MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 581 of 1273

-Wntmr Hncn andWater Pine

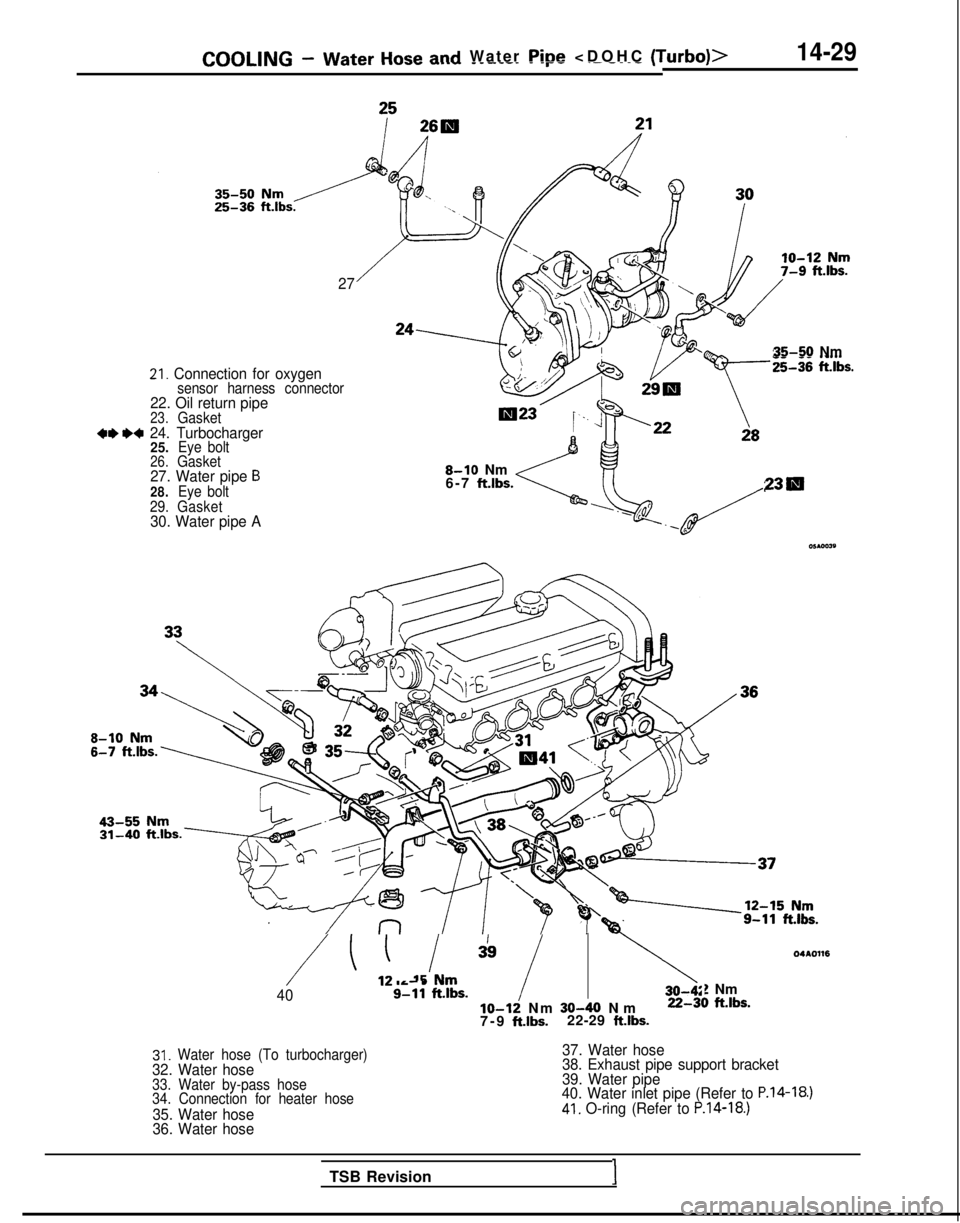

21. Connection for oxygensensor harness connector22. Oil return pipe23.Gasket+, I)+ 24. Turbocharger25.Eye bolt26.Gasket27. Water pipe B28. Eye bolt

29. Gasket

30. Water pipe A27

35-50 Nm

8-10 Nm

6-7 ftlbs.230

/ ’ ,! I,!, ” /40s-i1 ft.lbs.lo-12 Nm 30-40 N

m

22-3t

7-9 ft.lbs.22-29 ft.lbs.

04c.0116

! Nm1 ftlbs.

31. Water hose (To turbocharger)32. Water hose33. Water by-pass hose

34. Connection for heater hose

35. Water hose

36. Water hose

37. Water hose

38. Exhaust pipe support bracket

39. Water pipe

40. Water inlet pipe (Refer to

P.14-18.)41. O-ring (Refer to P.14-18.)

