MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 551 of 1273

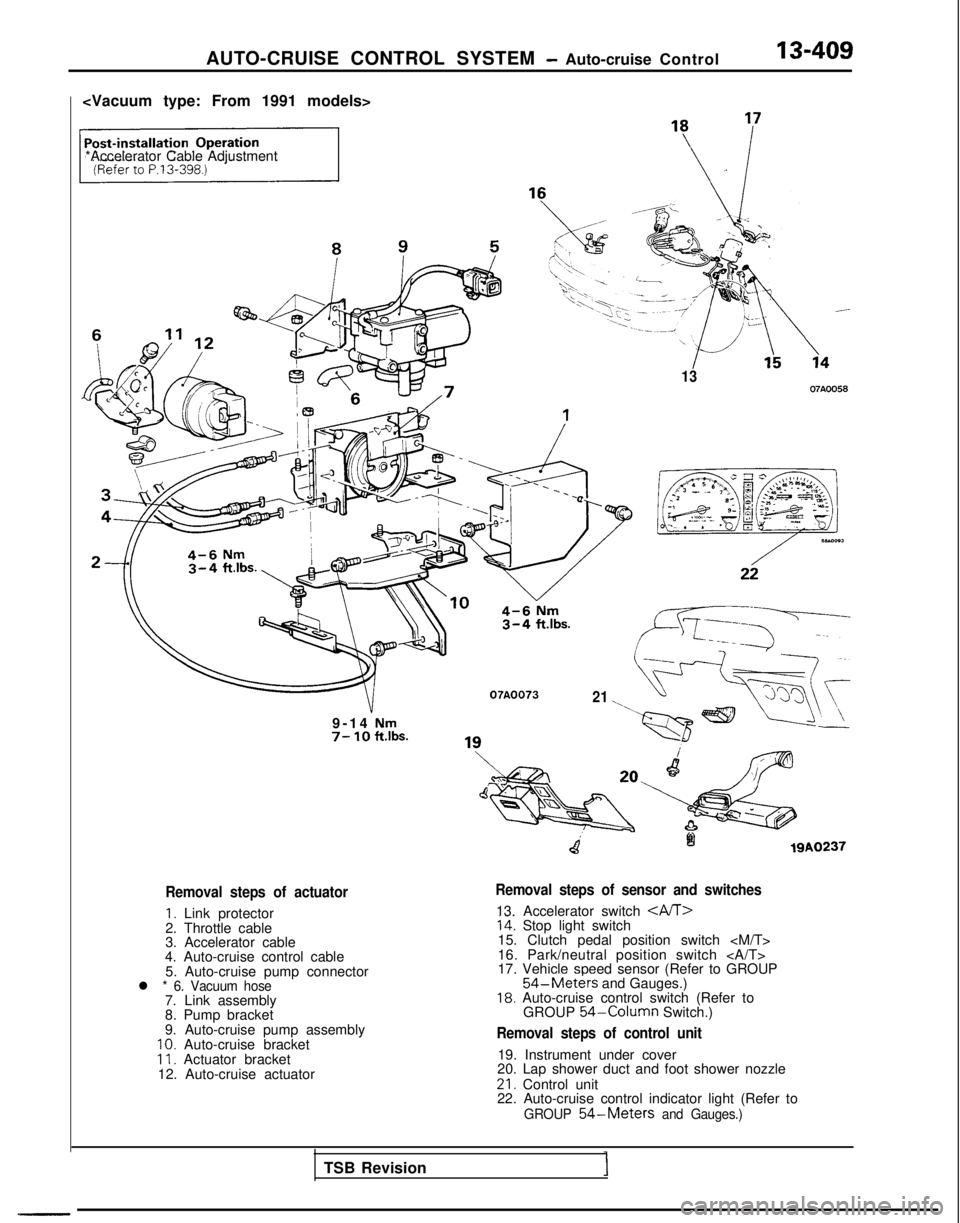

AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control

*Accelerator Cable Adjustment

Removal steps of actuator

1. Link protector

2. Throttle cable

3. Accelerator cable

4. Auto-cruise control cable

5. Auto-cruise pump connector

l * 6. Vacuum hose7. Link assembly

8. Pump bracket

9. Auto-cruise pump assembly

IO. Auto-cruise bracket11, Actuator bracket

12. Auto-cruise actuator

1307AOO58

9-14 Nm7- 10 ftlbs.

21

19AO237

Removal steps of sensor and switches

13. Accelerator switch

15. Clutch pedal position switch

16. Park/neutral position switch

17. Vehicle speed sensor (Refer to GROUP

54-Meters and Gauges.)18. Auto-cruise control switch (Refer to GROUP 54-Column Switch.)

Removal steps of control unit

19. Instrument under cover

20. Lap shower duct and foot shower nozzle

21. Control unit

22. Auto-cruise control indicator light (Refer to

GROUP 54-Meters and Gauges.)

