52a MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 300 of 788

WINDOW GLASS

BODY42-22

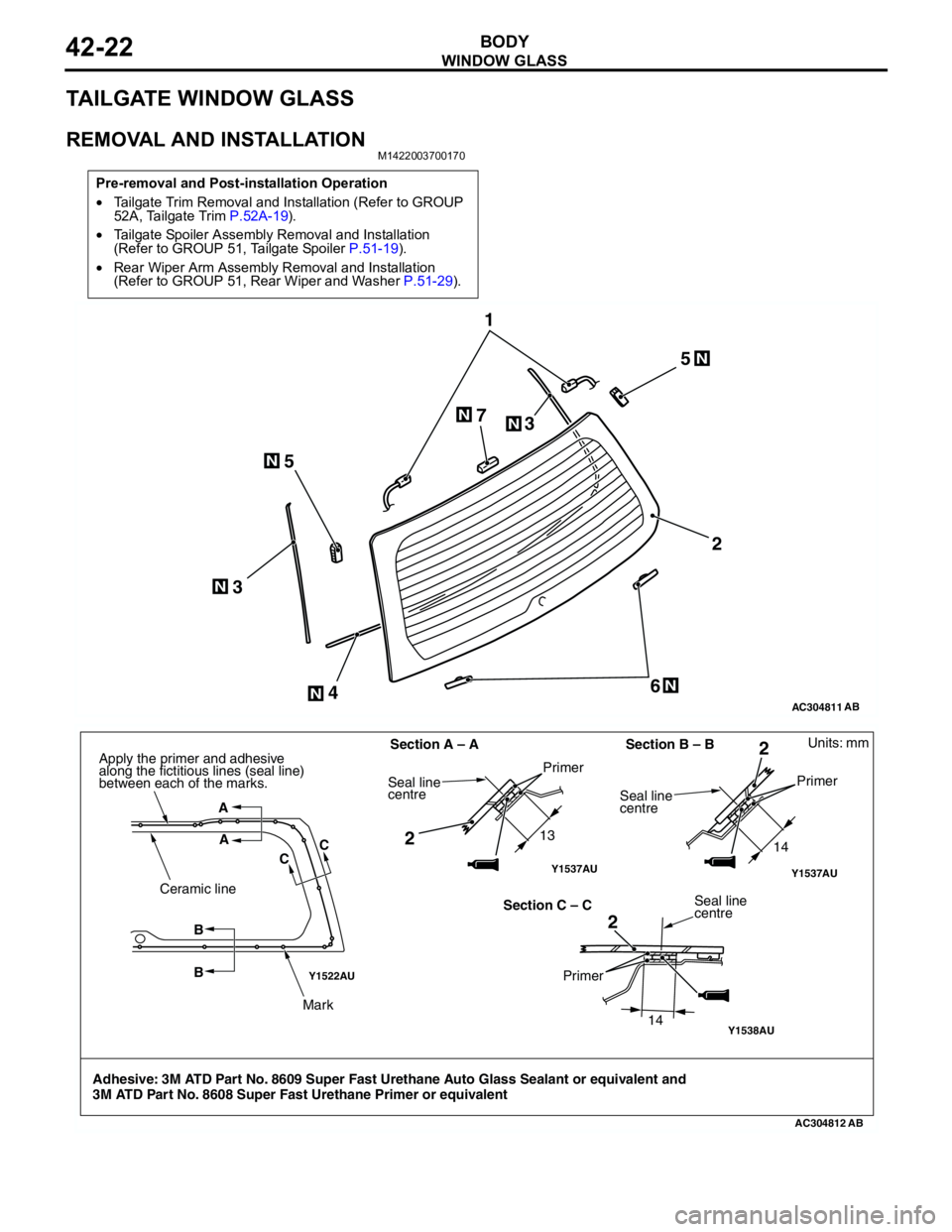

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATIONM1422003700170

Pre-removal and Post-installation Operation

•Tailgate Trim Removal and Installation (Refer to GROUP

52A, Tailgate Trim P.52A-19).

•Tailgate Spoiler Assembly Removal and Installation

(Refer to GROUP 51, Tailgate Spoiler P.51-19).

•Rear Wiper Arm Assembly Removal and Installation

(Refer to GROUP 51, Rear Wiper and Washer P.51-29).

AC304811

1

2

6 55

4 33 7

AB

N

NN

N

N

N

N

Y1522AU

Y1538AU

AC304812

Y1537AUY1537AU

AB

Units: mm

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalentSection A – A

13

14

14 Section B – B

Section C – C A

A

CC

B

B Ceramic line

Mark Apply the primer and adhesive

along the fictitious lines (seal line)

between each of the marks.

