air condition MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 566 of 788

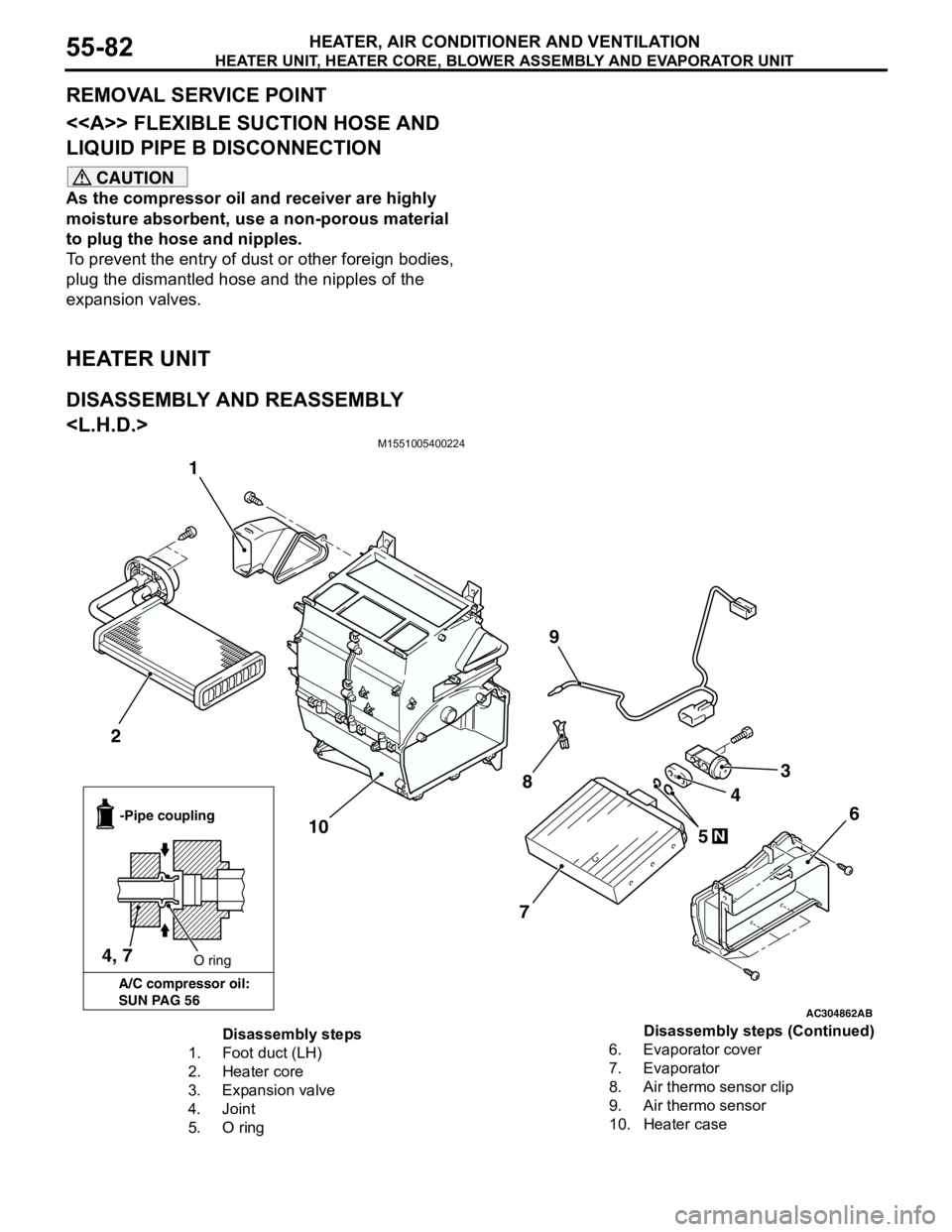

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-82

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

HEATER UNIT

DISASSEMBLY AND REASSEMBLY

M1551005400224

AC304862

1

2

3

4

5

6

7

8

9

10

AB

4, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

N

Disassembly steps

1. Foot duct (LH)

2. Heater core

3. Expansion valve

4. Joint

5. O ring6. Evaporator cover

7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

10. Heater caseDisassembly steps (Continued)

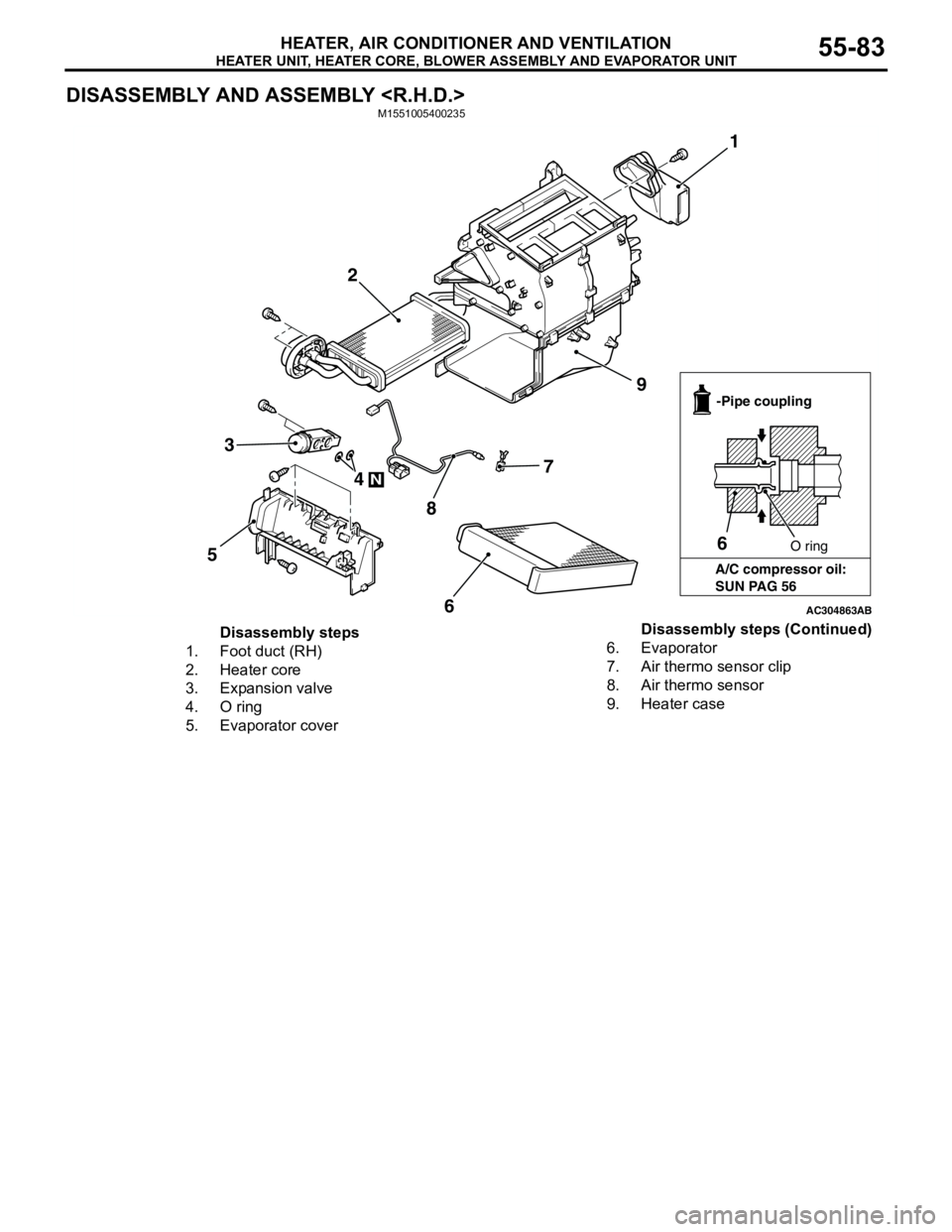