TSB Revision

.-

Page 552 of 1273

13-410AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control

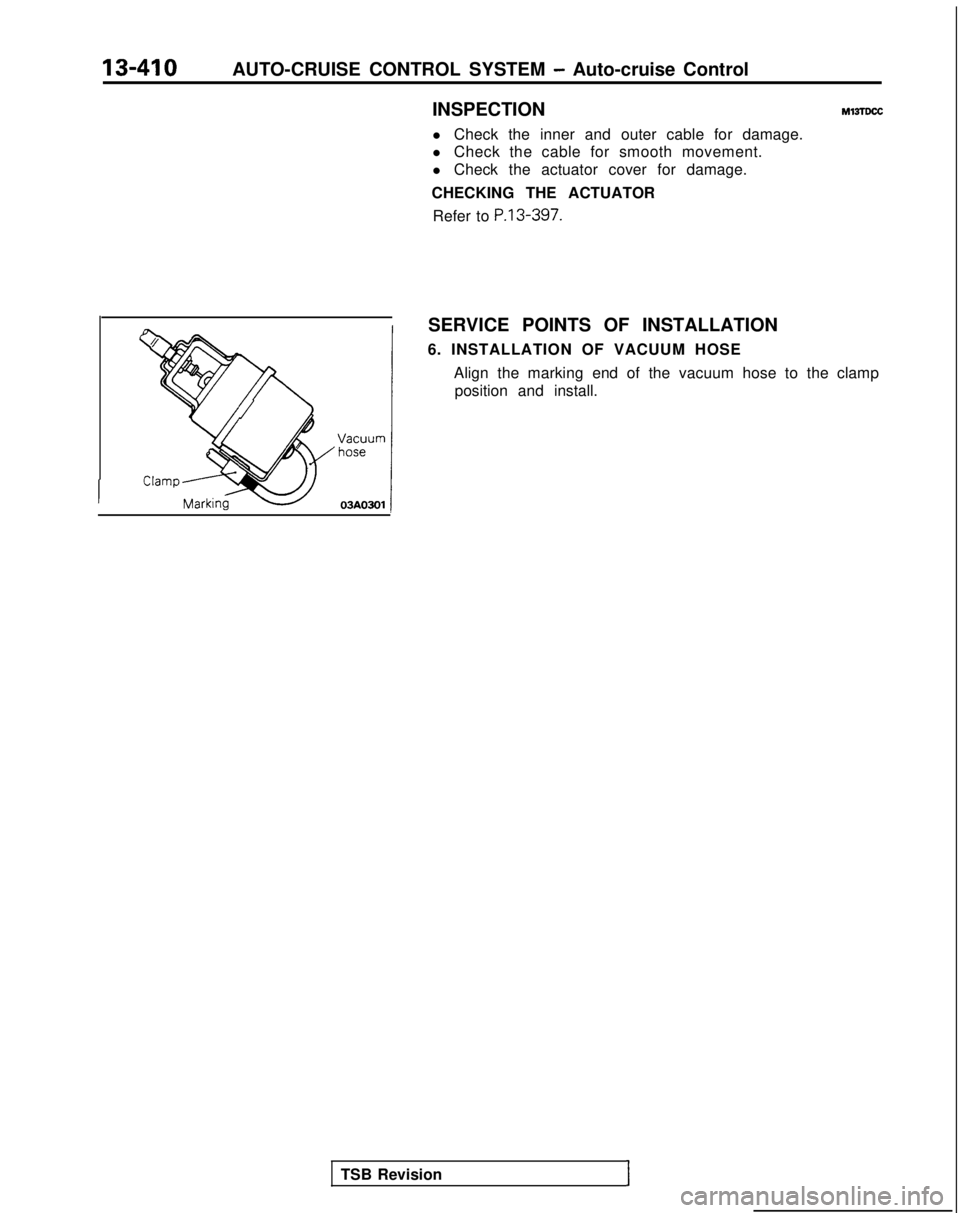

INSPECTION

l Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the actuator cover for damage.

CHECKING THE ACTUATOR Refer to

P.13-397.

M13lDCC

SERVICE POINTS OF INSTALLATION

6. INSTALLATION OF VACUUM HOSE Align the marking end of the vacuum hose to the clampposition and install.

TSB Revision

I

Page 553 of 1273

14-1

COOLING

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE

COOLANT TEMPERATURE

SWITCH.............

31

RADIATOR ....................................................... 9

RADIATOR FAN MOTOR ASSEMBLY ..........

12

SERVICE ADJUSTMENT PROCEDURES..

.....

8

Engine Coolant Concentration Test .............

8

Engine Coolant LeakCheck

........................8

Engine Coolant

Replacement .......................

8

Radiator Cap Pressure Test .........................

8

SPECIAL TOOL................................................5

SPECIFICATIONS .............................................

2

General Specifications ..................................

2

Lubricant

....................................................... 4

CONTENTS

IM14AA-

Sealant. . . . . . . . . . . . . ..__...........’ . . . . . . . . . . . . . \

. . . . . .._.........4

ServiceSpecifications . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . .13

