MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 541 of 1273

AUTO-CRUISE CONTROL SYSTEM - Setice Adjustment ~rccedures13-399

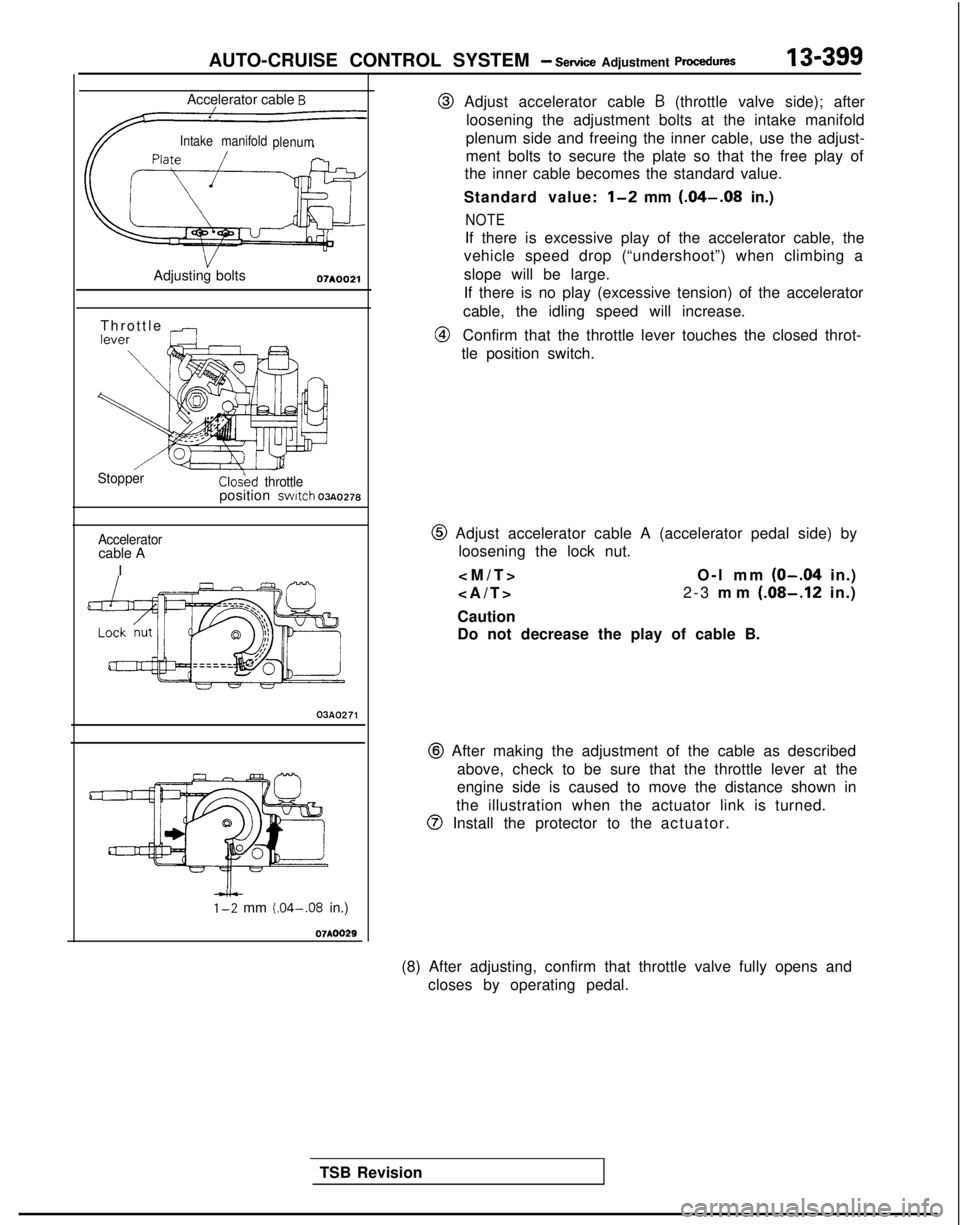

Accelerator cable B

Intake manifold

plenum

VAdjusting bolts07A0021

Throttle -.--

StopperCloskd throttleposition swrtch 03~0278

Acceleratorcable A

I

03A0271

-Ai+1-2 mm (.04-.08

in.)

TSB Revision

@ Adjust accelerator cable B (throttle valve side); after

loosening the adjustment bolts at the intake manifold

plenum side and freeing the inner cable, use the adjust-

ment bolts to secure the plate so that the free play of

the inner cable becomes the standard value.

Standard value:

l-2 mm (.04-.08 in.)

NOTE

If there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a

slope will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

@Confirm that the throttle lever touches the closed throt-

tle position switch.

@ Adjust accelerator cable A (accelerator pedal side) by loosening the lock nut.

O-l mm

(O-.04 in.)

>

2-3

mm

(.08-.12 in.)

Caution

Do not decrease the play of cable B.

@ After making the adjustment of the cable as described above, check to be sure that the throttle lever at the

engine side is caused to move the distance shown in

the illustration when the actuator link is turned.

@ Install the protector to the actuator.

(8) After adjusting, confirm that throttle valve fully opens and closes by operating pedal.

