ect MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 189 of 788

STRUT ASSEMBLY

FRONT SUSPENSION33-7

STRUT ASSEMBLY

REMOVAL AND INSTALLATIONM1332001100325

INSPECTIONM1332001200247

•Check for oil leaks from the strut assembly.

•Check the strut assembly for damage or

deformation.

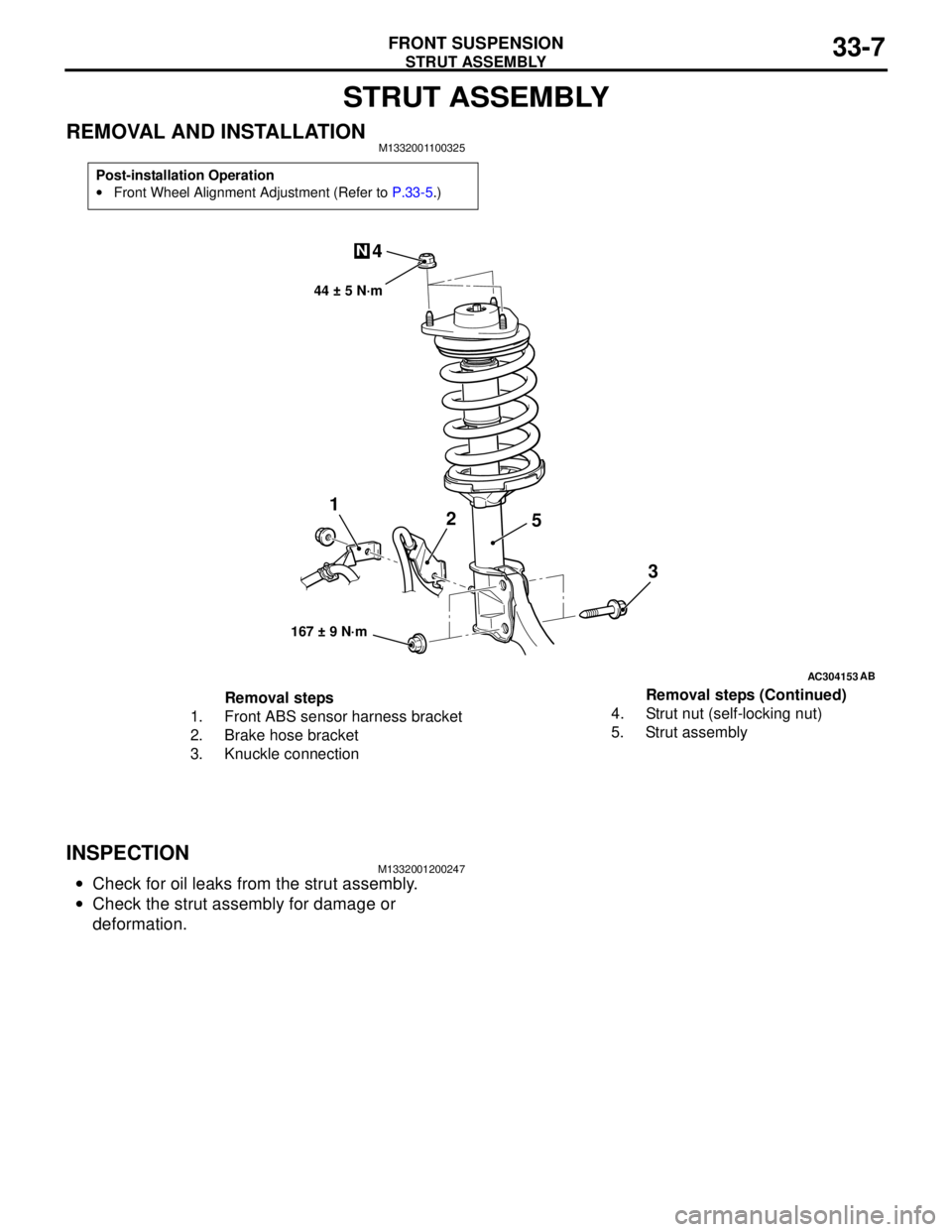

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-5.)

