MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 871 of 1273

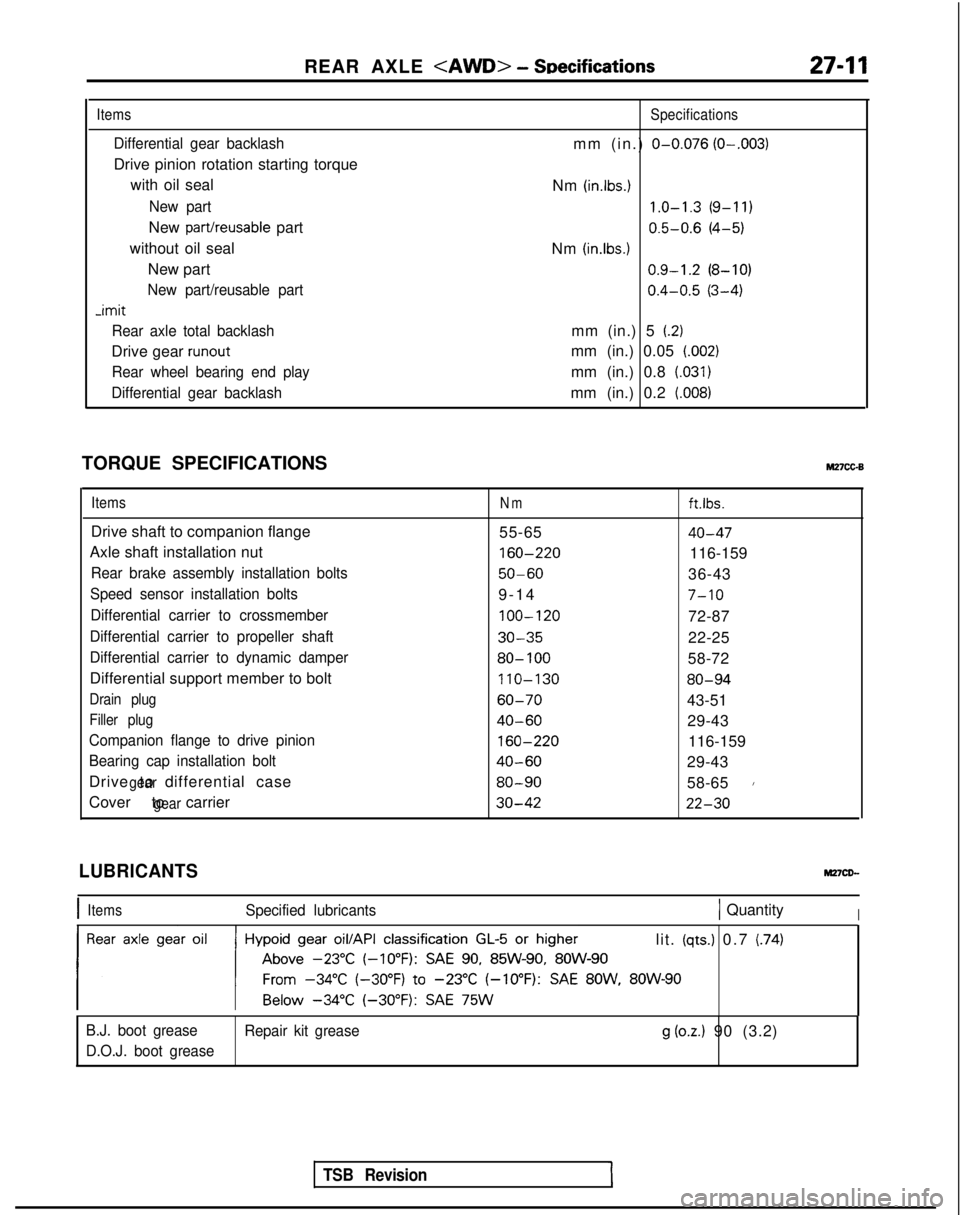

REAR AXLE

Items

Differential gear backlash

Drive pinion rotation starting torque

with oil seal

New part

New part/reusable part

without oil seal New part

New part/reusable part -imit

Rear axle total backlash

Drive gear runout

Rear wheel bearing end play

Differential gear backlash

Specifications

mm (in.) O-0.076 (O-.003)

Nm (in.lbs.) 1.0-1.3

(9-11)

0.5-0.6

(4-5)

Nm

(in.lbs.1 0.9-1.2

(8-10)

0.4-0.5

(3-4)

mm (in.) 5

(2)

mm (in.) 0.05 (.002)

mm (in.) 0.8 (.031)

mm (in.) 0.2 (008)

TORQUE SPECIFICATIONSM27cc-B

ItemsNmft.lbs.

Drive shaft to companion flange 55-6540-47

Axle shaft installation nut 160-220

116-159

Rear brake assembly installation bolts50-6036-43

Speed sensor installation bolts9-1

4

7-10

Differential carrier to crossmember

100-120

72-87

Differential carrier to propeller shaft30-3522-25

Differential carrier to dynamic damper80- 10058-72

Differential support member to bolt 110-130

80-94

Drain plug60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220

116-159

Bearing cap installation bolt40-6029-43

Drive to differential case

gear80-9058-651

Cover to carriergear30-4222-30

TSB Revision

LUBRICANTS

IItemsSpecified lubricants1 QuantityI

lit. (qts.) 0.7 (74)

B.J. boot grease Repair kit grease

g (oz.) 90 (3.2)