Page 542 of 1273

13-400AUTO-CRUISE CONTROL SYSTEM - Service Adjustment procedures

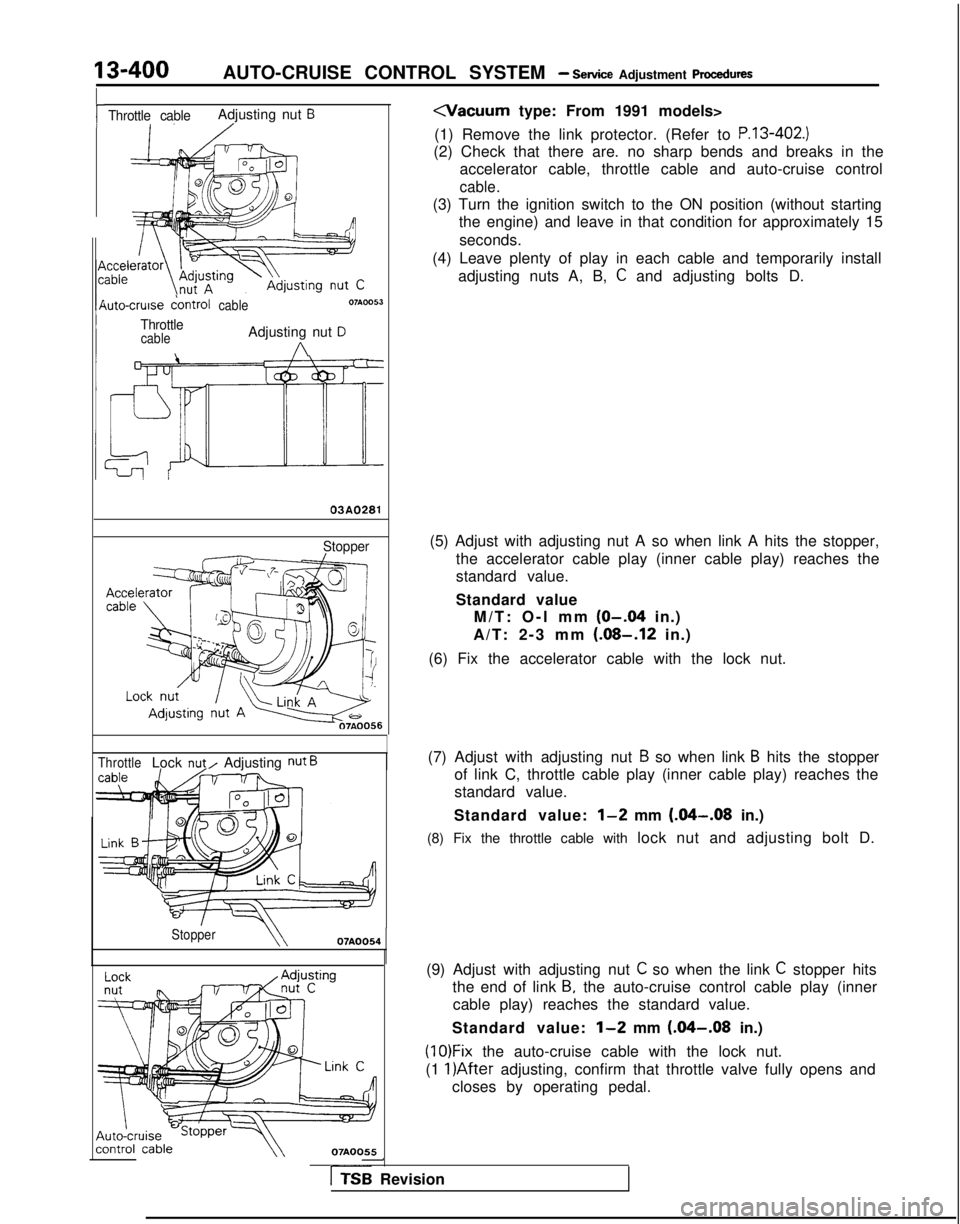

rThrottle cableAdjusting nut B

\uto-cruise dontrolcable

ThrottlecableAdjusting nut D

A

03A0281

Stopper

ThrottleLock nut/ Adjusting nut B

Stopper07AOO54

07AOO55

(1) Remove the link protector. (Refer to

P.13-402.)

(2) Check that there are. no sharp bends and breaks in the accelerator cable, throttle cable and auto-cruise control

cable.

(3) Turn the ignition switch to the ON position (without startingthe engine) and leave in that condition for approximately 15

seconds.

(4) Leave plenty of play in each cable and temporarily install adjusting nuts A, B,

C and adjusting bolts D.

(5) Adjust with adjusting nut A so when link A hits the stopper, the accelerator cable play (inner cable play) reaches the

standard value.

Standard valueM/T: O-l mm

(O-.04 in.)

A/T: 2-3 mm

(.08-.12 in.)

(6) Fix the accelerator cable with the lock nut.

(7) Adjust with adjusting nut

B so when link B hits the stopper

of link C, throttle cable play (inner cable play) reaches the

standard value.

Standard value:

l-2 mm (&I-.08 in.)

(8) Fix the throttle cable with lock nut and adjusting bolt D.

(9) Adjust with adjusting nut

C so when the link C stopper hits

the end of link

B, the auto-cruise control cable play (inner

cable play) reaches the standard value.

Standard value:

l-2 mm (.04-.08 in.)

(1O)Fix the auto-cruise cable with the lock nut.