AC304153

44 ± 5 N·m

1

2

3 4

N

AB

167 ± 9 N·m

5

Removal steps

1. Front ABS sensor harness bracket

2. Brake hose bracket

3. Knuckle connection4. Strut nut (self-locking nut)

5. Strut assemblyRemoval steps (Continued)

Page 191 of 788

Page 192 of 788

STRUT ASSEMBLY

FRONT SUSPENSION33-10

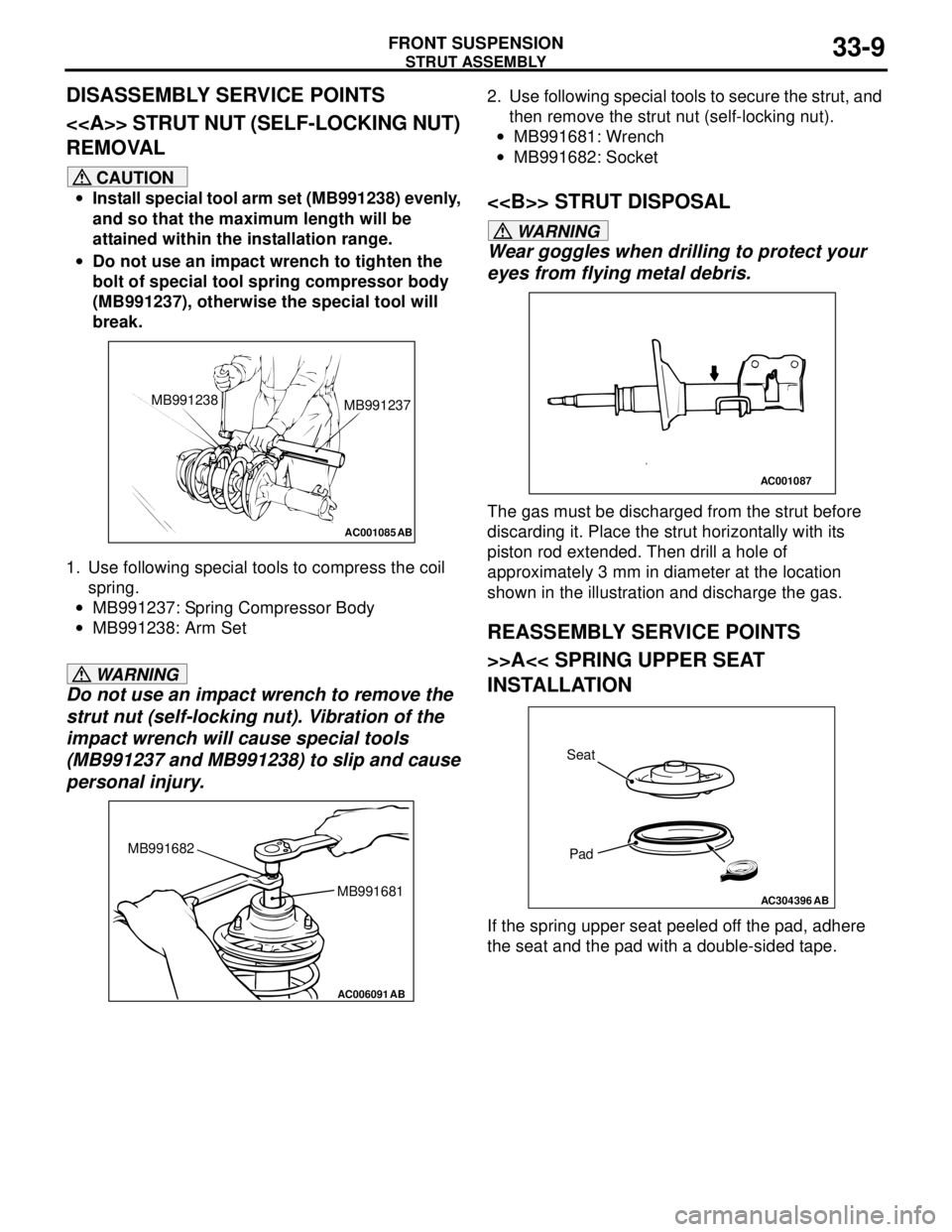

>>B<< STRUT NUT (SELF-LOCKING NUT)

INSTALLATION

1. Ensure that the bearing is seated correctly.

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237), otherwise the special tool will break.

2. Install following special tools to the strut assembly

same as its removal.

•MB991237: Spring Compressor Body

•MB991238: Arm Set

3. While the coil spring is being compressed by the

special tools, temporarily tighten the strut nut

(self-locking nut).

4. Align the hole in the strut spring lower seat with

the hole in the spring upper seat.

NOTE:

Using a rod as shown facilitates the alignment.5. Align lower end of the coil spring with the groove

in the spring lower seat, and then loosen the

special tools.CAUTION

Do not use an impact wrench to tighten the

self-locking nut, otherwise the strut nut

(self-locking nut) will be damaged.

6. Using following special tools, tighten the strut nut

(self-locking nut) to 60 ± 10 N⋅m.

•MB991681: Wrench

•MB991682: Socket

INSPECTIONM1332001400188

•Check the strut bearing for wear or rust.

•Check the rubber parts for damage or

deterioration.

•Check the coil spring for deformation,

deterioration or damage.

•Check the strut for deformation.

