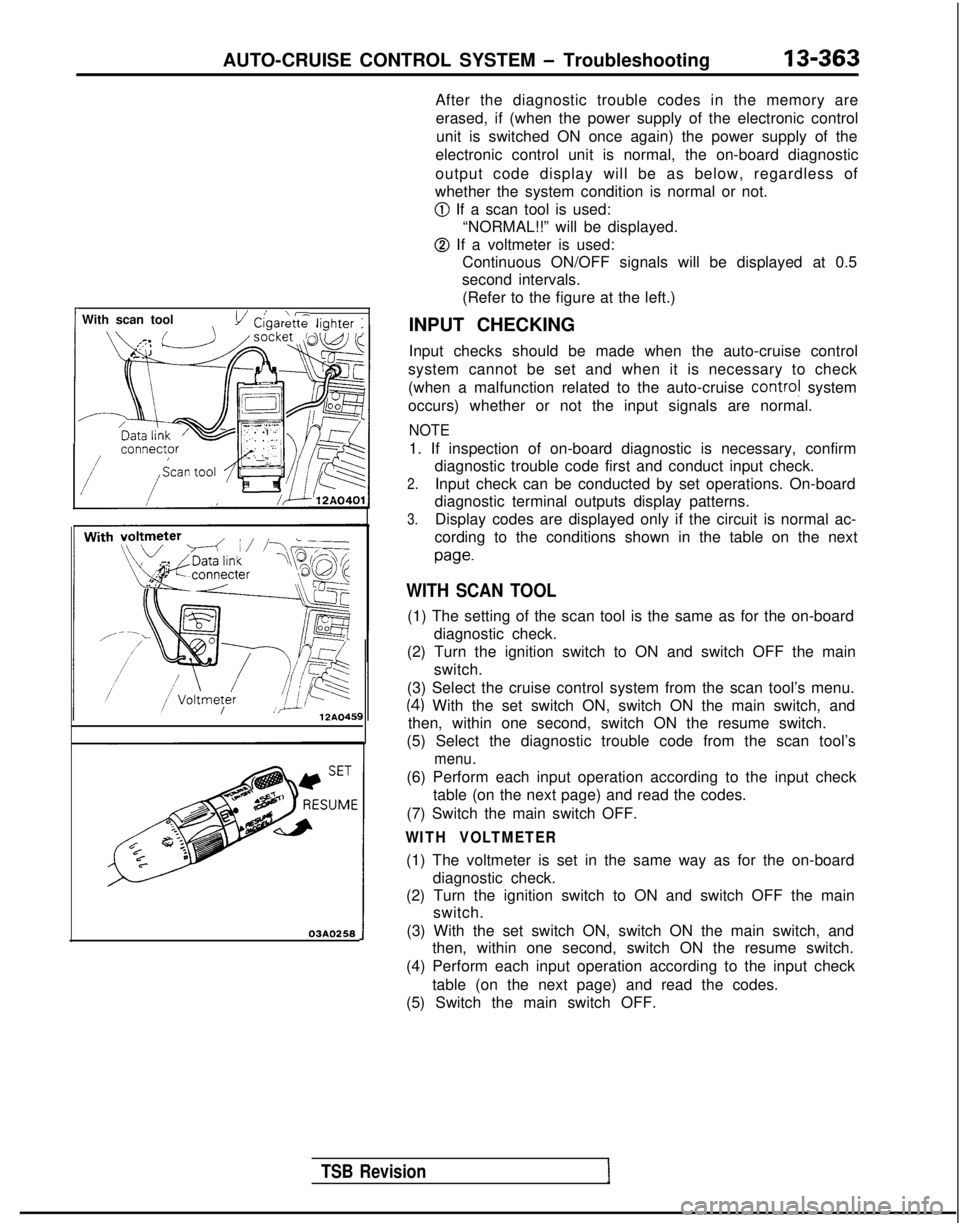

With scan toolri++, lighter ;

03A0258

TSB Revision

After the diagnostic trouble codes in the memory are

erased, if (when the power supply of the electronic controlunit is switched ON once again) the power supply of the

electronic control unit is normal, the on-board diagnostic

output code display will be as below, regardless of

whether the system condition is normal or not.

@ If a scan tool is used: “NORMAL!!” will be displayed.