(1

l)After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

-

rTSB Revision

Page 543 of 1273

AUTO-CRUISE CONTROL SYSTEM - Setice Adiustment Procedures13-401

16AO192

--

Ib/-

SJy-

iii

3 1

24

J

14LO142

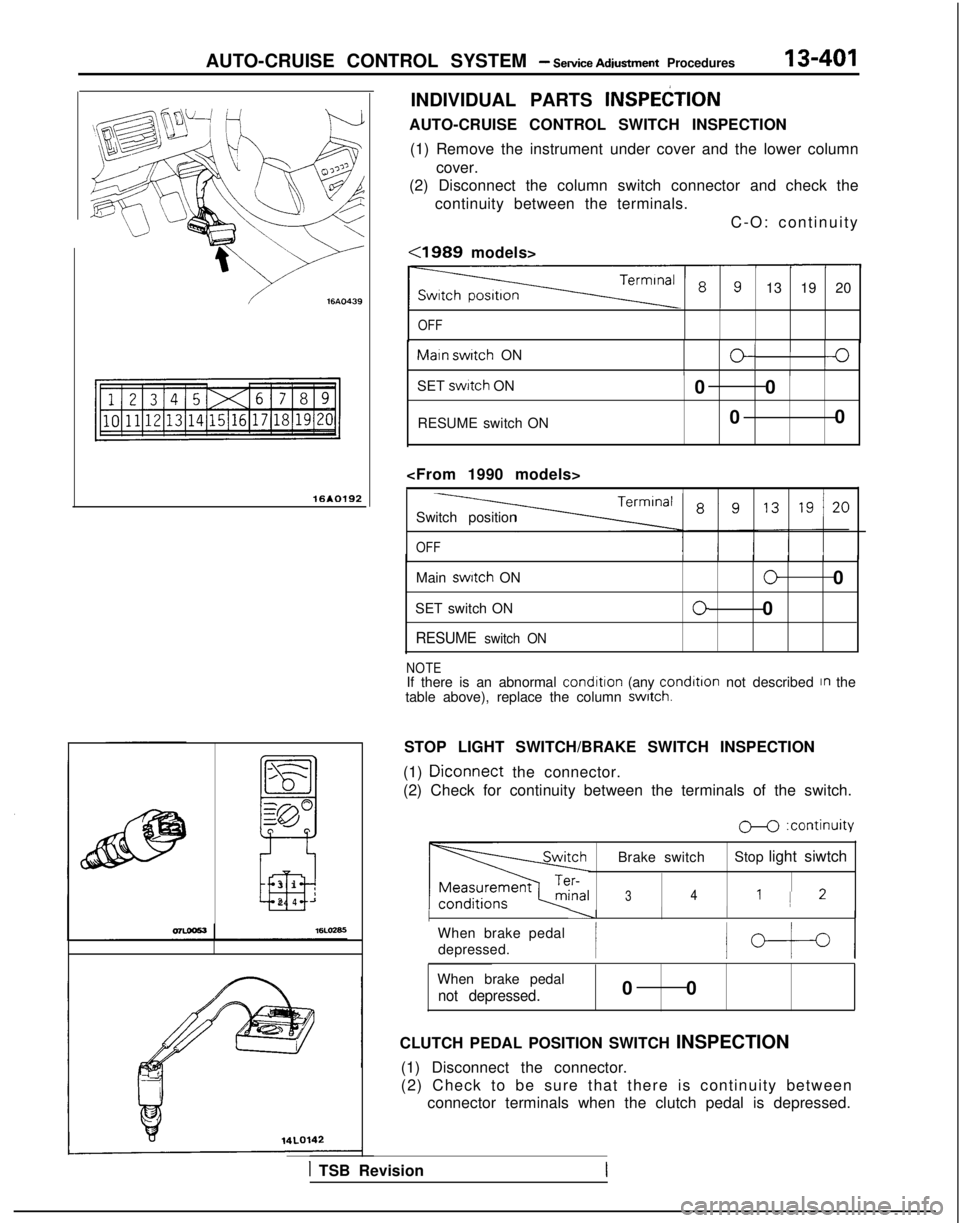

INDIVIDUAL PARTS INSPEtiTION

AUTO-CRUISE CONTROL SWITCH INSPECTION

(1) Remove the instrument under cover and the lower column cover.

(2) Disconnect the column switch connector and check the

continuity between the terminals.

C-O: continuity

<1989 models>

13 19 20

OFF Maln

switch

ON

O/I0IIIISET swttch

ON

RESUME switch ON 0 0

0 0

OFF

Main switch

ON

SET switch ON

RESUME switch ON

00

00

NOTEIf there is an abnormal condition

(any condltlon

not described In the

table above), replace the column switch.

STOP LIGHT SWITCH/BRAKE SWITCH INSPECTION

(1)

Diconnect the connector.

(2) Check for continuity between the terminals of the switch.

M :continuity

Brake switch Stop light siwtch

341 1 2

I----II I

When brake pedal

depressed.

/b-t-4

When brake pedal

not depressed.0 0

CLUTCH PEDAL POSITION SWITCH INSPECTION (1) Disconnect the connector.

(2) Check to be sure that there is continuity between connector terminals when the clutch pedal is depressed.

1 TSB Revision

Page 544 of 1273

13-402AUTO-CRUISE CONTROL SYSTEM - service Adjusbnent PWSXIU~S

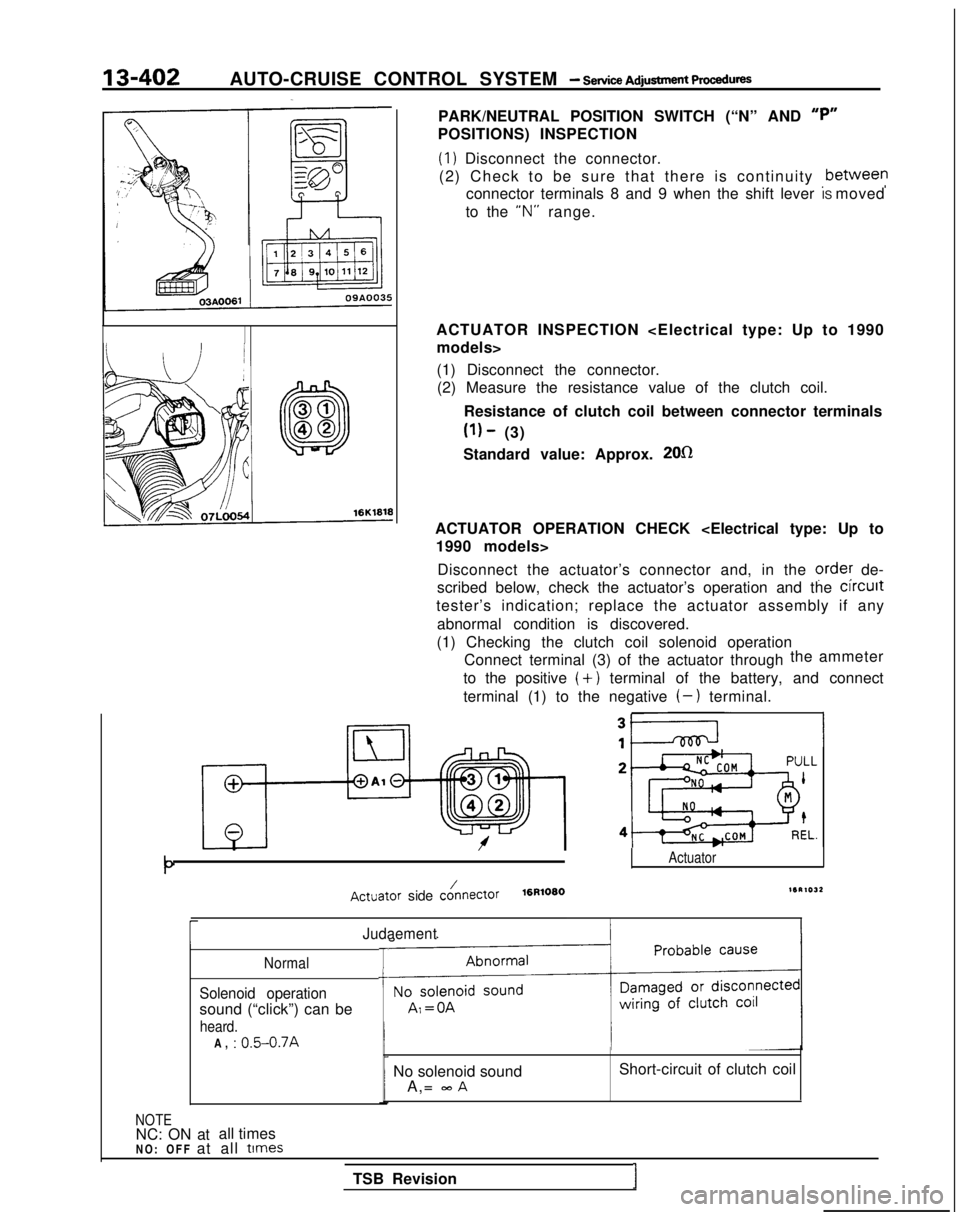

PARK/NEUTRAL POSITION SWITCH (“N” AND “P”

POSITIONS) INSPECTION

(1) Disconnect the connector.

(2) Check to be sure that there is continuity ,between

connector terminals 8 and 9 when the shift lever IS moved

to the “N”

range.

