light MITSUBISHI GALANT 1989 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 266 of 1273

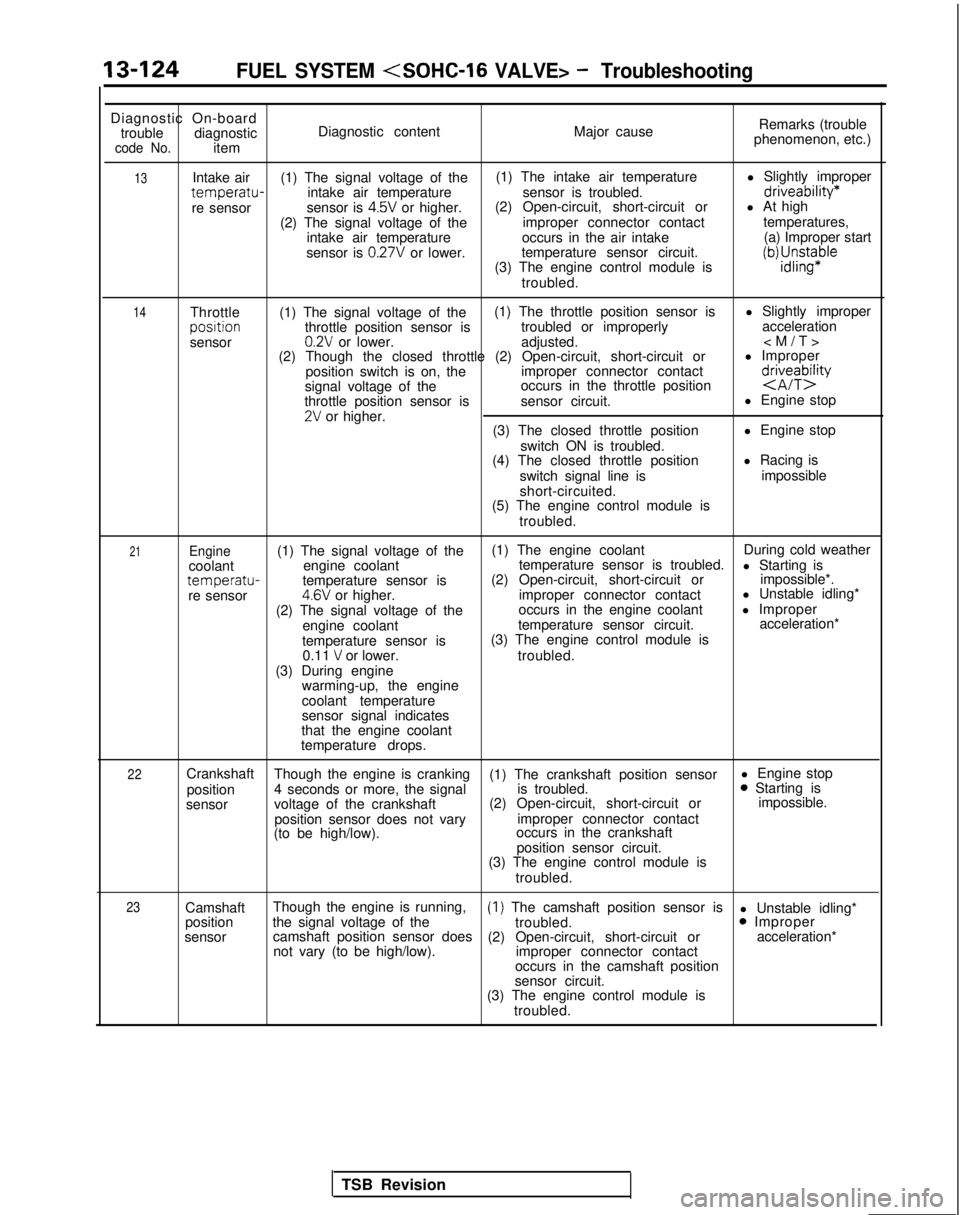

13-124FUEL SYSTEM

Diagnostic On-board

trouble diagnostic

code No.item Diagnostic content

Major causeRemarks (trouble

phenomenon, etc.)

13

14Intake air (1) The signal voltage of the (1) The intake air temperature

l Slightly impropertemperatu-intake air temperature

sensor is troubled.driveability*

re sensorsensor is 4.5V or higher.(2) Open-circuit, short-circuit or

l At high

(2) The signal voltage of the improper connector contacttemperatures,

intake air temperature occurs in the air intake (a) Improper start

sensor is

0.27V or lower. temperature sensor circuit.

(3) The engine control module isiWJ;sn$aple

troubled.

Throttle (1) The signal voltage of the (1) The throttle position sensor is

l Slightly improperposltion

throttle position sensor is troubled or improperly acceleration

sensor

0.2V or lower. adjusted.

(2) Though the closed throttle (2) Open-circuit, short-circuit or l Improper

position switch is on, the improper connector contact

signal voltage of the occurs in the throttle position

d&eTbQ

throttle position sensor is

sensor circuit. l Engine stop2V or higher.

(3) The closed throttle position l Engine stop

switch ON is troubled.

(4) The closed throttle position l Racing is

switch signal line is impossible

short-circuited.

(5) The engine control module is

troubled.

21Engine(1) The signal voltage of the (1) The engine coolant

During cold weather

coolant engine coolant temperature sensor is troubled.

l Starting is

temperatu-temperature sensor is(2) Open-circuit, short-circuit or

impossible*.

re sensor4.6V or higher. improper connector contact l Unstable idling*

(2) The signal voltage of the occurs in the engine coolant

l Improper

engine coolant temperature sensor circuit. acceleration*

temperature sensor is (3) The engine control module is

0.11

V or lower. troubled.

(3) During engine warming-up, the engine

coolant temperature

sensor signal indicates

that the engine coolant

temperature drops.

22Crankshaft Though the engine is cranking (1) The crankshaft position sensor l Engine stop

position 4 seconds or more, the signal is troubled.0 Starting is

sensor voltage of the crankshaft (2) Open-circuit, short-circuit or impossible.

position sensor does not vary improper connector contact

(to be high/low). occurs in the crankshaft

position sensor circuit.

(3) The engine control module is

troubled.

23Camshaft Though the engine is running,(1) The camshaft position sensor is

l Unstable idling*

position the signal voltage of the

troubled.0 Improper

sensor camshaft position sensor does

(2) Open-circuit, short-circuit or acceleration*

not vary (to be high/low). improper connector contact

occurs in the camshaft position

sensor circuit.