TSB Revision1

Page 582 of 1273

14-30COOLING - Water Hose and Water Pipe

05AOO26

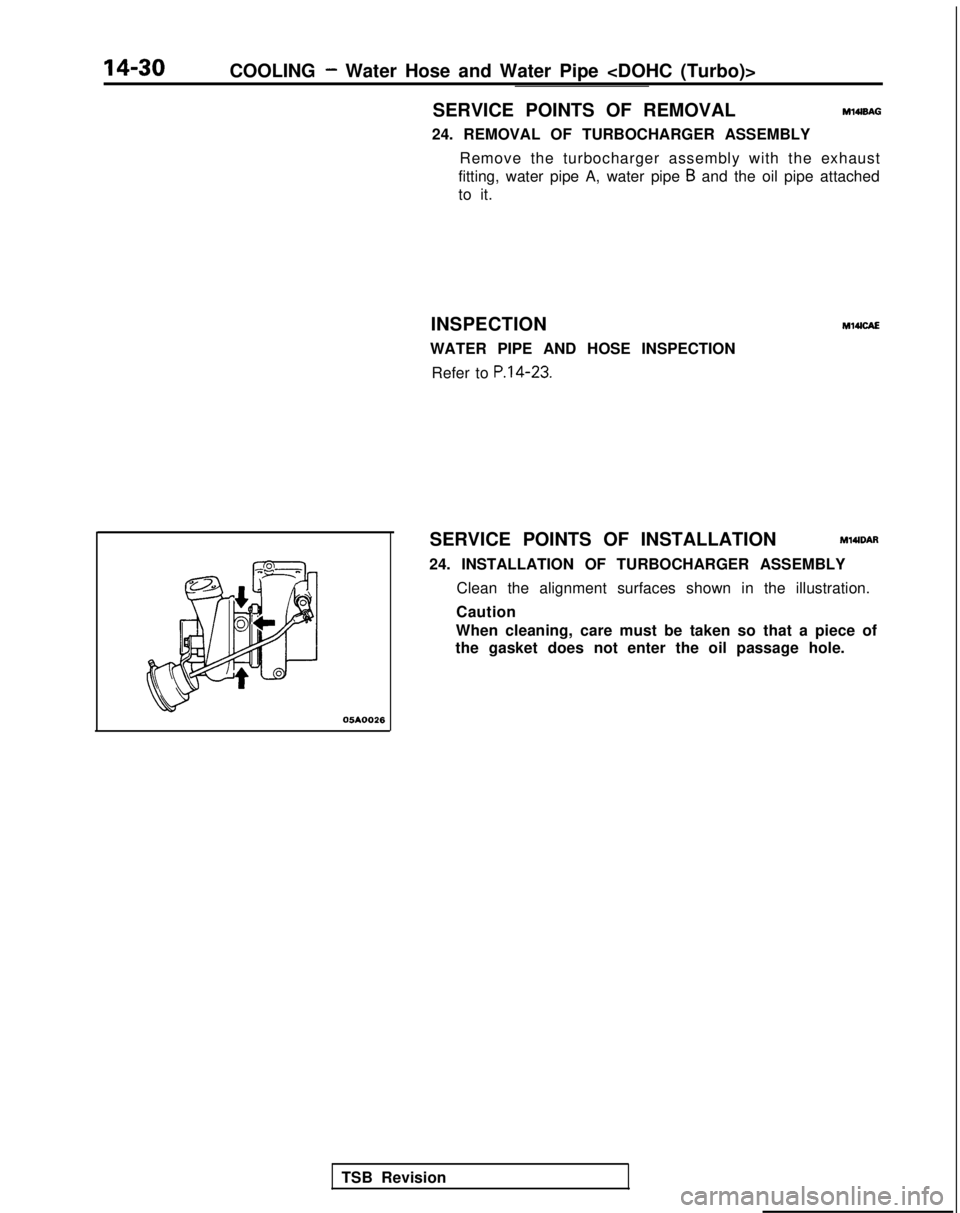

SERVICE POINTS OF REMOVALMWBAG

24. REMOVAL OF TURBOCHARGER ASSEMBLYRemove the turbocharger assembly with the exhaust

fitting, water pipe A, water pipe

B and the oil pipe attached

to it.

INSPECTION

WATER PIPE AND HOSE INSPECTION

Refer to

P.14-23.

Ml4lcAE

SERVICE POINTS OF INSTALLATIONMWDAR

24. INSTALLATION OF TURBOCHARGER ASSEMBLY Clean the alignment surfaces shown in the illustration.

Caution

When cleaning, care must be taken so that a piece of

the gasket does not enter the oil passage hole.

TSB Revision

Page 583 of 1273

COOLING -Engine Coolant Temperature Gauge Unit, Engine CoolantTemoerature Sensor and Engine Coolant Temperature Switch14-31

