Body MITSUBISHI LANCER 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 322 of 788

Page 323 of 788

TRUNK LID

BODY42-45

CAUTION

Install the trunk lid torsion bar

trunk lid torsion bar

reversed, the trunk lid torsion bar

be able to be installed because the special tool

will interfere with the trunk lid torsion bar

during installation of the trunk lid torsion bar

1. Identify the LH and RH torsion bars by the colour

mark made at the centre of each torsion bar.

2. Insert the left end of the trunk lid torsion bar

in the hole in the trunk lid hinge

3. Press portion A of the trunk lid torsion bar

right end against point A on the trunk lid hinge

4. Twist the portion B of the trunk lid torsion bar

moved from point B and pressed against point C

of the trunk lid hinge

Then force the portion into point D.

5. Twist the portion A of the trunk lid torsion bar

lid hinge

6. Attach the trunk lid torsion bar

lid hinge

trunk lid torsion bar

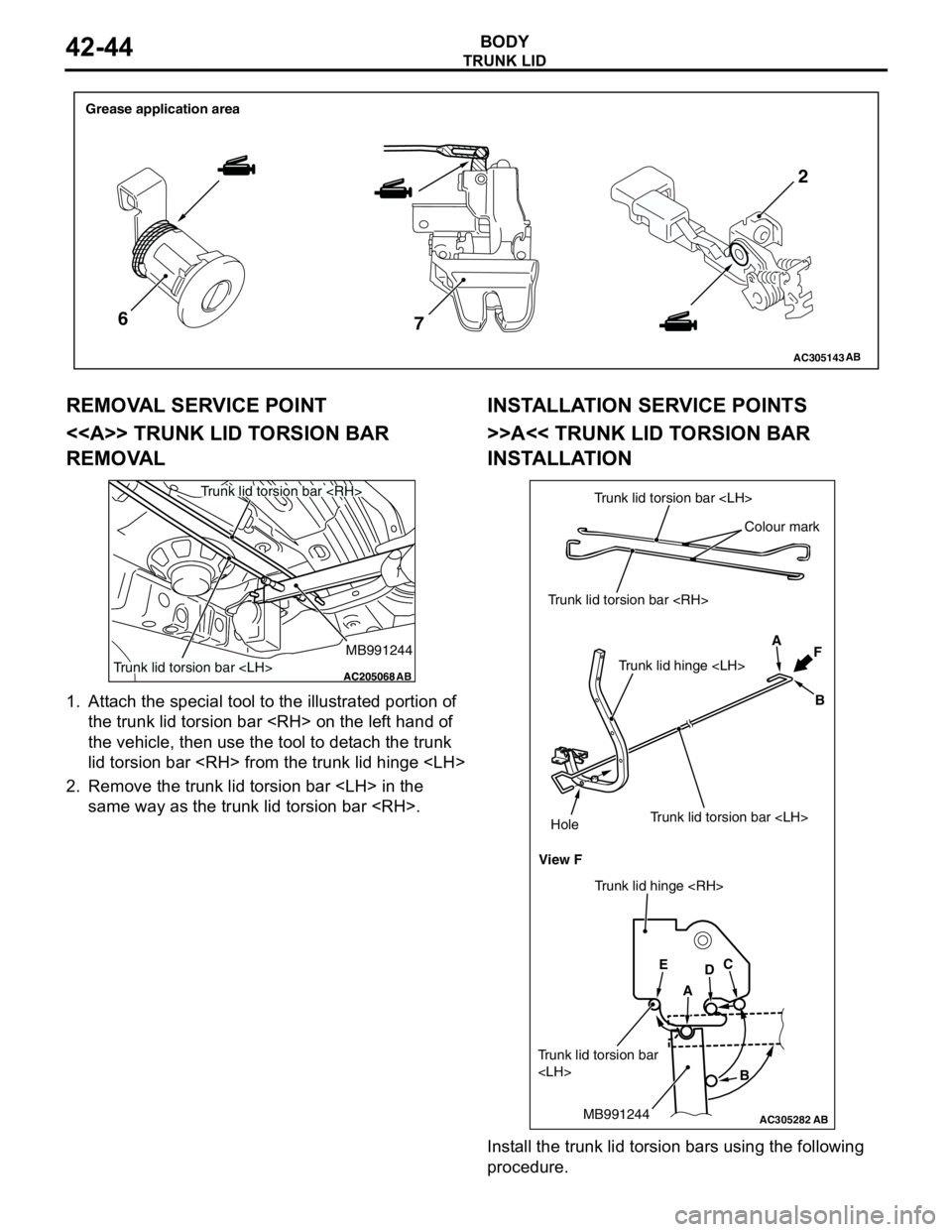

>>B<< TRUNK LID WEATHERSTRIP

INSTALLATION

Install the trunk lid weatherstrip so that the marking

and the joint are aligned with the body centre line,

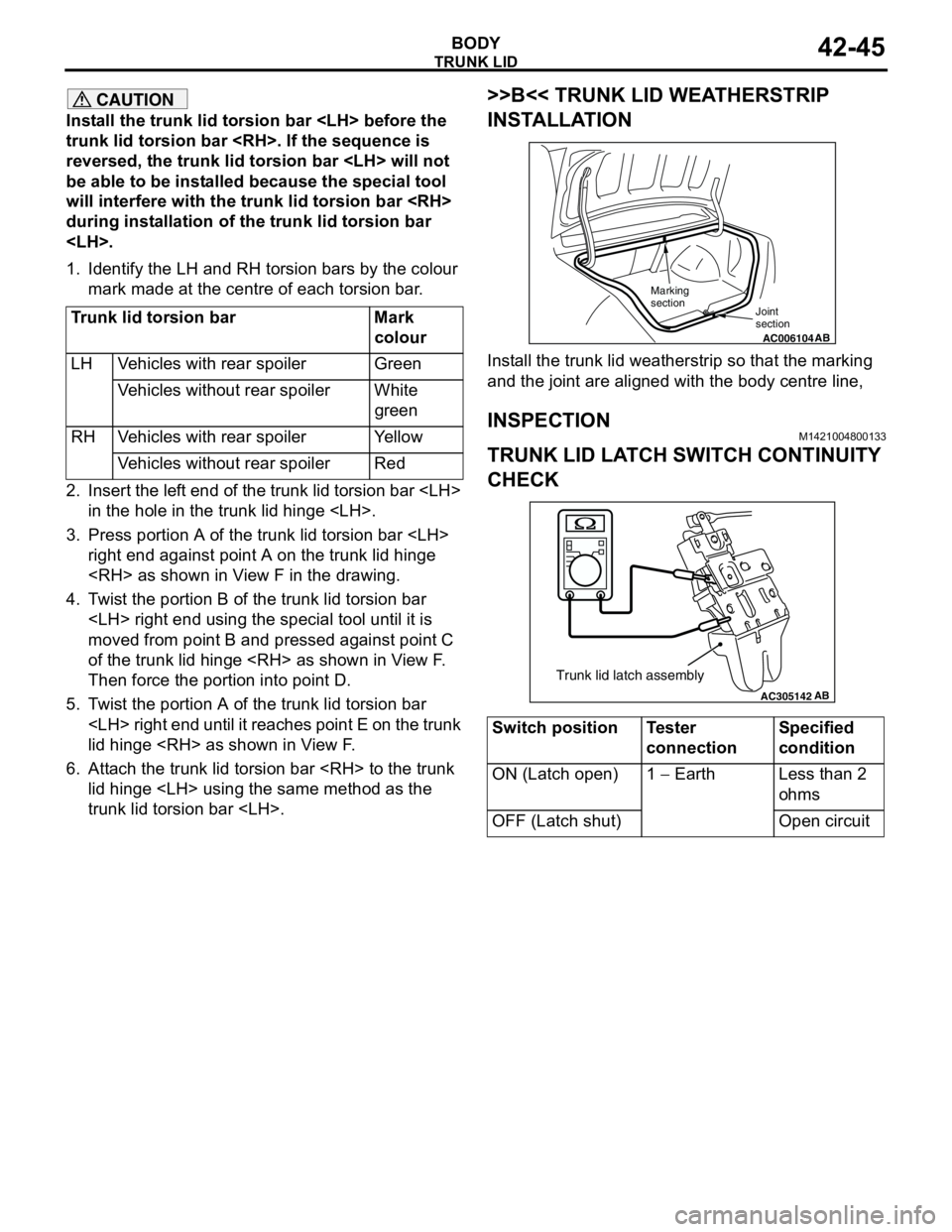

INSPECTIONM1421004800133

TRUNK LID LATCH SWITCH CONTINUITY

CHECK

Trunk lid torsion bar Mark

colour

LH Vehicles with rear spoiler Green

Vehicles without rear spoiler White

green

RH Vehicles with rear spoiler Yellow

Vehicles without rear spoiler Red

Switch position Tester

connectionSpecified

condition

ON (Latch open) 1 − Earth Less than 2

ohms

OFF (Latch shut) Open circuit

AC006104AB Joint

section

Marking

section

AC305142AB

Trunk lid latch assembly

Page 324 of 788

TA I L G AT E

BODY42-46

TA I L G AT E

SERVICE SPECIFICATIONSM1421000300288

SEALANTSM1424000500098

SPECIAL TOOLM1424000600170

TROUBLESHOOTINGM1424000700207

The tailgate system is controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to GROUP