ACTUATOR INSPECTION

(1) Disconnect the connector.(2) Measure the resistance value of the clutch coil.

Resistance of clutch coil between connector terminals

(1) - (3)

Standard value: Approx.

2Ofl

ACTUATOR OPERATION CHECK

Disconnect the actuator’s connector and, in the

ordey de-

scribed below, check the actuator’s operation and the clrcult

tester’s indication; replace the actuator assembly if any

abnormal condition is discovered.

(1) Checking the clutch coil solenoid operation Connect terminal (3) of the actuator through the

ammeter

to the positive

(+) terminal of the battery, and connect

terminal (1) to the negative

(-) terminal.

Actuator

Actuator side cO/nectOr16R10801SR1032

rJudaement

Normal

Solenoid operation

sound (“click”) can be

heard.

T

-t

A, : 0.5-0.7A

NOTENC: ON at all times No solenoid sound

A,=

mA

Short-circuit of clutch coil

NO: OFF at all

times

TSB RevisionI

Page 545 of 1273

AUTO-CRUISE CONTROL SYSTEM - Service Adjustment procedures13-403

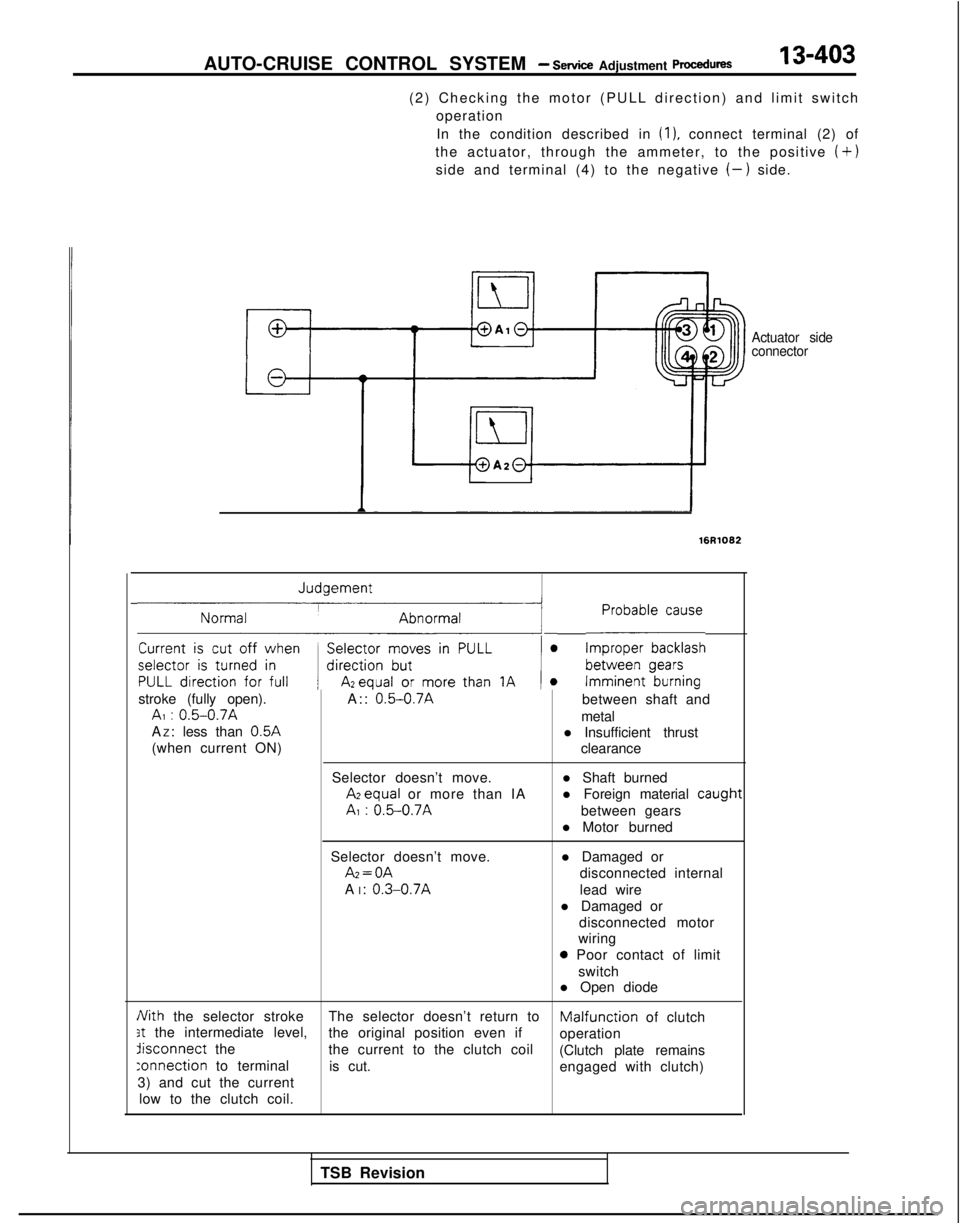

(2) Checking the motor (PULL direction) and limit switch

operation

In the condition described in

(1). connect terminal (2) of

the actuator, through the ammeter, to the positive

(+)

side and terminal (4) to the negative (-) side.

Actuator side

connector

16R1082

~1 L-E~~~~~~

stroke (fully open). A:: 0.5-0.7Abetween shaft andAI : 0.5-0.7Ametal

A Z: less than 0.5A

l Insufficient thrust

(when current ON) clearance

Selector doesn’t move. l Shaft burned Azequal

or more than IA l Foreign material

caugt

AI : 0.5-0.7Abetween gears

l Motor burned

Selector doesn’t move. Az=OA

A I:

0.3-0.7A

l Damaged or

disconnected internal

lead wire

l Damaged or disconnected motor

wiring

0 Poor contact of limit

switch

l Open diode

Nith the selector stroke The selector doesn’t return toMalfunciion of clutch3t the intermediate level,

the original position even if

operationdisconnect

the

the current to the clutch coil

(Clutch plate remains

:onnection to terminalis cut. engaged with clutch)

3) and cut the current

low to the clutch coil.

