MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 931 of 1273

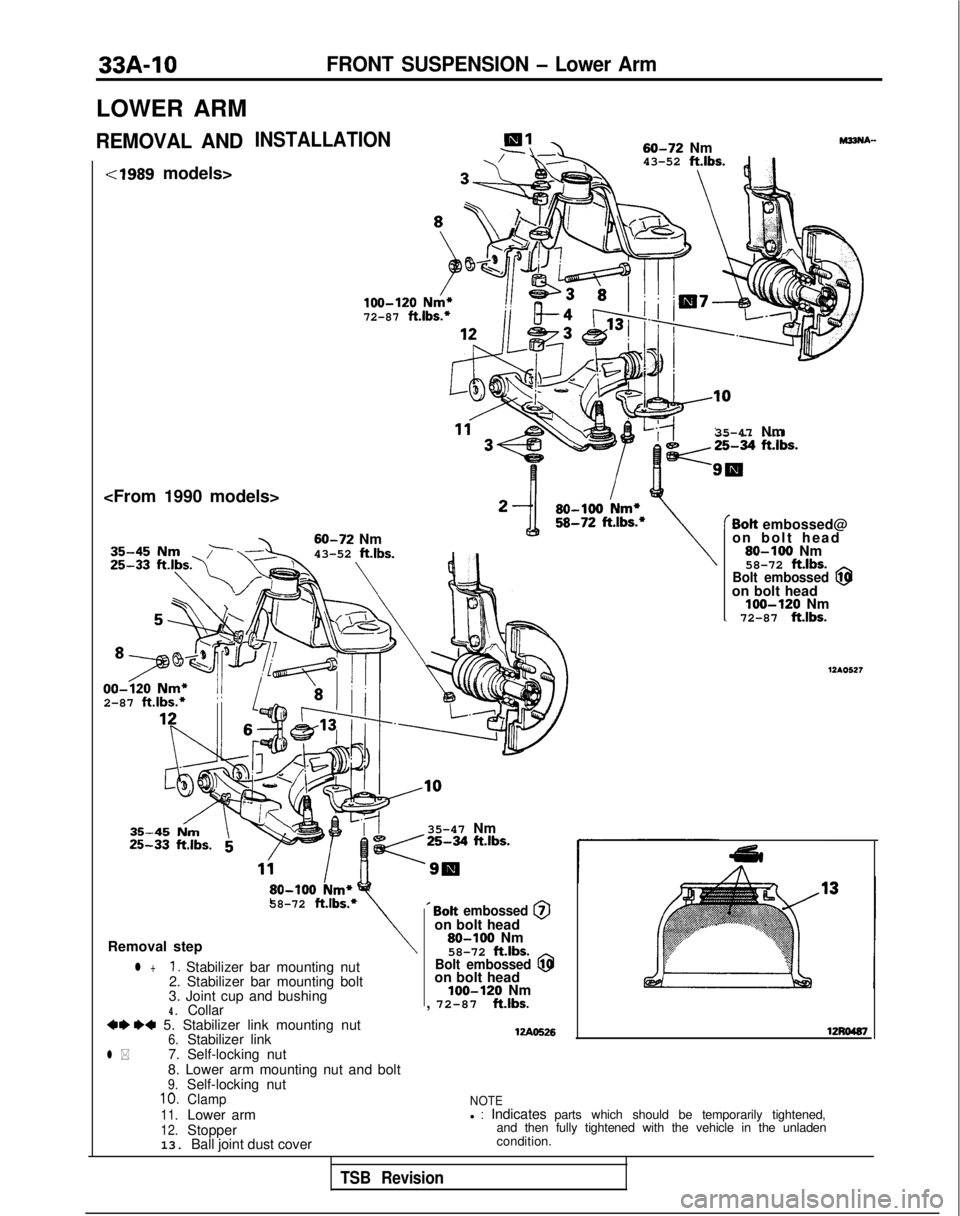

33A-10FRONT SUSPENSION - Lower Arm

LOWER ARM

REMOVAL ANDINSTALLATION

cl989 models>

Nm

43-52 ft.lbs.

;>J$Jj!jQg&

3 -\

(/100-120 Nm*72-87 ft.lbs.*

35-47 Nm

60-72

Nm

43-52

ft.lbs. 00-320

Nm*

2-87 ft.lbs.*

35-47 Nm

/25-34 ft.lbs.

‘9s80-100

km*58-72 ft.lbs.*

Removal step

l +1. Stabilizer bar mounting nut

2. Stabilizer bar mounting bolt

3. Joint cup and bushing

4.Collar4* *a 5. Stabilizer link mounting nut6.Stabilizer linkl *7. Self-locking nut

8. Lower arm mounting nut and bolt

9.Self-locking nut10.Clamp11.Lower arm12.Stopper

13. Ball joint dust cover ’

Bolt embossed @on bolt head

80-100

Nm

58-72

ftlbs.Bolt embossed @on bolt headloo-120 Nm

, 72-87 ft.lbs.

WA0526

(Bolt embossed@

on bolt head

80-100 Nm

58-72 ftlbs.

Bolt embossed @on bolt headloo-120 Nm\ 72-87 ft.lbs.

12AO527

12Ro487

NOTEl : Indicates parts which should be temporarily tightened,

and then fully tightened with the vehicle in the unladen

condition.

TSB Revision

Page 932 of 1273

FRONT SUSPENSION - Lower Arm33A-11

12u00~0

TSB tieviSion

L/&tag and excessive p\ay.

