MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 831 of 1273

26-1

FRONT AXLE

CONTENTS

DRIVE SHAFT..................................................12SPECIFICATIONS.............................................2

GeneralSpecifications

..................................2HUB AND KNUCKLE...................................... 6

Lubricants ......................................................3

SERVICE ADJUSTMENT PROCEDURES.......5Service Specifications ...................................

Hub

End PlayInspection5Torque Specifications2m............................. ...................................2

SPECIAL

TOOLS

.............................................3TROUBLESHOOTING ......................................5

Page 832 of 1273

26-2

SPECIFICATIONS

FRONT AXLE - Specifications

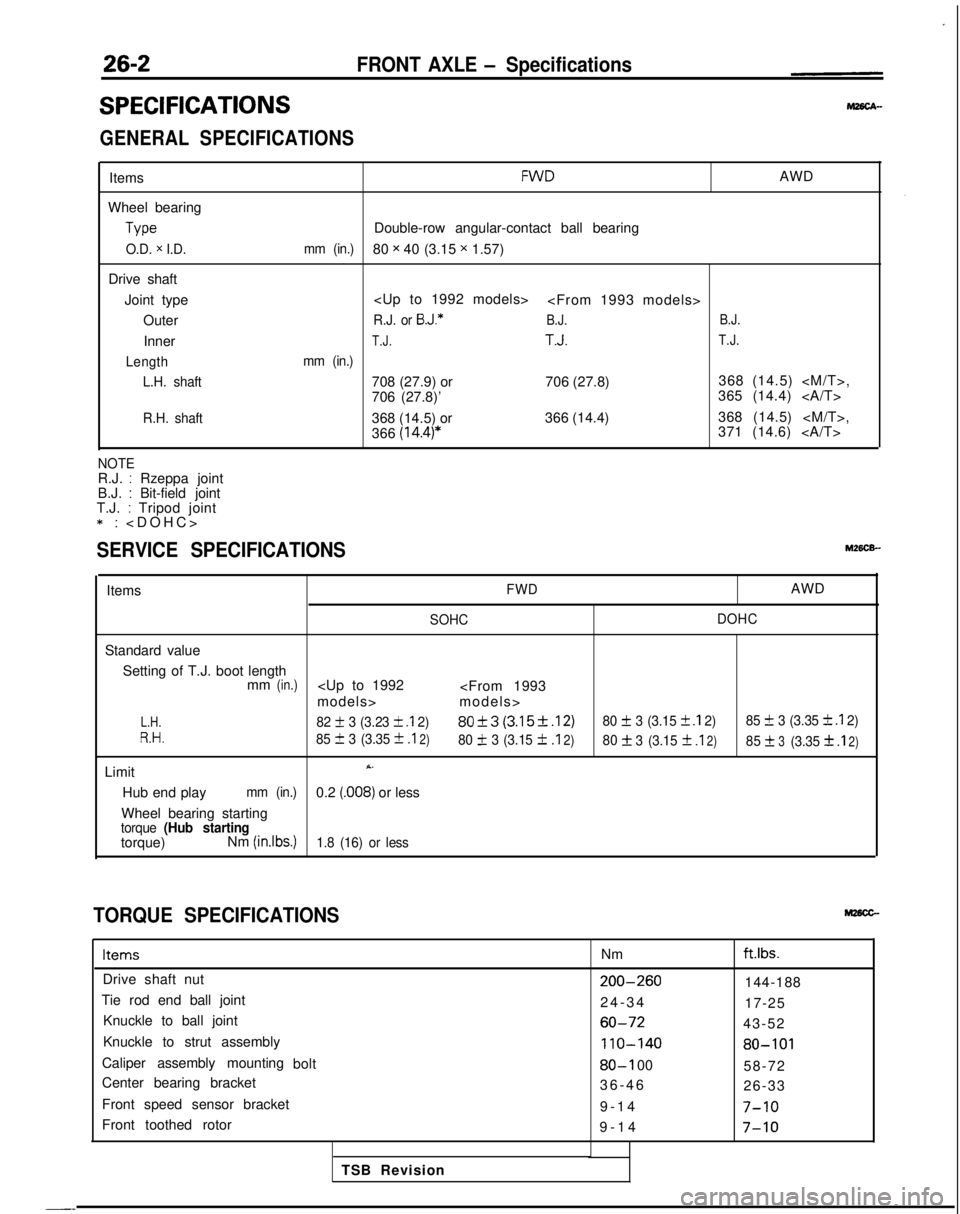

GENERAL SPECIFICATIONS

Items

Wheel bearing Type

O.D. x I.D.

Drive shaft

Joint type Outer

Inner

Length L.H. shaft

R.H. shaft

FWDAWD

Double-row angular-contact ball bearing

mm (in.)80 x 40 (3.15 x 1.57)

R.J. or B.J.*B.J. B.J.

T.J.T.J.T.J.

mm (in.)

708 (27.9) or

706 (27.8)368 (14.5)

706 (27.8)’ 365 (14.4)

368 (14.5) or 366 (14.4)368 (14.5)

366

(14.4)*371 (14.6)

NOTER.J. : Rzeppa joint

B.J. : Bit-field joint

T.J. : Tripod joint *:

>

SERVICE SPECIFICATIONS

ItemsFWDAWD

SOHC

DOHC

Standard value

Setting of T.J. boot length mm

(in.)

L.H.82 + 3 (3.23 k .I 2)80f3 (3.15f.12)80 + 3 (3.15 f .I 2)

85 f 3 (3.35 k .I 2)

R.H.85 III 3 (3.35 +

.I2)80 IL 3 (3.15 f.I2)80f3

(3.15f .I2)85f3(3.3531

.I2)

LimitX.