Seal line

centrePrimer

Seal line

centrePrimer

Seal line

centre

Primer

22

2

Page 306 of 788

DOOR

BODY42-28

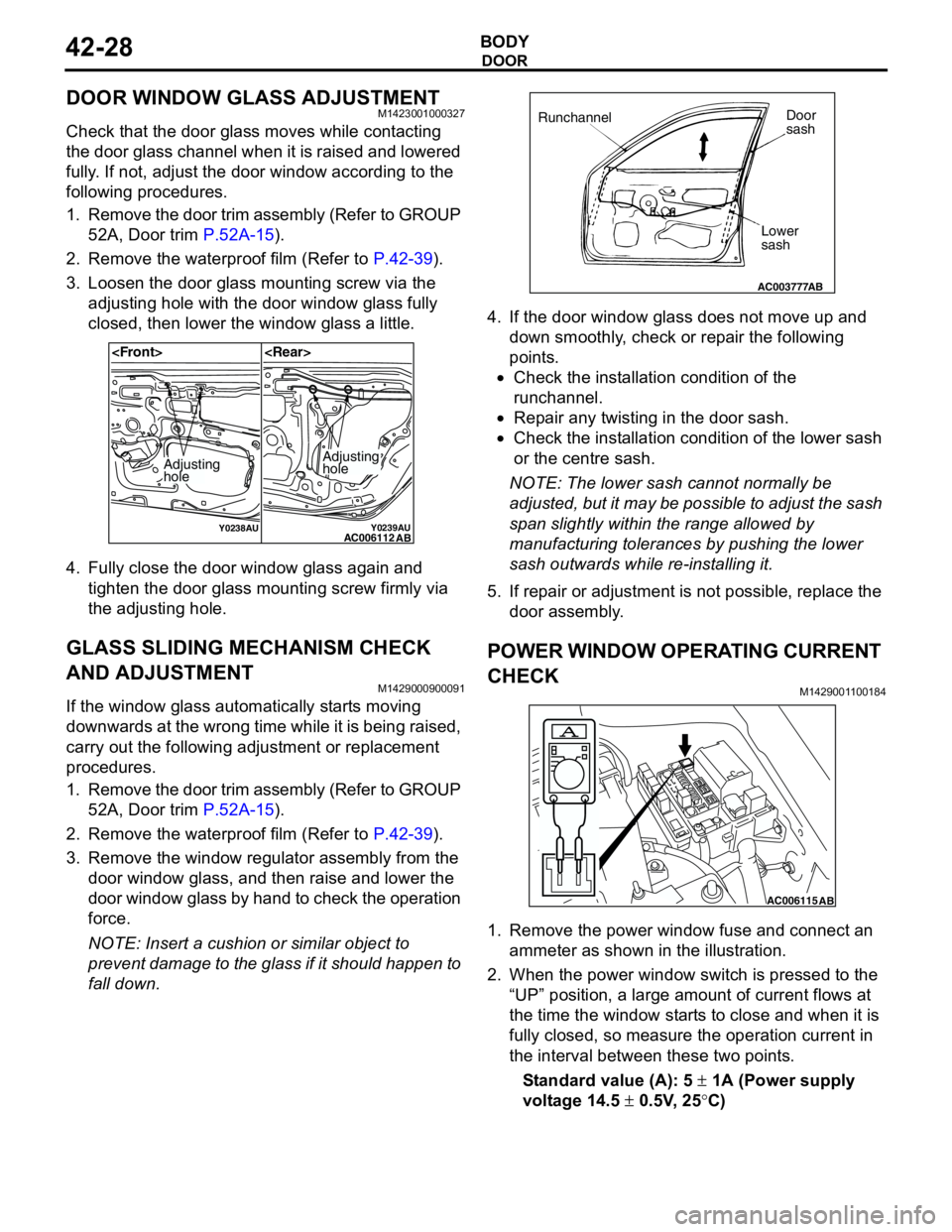

DOOR WINDOW GLASS ADJUSTMENTM1423001000327

Check that the door glass moves while contacting

the door glass channel when it is raised and lowered

fully. If not, adjust the door window according to the

following procedures.

1. Remove the door trim assembly (Refer to GROUP

52A, Door trim P.52A-15).

2. Remove the waterproof film (Refer to P.42-39).

3. Loosen the door glass mounting screw via the

adjusting hole with the door window glass fully

closed, then lower the window glass a little.

4. Fully close the door window glass again and

tighten the door glass mounting screw firmly via

the adjusting hole.

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT

M1429000900091

If the window glass automatically starts moving

downwards at the wrong time while it is being raised,

carry out the following adjustment or replacement

procedures.

1. Remove the door trim assembly (Refer to GROUP

52A, Door trim P.52A-15).

2. Remove the waterproof film (Refer to P.42-39).

3. Remove the window regulator assembly from the

door window glass, and then raise and lower the

door window glass by hand to check the operation

force.

NOTE: Insert a cushion or similar object to

prevent damage to the glass if it should happen to

fall down.4. If the door window glass does not move up and

down smoothly, check or repair the following

points.

•Check the installation condition of the

runchannel.

•Repair any twisting in the door sash.

•Check the installation condition of the lower sash

or the centre sash.

NOTE: The lower sash cannot normally be

adjusted, but it may be possible to adjust the sash

span slightly within the range allowed by

manufacturing tolerances by pushing the lower

sash outwards while re-installing it.

5. If repair or adjustment is not possible, replace the

door assembly.

POWER WINDOW OPERATING CURRENT

CHECK

M1429001100184

1. Remove the power window fuse and connect an

ammeter as shown in the illustration.

2. When the power window switch is pressed to the

“UP” position, a large amount of current flows at

the time the window starts to close and when it is

fully closed, so measure the operation current in

the interval between these two points.

Standard value (A): 5 ± 1A (Power supply

voltage 14.5 ± 0.5V, 25°C)