D.O.J. boot grease

Page 872 of 1273

27-12REAR AXLE

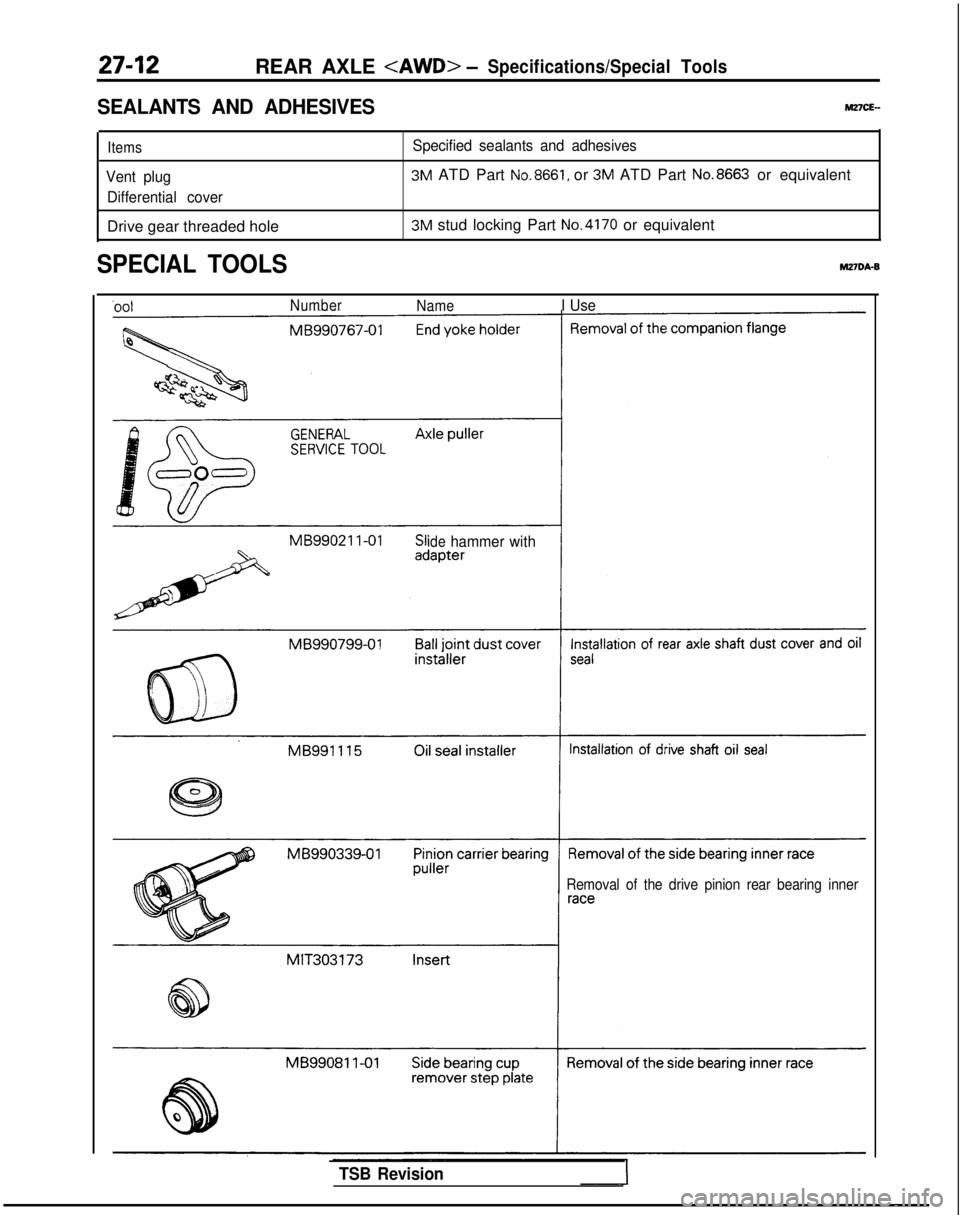

SEALANTS AND ADHESIVESMZICE-

ItemsSpecified sealants and adhesives

Vent plug

3M ATD Part No.8661, or 3M ATD Part No.8663 or equivalent

Differential cover

Drive gear threaded hole3M stud locking Part No.4170 or equivalent

SPECIAL TOOLSM27DA-B

‘nnlNumber NameI Use

idehammer with

Removal of the drive pinion rear bearing inner

TSB Revision

Page 873 of 1273

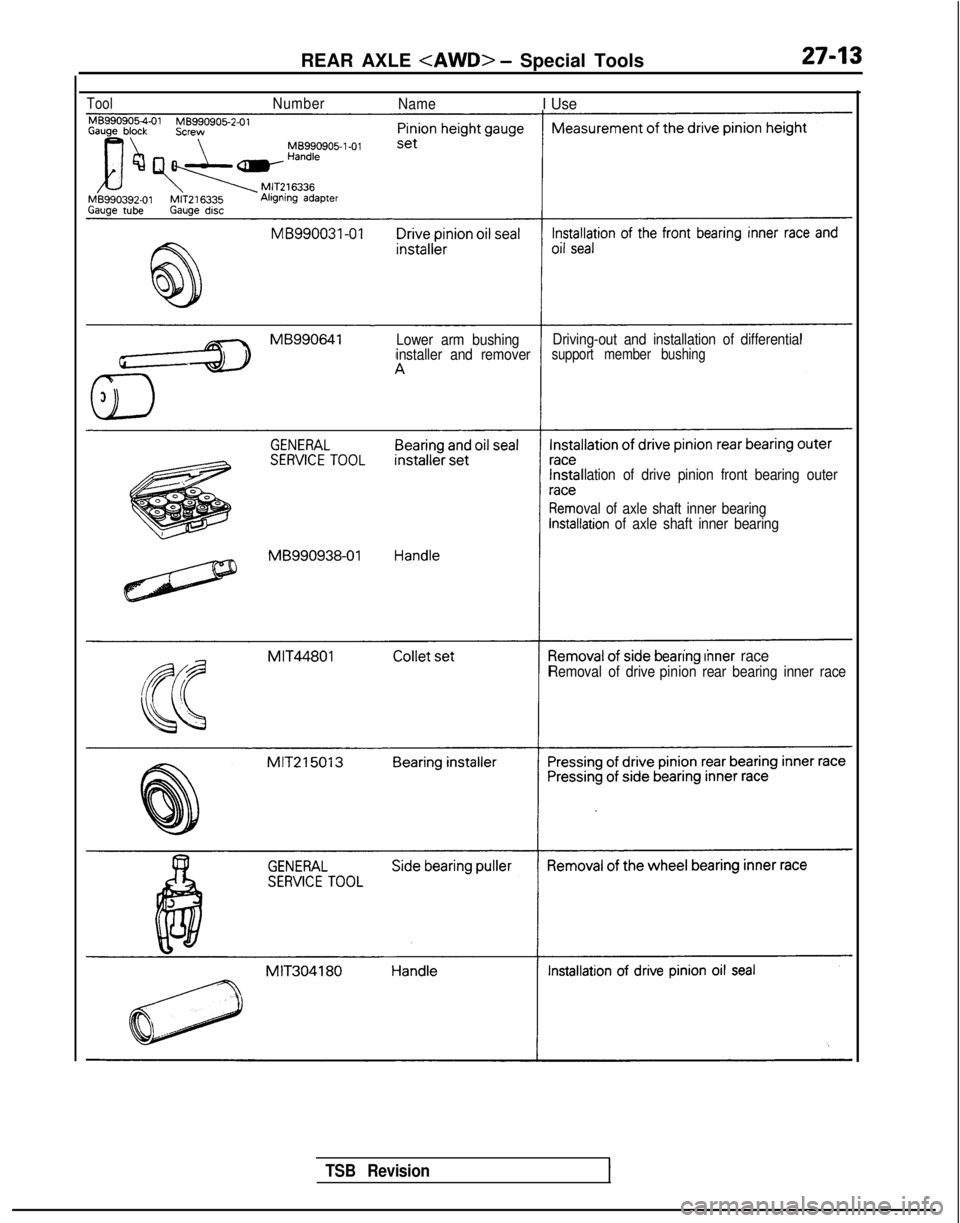

ToolNumberNameI Use MB990905-l-01

Lower arm bushing

Driving-out and installation of differential

installer and removersupport member bushing

MB990938-01 llation of drive pinion front bearing outer

oval of axle shaft inner bearing

llation of axle shaft inner bearing

