display MITSUBISHI GALANT 1989 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 966 of 1273

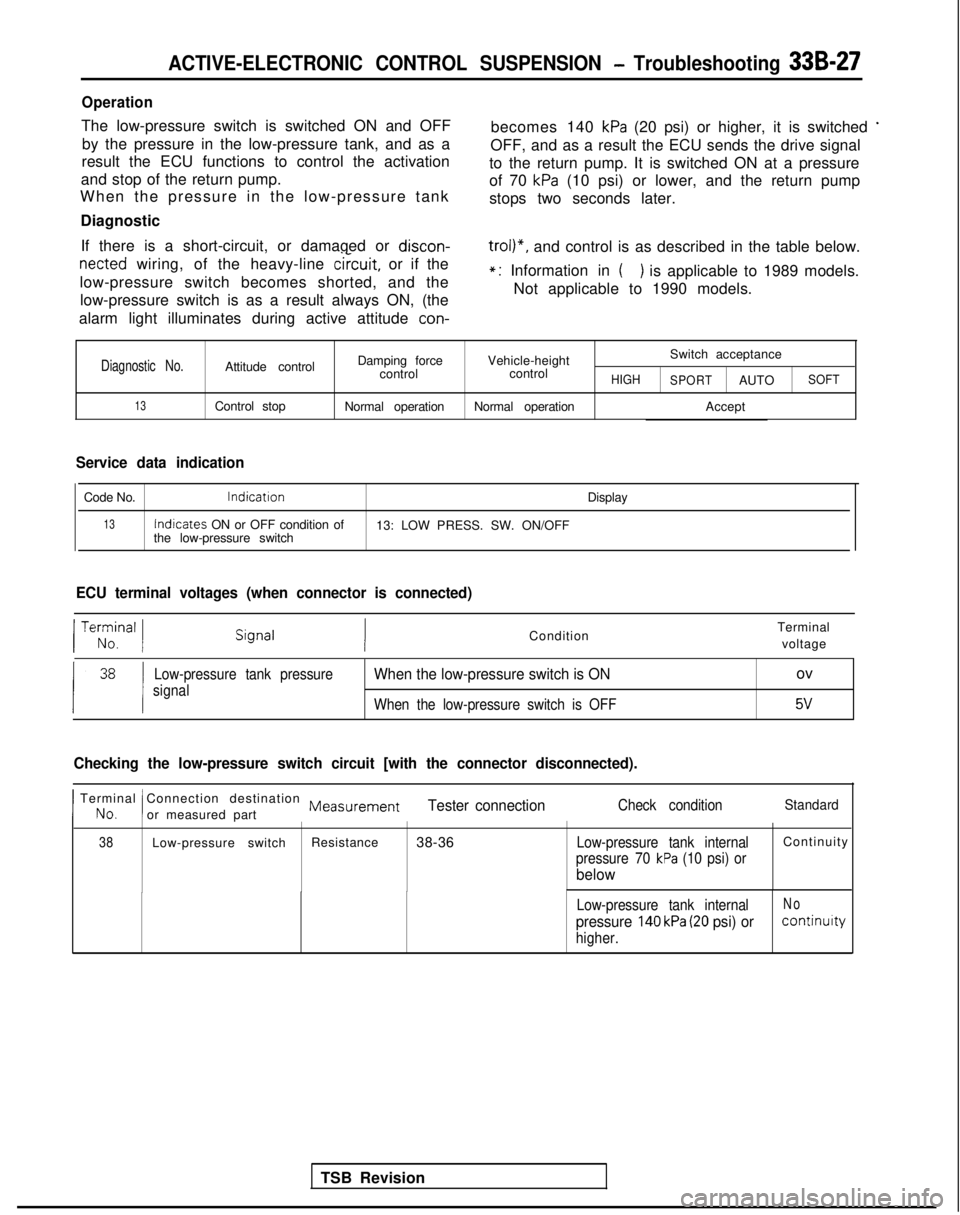

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-27

Operation

The low-pressure switch is switched ON and OFFby the pressure in the low-pressure tank, and as a becomes 140 kPa (20 psi) or higher, it is switched *

result the ECU functions to control the activation

OFF, and as a result the ECU sends the drive signal

and stop of the return pump. to the return pump. It is switched ON at a pressure

When the pressure in the low-pressure tank of 70

kPa (10 psi) or lower, and the return pump

stops two seconds later.

Diagnostic

If there is a short-circuit, or damaged or discon-

netted wiring, of the heavy-line

circuit,

or if the

low-pressure switch becomes shorted, and the low-pressure switch is as a result always ON, (the

trol)“, and control is as described in the table below.

alarm light illuminates during active attitude

con-

*: Information in () is applicable to 1989 models.

Not applicable to 1990 models.

Diagnostic No.Attitude control Damping force

Vehicle-height Switch acceptance

control controlHIGH

SPORTAUTOSOFT

13Control stop Normal operationNormal operation Accept

Service data indication

Code No.lndicatron

Display

13Indicates

ON or OFF condition of

13: LOW PRESS. SW. ON/OFF

the low-pressure switch

ECU terminal voltages (when connector is connected)

TSB Revision

/ Te;;,nal 1Condition Terminal

voltage

Low-pressure tank pressure

signalWhen the low-pressure switch is ONov

When the low-pressure switch is OFF5v

Checking the low-pressure switch circuit [with the connector disconnecte\

d).

I No.

Terminal Connection destination Measurement

!or measured partTester connectionCheck conditionStandard

38Low-pressure switch Resistance

38-36Low-pressure tank internalContinuit

y

pressure 70 kPa (10 psi) or

below

Low-pressure tank internalNo

pressure 140 kPa (20 psi) orcontinuity

higher.