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .5

No rise in temperature

Overheat

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a.....23

WATER PUMP

WATER PUMP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 554 of 1273

14-2

COOLING- Specifications

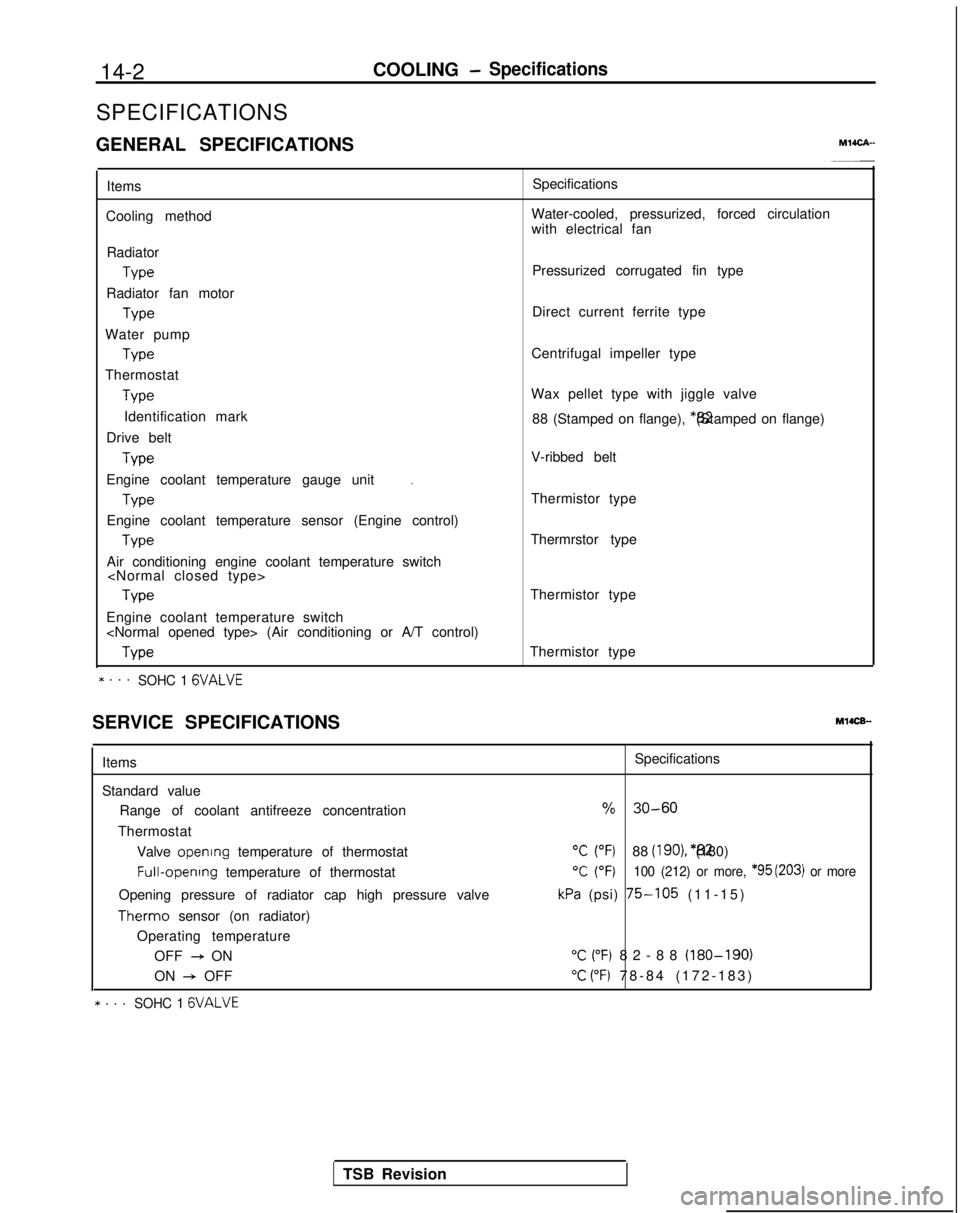

SPECIFICATIONS

GENERAL SPECIFICATIONS

MlICA-

Items

Cooling method Specifications

Water-cooled, pressurized, forced circulation

with electrical fan

Radiator Type

Radiator fan motor Type

Water pump Type

Thermostat Type

Identification mark

Drive belt Type

.Engine coolant temperature gauge unit

Type

Engine coolant temperature sensor (Engine control) Type

Air conditioning engine coolant temperature switch

Engine coolant temperature switch

* . . .SOHC 1 GVALVE

Pressurized corrugated fin type

Direct current ferrite type

Centrifugal impeller type

Wax pellet type with jiggle valve 88 (Stamped on flange), *82 (Stamped on flange)

V-ribbed belt

Thermistor type

Thermrstor type

Thermistor type

Thermistor type

SERVICE SPECIFICATIONS

MlOCB-

Items

Standard value Range of coolant antifreeze concentration

Thermostat Valve opening

temperature of thermostat Full-opening

temperature of thermostat

Opening pressure of radiator cap high pressure valve Therm0

sensor (on radiator)

Operating temperature OFF

+ ON

ON

+ OFF

* . . .SOHC 1 GVALVE

Specifications

% 30-60

“C (“F)88 (IgO), *82 (180)

T (OF)100 (212) or more, *95 (203) or more

kPa (psi) 75-105 (11-15

)

“C (“F) 82-88 (180-190)

“C (“F) 78-84 (172-183

)