Page 567 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-83

DISASSEMBLY AND ASSEMBLY

AC304863

1

2

3

4

5

N

6

7

8

9

AB

6O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

Disassembly steps

1. Foot duct (RH)

2. Heater core

3. Expansion valve

4. O ring

5. Evaporator cover6. Evaporator

7. Air thermo sensor clip

8. Air thermo sensor

9. Heater caseDisassembly steps (Continued)

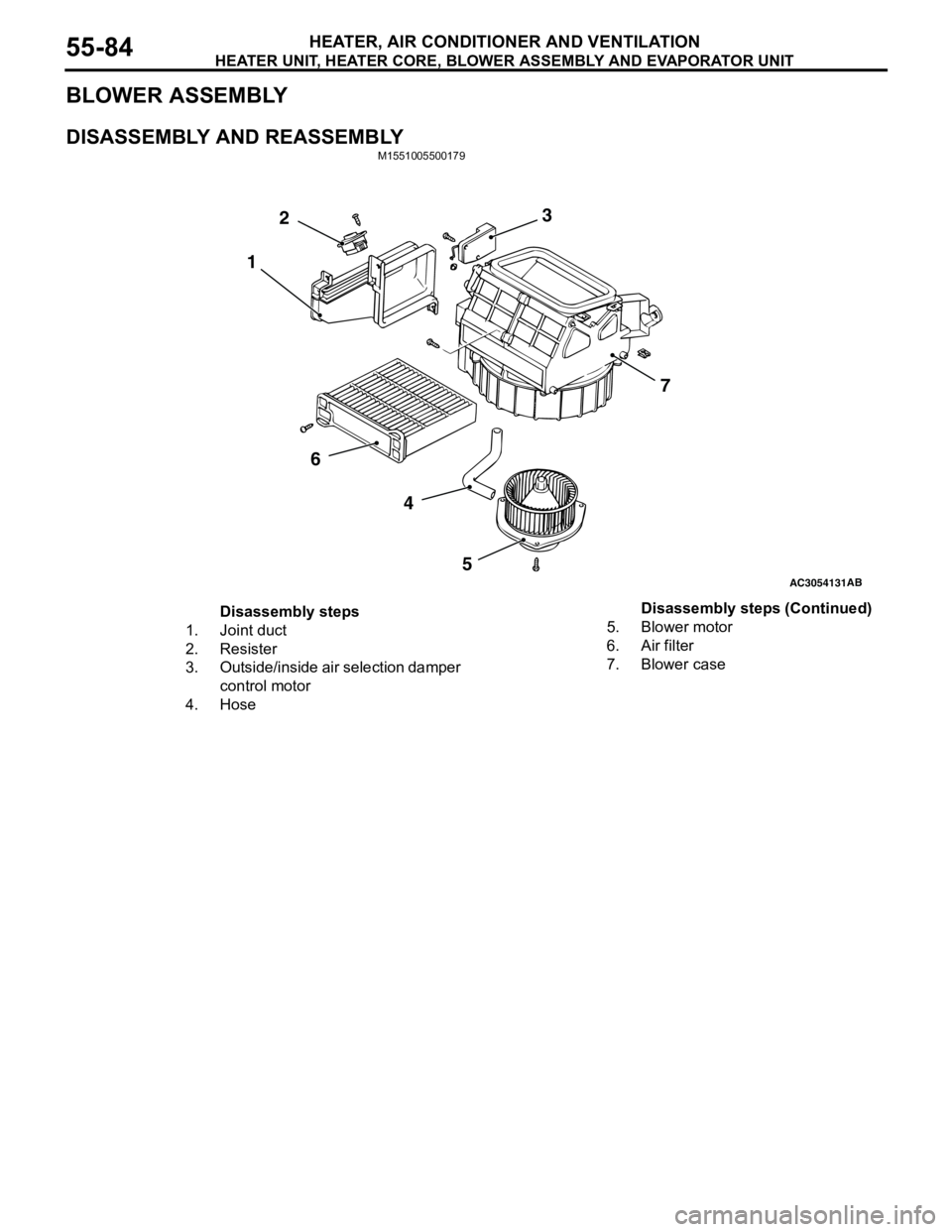

Page 568 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-84

BLOWER ASSEMBLY

DISASSEMBLY AND REASSEMBLYM1551005500179

AC3054131AB

3

4

57

6

12

Disassembly steps

1. Joint duct

2. Resister