(3) The engine control module is

troubled.

TSB Revision

Page 275 of 1273

FUEL SYSTEM

FUEL TANK AND FUEL LINEMIBEAAB

Symptom

Probable cause Remedy

Engine malfunctions

due to insufficient

fuel supply Bent or kinked fuel pipe or hose

Clogged fuel pipe or hose

Clogged fuel filter or in-tank fuel filter

Water in fuel filter Repair or replace

Clean or replace

Replace

Replace the fuel filter or clean the

fuel tank and fuel line

Dirty or rusted fuel tank interior

Clean or replace

Malfunctioning fuel pump

(Clogged filter in the pump)Replace

Evaporative emission

control system

malfunctions

[When fuel tank filler

tube cap is removed,

pressure releasingnoise is heard) Mispiping of vapor line

Disconnected vapor line piping joint

Folded, bent, cracked or clogged vapor line

Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control valve Correct

Correct

Replace

Replace

Replace

SERVICE ADJUSTMENT

PROCEDURES

CURB IDLE SPEED INSPECTIONhll3MAE

(1) The vehicle should be prepared as follows before th

e

inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral (P for vehicles with an automatic

transaxle)

(2) Connect a tachometer.

NOTE

Refer to

P.13-134 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC f 2”

(7) Stop grounding the terminal for adjustment of ignition timing.

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed: 700

31100 rpm

NOTE

The idling rpm is automatically regulated by the idle aircontrol system.

(lO)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check

the

MFI component,

TS6 Revision1

Page 276 of 1273

13-134FUEL SYSTEM (SOHC-16 VALVE> -Service Adjustment Procedures

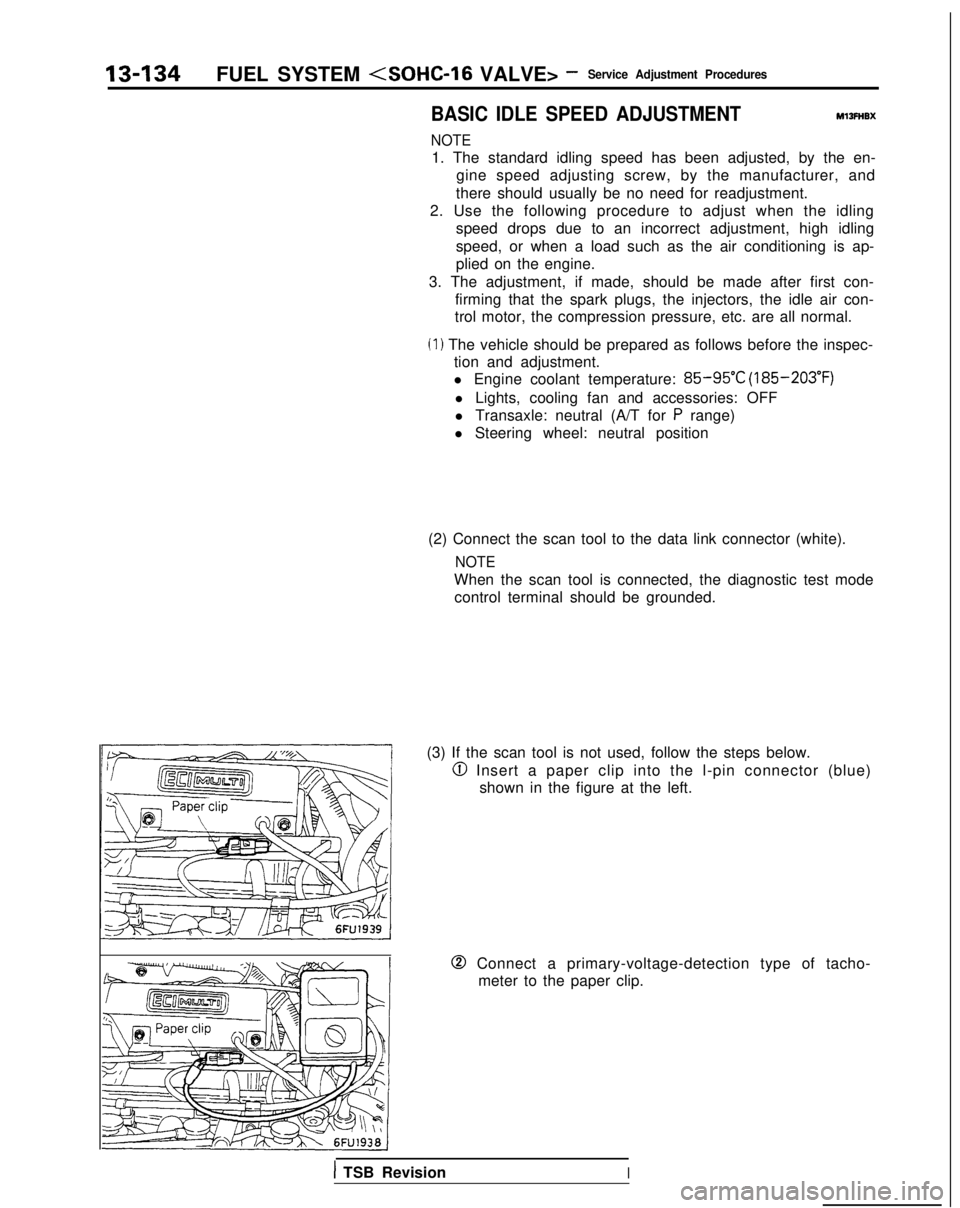

BASIC IDLE SPEED ADJUSTMENTMlIFHBX

NOTE

1. The standard idling speed has been adjusted, by the en-

gine speed adjusting screw, by the manufacturer, and

there should usually be no need for readjustment.

2. Use the following procedure to adjust when the idling speed drops due to an incorrect adjustment, high idling

speed, or when a load such as the air conditioning is ap-

plied on the engine.

3. The adjustment, if made, should be made after first con- firming that the spark plugs, the injectors, the idle air con-

trol motor, the compression pressure, etc. are all normal.

(I ) The vehicle should be prepared as follows before the inspec- tion and adjustment.

l Engine coolant temperature:

85-95°C (185-203°F)

l Lights, cooling fan and accessories: OFF

l Transaxle: neutral (A/T for

P range)

l Steering wheel: neutral position

(2) Connect the scan tool to the data link connector (white).