AC001085 AB

MB991238

MB991237

AC006091 AB

Rod

AC006091 AB

MB991681 MB991682

Page 194 of 788

Page 195 of 788

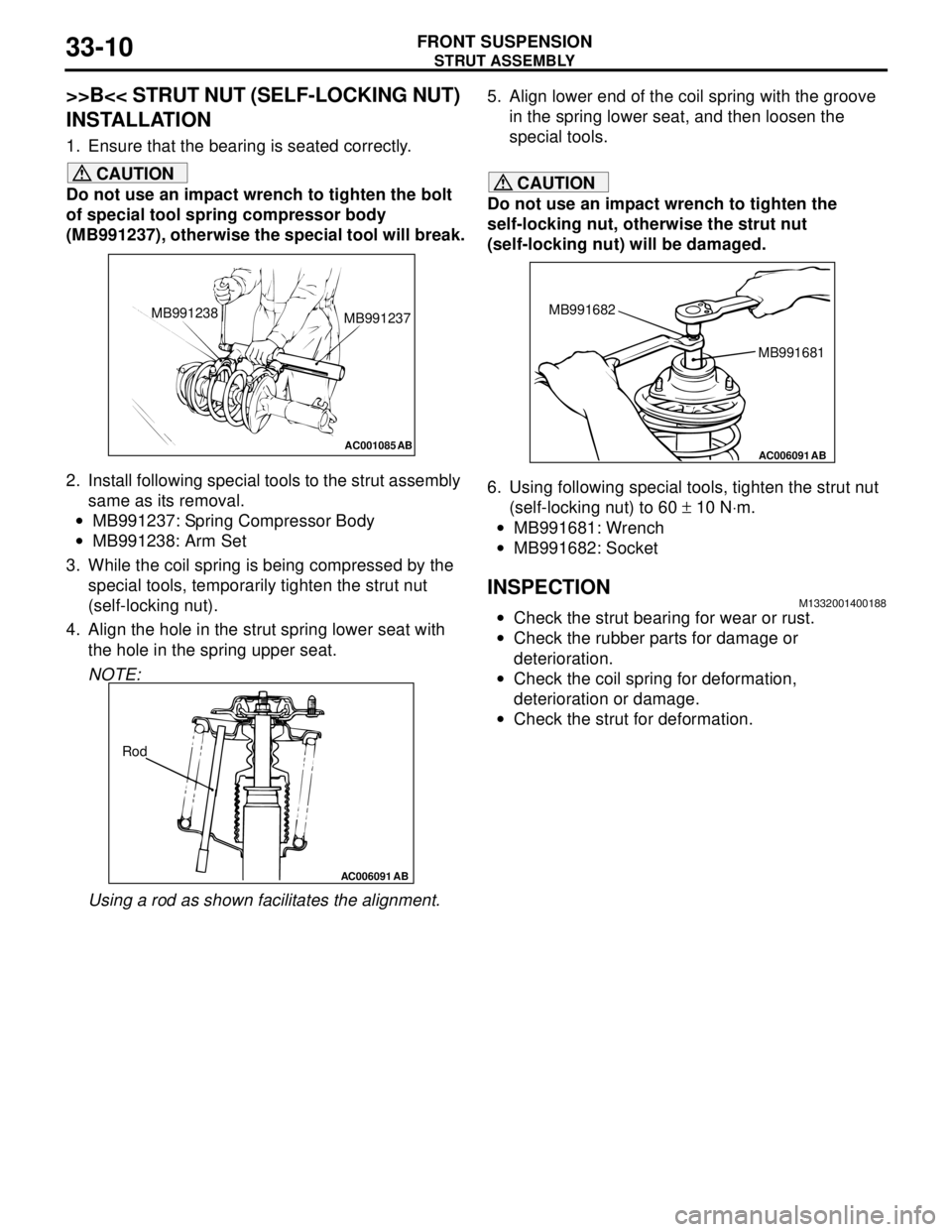

LOWER ARM

FRONT SUSPENSION33-13

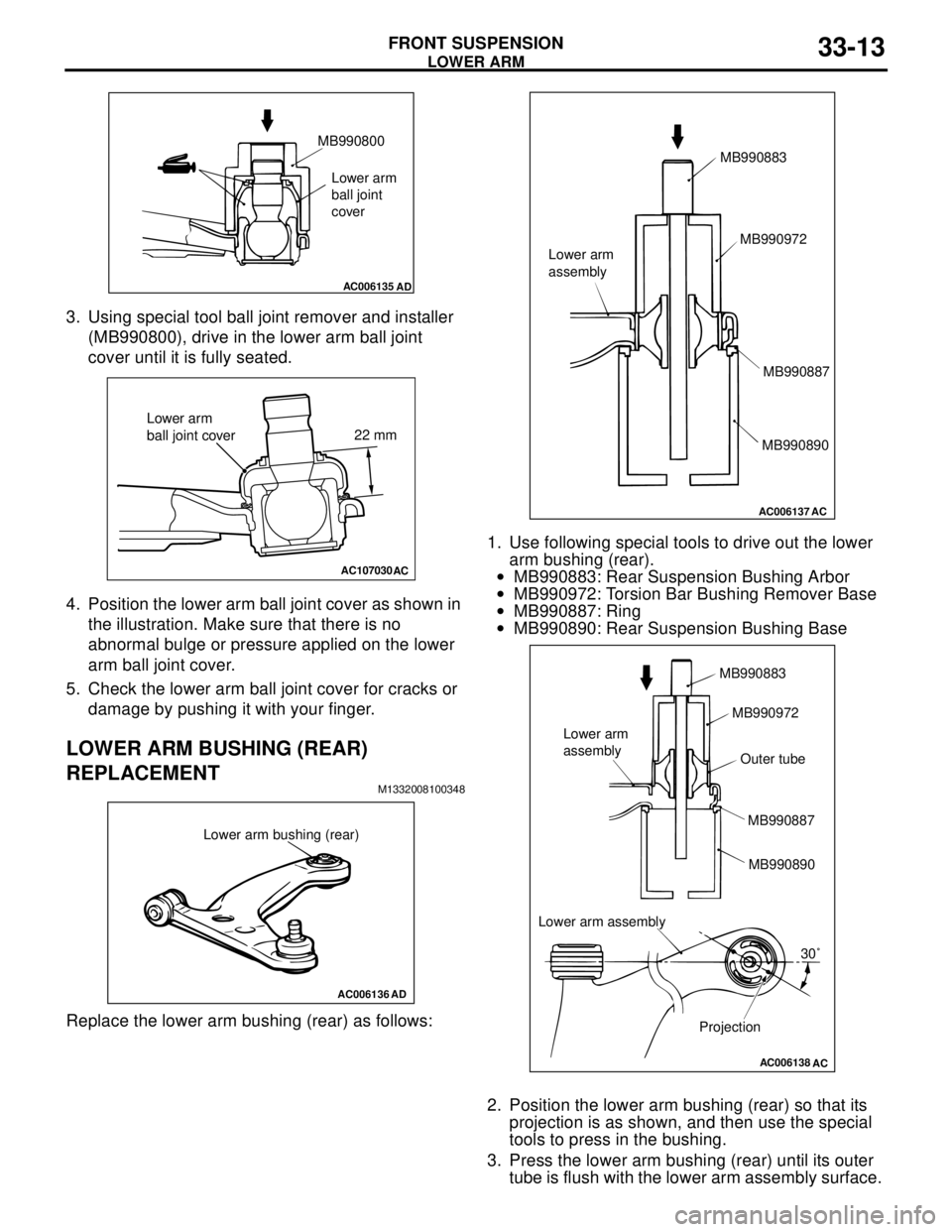

3. Using special tool ball joint remover and installer

(MB990800), drive in the lower arm ball joint

cover until it is fully seated.