Hub end playmm (in.)0.2 (.008) or less

Wheel bearing starting

torque (Hub startingtorque) Nm (inlbs.)1.8 (16) or less

TORQUE SPECIFICATIONS

ItemsNmftlbs.

Drive shaft nut200-260144-188

Tie rod end ball joint 24-3

4

17-25

Knuckle to ball joint

60-7243-52

Knuckle to strut assembly

110-14080-101

Caliper assembly mounting bolt80-I 0058-72

Center bearing bracket 36-4

6

26-33

Front speed sensor bracket 9-14

7-10

Front toothed rotor9-1

4

7-10

TSB Revision

-_

Page 833 of 1273

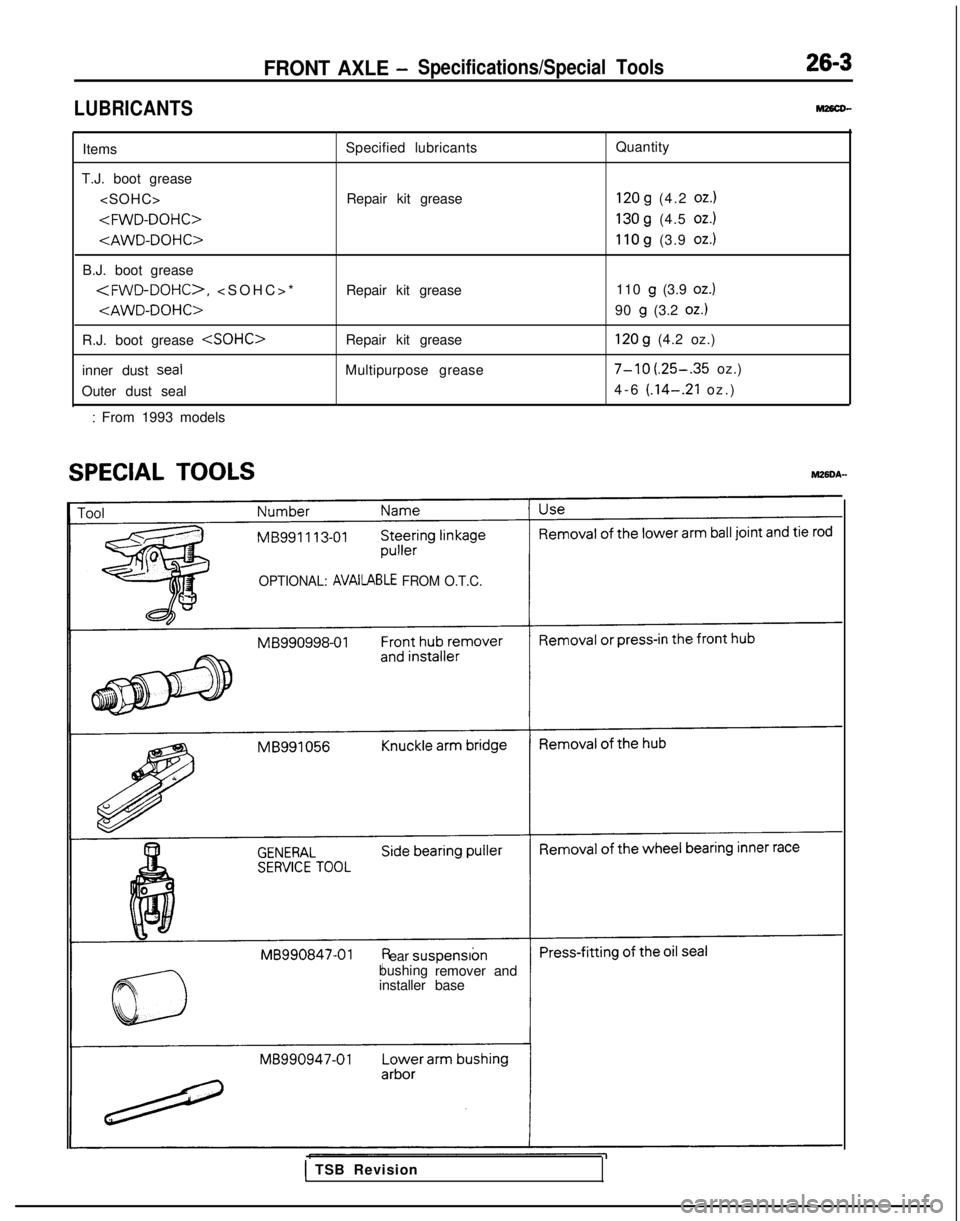

LUBRICANTS

FRONT AXLE -Specifications/Special Tools26-3

M26cD-

Items

T.J. boot grease

B.J. boot grease

*

R.J. boot grease

inner dust

seal

Outer dust seal

: From 1993 models Specified lubricants

Repair kit grease

Repair kit grease

Repair kit grease

Multipurpose grease Quantity

120 g (4.2 oz.)

130 g (4.5 oz.)

110 g (3.9 oz.)

110 g (3.9 oz.)

90 g (3.2 oz.)

120 g (4.2 oz.)

7-10 (.25-.35 oz.)

4-6

(.14-.21 oz.