Y0238AUY0239AUAC006112

AB

Adjusting

holeAdjusting

hole

AC003777

RunchannelDoor

sash

Lower

sash

AB

AC006115AB

Page 308 of 788

DOOR

BODY42-30

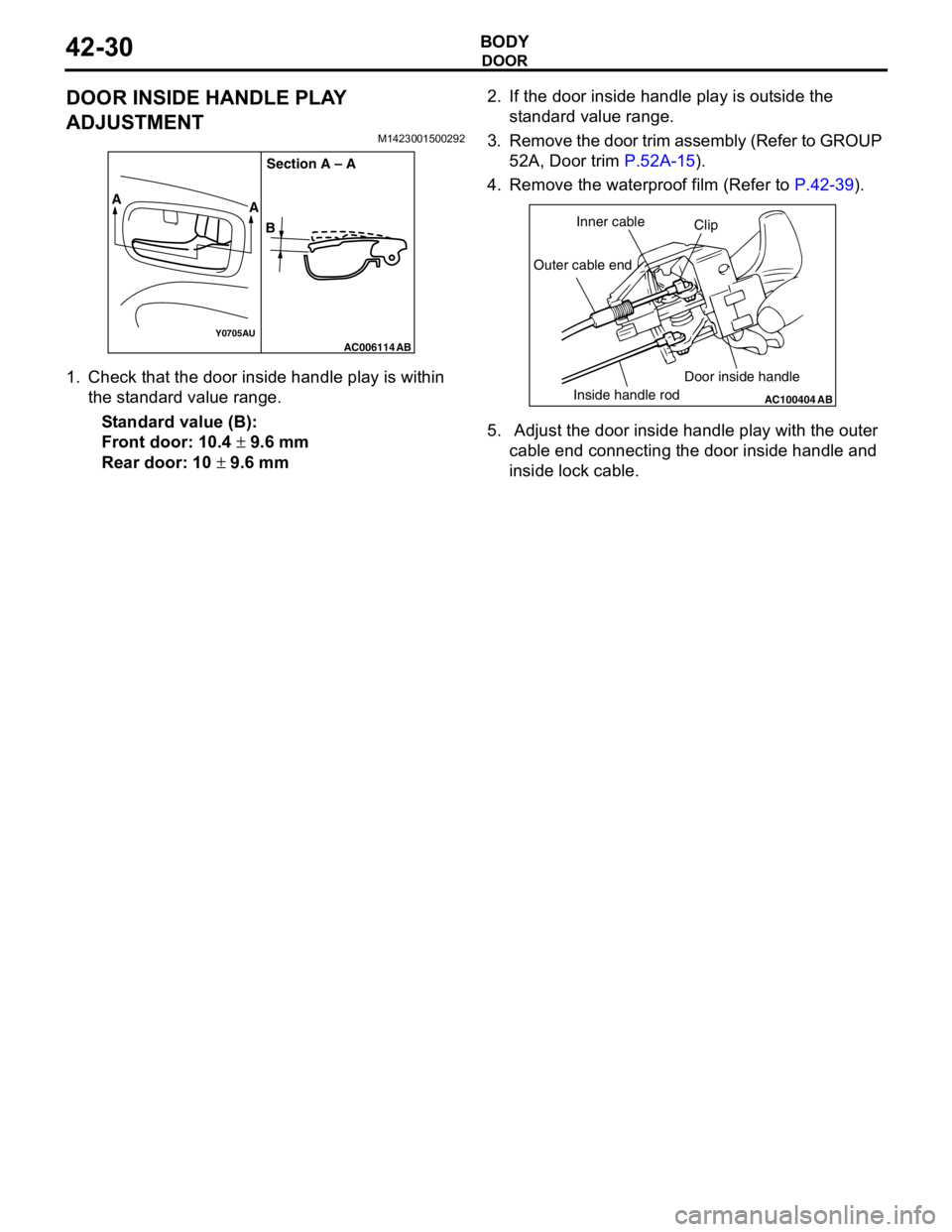

DOOR INSIDE HANDLE PLAY

ADJUSTMENT

M1423001500292

1. Check that the door inside handle play is within

the standard value range.

Standard value (B):

Front door: 10.4 ± 9.6 mm

Rear door: 10 ± 9.6 mm2. If the door inside handle play is outside the

standard value range.

3. Remove the door trim assembly (Refer to GROUP

52A, Door trim P.52A-15).

4. Remove the waterproof film (Refer to P.42-39).

5. Adjust the door inside handle play with the outer

cable end connecting the door inside handle and

inside lock cable.