Page 968 of 1273

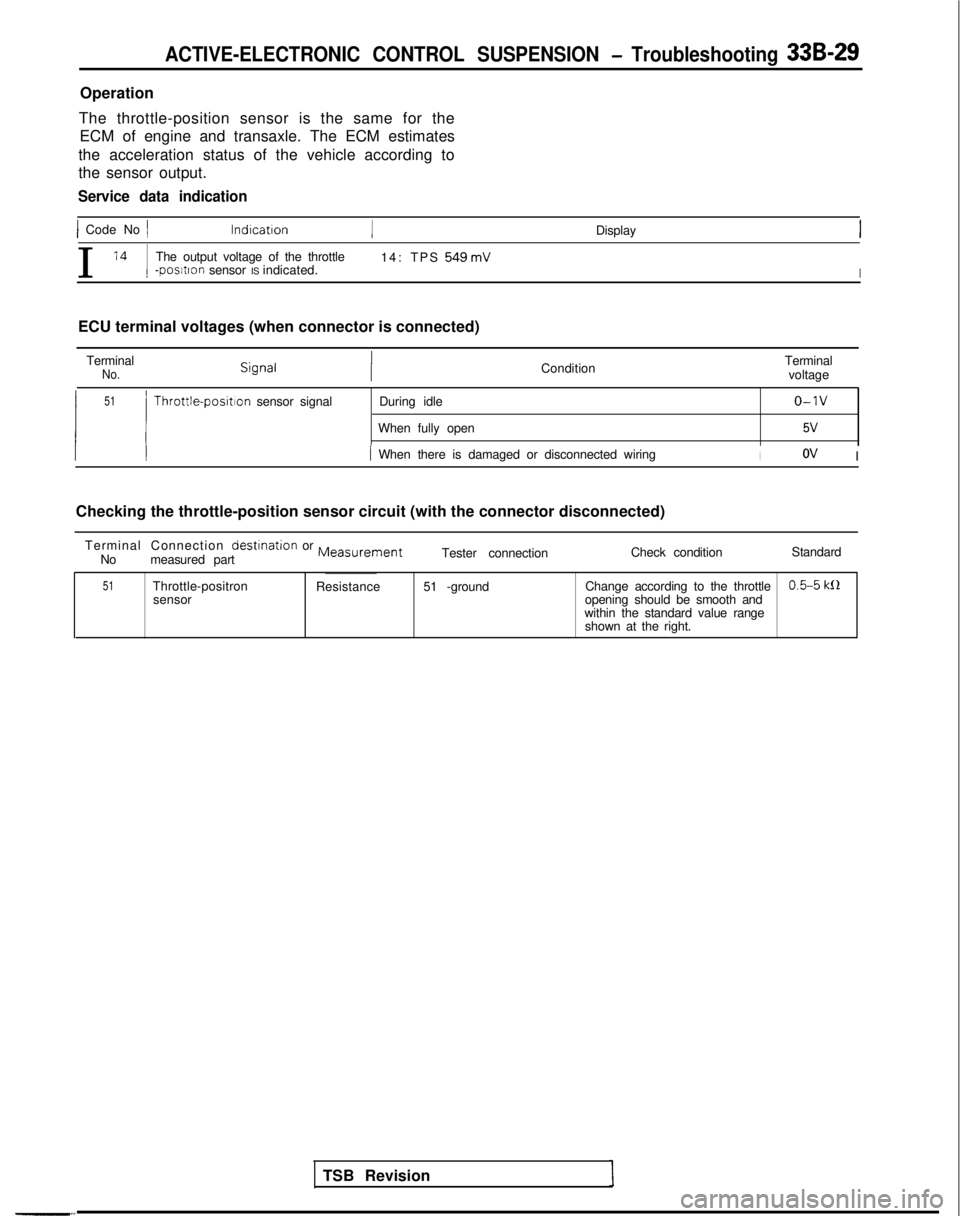

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-29

Operation

The throttle-position sensor is the same for the ECM of engine and transaxle. The ECM estimates

the acceleration status of the vehicle according to

the sensor output.

Service data indication

) Code No 1 lndrcatron

Display

I

l4 1

The output voltage of the throttle 14: TPS 549mV-postron sensor IS indicated.I

ECU terminal voltages (when connector is connected)

Terminal

No.Condition Terminal

voltage

51

1 !

Throttle-posrtlon sensor signal During idleo-1v

When fully open5v

/ When there is damaged or disconnected wiringIov I

Checking the throttle-position sensor circuit (with the connector disco\

nnected) Terminal Connection

destrnation or MeasurementNo measured part Tester connection

Check condition

Standard

51Throttle-positron

sensor Resistance

51 -ground Change according to the throttle0.5-5 k0opening should be smooth and

within the standard value range shown at the right.