NOTE

When the scan tool is connected, the diagnostic test mode control terminal should be grounded.

(3) If the scan tool is not used, follow the steps below.

@I Insert a paper clip into the l-pin connector (blue) shown in the figure at the left.

0 Connect a primary-voltage-detection type of tacho-meter to the paper clip.

1 TSB RevisionI

Page 278 of 1273

13-136FUEL SYSTEM

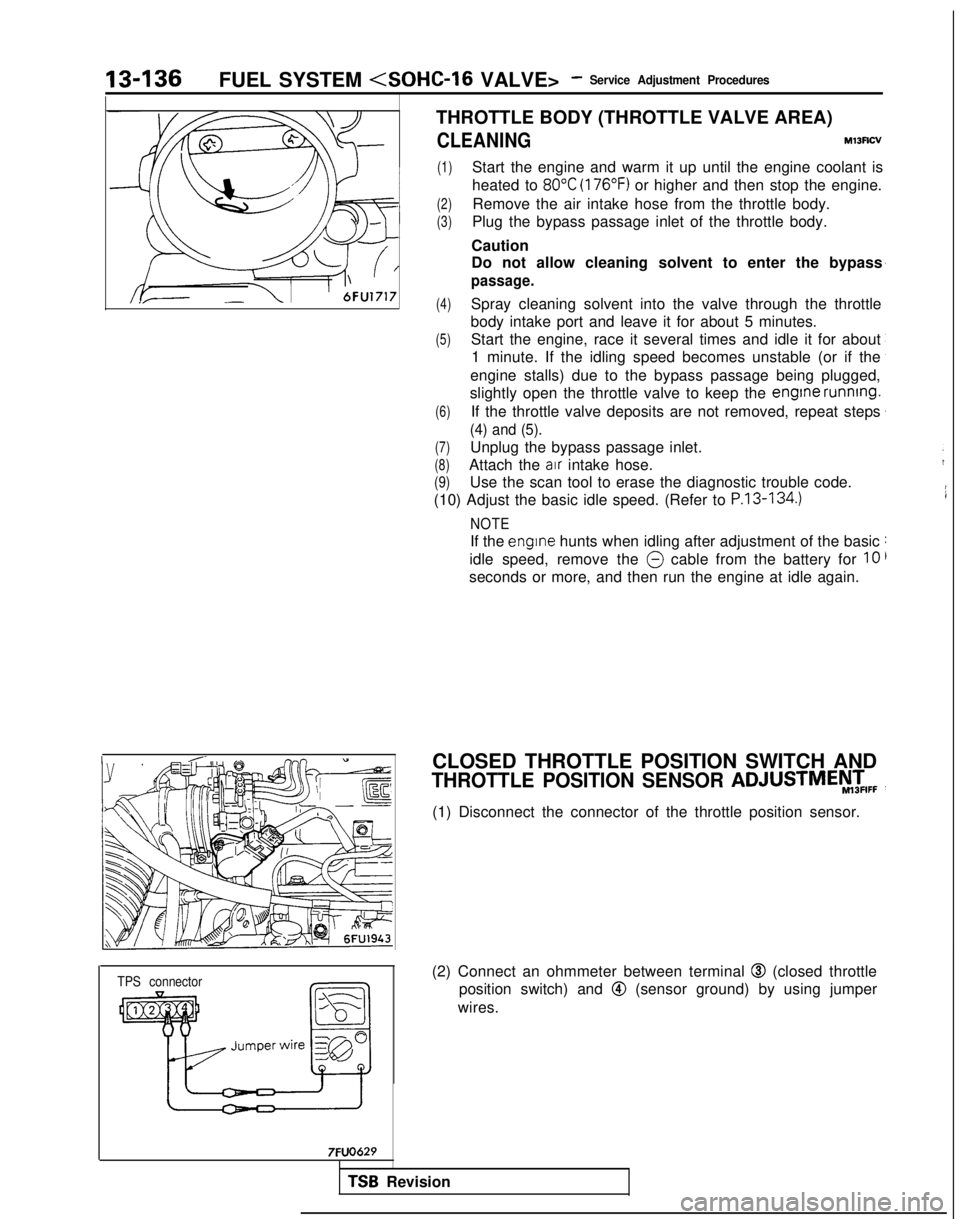

TPS connector

7FUO629

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANINGMl3Rcv

(1)Start the engine and warm it up until the engine coolant is

heated to

80°C (176°F) or higher and then stop the engine.

(2)Remove the air intake hose from the throttle body.

(3)Plug the bypass passage inlet of the throttle body.

Caution

Do not allow cleaning solvent to enter the bypass

passage.

(4)Spray cleaning solvent into the valve through the throttle

body intake port and leave it for about 5 minutes.

(5)Start the engine, race it several times and idle it for about 1 minute. If the idling speed becomes unstable (or if the

engine stalls) due to the bypass passage being plugged,

slightly open the throttle valve to keep the engine

running.

(6)If the throttle valve deposits are not removed, repeat steps

(4) and (5).

(7)Unplug the bypass passage inlet.

(8)Attach the air intake hose.

(9)Use the scan tool to erase the diagnostic trouble code.

(10) Adjust the basic idle speed. (Refer to

P.13-134.)

NOTE

If the engrne hunts when idling after adjustment of the basic

idle speed, remove the

@ cable from the battery for 10

seconds or more, and then run the engine at idle again.

CLOSED THROTTLE POSITION SWITCH AND

THROTTLE POSITION SENSOR ADJUSTMEy,zIFF

(1) Disconnect the connector of the throttle position sensor.

(2) Connect an ohmmeter between terminal

@I (closed throttle

position switch) and

@ (sensor ground) by using jumper

wires.