TSB Revision

Page 555 of 1273

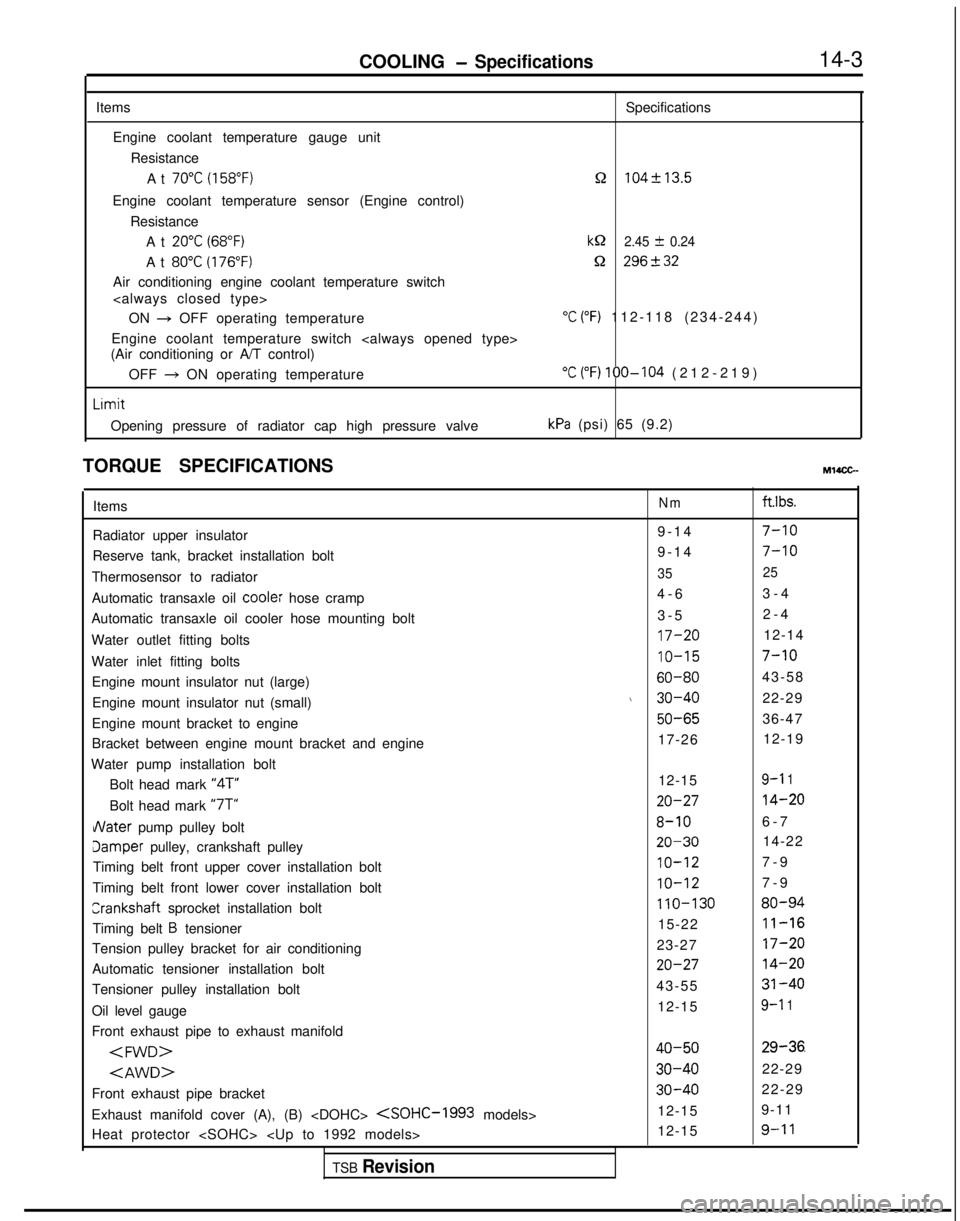

COOLING- Specifications14-3

Items Specifications

Engine coolant temperature gauge unit ResistanceAt

70°C (158°F)n 104f13.5

Engine coolant temperature sensor (Engine control) ResistanceAt

20°C (68°F)kQ 2.45 f 0.24

At 80°C (176°F)Q 296+32

Air conditioning engine coolant temperature switch

ON

+ OFF operating temperature“C (“F) 112-118 (234-244

)

Engine coolant temperature switch

(Air conditioning or A/T control)

OFF

+ ON operating temperature“C (“F) 100-104 (212-219

)

Limit

Opening pressure of radiator cap high pressure valvekPa (psi) 65 (9.2)

TORQUE SPECIFICATIONS

MWCG-

ItemsNm ft.lbs.

Radiator upper insulator 9-14

7-10

Reserve tank, bracket installation bolt9-1

4

7-10

Thermosensor to radiator35

25

Automatic transaxle oil coole: hose cramp 4-

6

3-4

Automatic transaxle oil cooler hose mounting bolt 3-5

2-4

Water outlet fitting bolts

17-2012-14

Water inlet fitting bolts

IO-157-10

Engine mount insulator nut (large)60-8043-58

Engine mount insulator nut (small)

\ 30-4022-29

Engine mount bracket to engine

50-6536-47

Bracket between engine mount bracket and engine 17-26

12-19

Water pump installation bolt Bolt head mark “4T”

12-15

9-l 1

Bolt head mark “7T”20-2714-20

dater pump pulley bolt8-106-

7

Jamper pulley, crankshaft pulley20-3014-22

Timing belt front upper cover installation bolt

IO-127-

9

Timing belt front lower cover installation bolt

IO-127-

9

Crankshaft

sprocket installation bolt

110-13080-94

Timing belt B tensioner 15-2211-16

Tension pulley bracket for air conditioning

23-2717-20

Automatic tensioner installation bolt20-2714-20

Tensioner pulley installation bolt43-5531-40

Oil level gauge 12-159-l 1

Front exhaust pipe to exhaust manifold

Front exhaust pipe bracket

30-4022-29

Exhaust manifold cover (A), (B)