TSB Revision

Page 972 of 1273

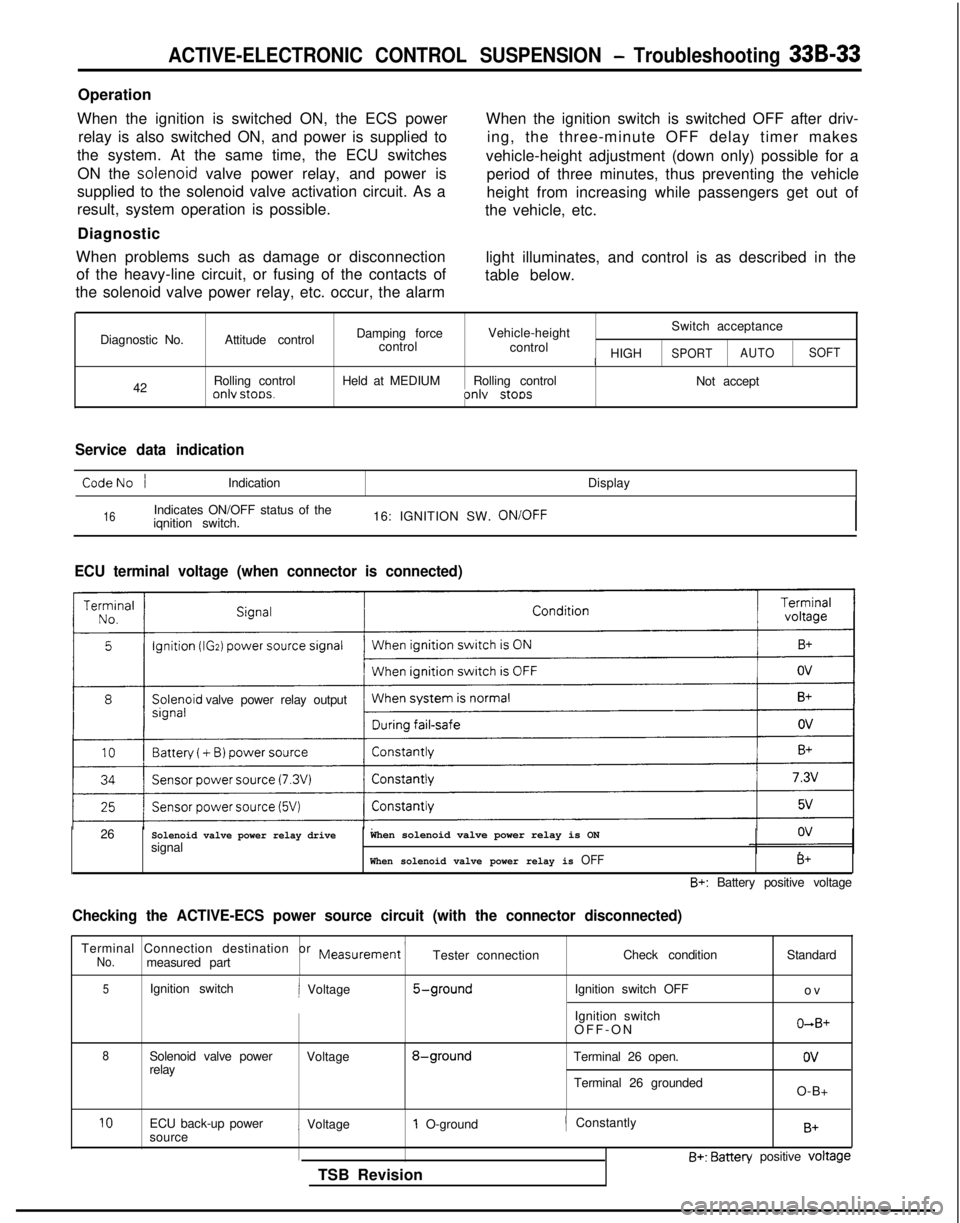

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-33

Operation

When the ignition is switched ON, the ECS power relay is also switched ON, and power is supplied to

the system. At the same time, the ECU switches

ON the solenoid

valve power relay, and power is

supplied to the solenoid valve activation circuit. As a

result, system operation is possible.

Diagnostic

When problems such as damage or disconnection of the heavy-line circuit, or fusing of the contacts of

the solenoid valve power relay, etc. occur, the alarm When the ignition switch is switched OFF after driv-

ing, the three-minute OFF delay timer makes

vehicle-height adjustment (down only) possible for a period of three minutes, thus preventing the vehicle

height from increasing while passengers get out of

the vehicle, etc.

light illuminates, and control is as described in the

table below.

Diagnostic No. 42 Attitude control

Rolling control

onlv stoos.

Damping force

Vehicle-height Switch acceptance

control control

/ HIGHSPORTAUTOSOFT

Held at MEDIUM

Rolling control

Not acceptonlv stoos

Service data indication

CodeNo /Indication Display

16Indicates ON/OFF status of the

iqnition switch. 16: IGNITION SW. ON/OFF

ECU terminal voltage (when connector is connected)

valve power relay output

26

Solenoid valve power relay drivesignalWhen solenoid valve power relay is ON

When solenoid valve power relay is OFFB+

B+: Battery positive voltage

Checking the ACTIVE-ECS power source circuit (with the connector discon\

nected)

Terminal Connection destination or Measurement ’No.measured part Tester connection

Check condition

5Ignition switchi Voltage5-groundIgnition switch OFF

Ignition switch

OFF-O

N

8Solenoid valve power

Voltage8-groundTerminal 26 open.