eanng Inner raceRemoval of drive pinionrear bearing inner race

REAR AXLE

TSB Revision

Page 874 of 1273

27-14REAR AXLE

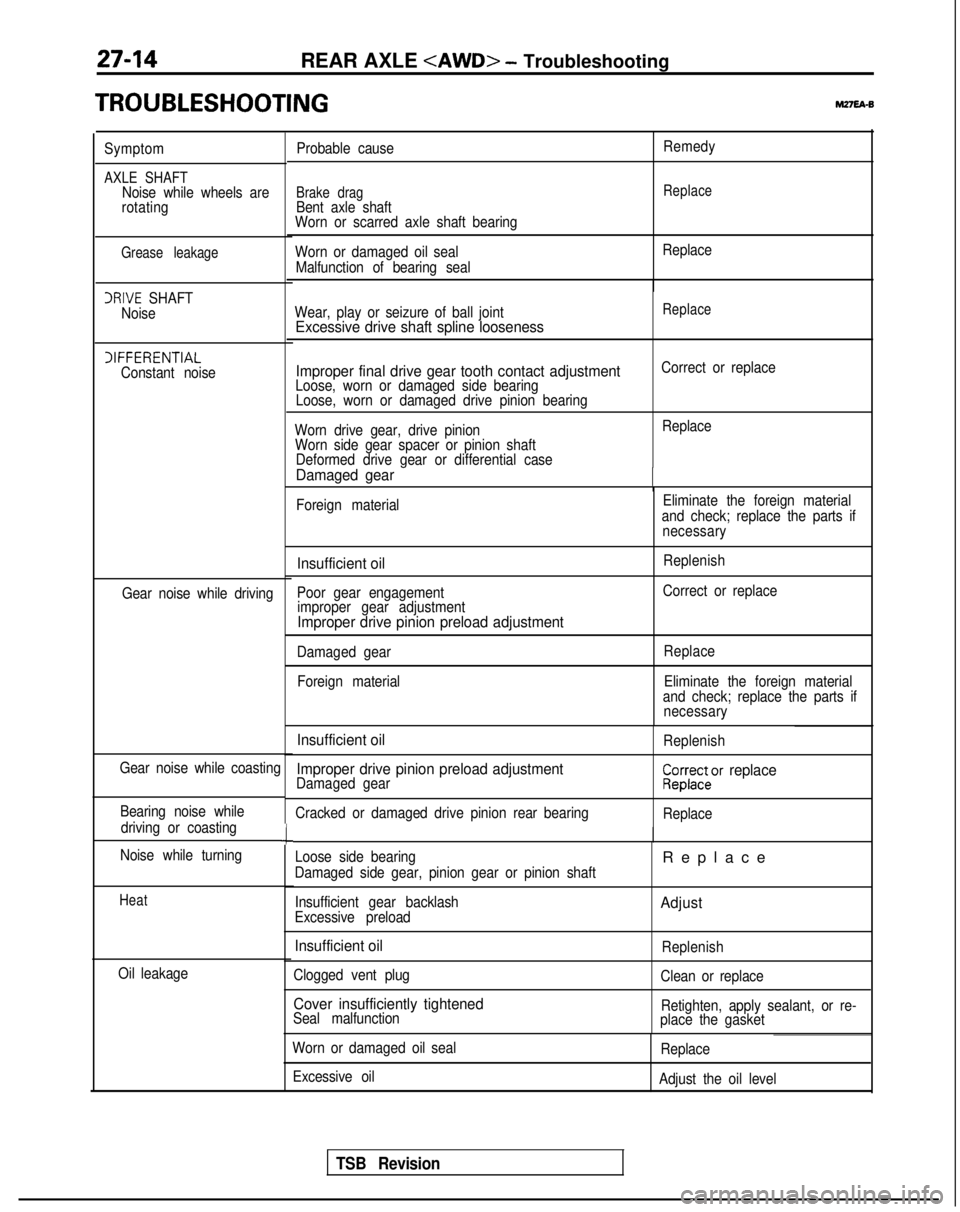

rROUBLESHOOTlNG

Symptom

AXLE SHAFTNoise while wheels are

rotating

Grease leakage

IRIVE SHAFT

Noise

IIFFERENTIAL Constant noise

Gear noise while driving

Gear noise while coasting Bearing noise while driving or coasting

Noise while turning

Heat

Oil leakage

c

Probable cause

Brake dragBent axle shaft

Worn or scarred axle shaft bearing

Worn or damaged oil seal

Malfunction of bearing seal Remedy

Replace

Replace

Wear, play or seizure of ball joint

Excessive drive shaft spline looseness

Replace

Improper final drive gear tooth contact adjustmentLoose, worn or damaged side bearing Loose, worn or damaged drive pinion bearing Correct or replace