TSB Revision

Page 292 of 1273

On-Vehicle Inspection of MFI

13450FUEL SYSTEM

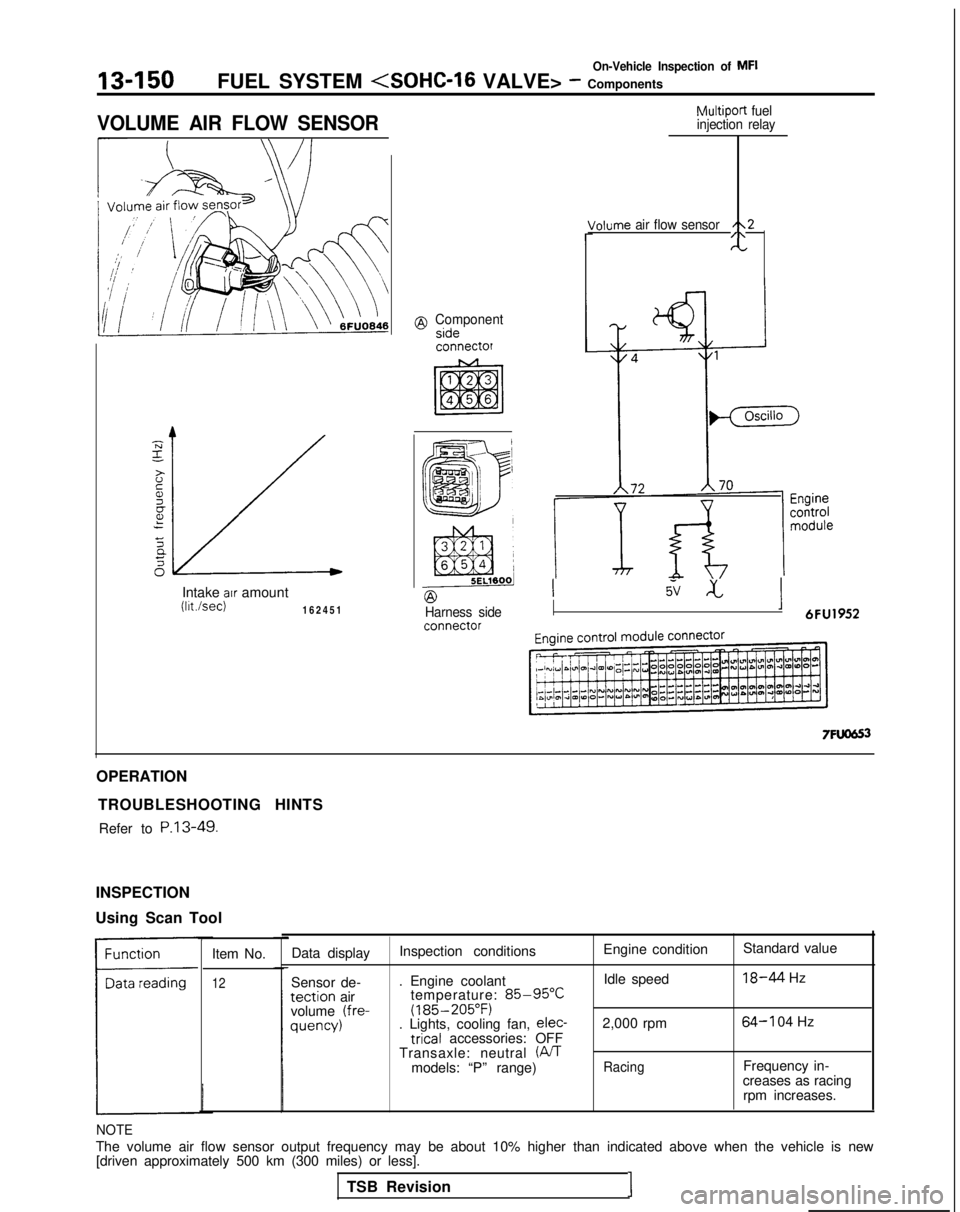

VOLUME AIR FLOW SENSOR

Intake air amountWsec)16245

1

@ Componentsideconnectof

Multiport

fuel

injection relay

/ohme air flow sensor/\2/\-

@Harness side

Isv xI 6FU1952

OPERATION TROUBLESHOOTING HINTSRefer to

P.13-49.

INSPECTION

Using Scan Tool

Item No.

12

Data displayInspection conditions Engine condition

Standard value

Sensor de- . Engine coolant Idle speed

18-44 Hz

tection airtemperature: 85-95°C

volume (fre- (185-205°F)

quency)

. Lights, cooling fan, elec-

2,000 rpm64-l 04 Hz tricaI

accessories: OFF

Transaxle: neutral

(PJTmodels: “P” range)RacingFrequency in-

creases as racing rpm increases.

NOTE

The volume air flow sensor output frequency may be about 10% higher than\

indicated above when the vehicle is new[driven approximately 500 km (300 miles) or less].

