MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 861 of 1273

27-1

mnAA-

AXLE SHAFT...................................................17

DIFFERENTIAL CARRIER................................26

DRIVE SHAFT.................................................. 20

SERVICE ADJUSTMENT PROCEDURES.......

15

Gear OilLevelCheck ...................................15

Rear Axle Total Backlash Check.................15

Rear Wheel Bearing End Play Check.........15

Rear Wheel Bearing Rotation Sliding

Resistance Check .........................................16

REAR AXLE HUB

SPECIAL

TOOLS.............................................12

SPECIFICATIONS

.............................................10

GeneralSpecifications..................................10

Lubricants

......................................................11

Sealants

andAdhesives...............................12

Service Specifications...................................10

TorqueSpecifications

...................................11

TROUBLESHOOTING ......................................14

Axle Shaft

Grease leakage

Noise while wheels are rotating

Differential

Bearing noise while driving or coasting

Constant noise

Gear noise while coasting Gear noise while driving

Heat

Noise while turning

Oil leakage

Drive Shaft

Noise

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

REAR AXLE HUB

. . . . . . . . . . . . . . . . . . . . .

SERVICE ADJUSTMENT PROCEDURES . . . . . . .h3

Rear Hub Rotary-Sliding Resistance

(Torque)Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . .5

Wheel Bearing End Play Adjustment . . . . . . . . . .3

SPECIAL

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . .2

General Specifications . . . . . . . .

.._.......................2

Service Specifications . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TROUBLESHOOtING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .2

Abnormal Sound

Page 862 of 1273

27-2REAR AXLE

REAR AXLE

SPECIFICATIONS

GENERAL SPECIFICATIONSM2?CA-A

Items

Wheel bearing

Type

O.D. x I.D.

Outer

inner SOHC

DOHC

Tapered roller bearing

Unit ball bearing

mm (in.)

39.9 x 17.5 (1.57 x ,691-

50.3 x 27.0 (1.98 x 1.06)-

SERVICE SPECIFICATIONShl27CEA

Items

Standard value

Rear hub rotary-sliding resistance

When a new bearing is used

When the bearing is reused

Limit Wheel bearing end playRear hub rotary-sliding resistance

SOHC

N (Ibs.)

14 (3.08) or less

11 (2.42) or less

mm (in.)

-

N (Ibs.) -

DOHC

-

-

0.05 i.020) or less

31

(7) or less

1i-ORQUE SPECIFICATIONS MnCGA

Items

Wheel bearing nut (vehicles with rear drum brakes)

Wheel bearing nut (vehicles with rear disc brakes)

Caliper assembly mounting nut

Feed tube to rear oil pump

Rear hub to rotor

Rear oil pump attaching bolt

Rear speed sensor brackets

Nmft.lbs.

20 + 0 + IO14+0+7 200-260

144-188

50-6036-43

14-21

IO-15

9-147-10

19-2814-20

9-1

4

7-10

TROUBLESHOOTINGM27EA-A

Symptom

Abnormal SoundProbable cause

Loose wheel nuts

Damaged or worn wheel bearings

Bent or distorted brake discs or drums

Remedy

Tighten

Replace

TSB Revision

Page 863 of 1273

REAR AXLE

SPECIAL TOOLS

MZ7VA-A

ToolNumber

GENERAL

SERVICE TOOL

NameUse

Bearing and oil sealinstaller setInstallation of outer bearing outer race

Installation of inner bearing outer race Installation of oil seal

M B990938-01Handle

MB990890-01Bushing removerand installer baseInstallation of the drive gear

OPTIONAL: AVAIlABLE FROM O.T.C.