54B, Troubleshooting P.54B-17 or GROUP 54C,

Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

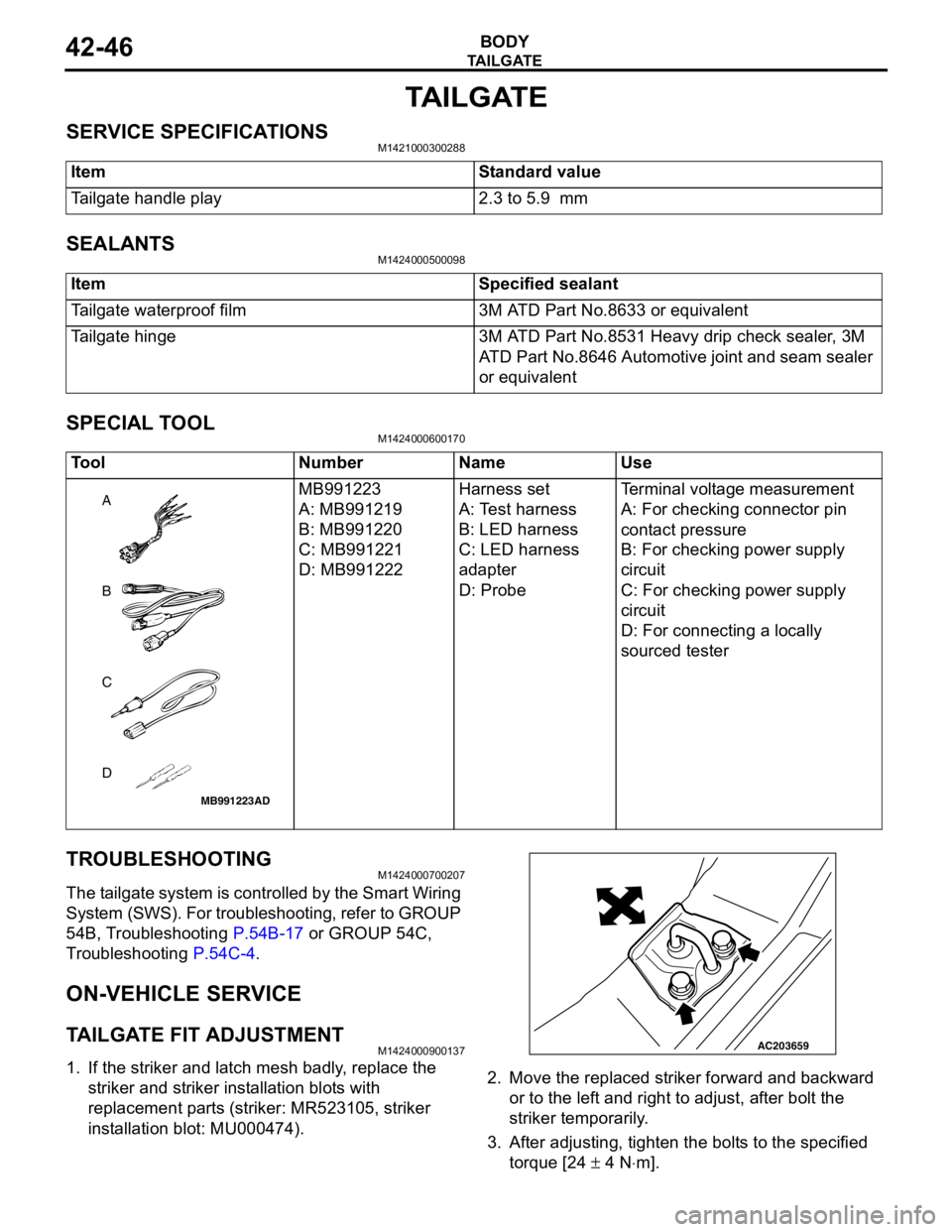

TAILGATE FIT ADJUSTMENTM1424000900137

1. If the striker and latch mesh badly, replace the

striker and striker installation blots with

replacement parts (striker: MR523105, striker

installation blot: MU000474).2. Move the replaced striker forward and backward

or to the left and right to adjust, after bolt the

striker temporarily.

3. After adjusting, tighten the bolts to the specified

torque [24 ± 4 N⋅m]. Item Standard value

Tailgate handle play 2.3 to 5.9 mm

Item Specified sealant

Tailgate waterproof film 3M ATD Part No.8633 or equivalent

Tailgate hinge 3M ATD Part No.8531 Heavy drip check sealer, 3M

ATD Part No.8646 Automotive joint and seam sealer

or equivalent

Tool Number Name Use

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeTerminal voltage measurement

A: For checking connector pin

contact pressure

B: For checking power supply

circuit

C: For checking power supply

circuit

D: For connecting a locally

sourced tester

MB991223

A

D C

B

AD

AC203659

Page 325 of 788

TA I L G AT E

BODY42-47

NOTE:

When the bolt head interferes with the rear end

trim, rasp the interference area with a round file.4. If uneven clearance is present between tailgate

and body, reposition the hinge to adjust the

clearance.

