MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 941 of 1273

33B-2ACTIVE-ELECTRONIC CONTROL SUSPENSION - Specifications

SPECIFICATIONSM33CA-

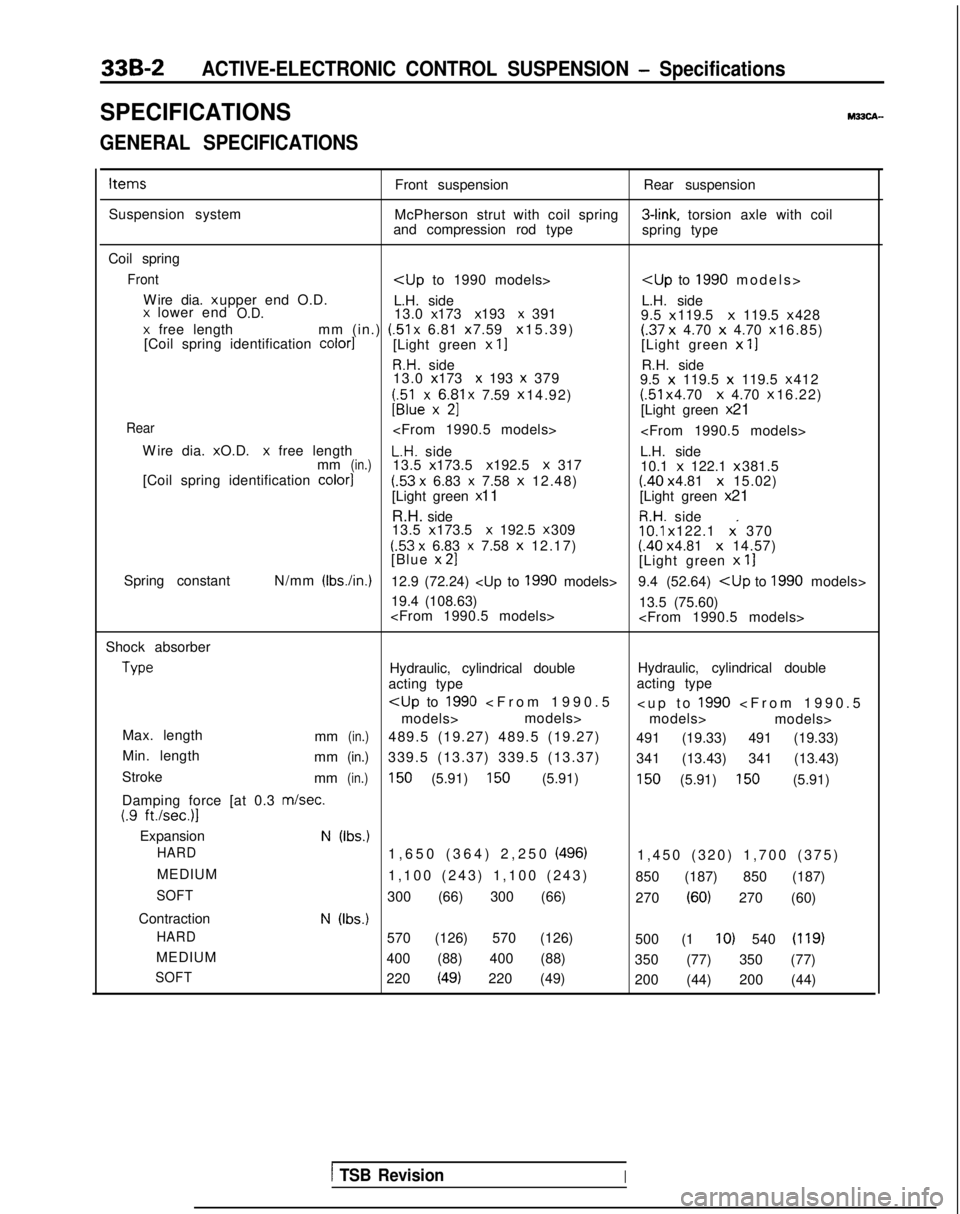

GENERAL SPECIFICATIONS

ItemsFront suspensionRear suspension

Suspension system McPherson strut with coil spring 3-link,

torsion axle with coil

and compression rod type spring type

Coil spring

Front

Wire dia. x upper end O.D.

L.H. side L.H. side

x lower endO.D.13.0 x 173 x 193 x 391

9.5 x 119.5 x

119.5 x 428x free length

mm (in.) (51

x 6.81 x 7.59 x 15.39)(.37

x

4.70 x 4.70 x 16.85)

[Coil spring identification color1[Light green x II[Light green x

11

R.H. side R.H. side

13.0 x 173 x 193 x 379

9.5 x

119.5 x

119.5 x 412

;;lexx6$1 x 7.59

x 14.92) (51

x 4.70 x

4.70 x 16.22)U[Light green

x 21

Rear

W

ire dia. x O.D.

x free lengthL.H. side

L.H. side

mm(in.)13.5 x 173.5 x 192.5 X 317

10.1 x

122.1 x 381.5

[Coil spring identification color]

(.53 x 6.83 x 7.58

x

12.48)(.40 x 4.81 x

15.02)

[Light green x 11

[Light green x 21

R.H. side

R.H. side

13.5 x 173.5 x 192.5 x 30910.1

x 122.1 x. 370(53 x 6.83 x 7.58

x

12.17)(.40 x 4.81 x

14.57)

[Blue x 21[Light green

x

11

Spring constant N/mm (Ibs./in.)12.9 (72.24)

19.4 (108.63) 13.5 (75.60)

Shock absorber Type

Hydraulic, cylindrical double

Hydraulic, cylindrical double

acting type acting type

models> models>

models> models>

Max. length mm

(in.)489.5 (19.27) 489.5 (19.27) 491 (19.33) 491 (19.33)

Min. length mm

(in.)339.5 (13.37) 339.5 (13.37) 341 (13.43) 341 (13.43)

Stroke mm

(in.)150 (5.91) 150 (5.91)150 (5.91) 150 (5.91)

Damping force [at 0.3

m/set.(.9 ft./sec.)l

ExpansionN (Ibs.)