.\

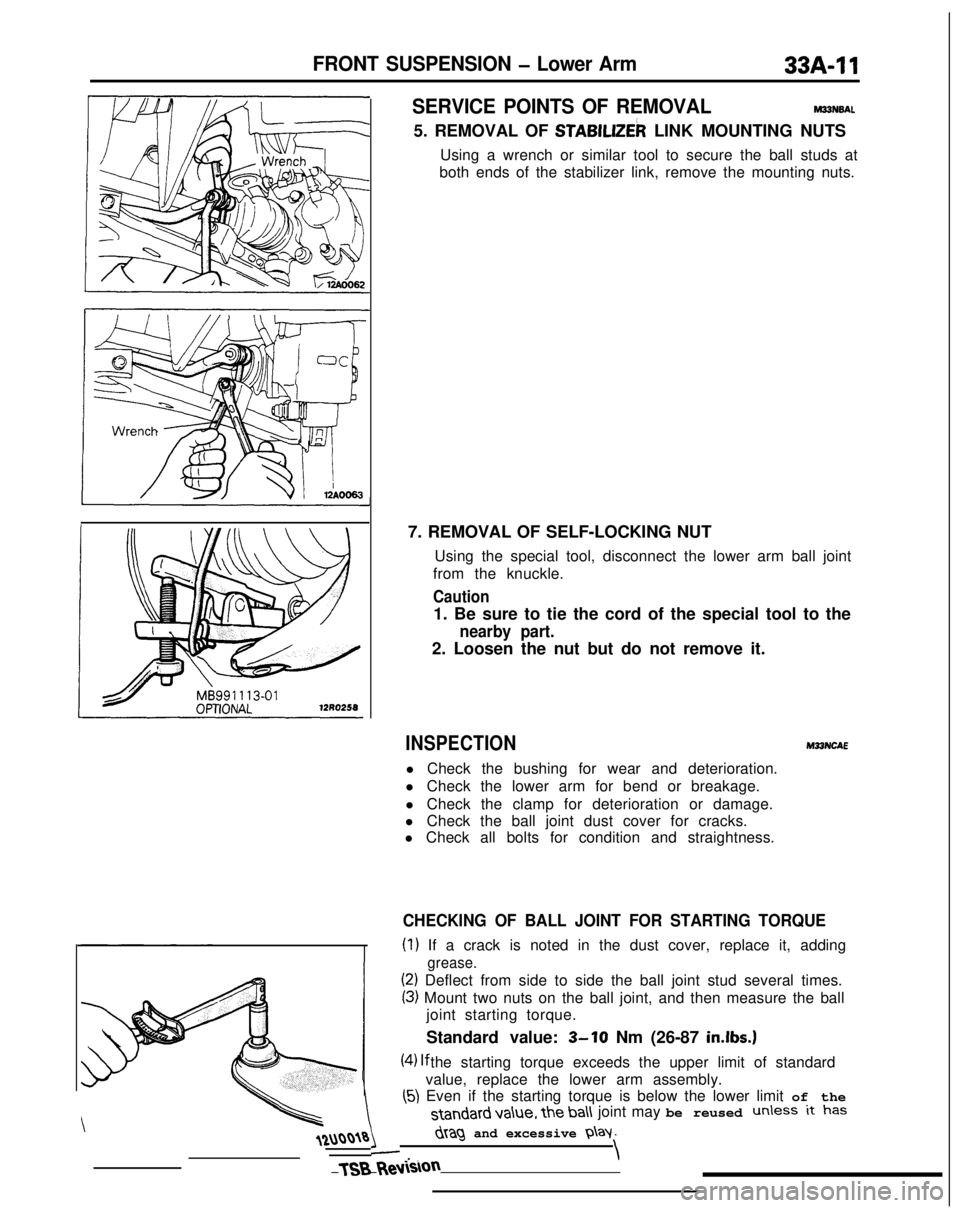

SERVICE POINTS OF REMOVALM33N6AL

5. REMOVAL OF STABlLlZEk LINK MOUNTING NUTS

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, remove the mounting nuts.

7. REMOVAL OF SELF-LOCKING NUT Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

INSPECTIONM33NCAE

l Check the bushing for wear and deterioration.

l Check the lower arm for bend or breakage.

l Check the clamp for deterioration or damage.

l Check the ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

CHECKING OF BALL JOINT FOR STARTING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

grease.

(2) Deflect from side to side the ball joint stud several times.

(3) Mount two nuts on the ball joint, and then measure the ball

joint starting torque.

Standard value:

3-10 Nm (26-87 in.lbs.)

(4) lf the starting torque exceeds the upper limit of standard

value, replace the lower arm assembly.