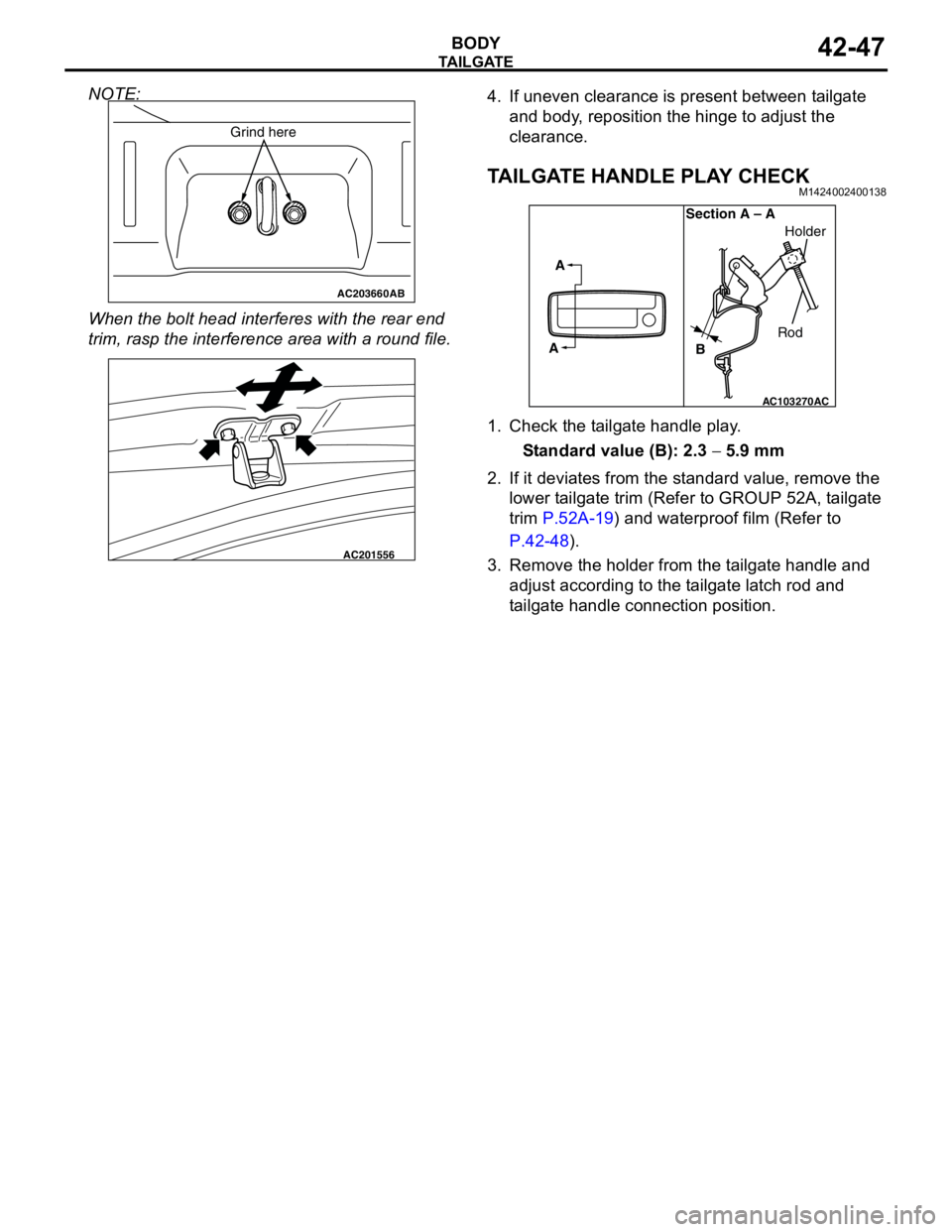

TAILGATE HANDLE PLAY CHECKM1424002400138

1. Check the tailgate handle play.

Standard value (B): 2.3 − 5.9 mm

2. If it deviates from the standard value, remove the

lower tailgate trim (Refer to GROUP 52A, tailgate

trim P.52A-19) and waterproof film (Refer to

P.42-48).

3. Remove the holder from the tailgate handle and

adjust according to the tailgate latch rod and

tailgate handle connection position.

AC203660AB

Grind here

AC201556

AC103270

A

ASection A – A

RodHolder

B

AC

Page 326 of 788

TA I L G AT E

BODY42-48

TAILGATE

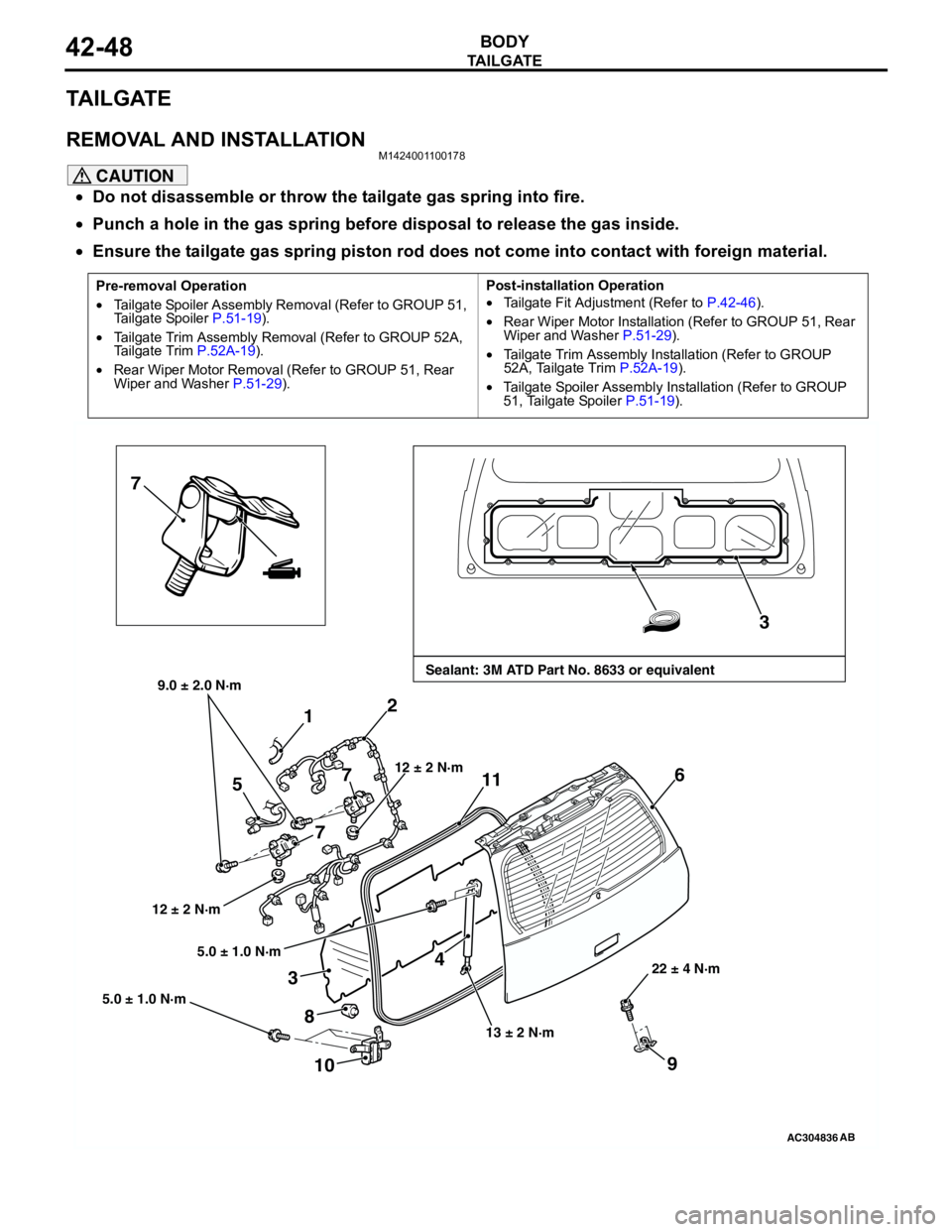

REMOVAL AND INSTALLATIONM1424001100178

CAUTION

•Do not disassemble or throw the tailgate gas spring into fire.

•Punch a hole in the gas spring before disposal to release the gas inside.

•Ensure the tailgate gas spring piston rod does not come into contact with foreign material.

Pre-removal Operation

•Tailgate Spoiler Assembly Removal (Refer to GROUP 51,

Tailgate Spoiler P.51-19).

•Tailgate Trim Assembly Removal (Refer to GROUP 52A,

Tailgate Trim P.52A-19).

•Rear Wiper Motor Removal (Refer to GROUP 51, Rear

Wiper and Washer P.51-29).Post-installation Operation

•Tailgate Fit Adjustment (Refer to P.42-46).

•Rear Wiper Motor Installation (Refer to GROUP 51, Rear

Wiper and Washer P.51-29).