HARD

1,650 (364) 2,250 (496)1,450 (320) 1,700 (375

)

MEDIUM 1,100 (243) 1,100 (243) 850 (187) 850 (187)

SOFT300 (66) 300 (66) 270 (60) 270 (60)

Contraction

N (Ibs.)

HARD

570 (126) 570 (126) 500 (1 IO) 540 (119)

MEDIUM400 (88) 400 (88) 350 (77) 350 (77)

SOFT220 (49) 220 (49)200 (44) 200 (44)

1 TSB RevisionI

Page 942 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Specifications33B-3

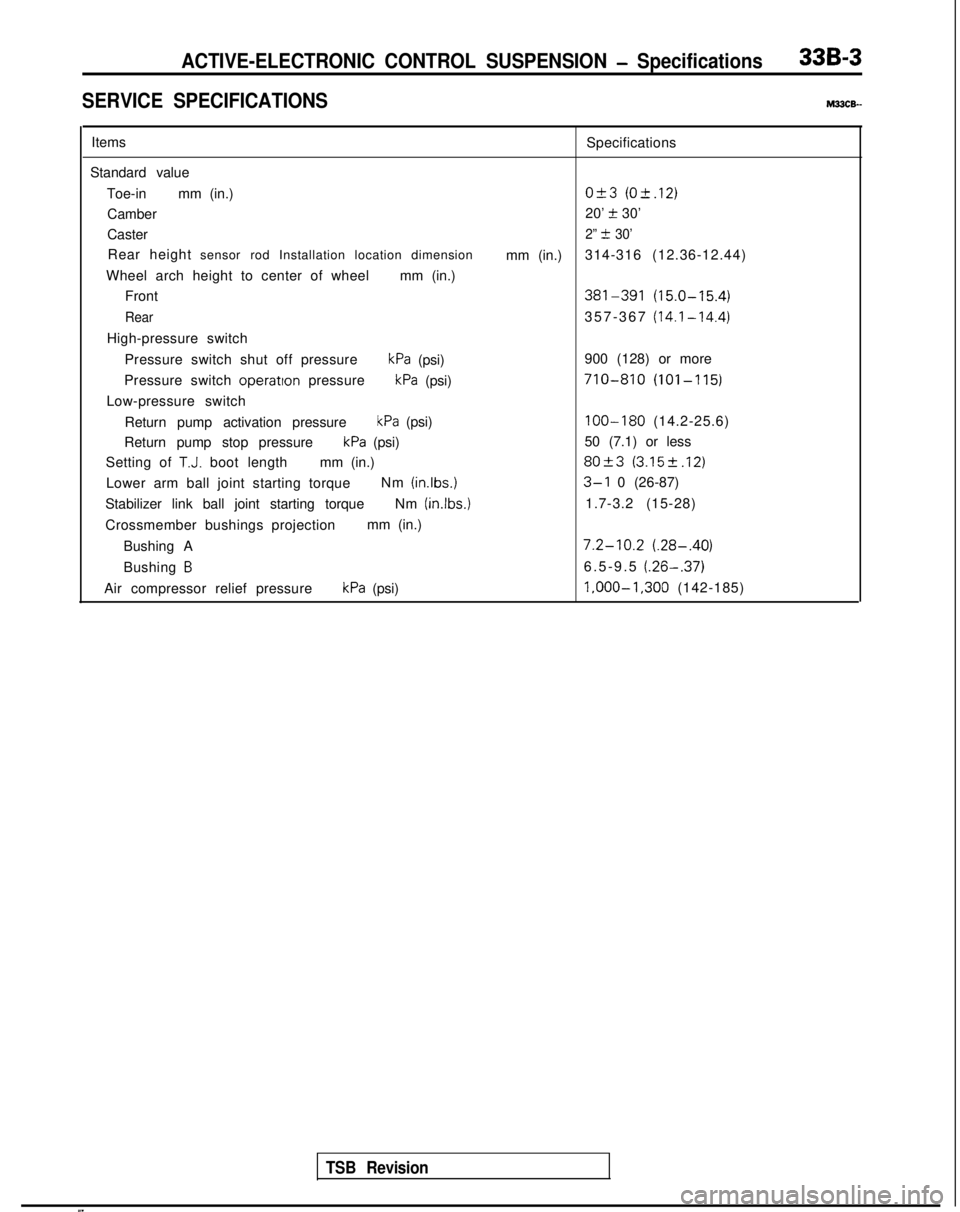

SERVICE SPECIFICATIONSM33cE-

ItemsSpecifications

Standard value Toe-in mm (in.)

O&3 (O-t.12)

Camber 20’ t 30’

Caster

2” t 30’

Rear height sensor rod Installation location dimension

mm (in.)314-316 (12.36-12.44)

Wheel arch height to center of wheel mm (in.)

Front

381-391 (15.0-15.4)

Rear357-367 (14.1-14.4)

High-pressure switch

Pressure switch shut off pressure

kPa (psi) 900 (128) or more

Pressure switch operatton

pressure

kPa (psi)710-810 (101-115)

Low-pressure switch

Return pump activation pressure

kPa (psi)100-180 (14.2-25.6)

Return pump stop pressure

kPa (psi) 50 (7.1) or less

Setting of

T.J. boot length mm (in.)80+3 (3.152.12)

Lower arm ball joint starting torque Nm (inlbs.)3-l 0 (26-87)

Stabilizer link ball joint starting torque Nm (in.lbs.)

1.7-3.2 (15-28)

Crossmember bushings projection mm (in.)