Worn drive gear, drive pinion Worn side gear spacer or pinion shaft Deformed drive gear or differential case

Damaged gear -

Replace

Foreign material Eliminate the foreign material

and check; replace the parts if necessary

Insufficient oil

Poor gear engagementimproper gear adjustment

Improper drive pinion preload adjustment

Replenish

Correct or replace

Damaged gear Foreign material Replace

Eliminate the foreign material

and check; replace the parts if necessary

Insufficient oil

Improper drive pinion preload adjustment

Damaged gear

Cracked or damaged drive pinion rear bearing ReplenishCZ23rar2cr replace

Replace

Loose side bearing

Damaged side gear, pinion gear or pinion shaft

Insufficient gear backlash

Excessive preload

Insufficient oil

Clogged vent plug

Cover insufficiently tightenedSeal malfunction

Replac

e

Adjust

Replenish

Clean or replace

Retighten, apply sealant, or re-

place the gasket

Worn or damaged oil seal

Excessive oil Replace

Adjust the oil level

TSB Revision

Page 875 of 1273

REAR AXLE

Matina marks/I

1

SERVICE ADJUSTMENT PROCEDURES

REAR AXLE TOTAL BACKLASH CHECKMZ’IFAAF

If the vehicle vibrates and produces a booming sound due to an

imbalance of the driving system, measure the rear axle total

backlash by the following procedures to see if the differential

carrier assembly requires removal.

(1) Place the gearshift lever in the neutral position, apply the

parking brake and jack up the vehicle.

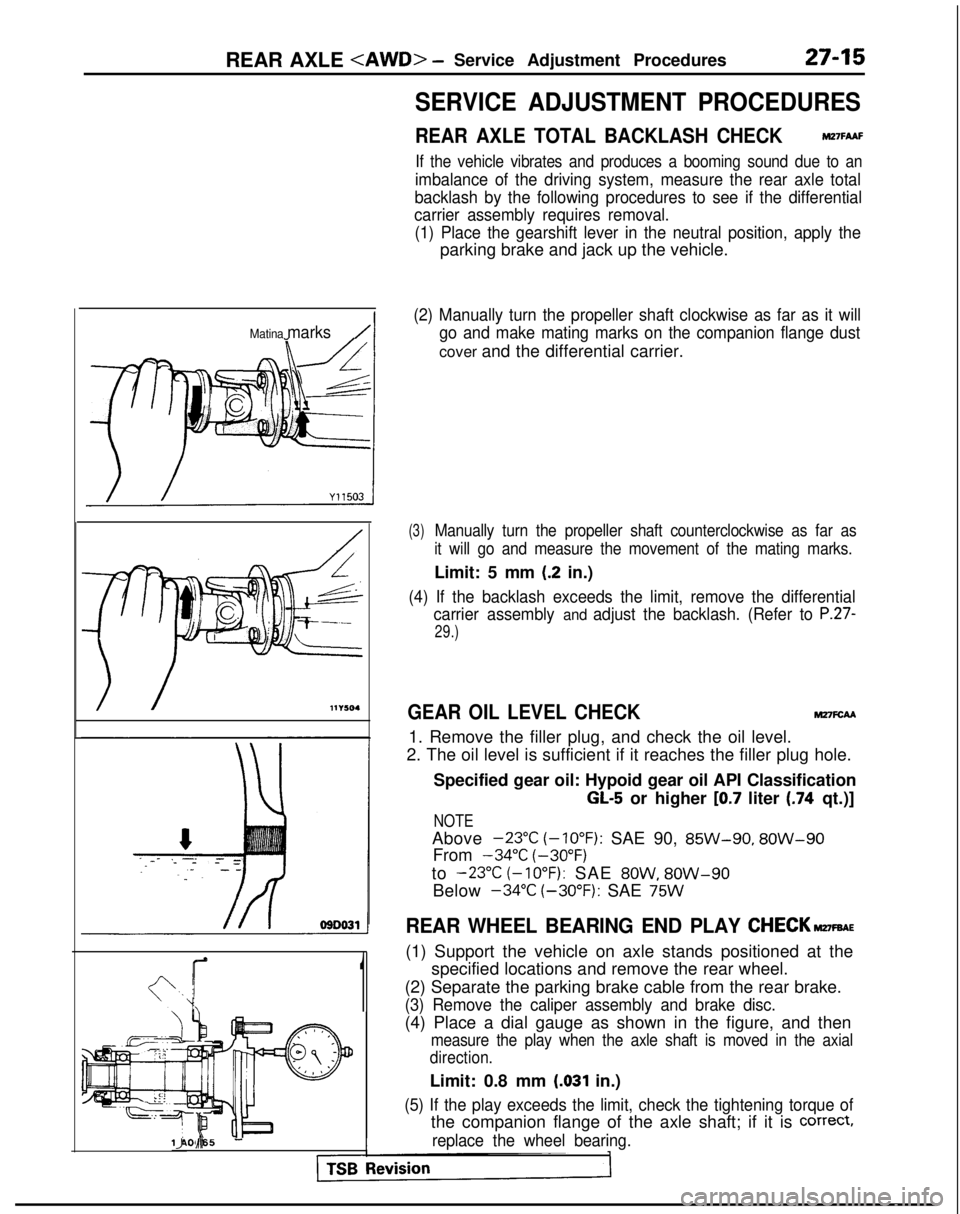

(2) Manually turn the propeller shaft clockwise as far as it will go and make mating marks on the companion flange dust

cover and the differential carrier.

(3)Manually turn the propeller shaft counterclockwise as far as

it will go and measure the movement of the mating marks.

Limit: 5 mm (.2 in.)

(4) If the backlash exceeds the limit, remove the differential carrier assembly

and adjust the backlash. (Refer to P.27-

29.)

GEAR OIL LEVEL CHECKM27FcAA

1. Remove the filler plug, and check the oil level.

2. The oil level is sufficient if it reaches the filler plug hole.

Specified gear oil: Hypoid gear oil API Classification

GL-5 or higher [0.7 liter (.74 qt.)]