@ If a voltmeter is used:Continuous ON/OFF signals will be displayed at 0.5

second intervals.

(Refer to the figure at the left.)

INPUT CHECKING

Input checks should be made when the auto-cruise control

system cannot be set and when it is necessary to check

(when a malfunction related to the auto-cruise

contra! system

occurs) whether or not the input signals are normal.

NOTE

1. If inspection of on-board diagnostic is necessary, confirm diagnostic trouble code first and conduct input check.

2.Input check can be conducted by set operations. On-board

diagnostic terminal outputs display patterns.

3.Display codes are displayed only if the circuit is normal ac-

cording to the conditions shown in the table on the next

paw

WITH SCAN TOOL

(1) The setting of the scan tool is the same as for the on-board diagnostic check.

(2) Turn the ignition switch to ON and switch OFF the main switch.

(3) Select the cruise control system from the scan tool’s menu.

(4) With the set switch ON, switch ON the main switch, and

then, within one second, switch ON the resume switch.

(5) Select the diagnostic trouble code from the scan tool’s

menu.

(6) Perform each input operation according to the input check table (on the next page) and read the codes.

(7) Switch the main switch OFF.

WITH VOLTMETER

(1) The voltmeter is set in the same way as for the on-board diagnostic check.

(2) Turn the ignition switch to ON and switch OFF the main switch.

(3) With the set switch ON, switch ON the main switch, and then, within one second, switch ON the resume switch.

(4) Perform each input operation according to the input check

table (on the next page) and read the codes.

(5) Switch the main switch OFF.

