light MITSUBISHI GALANT 1989 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 192 of 1273

13-50 FUEL SYSTEM

INSPECTION

Using Scan Tool

Item No. Data display Inspection conditions

12Sensor de-

tection air

volume (fre-

quency) . Engine coolant

temperature: 85-95°C(185-205°F). Lights, cooling fan, elec-

trical accessories: OFF

. Transaxle: neutral (iVT

models: “P” range)

RacingFrequency in-

creases as racing

rpm increases.

NOTEThe volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new [driven approximately 500 km (300 miles) or less].

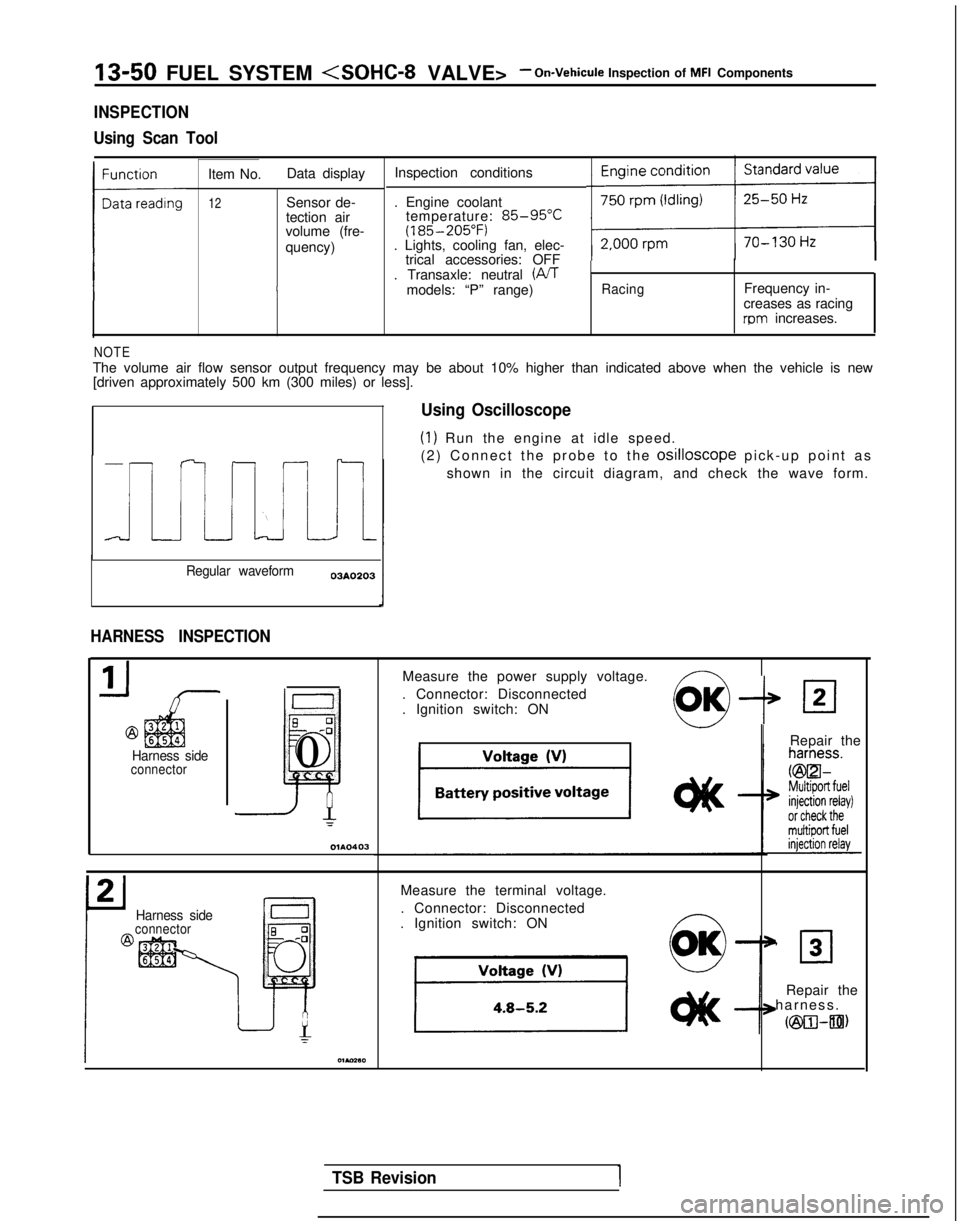

Regular waveform 03A0203

HARNESS INSPECTION

@

Harness sideconnector

6

0-0

~

0

=

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the

osilloscope pick-up point a

s

shown in the circuit diagram, and check the wave form.

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

--P

IRepair the

Harness sideconnector

Measure the terminal voltage.

. Connector: Disconnected

. Ignition switch: ON ~

0

OK’ 30

Repair the

harness

.

cm-an)

TSB Revision1

Page 204 of 1273

13-62 FUEL SYSTEM

INSPECTION

Using Scan tool

FunctionItem No.