9-11

Heat protector

TSB Revision

Page 556 of 1273

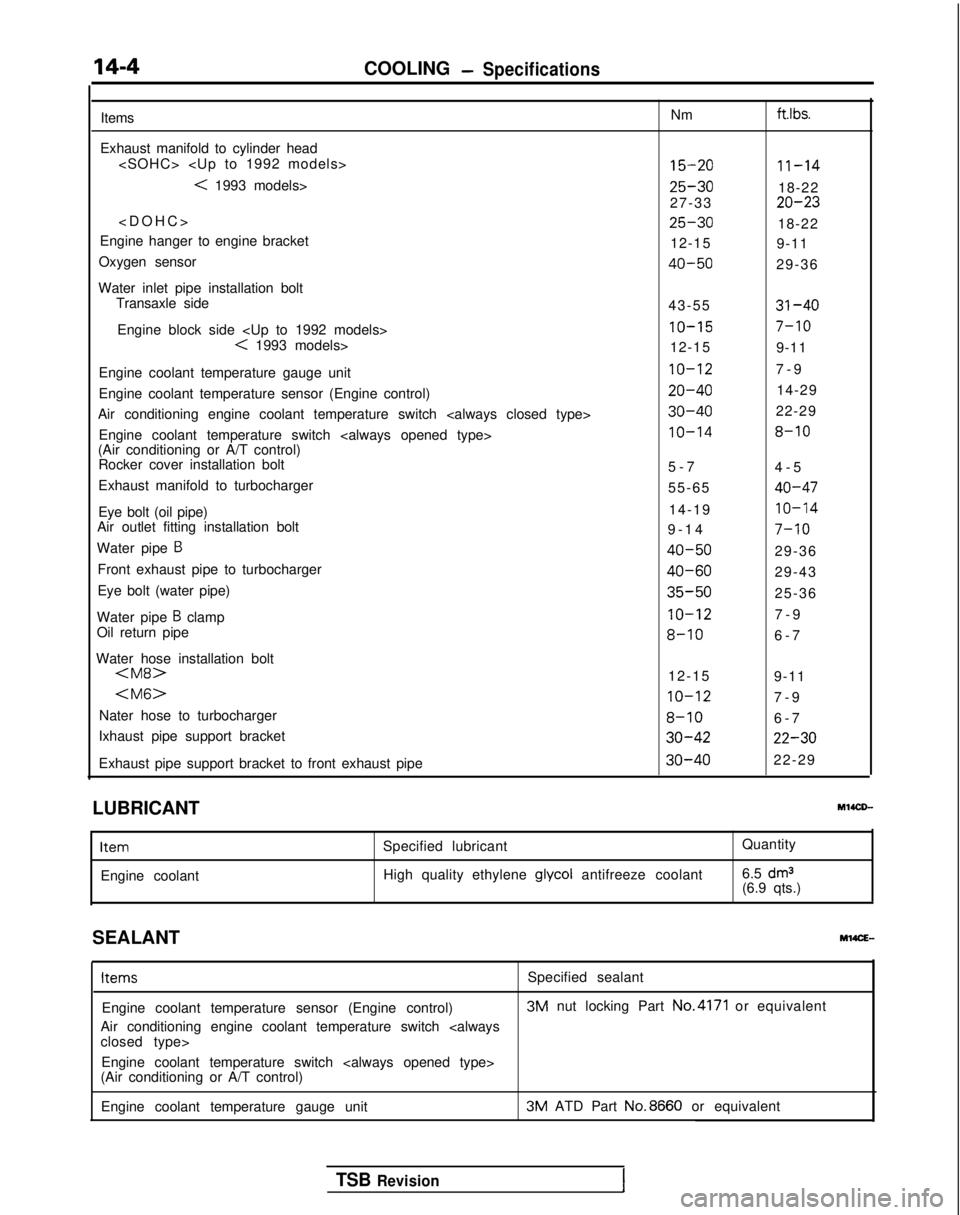

14-4COOLING-Specifications

Items

Exhaust manifold to cylinder head

< 1993 models>

Engine hanger to engine bracket

Oxygen sensor

Water inlet pipe installation bolt Transaxle side

Engine block side

< 1993 models>

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Air conditioning engine coolant temperature switch

Engine coolant temperature switch

(Air conditioning or A/T control) Rocker cover installation bolt

Exhaust manifold to turbocharger

Eye bolt (oil pipe)

Air outlet fitting installation bolt

Water pipe

B

Front exhaust pipe to turbocharger

Eye bolt (water pipe)

Water pipe

B clamp

Oil return pipe

Water hose installation bolt

Nater hose to turbocharger

Ixhaust pipe support bracket

Exhaust pipe support bracket to front exhaust pipe Nm ft.lbs.

15-2011-14

25-3018-22

27-3320-23

25-3018-22

12-15 9-11

40-5029-36

43-55

31-40

IO-157-10

12-15 9-11

IO-127-

9

20-4014-29

30-4022-29

IO-148-10

5-

7

4-5

55-65

40-47

14-19IO-14

9-1

4

7-10

40-5029-36

40-6029-43

35-5025-36

IO-127-

9

8-106-

7

12-15 9-11

IO-127-

9

8-106-

7

30-4222-30

30-4022-29

LUBRICANT Ml4CD-

Item

Engine coolant

Specified lubricant

High quality ethylene glycol

antifreeze coolant Quantity

6.5

dm3(6.9 qts.)

SEALANT

M14CE- Items

Specified sealant

Engine coolant temperature sensor (Engine control) 3M

nut locking Part No.4171

or equivalent

Air conditioning engine coolant temperature switch

(Air conditioning or A/T control)