Bushing A

7.2-10.2 (.28-.40)

Bushing B6.5-9.5 (.26-.37)

Air compressor relief pressurekPa (psi) l,OOO-1,300

(142-185)

TSB Revision

Page 943 of 1273

33B-4ACTIVE-ELECTRONIC CONTROL SUSPENSION - Specifications

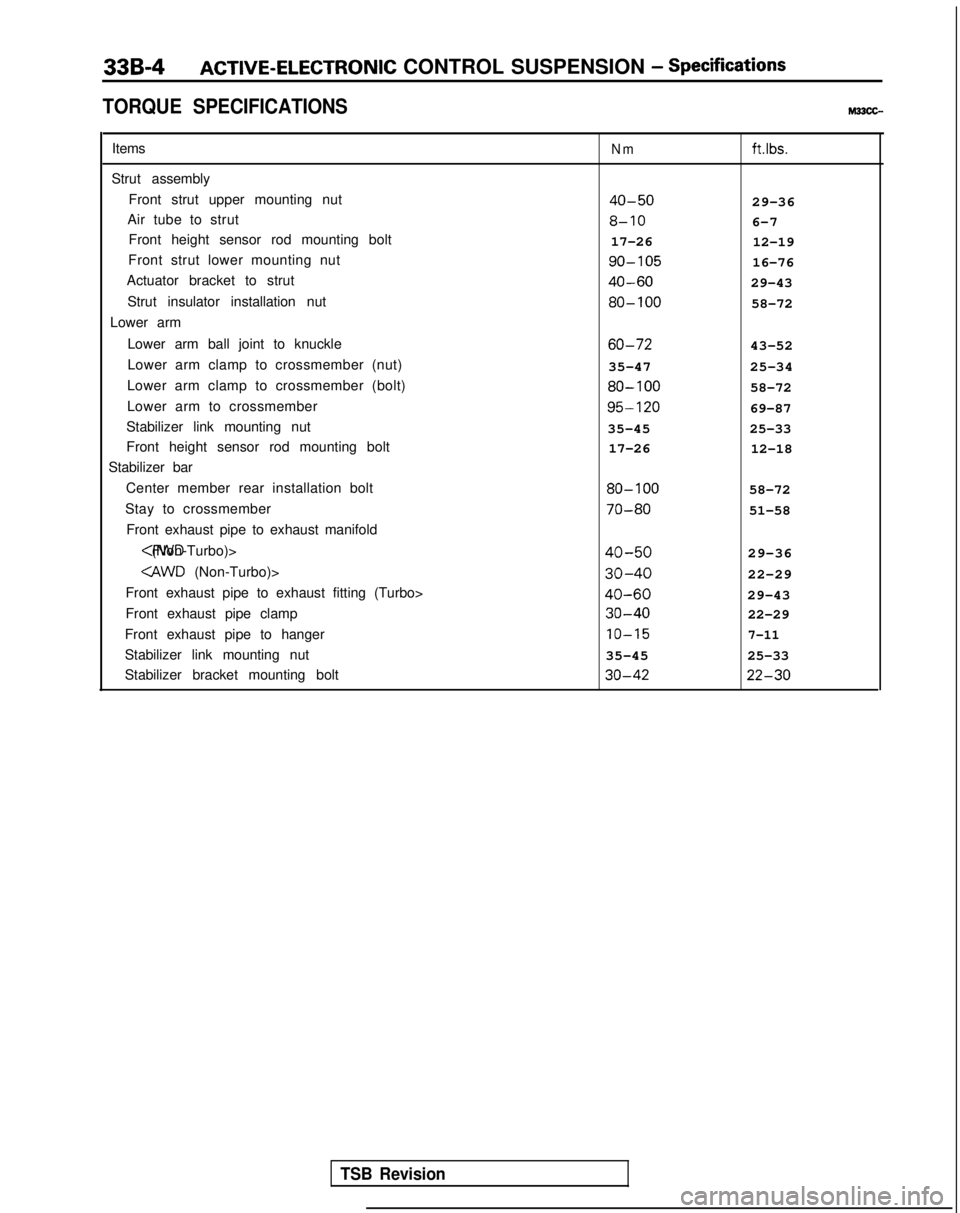

TORQUE SPECIFICATIONS

Items

Strut assembly Front strut upper mounting nut

Air tube to strut Front height sensor rod mounting bolt

Front strut lower mounting nut

Actuator bracket to strut

Strut insulator installation nut

Lower arm

Lower arm ball joint to knuckle

Lower arm clamp to crossmember (nut)

Lower arm clamp to crossmember (bolt)

Lower arm to crossmember

Stabilizer link mounting nut

Front height sensor rod mounting bolt

Stabilizer bar

Center member rear installation bolt

Stay to crossmember Front exhaust pipe to exhaust manifold

Front exhaust pipe to exhaust fitting (Turbo>

Front exhaust pipe clamp

Front exhaust pipe to hanger

Stabilizer link mounting nut

Stabilizer bracket mounting boltNmftlbs.

40-5029-36

8-106-7

17-26 12-19 go-105

16-76

40-6029-43 80-100

58-72 60-72

43-52

35-47 25-34 80-100

58-72 95-120

69-87

35-45 25-33

17-26 12-18 80-100

58-72 70-80

51-58

40-5029-36

30-4022-29

40-6029-43 30-40

22-29 IO-15

7-11

35-45

25-33 30-42 22-30

TSB Revision

Page 944 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Specifications33B-5