(5) Even if the starting torque is below the lower limit of the standard va\ue,

the ba\\ joint may be reused unless it has

Page 933 of 1273

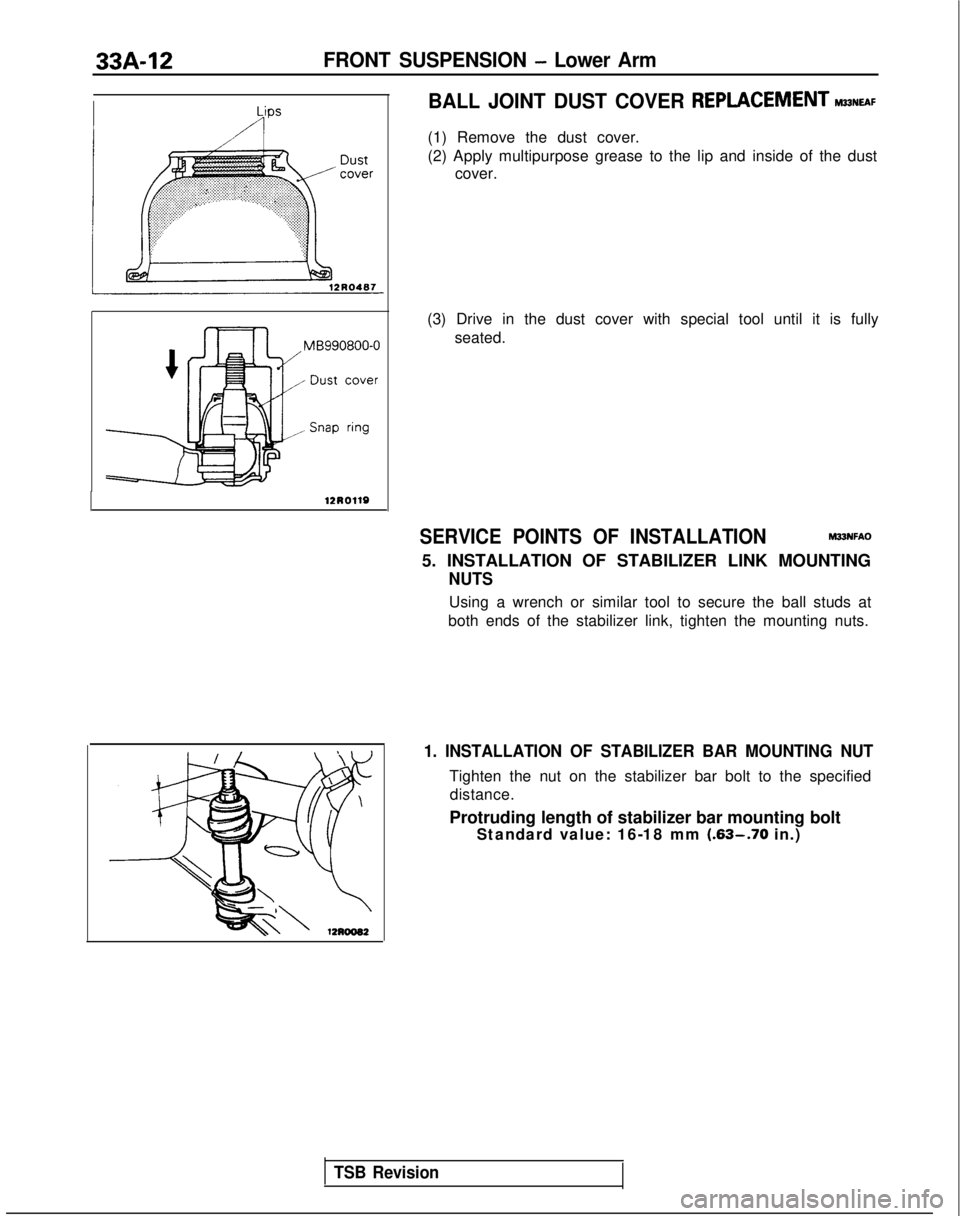

33/b12FRONT SUSPENSION - Lower Arm

BALL JOINT DUST COVER

REPLACEMENTM~~NEAF

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust cover.

(3) Drive in the dust cover with special tool until it is fully seated.

SERVICE POINTS OF INSTALLATIONM33NFAO

5. INSTALLATION OF STABILIZER LINK MOUNTING

NUTS

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, tighten the mounting nuts.

TSB Revision 1. INSTALLATION OF STABILIZER BAR MOUNTING NUT

Tighten the nut on the stabilizer bar bolt to the specified

distance.

Protruding length of stabilizer bar mounting bolt Standard value: 16-18 mm

(.63-.70 in.)