1t

TSB Revision

Page 546 of 1273

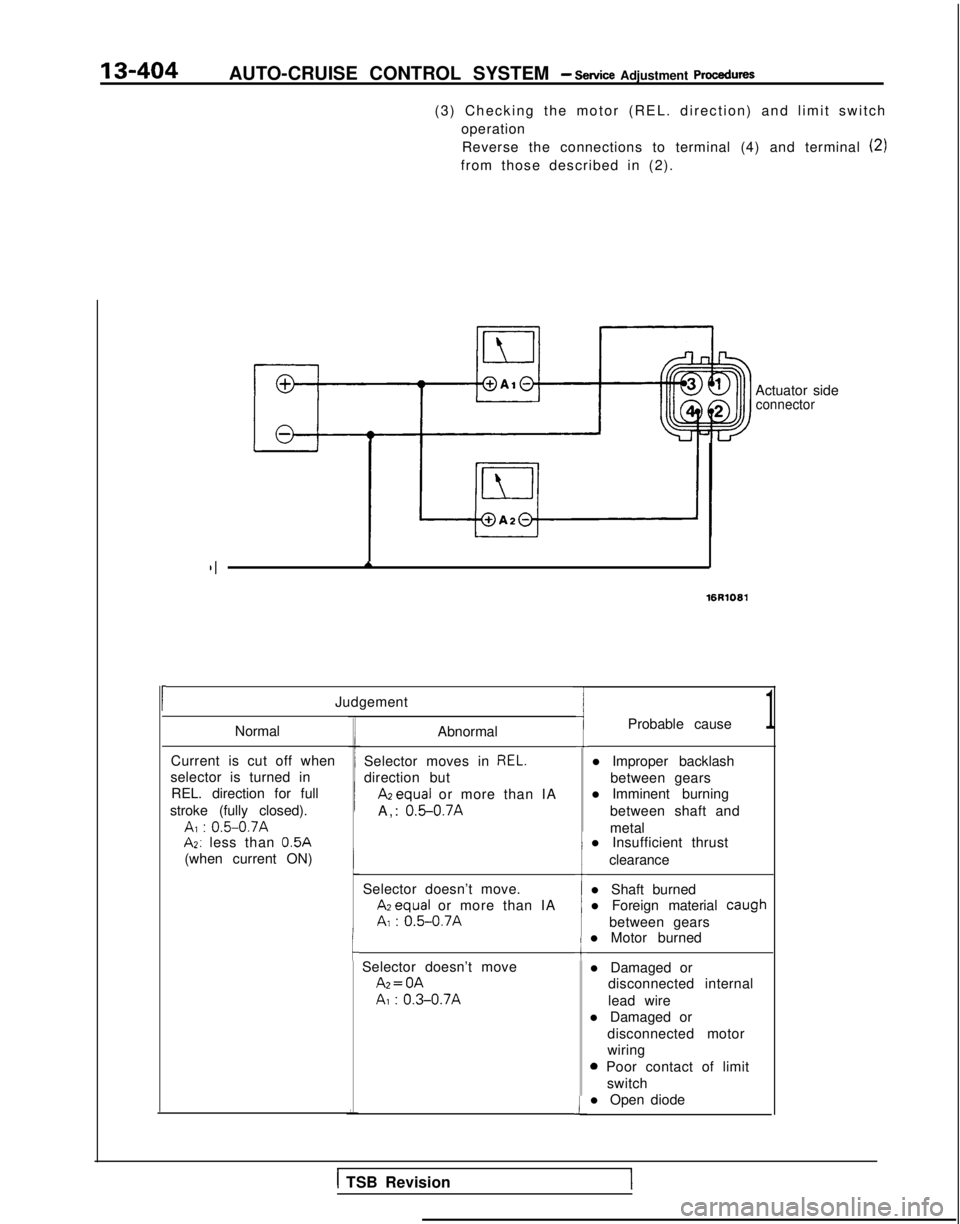

13-404AUTO-CRUISE CONTROL SYSTEM - Service Adjustment procedures

(3) Checking the motor (REL. direction) and limit switchoperationReverse the connections to terminal (4) and terminal

(2)

from those described in (2).

c

Actuator sideconnector

II*

16R1081

Judgement

Normal

Current is cut off when

selector is turned in REL. direction for full

stroke (fully closed).

A, : 0.5-0.7AAZ: less than

0.5A

(when current ON) Abnormal

Selector moves in

REL.

direction but

Apequa or more than IA

A,: 0.5-0.7A

Selector doesn’t move. ATequal

or more than IA

AI : 0.5-0.7AI

cSelector doesn’t move Az=OA

A, :