•Tailgate Trim Assembly Installation (Refer to GROUP

52A, Tailgate Trim P.52A-19).

•Tailgate Spoiler Assembly Installation (Refer to GROUP

51, Tailgate Spoiler P.51-19).

AC304836

7

3

4 1

6

8

12 ± 2 N·m

13 ± 2 N·m22 ± 4 N·m

AB

Sealant: 3M ATD Part No. 8633 or equivalent9.0 ± 2.0 N·m

2

712 ± 2 N·m

5

7

9

5.0 ± 1.0 N·m

5.0 ± 1.0 N·m

3

11

10

Page 327 of 788

TA I L G AT E

BODY42-49

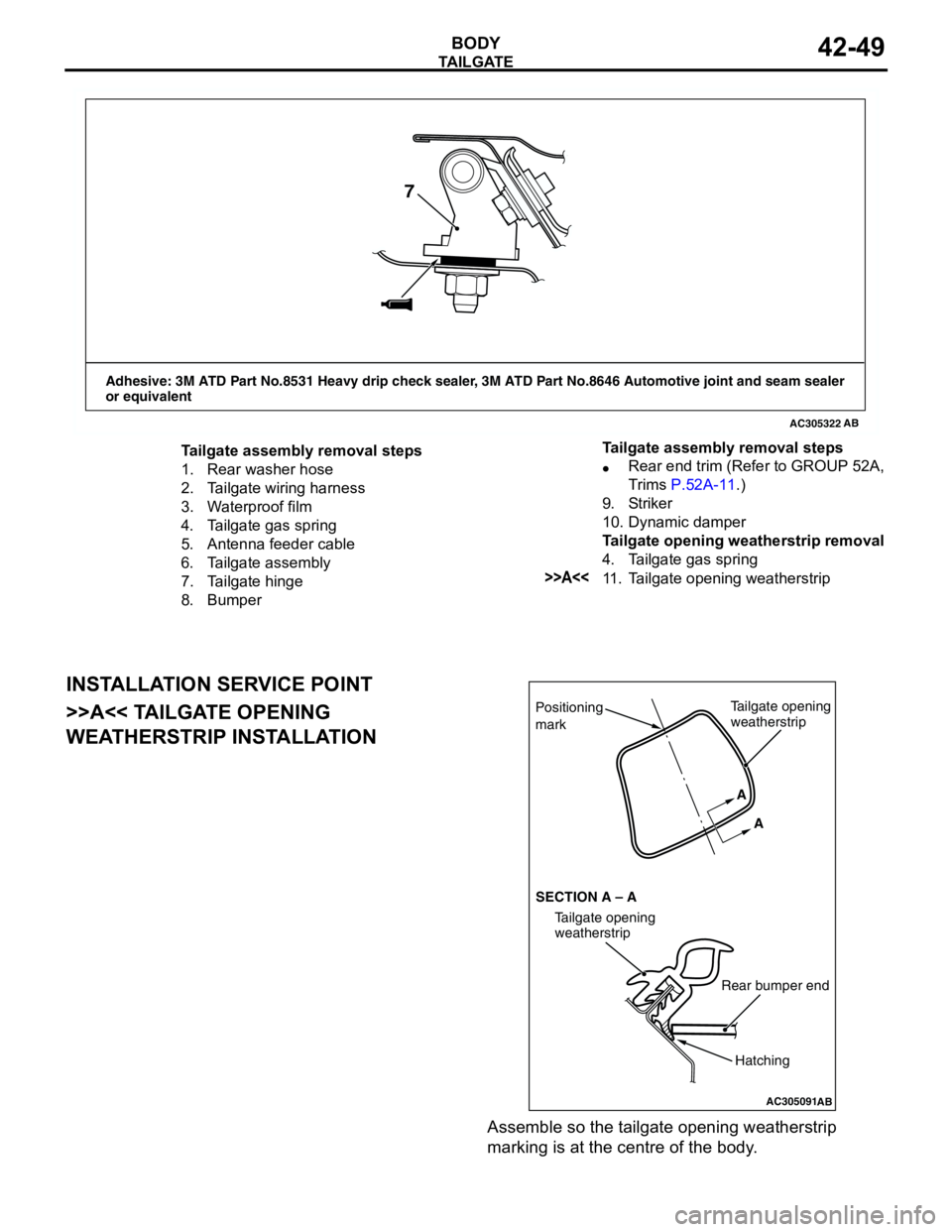

INSTALLATION SERVICE POINT

>>A<< TAILGATE OPENING

WEATHERSTRIP INSTALLATION

Assemble so the tailgate opening weatherstrip

marking is at the centre of the body.

AC305322

Adhesive: 3M ATD Part No.8531 Heavy drip check sealer, 3M ATD Part No.8646 Automotive joint and seam sealer