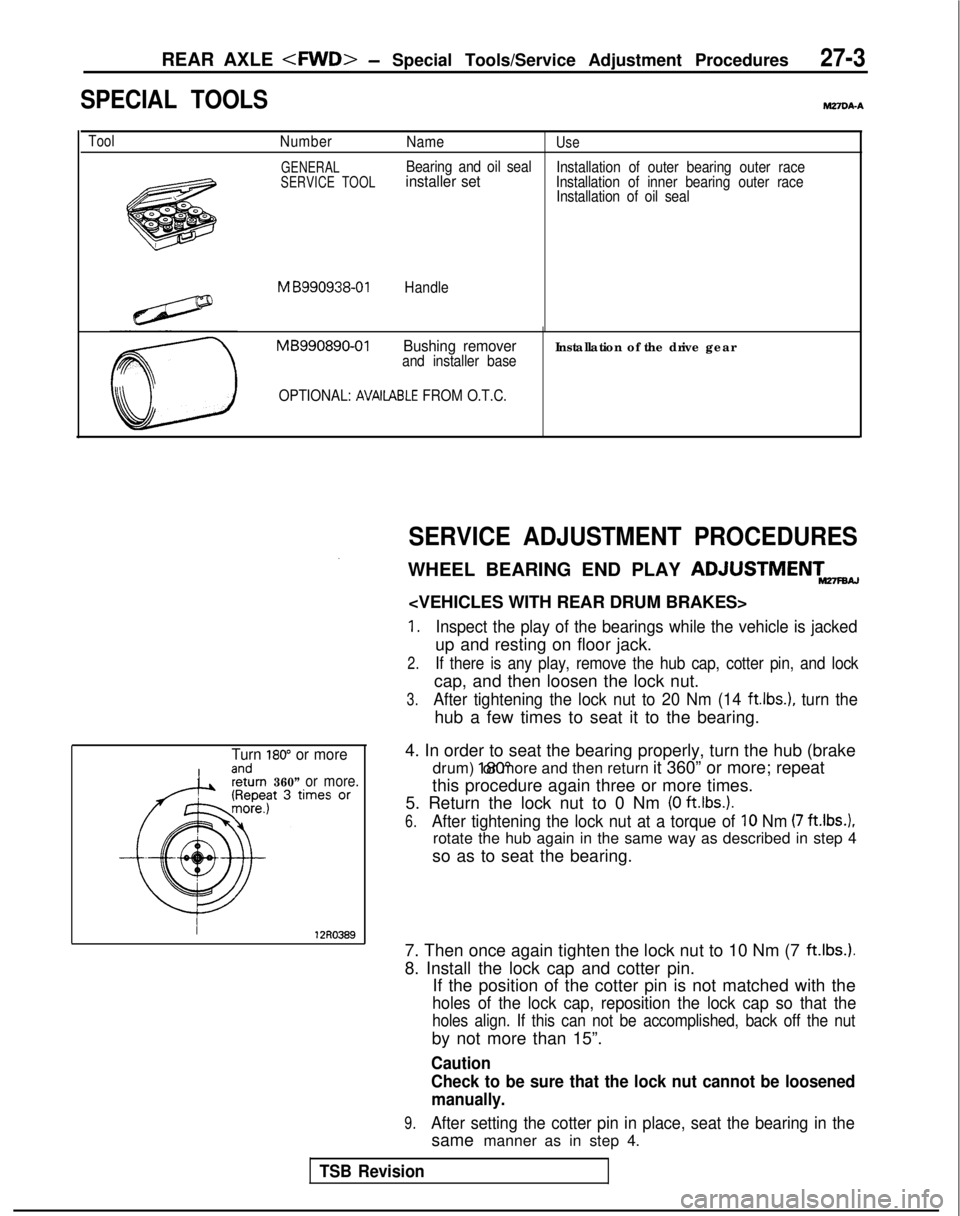

Turn 180” or more

360” or more.

SERVICE ADJUSTMENT PROCEDURES

WHEEL BEARING END PLAY ADJUSTMENTmw

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.If there is any play, remove the hub cap, cotter pin, and lock

cap, and then loosen the lock nut.

3.After tightening the lock nut to 20 Nm (14 ft.lbs.1, turn the

hub a few times to seat it to the bearing.

4. In order to seat the bearing properly, turn the hub (brake drum) 180” or more and then return it 360” or more; repeat

this procedure again three or more times.

5. Return the lock nut to 0 Nm

(0 ft.lbs.).

6.After tightening the lock nut at a torque of 10 Nm (7 ft.lbs.1,

rotate the hub again in the same way as described in step 4

so as to seat the bearing.

7. Then once again tighten the lock nut to 10 Nm (7

ft.lbs.).

8. Install the lock cap and cotter pin. If the position of the cotter pin is not matched with the

holes of the lock cap, reposition the lock cap so that the

holes align. If this can not be accomplished, back off the nut

by not more than 15”.

Caution

Check to be sure that the lock nut cannot be loosened

manually.

9.After setting the cotter pin in place, seat the bearing in the

same manner as in step 4.