Page 934 of 1273

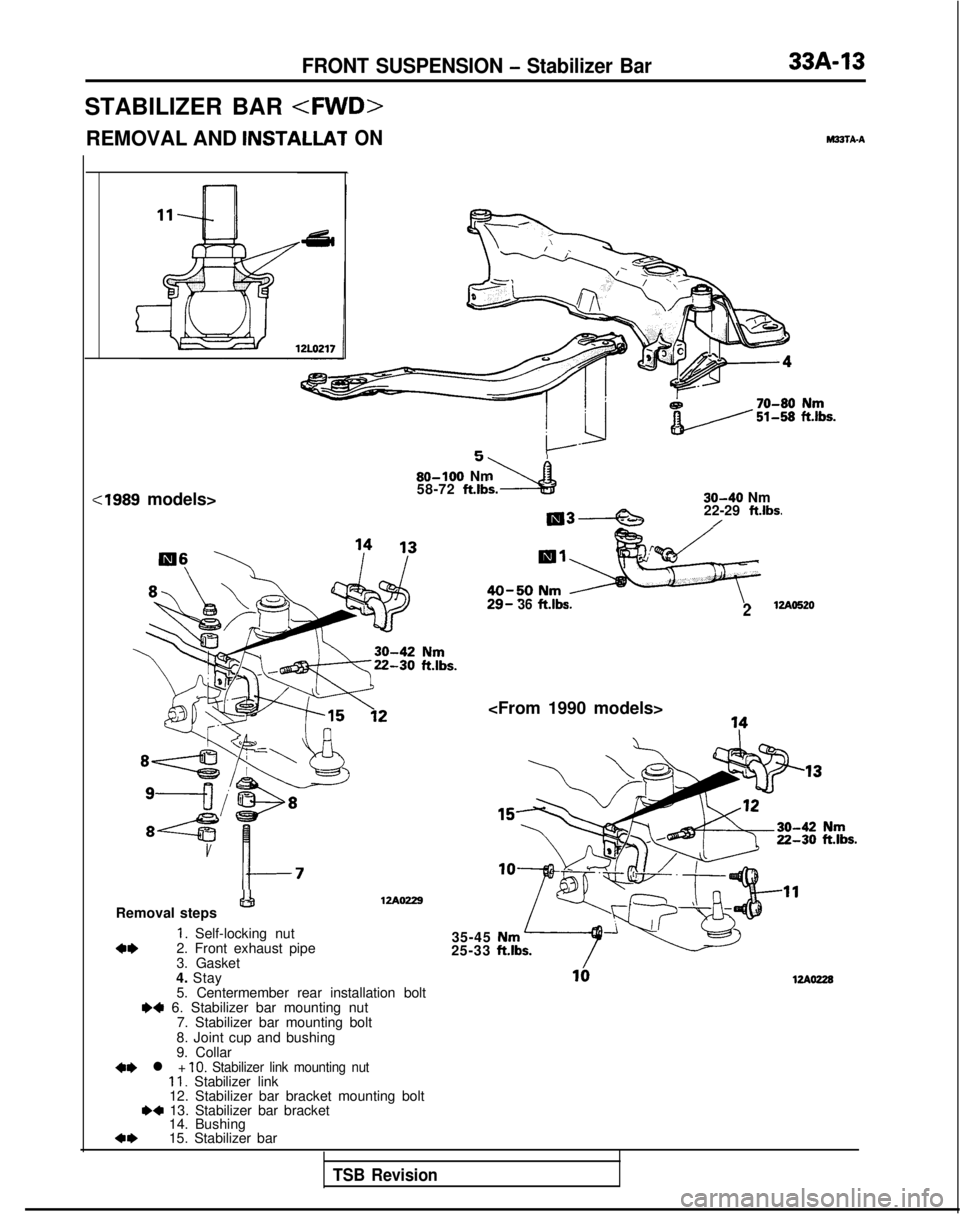

FRONT SUSPENSION - Stabilizer Bar

STABILIZER BAR

cl989 models>

P

80-100 Nm%?58-72 ft.lbs.30-40 Nm

22-29 ftlbs./

Removal steps&!I

1. Self-locking nuta*2. Front exhaust pipe

3. Gasket

29- 36ft.lbs.2

12Ao229

4. Stay 5. Centermember rear installation bolt

W 6. Stabilizer bar mounting nut 7. Stabilizer bar mounting bolt

8. Joint cup and bushing

9. Collar

+e l + 10. Stabilizer link mounting nut11. Stabilizer link

12. Stabilizer bar bracket mounting bolt

.+ 13. Stabilizer bar bracket 14. Bushing

*I)15. Stabilizer bar 35-45

25-33

UAW28

TSB Revision

Page 935 of 1273

33A-14

FRONT SUSPENSION - Stabilizer Bar

N-

;/fO’)/ --

Wire ’