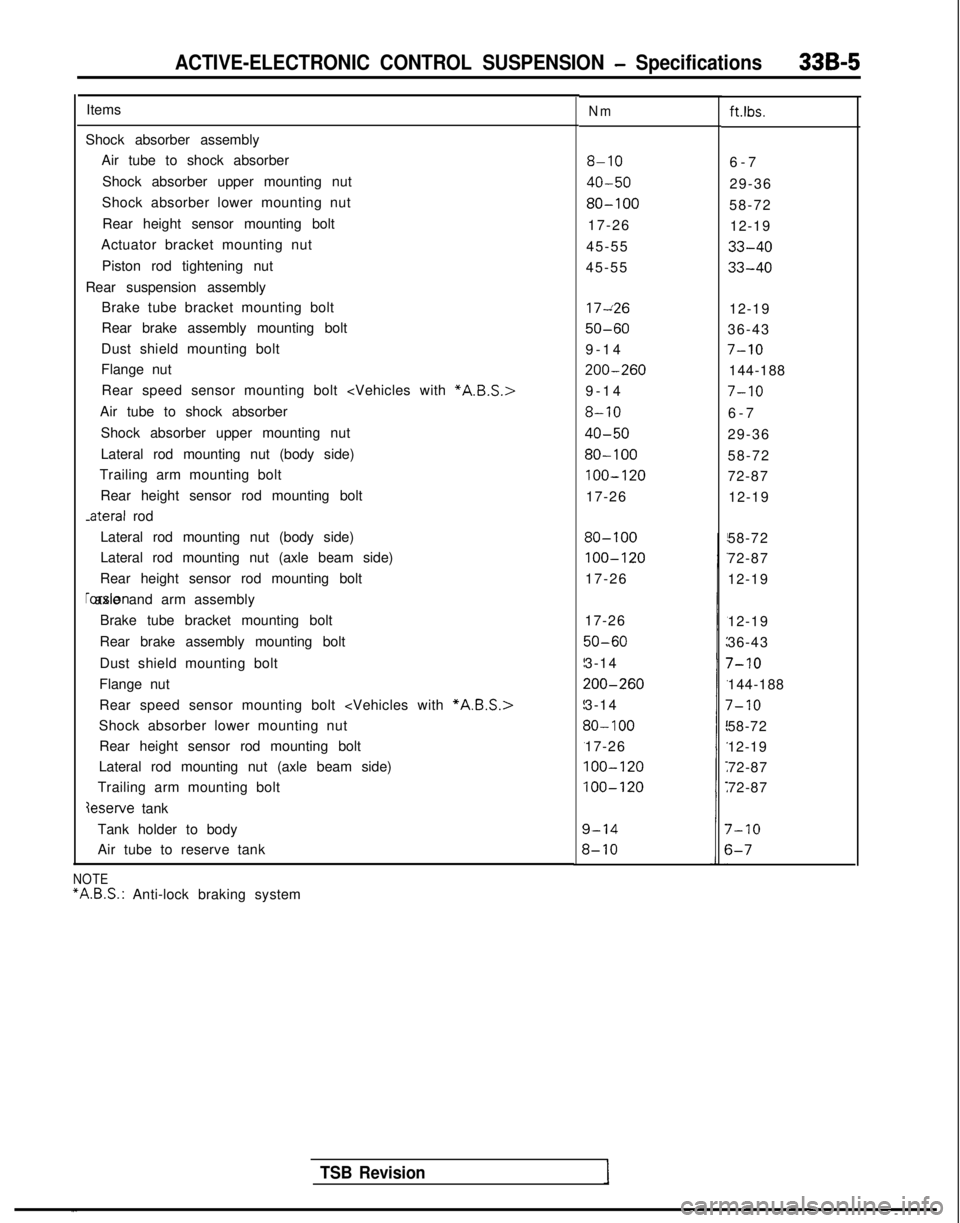

ItemsNmft.lbs.

Shock absorber assemblyAir tube to shock absorber

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Rear height sensor mounting bolt

Actuator bracket mounting nut

Piston rod tightening nut

Rear suspension assembly Brake tube bracket mounting bolt

Rear brake assembly mounting bolt

Dust shield mounting bolt

Flange nut

8-106-

7

40-5029-36

80-10058-72

17-26 12-19

45-55

33-40

45-5533-40

Rear speed sensor mounting bolt

Air tube to shock absorber

Shock absorber upper mounting nut

Lateral rod mounting nut (body side)

Trailing arm mounting bolt

Rear height sensor rod mounting bolt -ateral

rod 17~26

12-19

50-6036-43

9-1

4

7-10

200-260144-188

9-1

4

7-10

8-106-

7

40-5029-36

80-10058-72

100-12072-87

17-26 12-19

Lateral rod mounting nut (body side)

Lateral rod mounting nut (axle beam side)

Rear height sensor rod mounting bolt rorsion axle and arm assembly

Brake tube bracket mounting bolt

Rear brake assembly mounting bolt

Dust shield mounting bolt

Flange nut

80-100

100-120

17-26 58-72

72-87

12-19

Rear speed sensor mounting bolt

Shock absorber lower mounting nut Rear height sensor rod mounting bolt

Lateral rod mounting nut (axle beam side)

Trailing arm mounting bolt

deserve tank 17-26

50-60

3-14

200-260

3-14

30- 100

17-26

100-120

100-120

12-19

36-43

7-10

144-188

7-10

58-72

12-19

72-87

72-87

Tank holder to body

Air tube to reserve tank

7-10

s-7

TSB Revision

NOTE “A.B.S.:

Anti-lock braking system

Page 945 of 1273

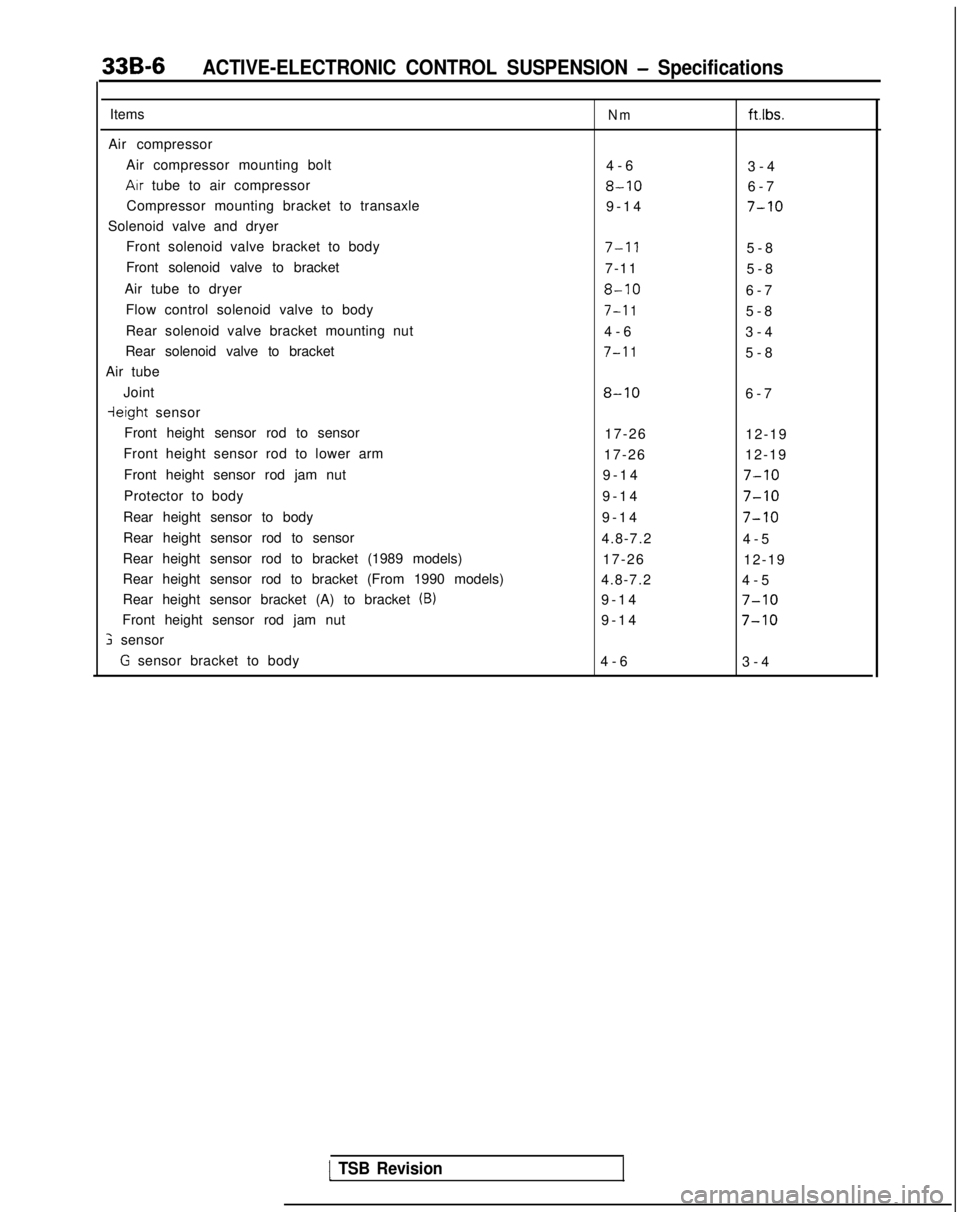

33B-6ACTIVE-ELECTRONIC CONTROL SUSPENSION - Specifications

Items

Air compressor Air compressor mounting bolt

Arr tube to air compressor

Compressor mounting bracket to transaxle

Solenoid valve and dryer Front solenoid valve bracket to body

Front solenoid valve to bracket

Air tube to dryer Flow control solenoid valve to body

Rear solenoid valve bracket mounting nut

Rear solenoid valve to bracket

Air tube

Joint

ieight sensor

Front height sensor rod to sensor

Front height sensor rod to lower arm

Front height sensor rod jam nut

Protector to body

Rear height sensor to body

Rear height sensor rod to sensor

Rear height sensor rod to bracket (1989 models)

Rear height sensor rod to bracket (From 1990 models)

Rear height sensor bracket (A) to bracket

(B)

Front height sensor rod jam nut

; sensor

G sensor bracket to body

Nmftlbs.