TSB Revision

Page 864 of 1273

27-4REAR AXLE

11 PO033

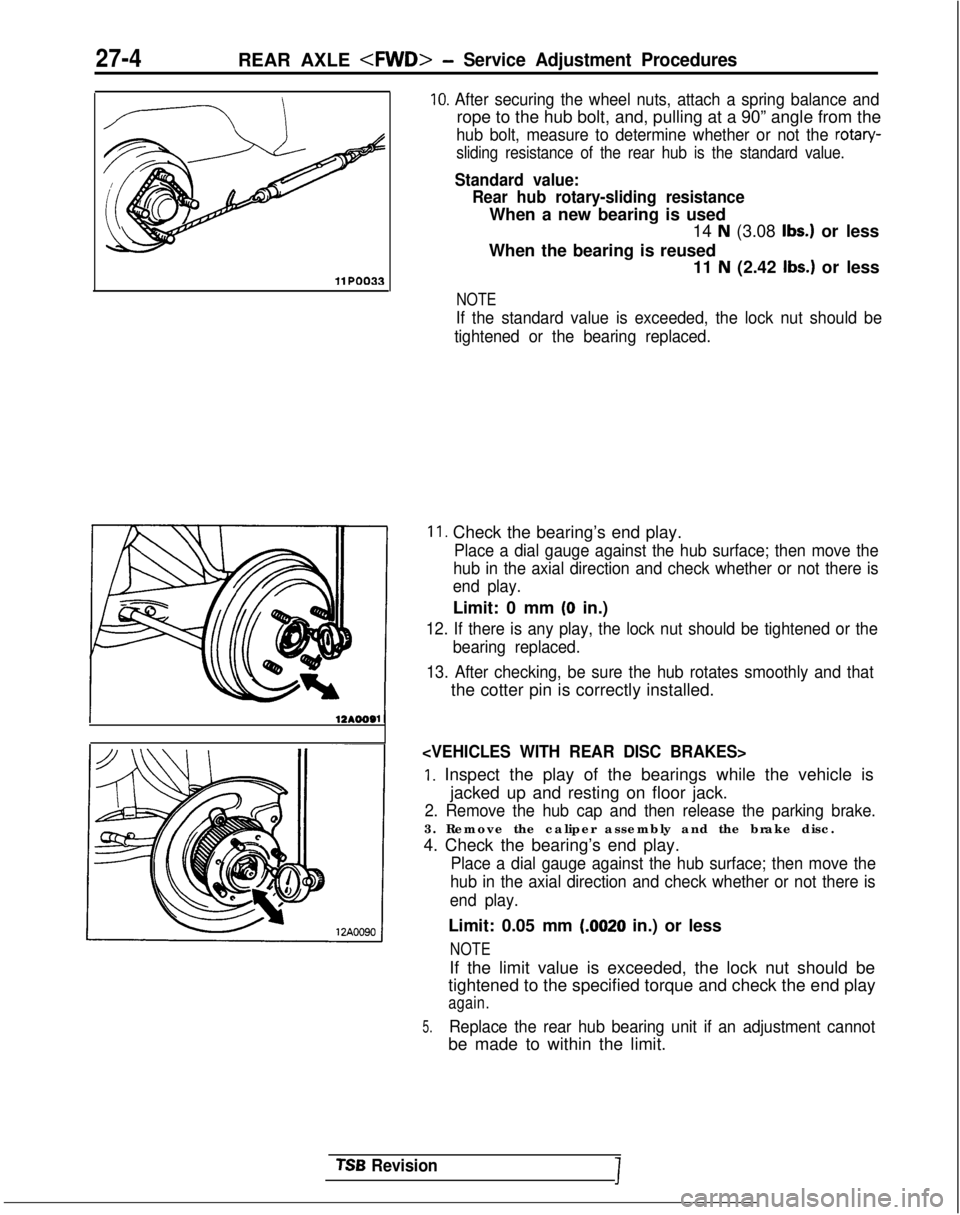

10. After securing the wheel nuts, attach a spring balance and

rope to the hub bolt, and, pulling at a 90” angle from the

hub bolt, measure to determine whether or not the rotary-

sliding resistance of the rear hub is the standard value.

Standard value: Rear hub rotary-sliding resistance

When a new bearing is used 14

N (3.08 Ibs.) or less

When the bearing is reused 11

N (2.42 Ibs.) or less

NOTE

If the standard value is exceeded, the lock nut should be

tightened or the bearing replaced.

11. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.

Limit: 0 mm (0 in.)

12. If there is any play, the lock nut should be tightened or the

bearing replaced.

13. After checking, be sure the hub rotates smoothly and that

the cotter pin is correctly installed.

1. Inspect the play of the bearings while the vehicle is jacked up and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.