relay

Terminal 26 groundedStandard

o

v

O+B+

ov

O-B+

10ECU back-up power

sourcei Voltage1 O-ground

TSB Revision/ ConstantlyB+

B+: Batten/ positive voltage

Page 978 of 1273

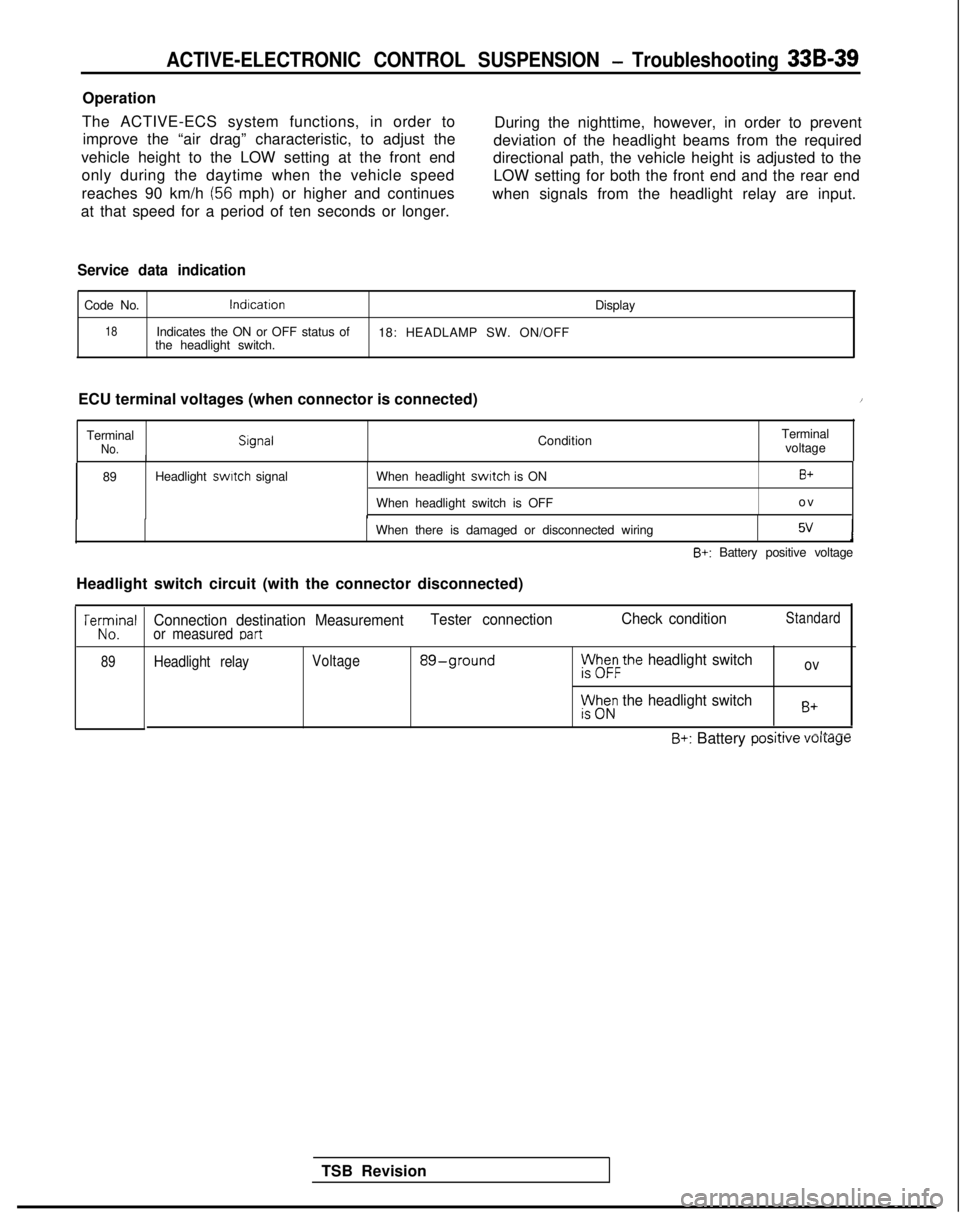

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-39

Operation

The ACTIVE-ECS system functions, in order to improve the “air drag” characteristic, to adjust the During the nighttime, however, in order to prevent

vehicle height to the LOW setting at the front end deviation of the headlight beams from the required

only during the daytime when the vehicle speed directional path, the vehicle height is adjusted to the

reaches 90 km/h

(56 mph) or higher and continues LOW setting for both the front end and the rear end

at that speed for a period of ten seconds or longer. when signals from the headlight relay are input.

Service data indication

Code No.lndlcation

Display

18Indicates the ON or OFF status of

18: HEADLAMP SW. ON/OFF

the headlight switch.

ECU terminal voltages (when connector is connected)

/

TerminalNo. Slgnal

ConditionTerminal

voltage

89 Headlight switch

signal When headlight

switch is ON

When headlight switch is OFFB+

o

v

When there is damaged or disconnected wiring

5vJ

B+: Battery positive voltage

Headlight switch circuit (with the connector disconnected)

TSB Revision

TeKJna’

89

Connection destination Measurement Tester connectionCheck conditionStandard

or measured Dart

Headlight relayVoltage 89-groundph&the headlight switchov

rt$z; the headlight switchB+

~.A.-II___B+: Battery posrrrve voltage

Page 980 of 1273

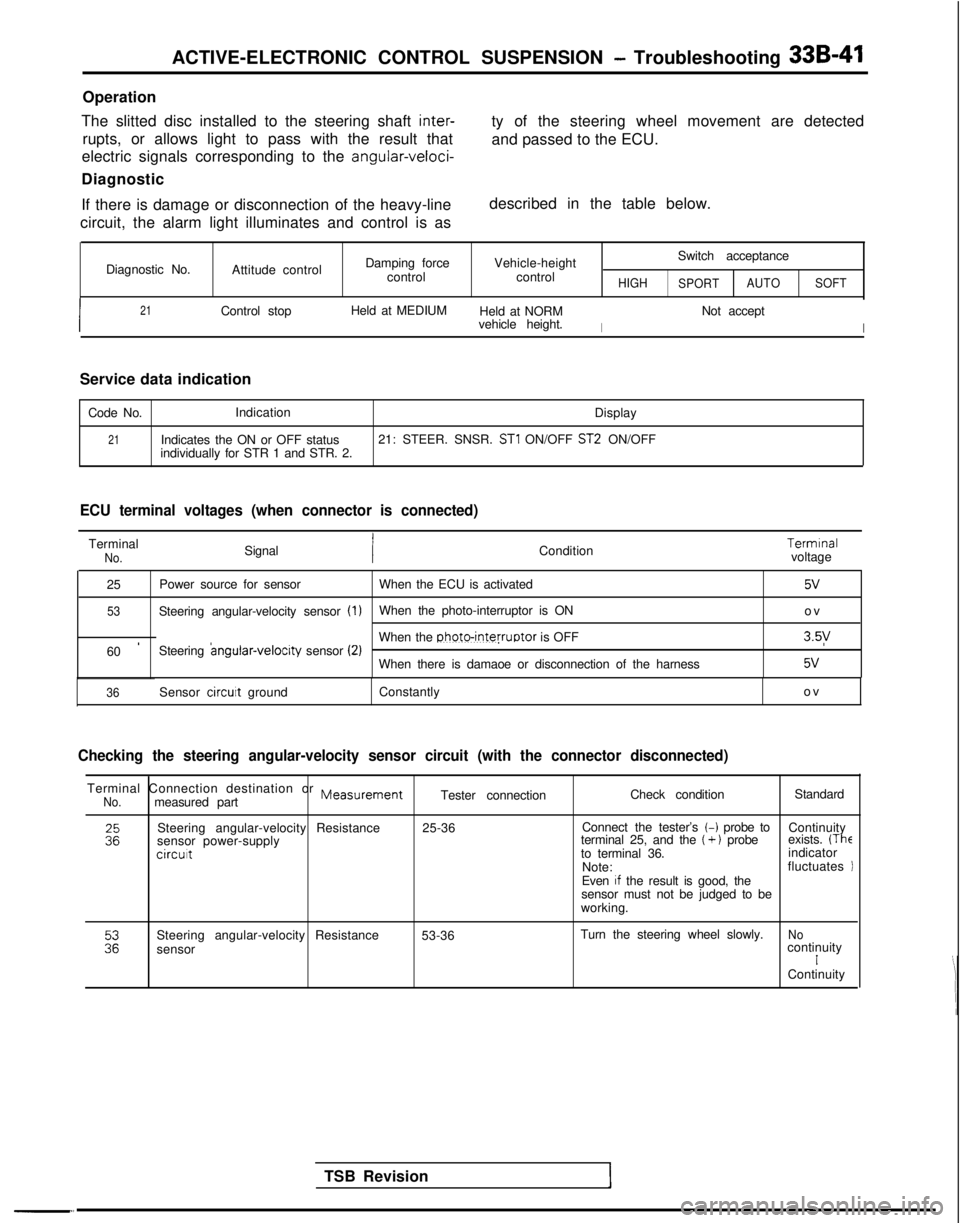

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-41

Operation

The slitted disc installed to the steering shaft

inter-

rupts, or allows light to pass with the result that

electric signals corresponding to the

angular-veloci-

Diagnostic

If there is damage or disconnection of the heavy-line

circuit, the alarm light illuminates and control is as ty of the steering wheel movement are detected

and passed to the ECU.

described in the table below.