Data reading 26 Data display

Inspection conditions Switch

status Ignition

switch: ON

(Check after pumping

accelerator several times.) Throttle valve

Normal indication

To idle position

ON

Slightly openedOFF

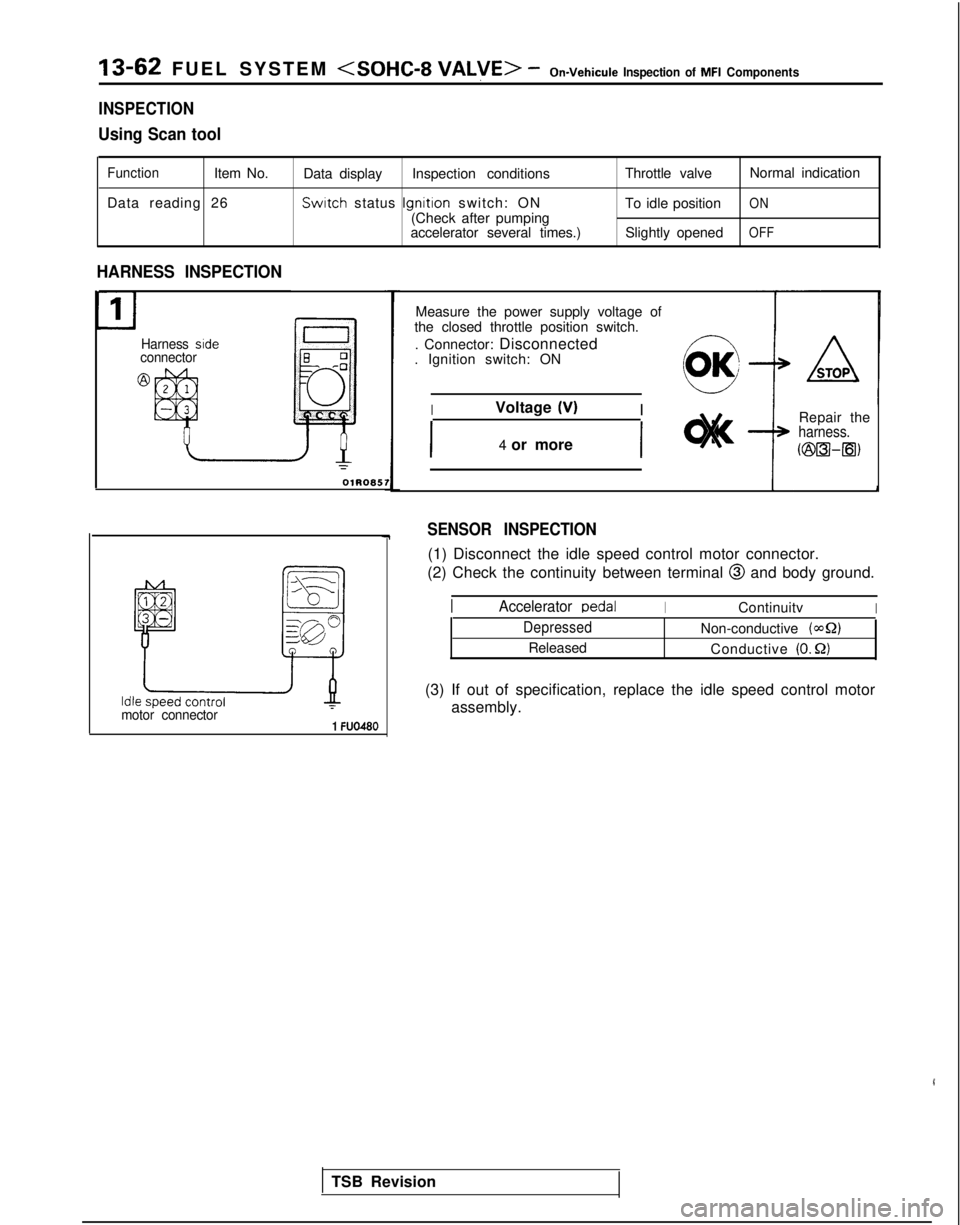

HARNESS INSPECTION

Harness sideconnector

Y

OlR085

motor connector1 FUO480

Measure the power supply voltage of

the closed throttle position switch.

. Connector: Disconnected

. Ignition switch: ON

IVoltage (V)I

I4 or moreI

Repair theharness.

c@a-m)

SENSOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check the continuity between terminal

@ and body ground.

TSB Revision

IAccelerator DedalIContinuitvI

DepressedNon-conductive (42)

Released Conductive (0. Q)

(3) If out of specification, replace the idle speed control motor

assembly.

Page 207 of 1273

FUEL SYSTEM

(1) Improper adjustment of the basic idling speed.

(2) Deposits adhering to the ttirottle valve.

(3) Air being taken into the intake manifold due to a gasket leak, etc.

OPERATION

ISC motor position sensor is a variable resistor type,

and is integrated in the

ISC motor system. The slid-

ing pin of

ISC motor position sensor is in contact

with the end of the plunger. Therefore, as the plun- ger moves, the internal resistance of

ISC motor pos-

ition sensor varies. This leads to the variation of the (4) Improper seating of the EGR valve seat.

(5) lmcomplete combustion within a cylinder. (Mal-

function of spark plugs, ignition coil, injectors,

compression pressure, etc.)

the plunger position of the

ISC motor system, and

sends the signal to ECM. ECM processes the

ISC

motor position sensor signal, idle signal, coolant

temperature signal, load signal (A/T &

A/C) and ve-

hicle speed signal to control the opening angle of

the throttle valve and revolution speed during

en-

output voltage. ISC motor position sensor detects gine idling.

TROUBLESHOOTING HINTS

Since idling is not controlled when ISC motor posi-

tion sensor is troubled, idling may not be evenly

maintained.