ENGINE COOLANT TEMPERATURE GAUGE UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE COOLANT TEMPERATURE

SWITCHM14oE-

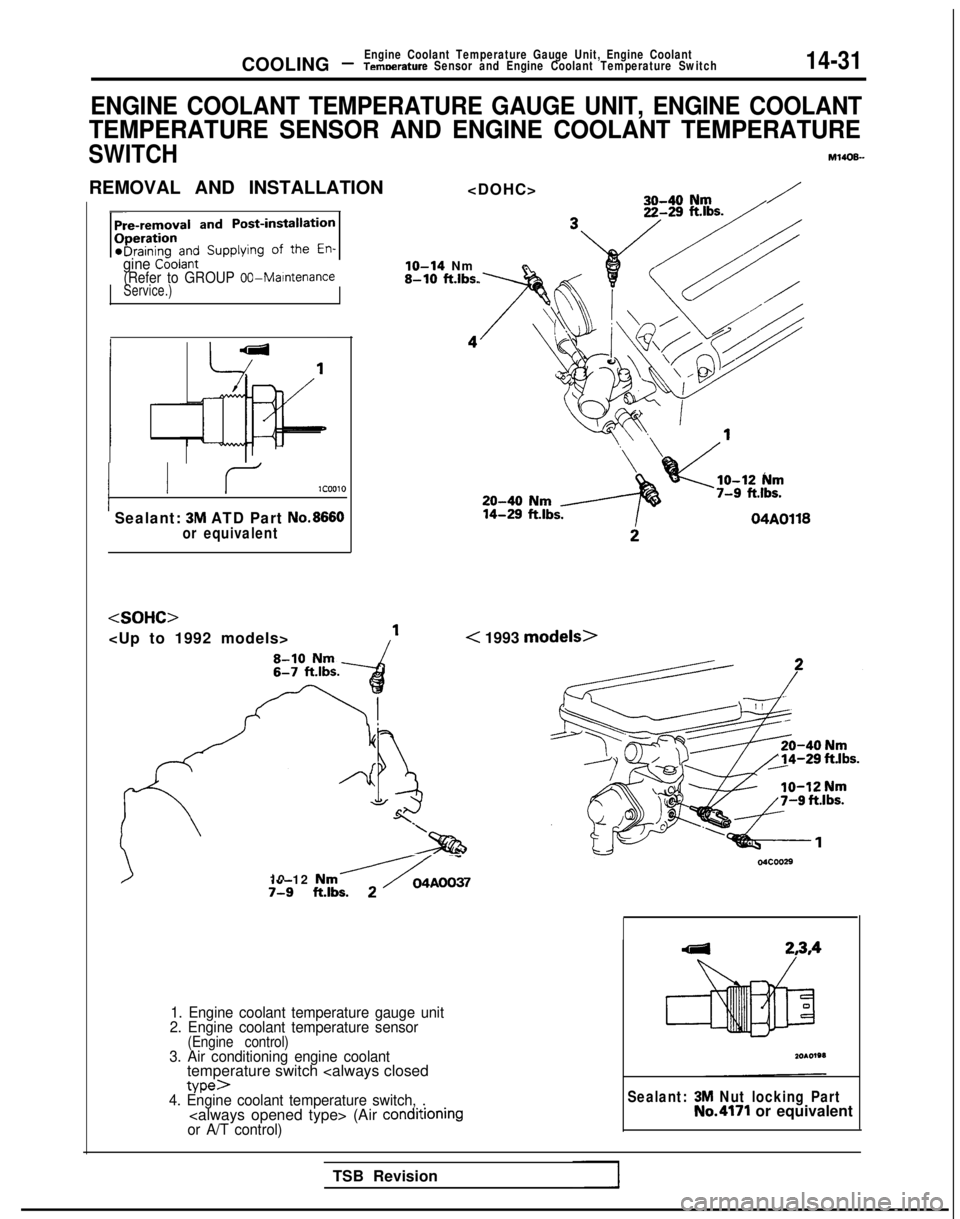

REMOVAL AND INSTALLATION

Nm/

gine Coolantlo-14 Nm(Refer to GROUP 00-Maintenance8-10 ft.lbs.Service.)

/ I r lcoolo

Sealant: 3M ATD Part No.8660or equivalent04A0118

10 12 Nrny~~~~~7-9 ft.lbs. 2

1. Engine coolant temperature gauge unit

2. Engine coolant temperature sensor

(Engine control)3. Air conditioning engine coolanttemperature switch

or A/T control)

Sealant: 3M Nut locking PartNo.4171 or equivalent

TSB Revision

Page 584 of 1273

14-32COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch

/

Sensor

J

046003

3

04GOO32

9FUO156

---

--I ‘Oi

l

QQQQQQ2cmn99

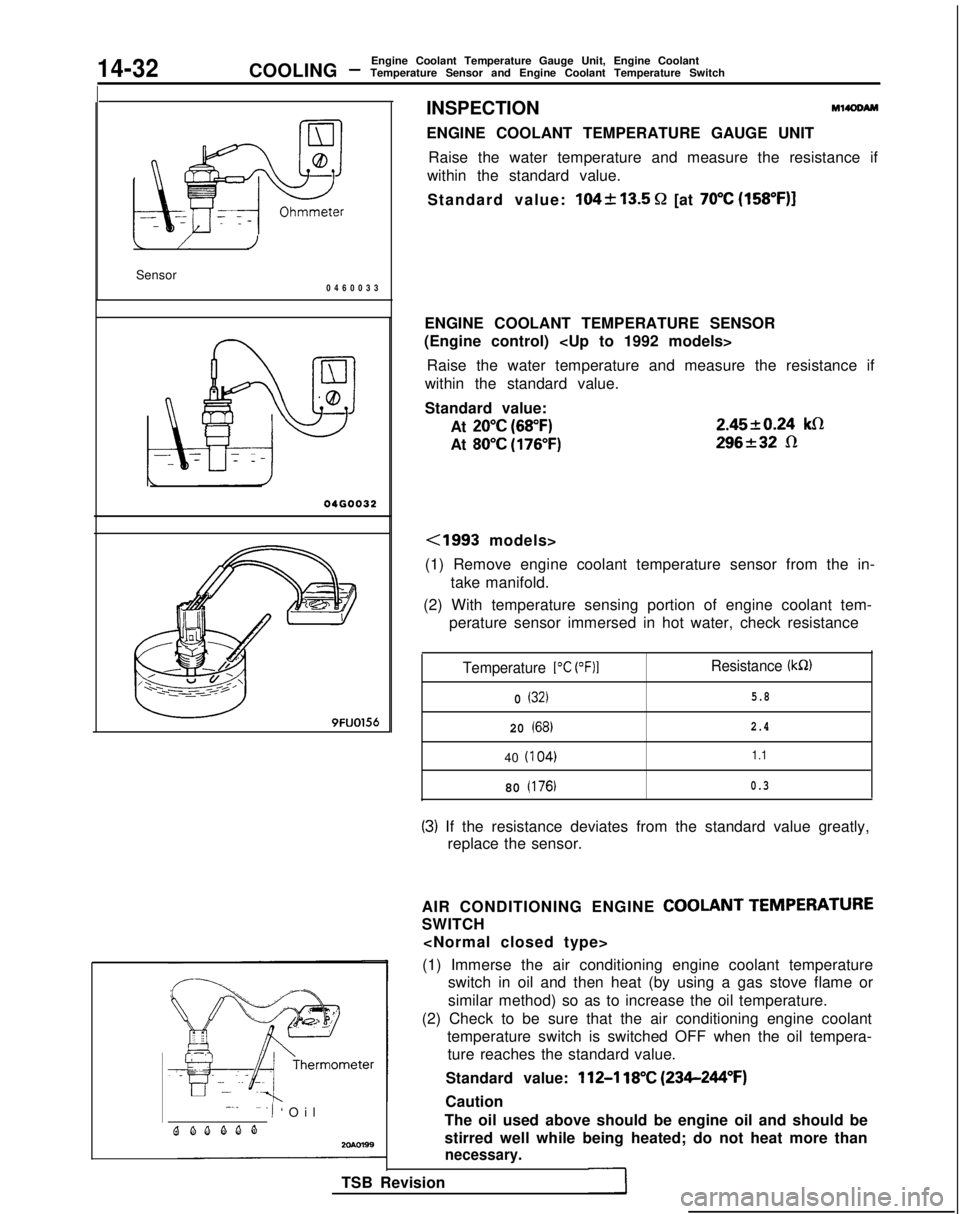

INSPECTIONM14OOAM

ENGINE COOLANT TEMPERATURE GAUGE UNIT

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

104k13.5 Q [at 70°C (158”F)]

ENGINE COOLANT TEMPERATURE SENSOR

(Engine control)

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

At

20°C (68°F)

At 80°C (176°F) 2.4520.24

klR

296232 R

<1993 models>

(1) Remove engine coolant temperature sensor from the in- take manifold.