)

SPECIAL TOOLSM26DA-

OPTIONAL: AVAilABLE FROM O.T.C.

ear

suspensron

bushing remover and

installer base

1 TSB Revision

Page 834 of 1273

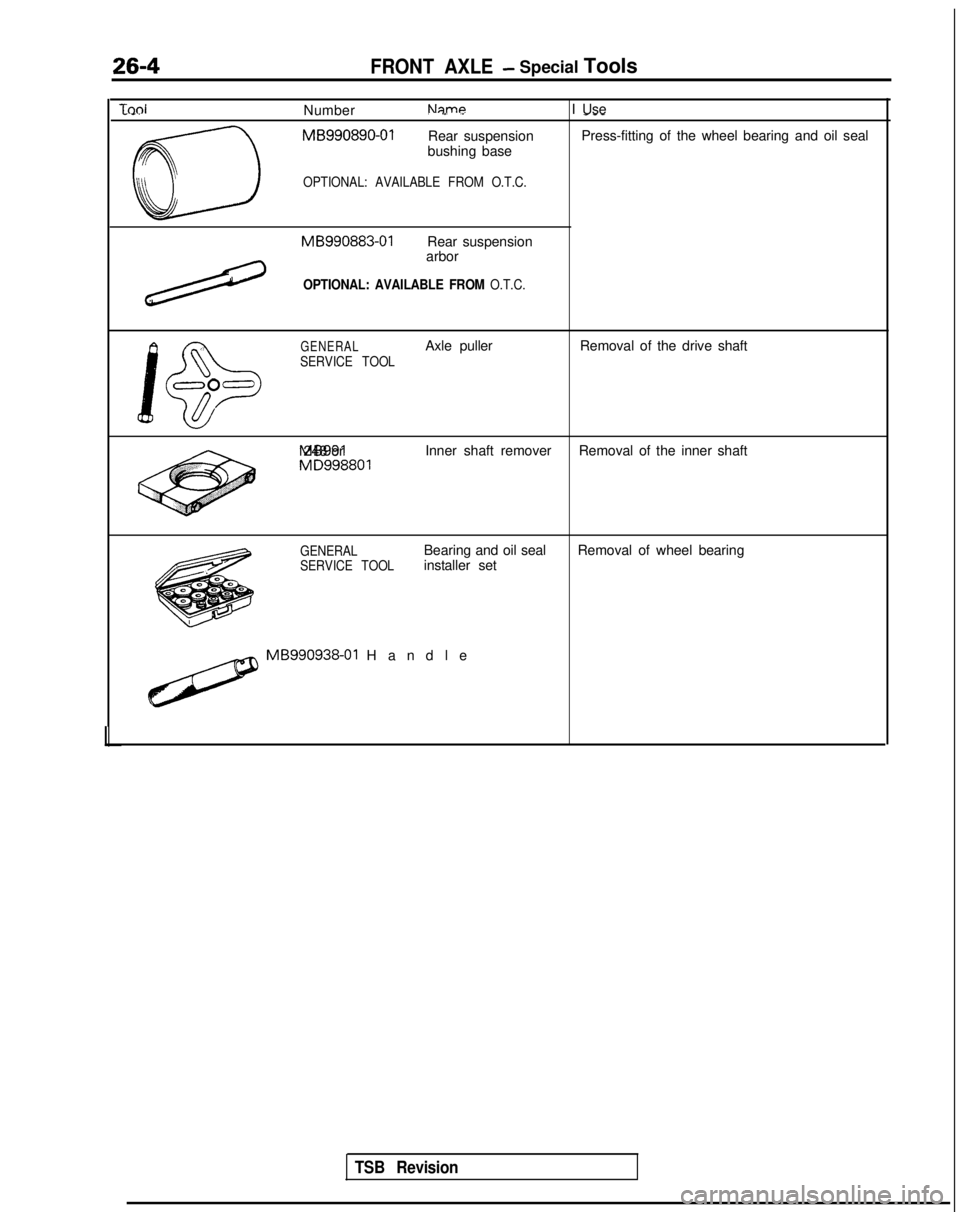

26-4FRONT AXLE- Special Tools

TdNumberNameI Use. .-. .------.

CD

MB990890-01

Rear suspension Press-fitting of the wheel bearing and oil seal

bushing base

OPTIONAL: AVAILABLE FROM O.T.C. MB990883-01

Rear suspension

arbor

/

OPTIONAL: AVAILABLE FROM O.T.C.