3. Outside/inside air selection damper

control motor

4. Hose5. Blower motor

6. Air filter

7. Blower caseDisassembly steps (Continued)

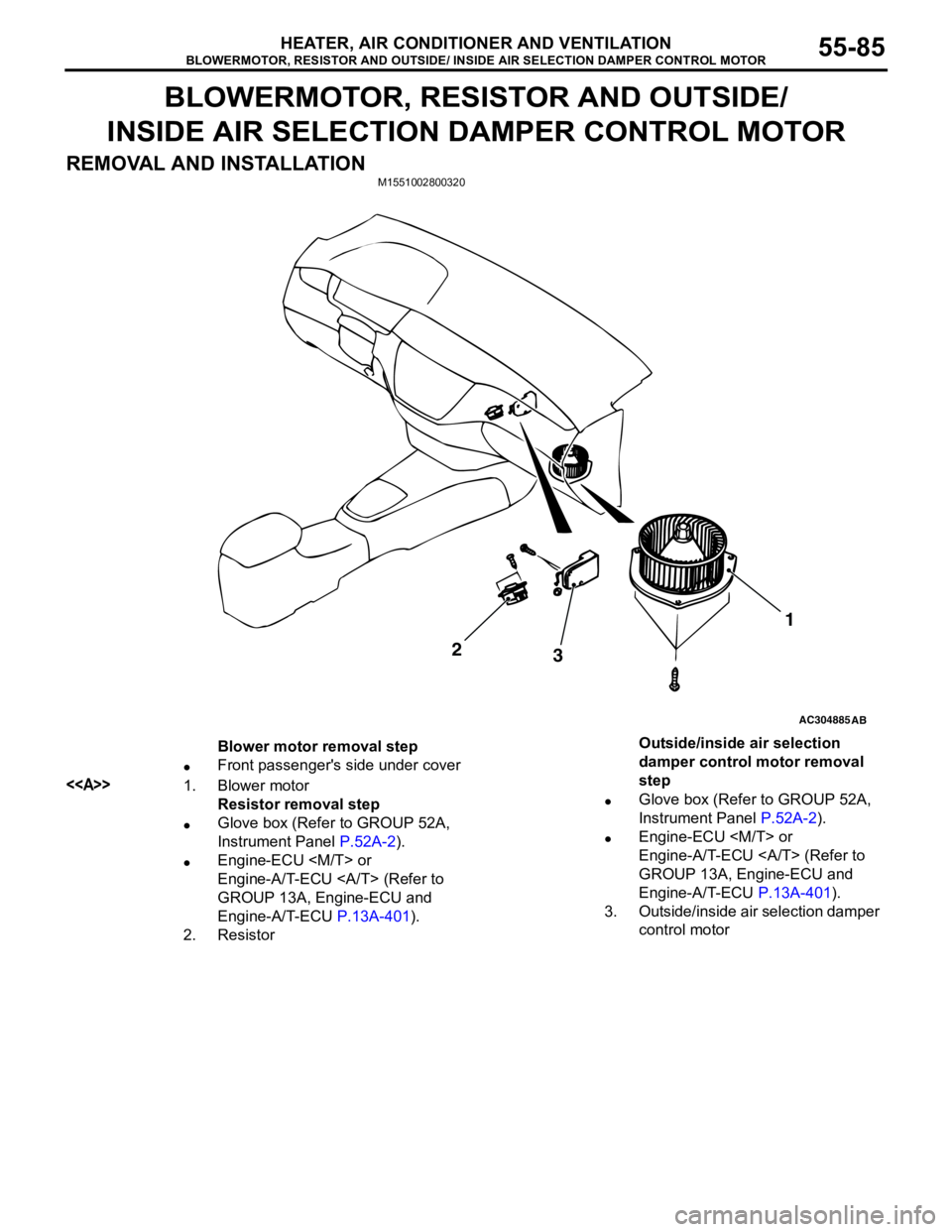

Page 569 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-85

BLOWERMOTOR, RESISTOR AND OUTSIDE/

INSIDE AIR SELECTION DAMPER CONTROL MOTOR

REMOVAL AND INSTALLATION

M1551002800320

AC304885AB

2

31

Blower motor removal step

•Front passenger's side under cover

<>1. Blower motor

Resistor removal step

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

2. ResistorOutside/inside air selection

damper control motor removal

step

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