Limit: 0.05 mm (.0020 in.) or less

NOTE

If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

TSB RevisionI

Page 865 of 1273

REAR AXLE

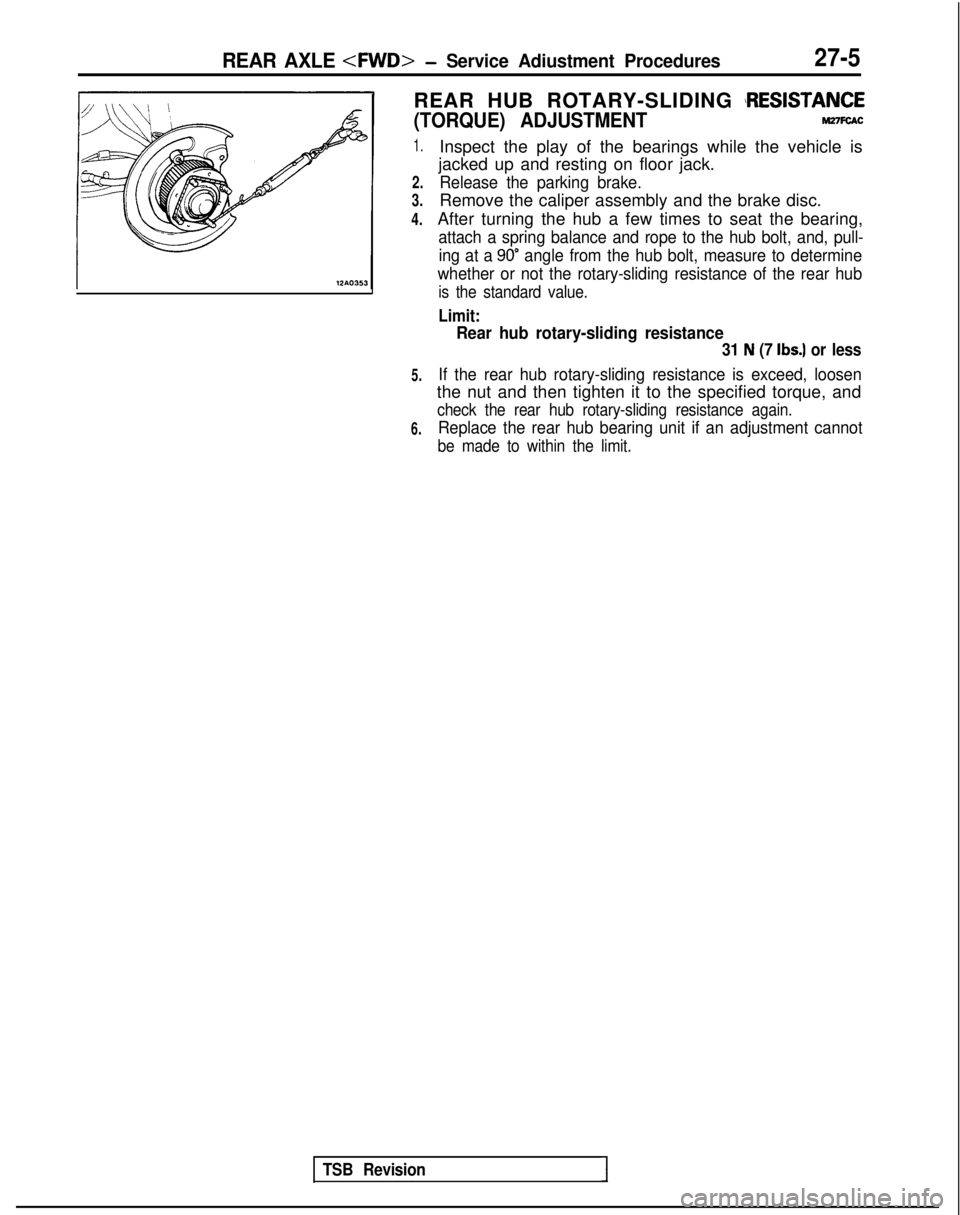

REAR HUB ROTARY-SLIDING !RESlSTANCE

(TORQUE) ADJUSTMENTMZ7FCAC

1.

2.

3.

4.

Inspect the play of the bearings while the vehicle is

jacked up and resting on floor jack.

Release the parking brake.

Remove the caliper assembly and the brake disc.

After turning the hub a few times to seat the bearing,

attach a spring balance and rope to the hub bolt, and, pull- ing at a

90” angle from the hub bolt, measure to determine

whether or not the rotary-sliding resistance of the rear hub

is the standard value.

Limit:

5.

6.

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or less

If the rear hub rotary-sliding resistance is exceed, loosen

the nut and then tighten it to the specified torque, and

check the rear hub rotary-sliding resistance again.

Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

TSB Revision1

Page 866 of 1273

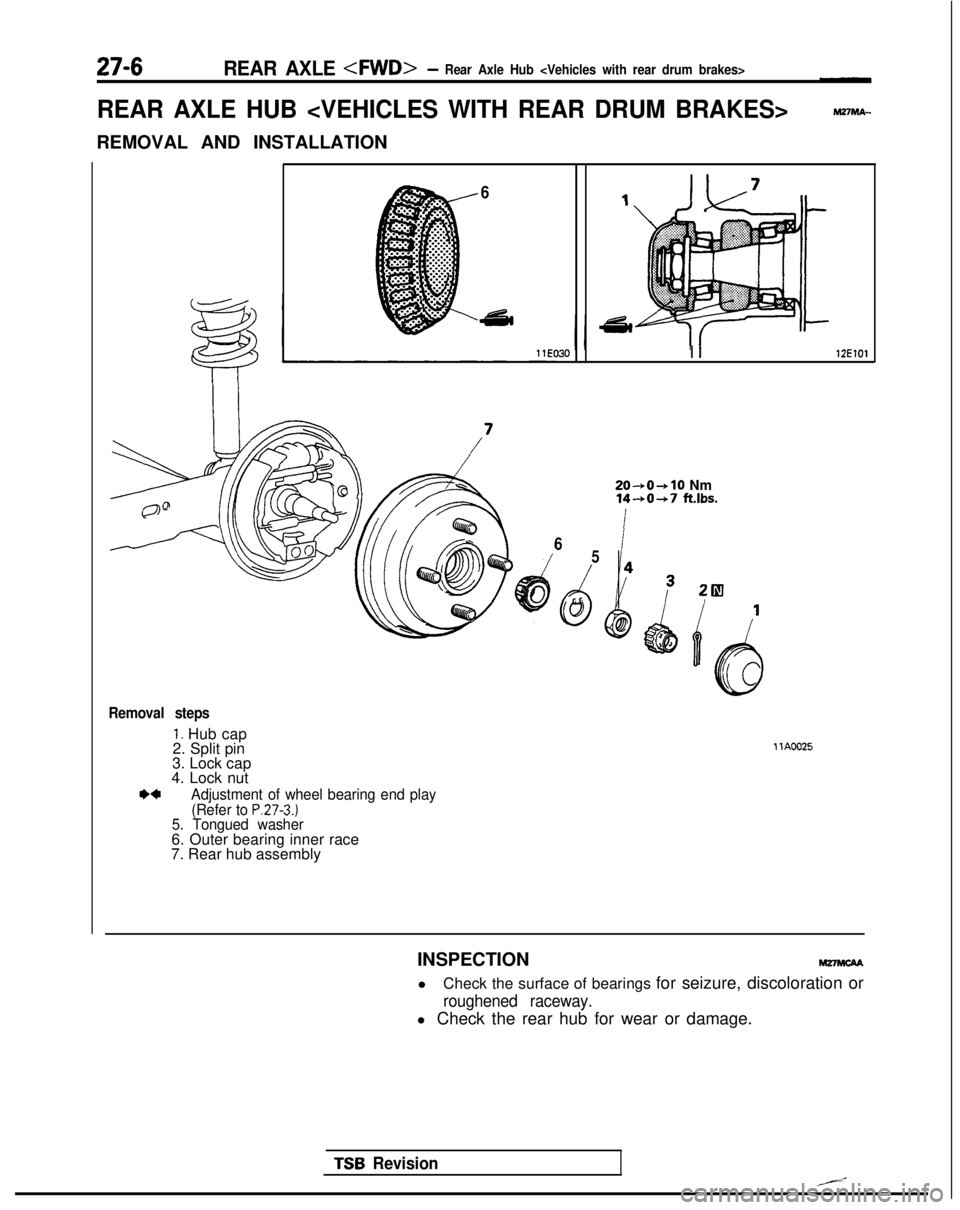

27-6REAR AXLE

REAR AXLE HUB

REMOVAL AND INSTALLATION

6

I 112ElOl

65

Removal steps

1. Hub cap

2. Split pin

3. Lock cap

4. Lock nut

I)+Adjustment of wheel bearing end play

(Refer to P.27-3.)5. Tongued washer6. Outer bearing inner race

7. Rear hub assembly

20+0+10 Nm14+0+7 ft.lbs. llAO025

INSPECTION l Check the surface of bearings for seizure, discoloration or

roughened raceway.

l Check the rear hub for wear or damage.

TSB Revision

Page 867 of 1273

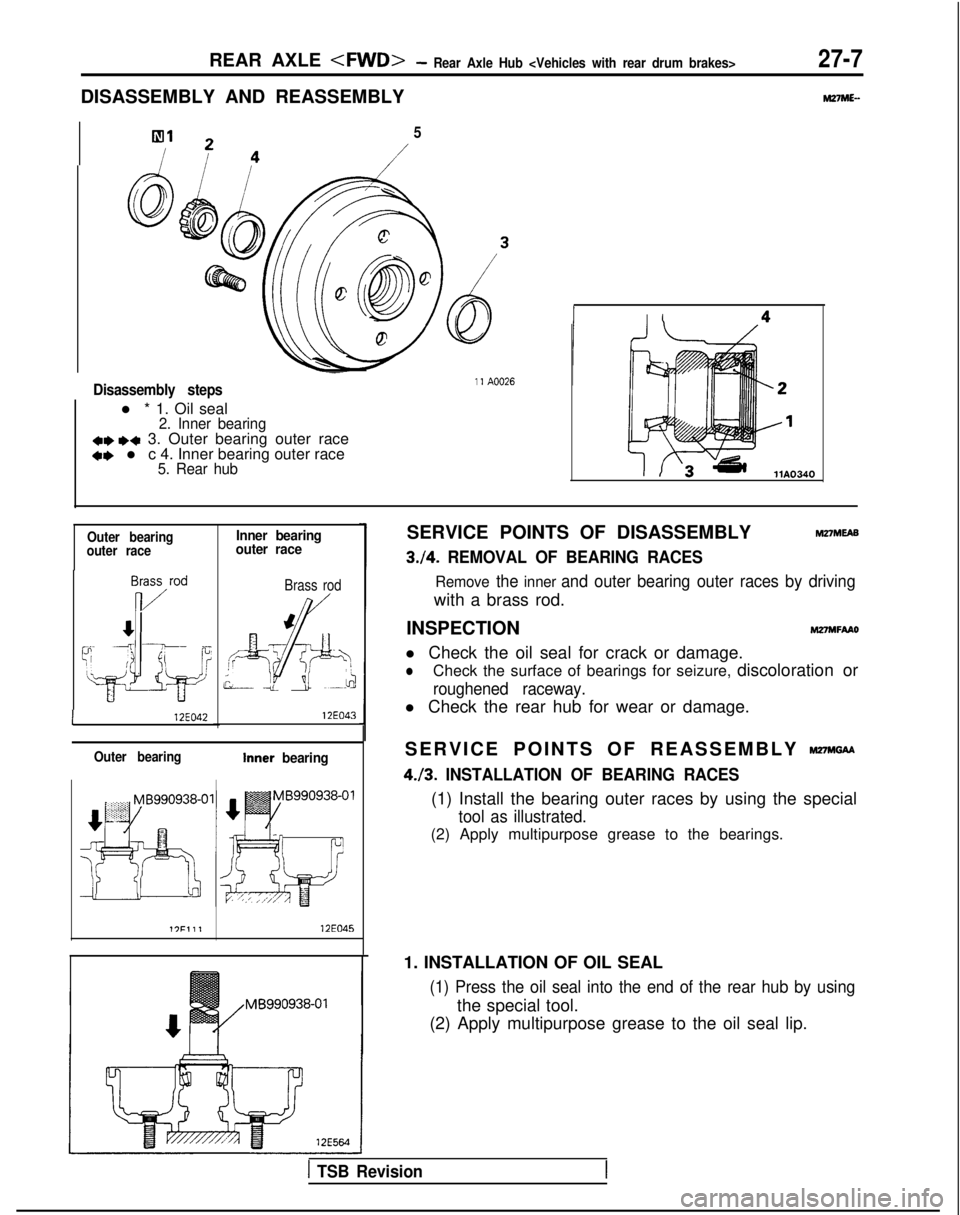

REAR AXLE

DISASSEMBLY AND REASSEMBLYM27ME-

5

Disassembly steps

-11 A0026

l * 1. Oil seal

2. Inner bearing*e ea 3. Outer bearing outer raceae l c 4. Inner bearing outer race5. Rear hub

Outer bearing

outer race

i

L 12E042

Inner bearing

outer race

Brass rod

4

*+I?(

-‘I!r%i3

LA-APh 12E043

Outer bearingInner bearing

,‘)!=,,I

12E045

MB990938-01

c

SERVICE POINTS OF DISASSEMBLYM27MEAB

3./4.