0.3-0.7A

-I

1

I

i

1

Probable cause1

l Improper backlash

between gears

l Imminent burning

between shaft and

metal

l Insufficient thrust

clearance

l Shaft burned

l Foreign material caugh

between gears

l Motor burned

l Damaged or

disconnected internal

lead wire

l Damaged or

disconnected motor

wiring

0 Poor contact of limitswitch

l Open diode

1 TSB RevisionI

Page 547 of 1273

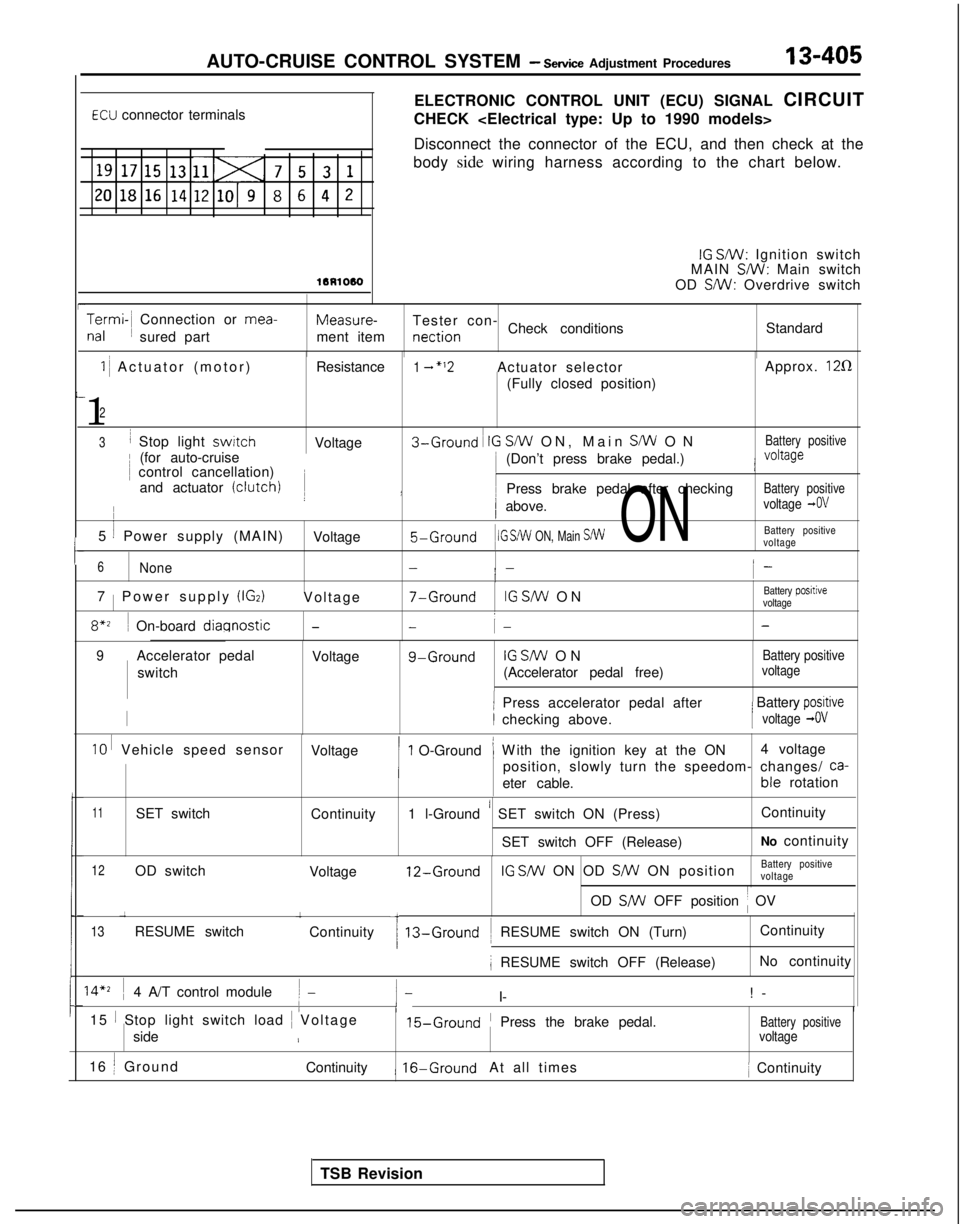

AUTO-CRUISE CONTROL SYSTEM - Sewice Adjustment Procedures

ECU connector terminals

19171513ll><7531

2018161412 101 98642

16A1060

ELECTRONIC CONTROL UNIT (ECU) SIGNAL CIRCUIT

CHECK

Disconnect the connector of the ECU, and then check at the

body side wiring harness according to the chart below.

IG SW: Ignition switch

MAIN SW: Main switch

OD SMI: Overdrive switch

Termi-~ Connection or mea-

nal

~

sured part Measure-

Tester con-

ment item nection

Check conditions

Standard

I-

I-

1 ~

Actuator (motor) Resistance1 - “‘2Actuator selector Approx. 120

(Fully closed position)

1

2

3I Stop light switchVoltage3-Ground ~

IG S/W ON, Main SW O

N

Battery positive

~

(for auto-cruise ~

control cancellation)

j )

i (Don’t press brake pedal.)j voltage

and actuator (clutch)I Press brake pedal after checkingBattery positive

5 1 Power supply (MAIN)

/ above.voltage -0V

Voltage5-Ground

1 IG S/W

ON, Main S/W ONBattery positive

voltage

6None-i -i-

7 1

Power supply (IGz)Voltag

e

7-GroundIG SfW O

N

Battery positive

voltage

8*z ~

On-board diagnostic--i- -

TSB Revision

9Accelerator pedal Voltageg-GroundIG SW O

N

Battery positive

switch

(Accelerator pedal free)voltage

1 Press accelerator pedal after/ Battery positive

II checking above.[voltage -0V

IO I Vehicle speed sensor

Voltage1 O-Ground’ W

ith the ignition key at the ON

’ ~

4 voltage

position, slowly turn the speedom- changes/

ca-

eter cable. ble

rotation

11SET switch

Continuity1 l-Ground ’ SET switch ON (Press) Continuity

SET switch OFF (Release) No continuity

12OD switch

13RESUME switch 1

Voltage

Continuity

12-GroundIG SNV ON OD SW ON position

Battery positive

voltage

OD

SW OFF position ~

OV

13-Ground ~

RESUME switch ON (Turn) Continuity

; RESUME switch OFF (Release)