3. Outside/inside air selection damper

control motor

Page 570 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-86

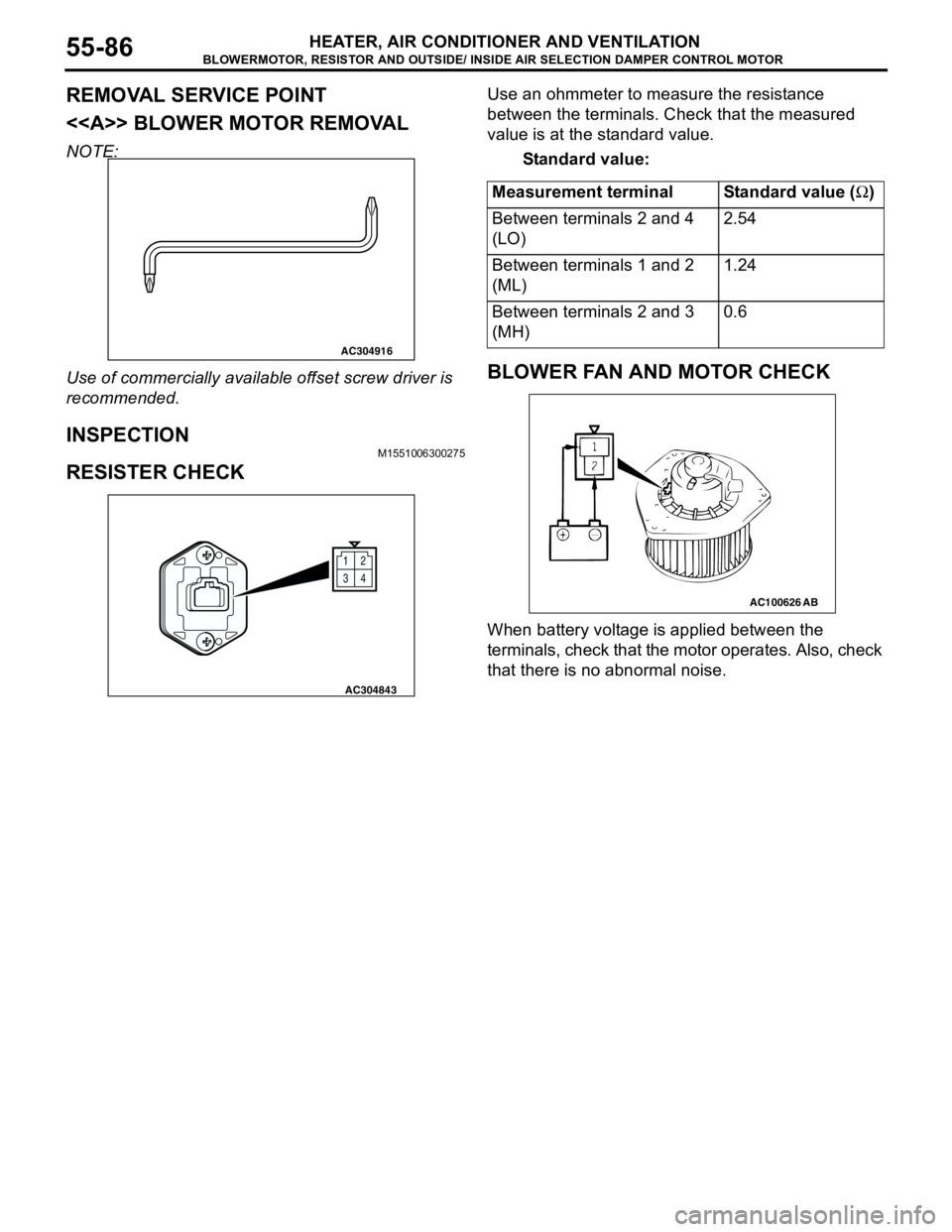

REMOVAL SERVICE POINT

<> BLOWER MOTOR REMOVAL

NOTE:

Use of commercially available offset screw driver is

recommended.

INSPECTIONM1551006300275

RESISTER CHECK

Use an ohmmeter to measure the resistance

between the terminals. Check that the measured

value is at the standard value.

Standard value:

BLOWER FAN AND MOTOR CHECK

When battery voltage is applied between the

terminals, check that the motor operates. Also, check

that there is no abnormal noise.