REMOVAL OF BEARING RACES

Remove the inner and outer bearing outer races by driving

with a brass rod.

INSPECTION

M7.7MFAAO

l Check the oil seal for crack or damage.

lCheck the surface of bearings for seizure, discoloration or

roughened raceway.

l Check the rear hub for wear or damage.

SERVICE POINTS OF REASSEMBLY

M~MOAP.

4./3. INSTALLATION OF BEARING RACES

(1) Install the bearing outer races by using the special

tool as illustrated.

(2) Apply multipurpose grease to the bearings.

1. INSTALLATION OF OIL SEAL

(1) Press the oil seal into the end of the rear hub by using

the special tool.

(2) Apply multipurpose grease to the oil seal lip.

1 TSB Revision

Page 868 of 1273

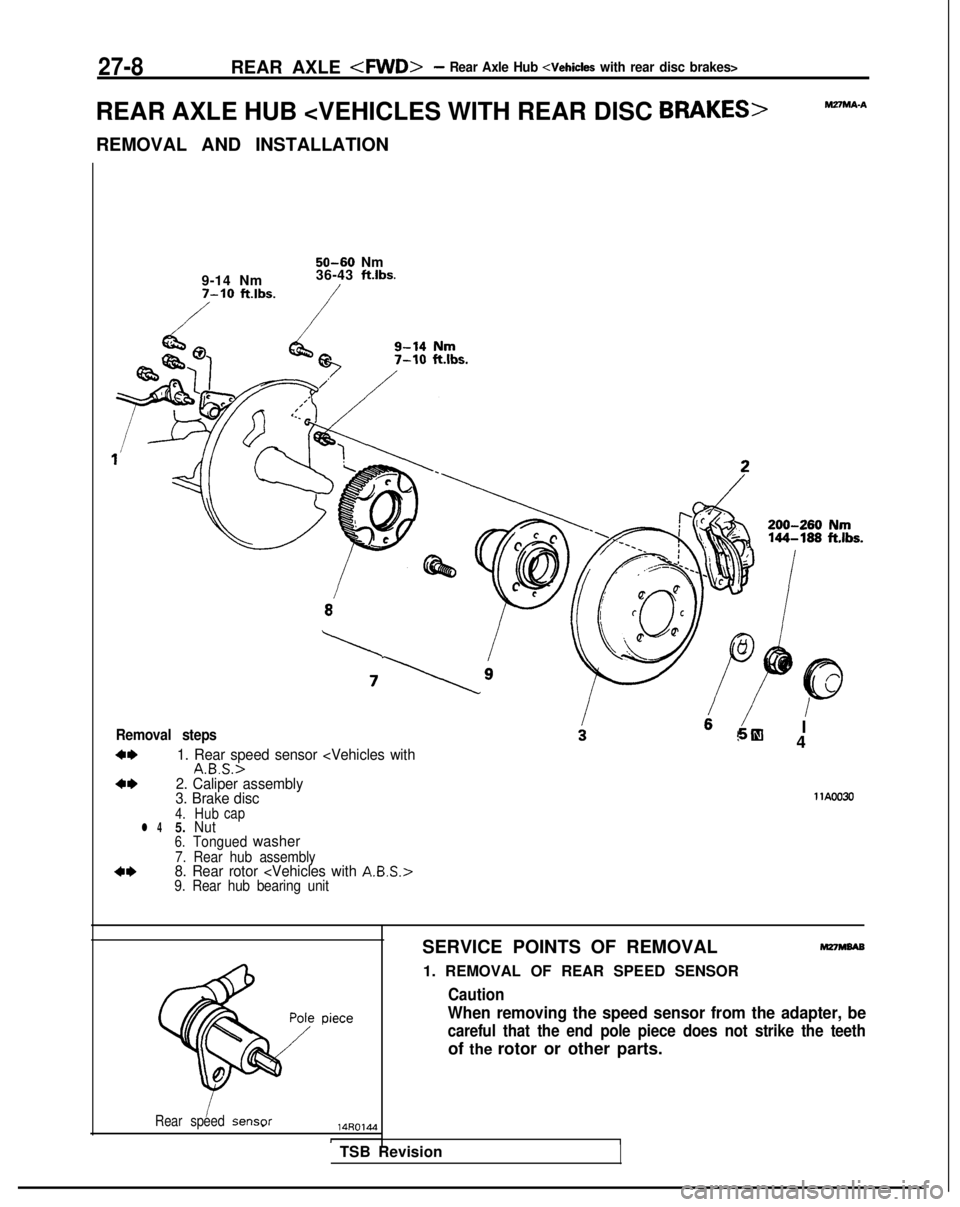

27-8REAR AXLE -4WD>- Rear Axle Hub

REAR AXLE HUB

REMOVAL AND INSTALLATION

M27MA-A

9-14 Nm7-10 ft.lbs.

50-60 Nm

36-43 ftlbs.