No continuity

14’2 ~

4 A/T control module( -/- I- !

-

I/15 1 Stop light switch load

~

Voltage15-Ground’ Press the brake pedal.Battery positiveside/voltage

16 j Ground

Continuity1 16-GroundAt all times ~

Continuity

Page 548 of 1273

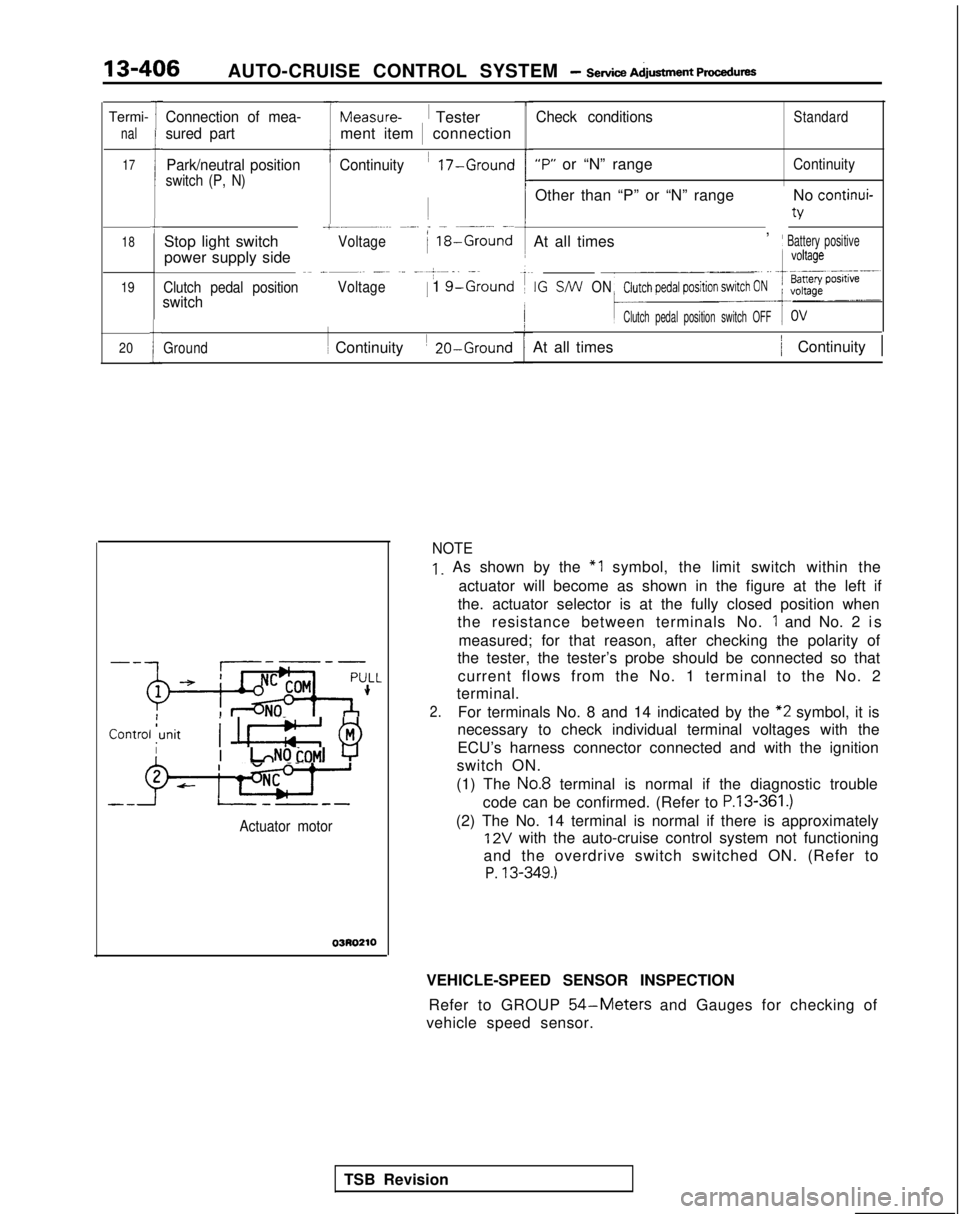

13-406AUTO-CRUISE CONTROL SYSTEM - Service A&tment ~mcec~ure~

Termi-

nal

17

18

19

20

l-

it

L

Connection of mea-

sured part Park/neutral position

switch (P, N)

T

f

+

Stop light switch

power supply side

Continuity ~

17-Ground

1

.~.~.~ ~.-. _ - ~~- -~/Voltage)

18-Ground

~~

____~ _~ ~.. ----+--.. .-~

Clutch pedal position

Voltage1 1 g-Groundswitch

Measure-1

Tester

ment item 1

connection

Ground

1 ~

Continuity ~

20-Ground

-Conrroljunitj I! @jIII LNOtOMl ‘-r’

+-j-

--J--L--

Actuator motor

03R0210

Check conditionsStandard

“P” or “N” rangeContinuity

Other than “P” or “N” range

,No continui-

v

At all timesj Battery positive

IG S/W

ON

Clutch pedal position switch OFF

At all times/ Continuity 1

NOTE

1. As shown by the “1 symbol, the limit switch within the

actuator will become as shown in the figure at the left if

the. actuator selector is at the fully closed position when

the resistance between terminals No.

1 and No. 2 i

s

measured; for that reason, after checking the polarity of

the tester, the tester’s probe should be connected so that

current flows from the No. 1 terminal to the No. 2

terminal.

2.For terminals No. 8 and 14 indicated by the “2

symbol, it is

necessary to check individual terminal voltages with the

ECU’s harness connector connected and with the ignition

switch ON.

(1) The

No.8 terminal is normal if the diagnostic trouble

code can be confirmed. (Refer to

P.13-361.)

(2) The No. 14 terminal is normal if there is approximately

12V with the auto-cruise control system not functioning

and the overdrive switch switched ON. (Refer to

P. 13-349.)

VEHICLE-SPEED SENSOR INSPECTION

Refer to GROUP

54-Meters and Gauges for checking of

vehicle speed sensor.

TSB Revision

Page 549 of 1273

AUTO-CRUISE CONTROL SYSTEM - Setice Adjustment procedures13-407

=\

07A005.1

Controlvalve

L2

07AOO50

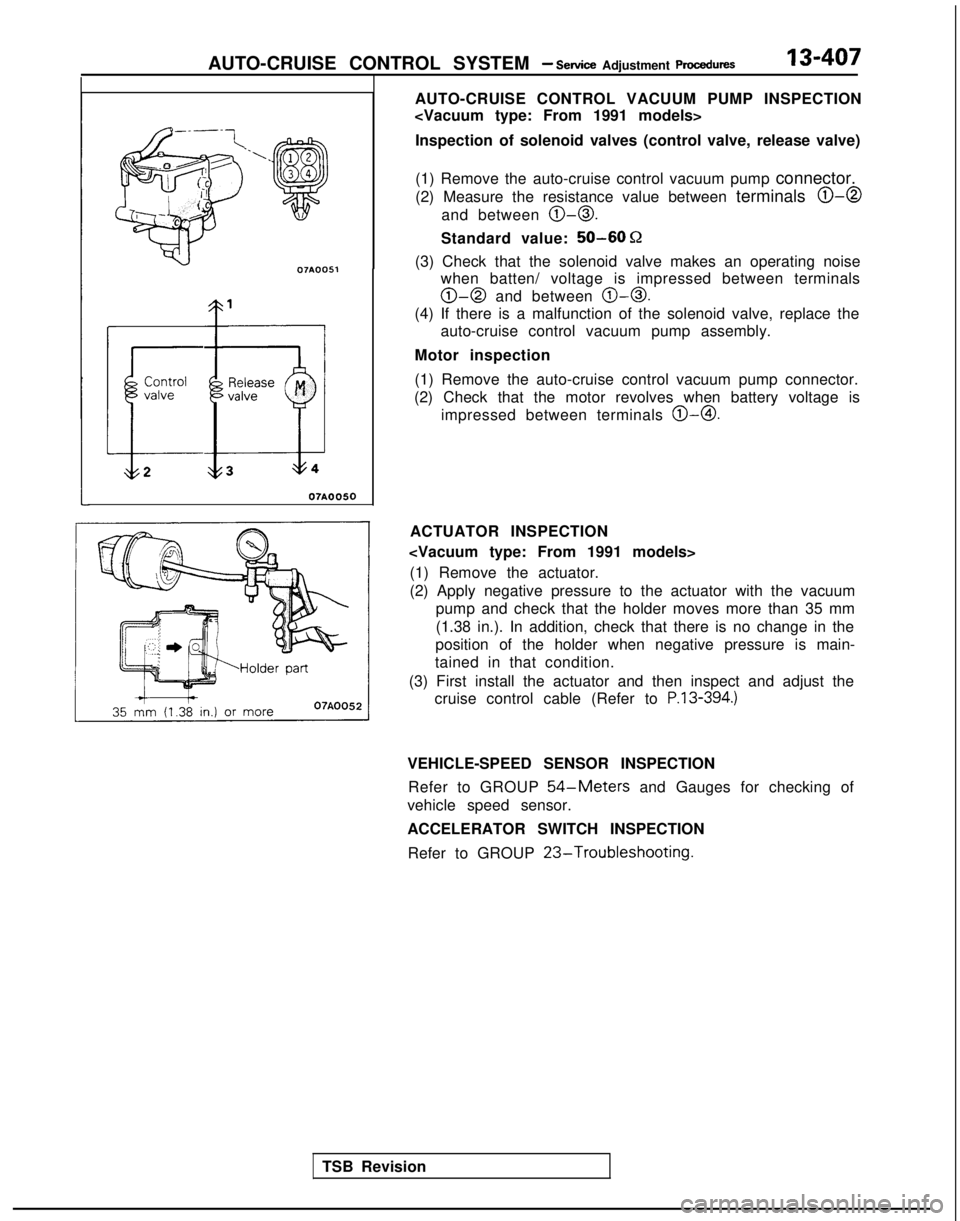

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)

(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0

and between 0-0.