Page 506 of 1273

13-364AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

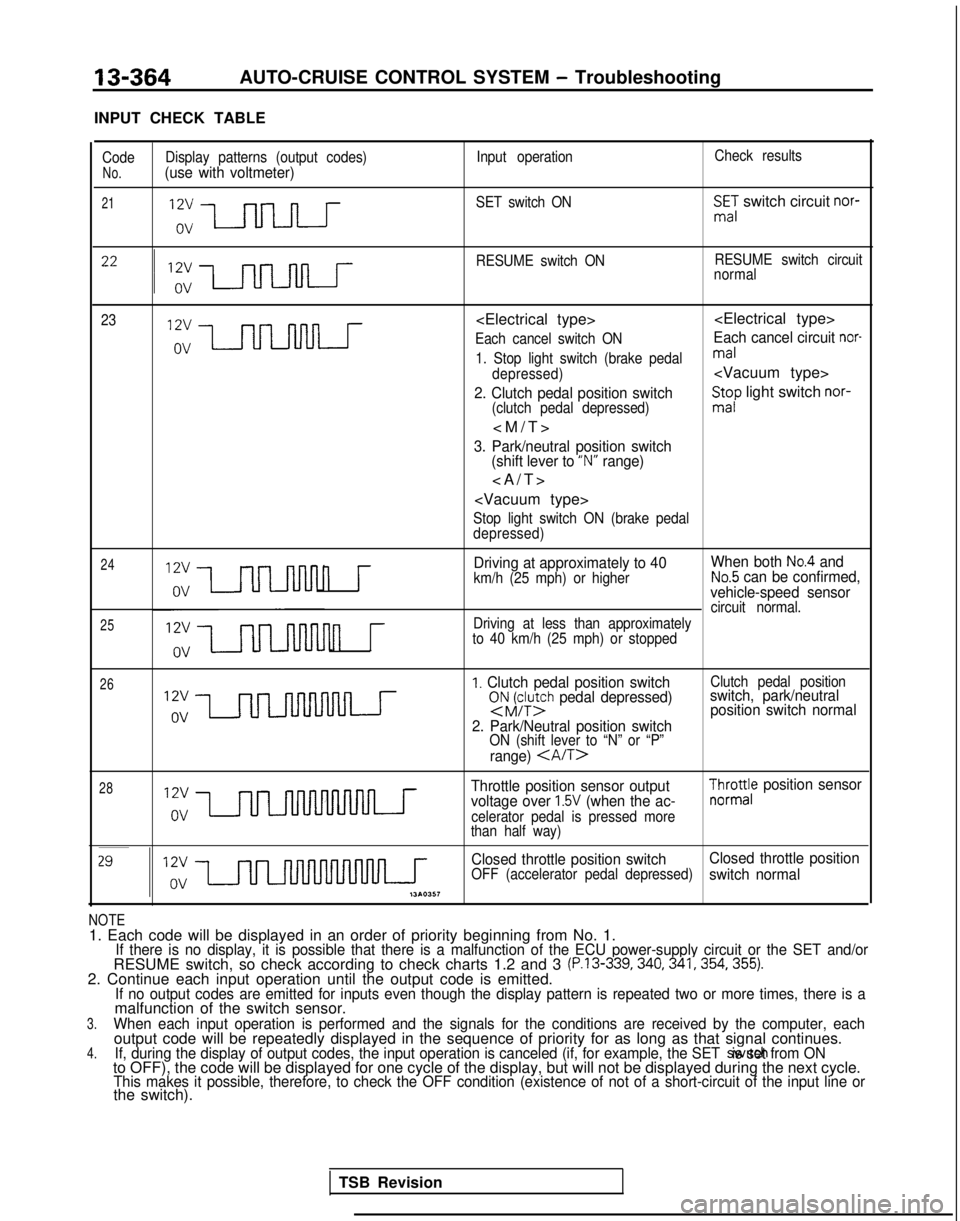

INPUT CHECK TABLE

Code Display patterns (output codes) Input operationCheck resultsNo.(use with voltmeter)

21SET switch ONSmE,: switch circuit nor-

RESUME switch ON RESUME switch circuit

normal

23

Each cancel switch ONEach cancel circuit nor-

1. Stop light switch (brake pedalmal

depressed)

2. Clutch pedal position switch(clutch pedal depressed)

St;p light switch nor-

3. Park/neutral position switch

(shift lever to “N” range)

>

Stop light switch ON (brake pedal

depressed)

24

25

n r

Driving at approximately to 40 When both No.4 and

km/h (25 mph) or higherNo.5 can be confirmed,

vehicle-speed sensor

circuit normal.

n r

Driving at less than approximately

to 40 km/h (25 mph) or stopped

26I. Clutch pedal position switchsNJFy;h pedal depressed)

2. Park/Neutral position switch

ON (shift lever to “N” or “P”

range)

Clutch pedal positionswitch, park/neutral position switch normal

28Throttle position sensor output

voltage over 1.5V (when the ac-celerator pedal is pressed more

than half way)

$yro;e position sensor

Closed throttle position switch Closed throttle position

OFF (accelerator pedal depressed)switch normal

NOTE1. Each code will be displayed in an order of priority beginning from No\

. 1.If there is no display, it is possible that there is a malfunction of th\

e ECU power-supply circuit or the SET and/orRESUME switch, so check according to check charts 1.2 and 3 (P.13-339,340,341,354,355).2. Continue each input operation until the output code is emitted.If no output codes are emitted for inputs even though the display patter\

n is repeated two or more times, there is amalfunction of the switch sensor.3.When each input operation is performed and the signals for the condition\

s are received by the computer, eachoutput code will be repeatedly displayed in the sequence of priority for\

as long as that signal continues.4.If, during the display of output codes, the input operation is canceled \

(if, for example, the SET switch is set from ONto OFF), the code will be displayed for one cycle of the display, but w\

ill not be displayed during the next cycle.This makes it possible, therefore, to check the OFF condition (existenc\

e of not of a short-circuit of the input line orthe switch).

TSB Revision

Page 955 of 1273

33B-16 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

NOT’=

(1)

(2)

13)

(4)

(5)

‘T‘he alarm light does not illuminate for an abnormal condition (code No.12) of the generator output voltage (#,.terminal) or for air leakage (code No.56) within the front or rear valves.

For malfunctions represented by a code number with the* symbol, if the malfunction is of a temporary nature (such

as improper contact of a connector, etc.), the warning lamp’s illumi\

nation will stop when the malfunction stops, and

the function will return to normal.

When the alarm light is illuminated (i.e. when a malfunction has been d\

etected), the control mode cannot be switched (with the exception of a certain few malfunctions) when the c\

ontrol switch is pressed,.

If two or more malfunctions occur at the same time, the corresponding co\

de numbers will be displayed

In order from

the lowest one.