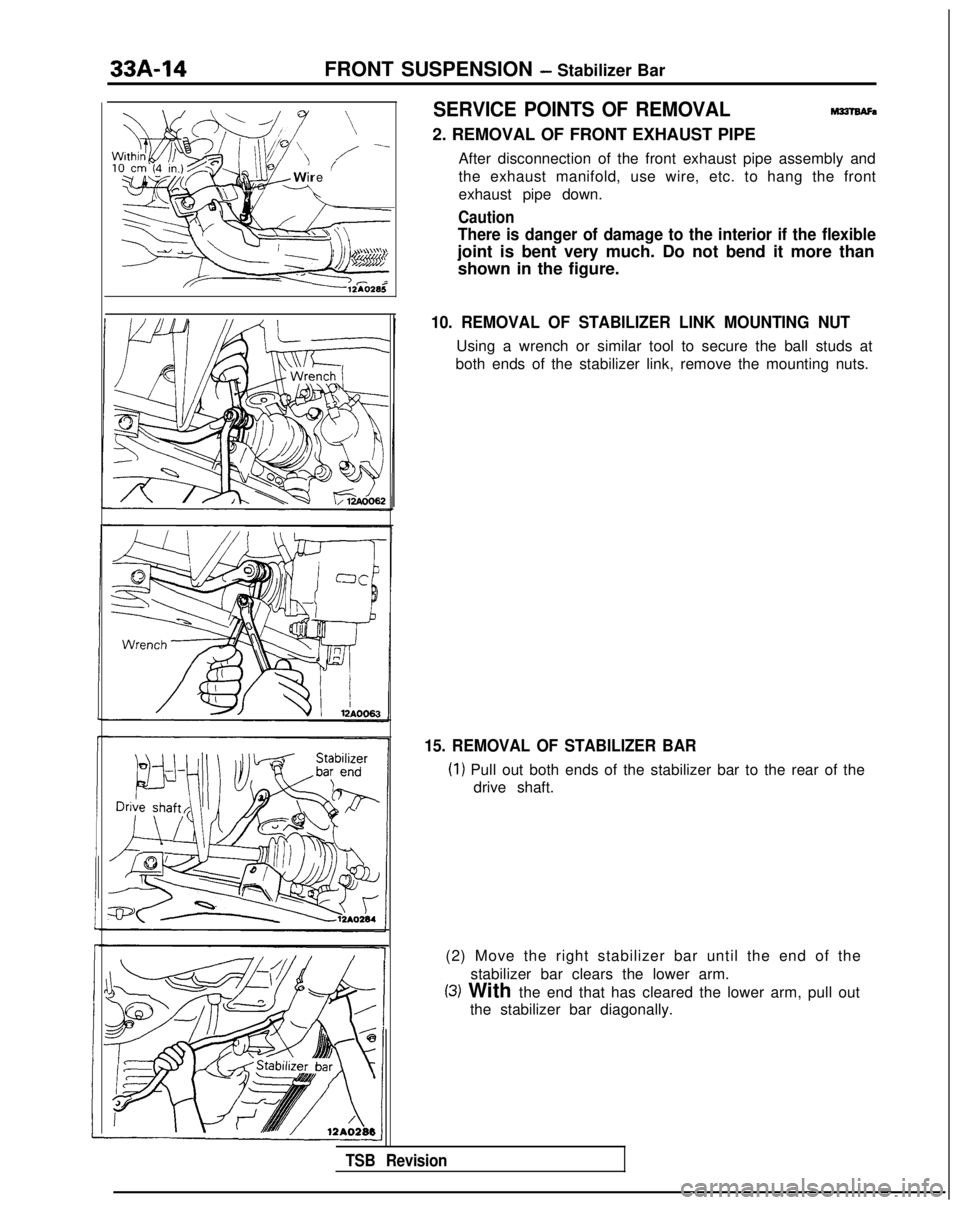

SERVICE POINTS OF REMOVALMalBAFa

2. REMOVAL OF FRONT EXHAUST PIPE

After disconnection of the front exhaust pipe assembly and

the exhaust manifold, use wire, etc. to hang the front

exhaust pipe down.

Caution

There is danger of damage to the interior if the flexible

joint is bent very much. Do not bend it more thanshown in the figure.

10. REMOVAL OF STABILIZER LINK MOUNTING NUT

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, remove the mounting nuts.

15. REMOVAL OF STABILIZER BAR

(1) Pull out both ends of the stabilizer bar to the rear of the drive shaft.

(2) Move the right stabilizer bar until the end of the stabilizer bar clears the lower arm.

(3) With the end that has cleared the lower arm, pull outthe stabilizer bar diagonally.

TSB Revision

Page 936 of 1273

FRONT SUSPENSION - Stabilizer Bar 33A-15

12LO244

rpose

12LO217

lZLO242

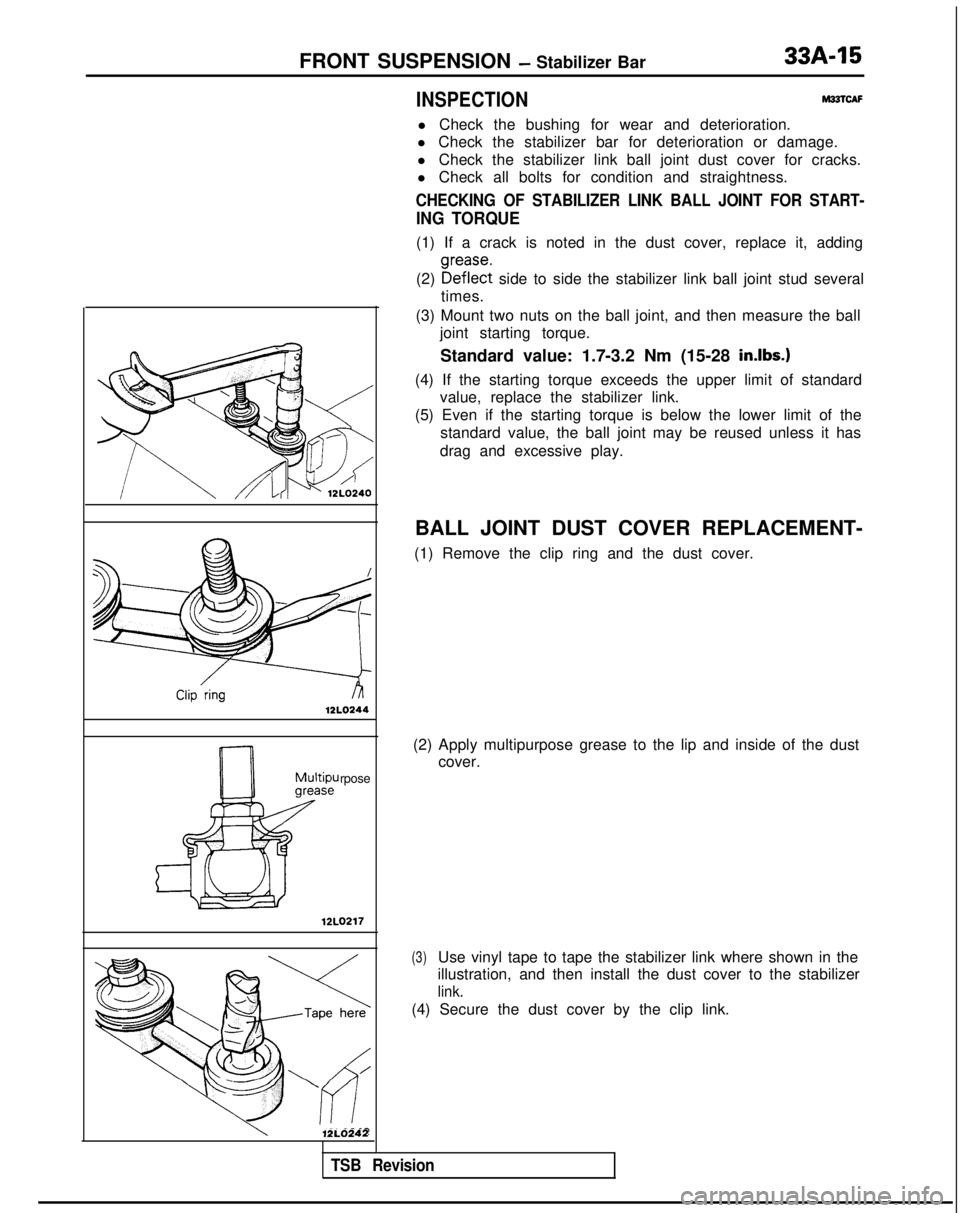

INSPECTIONM22lCAF

l Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage.

l Check the stabilizer link ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

CHECKING OF STABILIZER LINK BALL JOINT FOR START-

ING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

(2)

!%% side to side the stabilizer link ball joint stud several

times.