(2) With temperature sensing portion of engine coolant tem- perature sensor immersed in hot water, check resistance

Temperature 1°C (OF)1Resistance (kR)

0 (32)5.8

20 (68)2.4

40

(I

04)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

AIR CONDITIONING ENGINE

COOLANT TEMPERATURE

SWITCH

(1) Immerse the air conditioning engine coolant temperature switch in oil and then heat (by using a gas stove flame or

similar method) so as to increase the oil temperature.

(2) Check to be sure that the air conditioning engine coolant temperature switch is switched OFF when the oil tempera-ture reaches the standard value.

Standard value:

112-l 18°C (234-244°F)

Caution

The oil used above should be engine oil and should be

stirred well while being heated; do not heat more than

necessary.

TSB Revision

Page 585 of 1273

COOLING -Engine Coolant Temperature Gauge Unit, Engine Coolant

Temperature Sensor and Engine Coolant Temperature Switch14-33

20R0586

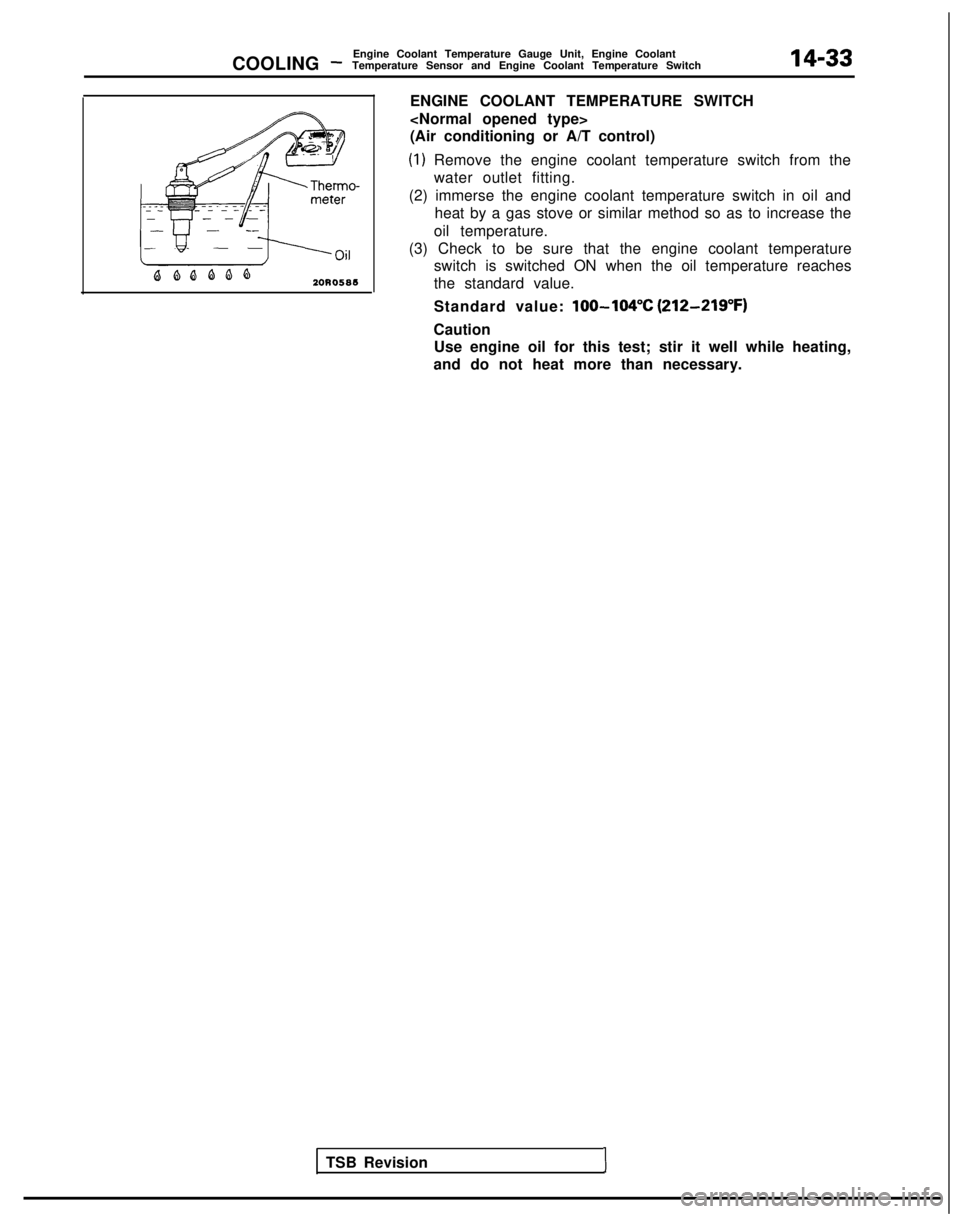

ENGINE COOLANT TEMPERATURE SWITCH

(Air conditioning or A/T control)

(1) Remove the engine coolant temperature switch from the

water outlet fitting.

(2) immerse the engine coolant temperature switch in oil and heat by a gas stove or similar method so as to increase the

oil temperature.