\

J!D

GENERALAxle puller Removal of the drive shaft

SERVICE TOOL

000

1 MB991 248 or

Inner shaft remover

Removal of the inner shaft MD998801

GENERAL

SERVICE TOOLBearing and oil seal

installer set

Removal of wheel bearing

H MB990938-01

Handle

TSB Revision

Page 835 of 1273

FRONT AXLE - Troubleshooting/Service Adjustment Procedures26-5

TROUBLESHOOTINGm6E6AA

Symptom

Vehicle pulls to one side Probable cause

Seizure of drive shaft ball joint

Abnormal wear, play or seizure of wheel bear-

ing

Remedy

Replace

Replace

Vibration

Shimmy Excessive noise Malfunction of front suspension or steering

Bend, damage or abnormal wear of drive shaft

Play in drive shaft and hub serration

Abnormal wear, play or seizure of wheel bear-

ing

Improper wheel alignment

Malfunction of front suspension or steering

Broken boot, grease leakage

Bend, damage or abnormal wear of drive shaft

Play of drive shaft and hub serration

Abnormal wear, play or seizure of center bearing Adjust or replace

Replace

Replace

Replace

Adjust or replace

Adjust or replace

Replace, repack grease

Replace

Replace

Replace

Abnormal wear, play or seizure of wheel bear-ing

Loose wheel nut

Malfunction of front suspension and steering

Replace

Retighten

Adjust or replace

SERVICE ADJUSTMENT

PROCEDURES

HUB END PLAY INSPECTIONM26FAAB

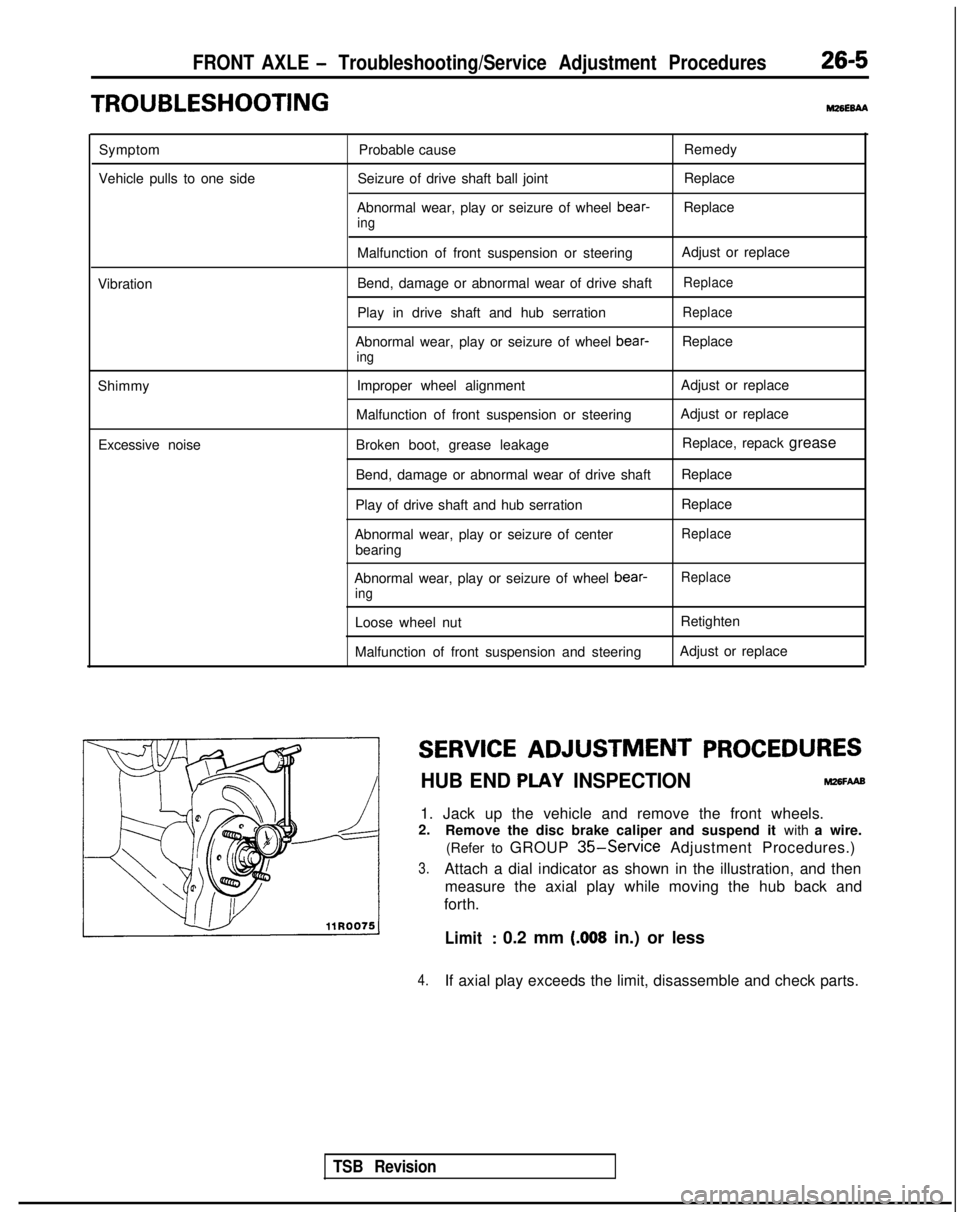

1. Jack up the vehicle and remove the front wheels.

2. Remove the disc brake caliper and suspend it with a wire.

(Refer to GROUP

35-Service Adjustment Procedures.)

3.Attach a dial indicator as shown in the illustration, and then measure the axial play while moving the hub back and

forth.

Limit: 0.2 mm (.008 in.) or less

4.If axial play exceeds the limit, disassemble and check parts.