4-

6

3-4

8-106-

7

9-14

7-10

7-l 15-

8

7-11 5-8

8-106-

7

7-l 15-

8

4-6 3-4

7-l 15-

8

8-106-

7

17-26 12-19

17-26 12-19

9-14

7-10

9-1

4

7-10

9-1

4

7-10

4.8-7.2

4-

5

17-26 12-19

4.8-7.2 4-5

9-14

7-10

9-1

4

7-10

4-

6

3-4

1 TSB Revision

Page 946 of 1273

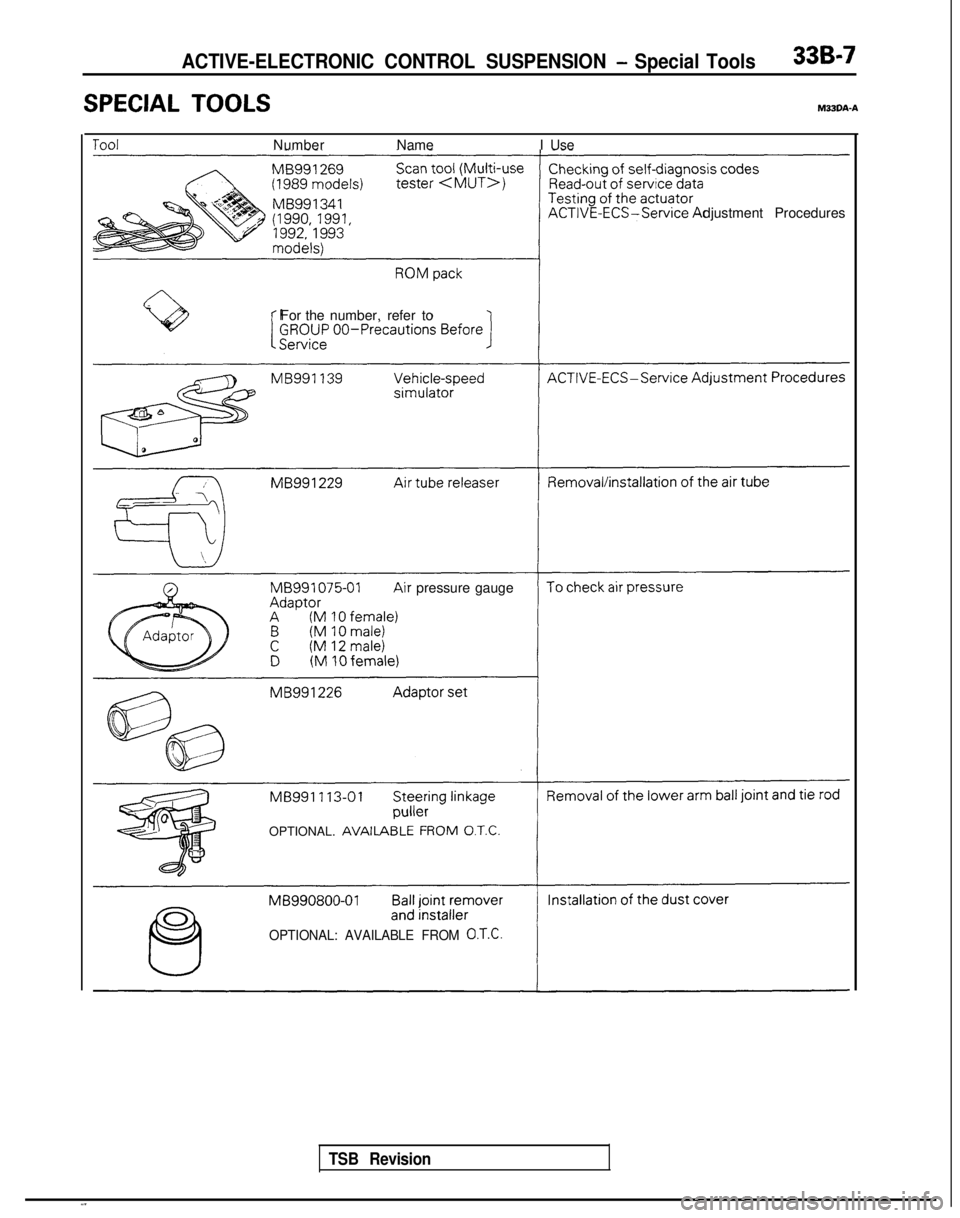

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Special Tools336-7

SPECIAL TOOLSM33DA-A

NumberName I Use

djustment Procedures

For the number, refer to

tr pressure gauge

OPTIONAL.

AVAILA

OPTIONAL: AVAILABLE FROM O.T.C.