Engine coolant temperature gauge unit 3M

ATD Part No.8660

or equivalent

TSB Revision

Page 557 of 1273

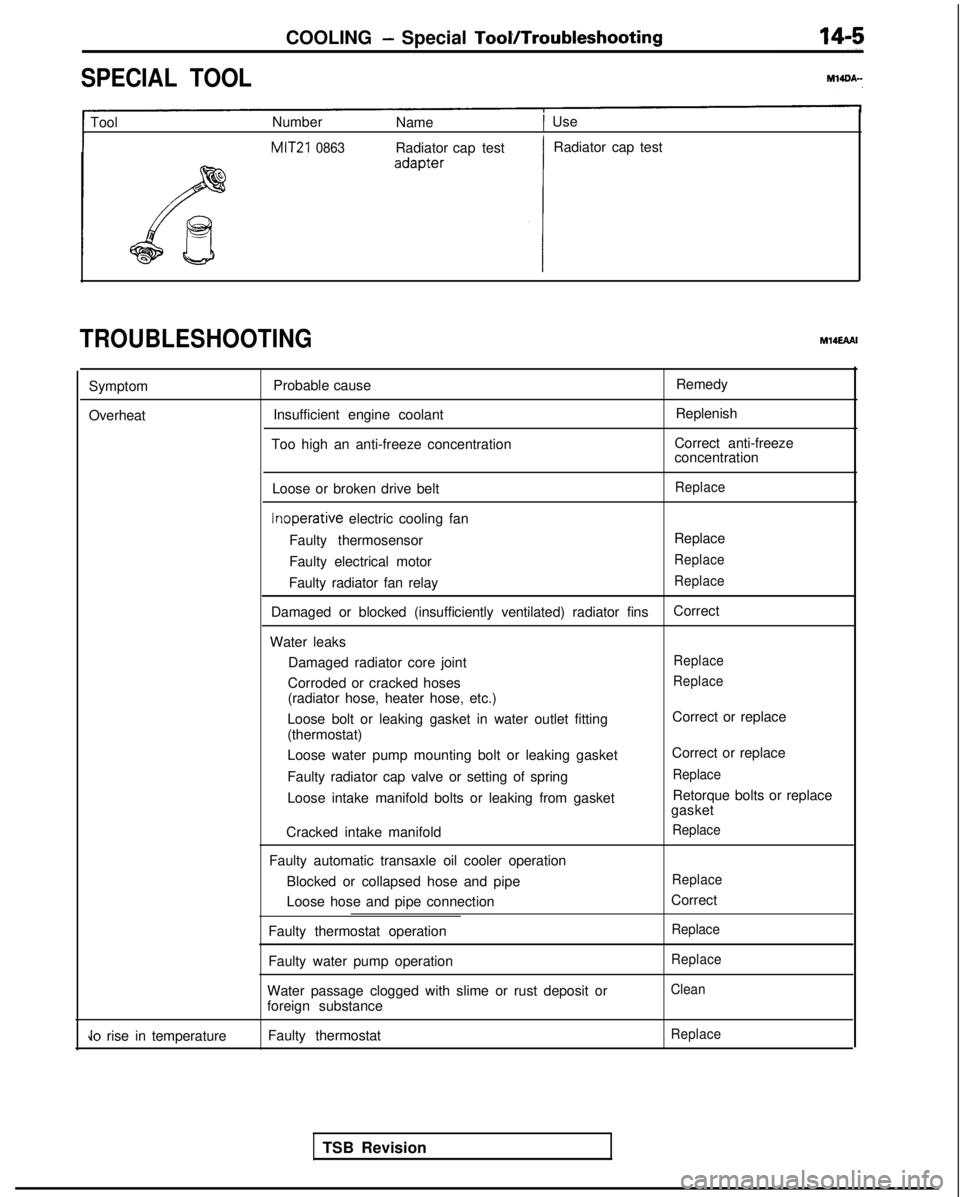

COOLING - Special TooVTroubleshooting

SPECIAL TOOL

1 Tool

Number

Name1 Use

MIT21 0863Radiator cap test Radiator cap test

TROUBLESHOOTINGM14EAAI

Symptom

Overheat Probable cause

Insufficient engine coolant

Too high an anti-freeze concentration Remedy

Replenish

Correct anti-freeze

concentration

Loose or broken drive belt

Replace Inoperative

electric cooling fan

Faulty thermosensor Replace

Faulty electrical motor

Replace

Faulty radiator fan relayReplace

Damaged or blocked (insufficiently ventilated) radiator fins Correct

Water leaks Damaged radiator core joint

Replace

Corroded or cracked hosesReplace

(radiator hose, heater hose, etc.)

Loose bolt or leaking gasket in water outlet fitting

(thermostat)

Loose water pump mounting bolt or leaking gasket

Faulty radiator cap valve or setting of spring

Loose intake manifold bolts or leaking from gasket

Cracked intake manifold

Faulty automatic transaxle oil cooler operation Blocked or collapsed hose and pipe