NOTE

Above -23°C

(-10°F):

SAE 90, 85W-90,

8OW-90

From -34°C

(-30°F)

to

-23°C (-10°F): SAE 8OW, 8OW-90

Below -34°C

(-30°F):

SAE

75W

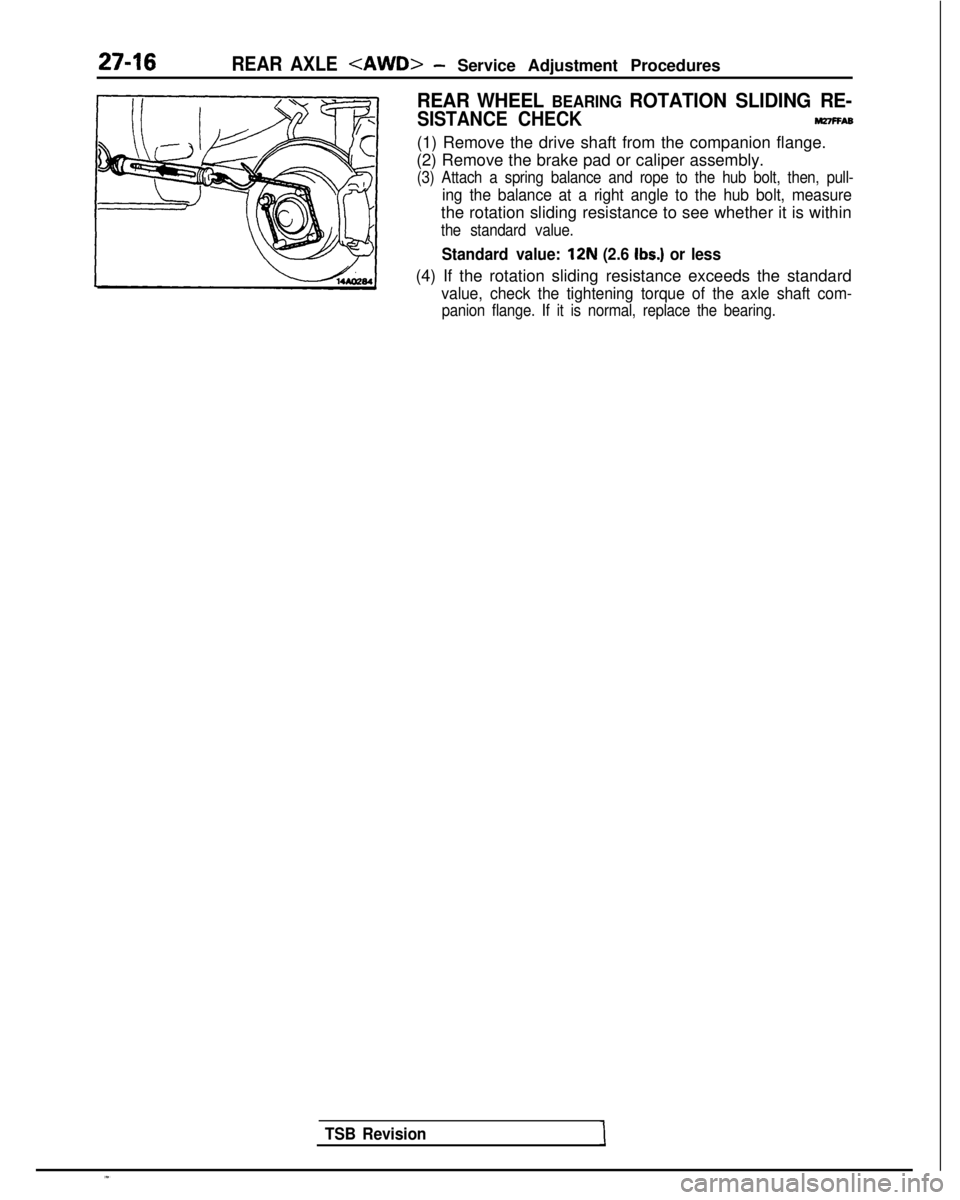

REAR WHEEL BEARING END PLAY CHECK~FBAE

(1) Support the vehicle on axle stands positioned at the

specified locations and remove the rear wheel.

(2) Separate the parking brake cable from the rear brake.

(3) Remove the caliper assembly and brake disc.

(4) Place a dial gauge as shown in the figure, and then

measure the play when the axle shaft is moved in the axial

direction.

Limit: 0.8 mm (.031 in.)

(5) If the play exceeds the limit, check the tightening torque of

the companion flange of the axle shaft; if it is correct,

replace the wheel bearing.llA0065 IJ d-

Page 876 of 1273

REAR AXLE

REAR WHEEL BEARING ROTATION SLIDING RE-

SISTANCE CHECKnnnFFA6

(1) Remove the drive shaft from the companion flange.

(2) Remove the brake pad or caliper assembly.

(3) Attach a spring balance and rope to the hub bolt, then, pull-

ing the balance at a right angle to the hub bolt, measure

the rotation sliding resistance to see whether it is within

the standard value.

Standard value: 12N (2.6 Ibs.) or less

(4) If the rotation sliding resistance exceeds the standard

value, check the tightening torque of the axle shaft com-

panion flange. If it is normal, replace the bearing.