Removal steps

+*1. Rear speed sensor

3. Brake disc

I!jiEl 4

llA0030

4. Hub capl 45.

Nut6.Tonguedwasher

7. Rear hub assembly+*8. Rear rotor

Rear speedsensor14ROlMI

SERVICE POINTS OF REMOVAL

1. REMOVAL OF REAR SPEED SENSOR

Caution

M27wBAB

When removing the speed sensor from the adapter, be

careful that the end pole piece does not strike the teeth

of the rotor or other parts.

TSB Revision

Page 869 of 1273

REAR AXLE

27-

9

2. REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend it with a piece

of wire.

8. REMOVAL OF REAR ROTOR

Caution

Care must be taken not to scratch or otherwise damage

the teeth of the rotor. The rotor must never be dropped.

If the teeth of the rotor are chipped, resulting in a

deformation of the rotor, it will not be able to accurate- ly detect the wheel rotation speed, and the system will

not function normally.

INSPECTIONM27MFAAI

l Check the oil seal for crack or damage.

l

Check the surface of bearings for seizure, discoloration or

roughened raceway.

l Check the rear hub for wear or damage.

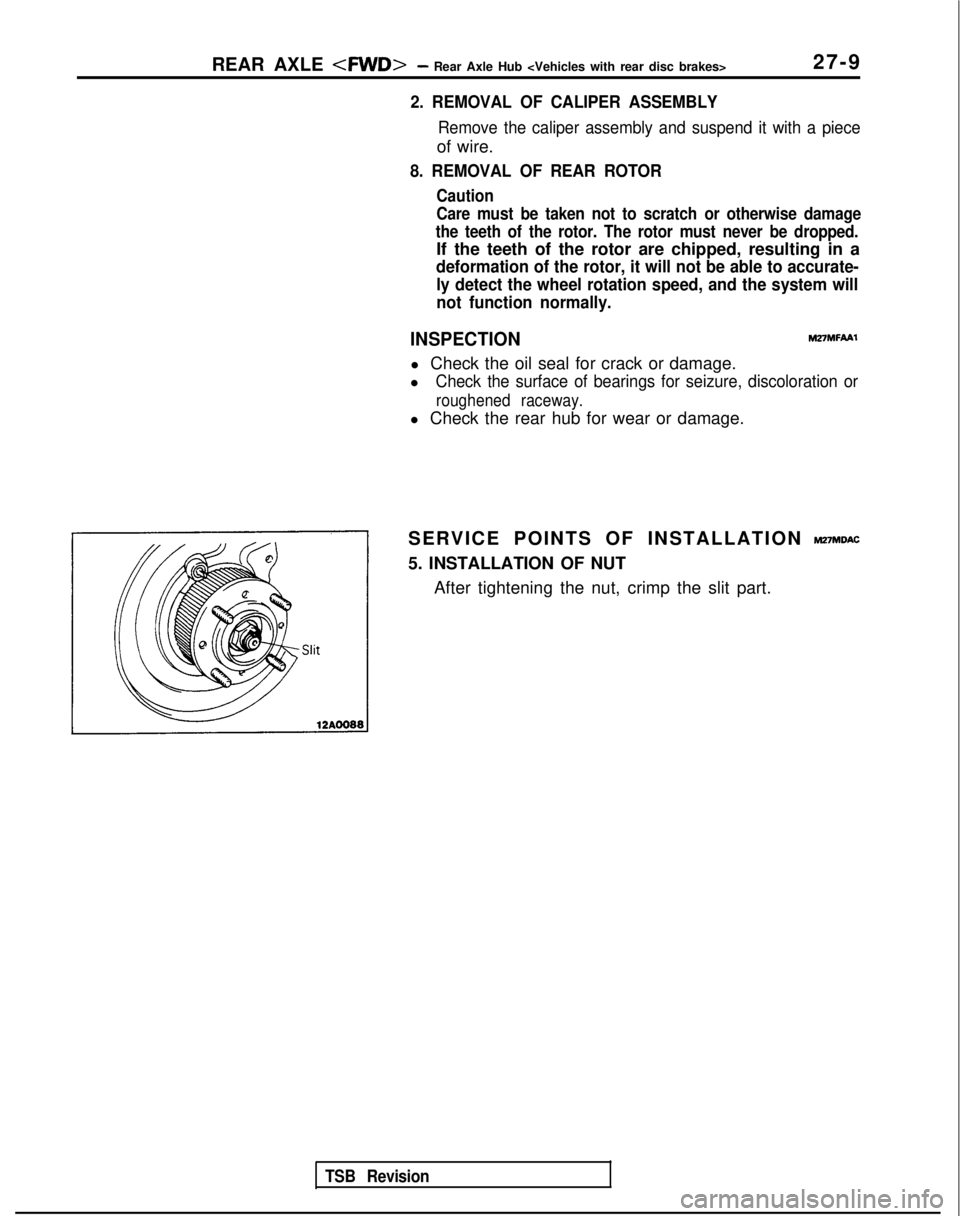

SERVICE POINTS OF INSTALLATION

MnMDAC

5. INSTALLATION OF NUT After tightening the nut, crimp the slit part.

TSB Revision

Page 870 of 1273