AC006114Y0705AUAB

A

A

BSection A – A

AC100404

AB

Clip Inner cable

Outer cable end

Inside handle rodDoor inside handle

Page 309 of 788

DOOR

BODY42-31

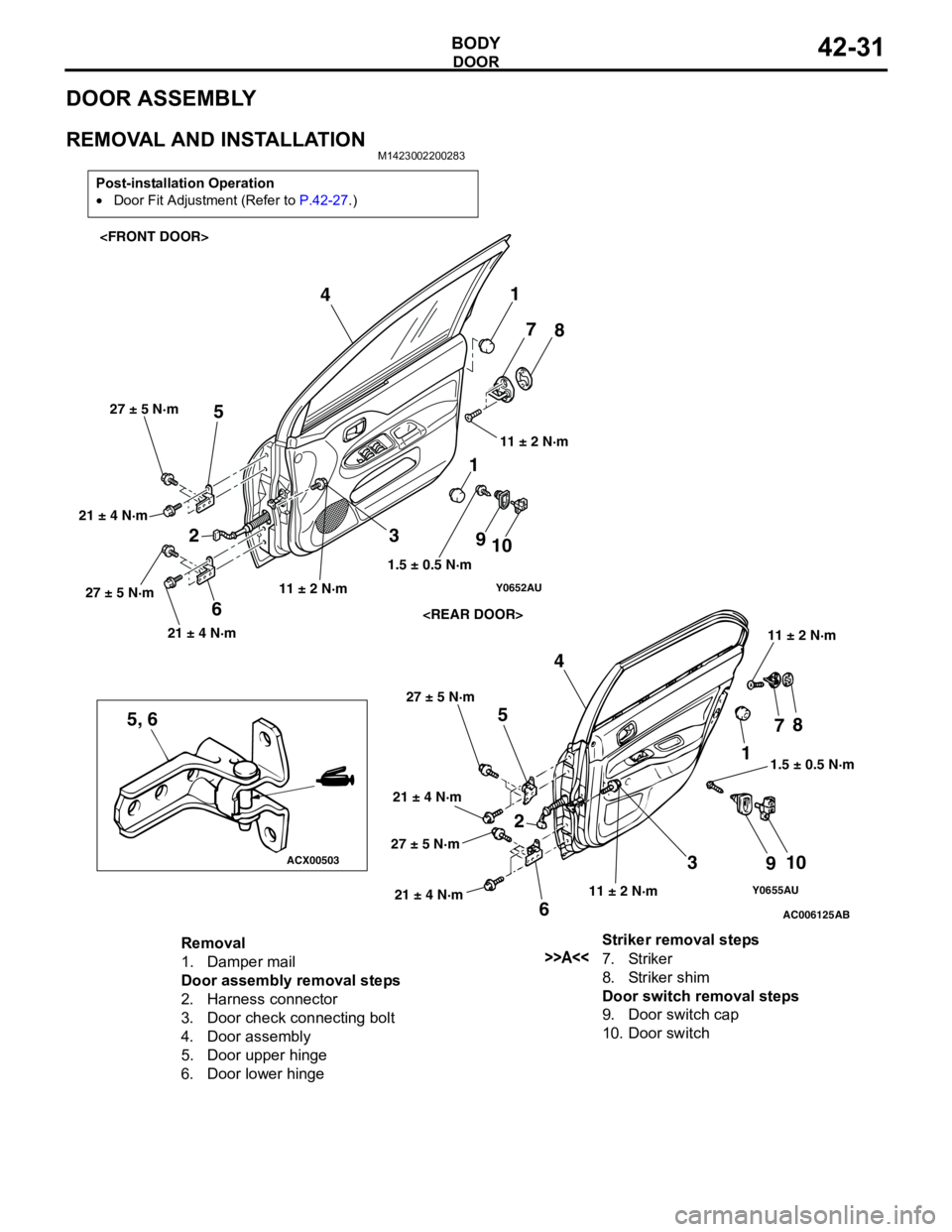

DOOR ASSEMBLY

REMOVAL AND INSTALLATIONM1423002200283

Post-installation Operation

•Door Fit Adjustment (Refer to P.42-27.)