Diagnostic No. Attitude control Damping force

control Vehicle-height

control

HIGH

Switch acceptance

SPORT AUTO

SOFT

I

21Control stop Held at MEDIUM

Held at NORM

I

Not accept

vehicle height.

I

Service data indication

Code No. Indication

Display

21Indicates the ON or OFF status21: STEER. SNSR. ST1 ON/OFF ST2 ON/OFF

individually for STR 1 and STR. 2.

ECU terminal voltages (when connector is connected)

TerminalNo.Signal Condition Termrnal

voltage

25 Power source for sensor

When the ECU is activated

5v

53Steering angular-velocity sensor (1)When the photo-interruptor is ON

o

v

60

’Steering angular-velocrty

sensor (2)When the photo-interruptor is OFF3.5y

When there is damaoe or disconnection of the harness5v

-“.

TSB Revision

36Sensor circuit

ground Constantly ov

Checking the steering angular-velocity sensor circuit (with the connect\

or disconnected)

Terminal Connection destination or MeasurementNo.measured partTester connection

Check condition

Standard

Steering angular-velocity Resistance

sensor power-supply

circut

25-36 Connect the tester’s t-i probe to

Continuity

terminal 25, and the (+ ) probe exists. (Theto terminal 36. indicator

Note: fluctuates

Even

If the result is good, the

sensor must not be judged to be

working.

Steering angular-velocity Resistance

sensor 53-36

Turn the steering wheel slowly.

NocontinuityIContinuity

Page 986 of 1273

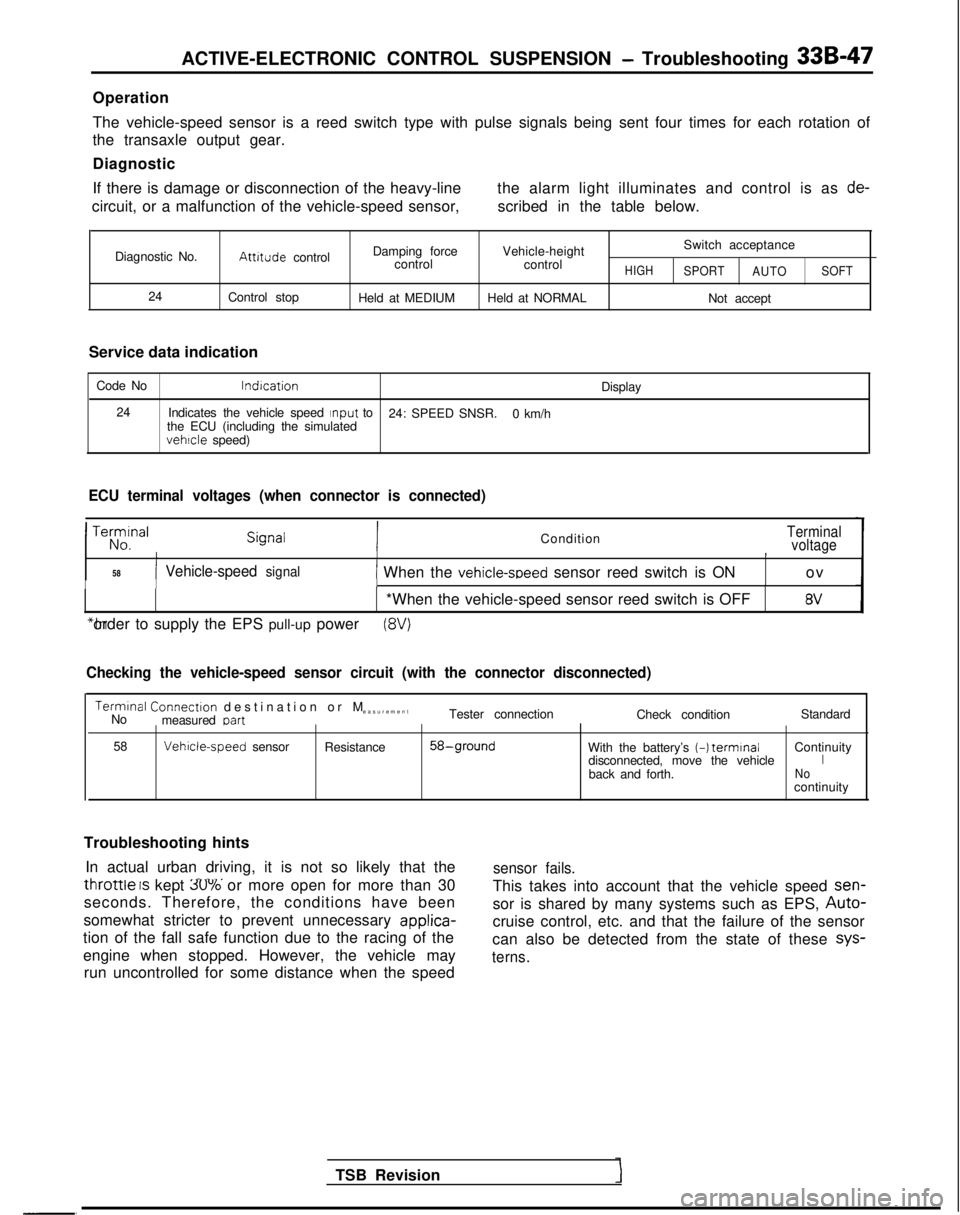

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-47

Operation

The vehicle-speed sensor is a reed switch type with pulse signals being \

sent four times for each rotation of

the transaxle output gear.

Diagnostic

If there is damage or disconnection of the heavy-line

the alarm light illuminates and control is as

de-

circuit, or a malfunction of the vehicle-speed sensor, scribed in the table below.