TSB Revision

Page 836 of 1273

26-6FRONT AXLE -Hub and Knuckle

HUB AND

KNUCKLE

REMOVAL AND INSTALLATION

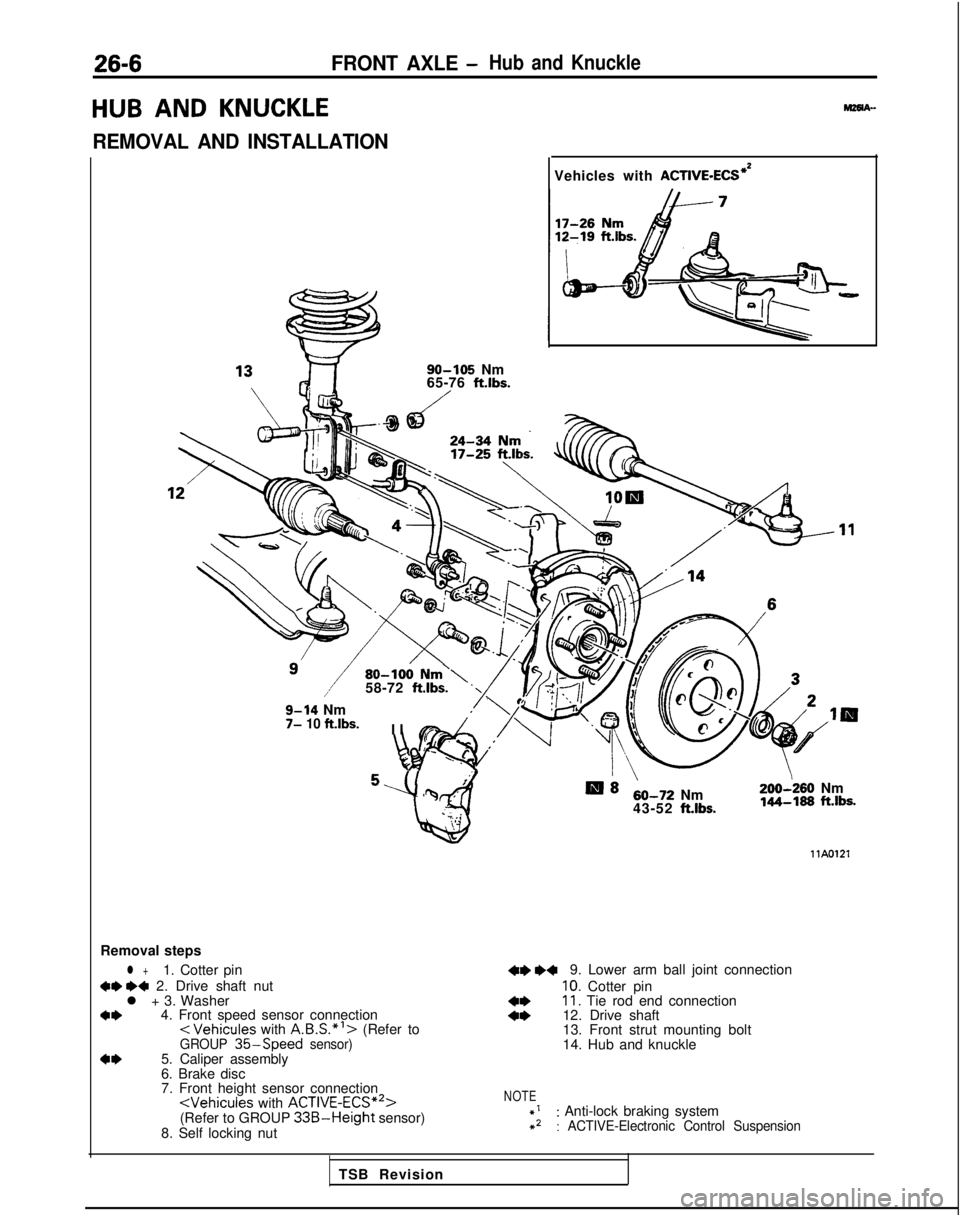

SO-105 Nm

65-76 ft.lbs.

Vehicles with ACTIVE-ECS*’

80-100 Nm’\58-72 ftlbs.

9-14 Nm7- 10 ft.lbs.I

I

5rq :I

u

- 4. .i,'-

B860-72 Nm200-‘260 Nm

43-52

ft.lbs.IU-188 ft.lbs.

llA0121

Removal steps

l +1. Cotter pin

+e I)+ 2. Drive shaft nut

l + 3. Washer

a*4. Front speed sensor connection< Vehicules

with A.B.S.*‘> (Refer toGROUP 35-Speed sensor)a*5. Caliper assembly

6. Brake disc

7. Front height sensor connection

(Refer to GROUP 33B-Height sensor)

8. Self locking nut

+e ~~9. Lower arm ball joint connection

10. Cotter pin

::11. Tie rod end connection

12. Drive shaft

13. Front strut mounting bolt

14. Hub and knuckle

NOTE

::: Anti-lock braking system: ACTIVE-Electronic Control Suspension

TSB Revision

Page 837 of 1273

FRONT AXLE - Hub and Knuckle26-7

SERVICE POINTS OF REMOVALM261sAE

2.

4.

REMOVAL OF DRIVE SHAFT NUTLoosen the drive shaft nut while the vehicle is on the floor

with the brakes applied.