Y0655AU

AC006125

ACX00503

Y0652AU

5, 6

AB

1

2

3 4

5

678

910 1

234

5

67

8

9

10 11.5 ± 0.5 N·m 1.5 ± 0.5 N·m

11 ± 2 N·m11 ± 2 N·m

11 ± 2 N·m

11 ± 2 N·m 21 ± 4 N·m 27 ± 5 N·m 21 ± 4 N·m 27 ± 5 N·m

21 ± 4 N·m 27 ± 5 N·m

21 ± 4 N·m 27 ± 5 N·m

Removal

1. Damper mail

Door assembly removal steps

2. Harness connector

3. Door check connecting bolt

4. Door assembly

5. Door upper hinge

6. Door lower hingeStriker removal steps>>A<<7. Striker

8. Striker shim

Door switch removal steps

9. Door switch cap

10. Door switch

Page 311 of 788

DOOR

BODY42-33

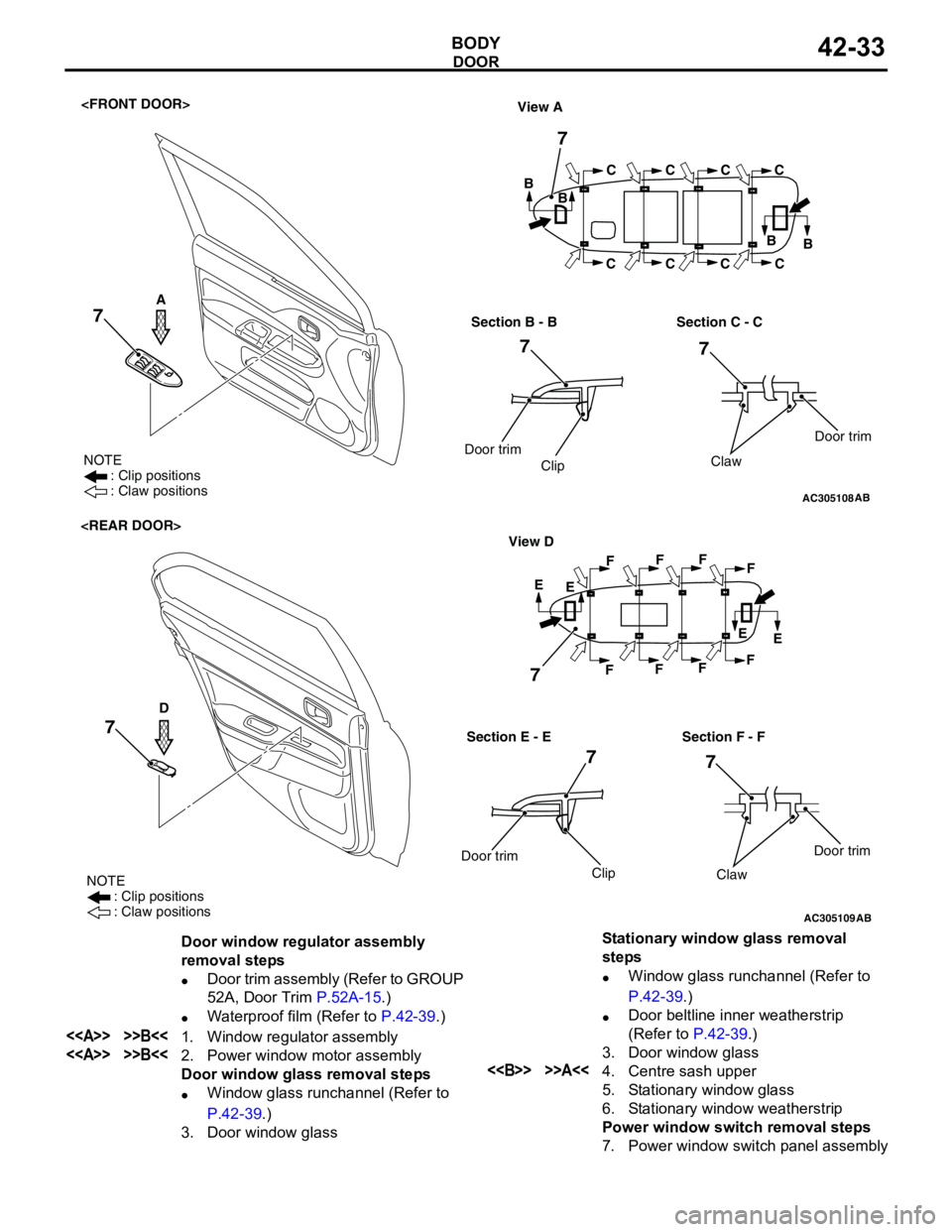

AC305108

NOTE

: Clip positions

: Claw positions

View A

B

B

B

B C

CC

CC

CC

C

Section B - B

Door trim

ClipSection C - C

AB

Door trim

Claw

7

7

7 7

A

AC305109

NOTE

: Clip positions

: Claw positions

E

E

E

E F

FF

FF

FF

F

Section E - EView D

Door trim

ClipSection F - F

Door trim

Claw

D

7

7 7

AB

7

Door window regulator assembly

removal steps

•Door trim assembly (Refer to GROUP

52A, Door Trim P.52A-15.)

•Waterproof film (Refer to P.42-39.)

<> >>B<<1. Window regulator assembly

<> >>B<<2. Power window motor assembly

Door window glass removal steps

•Window glass runchannel (Refer to

P.42-39.)

3. Door window glassStationary window glass removal

steps

•Window glass runchannel (Refer to

P.42-39.)

•Door beltline inner weatherstrip

(Refer to P.42-39.)

3. Door window glass<> >>A<<4. Centre sash upper

5. Stationary window glass

6. Stationary window weatherstrip

Power window switch removal steps

7. Power window switch panel assembly

Page 314 of 788

DOOR

BODY42-36

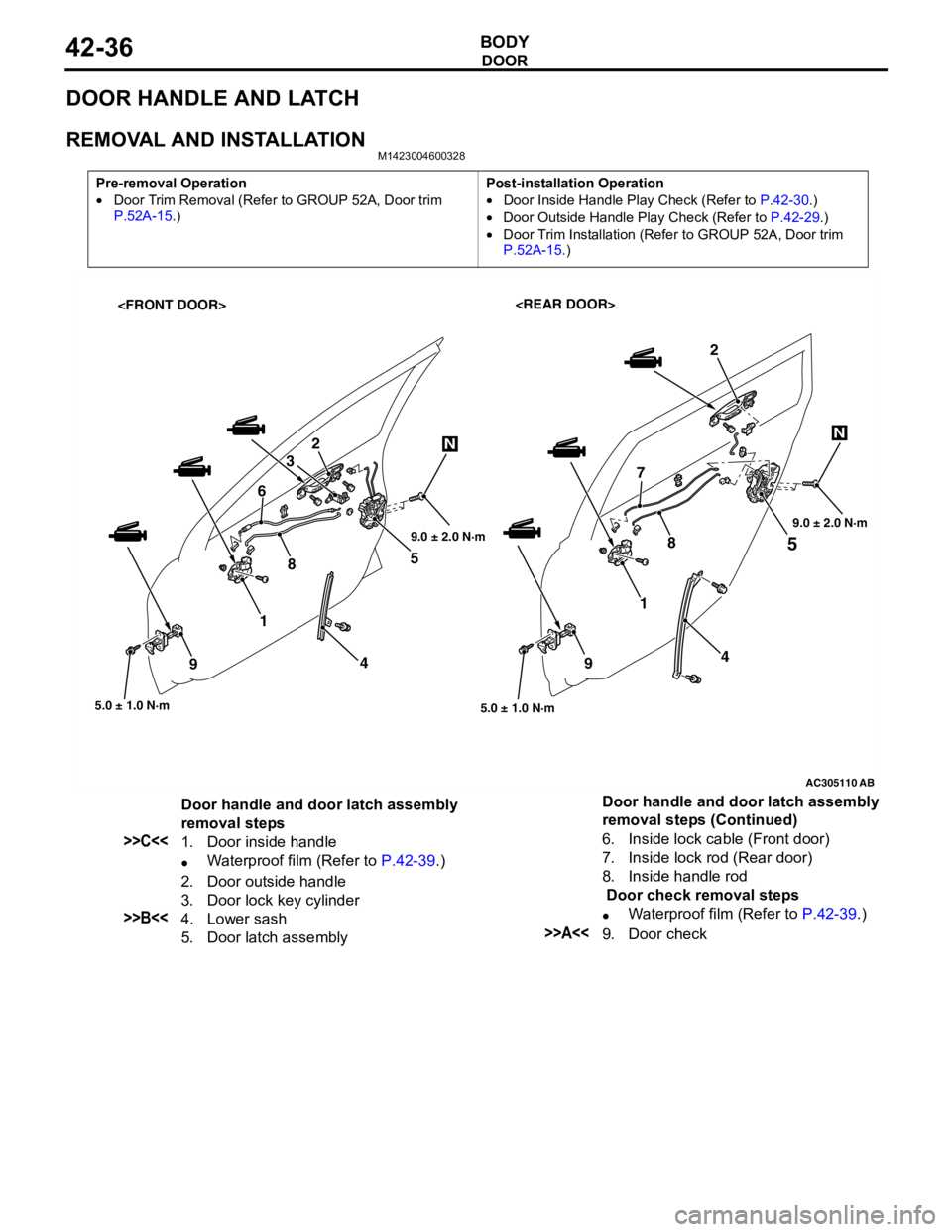

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATIONM1423004600328

Pre-removal Operation

•Door Trim Removal (Refer to GROUP 52A, Door trim

P.52A-15.)Post-installation Operation

•Door Inside Handle Play Check (Refer to P.42-30.)