Loose hose and pipe connection

Faulty thermostat operation

Faulty water pump operation

Water passage clogged with slime or rust deposit or

foreign substance Correct or replace

Correct or replace

Replace

Retorque bolts or replace

gasket

Replace

Replace

Correct

Replace

Replace

Clean

Jo rise in temperature Faulty thermostatReplace

TSB Revision

Page 558 of 1273

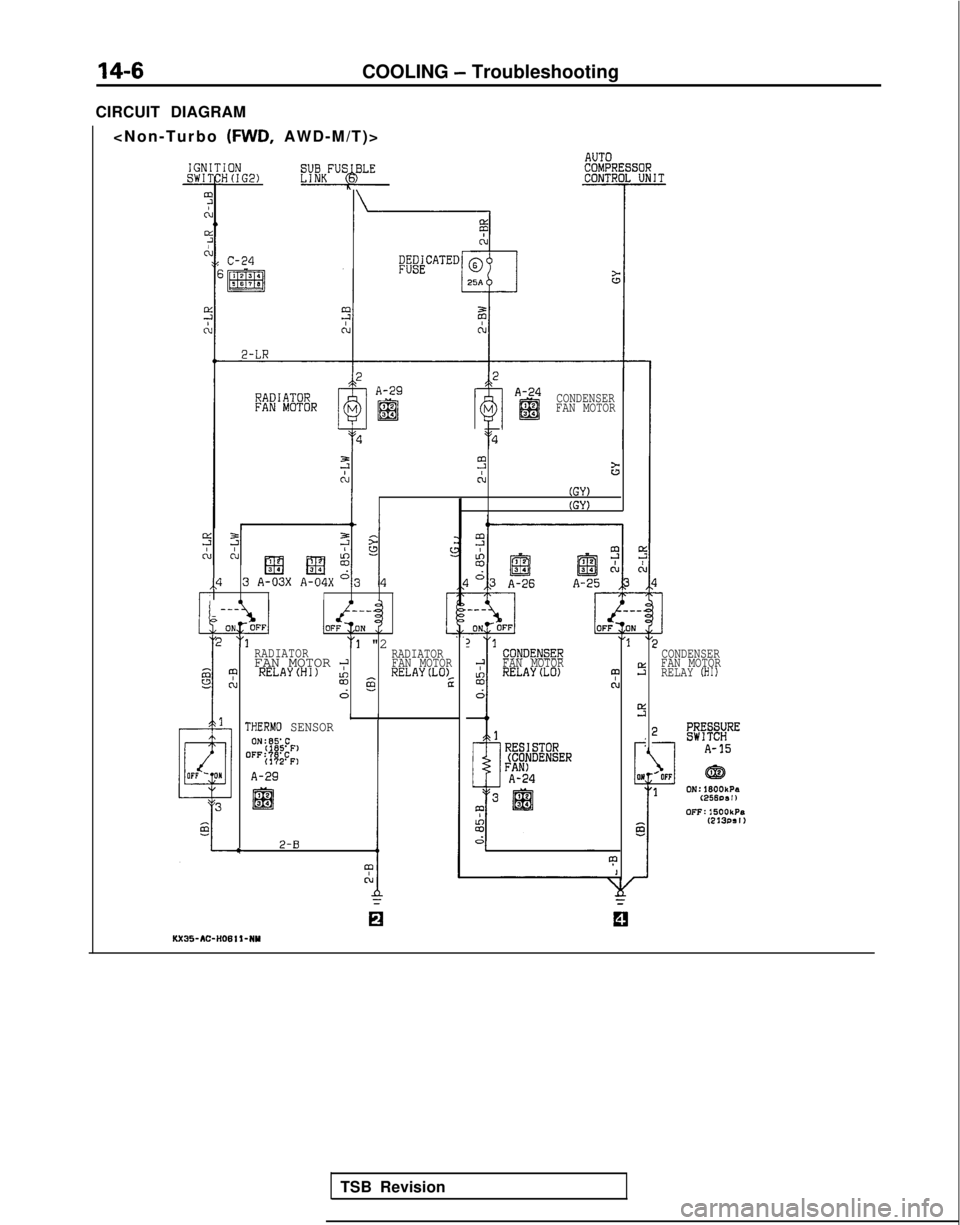

14-6COOLING - Troubleshooting

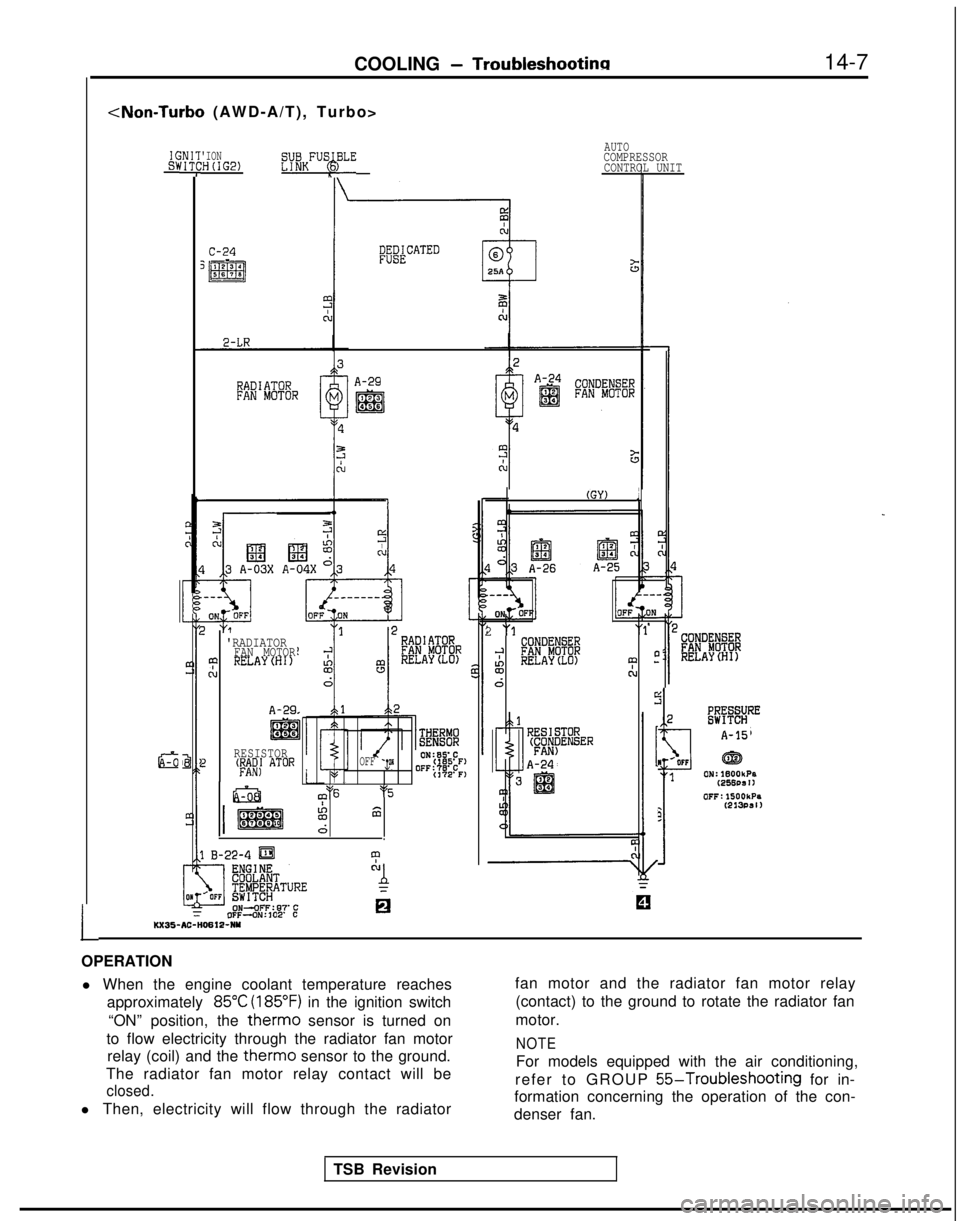

CIRCUIT DIAGRAM

IGNJvJc

c

c

c

IONH(IG2)W&FUj$?LE

C-24

3

CONDENSER

FAN MOTOR

5r; 5(GY)(GY)

,,43AExAy4x3,“4 s

[“1“1 "2RADIATOR

RADIATORFAN MOTOR +FAN MOTOR1 RELAYCHI) gRELAYCLO)J5Ed

I ITHERM0 SENSOR

ON:85’C

(185’F)OFF38 C(172’Fl

A-29

*2-E

40---4

g 51

Pu

411

d

i

FAN MOTOR

2CONDENSER

FAN MOTOR

RELAY

(HI)

&WE;""

A-15

a3 ON:1800kPa

e56Ds I )

OFF:1500kPe

(233DSl)

KXBS-AC-HOEIf-NY

TSB Revision

Page 559 of 1273

COOLING -Troubleshootina14-7

L

ICSk-iNIq

ci

'ION:H(IG2)

W&FUS$BLE

AUTOCOMPRESSOR

CONTROL UNIT

A-29

'RADIATORFAN MOTOR43 RELAYCHI)cu

A-29

RESISTOR

> 'Mf AToR

m ON:SSC

OFF -p(165'F)

OFF:?8’C(172’F)$5m6‘5I%

66.