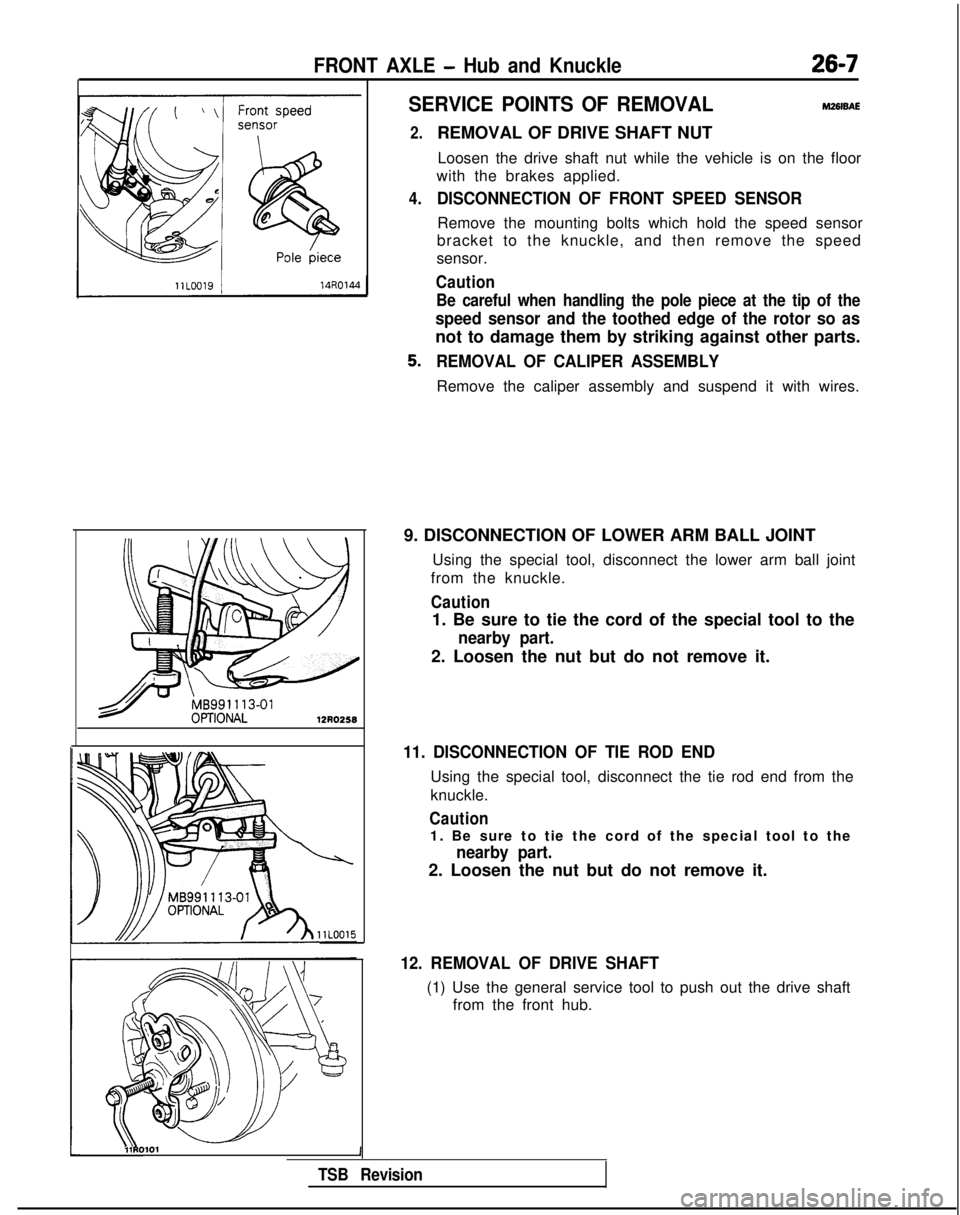

DISCONNECTION OF FRONT SPEED SENSOR

Remove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove the speed

sensor.

Caution

Be careful when handling the pole piece at the tip of the

speed sensor and the toothed edge of the rotor so as

not to damage them by striking against other parts.

REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend it with wires.

9. DISCONNECTION OF LOWER ARM BALL JOINT Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

11. DISCONNECTION OF TIE ROD END

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

12. REMOVAL OF DRIVE SHAFT

(1) Use the general service tool to push out the drive shaft from the front hub.

l\\11RO101 1

TSB Revision

Page 838 of 1273

26-8FRONT AXLE -Hub and Knuckle

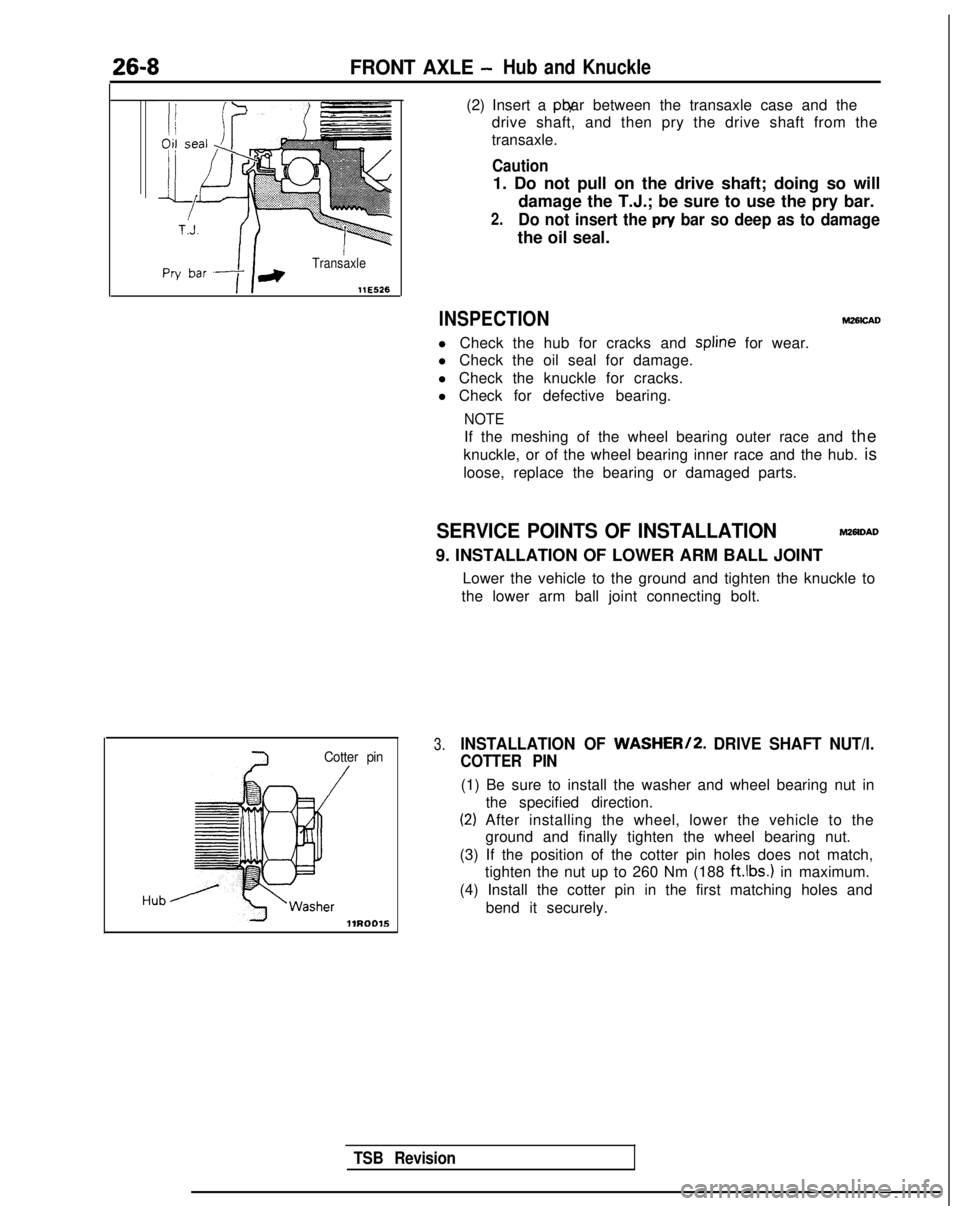

Transaxle

Cotter pin

/

(2) Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft from the

transaxle.