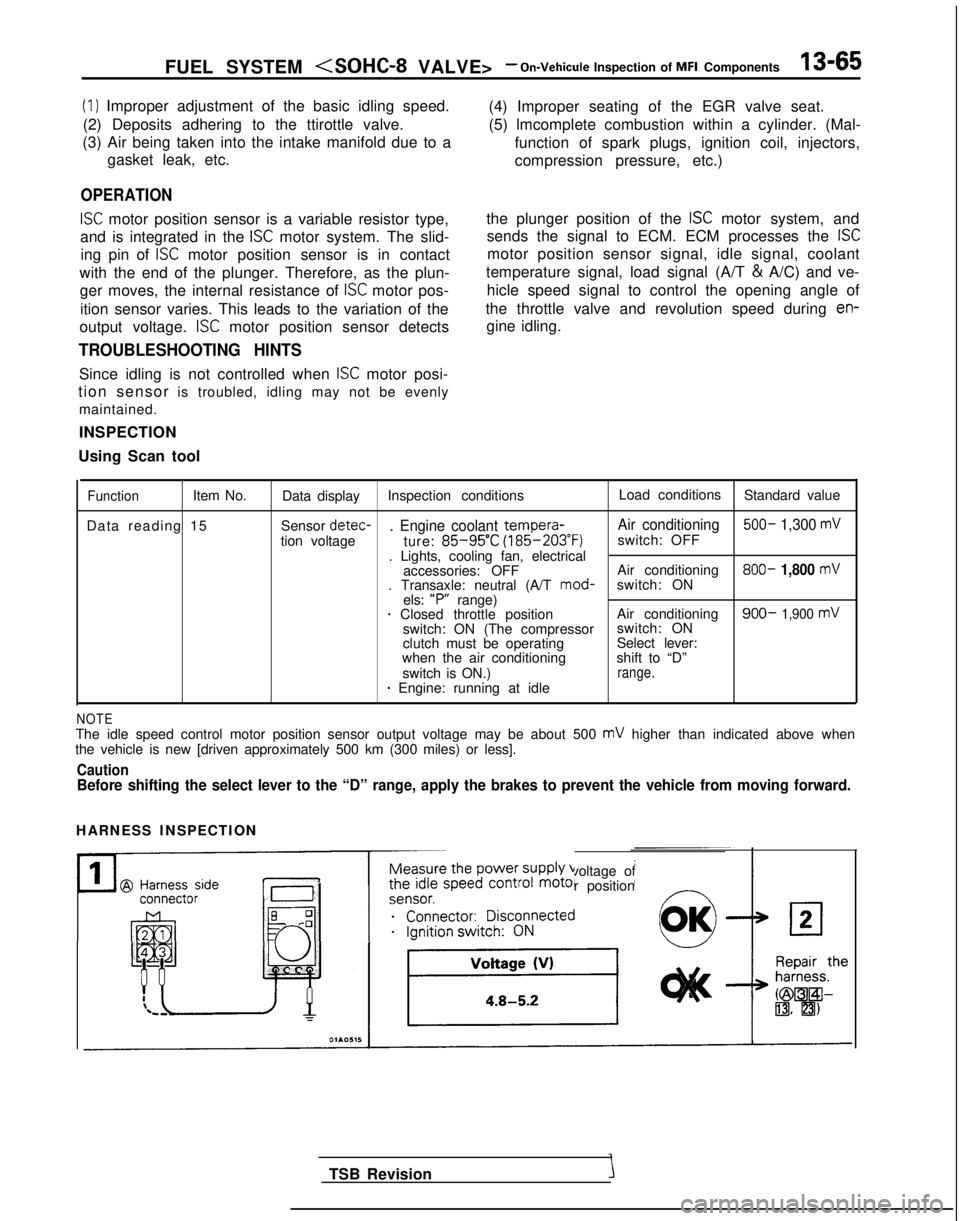

INSPECTION

Using Scan tool

FunctionItem No. Data display Inspection conditions Load conditions

Standard value

Data reading 15 Sensor detec-

. Engine coolant tempera-

Air conditioning 500- 1,300 mV

tion voltage

ture: 85-95’C (185-203°F)

switch: OFF

. Lights, cooling fan, electrical accessories: OFF Air conditioning 800-

1,800 mV. Transaxle: neutral (A/T

mod-

switch: ON

els: “P”

range)

1 Closed throttle position Air conditioning900- 1,900 mVswitch: ON (The compressorswitch: ON

clutch must be operating Select lever:

when the air conditioning shift to “D”

switch is ON.)

range.* Engine: running at idle

NOTEThe idle speed control motor position sensor output voltage may be about\

500 mV higher than indicated above when

the vehicle is new [driven approximately 500 km (300 miles) or less].

CautionBefore shifting the select lever to the “D” range, apply the brake\

s to prevent the vehicle from moving forward.

HARNESS INSPECTION

Measure the power supply voltage of

the idle speed control motor position

ei;;;it;;sco$ected

__...._ -.-

TSB Revision

Page 233 of 1273

FUEL SYSTEM

Inspection of MFI Components13-91

INSPECTION

Using Scan tool

FunctionItem No. Data display

Data reading 41

III~~~ion

Inspection conditions Engine coolant temperature Standard value

Engine cranking At

0°C (3~2°F)“~Approx. 21 ms

At

20°C (68°F)Approx. 43 ms

At

80°C (176°F)Approx. 10 ms

FunctionItem No.

Data reading 41

L

Data display

Ac&a$ion

Inspection conditions

. Engine coolant tempera- ture:

85-95°C (185-205°F)* Lights, cooling fan, electric-al accessories: OFF

. Transaxle: neutral

(A/T models: “P” range) Engine condition

Standard value

I

750 rpm (Idling)2.5-4.0 ms

I

NOTE*I: The injector activation time indicates the time under the following con\

ditions: a power source voltage of 11V and a

cranking rpm of 250 rpm or less.

**: Simultaneous injection at four cylinders when engine coolant temperatur\

e is 0°C (32°F).*3: The injector activation time may be about 10% longer than indicated abo\

ve when the vehicle is new [driven approximately 500 km (300 miles) or less].

FunctionItem No.

Actuator test

01

02

03

04

Description

No.

1 injector is shut off.

No. 2 injector is shut off.

No. 3 injector is shut off.

No. 4 injector is shut off. Inspection conditions

Normal indication

Engine: idling after warm The idling condition

changes more.

r”sput off the injectors in(Either becomes more un-sequence during after stable, or engine stalls.)

engine warm-up, check

the idling condition.)

-

I i-. --.-~-db$- A: Injector~__

Normal waveformdrrve time

HARNESS INSPECTION

1

P

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

Measure the power supply voltage of

the injector.