(3) Mount two nuts on the ball joint, and then measure the ball joint starting torque.

Standard value: 1.7-3.2 Nm (15-28

in.lbs.1

(4) If the starting torque exceeds the upper limit of standard value, replace the stabilizer link.

(5) Even if the starting torque is below the lower limit of the standard value, the ball joint may be reused unless it has

drag and excessive play.

BALL JOINT DUST COVER REPLACEMENT-

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust cover.

(3)Use vinyl tape to tape the stabilizer link where shown in the

illustration, and then install the dust cover to the stabilizer

link.

(4) Secure the dust cover by the clip link.

TSB Revision

Page 937 of 1273

33A-16FRONT SUSPENSION - Stabilizer Bar

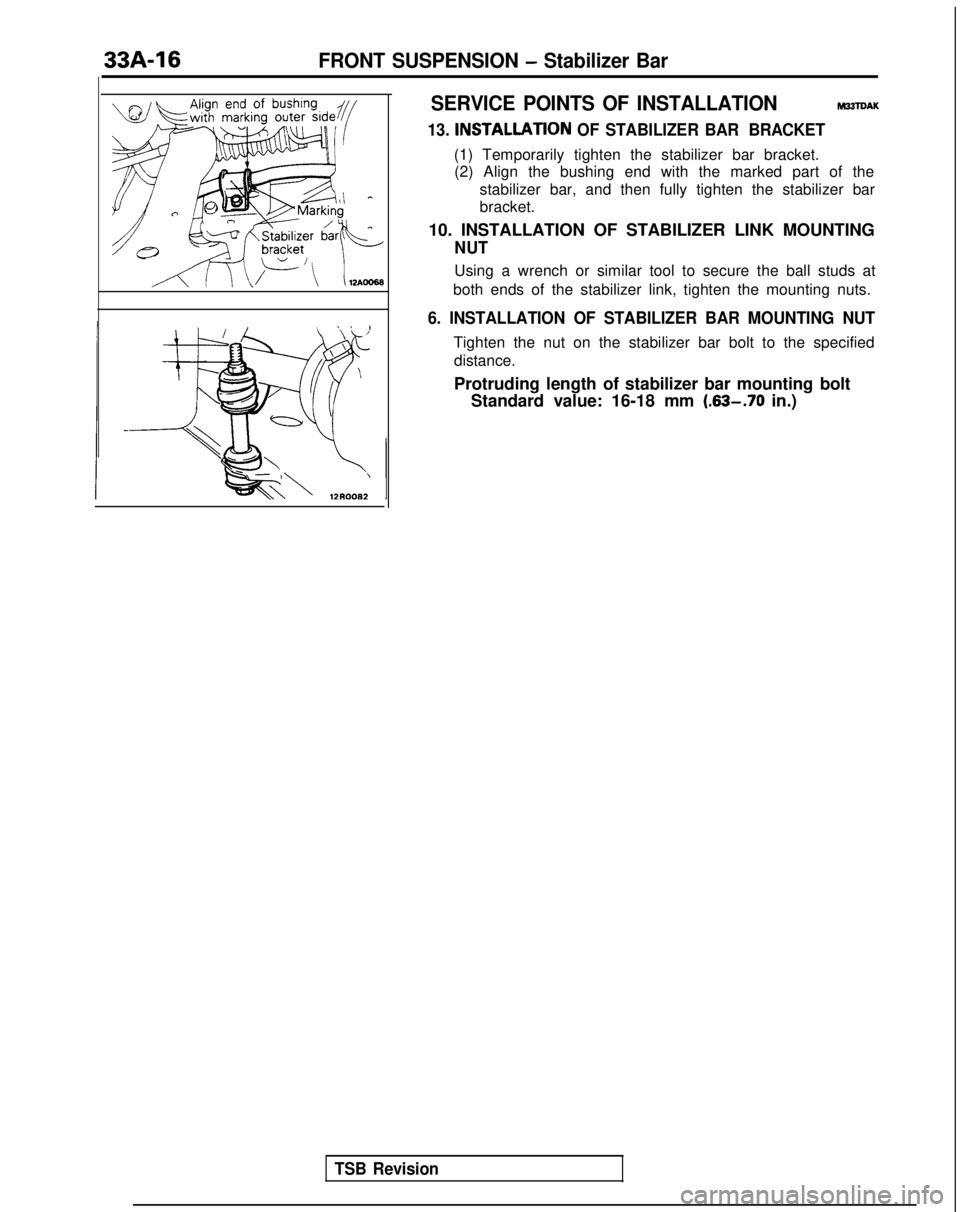

SERVICE POINTS OF INSTALLATION

M33TDAK

13. INSTALLATlON OF STABILIZER BAR BRACKET

(1) Temporarily tighten the stabilizer bar bracket.

(2) Align the bushing end with the marked part of the

stabilizer bar, and then fully tighten the stabilizer bar

bracket.

10. INSTALLATION OF STABILIZER LINK MOUNTING

NUT

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, tighten the mounting nuts.