Caution

1. Do not pull on the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damage

the oil seal.

INSPECTION

l Check the hub for cracks and spline

for wear.

l Check the oil seal for damage.

l Check the knuckle for cracks.

l Check for defective bearing.

NOTE

M26icAD

If the meshing of the wheel bearing outer race and the

knuckle, or of the wheel bearing inner race and the hub. is

loose, replace the bearing or damaged parts.

SERVICE POINTS OF INSTALLATIONMZMDAD

9. INSTALLATION OF LOWER ARM BALL JOINT

Lower the vehicle to the ground and tighten the knuckle to

the lower arm ball joint connecting bolt.

3.INSTALLATION OF WASHER/2. DRIVE SHAFT NUT/l.

COTTER PIN

(1) Be sure to install the washer and wheel bearing nut in

the specified direction.

(2) After installing the wheel, lower the vehicle to theground and finally tighten the wheel bearing nut.

(3) If the position of the cotter pin holes does not match, tighten the nut up to 260 Nm (188 ft.lbs.)

in maximum.

(4) Install the cotter pin in the first matching holes and bend it securely.

TSB Revision

Page 839 of 1273

FRONT AXLE - Hub and Knuckle26-9

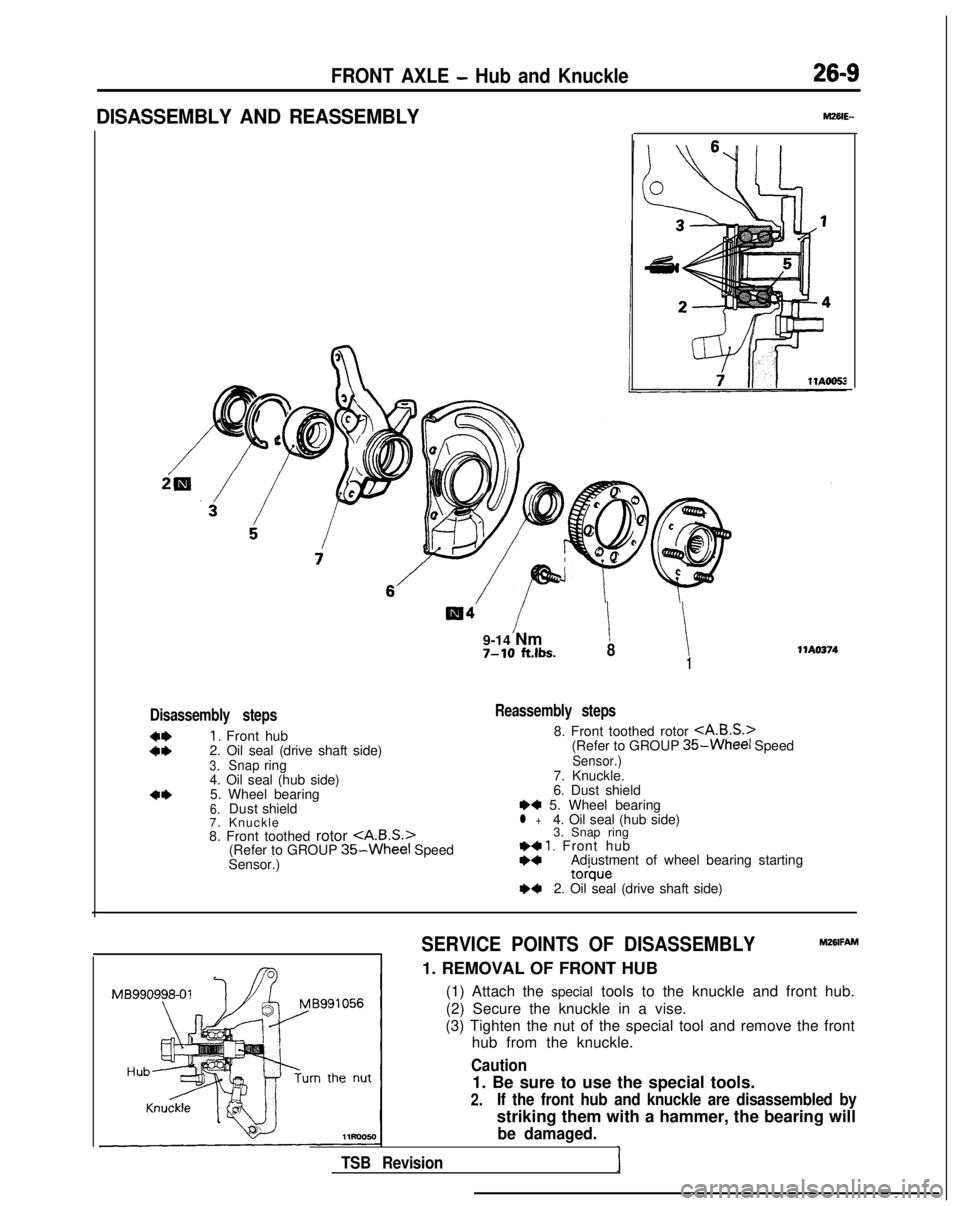

DISASSEMBLY AND REASSEMBLY

9-14 Nm7-10 ft.lbs.i !81

Disassembly steps

::

I. Front hub

2. Oil seal (drive shaft side)

3.Snapring

4. Oil seal (hub side)

4*5. Wheel bearing6.Dust shield

7. Knuckl

e

8. Front toothed rotor

(Refer to GROUP

35-Wheel Speed

Sensor.)