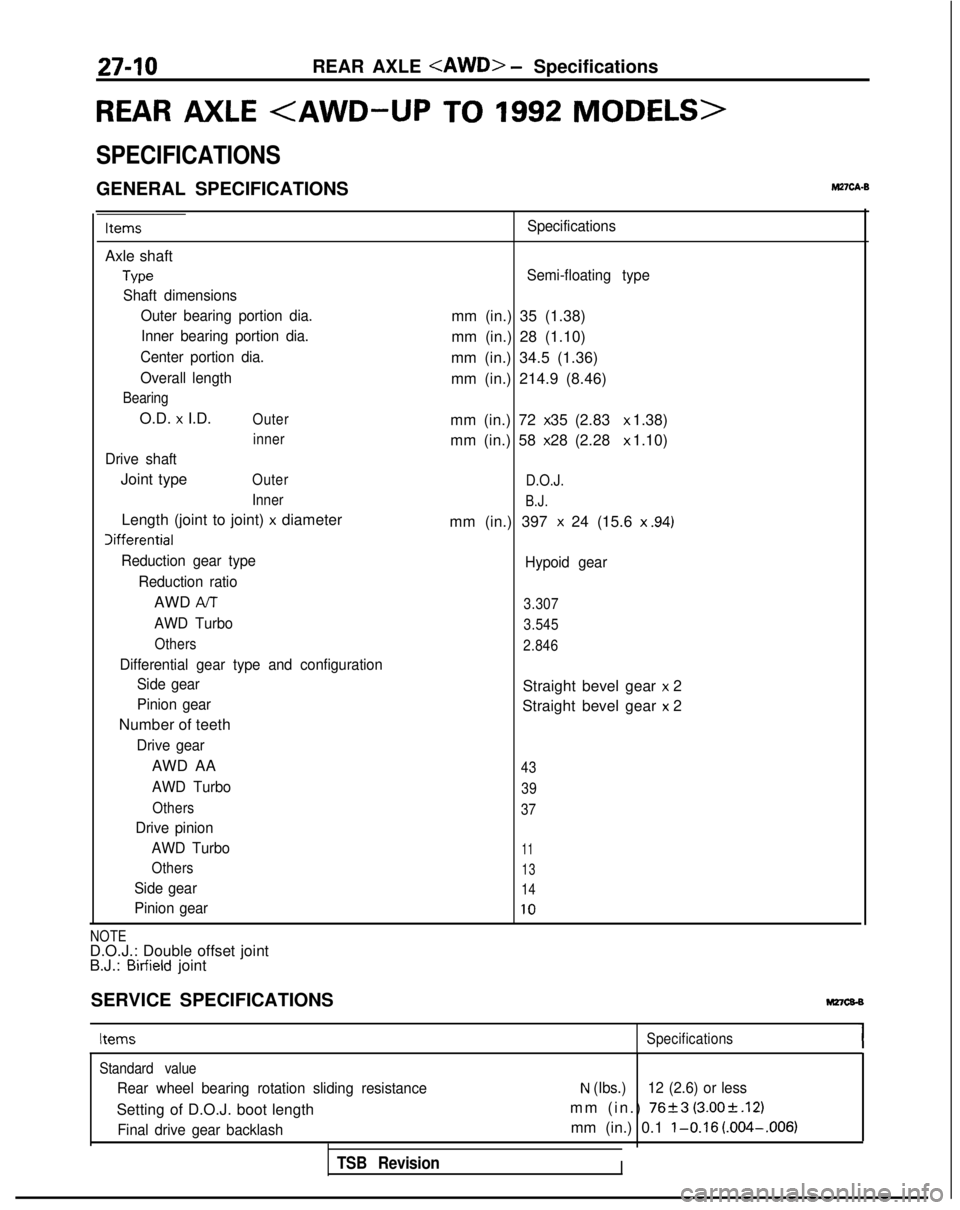

27-10REAR AXLE

REAR AXLE

SPECIFICATIONS

GENERAL SPECIFICATIONSM27cA.B

Items

Axle shaft

Type

Shaft dimensionsOuter bearing portion dia.Inner bearing portion dia.

Center portion dia.

Overall length

Bearing

O.D. x I.D.Outer inner

Drive shaft

Joint typeOuter

Inner

Length (joint to joint) x diameter Iifferential

Reduction gear type

Reduction ratio

AWD AIT

AWD Turbo

Others

Differential gear type and configurationSide gear

Pinion gear

Number of teeth

Drive gear

AWD AA

AWD Turbo

Others

Drive pinion

AWD Turbo

Others

Side gear

Pinion gear Specifications

Semi-floating type

mm (in.) 35 (1.38)

mm (in.) 28 (1.10)

mm (in.) 34.5 (1.36)

mm (in.) 214.9 (8.46)

mm (in.) 72 x 35 (2.83 x 1.38)

mm (in.) 58 x 28 (2.28 x 1.10)

D.O.J.

B.J.

mm (in.) 397 x 24 (15.6

x .94)

Hypoid gear

3.307

3.545

2.846

Straight bevel gear x 2

Straight bevel gear

x 2

43

39

37

11

13

14

10

NOTED.O.J.: Double offset joint

B.J.: Birfield joint

SERVICE SPECIFICATIONS

Mz7cs-s

Items Specifications

Standard value

Rear wheel bearing rotation sliding resistance

Setting of D.O.J. boot length

Final drive gear backlash

TSB Revision

N (Ibs.) 12 (2.6) or less

mm (in.) 7623 (3.00rt.12)

mm (in.) 0.1 l-0.16 (.004-.006)

I