6. INSTALLATION OF STABILIZER BAR MOUNTING NUT

Tighten the nut on the stabilizer bar bolt to the specified distance.

Protruding length of stabilizer bar mounting bolt Standard value: 16-18 mm (.63-.70

in.)

TSB Revision

Page 938 of 1273

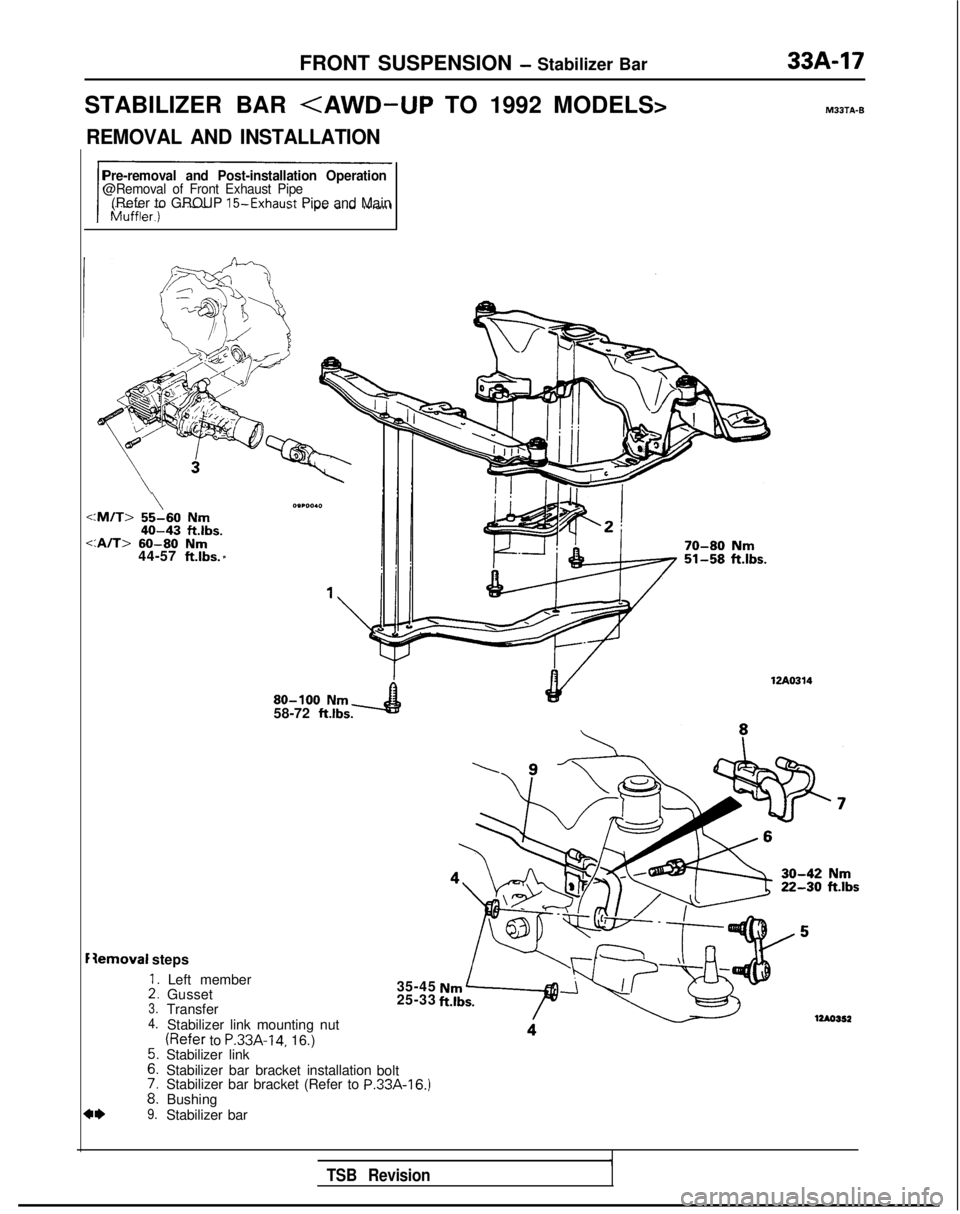

FRONT SUSPENSION - Stabilizer Bar

STABILIZER BAR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation@Removal of Front Exhaust Pipe(Refer to GROUP 15-Exhaust Pipe and Main

\:M/T> 55-60 Nm40-43 ftlbs.

:A/T>

60-80 Nm44-57 ft.lbs. *

Iemoval steps

::3.4.

::

i:9.

Left member

Gusset

Transfer

Stabilizer link mounting nut

(Refer to P.33A-14, 16.)

Stabilizer link

Stabilizer bar bracket installation

Stabilizer bar bracket (Refer to

PBushing

Stabilizer bar 80-100

Nm58-72 ftlbs.

35-45

25-33

bolt

.33A-16.)