WA0374

Reassembly steps

8. Front toothed rotor

(Refer to GROUP 35-Wheel SpeedSensor.)7. Knuckle.

6. Dust shield

I)+ 5. Wheel bearingl +4. Oil seal (hub side) 3. Snap ring

I)+ 1. Front hubI)*Adiustment of wheel bearing starting torque

I)+2. Oil seal (drive shaft side)

SERVICE POINTS OF DISASSEMBLY

Mz6lFAM

1. REMOVAL OF FRONT HUB (1) Attach the special tools to the knuckle and front hub.

(2) Secure the knuckle in a vise.

(3) Tighten the nut of the special tool and remove the front hub from the knuckle.

Caution

1. Be sure to use the special tools.

2.If the front hub and knuckle are disassembled by

striking them with a hammer, the bearing will

be damaged.

TSB RevisionI

Page 840 of 1273

26-10FRONT AXLE -Hub and Knuckle

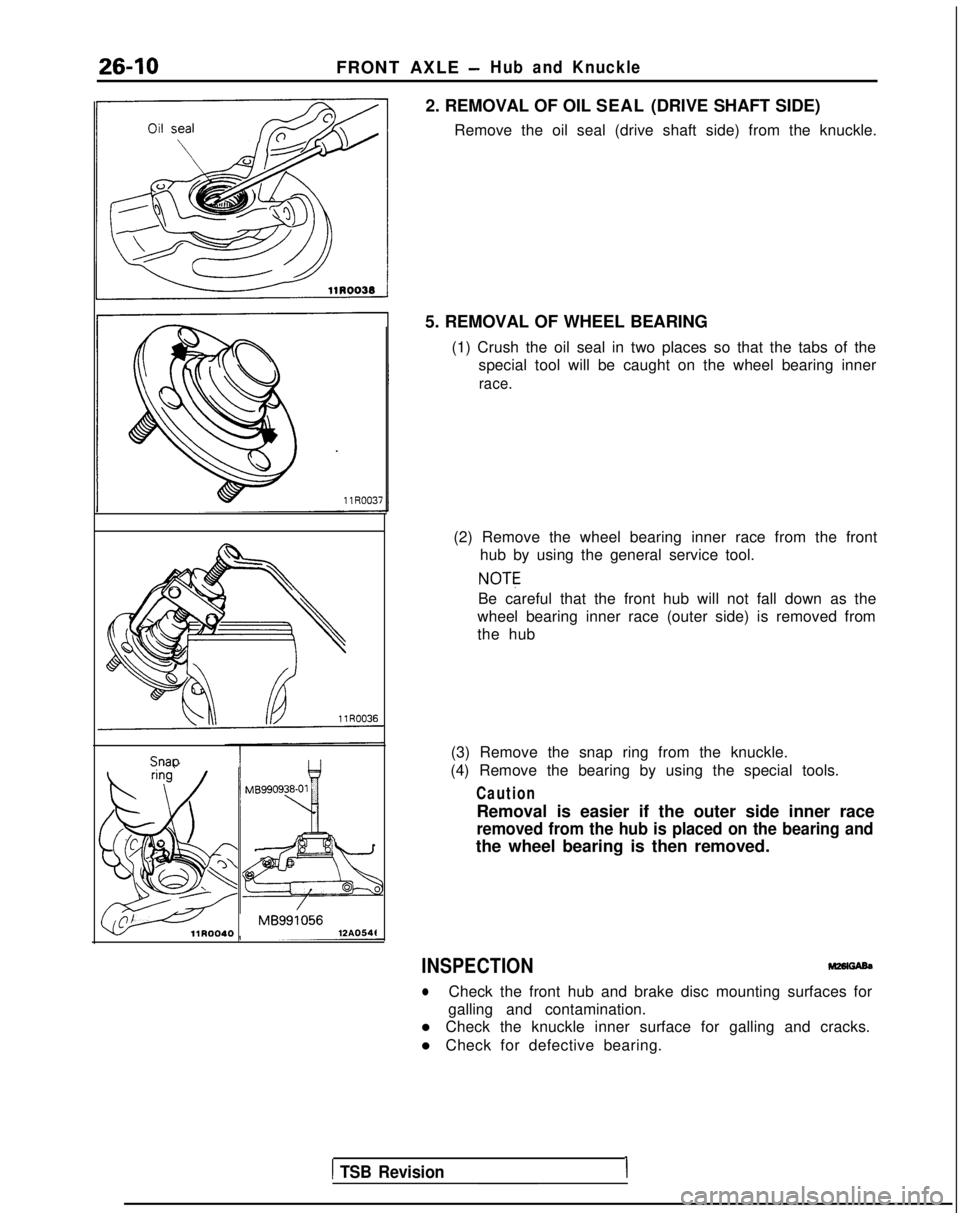

2. REMOVAL OF OIL SEAL (DRIVE SHAFT SIDE)Remove the oil seal (drive shaft side) from the knuckle. Snao

MB991056llROO40

12AO54t5. REMOVAL OF WHEEL BEARING

(1) Crush the oil seal in two places so that the tabs of the special tool will be caught on the wheel bearing inner

race.

(2) Remove the wheel bearing inner race from the fronthub by using the general service tool.

NOTE

Be careful that the front hub will not fall down as the

wheel bearing inner race (outer side) is removed from

the hub

(3) Remove the snap ring from the knuckle.

(4) Remove the bearing by using the special tools.

Caution

Removal is easier if the outer side inner race

removed from the hub is placed on the bearing and

the wheel bearing is then removed.

INSPECTION

lCheck the front hub and brake disc mounting surfaces for

galling and contamination.

l Check the knuckle inner surface for galling and cracks.

l Check for defective bearing.

1 TSB Revision1