AC304916

12

34

AC304843

Measurement terminal Standard value (Ω)

Between terminals 2 and 4

(LO)2.54

Between terminals 1 and 2

(ML)1.24

Between terminals 2 and 3

(MH)0.6

AC100626AB

Page 571 of 788

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-87

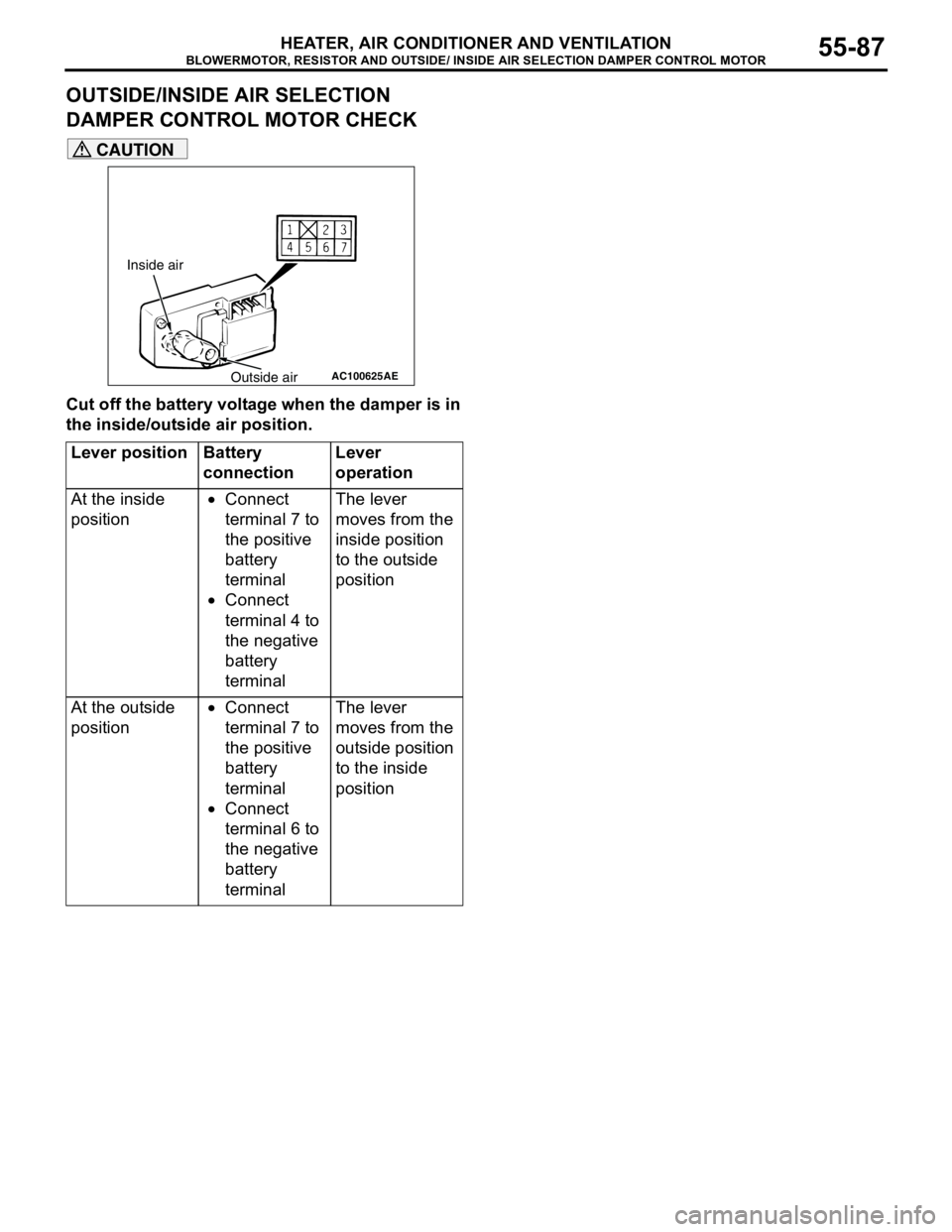

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR CHECK

CAUTION

Cut off the battery voltage when the damper is in

the inside/outside air position.