TSB Revision

1

Page 305 of 1273

FUEL SYSTEM

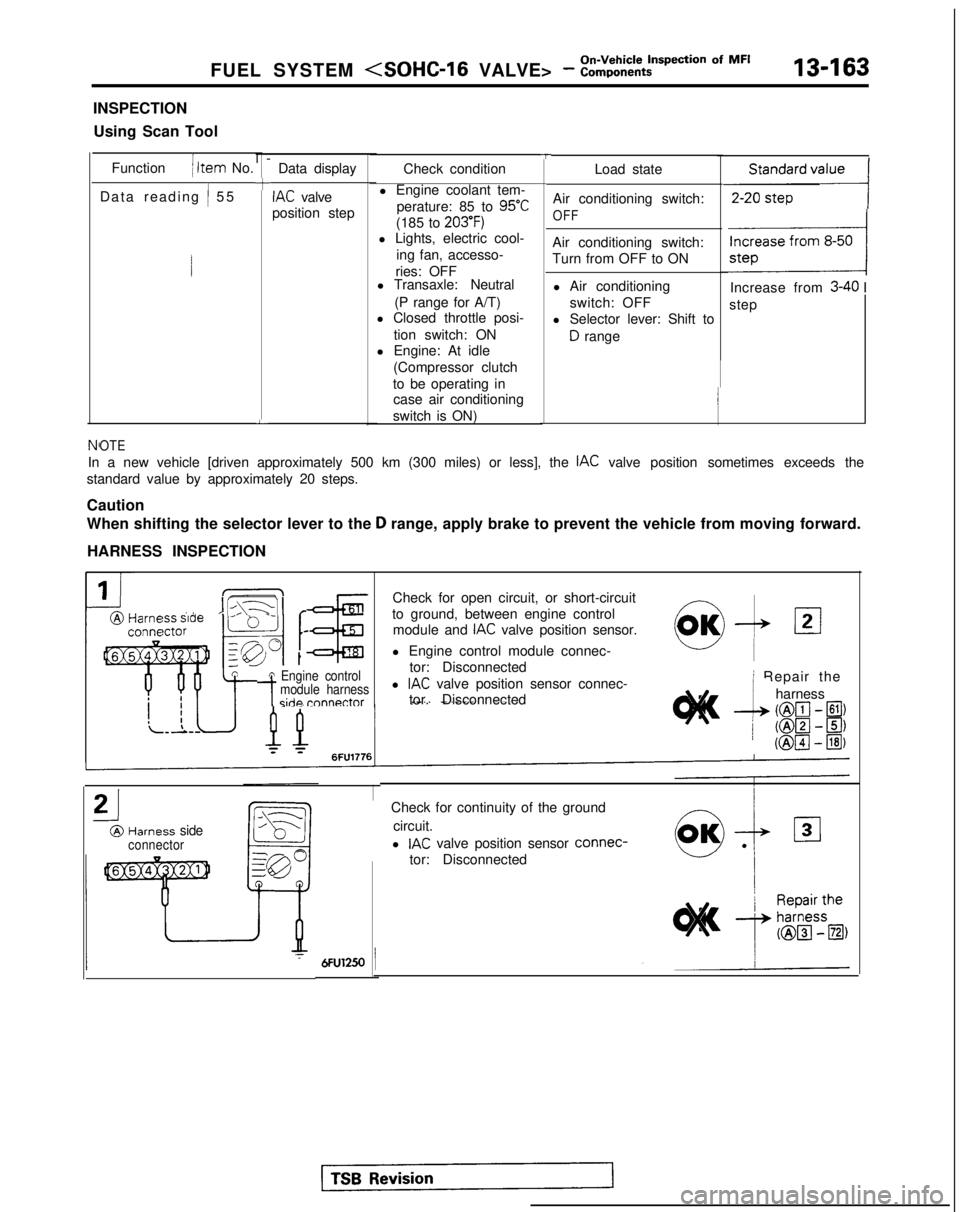

INSPECTION

Using Scan Tool

Function

( Item No.

Data reading

/ 5

5

l-

+

L

Data display

IAC valve

position step

TCheck condition

l Engine coolant tem- perature: 85 to

95°C

(185 to 203’F)l Lights, electric cool- ing fan, accesso-

ries: OFF

l Transaxle: Neutral

(P range for A/T)

l Closed throttle posi-

tion switch: ON

l Engine: At idle

(Compressor clutch

to be operating in case air conditioning

switch is ON) Load state

Air conditioning switch:

OFF

Air conditioning switch:

Turn from OFF to ON l Air conditioning switch: OFF

l Selector lever: Shift to

D range

,,,,,,,,,I

Increase from 3-40 I

step

NfOTE

In a new vehicle [driven approximately 500 km (300 miles) or less], th\

e IAC valve position sometimes exceeds the

standard value by approximately 20 steps.

Caution

When shifting the selector lever to the

D range, apply brake to prevent the vehicle from moving forward.

HARNESS INSPECTION

IIL\-11 r@Harm ” ’ -conna

tA Engine control

-tmodule harnessside rnnnnctor

Check for open circuit, or short-circuit

to ground, between engine control module and

IAC valve position sensor.

l Engine control module connec- tor: Disconnected

l

IAC valve position sensor connec-

tor. Disconnected

21

@Harness sideconnector

0,OK-& 121

i Repair the

--L

harness

(@lcl- El)

/ ml-~) (@pJ

- @I)

Check for continuity of the ground

circuit.