Cancellation of malfunction codes after checking and repair (from 1990 \

models)

Method 1: Connect a scan tool and cancel as described below.

1

w

Select “4 SPECIAL TEST” of the scan tool’s function-select menu\

.2 Next, select item No.5

“ERASE DIAG.“.

3 Press the YES key when “ERASE DIAG. DODE?” is displayed.

4

lnout ID NBR. “37”

.

8

5 Press the CLEAR key when “FINISHED ERASING DIAG. CODE” is displayed.6Disconnect the scan tool.

Method 2: Disconnect the ground cable from the battery’s negative terminal for \

10 seconds or longer, and then

reconnect.

If this method is used, note that data entered to the memory of the radi\

o and the clock will be erased,

so readjustment is necessary after the work is completed.

TSB Revision

1

Page 962 of 1273

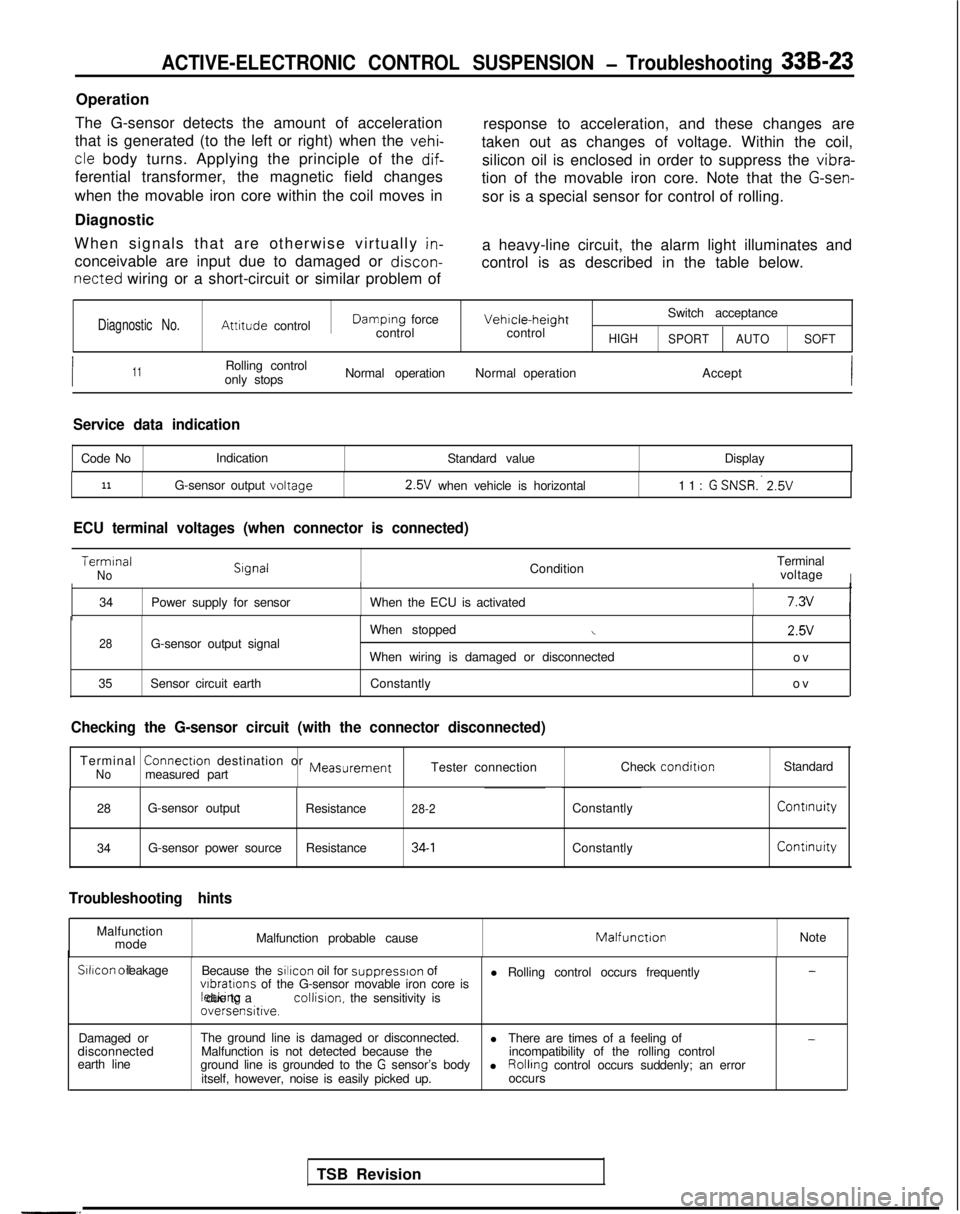

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-23

Operation

The G-sensor detects the amount of acceleration

that is generated (to the left or right) when the

vehi-

response to acceleration, and these changes are

cle body turns. Applying the principle of the dif-

taken out as changes of voltage. Within the coil,

ferential transformer, the magnetic field changes silicon oil is enclosed in order to suppress the vibra-

tion of the movable iron core. Note that the

G-sen-

when the movable iron core within the coil moves in

Diagnostic sor is a special sensor for control of rolling.

When signals that are otherwise virtually

in-

conceivable are input due to damaged or discon-

a heavy-line circuit, the alarm light illuminates and