TSB Revision

Page 947 of 1273

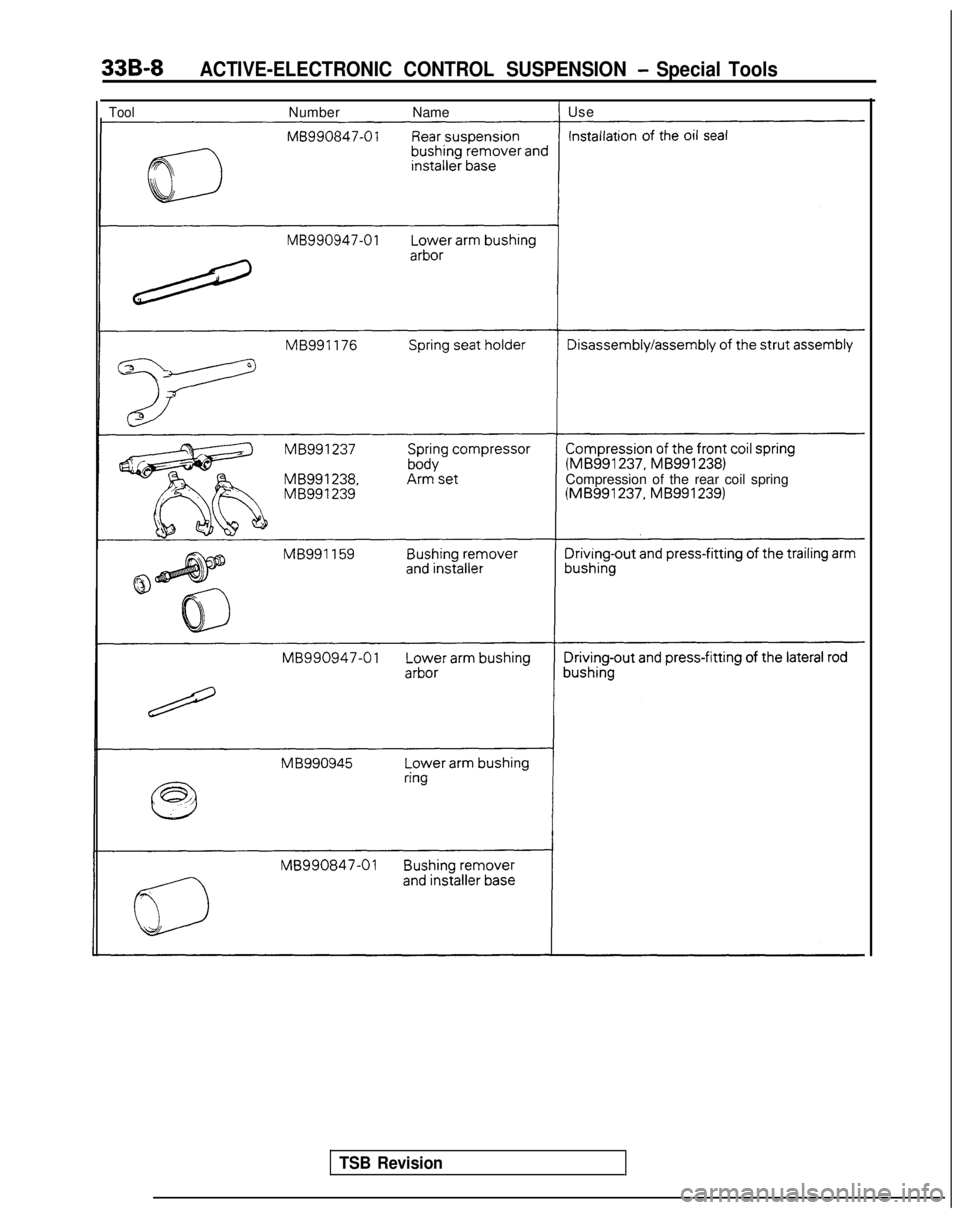

33B-8ACTIVE-ELECTRONIC CONTROL SUSPENSION - Special Tools

ToolNumberNameI Use (MB991237,

MB9912381Compression of the rear coil spring (MB991237,

MB9912391

TSB Revision

Page 948 of 1273

33B-9

NOTES

Page 949 of 1273

33B-10 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

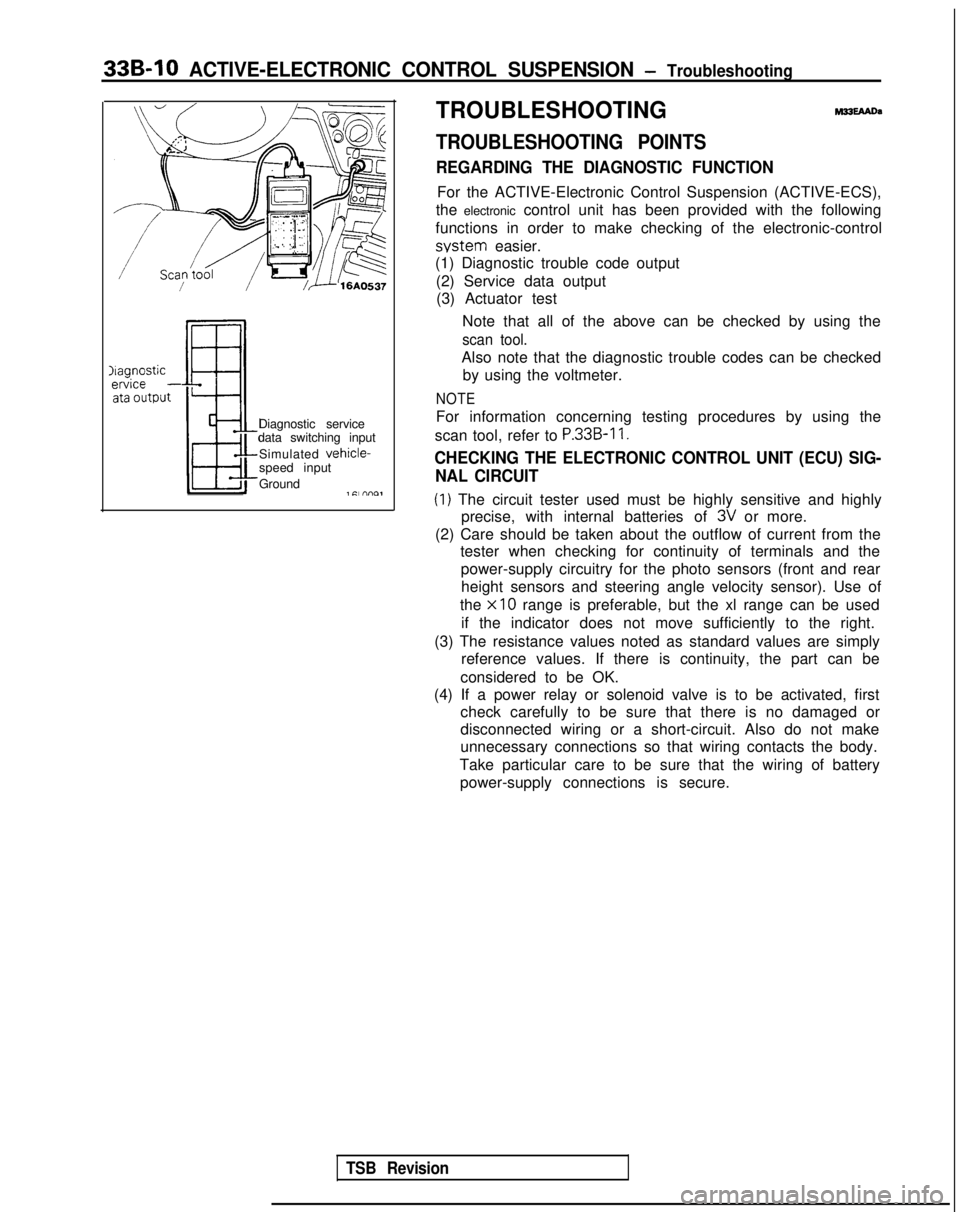

Ifagnosticervice

- ata 0utDut

Diagnostic service

data switching input

Simulated

vehicle-speed input

Ground

1 Cl nno,

TROUBLESHOOTINGhw3EAAtm

TROUBLESHOOTING POINTS

REGARDING THE DIAGNOSTIC FUNCTION

For the ACTIVE-Electronic Control Suspension (ACTIVE-ECS),

the electronic control unit has been provided with the following

functions in order to make checking of the electronic-control system

easier.

(1) Diagnostic trouble code output

(2) Service data output(3) Actuator test

Note that all of the above can be checked by using the

scan tool.

Also note that the diagnostic trouble codes can be checkedby using the voltmeter.

NOTE

For information concerning testing procedures by using the

scan tool, refer to

P.33B-11.

CHECKING THE ELECTRONIC CONTROL UNIT (ECU) SIG- NAL CIRCUIT

(1) The circuit tester used must be highly sensitive and highly precise, with internal batteries of

3V or more.

(2) Care should be taken about the outflow of current from the tester when checking for continuity of terminals and the

power-supply circuitry for the photo sensors (front and rearheight sensors and steering angle velocity sensor). Use of

the

x10 range is preferable, but the xl range can be used

if the indicator does not move sufficiently to the right.

(3) The resistance values noted as standard values are simply reference values. If there is continuity, the part can be

considered to be OK.

(4) If a power relay or solenoid valve is to be activated, first check carefully to be sure that there is no damaged or

disconnected wiring or a short-circuit. Also do not make

unnecessary connections so that wiring contacts the body.

Take particular care to be sure that the wiring of battery power-supply connections is secure.