l

IAC valve position sensor connec-

tor: Disconnected

Page 324 of 1273

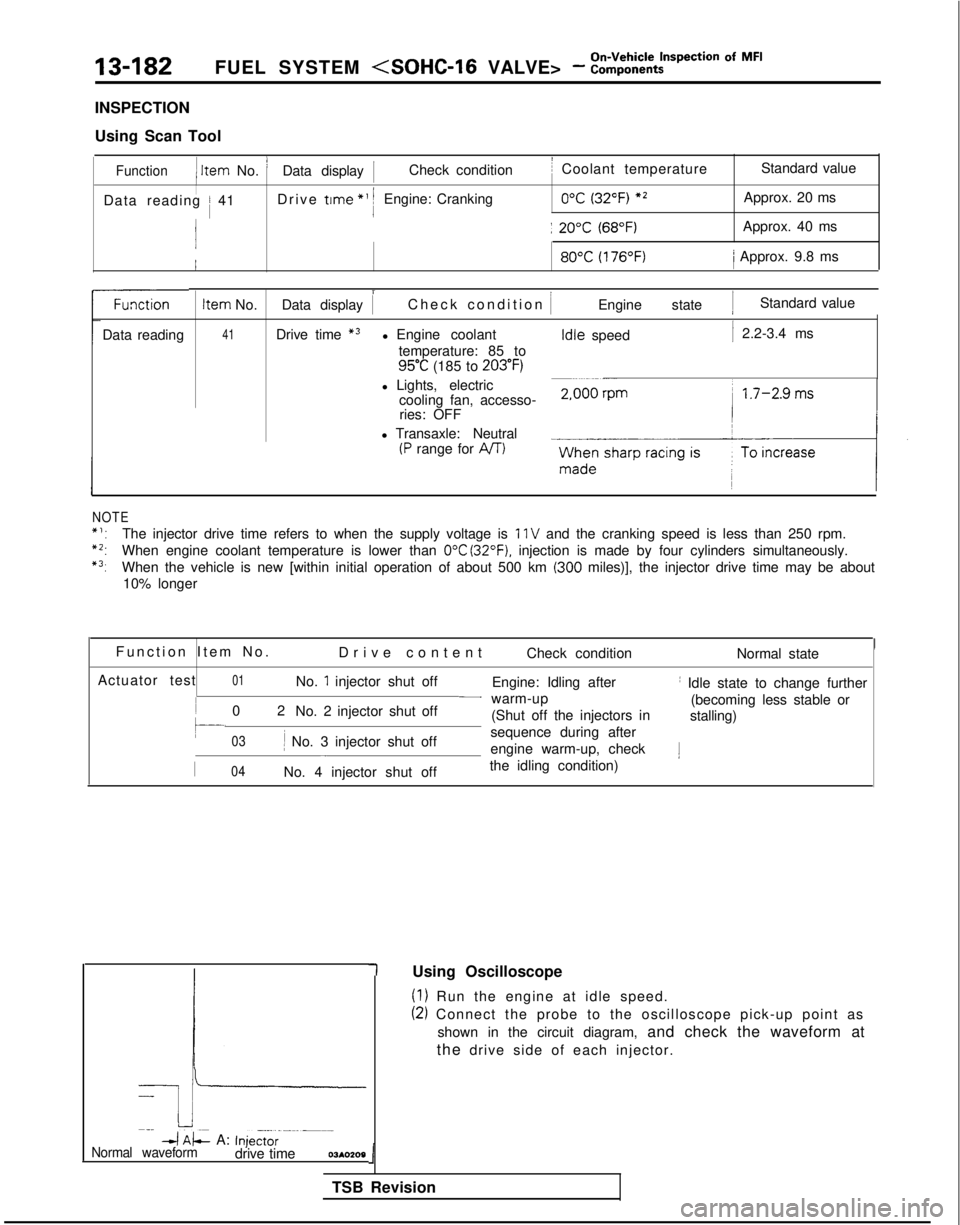

13-182FUEL SYSTEM

INSPECTION

Using Scan Tool

Function1 Item

No. ’Data display 1Check conditionI Coolant temperature Standard value

IData reading / 41Drive trme

*’ 1Engine: Cranking0°C (32°F) *2Approx. 20 ms

j: 20°C (68°F)Approx. 40 ms 80°C

(176°F)/ Approx. 9.8 ms

Data reading

NOTE Item

No.

41 i

Data display 1

Check condition

IEngine state 1Standard value

Drive time

*3l Engine coolant temperature: 85 to

95°C (185 to 203°F)

l Lights, electric cooling fan, accesso-ries: OFF

l Transaxle: Neutral

(P range for AIT) Idle

speed

1 2.2-3.4 ms

*‘:The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

*2:When engine coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

*3:When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer

Function Item No

.

Drive content Check condition Normal state

Actuator test

01No. 1 injector shut off Engine: Idling afterI Idle state to change further

0

2

No. 2 injector shut off

- warm-up

(becoming less stable or

(Shut off the injectors in stalling)

03li No. 3 injector shut off sequence during after-engine warm-up, check1

I04No. 4 injector shut off

the idling condition)

-k

Imp

4 AL A: Inje,t,r--m--m-Normal waveformdrive time03*0209

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

1

TSB Revision 1

Using Oscilloscope

Page 328 of 1273

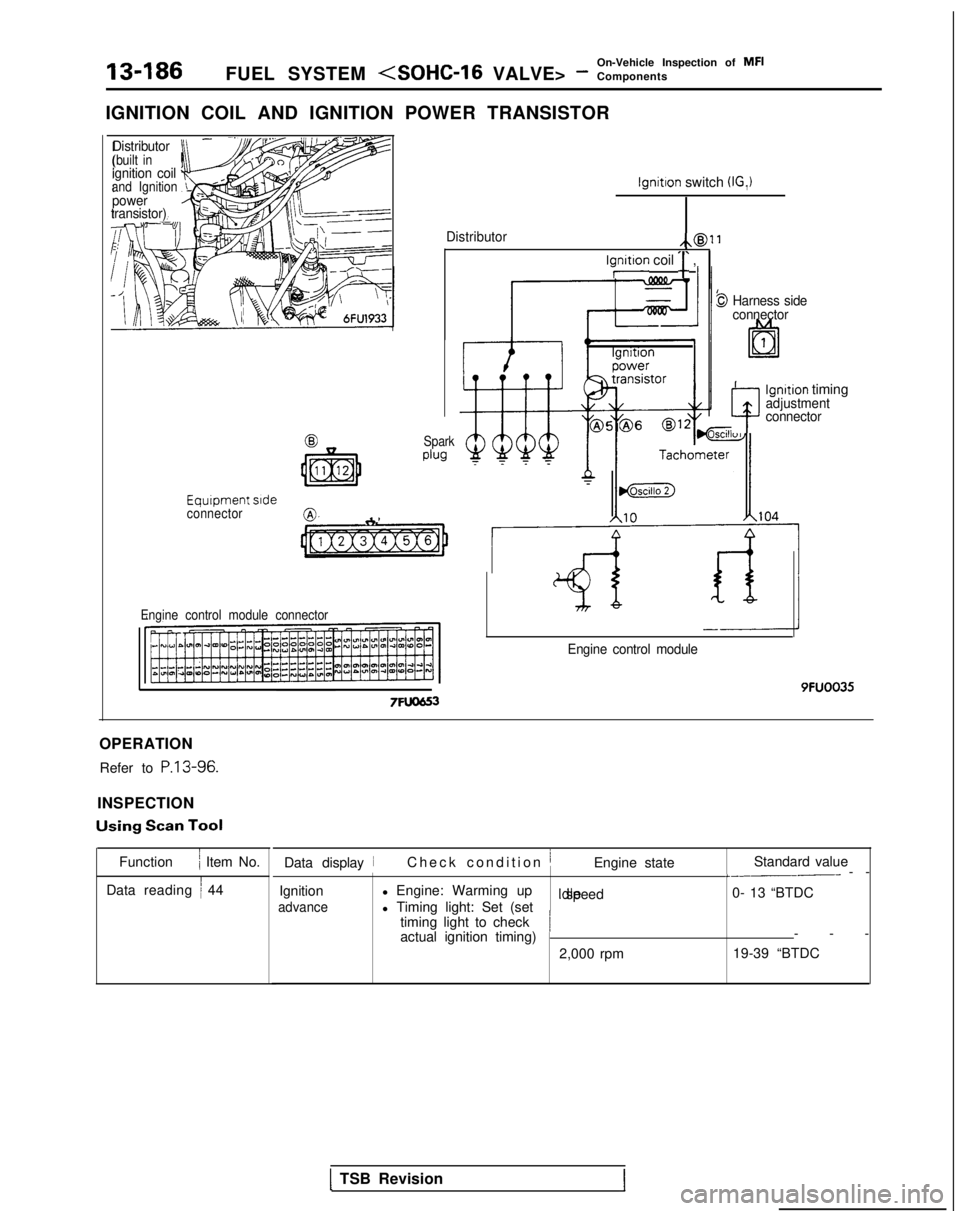

13-186On-Vehicle Inspection of MFI

FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

-Distributor(built inignition coiland Ignitionpower

transistor)

Equrpment srdeconnector8”

Engine control module connector Spark

plug

Iynitron coil ‘r ,

lgnitron switch (IG,)

Distributor/,@)f1

9 Harness side

connector

4

lgnrtion timingadjustment

connector

7FU0653

Engine control module 9FUOO35

OPERATION Refer to

P.13-96.

INSPECTION Using

Scan Tool

Function

/ Item No.