(3) Check to be sure that the engine coolant temperature switch is switched ON when the oil temperature reaches

the standard value.

Standard value:

lOO-104% (212-219°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

TSB Revision

1

Page 586 of 1273

NOTES

Page 587 of 1273

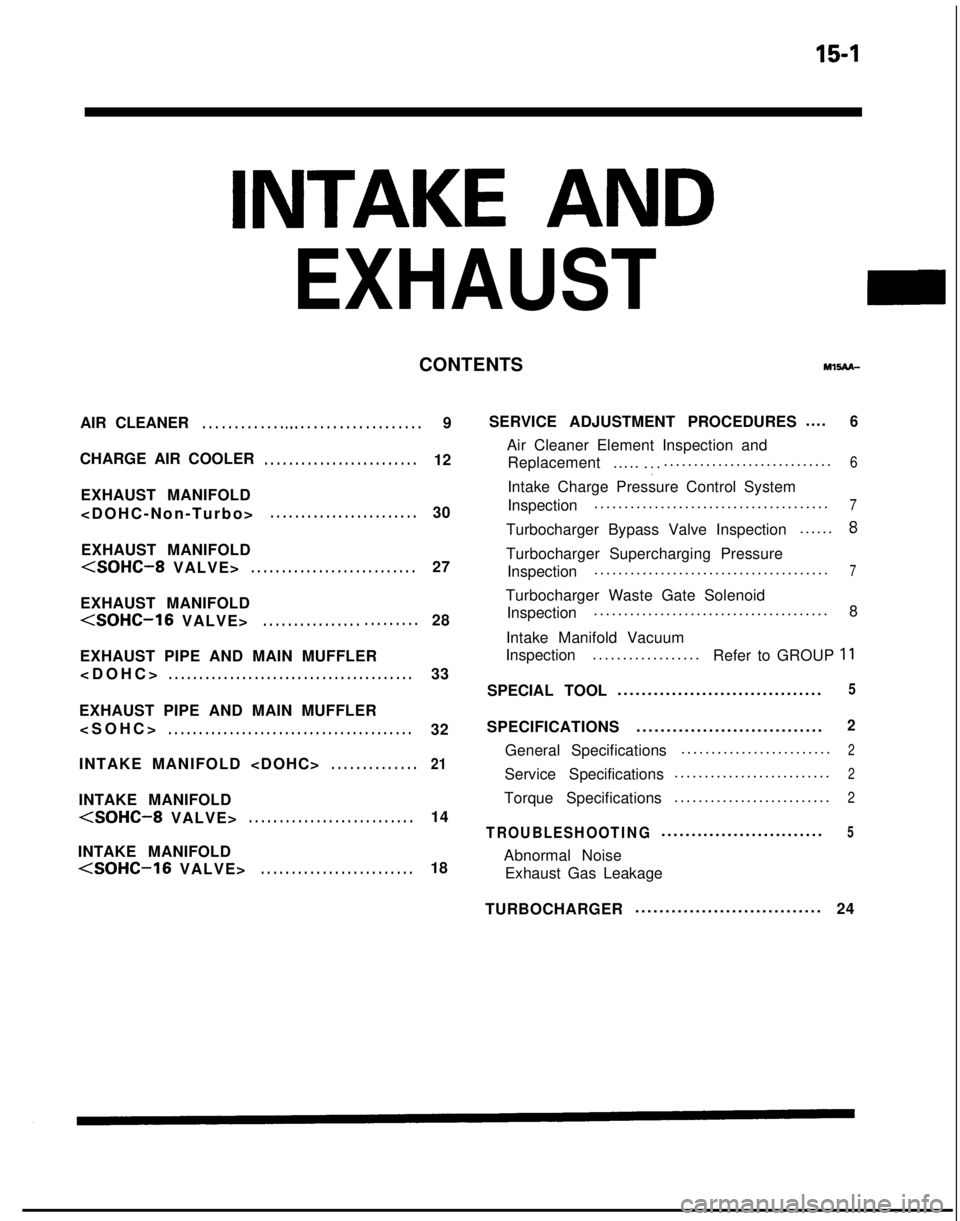

15-1

INTAKE AND

EXHAUST

CONTENTSMl!iAn-

AIR CLEANER. . . . . . . . . . . . . a.. . . . . . . . . . . . . . . . . . . .9

CHARGE AIR COOLER

. . . . . . . . . . . . . . . . . . . . . . . . .12

EXHAUST MANIFOLD

. . . . . . . . . . . . . . . . . . . . . . . .30

EXHAUST MANIFOLD

EXHAUST MANIFOLD

EXHAUST PIPE AND MAIN MUFFLER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .33

EXHAUST PIPE AND MAIN MUFFLER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . .32

INTAKE MANIFOLD

. . . . . . . . . . . . . .21

INTAKE MANIFOLD

INTAKE MANIFOLD

(SOHC-16 VALVE>. . . . . . . . . . . . . . . . . . . . . . . . .18 SERVICE ADJUSTMENT PROCEDURES

....

6

Air Cleaner Element Inspection and

Replacement .....

.:............................

.

6

Intake Charge Pressure Control System

Inspection

......................................

.

7

Turbocharger Bypass Valve Inspection

.....

.

8

Turbocharger Supercharging Pressure

Inspection ......................................

.

7

Turbocharger Waste Gate Solenoid

Inspection ......................................

.

8

Intake Manifold Vacuum

Inspection ..................

Refer to GROUP

11

SPECIAL TOOL .................................

.

5

SPECIFICATIONS

..............................

.

2

General Specifications

........................

.

2

Service Specifications

.........................

.

2

Torque Specifications

.........................

.

2

TROUBLESHOOTING...........................5

Abnormal Noise

Exhaust Gas Leakage

TURBOCHARGER ..............................

.