TSB Revision

Page 877 of 1273

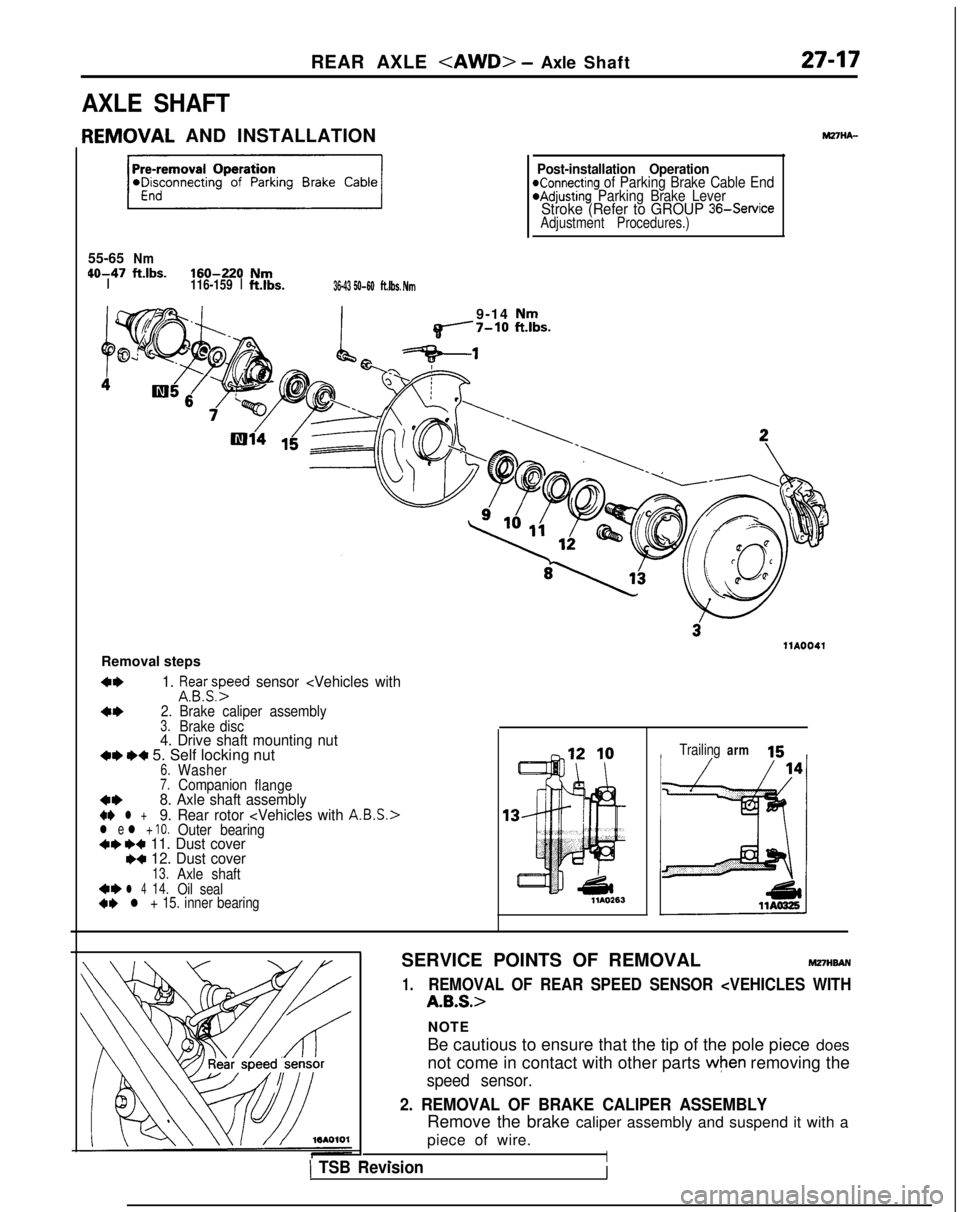

REAR AXLE

AXLE SHAFT

IEMOVAL

AND INSTALLATION

55-65

Nm 40-47

ftlbs.160-220NmI116-159

Ift.lbs.36-43 50-60ft.lbs. Nm

Post-installation OperationKonnecting of Parking Brake Cable End@Adjusting Parking Brake LeverStroke (Refer to GROUP 36-Service

Adjustment Procedures.)

9-14 Nmq------7-10 ft.lbs.

llA0041

Removal steps

4*1. ifsa.yyed sensor

arm 15

SERVICE POINTS OF REMOVAL

MmwAN

1.REMOVAL OF REAR SPEED SENSOR

NOTE

Be cautious to ensure that the tip of the pole piece does

not come in contact with other parts

when removing the

speed sensor.

2. REMOVAL OF BRAKE CALIPER ASSEMBLY

Remove the brake caliper assembly and suspend it with a

piece of wire.