Lever position Battery

connectionLever

operation

At the inside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 4 to

the negative

battery

terminalThe lever

moves from the

inside position

to the outside

position

At the outside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 6 to

the negative

battery

terminalThe lever

moves from the

outside position

to the inside

position

AC100625

Inside air

Outside air

AE

Page 572 of 788

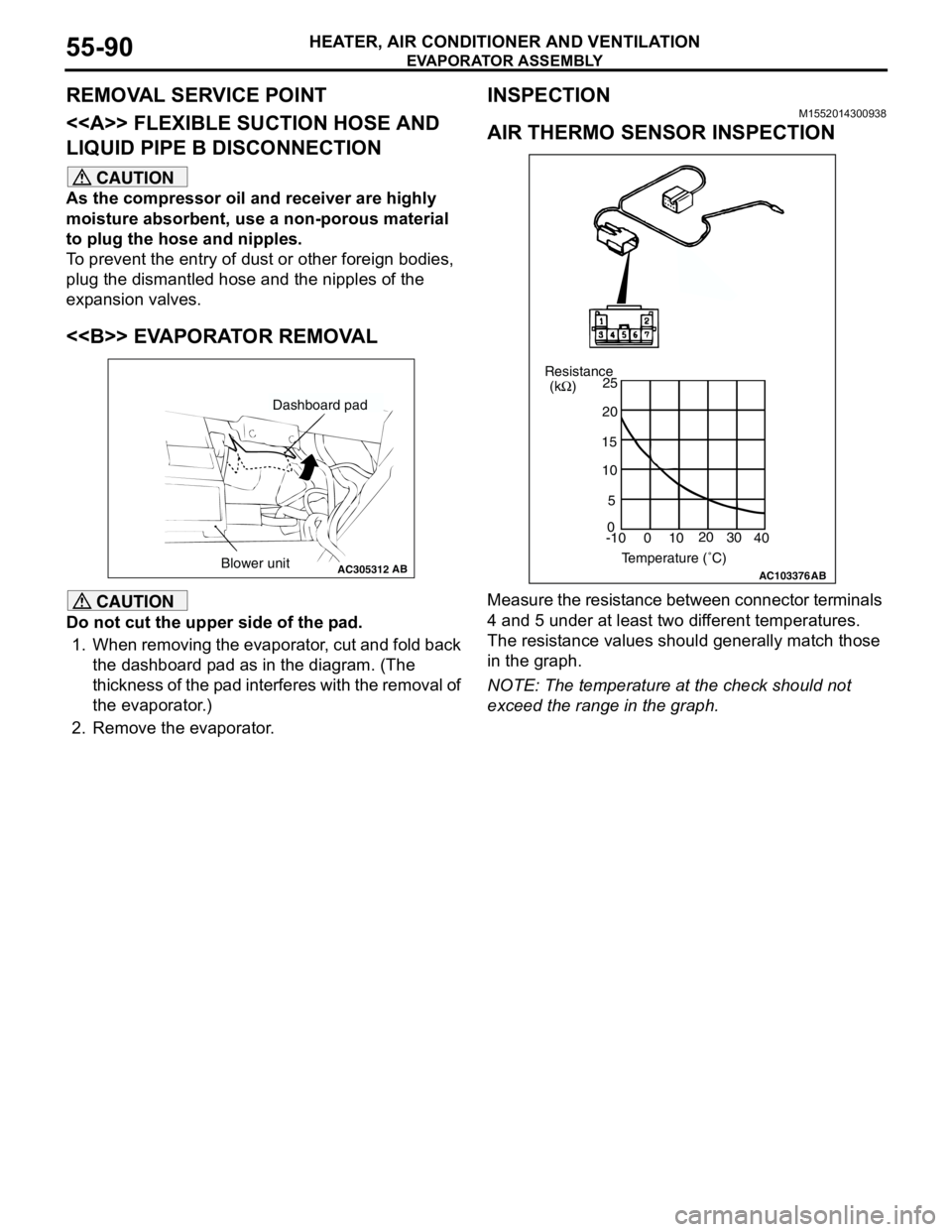

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-88

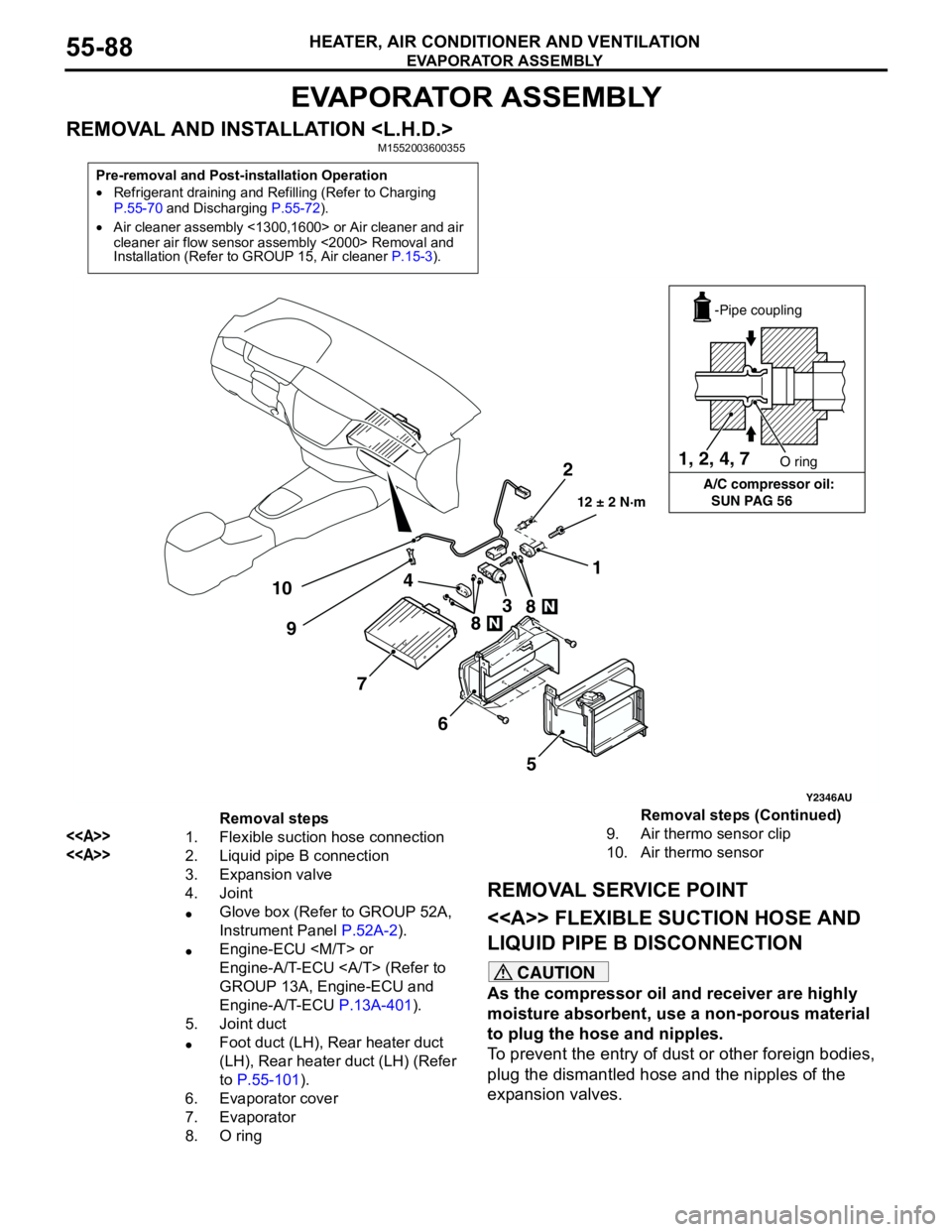

EVAPORATOR ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

Y2346AU

1, 2, 4, 7

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

2