or equivalent

AB

7

Tailgate assembly removal steps

1. Rear washer hose

2. Tailgate wiring harness

3. Waterproof film

4. Tailgate gas spring

5. Antenna feeder cable

6. Tailgate assembly

7. Tailgate hinge

8. Bumper•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

9. Striker

10. Dynamic damper

Tailgate opening weatherstrip removal

4. Tailgate gas spring

>>A<<11. Tailgate opening weatherstrip Tailgate assembly removal steps

AC305091

Positioning

mark

AB

Tailgate opening

weatherstrip

Rear bumper end

Tailgate opening

weatherstrip SECTION A – AA

A

Hatching

Page 328 of 788

TA I L G AT E

BODY42-50

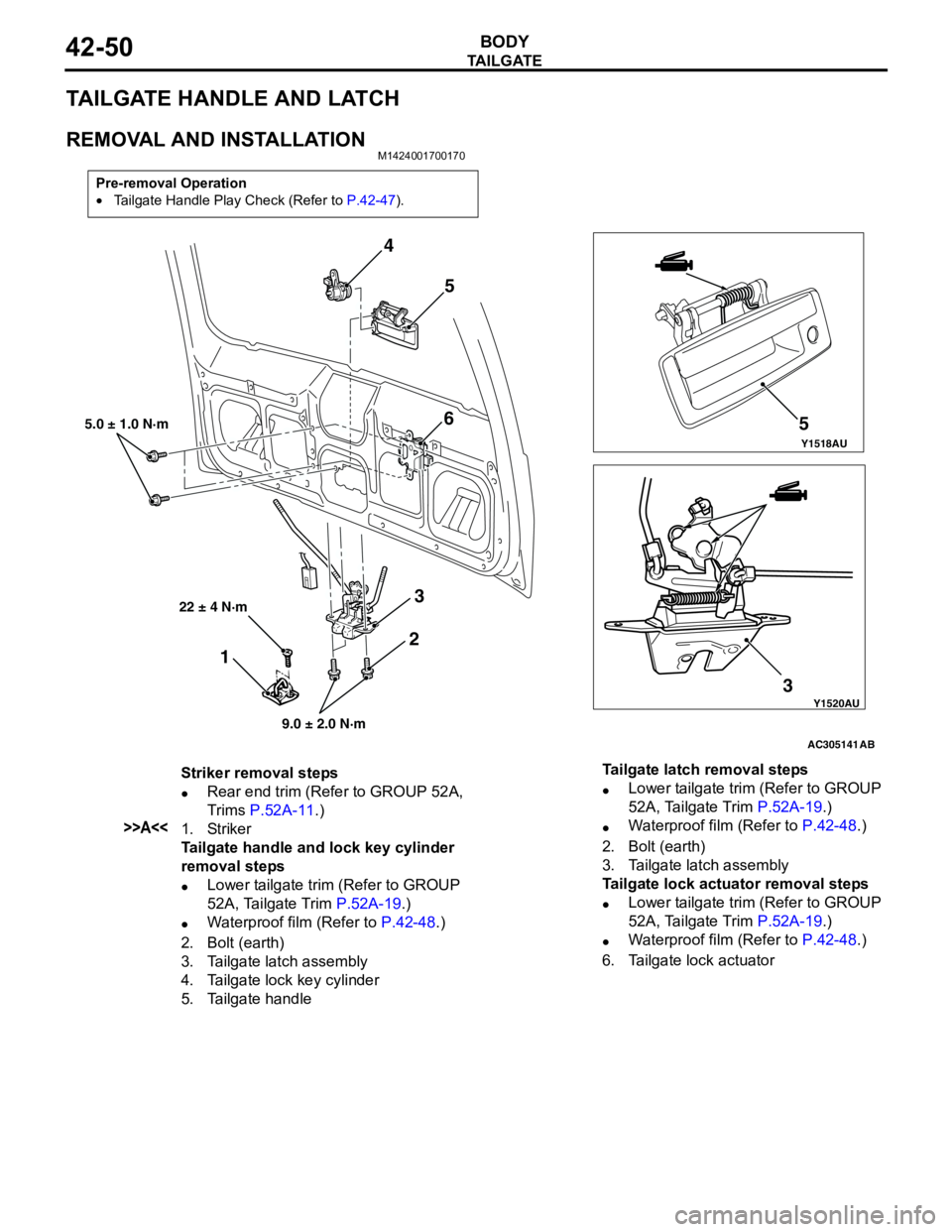

TAILGATE HANDLE AND LATCH

REMOVAL AND INSTALLATIONM1424001700170

Pre-removal Operation

•Tailgate Handle Play Check (Refer to P.42-47).

Y1518AU

Y1520AU

AC305141

4

5

6

3 35

5.0 ± 1.0 N·m

9.0 ± 2.0 N·m

AB

2

1

22 ± 4 N·m

Striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

>>A<<1. Striker

Tailgate handle and lock key cylinder

removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

2. Bolt (earth)

3. Tailgate latch assembly

4. Tailgate lock key cylinder

5. Tailgate handleTailgate latch removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

2. Bolt (earth)

3. Tailgate latch assembly

Tailgate lock actuator removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