. Connector: Disconnected. Ignition switch: ON

TSB Revision

I

I

4

i1

k ji,v,11

\

YIY’.

Page 238 of 1273

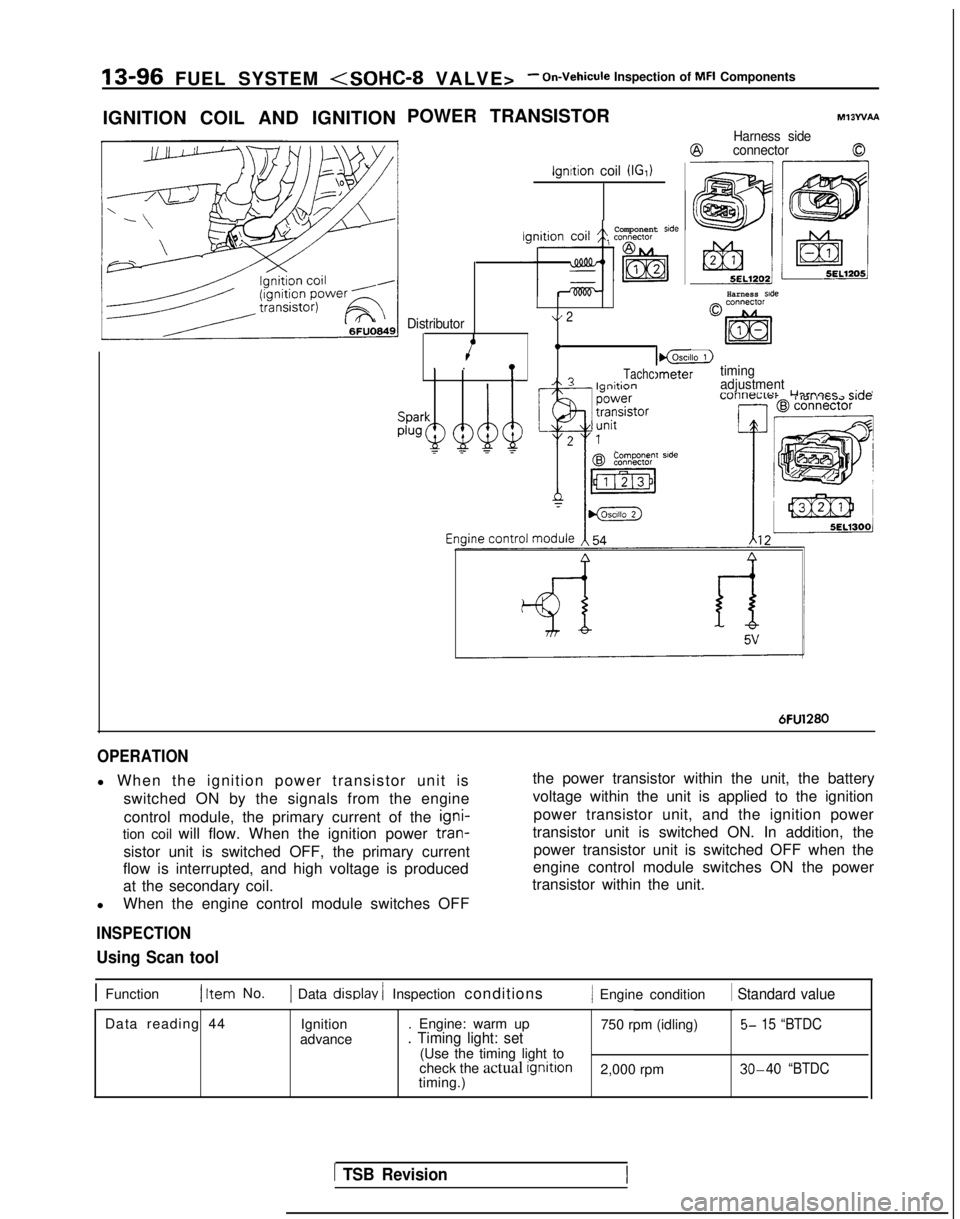

13-96 FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

ignition coil (IGI)

Ml3WAA

Harness side

@connector0

Harness side

Component side

Distributor\/ 2

4.I_lgnltion. .!

I@LZ)

TachcImetertimingA? I--:*:^^adjustment-_

Lllrnacr

r;rlnI 101 i IG.72 Jl”F

Componenr side

6FU1280

OPERATION

l When the ignition power transistor unit is

switched ON by the signals from the engine

control module, the primary current of the igni-

tion coil will flow. When the ignition power tran-

sistor unit is switched OFF, the primary current

flow is interrupted, and high voltage is produced

at the secondary coil.

l When the engine control module switches OFF

INSPECTION

the power transistor within the unit, the battery

voltage within the unit is applied to the ignition

power transistor unit, and the ignition power

transistor unit is switched ON. In addition, the power transistor unit is switched OFF when the

engine control module switches ON the power

transistor within the unit.

Using Scan tool

1 Function1 Item No.1 Data display / Inspection conditions/ Engine condition 1 Standard value

Data reading 44

Ignition

advance . Engine: warm up

750 rpm (idling)5- 15 “BTDC. Timing light: set(Use the timing light to

check the actual ignition

2,000 rpm 30-40 “BTDCtiming.)