Data reading

i 44 Data display

iCheck condition jEngine state

Standard value_.-___-- -

-

Ignition

advance

l Engine: Warming up Idle speed

0- 13 “BTDC

l Timing light: Set (set

timing light to check

actual ignition timing)

/--

-

2,000 rpm 19-39 “BTDC

1 TSB Revision1

Page 335 of 1273

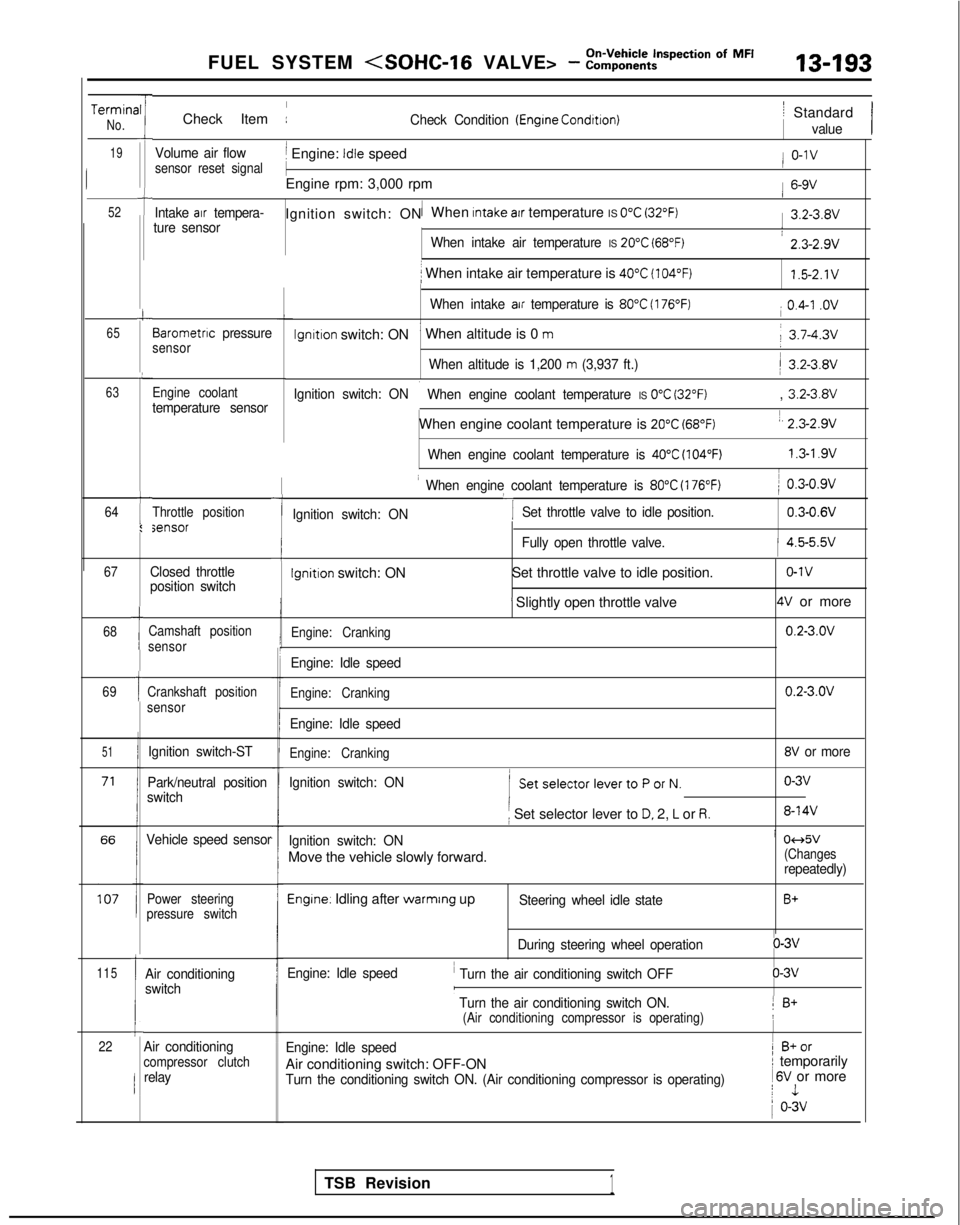

FUEL SYSTEM

TerminaNo.

19

52

-rII

i

t

c

65

L

63

64t

I:

I

Check Item :Check Condition (Engrne Condrtron)

Volume air flowj Engine: Idle speedsensor reset signal

1

Engine rpm: 3,000 rpm

Intake air tempera-1Ignition switch: ON When Intake atr temperature IS 0°C (32°F)ture sensor

When intake air temperature IS 20°C (68°F)

i When intake air temperature is 40°C (104°F)

When intake air temperature is 80°C (176°F)

lgnltlon switch: ON’ When altitude is 0 m

When altitude is 1,200 m (3,937 ft.)

Ignition switch: ON

i When engine coolant temperature IS 0°C (32°F)

When engine coolant temperature is 20°C (68°F)

When engine coolant temperature is 40°C (104°F)

Barometnc pressuresensor

Engine coolant

temperature sensor

Throttle positionsensor

67

68

69

51

115

1

1

Ic22

Closed throttle

position switch

Camshaft position

sensor

Crankshaft position

sensor

Ignition switch-ST

Park/neutral position

switch

Vehicle speed sensor

Power steering

pressure switch

Air conditioning

switch

-I

I When engine coolant temperature is 80°C (176°F)

‘I

) 0.3-0.9v

Ignition switch: ON Set throttle valve to idle position.

0.3-0.6V

iFully open throttle valve.1 4.5-5.5v

Ignition switch: ON

Set throttle valve to idle position.o-1v

’ Slightly open throttle valve4V or more

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking8V or more

Ignition switch: ON

( SetselectorlevertoPorN.o-3v

i Set selector lever to D. 2, L or R.8-14V

Ignition switch: ONi 04d5v

Move the vehicle slowly forward.(Changesrepeatedly)

Engine. Idling after warmrng upSteering wheel idle stateB+

During steering wheel operationo-3v

Engine: Idle speed

’ Turn the air conditioning switch OFFo-3vI

’ Turn the air conditioning switch ON.1 B+(Air conditioning compressor is operating)!