6. Tailgate lock actuator

Page 329 of 788

KEYLESS ENTRY SYSTEM

BODY42-51

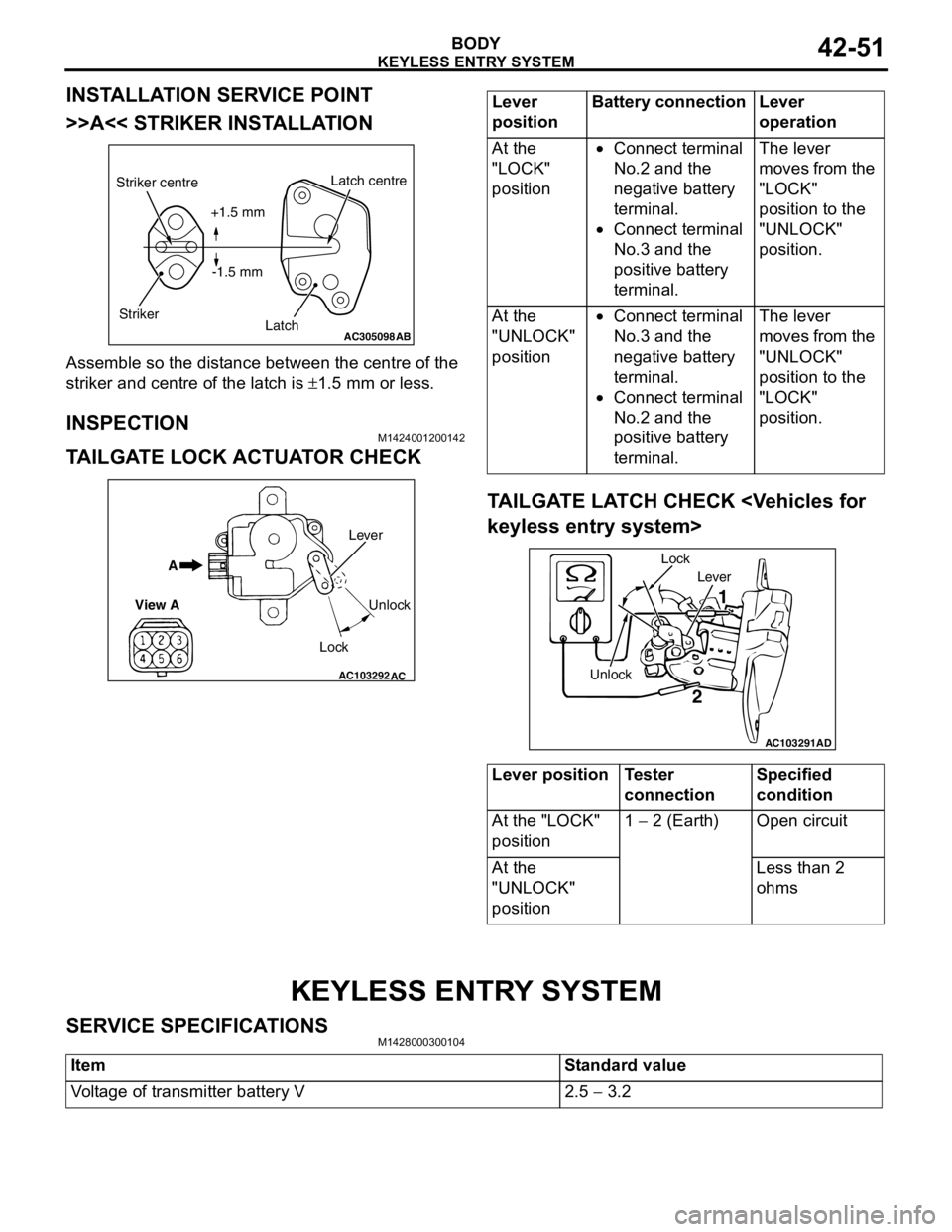

INSTALLATION SERVICE POINT

>>A<< STRIKER INSTALLATION

Assemble so the distance between the centre of the

striker and centre of the latch is ±1.5 mm or less.

INSPECTIONM1424001200142

TAILGATE LOCK ACTUATOR CHECK

TAILGATE LATCH CHECK

KEYLESS ENTRY SYSTEM

SERVICE SPECIFICATIONSM1428000300104

AC305098AB

Striker centre

StrikerLatch centre

Latch +1.5 mm

-1.5 mm

AC103292

A

View A

Unlock

Lock Lever

AC

Lever

positionBattery connection Lever

operation

At the

"LOCK"

position•Connect terminal

No.2 and the

negative battery

terminal.

•Connect terminal

No.3 and the

positive battery

terminal.The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No.3 and the

negative battery

terminal.

•Connect terminal

No.2 and the

positive battery

terminal.The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

Lever position Tester

connectionSpecified

condition

At the "LOCK"

position1 − 2 (Earth) Open circuit

At the

"UNLOCK"

