electrical MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 455 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-67

NOTE: Height from the floor to the centre of

the headlamps (Reference value): 840 mm

(3) Measure the distance from the centre line of

the vehicle to the centre of each headlamp.

Transfer the measurement to the screen.

Vertical tape or mark on the screen with

reference to the centre line of each headlamp

bulb.

HEADLAMP ADJUSTMENT

CAUTION

•Do not cover a headlamp for more than three

minutes to prevent the plastic headlamp lens

deformation.

•When adjusting one headlamp beam, make

sure that another headlamp is off by

disconnecting the connector from it. When

reconnecting the connector, make sure that

the headlamp beam is not disturbed

accidentally.

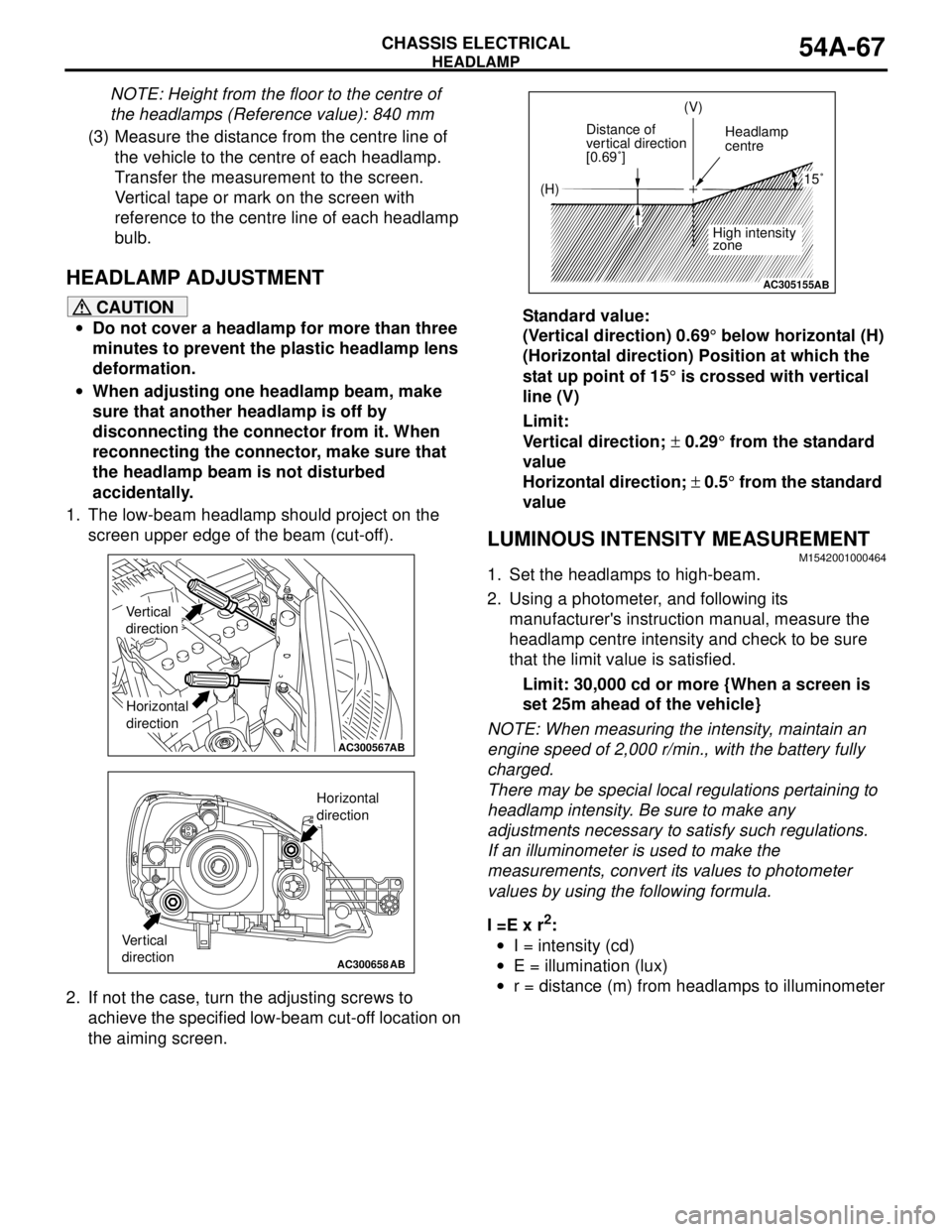

1. The low-beam headlamp should project on the

screen upper edge of the beam (cut-off).

2. If not the case, turn the adjusting screws to

achieve the specified low-beam cut-off location on

the aiming screen.Standard value:

(Vertical direction) 0.69° below horizontal (H)

(Horizontal direction) Position at which the

stat up point of 15° is crossed with vertical

line (V)

Limit:

Vertical direction; ± 0.29° from the standard

value

Horizontal direction; ± 0.5° from the standard

value

LUMINOUS INTENSITY MEASUREMENTM1542001000464

1. Set the headlamps to high-beam.

2. Using a photometer, and following its

manufacturer's instruction manual, measure the

headlamp centre intensity and check to be sure

that the limit value is satisfied.

Limit: 30,000 cd or more {When a screen is

set 25m ahead of the vehicle}

NOTE: When measuring the intensity, maintain an

engine speed of 2,000 r/min., with the battery fully

charged.