•Door Outside Handle Play Check (Refer to P.42-29.)

•Door Trim Installation (Refer to GROUP 52A, Door trim

P.52A-15.)

AC305110

5

5.0 ± 1.0 N·m

1

4

9

2

AB

45 2

3

87

5.0 ± 1.0 N·m

1 6

9

NN

89.0 ± 2.0 N·m9.0 ± 2.0 N·m

Door handle and door latch assembly

removal steps

>>C<<1. Door inside handle

•Waterproof film (Refer to P.42-39.)

2. Door outside handle

3. Door lock key cylinder

>>B<<4. Lower sash

5. Door latch assembly6. Inside lock cable (Front door)

7. Inside lock rod (Rear door)

8. Inside handle rod

Door check removal steps

•Waterproof film (Refer to P.42-39.)>>A<<9. Door check Door handle and door latch assembly

removal steps (Continued)

Page 317 of 788

DOOR

BODY42-39

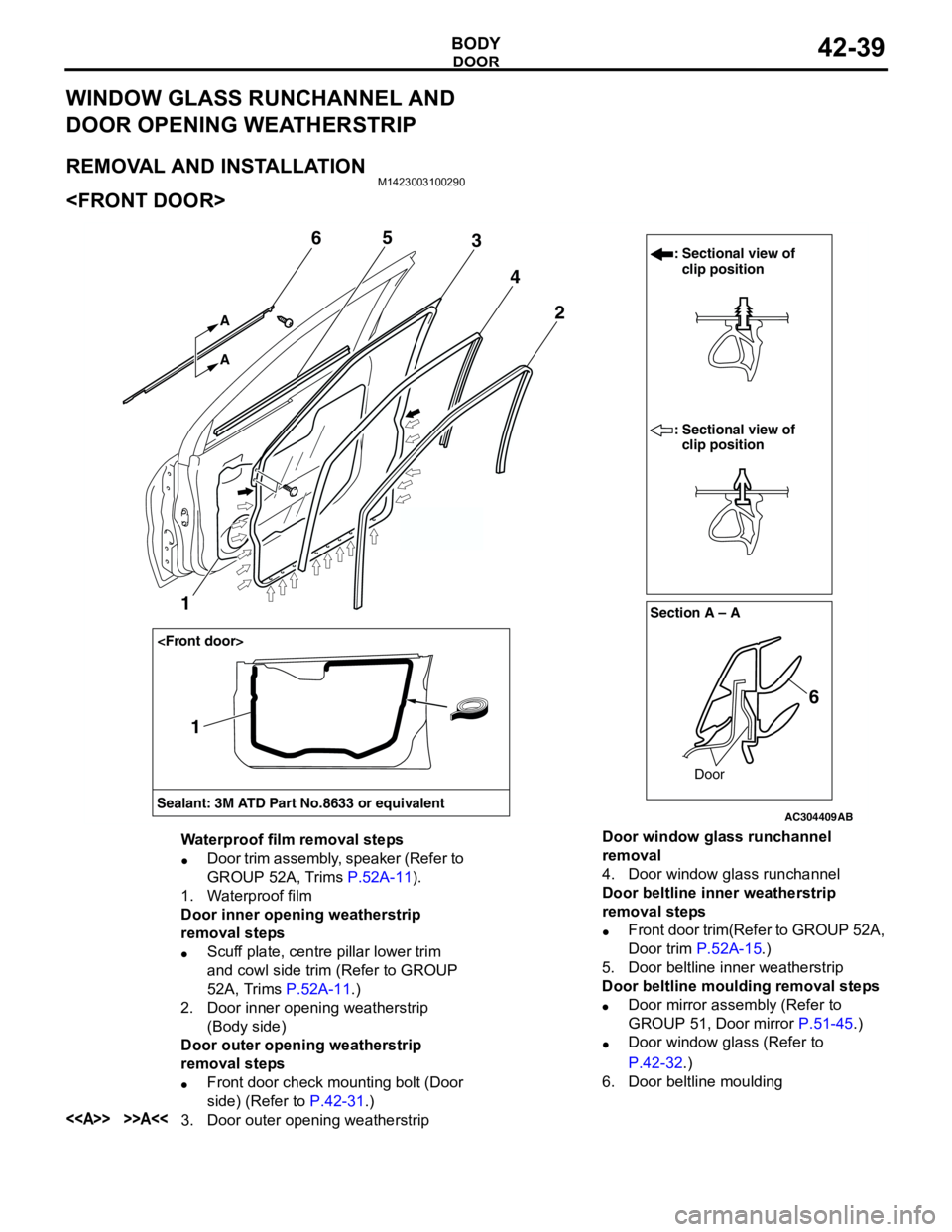

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP

REMOVAL AND INSTALLATIONM1423003100290

AC304409AB

Section A – A

Sealant: 3M ATD Part No.8633 or equivalentDoor

: Sectional view of

clip position

: Sectional view of

clip position

6 2

1

4

365

A A

1

Waterproof film removal steps

•Door trim assembly, speaker (Refer to

GROUP 52A, Trims P.52A-11).

1. Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims P.52A-11.)

2. Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Front door check mounting bolt (Door

side) (Refer to P.42-31.)

<> >>A<<3. Door outer opening weatherstripDoor window glass runchannel

removal

4. Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Front door trim(Refer to GROUP 52A,

Door trim P.52A-15.)

5. Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door mirror assembly (Refer to

GROUP 51, Door mirror P.51-45.)

•Door window glass (Refer to

P.42-32.)

6. Door beltline moulding

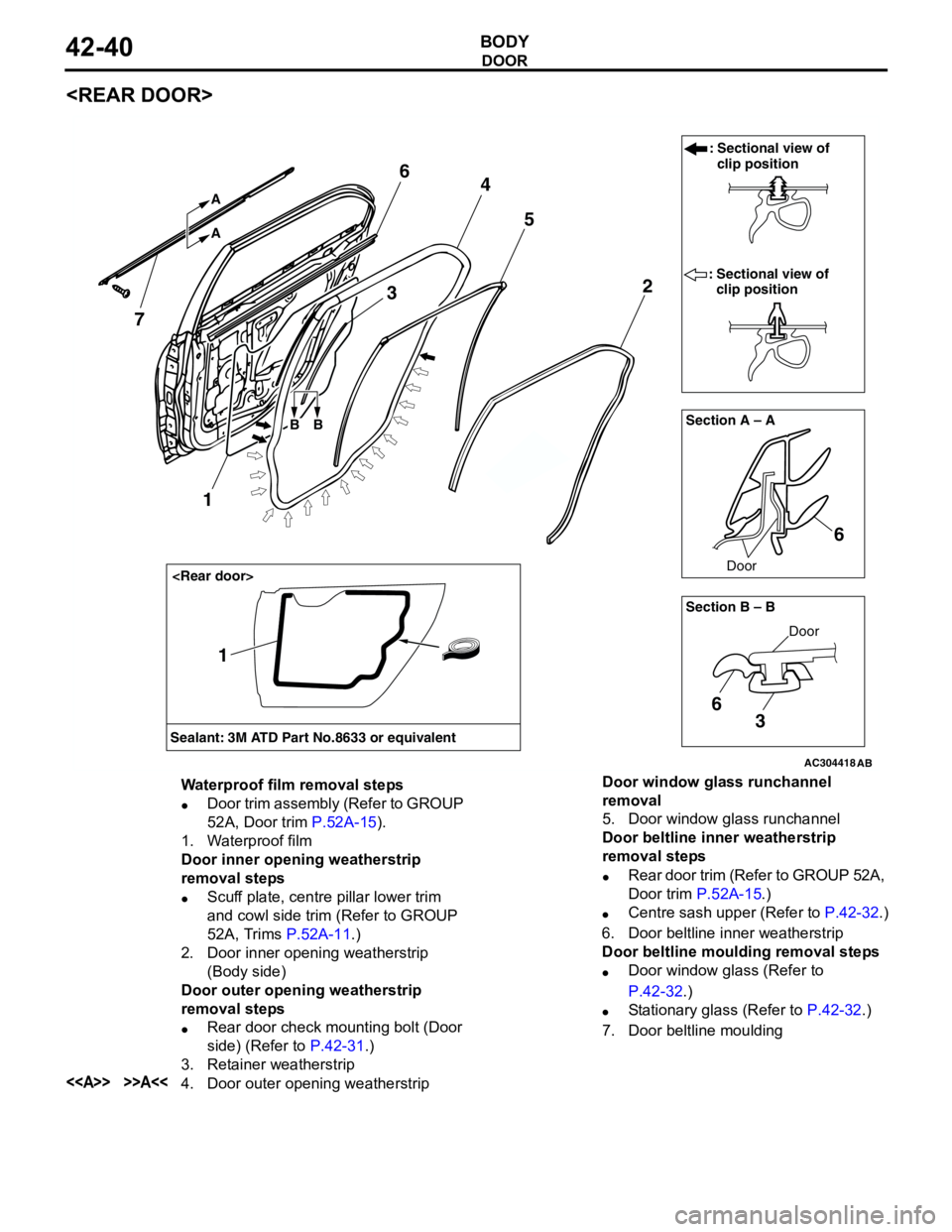

Page 318 of 788

DOOR

BODY42-40

AC304418AB

Section A – A

Door

: Sectional view of

clip position

: Sectional view of

clip position

6 2 4

5

7

A A

3

Section B – B

Door

6

3

6

BB

Sealant: 3M ATD Part No.8633 or equivalent

1

1

Waterproof film removal steps

•Door trim assembly (Refer to GROUP

52A, Door trim P.52A-15).

1. Waterproof film

Door inner opening weatherstrip

removal steps

•Scuff plate, centre pillar lower trim

and cowl side trim (Refer to GROUP

52A, Trims P.52A-11.)

2. Door inner opening weatherstrip

(Body side)

Door outer opening weatherstrip

removal steps

•Rear door check mounting bolt (Door

side) (Refer to P.42-31.)

3. Retainer weatherstrip

<> >>A<<4. Door outer opening weatherstripDoor window glass runchannel

removal

5. Door window glass runchannel

Door beltline inner weatherstrip

removal steps

•Rear door trim (Refer to GROUP 52A,

Door trim P.52A-15.)

•Centre sash upper (Refer to P.42-32.)

6. Door beltline inner weatherstrip

Door beltline moulding removal steps

•Door window glass (Refer to

P.42-32.)

•Stationary glass (Refer to P.42-32.)