Diagnostic No. 24

Attitude control Damping force

Vehicle-height Switch acceptance

control controlHIGHSPORTAUTO SOFT

Control stop

Held at MEDIUMHeld at NORMAL

Not accept

Service data indication Code No lndrcation

Display

24 Indicates the vehicle speed Input

to

24: SPEED SNSR. 0 km/h

the ECU (including the simulated

vehicle speed)

ECU terminal voltages (when connector is connected)

ITerNmo_na’ConditionTerminal

voltage

I I

58 /

I

Vehicle-speed signal1 When the vehicle-speed sensor reed switch is ONo

v

IIII

*When the vehicle-speed sensor reed switch is OFF8V

TSB Revision

*In order to supply the EPS pull-up power

(8V)

Checking the vehicle-speed sensor circuit (with the connector disconnec\

ted)

Termrnal

Connectron

destination or M

easurement

No measured part

Tester connection

Check conditionStandard

58 Vehrcle-speed

sensor

Resistance

58-groundWith the battery’s (-1 termrnal

Continuity

disconnected, move the vehicleIback and forth.Nocontinuity

Troubleshooting hints In actual urban driving, it is not so likely that the

sensor fails.., ^_^.tnrottle IS kept 3U% or more open for more than 30

seconds. Therefore, the conditions have been This takes into account that the vehicle speed sen-

somewhat stricter to prevent unnecessary applica-

sor is shared by many systems such as EPS,

Auto-

tion of the fall safe function due to the racing of the cruise control, etc. and that the failure of the sensor

engine when stopped. However, the vehicle may can also be detected from the state of these sys-

terns.run uncontrolled for some distance when the speed

Page 988 of 1273

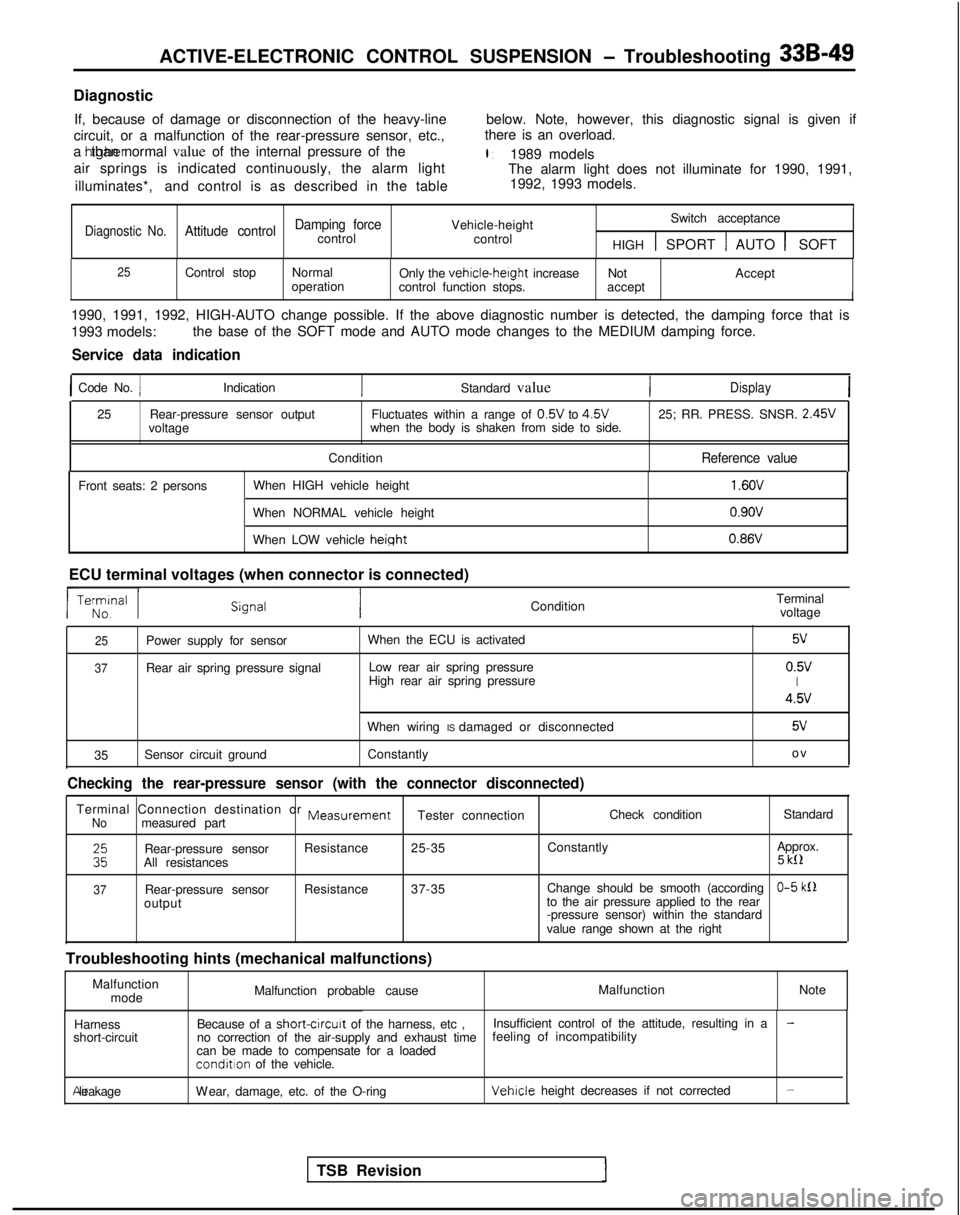

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-49

Diagnostic

If, because of damage or disconnection of the heavy-line below. Note, however, this diagnostic signal is given if

circuit, or a malfunction of the rear-pressure sensor, etc., there is an overload.

a htgher than normal value of the internal pressure of the

l :1989 models

air springs is indicated continuously, the alarm light The alarm light does not illuminate for 1990, 1991,

illuminates*, and control is as described in the table 1992, 1993 models.

I1

Damping forceVehicle-heightSwitch acceptanceDiagnostic No.Attitude controlcontrol

control

HIGH 1 SPORT 1 AUTO 1 SOFT

25Control stopNormal

Only the vehicle-height

increase Not Accept

operation control function stops. accept

I

1990, 1991, 1992, HIGH-AUTO change possible. If the above diagnostic num\

ber is detected, the damping force that is

1993 models:the base of the SOFT mode and AUTO mode changes to the MEDIUM damping fo\

rce.

Service data indication

1 Code No. 1Indication

Standard valueDisplay

25Rear-pressure sensor output Fluctuates within a range of 0.5V

to 4.5V

25; RR. PRESS. SNSR. 2.45V

voltage when the body is shaken from side to side.