Engine: Idle speed1 B+or

Air conditioning switch: OFF-ONI temporarily

Turn the conditioning switch ON. (Air conditioning compressor is operat\

ing) 1

6V or morej 1

1 o-3v

/ Standard

value

/ o-1v

1 6-9V

1 3.2-3.8V

: 2.3-2.9v

1.5-2.1V

i 0.4-I .ov

j 3.7-4.3v

/ 3.2-3.8V

, 3.2-3.8V

1, 2.3-2.9v

1.3-l .9vI

Air conditioningcompressor clutchrelay

TSB Revision1

Page 336 of 1273

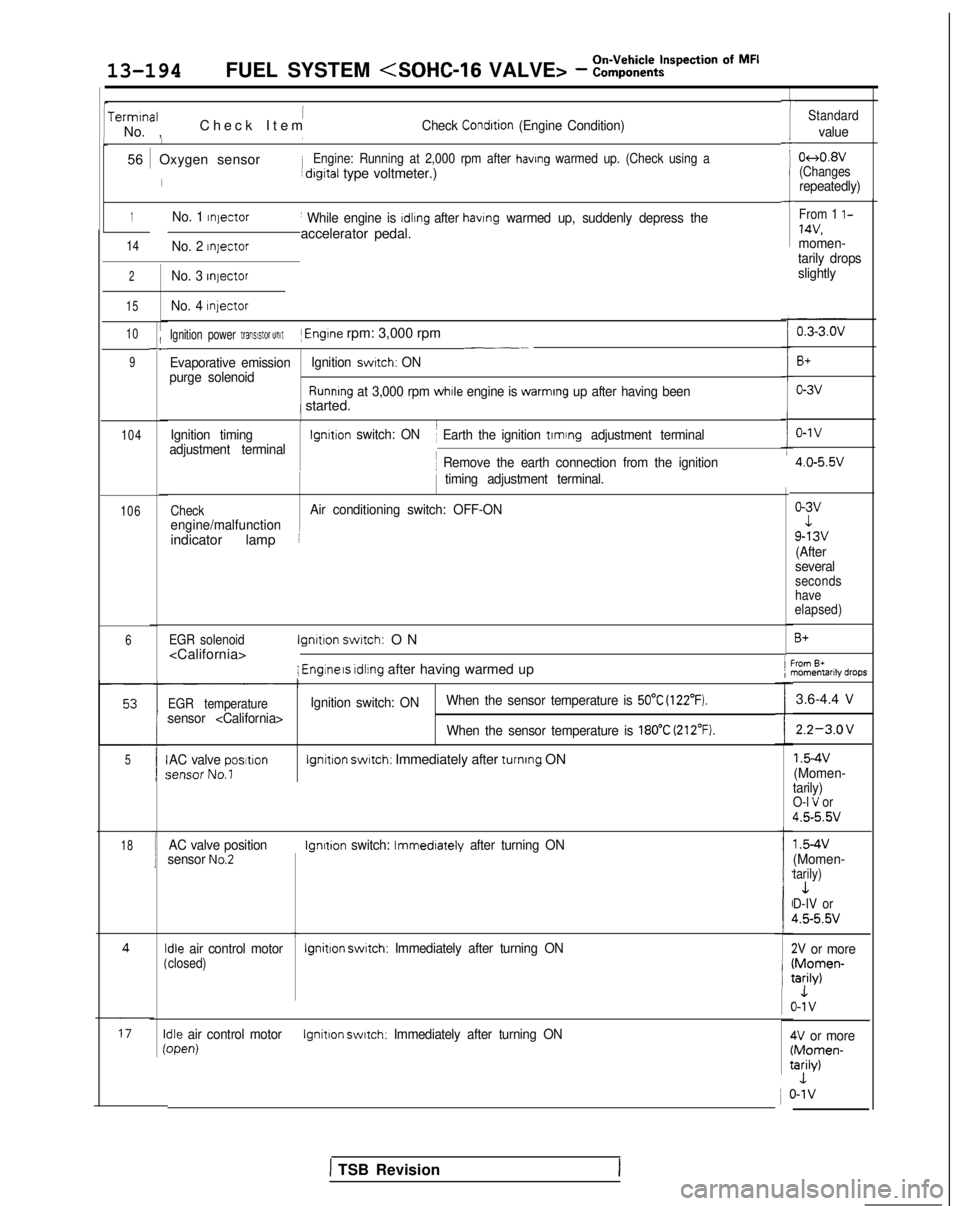

13-194FUEL SYSTEM

7-

i

TermrnalI

No. ,Check Ite

m

,Check Condrtion (Engine Condition)Standard

value

OttO.8V(Changesrepeatedly)

TFrom 1 l-14v.momen-

tarily drops

slightly

B+

o-1v

4.0-5.5v

o-3v19-13v

(After

several

seconds

have

elapsed)

B+

‘rom B+nomentarlly dropIS

I

56 1 Oxygen sensoriEngine: Running at 2,000 rpm after havrng warmed up. (Check using a

I ~

drgltal type voltmeter.)

3.6-4.4

V 2.2-3.OV

1.5-4v

(Momen-

tarily)

O-l V or 4.55.5v

1.5-4v

(Momen-

tarily)1D-IV or4.5-5.5v

2V or moreIMomen-tarily)LI-1 v

4V or moreMomen-:arily)1 I-1v

No. 1 Injector

No. 2 Injector

’ While engine is Idling after having warmed up, suddenly depress the

accelerator pedal.

1

14

2No. 3 Injector

15No. 4 Injector

Ignition power transistor unit~

Engine rpm: 3,000 rpm___-

Evaporative emission Ignition swatch: ON

purge solenoid

Runnrng at 3,000 rpm while engine is warmrng up after having beeni started.I

10II-

9

104Ignition timing

adjustment terminallgnttion switch: ON1 Earth the ignition trming adjustment terminal

I Remove the earth connection from the ignition

timing adjustment terminal.

CheckAir conditioning switch: OFF-ON

engine/malfunction

indicator lamp i

106

6

EGR solenoid

N

; Engine IS idling after having warmed up/j

EGR temperaturesensor

Ignition switch: ON

When the sensor temperature is

50°C (122°F).

When the sensor temperature is 180°C (212°F).

I 1I

AC valve positlonsensor No.1Ignition switch: Immediately after turnrng ON5

18

AC valve position

sensor No.2lgnltion switch: lmmedlately after turning ON

dle air control motorclosed)Ignition switch: Immediately after turning ON

3le air control motor wen)lgnitlon switch:

Immediately after turning ON1

( t

i (

1 TSB Revision