TSB Revision

Page 950 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-11

CHECKING BY USING THE SCAN TOOL

1. DIAGNOSTIC TROUBLE CODE OUTPUT

TROUBLESHOOTING CHART

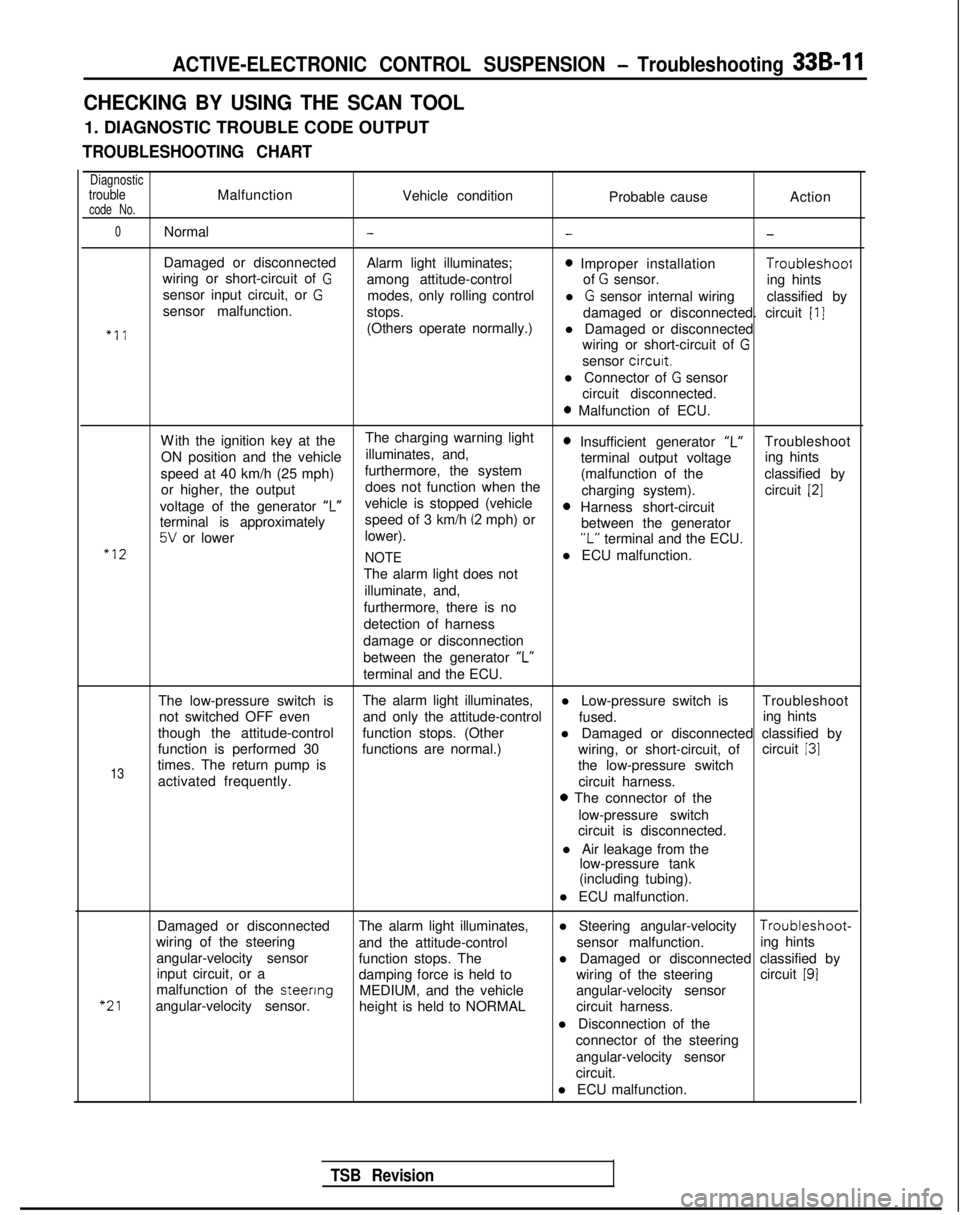

DiagnostictroubleMalfunctionVehicle conditioncode No.Probable causeAction

0Normal---

Damaged or disconnected

Alarm light illuminates;0 Improper installation Troubleshoof

wiring or short-circuit of Gamong attitude-control of G sensor.

sensor input circuit, or Ging hints

modes, only rolling control

sensor malfunction. l

G sensor internal wiring

classified by

stops. damaged or disconnected. circuit

[I]

“11(Others operate normally.)l Damaged or disconnected

wiring or short-circuit of

G

sensor circurt.

l Connector of

G sensor

circuit disconnected.

0 Malfunction of ECU.

W

ith the ignition key at the

The charging warning light

ON position and the vehicle illuminates, and,

0 Insufficient generator “L”Troubleshoot

speed at 40 km/h (25 mph) furthermore, the system terminal output voltage

ing hints

or higher, the output does not function when the (malfunction of the

classified by

charging system). circuit

[2]

voltage of the generator ‘I”vehicle is stopped (vehicle0 Harness short-circuit

terminal is approximately speed of 3 km/h (2 mph) or

5V or lower

lower). between the generator“L” terminal and the ECU.“12

NOTEl ECU malfunction.

The alarm light does not illuminate, and,

furthermore, there is no

detection of harness

damage or disconnection

between the generator “L”

terminal and the ECU.

The low-pressure switch is The alarm light illuminates,

l Low-pressure switch is Troubleshoot

not switched OFF even and only the attitude-control

fused.

though the attitude-control ing hints

function stops. (Other l Damaged or disconnected classified by

function is performed 30 functions are normal.) circuit

131

13times. The return pump is wiring, or short-circuit, of

the low-pressure switch

activated frequently. circuit harness.

0 The connector of the

low-pressure switch

circuit is disconnected.

l Air leakage from the low-pressure tank

(including tubing).

l ECU malfunction.

“21

Damaged or disconnected The alarm light illuminates,l Steering angular-velocity Troubleshoot-

wiring of the steering and the attitude-control sensor malfunction.

angular-velocity sensor ing hints

function stops. The

input circuit, or a l Damaged or disconnected classified by

damping force is held to wiring of the steeringcircuit

191malfunction of the steenng

MEDIUM, and the vehicle

angular-velocity sensor. angular-velocity sensor

height is held to NORMAL circuit harness.

l Disconnection of the connector of the steering

angular-velocity sensor

circuit.

l ECU malfunction.

TSB Revision