Standard value: 50-60 Q

(3) Check that the solenoid valve makes an operating noise

when batten/ voltage is impressed between terminals

0-0 and between 0-0.

(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection

(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is impressed between terminals

@-0.

TSB Revision ACTUATOR INSPECTION

(1) Remove the actuator.

(2) Apply negative pressure to the actuator with the vacuum pump and check that the holder moves more than 35 mm

(1.38 in.). In addition, check that there is no change in the

position of the holder when negative pressure is main-

tained in that condition.

(3) First install the actuator and then inspect and adjust the cruise control cable (Refer to

P.13-394.)

VEHICLE-SPEED SENSOR INSPECTION

Refer to GROUP

54-Meters and Gauges for checking of

vehicle speed sensor.

ACCELERATOR SWITCH INSPECTION

Refer to GROUP

23-Troubleshooting.

Page 550 of 1273

13-408AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control

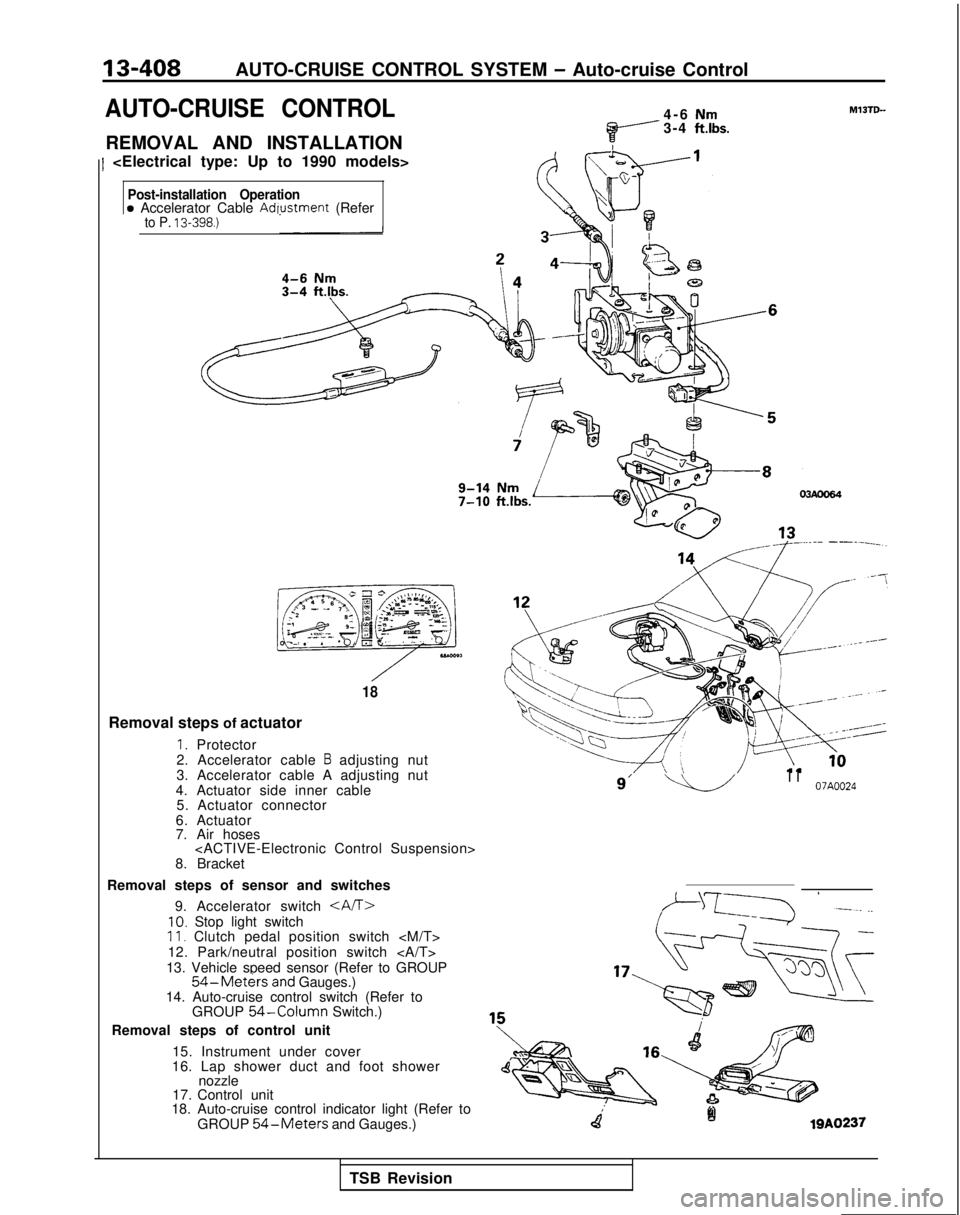

AUTO-CRUISE CONTROL

REMOVAL AND INSTALLATION

1

Nm3-4 ft.lbs.

Post-installation Operationa Accelerator Cable Adwstment (Referto P. 13-398.)

,**.“qy “y ,,,,ezls:’ 3 -. .- ,*%L’J

01

,\@&&,

-<28- E+c- - - --.c,

T

$$y= *g i ;g+j$T

-3

18

Removal steps of actuator

1. Protector

2. Accelerator cable B adjusting nut

3. Accelerator cable A adjusting nut

4. Actuator side inner cable 5. Actuator connector

6. Actuator

7. Air hoses

8. Bracket

Removal steps of sensor and switches 9. Accelerator switch

10. Stop light switch11. Clutch pedal position switch

12. Park/neutral position switch

13. Vehicle speed sensor (Refer to GROUP

54-Met&sand Gauges.)

14. Auto-cruise control switch (Refer to GROUP

54-Column Switch.)

Removal steps of control unit

15. Instrument under cover

16. Lap shower duct and foot shower nozzle

17. Control unit

18. Auto-cruise control indicator light (Refer to

GROUP

54-Meters and Gauges.)

9’ -L.-lI I07A0024

falQA0237

TSB Revision