I- _,1 TSB RevisionI

Page 878 of 1273

27-18REAR AXLE

-MB990938-01

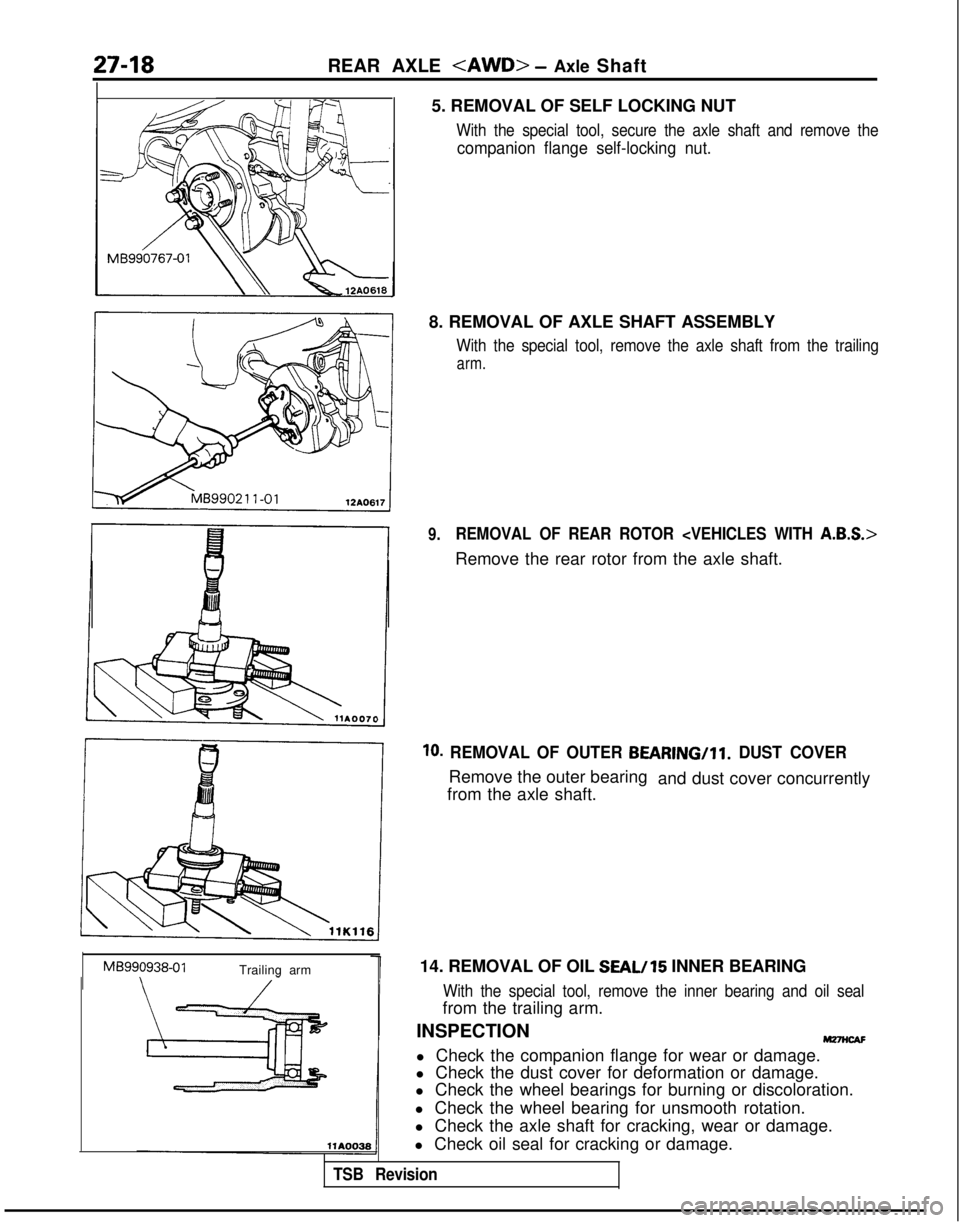

Trailing arm 5. REMOVAL OF SELF LOCKING NUT

With the special tool, secure the axle shaft and remove the

companion flange self-locking nut.

8. REMOVAL OF AXLE SHAFT ASSEMBLY

With the special tool, remove the axle shaft from the trailing

arm.

9.REMOVAL OF REAR ROTOR

Remove the rear rotor from the axle shaft.

10. REMOVAL OF OUTER BEARING/ll. DUST COVER

Remove the outer bearing

from the axle shaft. and dust cover concurrently

14. REMOVAL OF OIL

SEAL/15 INNER BEARING

With the special tool, remove the inner bearing and oil seal

from the trailing arm.

INSPECTION

M27wAF

l Check the companion flange for wear or damage.

l Check the dust cover for deformation or damage.

l Check the wheel bearings for burning or discoloration.

l Check the wheel bearing for unsmooth rotation.

l Check the axle shaft for cracking, wear or damage.

l Check oil seal for cracking or damage.

TSB Revision

Page 879 of 1273

REAR AXLE

Trailing arm

/MB990938-01

Trailing arm MB990799-01

llAOO40

11 A0033

Outer bearing

Seal lip

surfac’111026

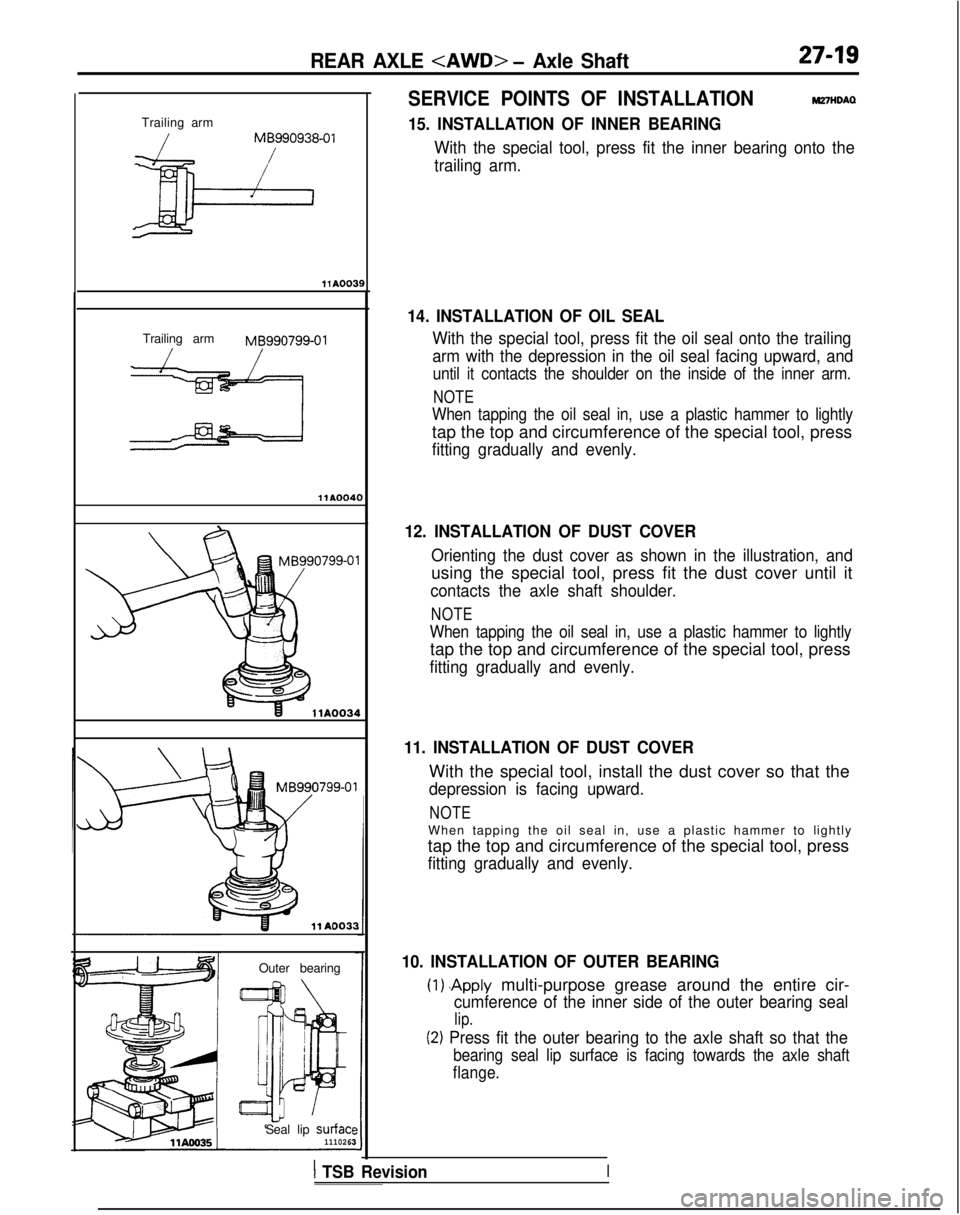

SERVICE POINTS OF INSTALLATIONW7HDAQ

15. INSTALLATION OF INNER BEARING

With the special tool, press fit the inner bearing onto the

trailing arm.