4. Position the lower arm ball joint cover as shown in

the illustration. Make sure that there is no

abnormal bulge or pressure applied on the lower

arm ball joint cover.

5. Check the lower arm ball joint cover for cracks or

damage by pushing it with your finger.

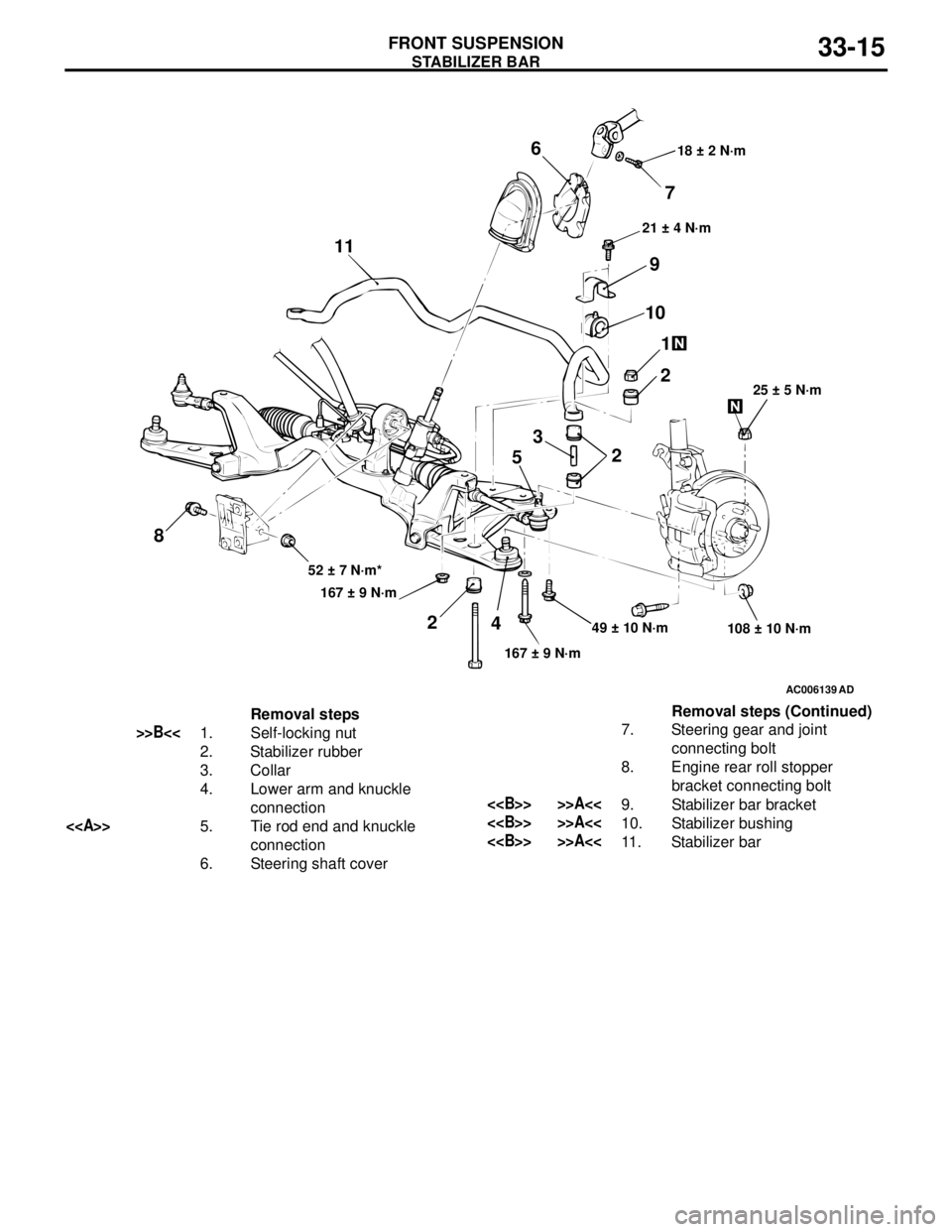

LOWER ARM BUSHING (REAR)

REPLACEMENT

M1332008100348

Replace the lower arm bushing (rear) as follows:1. Use following special tools to drive out the lower

arm bushing (rear).

•MB990883: Rear Suspension Bushing Arbor

•MB990972: Torsion Bar Bushing Remover Base

•MB990887: Ring

•MB990890: Rear Suspension Bushing Base

2. Position the lower arm bushing (rear) so that its

projection is as shown, and then use the special

tools to press in the bushing.

3. Press the lower arm bushing (rear) until its outer

tube is flush with the lower arm assembly surface.