There may be special local regulations pertaining to

headlamp intensity. Be sure to make any

adjustments necessary to satisfy such regulations.

If an illuminometer is used to make the

measurements, convert its values to photometer

values by using the following formula.

I =E x r

2:

•I = intensity (cd)

•E = illumination (lux)

•r = distance (m) from headlamps to illuminometer

AC300567AB

Vertical

direction

Horizontal

direction

AC300658AB

Vertical

direction

Horizontal

direction

AC305155

(H)(V)

Distance of

vertical direction

[0.69˚]Headlamp

centre

High intensity

zone

15˚

AB

Page 456 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-68

BULB REPLACEMENTM1542001300658

Headlamp Bulb

CAUTION

Do not touch the surface of the bulb with hands

or dirty gloves as the bulb may pop after a short

time. If the surface does become dirty, clean it

with alcohol or thinner, and let it dry thoroughly

before installing.

1. Disconnect the battery.

2. Disconnect the connector.

3. Remove the socket cover.

4. Remove bulb mounting spring to pull out bulb.

5. After bulb is replaced, properly reconnect

connector.

Position Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out position lamp socket to pull out

position lamp bulb.

Front Turn-Signal Lamp Bulb

CAUTION

Do not touch the bulb surface bare-handed or

with dirty gloves. If dirt is attached on surface of

the bulb, immediately use alcohol or thinner to

remove dirt, and install the bulb after well dried.

1.

Disconnect the connector.

2. Screw out front turn-signal lamp socket to pull out

front turn-signal lamp bulb.

AC300667AC300667

Headlamp bulb

AB

Spring

AC300668

Position lamp

AB

AC300669

Front turn signal lamp

AB

Page 457 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-69

HEADLAMP

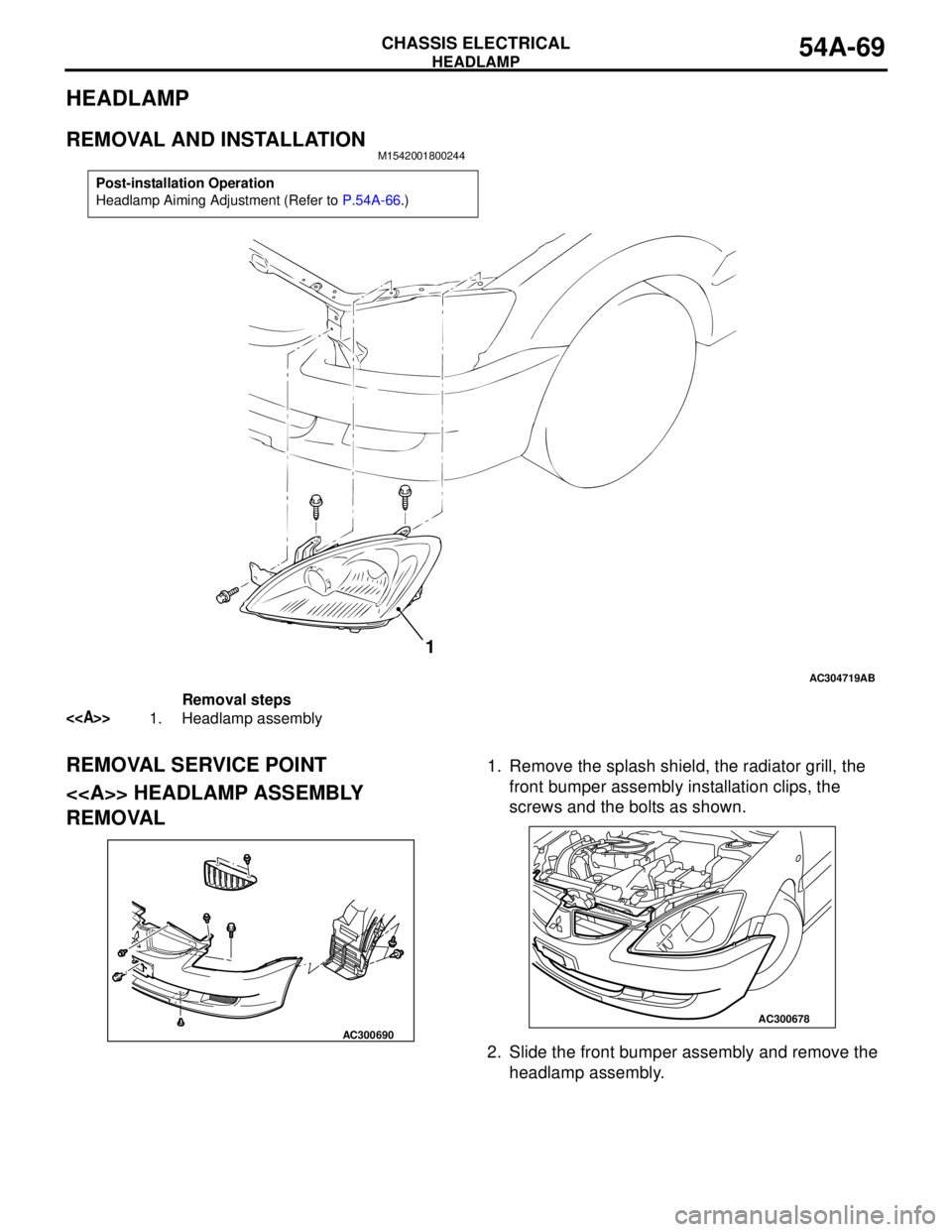

REMOVAL AND INSTALLATIONM1542001800244

REMOVAL SERVICE POINT

<> HEADLAMP ASSEMBLY

REMOVAL1. Remove the splash shield, the radiator grill, the

front bumper assembly installation clips, the

screws and the bolts as shown.