1 TSB Revision

Page 248 of 1273

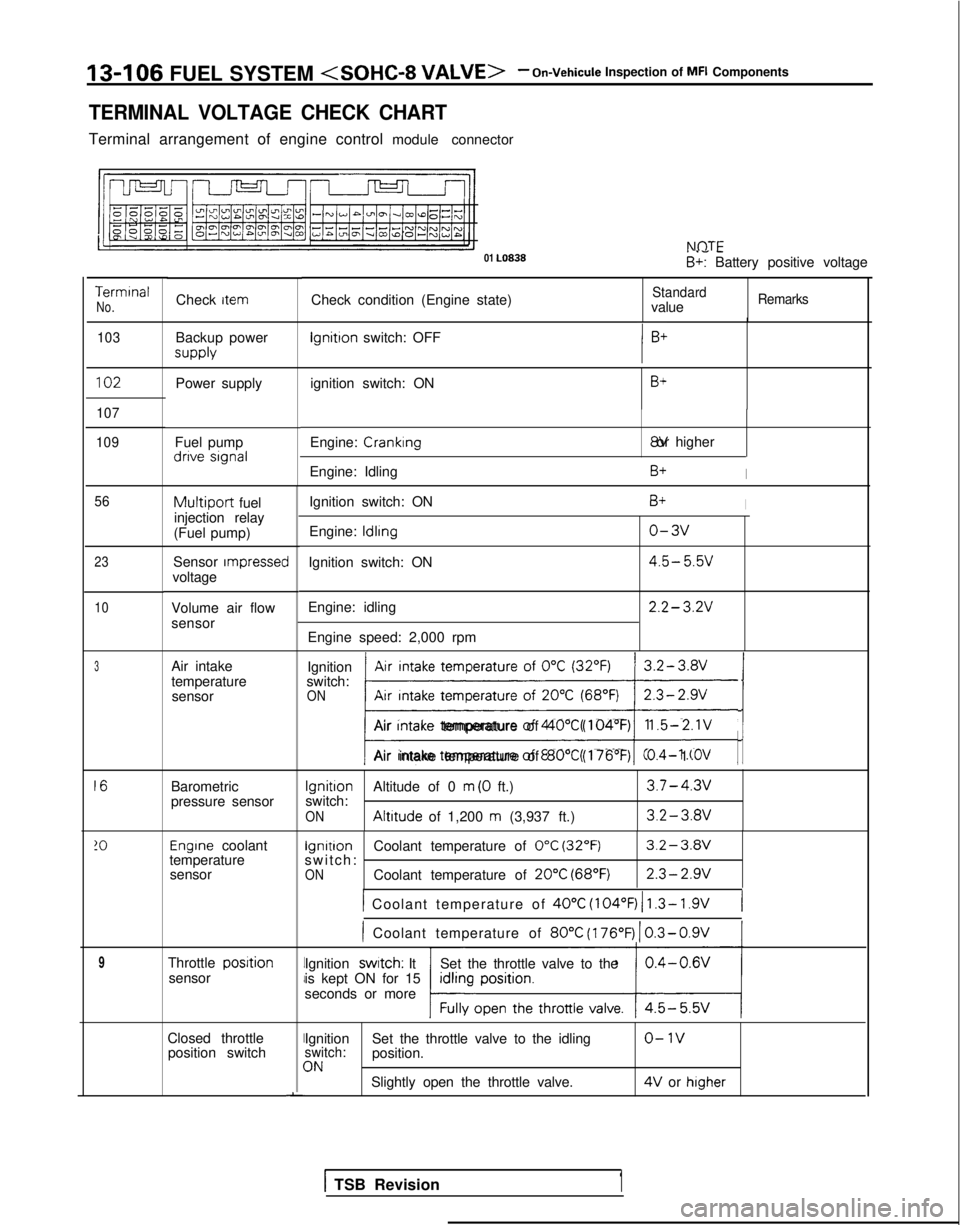

13-106

FUEL SYSTEM

TERMINAL VOLTAGE CHECK CHART

Terminal arrangement of engine control module connector NflTF

01 LO838

. .- -B+: Battery positive voltage

Terminal

No.Check condition (Engine state)StandardvalueRemarksCheck item

103

Backup power supply lgnitron

switch: OFF

102Power supply ignition switch: ONB+

107

109

Fuel pump dnve signal

Engine: Cranking 8V or higher

Engine: Idling

B+I

Ignition switch: ON

Engine:

ldlrng

Ignition switch: ON

Engine: idling

Engine speed: 2,000 rpm

B+I

o-3v

4.5- 5.5v

2.2- 3.2V

56

23

10

Multiport fuel

injection relay

(Fuel pump)

Sensor

rmpressecvoltage

Volume air flow

sensor

Air intake

temperature sensor Ignition

Air intake temperature of

0°C (32°F)switch:ONAir Intake temperature of 20°C (68°F); ji/

Air Intake temperature of 40°C (104°F)1.5-2.1V

Air intake temperature of 80°C (176’F)0.4- 1 .OV

Barometric

pressure sensor

Ignition

Altitude of 0 m (0 ft.)3.7-4.3vswitch:ON Altitude

of 1,200 m (3,937 ft.)3.2-3.av

Engrne coolant lgnitron

Coolant temperature of 0°C (32°F)3.2-3.Wtemperature switch: -sensorONCoolant temperature of 20°C (68°F)2.3-2.9v

1 Coolant temperature of 40°C

(104°F) 1 1.3- 1.9V(

) Coolant temperature of 80°C

(176’F)

1 0.3-0.9V

Throttle posrtionsensor Ignition swatch: It

Set the throttle valve to the

is kept ON for 15

seconds or more

Closed throttle position switchII

I

I

-

Ignition Set the throttle valve to the idlingo-1vswitch:position.3NSlightly open the throttle valve. 4V