24

Page 588 of 1273

15-2INTAKE AND EXHAUST - Specifications

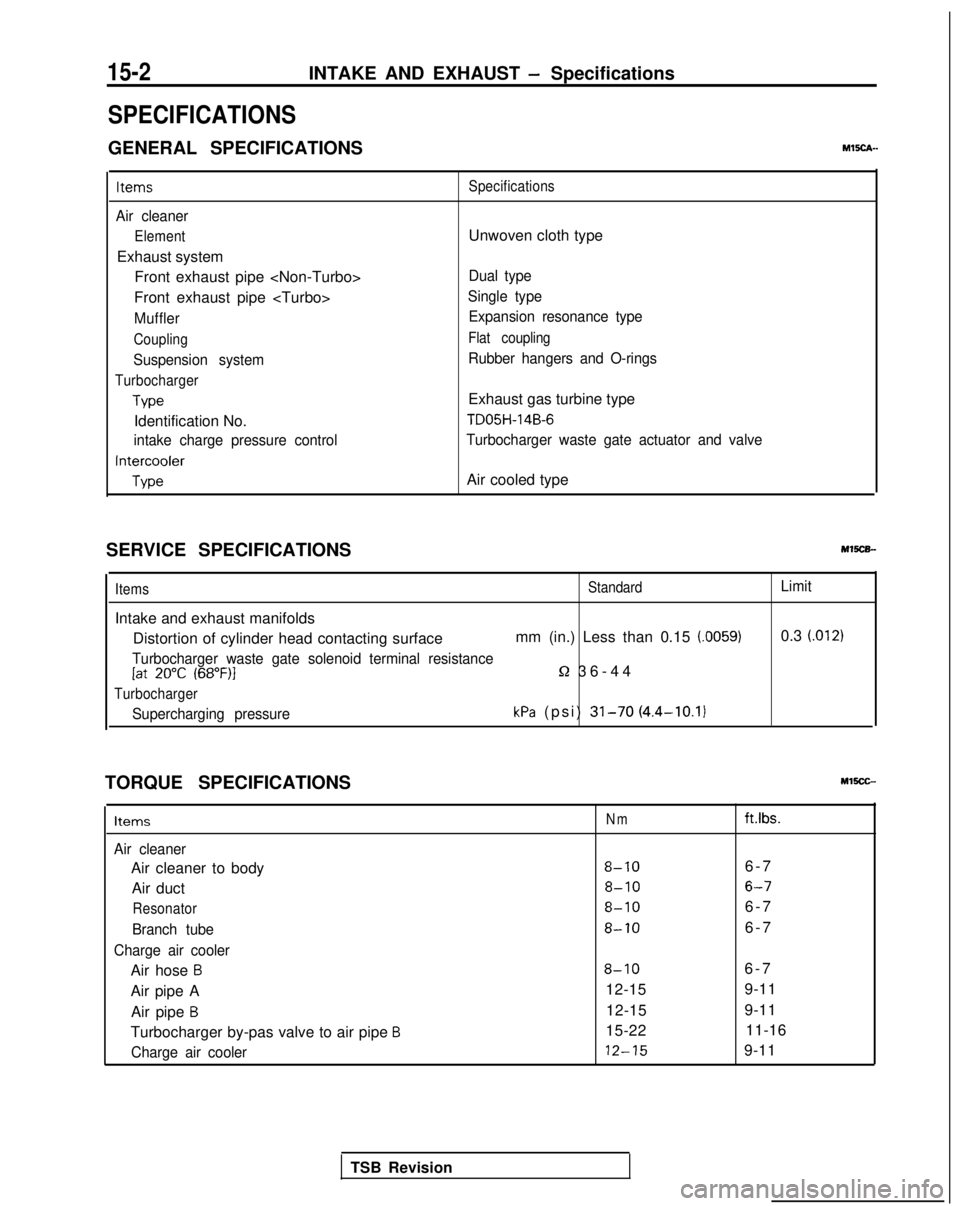

SPECIFICATIONS

GENERAL SPECIFICATIONSMEch-

Items

Air cleaner

Element

Exhaust systemFront exhaust pipe

Front exhaust pipe

Muffler

Coupling

Suspension system

Turbocharger

Type

Identification No.

intake charge pressure control

Intercooler

Type Specifications

Unwoven cloth type

Dual type

Single type Expansion resonance type

Flat coupling

Rubber hangers and O-rings

Exhaust gas turbine type

TD05H-14B-6

Turbocharger waste gate actuator and valve

Air cooled type

SERVICE SPECIFICATIONS

Items

Intake and exhaust manifolds

StandardLimit

Distortion of cylinder head contacting surface mm (in.) Less than 0.15 (0059)0.3 (.012)

Turbocharger waste gate solenoid terminal resistance[at 20°C (68”F)l5-2 36-4

4

Turbocharger

Supercharging pressurekPa (psi) 31-70 (4.4-10.1)

TORQUE SPECIFICATIONS

Items

Air cleaner

Air cleaner to body

Air duct

Resonator

Branch tube

Charge air cooler

Air hose B

Air pipe A Air pipe

B

Turbocharger by-pas valve to air pipe B

Charge air cooler

Nmft.lbs.