2. Slide the front bumper assembly and remove the

headlamp assembly.

Post-installation Operation

Headlamp Aiming Adjustment (Refer to P.54A-66.)

AC304719

1

AB

Removal steps

<>1. Headlamp assembly

AC300690

AC300678

Page 458 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-70

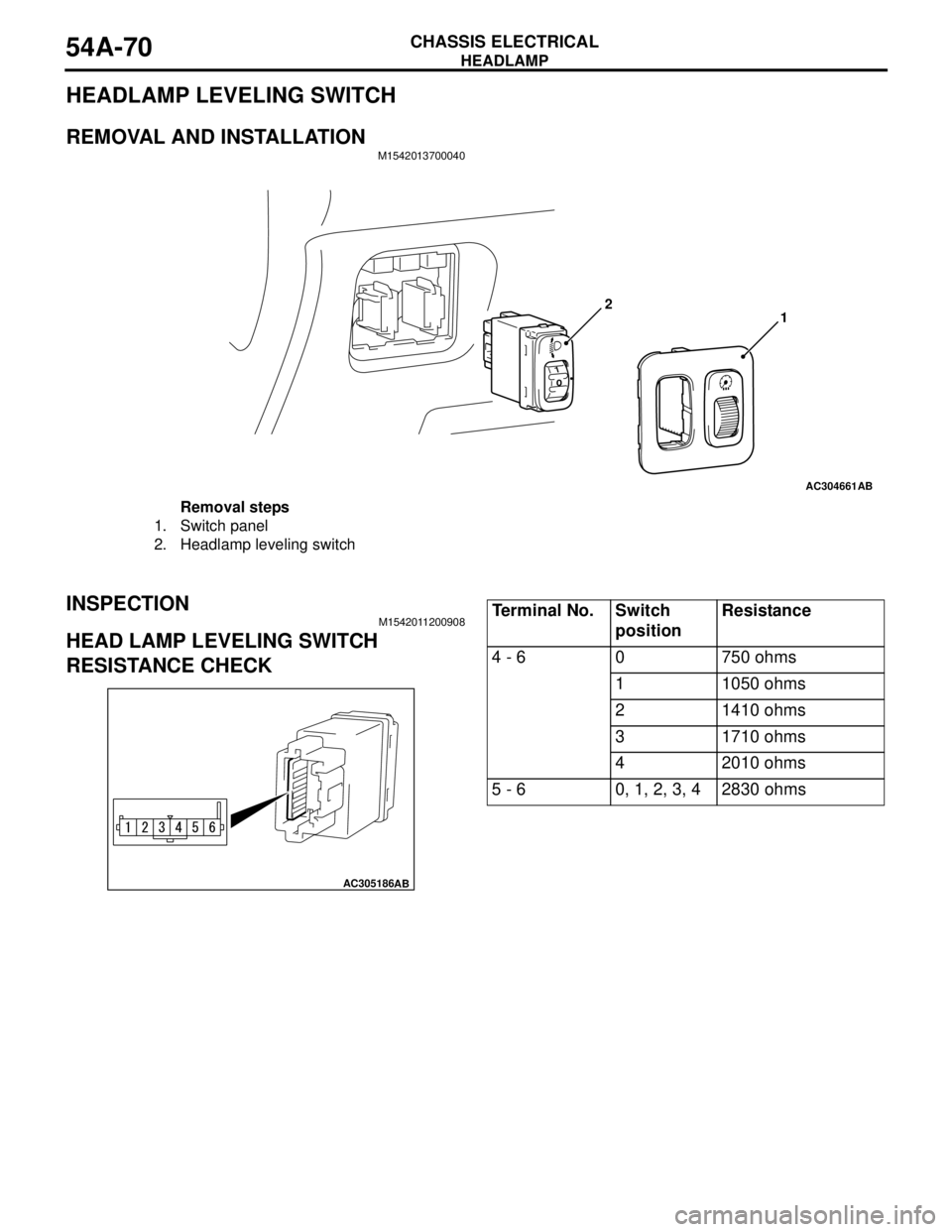

HEADLAMP LEVELING SWITCH

REMOVAL AND INSTALLATIONM1542013700040

INSPECTIONM1542011200908

HEAD LAMP LEVELING SWITCH

RESISTANCE CHECK

AC304661AB

2

1

Removal steps

1. Switch panel

2. Headlamp leveling switch

AC305186AB

Te r m i n a l N o . S w i t c h

positionResistance

4 - 6 0 750 ohms

1 1050 ohms

2 1410 ohms

3 1710 ohms

4 2010 ohms

5 - 6 0, 1, 2, 3, 4 2830 ohms

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

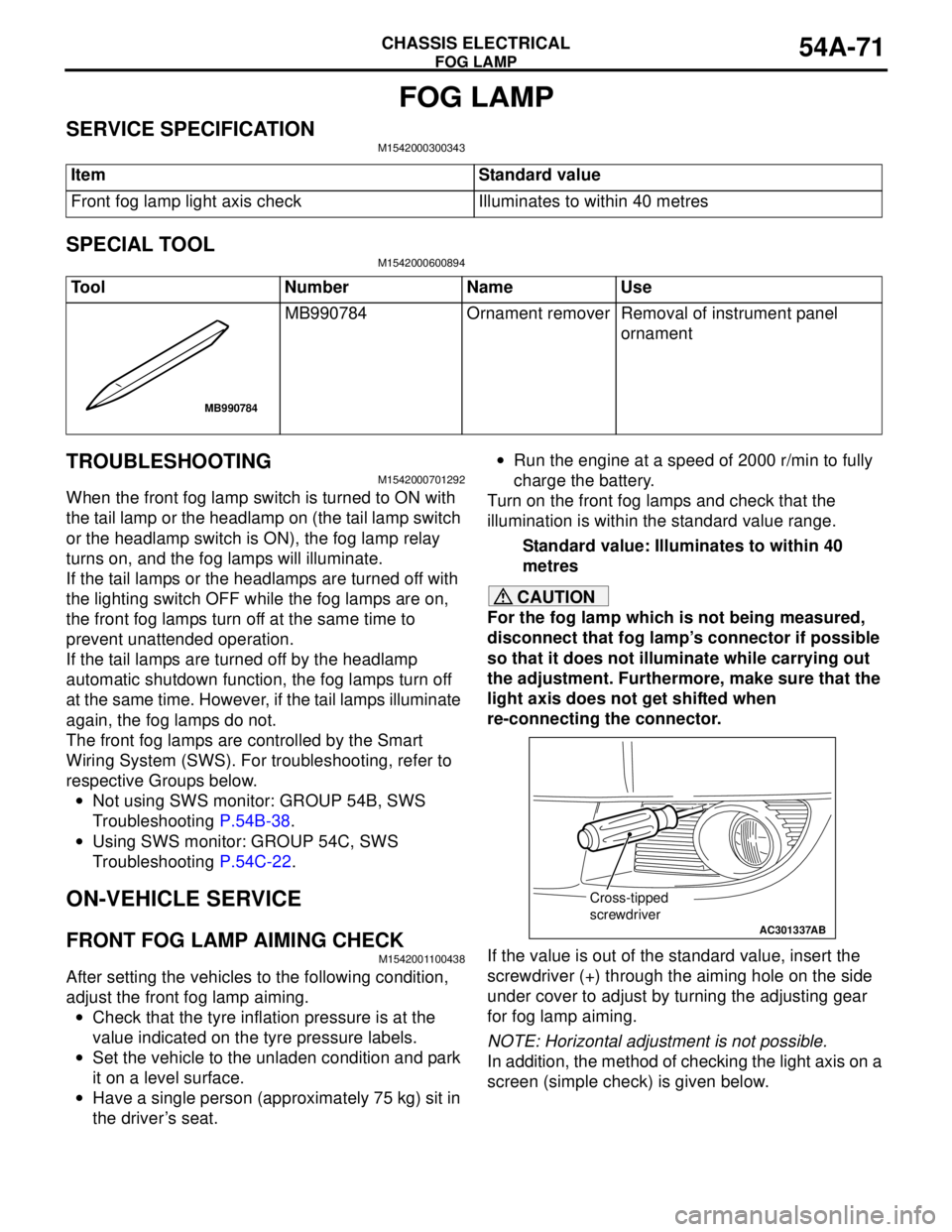

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB

Page 460 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-72

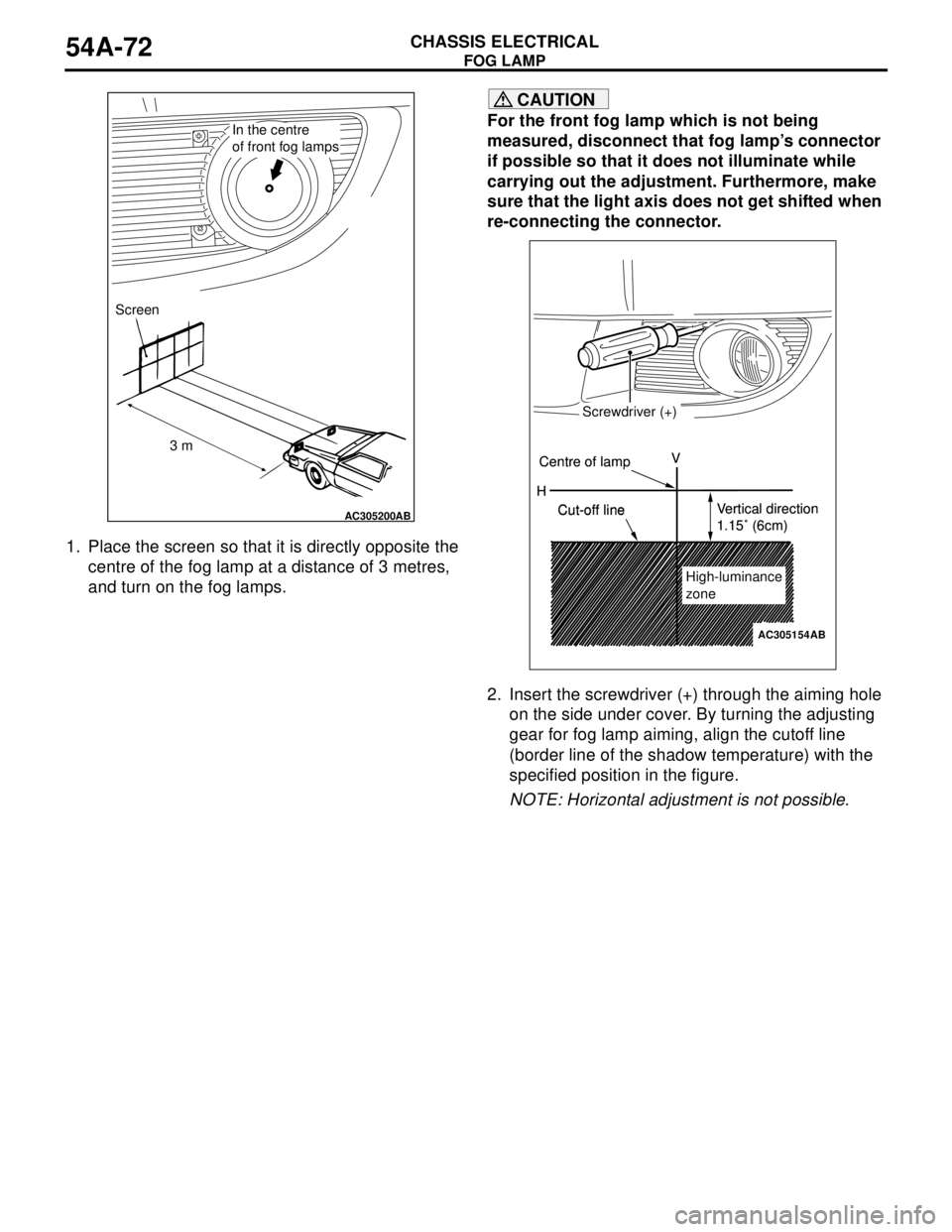

1. Place the screen so that it is directly opposite the

centre of the fog lamp at a distance of 3 metres,

and turn on the fog lamps.

CAUTION

For the front fog lamp which is not being

measured, disconnect that fog lamp’s connector

if possible so that it does not illuminate while

carrying out the adjustment. Furthermore, make

sure that the light axis does not get shifted when

re-connecting the connector.

2. Insert the screwdriver (+) through the aiming hole

on the side under cover. By turning the adjusting

gear for fog lamp aiming, align the cutoff line

(border line of the shadow temperature) with the

specified position in the figure.

NOTE: Horizontal adjustment is not possible.

AC305200AB

In the centre

of front fog lamps

Screen

3 m

H V

AC305154

Screwdriver (+)

Centre of lamp

Cut-off lineVertical direction

1.15˚ (6cm)

High-luminance

zone H V

Screwdriver (+)

Centre of lamp

Cut-off lineVertical direction

1.15˚ (6cm)