Condition

Reference value

Front seats: 2 persons When HIGH vehicle height

When NORMAL vehicle height

When LOW vehicle

height

1.6OV

0.9ov 0.86V

ECU terminal voltages (when connector is connected) ConditionTerminal

voltage

25Power supply for sensor

37Rear air spring pressure signal When the ECU is activated

Low rear air spring pressure

High rear air spring pressure

5v

0.5vI

4.5v

When wiring IS damaged or disconnected5v

35 Sensor circuit ground

Constantly o

v

Checking the rear-pressure sensor (with the connector disconnected)

Terminal Connection destination or MeasurementNomeasured part

Tester connection

Check condition

Standard

ERear-pressure sensorResistance

25-35 Constantly Approx.

All resistances 5 kll

37Rear-pressure sensor

Resistance

37-35 Change should be smooth (accordingO-5 klloutput to the air pressure applied to the rear

-pressure sensor) within the standard

value range shown at the right

Troubleshooting hints (mechanical malfunctions) Malfunctionmode Malfunction probable cause

Malfunction

Note

Harness

short-circuit Because of a short-circurt

of the harness, etc , Insufficient control of the attitude, resulting in a

-no correction of the air-supply and exhaust time feeling of incompatibility

can be made to compensate for a loaded

condition of the vehicle. Air leakage

Wear, damage, etc. of the O-ring

Vehicle height decreases if not corrected-

TSB Revision

Page 990 of 1273

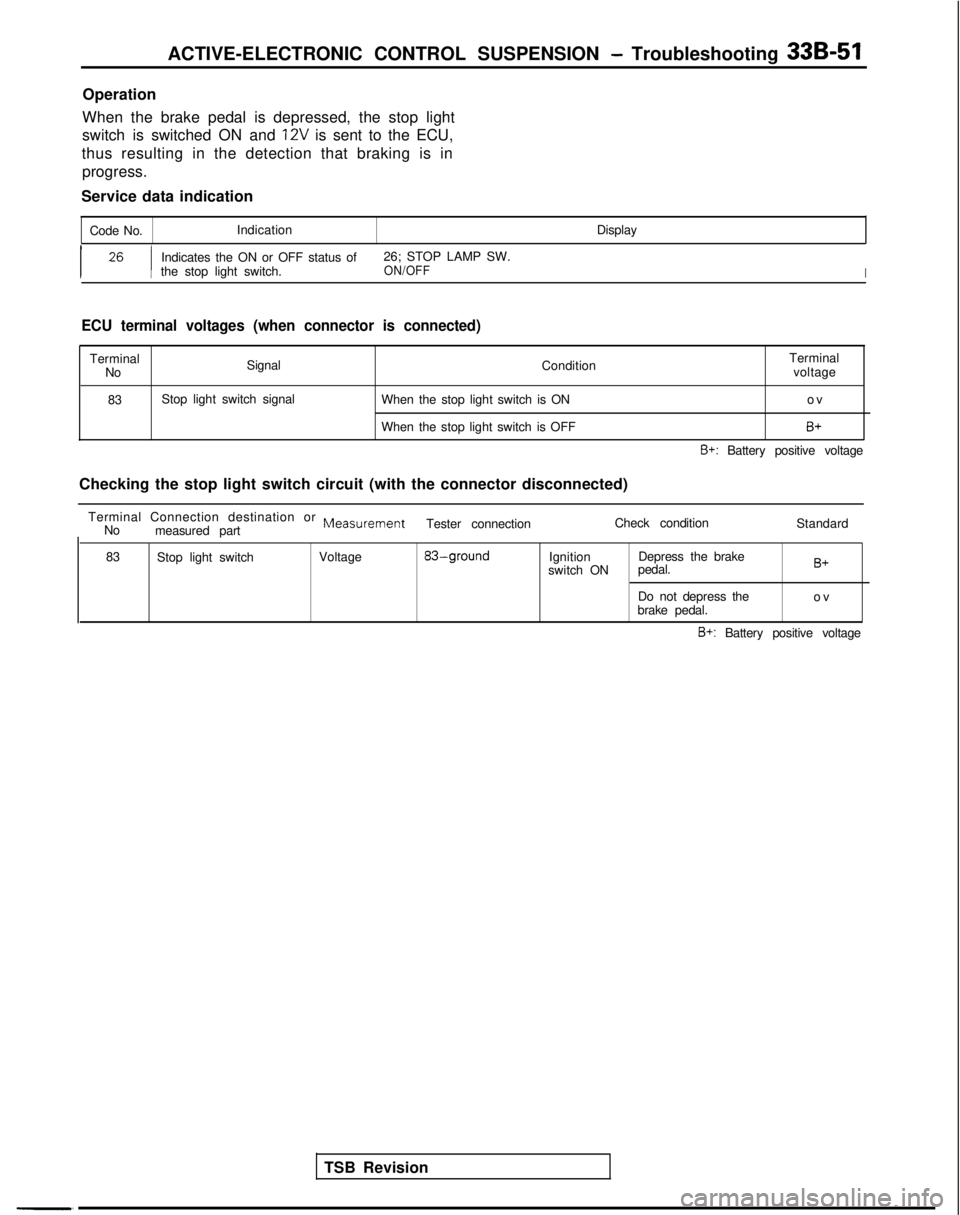

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-51

Operation

When the brake pedal is depressed, the stop light

switch is switched ON and

1% is sent to the ECU,

thus resulting in the detection that braking is in progress.

Service data indication

Code No. Indication

Display

I 26 I

Indicates the ON or OFF status of26; STOP LAMP SW.

the stop light switch.ON/OFFI

ECU terminal voltages (when connector is connected)

Terminal Signal ConditionTerminal

No voltage

83 Stop light switch signal

When the stop light switch is ON o

v

When the stop light switch is OFF

B+

B+: Battery positive voltage

Checking the stop light switch circuit (with the connector disconnected\

) Terminal Connection destination or

MeasurementNo measured part Tester connection

Check condition

Standard

83 Stop light switch Voltage

83-groundIgnitionDepress the brake

switch ON pedal.B+

Do not depress the

o

v

brake pedal.