or higher

3

16

!O

9

1 TSB Revision1

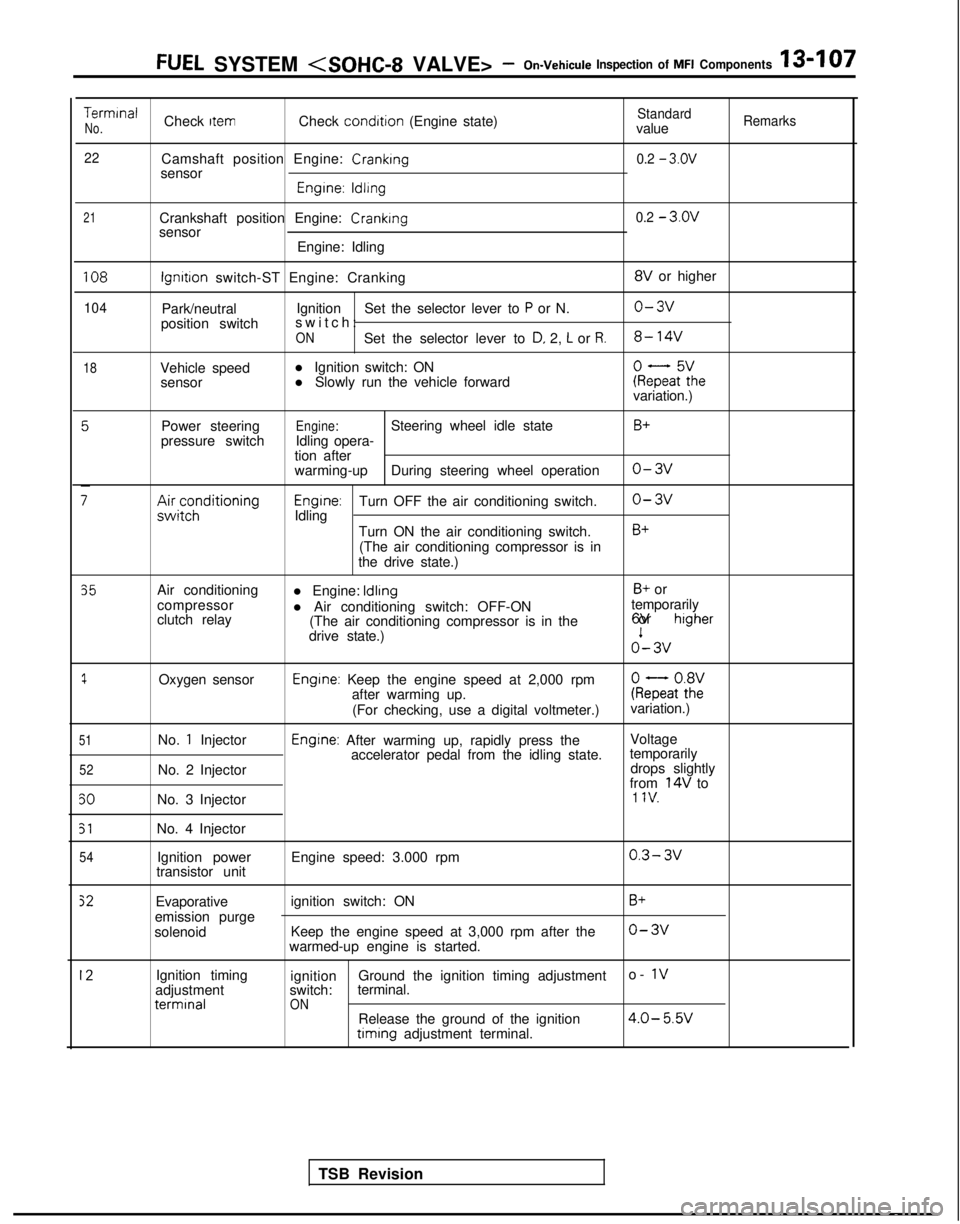

Page 249 of 1273

FUEL SYSTEM

TerminalCheck ItemCheck condition

(Engine state)StandardNo.valueRemarks

22

Camshaft position Engine: Cranking0.2 - 3.ov

sensor

Engrne: ldllng

21Crankshaft position Engine: Crankingsensor

Engine: Idling0.2 - 3.ov

108

104

18

lgnrtron switch-ST Engine: Cranking 8V

or higher

Park/neutral Ignition

Set the selector lever to

P or N.o-3v

position switch switch

:

ONSet the selector lever to D, 2, L or R.8- 14V

Vehicle speed

l Ignition switch: ON

sensor l Slowly run the vehicle forwardkeFaF:hevariation.)

Power steering

pressure switch

;;ir;z;ditioning

Engine:Steering wheel idle state

Idling opera-

tion after

warming-up During steering wheel operation

Engrne:Turn OFF the air conditioning switch.

Idling

Turn ON the air conditioning switch.(The air conditioning compressor is in

the drive state.)

B+

o-3v

o-3v

B+

35

1

51

52

50

51

54

Air conditioning

compressor

clutch relay

Oxygen sensor

No.

1 Injector

No. 2 Injector

No. 3 Injector

No. 4 Injector Ignition power

transistor unit l Engine: Idling

B+ or

l Air conditioning switch: OFF-ON temporarily

(The air conditioning compressor is in the 6V or

higher

drive state.)o’- 3v

Engine: Keep the engine speed at 2,000 rpm

after warming up. kQatot8h2:

(For checking, use a digital voltmeter.) variation.)

Engine: After warming up, rapidly press the

Voltage

accelerator pedal from the idling state. temporarily

drops slightly

from

14V to1 IV.

Engine speed: 3.000 rpm0.3- 3v

Evaporative

emission purge

solenoid ignition switch: ON

Keep the engine speed at 3,000 rpm after the

warmed-up engine is started.B+

o-3v

12Ignition timing

adjustment terminal

ignition

Ground the ignition timing adjustment o- 1vswitch:

terminal.ONRelease the ground of the ignition4.0- 5.W timing

adjustment terminal.