AC006135

AD

MB990800

Lower arm

ball joint

cover

AC107030AC

22 mm

Lower arm

ball joint cover

AC006136

AD

Lower arm bushing (rear)

AC006137

AC

MB990883

MB990972

MB990887

MB990890 Lower arm

assembly

AC006138

AC

MB990883

MB990972

MB990887

MB990890 Lower arm

assembly

Projection30˚ Lower arm assemblyOuter tube

Page 197 of 788

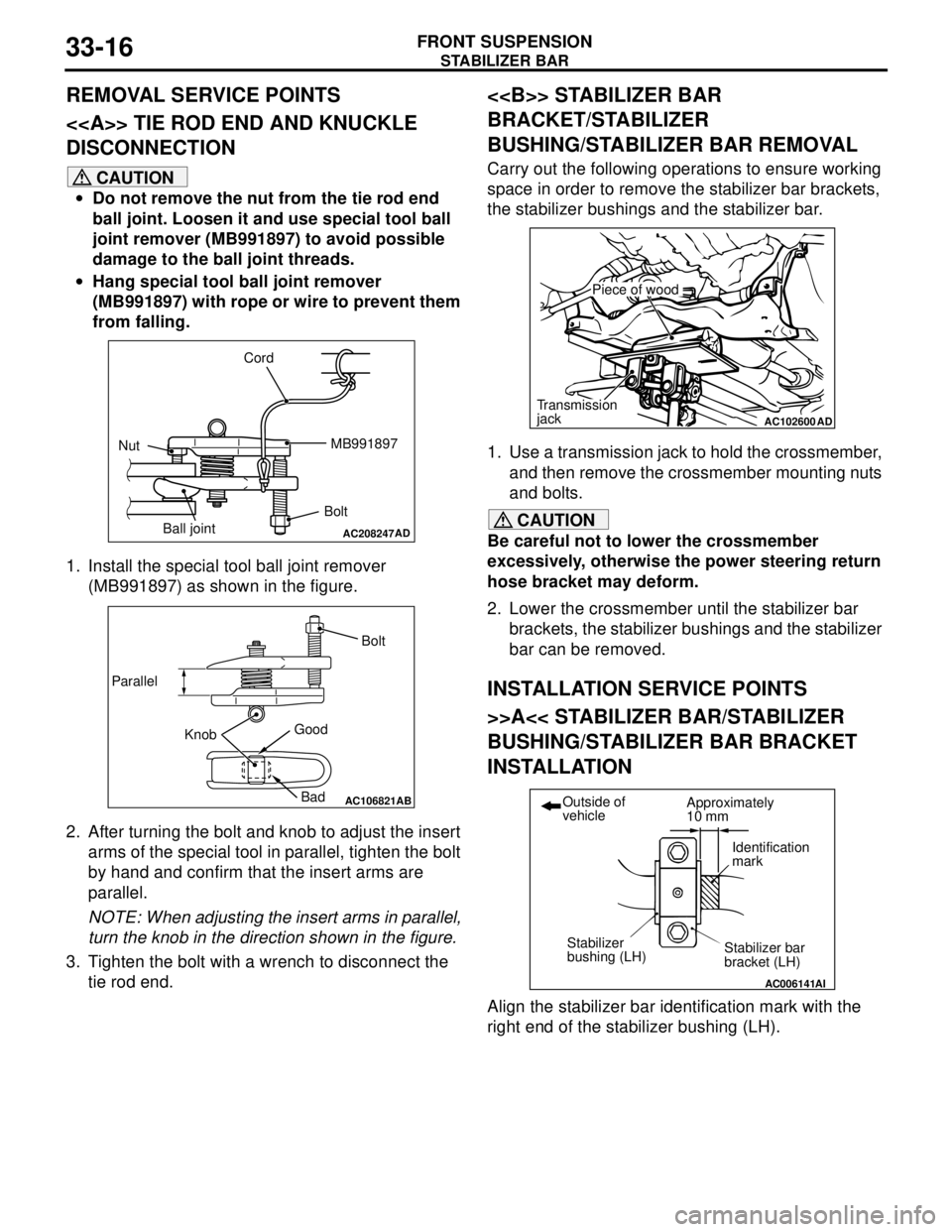

STABILIZER BAR

FRONT SUSPENSION33-15

AC006139

AD

49 ± 10 N·m

108 ± 10 N·m

167 ± 9 N·m 167 ± 9 N·m 52 ± 7 N·m*25 ± 5 N·m 21 ± 4 N·m 18 ± 2 N·m

7 6

9

10

1

2

2 3

5

4 2 11

8

Removal steps

>>B<<1. Self-locking nut

2. Stabilizer rubber

3. Collar

4. Lower arm and knuckle

connection

<>5. Tie rod end and knuckle

connection

6. Steering shaft cover7. Steering gear and joint

connecting bolt

8. Engine rear roll stopper

bracket connecting bolt

<> >>A<<9. Stabilizer bar bracket

<> >>A<<10. Stabilizer bushing

<> >>A<<11. Stabilizer barRemoval steps (Continued)