101

3 4

7

6

5 98

8

12 ± 2 N·m

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

4. Joint

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

5. Joint duct

•Foot duct (LH), Rear heater duct

(LH), Rear heater duct (LH) (Refer

to P.55-101).

6. Evaporator cover

7. Evaporator

8. O ring 9. Air thermo sensor clip

10. Air thermo sensorRemoval steps (Continued)

Page 573 of 788

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-89

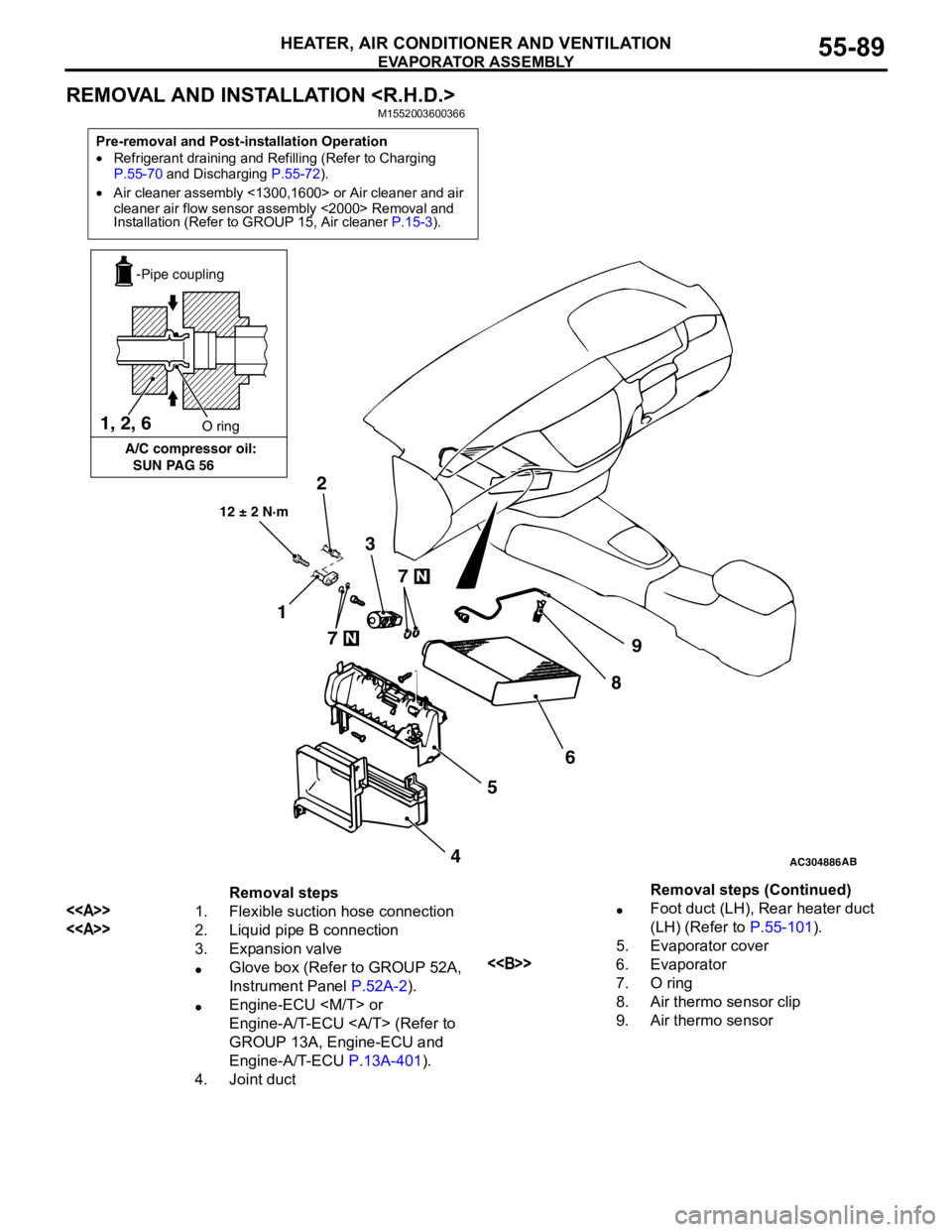

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

AC304886AB

12 ± 2 N·m

7

7

2

1

9

8

6

5

4 3 1, 2, 6

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

4. Joint duct•Foot duct (LH), Rear heater duct

(LH) (Refer to P.55-101).