TSB Revision

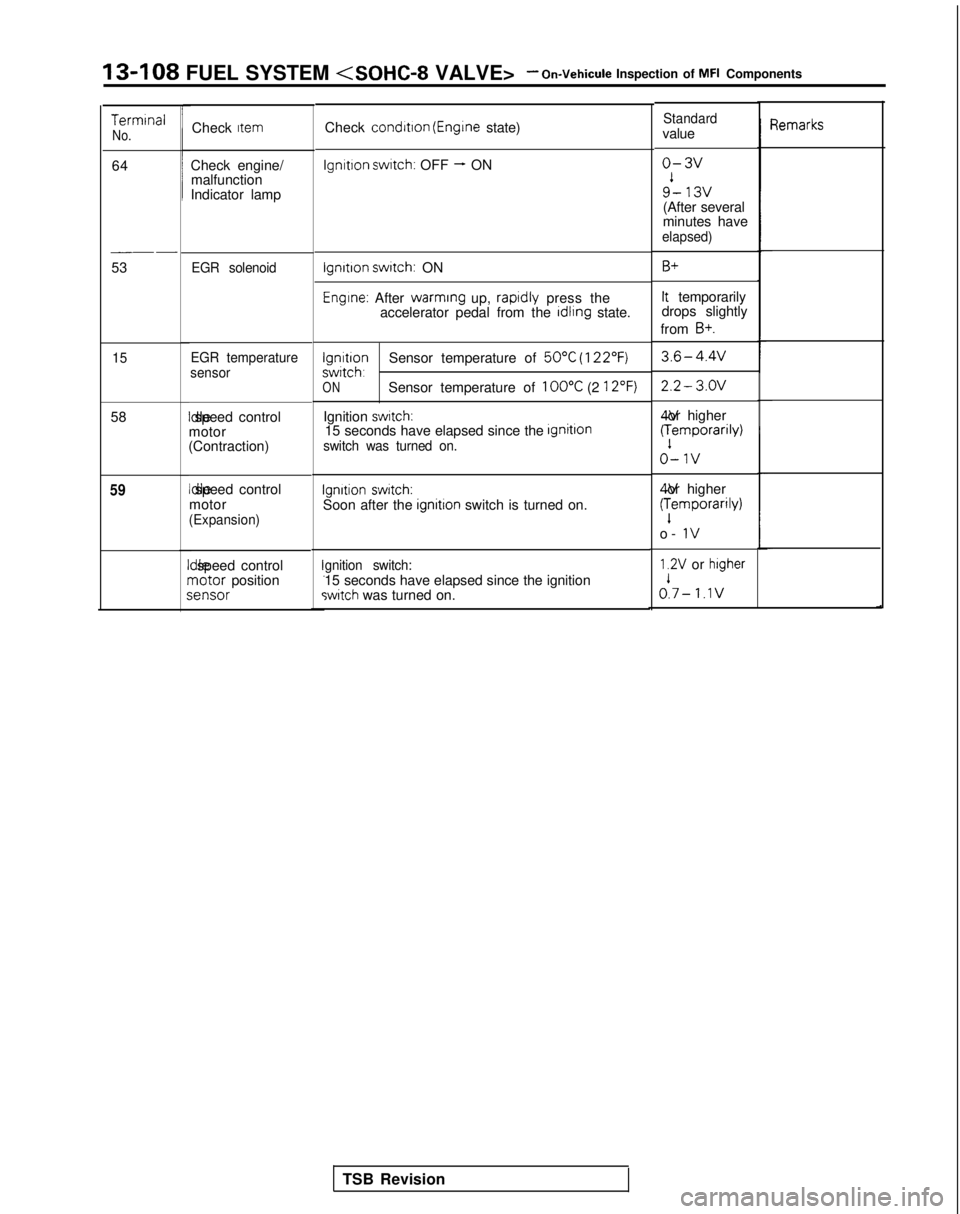

Page 250 of 1273

13-108 FUEL SYSTEM

TermrnalNo.

64

__-

53

15

58

59

Check Item

Check engine/

malfunction

Indicator lamp

EGR solenoid

EGR temperature

sensor Idle speed control

motor

(Contraction) Idle speed control

motor

(Expansion)

II

dle speed controlrnotor positions

;ensor

Check

condrtron (Engrne state)

lgnrtron swatch: OFF - ON

lgnrtron swatch: ON

Engine: After warming

up, raprdly press the

accelerator pedal from the rdlrng state.

lgnrtronSensor temperature of 50°C (122°F)swrtch,ONSensor temperature of 100°C (2 12°F)

Ignition swatch:15 seconds have elapsed since the IgnitlOnswitch was turned on.

Ignition switch:Soon after the ignitron switch is turned on.

gnition switch:15 seconds have elapsed since the ignitionswitch was turned on.

Standardvalue

o-3v

9’- 13v(After several

minutes have

elapsed)

B+

It temporarily

drops slightly

from

B+.

3.6-4.4v

2.2- 3.OV 4V or higher

(:emporarily)

o-1v

4V or higher

(:emporarily)