70-80 Nm51-58 ftlbs. MBJTA-B

-42

Nmiik.30 ft.lbs

TSB Revision

Page 939 of 1273

33A-18FRONT SUSPENSION - Stabilizer Bar

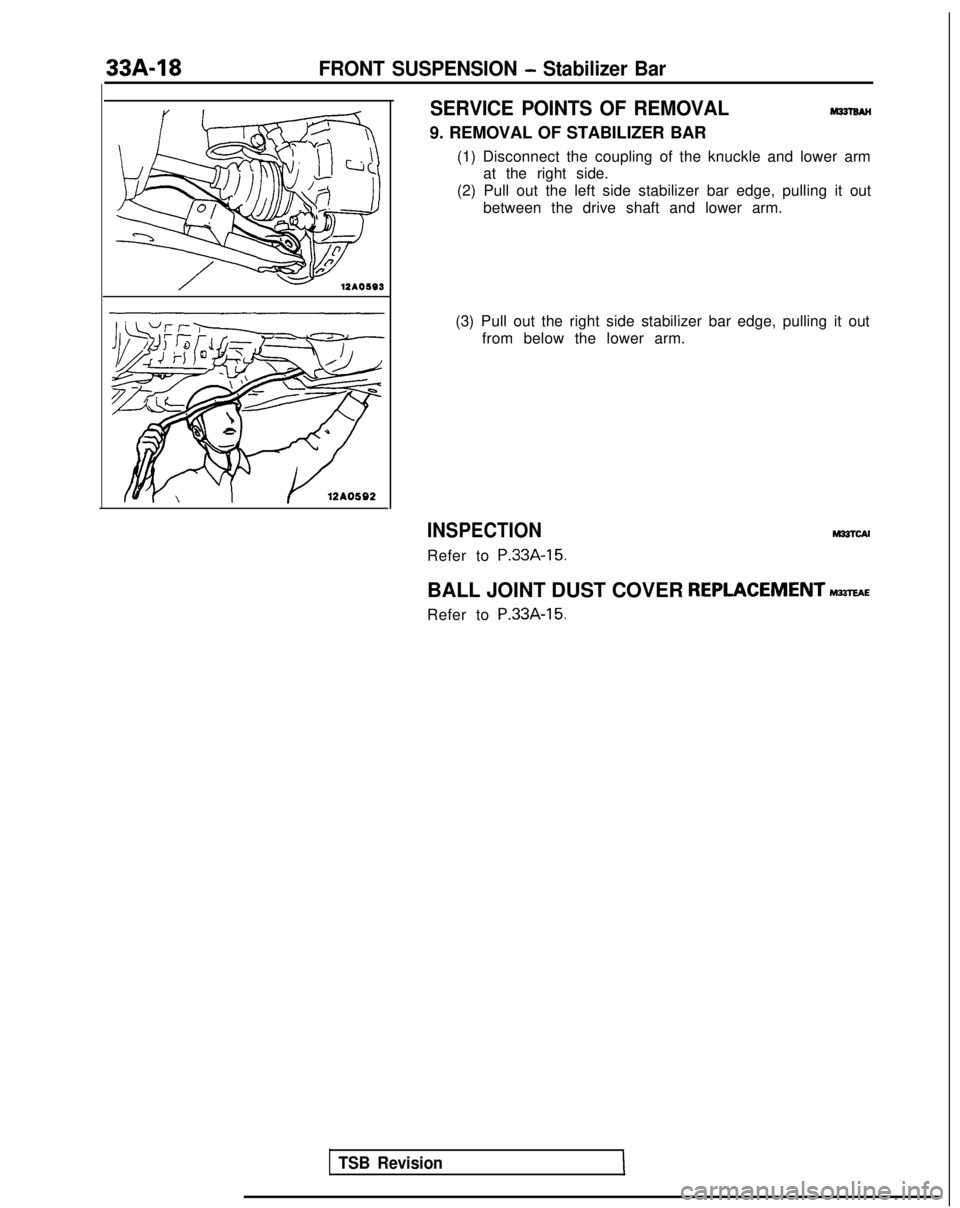

SERVICE POINTS OF REMOVAL

9. REMOVAL OF STABILIZER BAR (1) Disconnect the coupling of the knuckle and lower armat the right side.

(2) Pull out the left side stabilizer bar edge, pulling it out between the drive shaft and lower arm.

(3) Pull out the right side stabilizer bar edge, pulling it out from below the lower arm.

INSPECTION

Refer to P.33A-15.

hl33lcAI

BALL JOINT DUST COVER REPLACEMENTM~E

Refer to P.33A-15.

TSB Revision

Page 940 of 1273

339-l

ACTIVE-ELECTRONIC

CONTROL

SUSPENSION

ACTIVE-ECS RELAY......................................141

ACTIVE-ECSSENSOR.................................. 138

AIRCOMPRESSOR.......................................125

AIR TUBE.......................................................133

CONTROLUNIT............................................ 140

HEIGHT SENSOR ..........................................

135

INDICATORASSEMBLY............................... 140

LATERALROD...............................................117

LOWER

ARM.................................................103

REAR

SUSPENSION ASSEMBLY................114

RESERVETANK............................................ 122

SERVICE ADJUSTMENT PROCEDURES.....86

Alarm Light Check.....................................87

Checking by On-board Diagnostic ..............88

FrontWheelAlignment .............................. 86

G sensor Output Voltage Check ...............96

High-pressure Switch

(High-pressure Tank Side)

Actuation Pressure Check

.......................... 94

Hub End Play Inspection ...........................86 M33AA-

Low-pressure Switch

(Low-pressure Tank Side)

Actuation

PressureCheck . . . . . . . . . . . . . . . . . . . . . . . . .95

Normal Vehicle Height Check and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . .88

Rolling Diaphragm Check . . . . . . . . . . .._.............. 89

System Checking by Using Alarm

Light

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . .87

System OperationCheck . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Wheel Bearing Adjustment . . . . . . . . . .

.._........... 87

SHOCKABSORBER ASSEMBLY. . . . . . . . . . . . . . . . .110

SOLENOIDVALVEANDDRYER . . . . . . . . . . . . . . . . .127

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .2

GeneralSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ServiceSpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . .3

TorqueSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .106

STRUT ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . .97

TORSION AXLE AND ARM

ASSEMBLY. . . . . . . . ..*.........................................119,

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10