5. Evaporator cover

<>6. Evaporator

7. O ring

8. Air thermo sensor clip

9. Air thermo sensorRemoval steps (Continued)

Page 574 of 788

Page 575 of 788

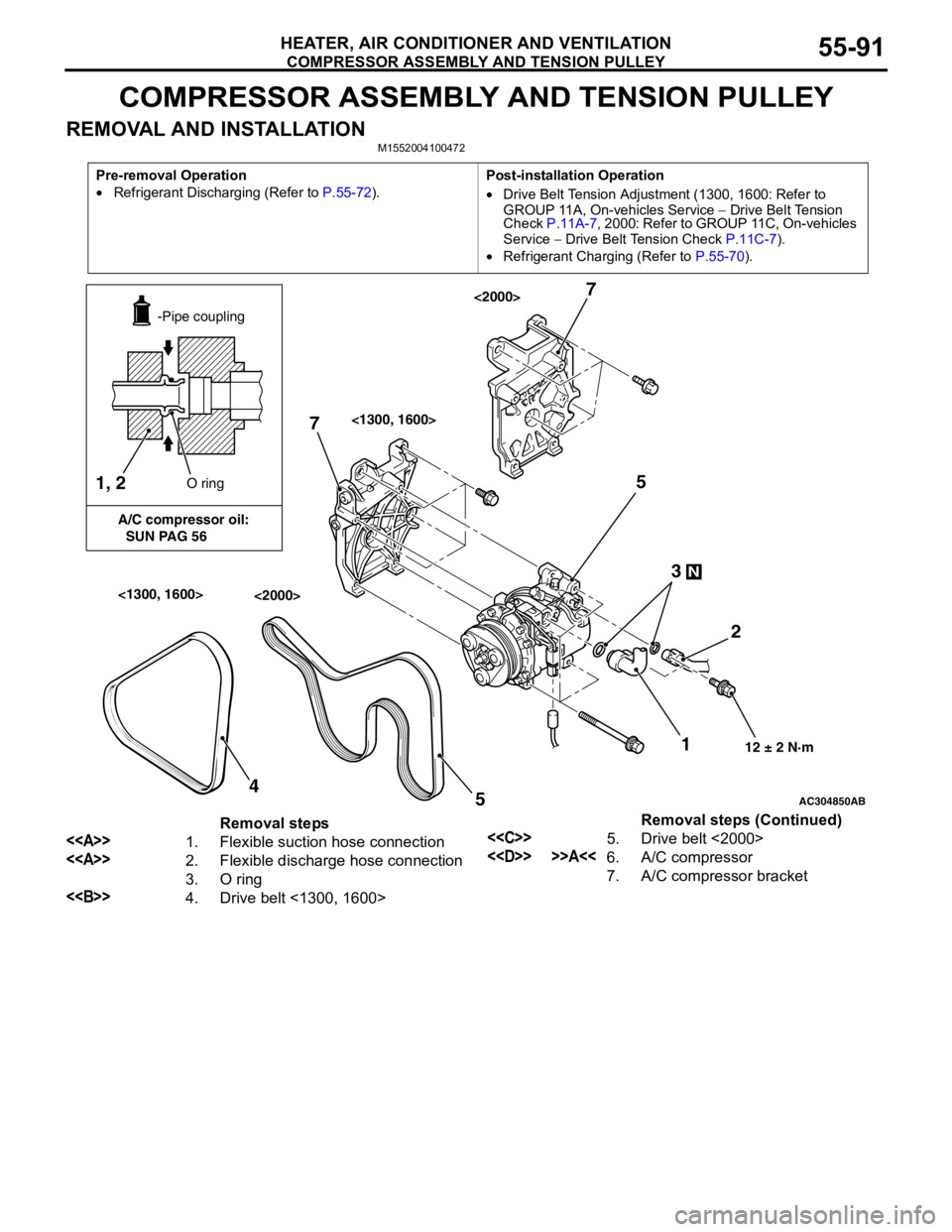

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-91

COMPRESSOR ASSEMBLY AND TENSION PULLEY

REMOVAL AND INSTALLATIONM1552004100472

Pre-removal Operation

•Refrigerant Discharging (Refer to P.55-72).Post-installation Operation

•Drive Belt Tension Adjustment (1300, 1600: Refer to

GROUP 11A, On-vehicles Service − Drive Belt Tension

Check P.11A-7, 2000: Refer to GROUP 11C, On-vehicles

Service − Drive Belt Tension Check P.11C-7).

•Refrigerant Charging (Refer to P.55-70).

AC304850

1, 2

A/C compressor oil:

SUN PAG 56-Pipe coupling

O ring

12 ± 2 N·m

N

12 3 5

AB

7

54

7

<1300, 1600>

<1300, 1600><2000>

<2000>

Removal steps

<>1. Flexible suction hose connection

<>2. Flexible discharge hose connection

3. O ring

<>4. Drive belt <1300, 1600>

<

<

7. A/C compressor bracketRemoval steps (Continued)