High-luminance

zone

AB

Page 461 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-73

FOG LAMP

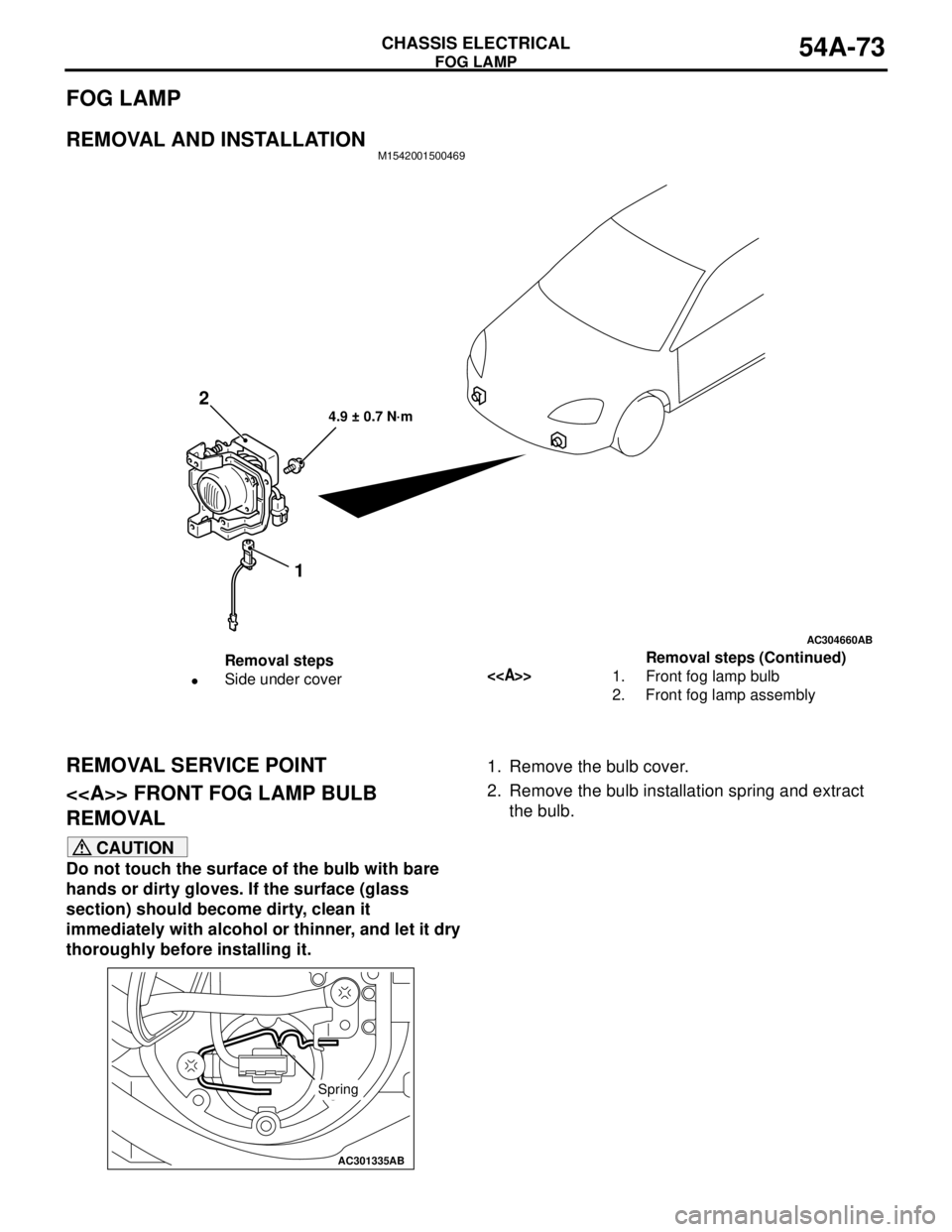

REMOVAL AND INSTALLATIONM1542001500469

REMOVAL SERVICE POINT

<> FRONT FOG LAMP BULB

REMOVAL

CAUTION

Do not touch the surface of the bulb with bare

hands or dirty gloves. If the surface (glass

section) should become dirty, clean it

immediately with alcohol or thinner, and let it dry

thoroughly before installing it.1. Remove the bulb cover.

2. Remove the bulb installation spring and extract

the bulb.