B+: Battery positive voltage

TSB Revision

-,

Page 991 of 1273

![MITSUBISHI GALANT 1989 Service Workshop Manual 33B-52

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[15] BACK-UP LIGHT SWITCH CIRCUIT Ignition switch (IG,)

c-43

-T----

From 1990 models 1989

models

C-23

-1

From 1990 models Junction

blo MITSUBISHI GALANT 1989 Service Workshop Manual 33B-52

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[15] BACK-UP LIGHT SWITCH CIRCUIT Ignition switch (IG,)

c-43

-T----

From 1990 models 1989

models

C-23

-1

From 1990 models Junction

blo](/img/19/57312/w960_57312-990.png)

33B-52

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[15] BACK-UP LIGHT SWITCH CIRCUIT Ignition switch (IG,)

c-43

-T----

From 1990 models 1989

models

C-23

-1

From 1990 models Junction

block

B-21

C-23 A

fiYl%mq

1989 models

F-lfi

& 12 *

c

2 12,16

ifi

Back-up

light switch

+ From 1990

models

*

To back-up

light

ECU12AO400

Checking the back-up light switch circuit (with the connector disconnec\

ted)

Terminal Connection destination or

,v,easurement TesterNo.measured Dartconnection Check condition

Standard

72Back-up light

Voltage72-groundWith the shift leverIgnition switch OFFo

v

shifted to the REVERSE position Ignition switch ON

B+

Service data indicationB+: Battery positive voltage

Code No. Indication Display

32Indicates the ON or OFF status of

32; M/T

BACK LAMP ON/OFF

the back-up light switch.

ECU terminal voltages (when connector is connected)

TerminalNoCondition Terminal

voltage

72Manual transaxle back-up signal

I

When the back-up light switch is ON

When the back-up light switch is OFF

1

1 TSB Revision

B+

o

v

I1B+: Battery positive voltage

Page 992 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-53

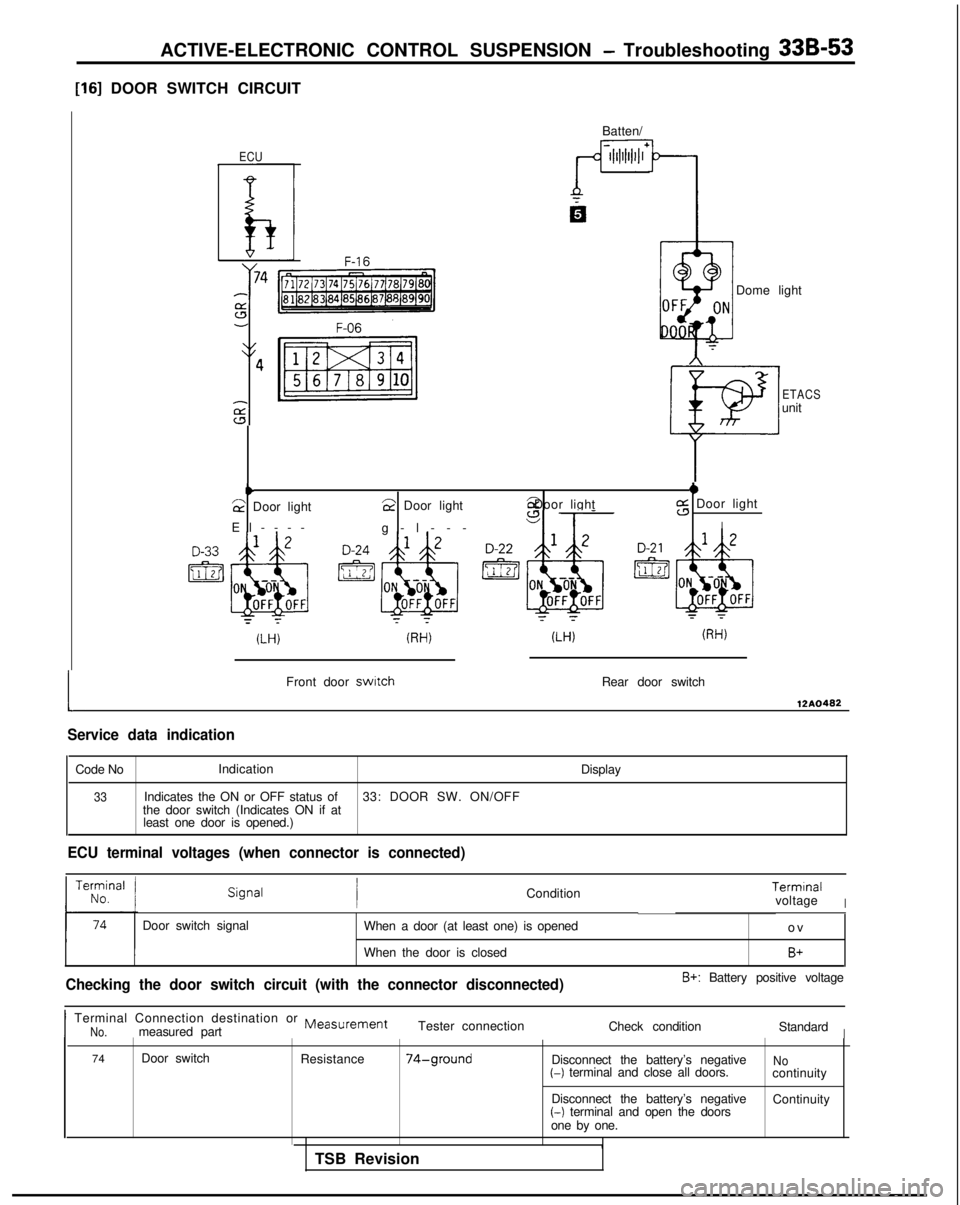

1161 DOOR SWITCH CIRCUIT

L

ECU

Batten/

Dome light

ETACSunit

b +G Door light2 Door light

6? Door light

El---- g-l---

sl--

z Door light

I

Front door swatchRear door switch

Service data indication

Code NoIndication

Display

33Indicates the ON or OFF status of33: DOOR SW. ON/OFF

the door switch (Indicates ON if at least one door is opened.)

ECU terminal voltages (when connector is connected)

Condition Termrnal

voltageI

Door switch signal When a door (at least one) is opened

When the door is closed o

v

B+

Checking the door switch circuit (with the connector disconnected)B+: Battery positive voltage

ITerminal Connection destination or MeasurementNo.measured part

Tester connection

Check conditionStandardI

74Door switch

Resistance74-groundDisconnect the battery’s negative (-)

terminal and close all doors.

Disconnect the battery’s negative (-)

terminal and open the doors

one by one.Nocontinuity

Continuity

TSB Revision