B-22-4 m

?

"A

OFF-ON:

102’

C0 KX35-AC-H0612-NY

I(GY) ;

2 "1"1

;-'SX!D%% BRELAY(L0) 0? -

N

d

0-

A-24

2

f

A-15

I

/OFFGE3

1

0N:lBOOkPa(256DS

II 0FF:lSOOkPs

2

(213PSl)

OPERATION l When the engine coolant temperature reaches approximately

85°C (185°F) in the ignition switch

“ON” position, the

therm0 sensor is turned on

to flow electricity through the radiator fan motor relay (coil) and the

therm0 sensor to the ground.

The radiator fan motor relay contact will be

closed.

l Then, electricity will flow through the radiator fan motor and the radiator fan motor relay

(contact) to the ground to rotate the radiator fan

motor.

NOTE

For models equipped with the air conditioning,

refer to GROUP

55-Troubleshooting for in-

formation concerning the operation of the con-

denser fan.

TSB Revision

Page 560 of 1273

14-8

COOLING -Service Adjustment Procedures T210863

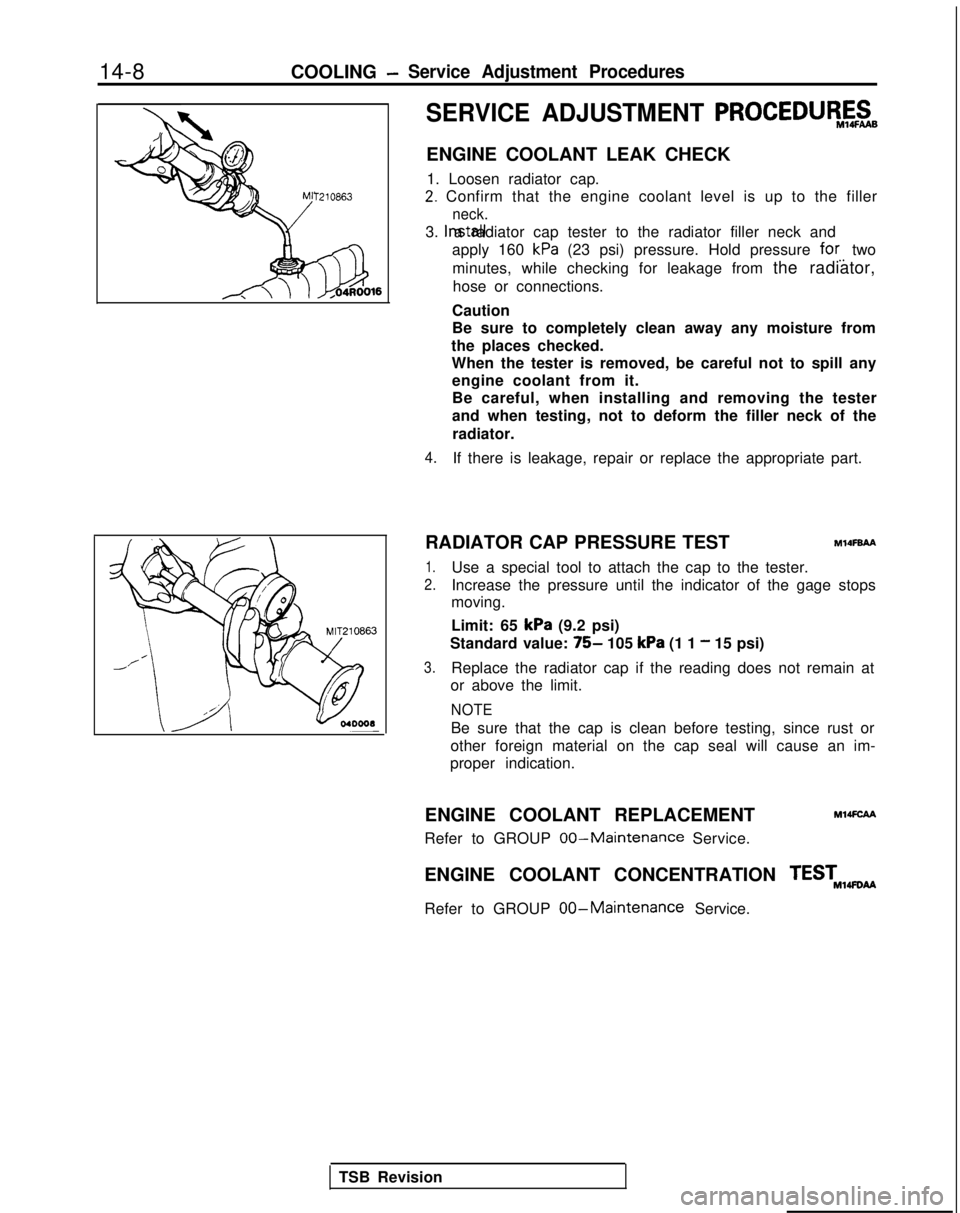

SERVICE ADJUSTMENT PROCEDUl$t&

ENGINE COOLANT LEAK CHECK

1. Loosen radiator cap.

2. Confirm that the engine coolant level is up to the filler

neck.

3. Install a radiator cap tester to the radiator filler neck and

apply 160

kPa (23 psi) pressure. Hold pressure for. two

minutes, while checking for leakage from the radiator, hose or connections.

Caution

Be sure to completely clean away any moisture from

the places checked. When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester

and when testing, not to deform the filler neck of the

radiator.

4.If there is leakage, repair or replace the appropriate part.

RADIATOR CAP PRESSURE TEST

MlOFBAA

1.Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gage stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value:

75- 105 kPa (1 1 - 15 psi)

3.Replace the radiator cap if the reading does not remain at

or above the limit.

NOTE

Be sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an im-

proper indication.

ENGINE COOLANT REPLACEMENT

MMFCAA

Refer to GROUP 00-Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST,,wti

Refer to GROUP

00-Maintenance Service.

TSB Revision