AC304660

4.9 ± 0.7 N·m

AB

2

1

Removal steps

•Side under cover<>1. Front fog lamp bulb

2. Front fog lamp assemblyRemoval steps (Continued)

AC301335AB

Spring

Page 462 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-74

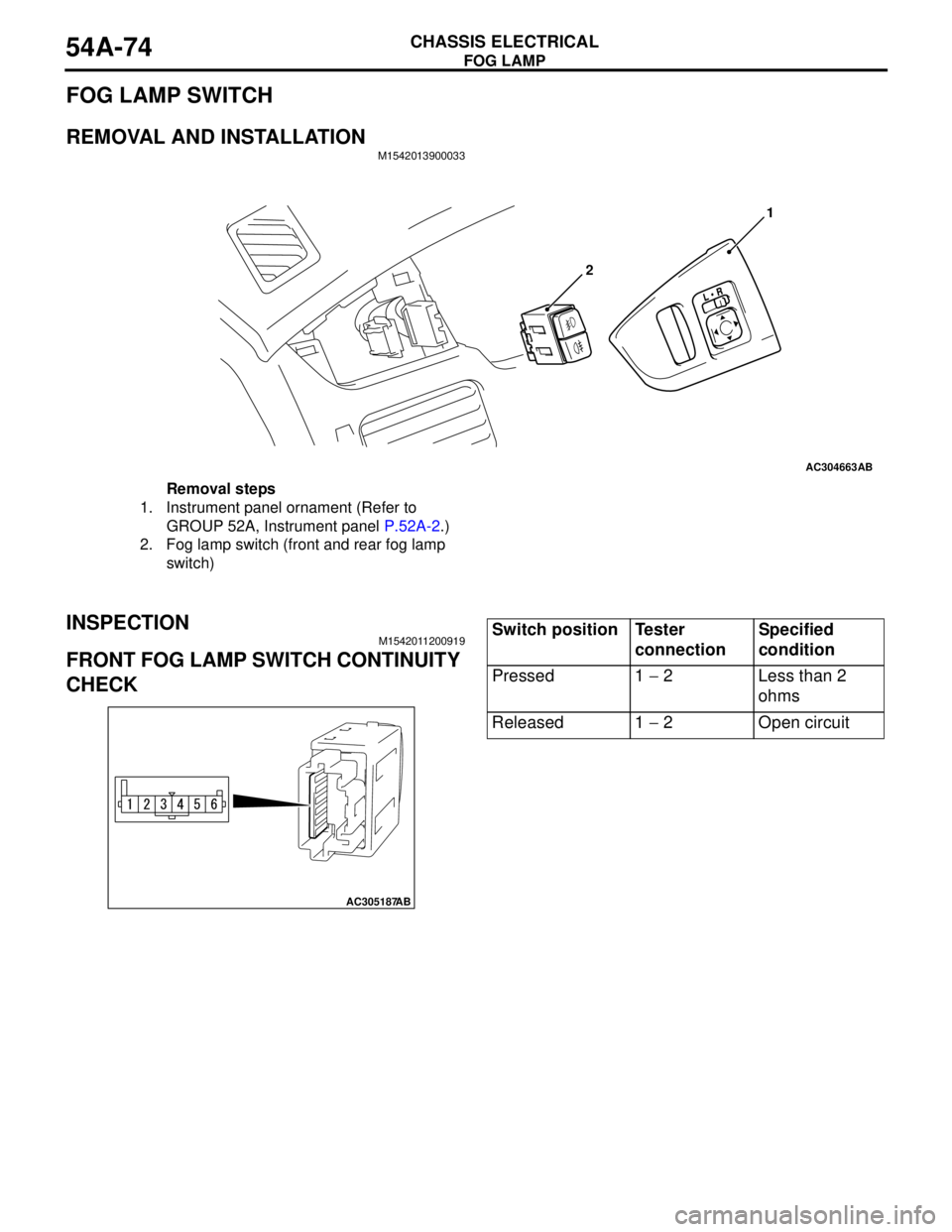

FOG LAMP SWITCH

REMOVAL AND INSTALLATIONM1542013900033

INSPECTIONM1542011200919

FRONT FOG LAMP SWITCH CONTINUITY

CHECK

AC304663AB

21

Removal steps

1. Instrument panel ornament (Refer to

GROUP 52A, Instrument panel P.52A-2.)