control is as described in the table below.

netted wiring or a short-circuit or similar problem of

Diagnostic No.Attitude controlDamplng force

controlVehicle-heightcontrol Switch acceptanceHIGH

SPORT AUTO SOFT

I11Rolling control

only stops Normal operation

Normal operation Accept

Service data indication

Code NoIndication

Standard value Display

11G-sensor output voltage 2.5V

when vehicle is horizontal 11: G SNSR:

2.5V

ECU terminal voltages (when connector is connected)

Terminal

NoCondition

Terminal

voltageIII

34 Power supply for sensor When the ECU is activated7.3vI

28G-sensor output signal

35 Sensor circuit earth When stoppedi

When wiring is damaged or disconnected

Constantly 2.5V

ov

ov

TSB Revision

-.

Checking the G-sensor circuit (with the connector disconnected)

Terminal ConnectIon

destination or MeasurementNomeasured part Tester connection

Check conditionStandard

28 G-sensor output

Resistance

28-2ConstantlyContinuity

34G-sensor power source

Resistance34-1ConstantlyContinuity

Troubleshooting hints

Malfunction

mode Malfunction probable causeMatfunctIonNoteSilicon

oil leakage

Because the sillcon

oil for

suppresslon of

l Rolling control occurs frequently-

vlbratlons of the G-sensor movable iron core is leaktng due to a collision.

the sensitivity is

oversensitive.

Damaged or

disconnected

earth line The ground line is damaged or disconnected.

l-Malfunction is not detected because the There are times of a feeling of

ground line is grounded to the G sensor’s body incompatibility of the rolling control