o-

IV

1.2V or higher

A- 1.1v

qemarks

TSB Revision

Page 252 of 1273

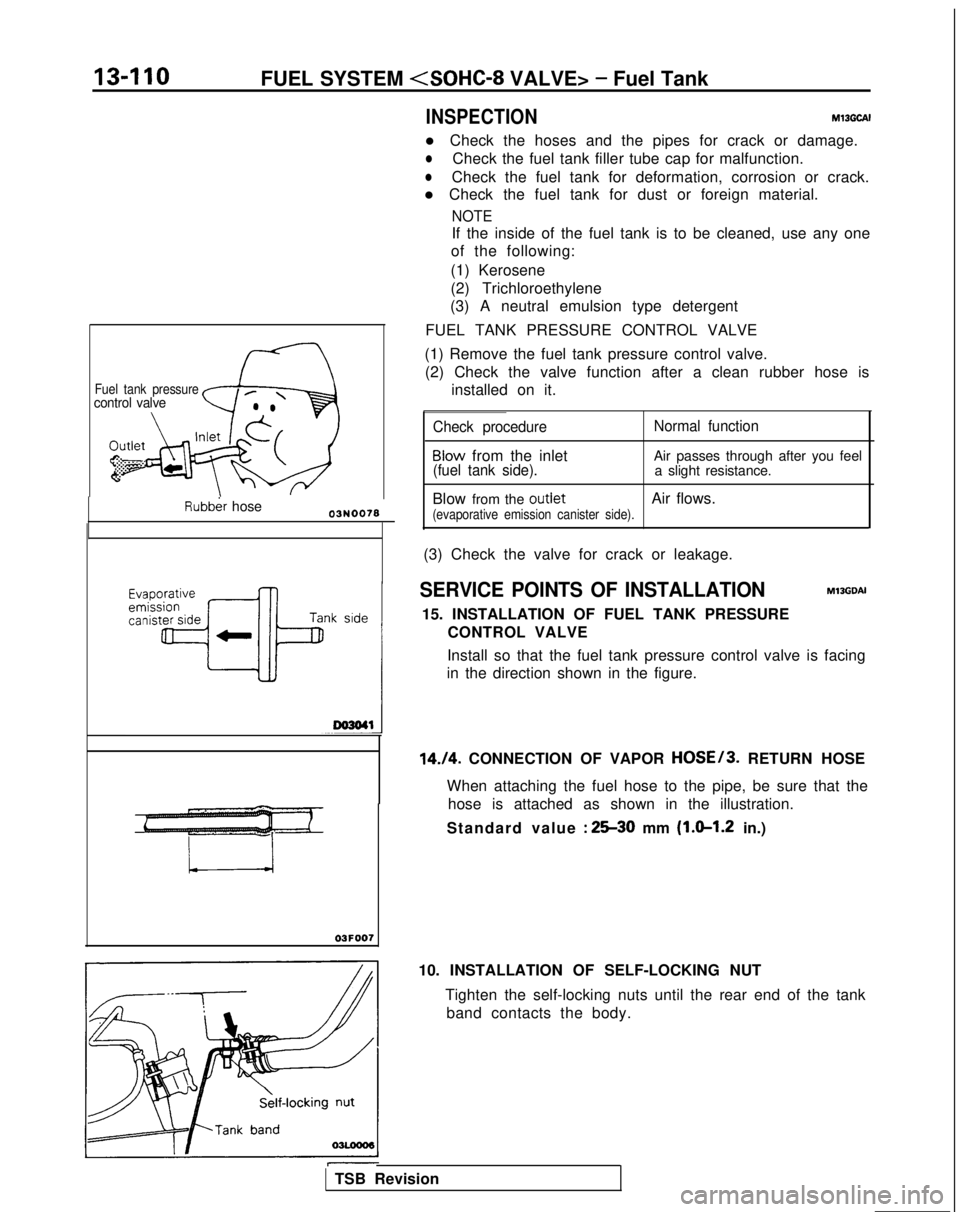

Fuel tank pressurecontrol valve

Rubber hose

n-110FUEL SYSTEM

INSPECTIONMl3GCAI

l Check the hoses and the pipes for crack or damage.

lCheck the fuel tank filler tube cap for malfunction.

lCheck the fuel tank for deformation, corrosion or crack.

l Check the fuel tank for dust or foreign material.

NOTE

If the inside of the fuel tank is to be cleaned, use any one

of the following:

(1) Kerosene

(2) Trichloroethylene

(3) A neutral emulsion type detergent

FUEL TANK PRESSURE CONTROL VALVE

(1) Remove the fuel tank pressure control valve. (2) Check the valve function after a clean rubber hose is installed on it.

Check procedure Normal function

Blow from the inlet

Air passes through after you feel(fuel tank side).a slight resistance.

Blow from the

outletAir flows.(evaporative emission canister side).

(3) Check the valve for crack or leakage.

SERVICE POINTS OF INSTALLATIONM13GDAI

15. INSTALLATION OF FUEL TANK PRESSURE CONTROL VALVE

Install so that the fuel tank pressure control valve is facing

in the direction shown in the figure.

14./4. CONNECTION OF VAPOR HOSE/3. RETURN HOSE

When attaching the fuel hose to the pipe, be sure that the hose is attached as shown in the illustration.

Standard value

: 2530 mm (l.sl.2 in.)

03F007

10. INSTALLATION OF SELF-LOCKING NUT

Tighten the self-locking nuts until the rear end of the tankband contacts the body.

TSB Revision

Page 262 of 1273

13-120FUEL SYSTEM

CHH;K

ENGINE/MALFUNCTION INDICATOR

Among the on-board diagnostic items, a check engine/mal-

function indicator lamp comes on to notify the driver

of the

emission control items when an irregurality is detected. However, when an irregular signal returns to normal and the

engine control module judges that it has returned to normal,

the check engine/malfunction indicator lamp goes out. Moreover, when the ignition switch is turned off, the light goes

Check engine/malfunctionout. Even if the ignition switch is turned on again, the light doesindicator lamp68A.0093not come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

check engine/malfunction indicator lamp is lit for 5 seconds to indicate that the check engine/malfunction indicator lamp op-

erates normally.

ITEMS INDICATED BY THE CHECK ENGINE/

MALFUNCTION INDICATOR LAMP

Engine control module

Oxygen sensor

Volume air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crankshaft position sensor Camshaft position sensor

Barometric pressure sensor

Ignition timing adjustment signal

Injector

EGR

Caution

Check engine/malfunction indicator lamp will come on

even when terminal for ignition timing adjustment is short-circuited. Therefore, it is not abnormal that the

light comes on even when terminal for ignition timing

adjustment is short-circuited at the time of ignition tim-

ing adjustment.

CHECK ENGINE/MALFUNCTION INDICATOR LAM

P

INSPECTION

(1) Check to be sure, when the ignition switch is set to the “ON” position, that the lamp illuminates for about five

seconds and then switches OFF.

(2) If the lamp does not illuminate, check for damage or dis- connection of the harness, or for a blown fuse or a failedlight bulb.

TSB Revision