2. Fog lamp switch (front and rear fog lamp

switch)

AC305187

AB

Switch position Tester

connectionSpecified

condition

Pressed 1 − 2 Less than 2

ohms

Released 1 − 2 Open circuit

Page 463 of 788

REAR FOG LAMP

CHASSIS ELECTRICAL54A-75

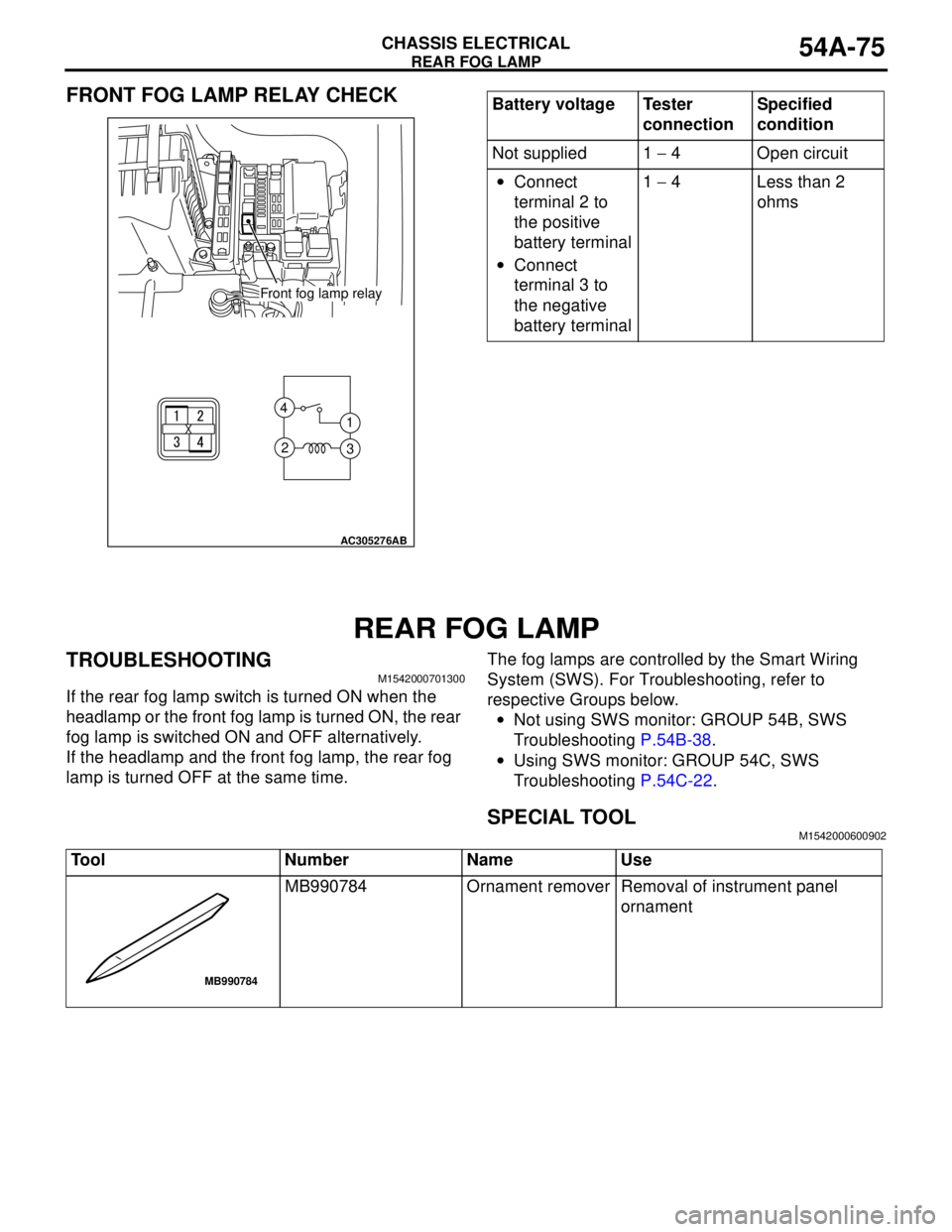

FRONT FOG LAMP RELAY CHECK

REAR FOG LAMP

TROUBLESHOOTINGM1542000701300

If the rear fog lamp switch is turned ON when the

headlamp or the front fog lamp is turned ON, the rear

fog lamp is switched ON and OFF alternatively.