Page 198 of 788

Page 199 of 788

STABILIZER BAR

FRONT SUSPENSION33-17

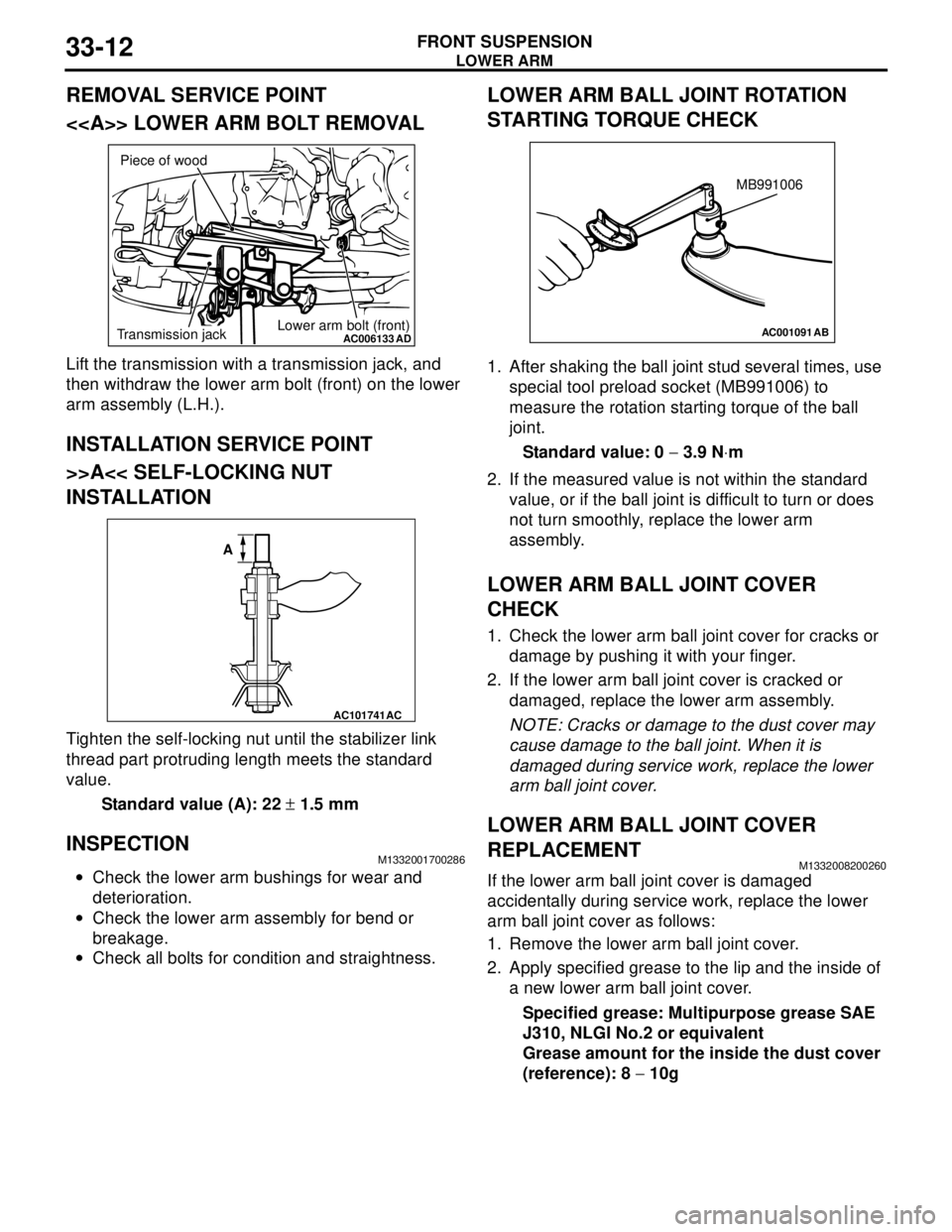

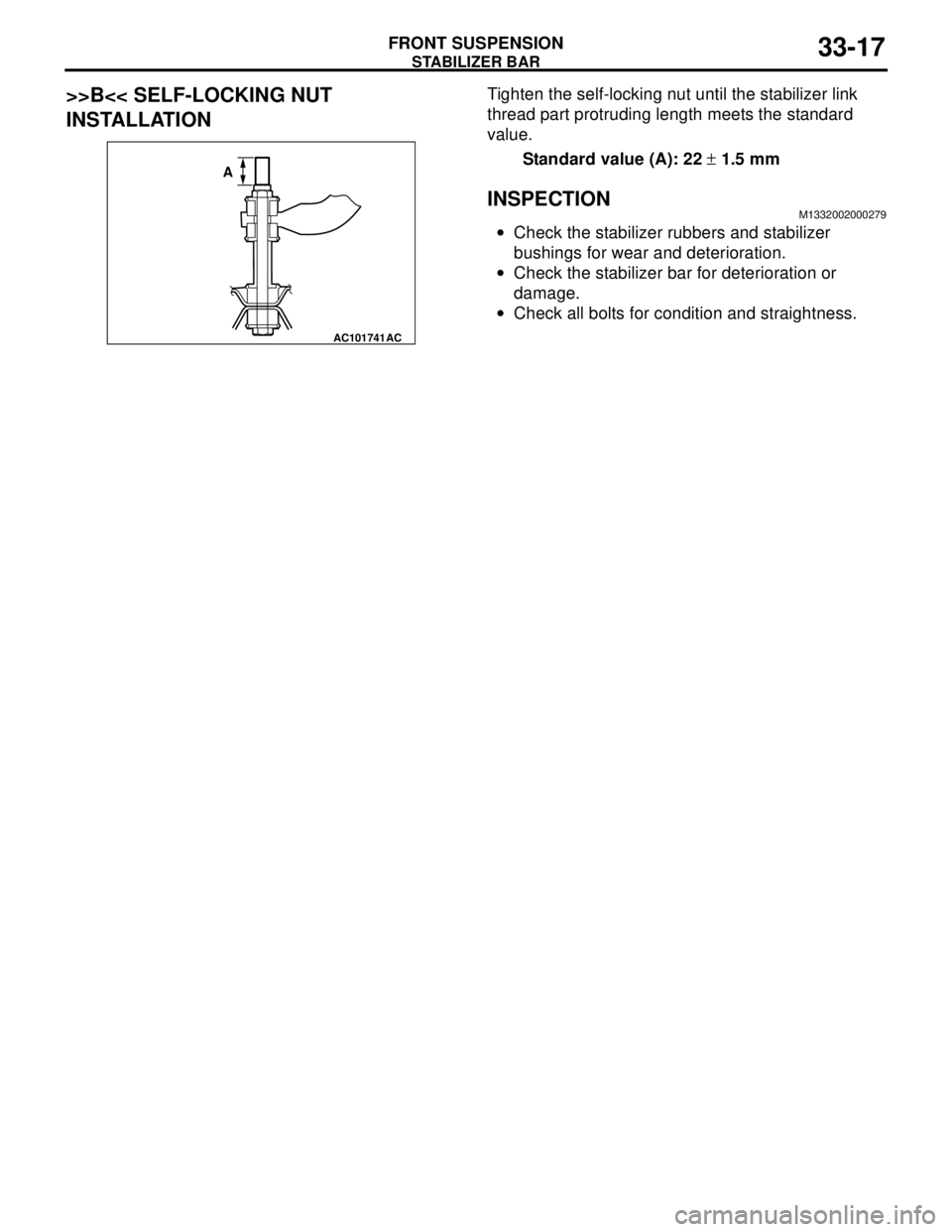

>>B<< SELF-LOCKING NUT

INSTALLATIONTighten the self-locking nut until the stabilizer link

thread part protruding length meets the standard

value.

Standard value (A): 22 ± 1.5 mm

INSPECTIONM1332002000279

•Check the stabilizer rubbers and stabilizer

bushings for wear and deterioration.

•Check the stabilizer bar for deterioration or

damage.

•Check all bolts for condition and straightness.

AC101741AC

A

Page 201 of 788

34-1

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .34-2

SERVICE SPECIFICATIONS . . . . . . .34-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .34-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .34-4

ON-VEHICLE SERVICE . . . . . . . . . . .34-5

REAR WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 34-5

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK . . . . . . . . . . . . . . . . . 34-7

STABILIZER LINK BALL JOINT

DUST COVER INSPECTION . . . . . . . . . . . 34-7

CONTROL LINK, UPPER ARM AND

LOWER ARM . . . . . . . . . . . . . . . . . . .34-8

REMOVAL AND INSTALLATION . . . . . . . . 34-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-9

LOWER ARM BUSHING AND LOWER

ARM PILLOW BALL BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-10

TRAILING ARM ASSEMBLY . . . . . . .34-12

REMOVAL AND INSTALLATION . . . . . . . . 34-12

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-13

TRAILING ARM BUSHING

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 34-13

SHOCK ABSORBER ASSEMBLY . . .34-15

REMOVAL AND INSTALLATION . . . . . . . . 34-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-16