l

itself, however, noise is easily picked up. Rolling

control occurs suddenly; an error

occurs

Page 964 of 1273

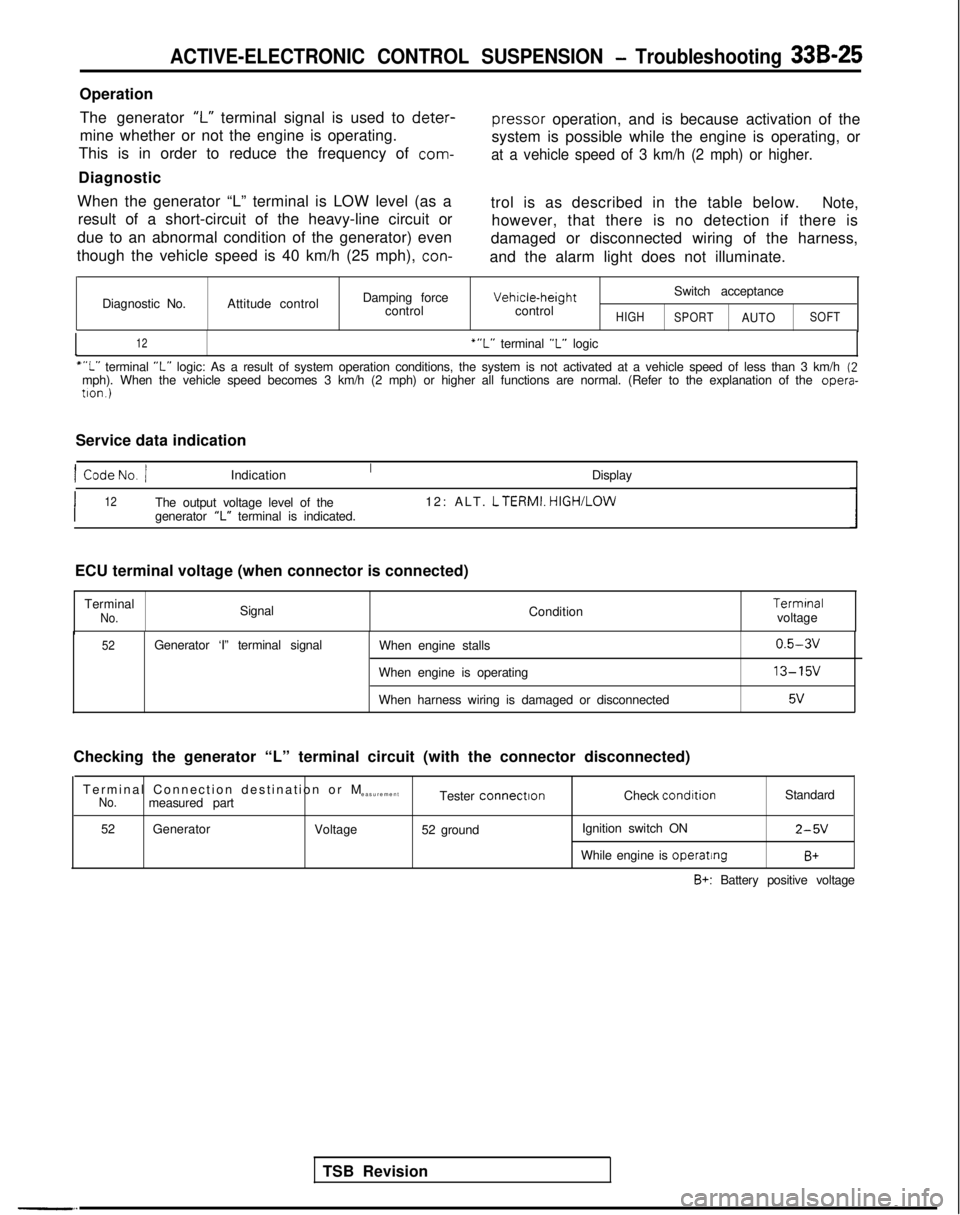

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-25

OperationThe generator

‘I-” terminal signal is used to deter-

pressor

operation, and is because activation of the

mine whether or not the engine is operating.

This is in order to reduce the frequency of

com-

system is possible while the engine is operating, or

at a vehicle speed of 3 km/h (2 mph) or higher.

Diagnostic

When the generator “L” terminal is LOW level (as a result of a short-circuit of the heavy-line circuit or

due to an abnormal condition of the generator) even

though the vehicle speed is 40 km/h (25 mph),

con-

trol is as described in the table below.Note,

however, that there is no detection if there is

damaged or disconnected wiring of the harness,

and the alarm light does not illuminate.

Diagnostic No. Attitude control Damping force

control Vehrcle-height

control

HIGH

Switch acceptance

SPORTAUTOSOFT

I12‘“L” terminal “L” logic

““L” terminal “L” logic: As a result of system operation conditions, the system is not ac\

tivated at a vehicle speed of less than 3 km/h (2mph). When the vehicle speed becomes 3 km/h (2 mph) or higher all fun\

ctions are normal. (Refer to the explanation of the opera-

tron.)

Service data indication

1 CodeNo. /Indication Display

I12The output voltage level of the12: ALT. LTERMI.

HIGH/LOW

generator “L” terminal is indicated.

TSB Revision

ECU terminal voltage (when connector is connected)

Terminal

No.Signal Condition Termrnal

voltage

52Generator ‘I” terminal signal When engine stalls

When engine is operating

When harness wiring is damaged or disconnected0.5-3v

13-15v

5v

Checking the generator “L” terminal circuit (with the connector d\

isconnected)

Terminal Connection destination or

M

easurement

No.measured part Tester connectronCheck condrtion

Standard

52 Generator

Voltage52 ground Ignition switch ON

2-5V

While engine is operatingB+

B+: Battery positive voltage