8-106-

7

8-106-7

8-106-

7

8-106-

7

8-106-

7

12-15 9-11

12-15 9-11

15-22 11-16 12-15

9-11

TSB Revision

Page 589 of 1273

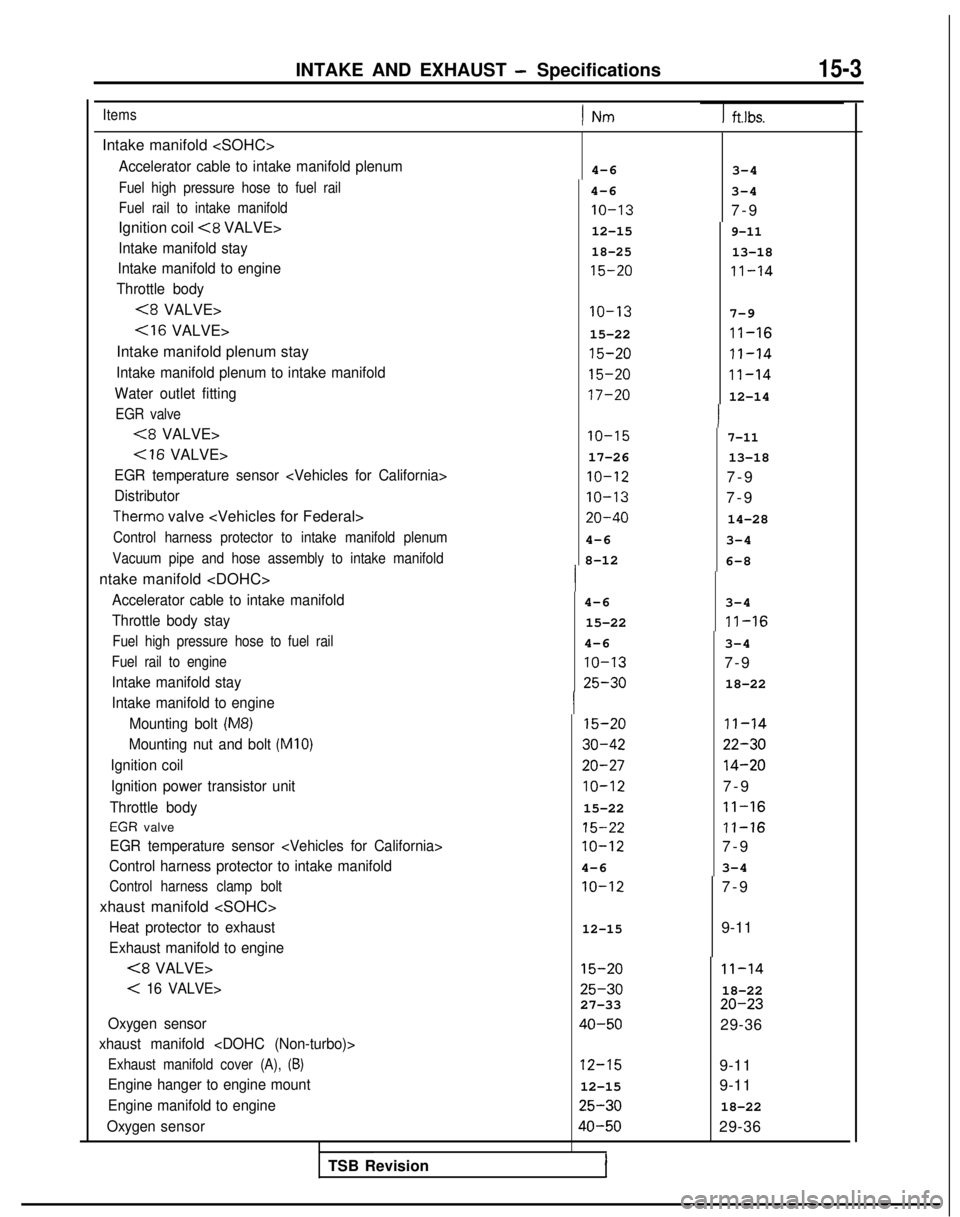

INTAKE AND EXHAUST - Specifications15-3

Items) Nm1

ftlbs.

Intake manifold

Accelerator cable to intake manifold plenum

Fuel high pressure hose to fuel rail

Fuel rail to intake manifold

Ignition coil <8 VALVE>

Intake manifold stay

Intake manifold to engine

Throttle body

<8 VALVE>

Intake manifold plenum stay

Intake manifold plenum to intake manifold

Water outlet fitting

EGR valve

(8 VALVE>

Cl6 VALVE>

EGR temperature sensor

Distributor

Therm0 valve

Control harness protector to intake manifold plenum

Vacuum pipe and hose assembly to intake manifold

ntake manifold

Accelerator cable to intake manifold

Throttle body stay

Fuel high pressure hose to fuel rail

Fuel rail to engine

Intake manifold stay

Intake manifold to engine

Mounting bolt

(M8)

Mounting nut and bolt (MIO)

Ignition coilIgnition power transistor unit

Throttle body

EGR valve

EGR temperature sensor

Control harness protector to intake manifold

Control harness clamp bolt

xhaust manifold

Heat protector to exhaust

Exhaust manifold to engine

(8 VALVE>

< 16 VALVE>

Oxygen sensor

xhaust manifold

Exhaust manifold cover (A), (8)