DISASSEMBLY AND REASSEMBLY . . . . . 34-17

STABILIZER BAR. . . . . . . . . . . . . . . .34-20

REMOVAL AND INSTALLATION . . . . . . . . 34-20

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 34-21

STABILIZER LINK BALL JOINT

DUST COVER REPLACEMENT . . . . . . . . . 34-21

Page 205 of 788

ON-VEHICLE SERVICE

REAR SUSPENSION34-5

ON-VEHICLE SERVICE

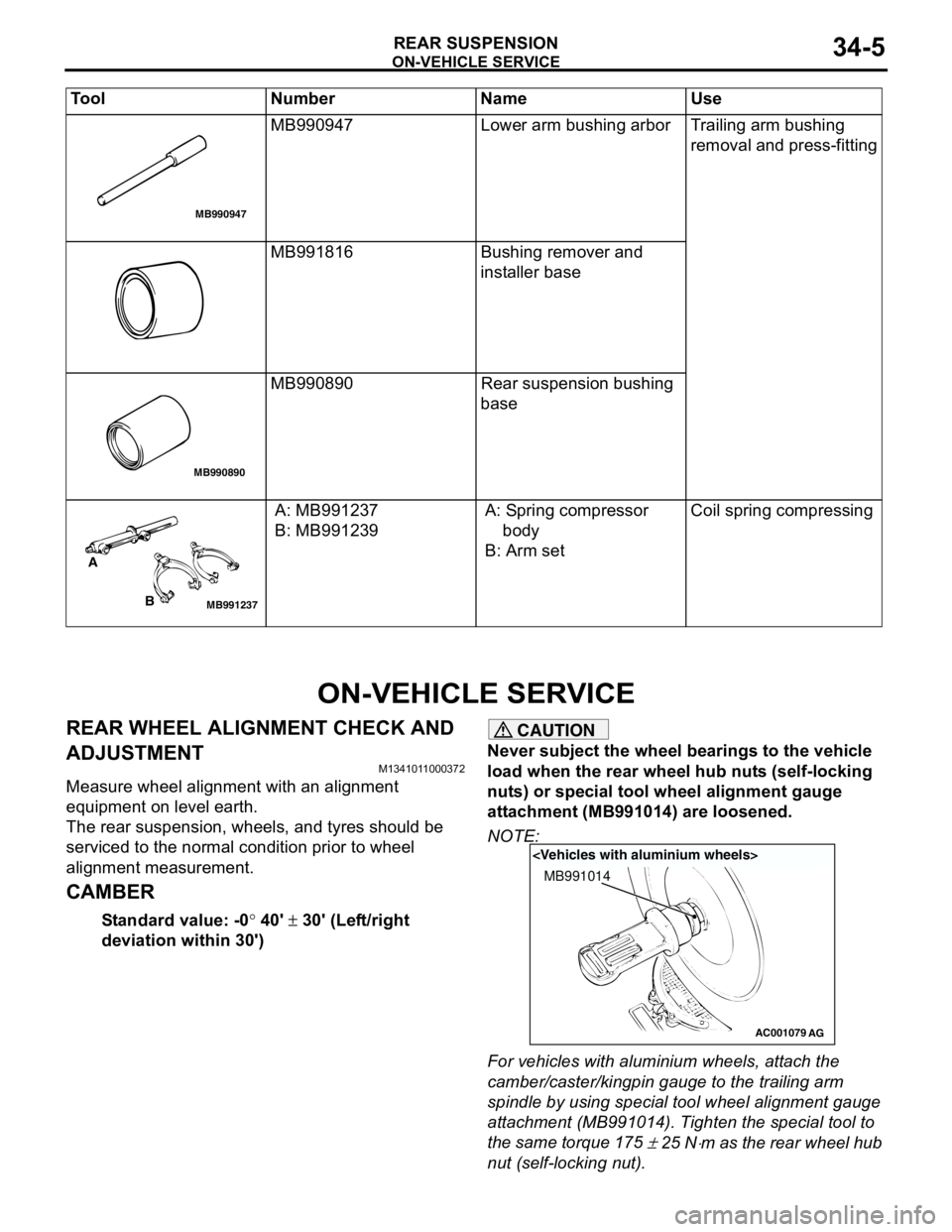

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment

equipment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel

alignment measurement.

CAMBER

Standard value: -0° 40' ± 30' (Left/right

deviation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

NOTE:

For vehicles with aluminium wheels, attach the

camber/caster/kingpin gauge to the trailing arm

spindle by using special tool wheel alignment gauge

attachment (MB991014). Tighten the special tool to

the same torque 175

± 25 N⋅m as the rear wheel hub

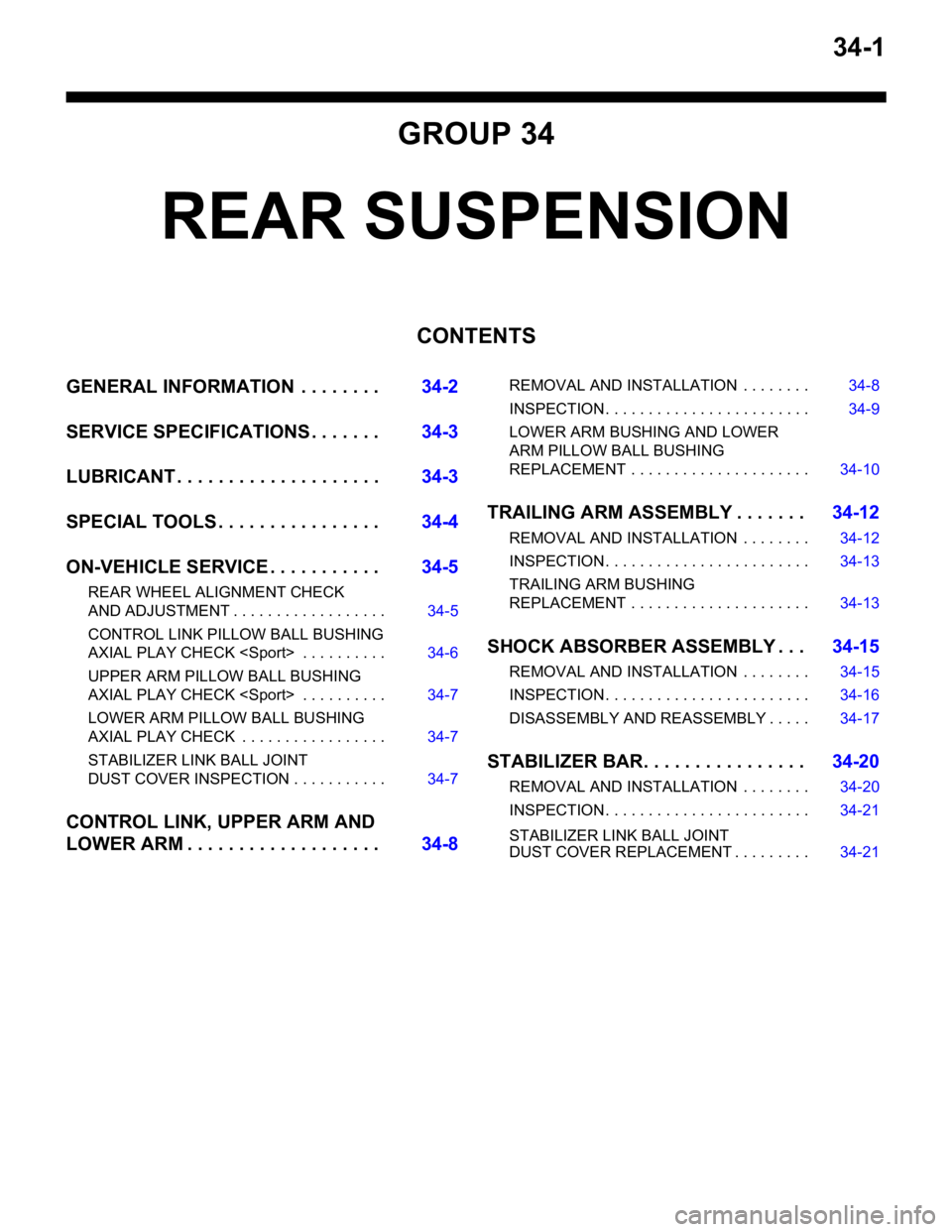

nut (self-locking nut). MB990947 Lower arm bushing arbor Trailing arm bushing

removal and press-fitting

MB991816 Bushing remover and

installer base

MB990890 Rear suspension bushing

base

A: MB991237

B: MB991239A: Spring compressor

body

B: Arm setCoil spring compressing Tool Number Name Use

MB990947

MB990890

MB991237

A

B

AC001079

MB991014

AG