14. INSTALLATION OF OIL SEAL

With the special tool, press fit the oil seal onto the trailing

arm with the depression in the oil seal facing upward, and

until it contacts the shoulder on the inside of the inner arm.

NOTE

When tapping the oil seal in, use a plastic hammer to lightly

tap the top and circumference of the special tool, press

fitting gradually and evenly.

12. INSTALLATION OF DUST COVER

Orienting the dust cover as shown in the illustration, and

using the special tool, press fit the dust cover until it

contacts the axle shaft shoulder.

NOTE

When tapping the oil seal in, use a plastic hammer to lightly

tap the top and circumference of the special tool, press

fitting gradually and evenly.

11. INSTALLATION OF DUST COVER

With the special tool, install the dust cover so that the

depression is facing upward.

NOTE

When tapping the oil seal in, use a plastic hammer to lightl

y

tap the top and circumference of the special tool, press

fitting gradually and evenly.

10. INSTALLATION OF OUTER BEARING

(1) .Apply multi-purpose grease around the entire cir-

cumference of the inner side of the outer bearing seal

lip.

(2) Press fit the outer bearing to the axle shaft so that the

bearing seal lip surface is facing towards the axle shaft

flange.

1 TSB RevisionI

Page 880 of 1273

27-20REAR AXLE

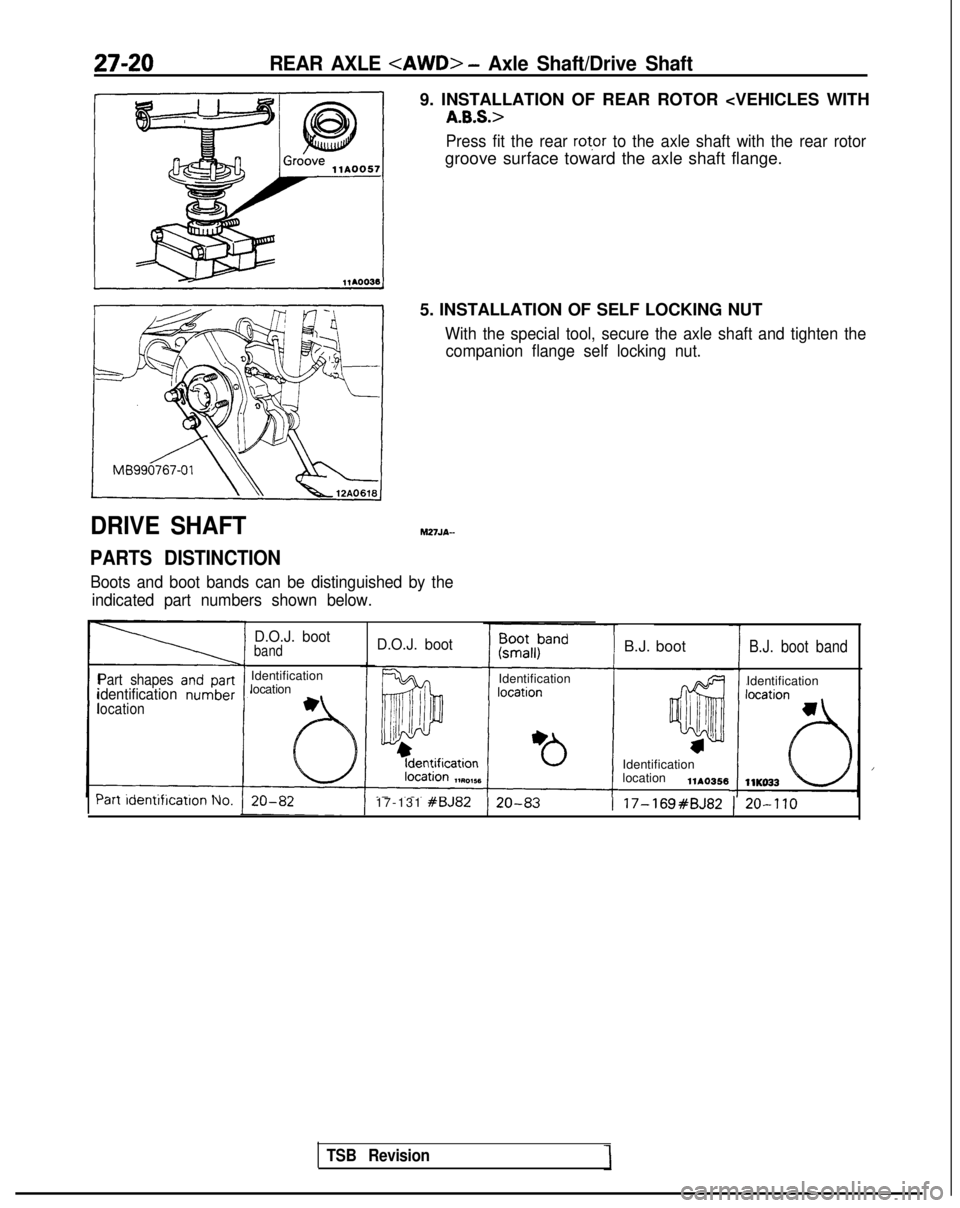

DRIVE SHAFT

PARTS DISTINCTION

9. INSTALLATION OF REAR ROTOR

Press fit the rear rot,or to the axle shaft with the rear rotor

groove surface toward the axle shaft flange.

5. INSTALLATION OF SELF LOCKING NUT

With the special tool, secure the axle shaft and tighten the companion flange self locking nut.

M27JA-

Boots and boot bands can be distinguished by the

indicated part numbers shown below.

TSB Revision

Part shapesidentificationlocation

D.O.J. bootband

Identification

location

D.O.J. boot

Identification B.J. boot

B.J. boot band

Identification

Identification

location

llAO356 ran

laenrirrcarlon 110.17-131 #BJ82) 20-83I 17-169#BJ82 ) 20-110