Engine hanger to engine mount

Engine manifold to engine

Oxygen sensor

4-6

4-6 IO-13

12-15

18-25

15-20

3-4

3-4

7-

9

9-11

13-18

11-14

IO-13

7-9

15-22 II-16

15-20

II-14

15-20

11-14

17-20

12-14 IO-15

7-11

17-26

13-18 IO-12

7-9 IO-13

7-9 20-40

14-28

4-6 3-4

8-12 6-8

4-6 3-4

15-22 II-16

4-6 3-4 IO-13

7-9 25-30

18-22 15-20

30-42

20-27

IO-12

15-22

15-22

IO-12

4-6 IO-12 II-14

22-30

14-20

7-9 11-16

11-16

7-9

3-4

12-15

7-

9

9-11 15-20 11-14

25-30

18-22

27-33 20-23

40-50

29-36

12-159-11

12-15 9-11 25-30

18-22 40-50

29-36

TSB Revision

I

Page 590 of 1273

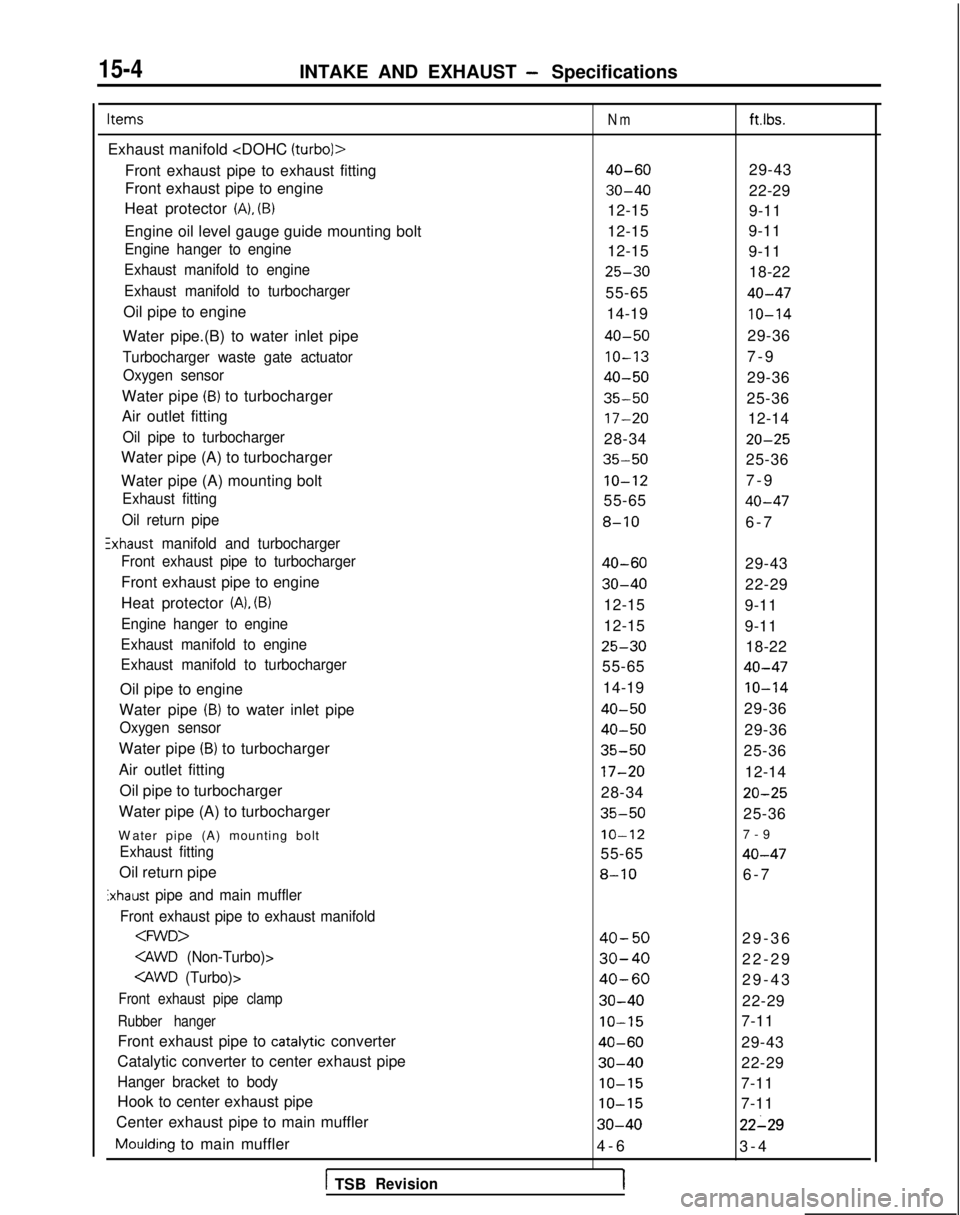

15-4INTAKE AND EXHAUST - Specifications

Items

Exhaust manifold

Front exhaust pipe to exhaust fitting

Front exhaust pipe to engine

Heat protector

(A), (B)

Engine oil level gauge guide mounting bolt

Engine hanger to engine

Exhaust manifold to engine

Exhaust manifold to turbocharger

Oil pipe to engine

Water pipe.(B) to water inlet pipe

Turbocharger waste gate actuator Oxygen sensor

Water pipe (B) to turbocharger

Air outlet fitting

Oil pipe to turbocharger

Water pipe (A) to turbocharger

Water pipe (A) mounting bolt

Exhaust fitting

Oil return pipe

!xhaust manifold and turbocharger

Front exhaust pipe to turbocharger

Front exhaust pipe to engine

Heat protector

(A), (B)

Engine hanger to engine

Exhaust manifold to engine

Exhaust manifold to turbocharger

Oil pipe to engine

Water pipe

(B) to water inlet pipe

Oxygen sensor

Water pipe (B) to turbocharger

Air outlet fitting Oil pipe to turbocharger

Water pipe (A) to turbocharger

W

ater pipe (A) mounting bolt

Exhaust fitting

Oil return pipe

Exhaust pipe and main muffler

Front exhaust pipe to exhaust manifold

Front exhaust pipe clamp

Rubber hanger

Front exhaust pipe to catalytic converter

Catalytic converter to center exhaust pipe

Hanger bracket to body

Hook to center exhaust pipe

Center exhaust pipe to main muffler

Moulding to main muffler

1 TSBRevision

Nm

40-60

30-40

12-15

12-15

12-15

25-30

55-65

14-19

40-50

IO-13

40-50

35-50

17-20

28-34

35-50

IO-12

55-65

8-10

40-60

30-40

12-15

12-15

25-30

55-65

14-19

40-50

40-50

35-50

17-20

28-34

35-50

IO-12

55-65

8-10

40-50

30-40

40-60

30-40

IO-15

40-60

30-40

IO-15

IO-15

30-40

4-

6

1

ft.lbs.

29-43

22-29

9-11

9-11

9-11

18-22

40-47

10-14

29-36

7-

9

29-36

25-36 12-14

20-25

25-36

7-

9

40-47

6-

7

29-43

22-29

9-11

9-11 18-22

40-47

IO-14

29-36

29-36

25-36

12-14

20-25

25-36

7-

9

40-47

6-

7

29-36

22-29

29-43

22-29

7-11

29-43

22-29

7-11

7-11

22-29

3-

4