If the headlamp and the front fog lamp, the rear fog

lamp is turned OFF at the same time.The fog lamps are controlled by the Smart Wiring

System (SWS). For Troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

SPECIAL TOOLM1542000600902

1 4

3 2

AC305276

AB

Front fog lamp relay

Battery voltage Tester

connectionSpecified

condition

Not supplied 1 − 4 Open circuit

•Connect

terminal 2 to

the positive

battery terminal

•Connect

terminal 3 to

the negative

battery terminal1 − 4 Less than 2

ohms

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

Page 464 of 788

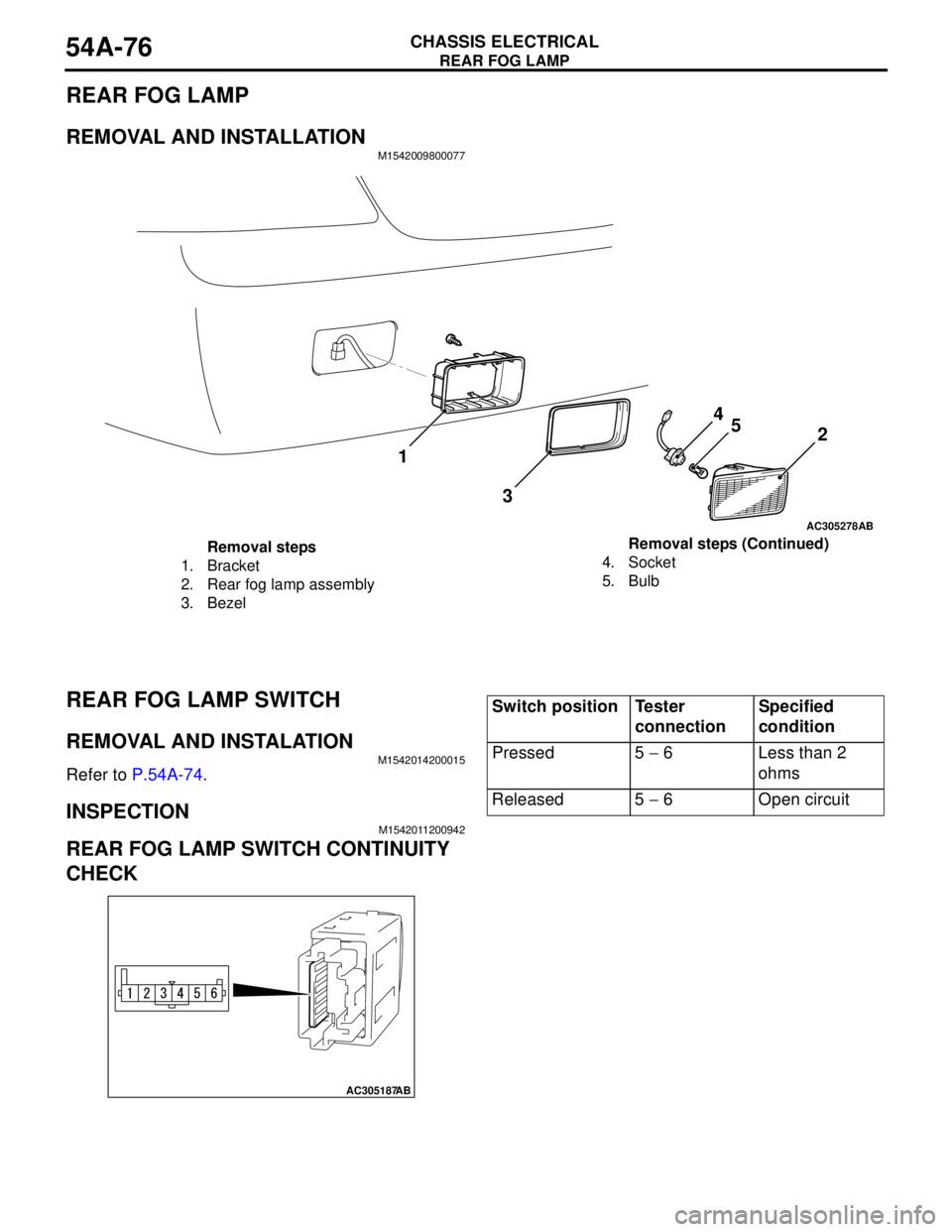

REAR FOG LAMP

CHASSIS ELECTRICAL54A-76

REAR FOG LAMP

REMOVAL AND INSTALLATIONM1542009800077

REAR FOG LAMP SWITCH

REMOVAL AND INSTALATIONM1542014200015

Refer to P.54A-74.

INSPECTIONM1542011200942

REAR FOG LAMP SWITCH CONTINUITY

CHECK

AC305278AB

32

1

4

5

Removal steps

1. Bracket

2. Rear fog lamp assembly

3. Bezel4. Socket

5. BulbRemoval steps (Continued)

AC305187

AB

Switch position Tester

connectionSpecified

condition

Pressed 5 − 6 Less than 2

ohms

Released 5 − 6 Open circuit