positionLess than 2

ohms

AC103291

Lever

Unlock Lock

1

2

AD

Item Standard value

Voltage of transmitter battery V 2.5 − 3.2

Page 330 of 788

KEYLESS ENTRY SYSTEM

BODY42-52

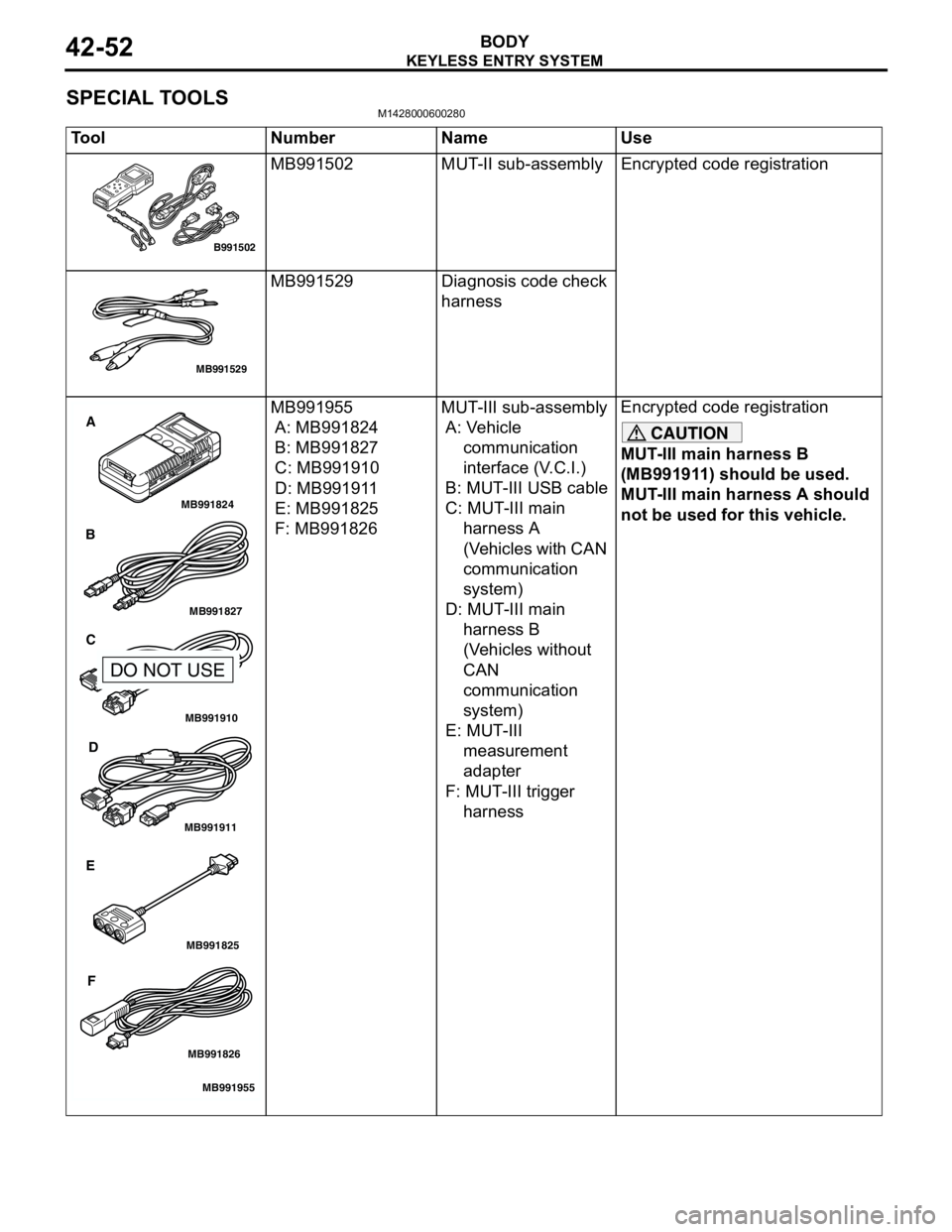

SPECIAL TOOLSM1428000600280

Tool Number Name Use

MB991502 MUT-II sub-assembly Encrypted code registration

MB991529 Diagnosis code check

harness

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826MUT-III sub-assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main

harness A

(Vehicles with CAN

communication

system)

D: MUT-III main

harness B

(Vehicles without

CAN

communication

system)

E: MUT-III

measurement

adapter

F: MUT-III trigger

harnessEncrypted code registration

CAUTION

MUT-III main harness B

(MB991911) should be used.

MUT-III main harness A should

not be used for this vehicle.

B991502

MB991529

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE

Page 331 of 788

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTINGM1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTRY SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the

answerback function works in response to door

and tailgate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the

hazard warning lamp flashes (hazard answerback

function). The hazard answerback function can be

enabled or disabled according to the following

procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

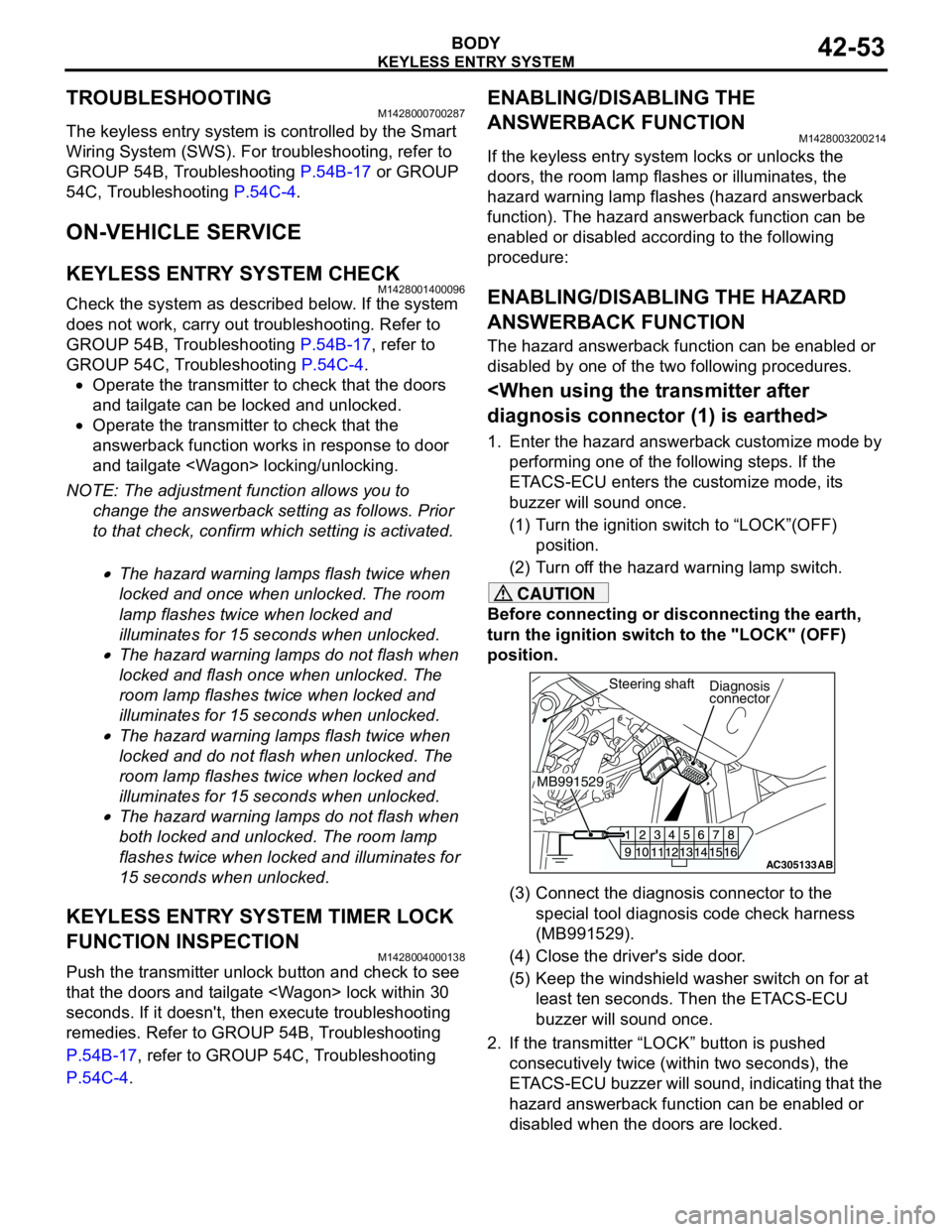

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF)

position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

(3) Connect the diagnosis connector to the

special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at

least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (within two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

AC305133AB

Diagnosis

connector

MB991529Steering shaft