7. Door beltline moulding

Page 321 of 788

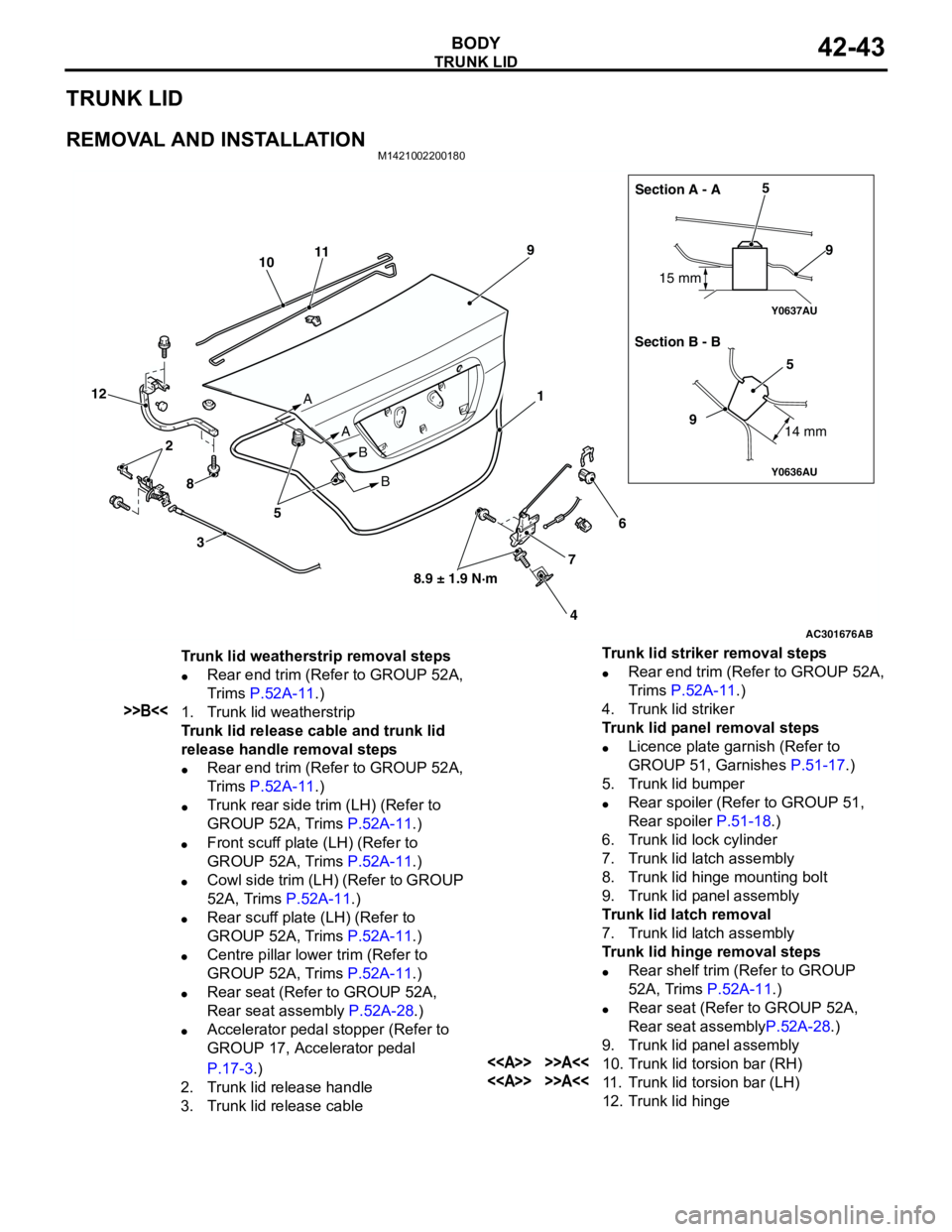

TRUNK LID

BODY42-43

TRUNK LID

REMOVAL AND INSTALLATIONM1421002200180

AC301676

Y0636AU

Y0637AU

AB

1

2

3

45

5

6

7 89

10

99

11

12

8.9 ± 1.9 N·m A

A

B

B15 mm

14 mm

5Section A - A

Section B - B

Trunk lid weatherstrip removal steps

•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

>>B<<1. Trunk lid weatherstrip

Trunk lid release cable and trunk lid

release handle removal steps

•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

•Trunk rear side trim (LH) (Refer to

GROUP 52A, Trims P.52A-11.)

•Front scuff plate (LH) (Refer to

GROUP 52A, Trims P.52A-11.)

•Cowl side trim (LH) (Refer to GROUP

52A, Trims P.52A-11.)

•Rear scuff plate (LH) (Refer to

GROUP 52A, Trims P.52A-11.)

•Centre pillar lower trim (Refer to

GROUP 52A, Trims P.52A-11.)

•Rear seat (Refer to GROUP 52A,

Rear seat assembly P.52A-28.)

•Accelerator pedal stopper (Refer to

GROUP 17, Accelerator pedal

P.17-3.)

2. Trunk lid release handle

3. Trunk lid release cableTrunk lid striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

4. Trunk lid striker

Trunk lid panel removal steps

•Licence plate garnish (Refer to

GROUP 51, Garnishes P.51-17.)

5. Trunk lid bumper

•Rear spoiler (Refer to GROUP 51,

Rear spoiler P.51-18.)

6. Trunk lid lock cylinder

7. Trunk lid latch assembly

8. Trunk lid hinge mounting bolt

9. Trunk lid panel assembly

Trunk lid latch removal

7. Trunk lid latch assembly

Trunk lid hinge removal steps

•Rear shelf trim (Refer to GROUP

52A, Trims P.52A-11.)

•Rear seat (Refer to GROUP 52A,

Rear seat assemblyP.52A-28.)

9. Trunk lid panel assembly

<> >>A<<10. Trunk lid torsion bar (RH)

<> >>A<<11. Trunk lid torsion bar (LH)

12. Trunk lid hinge

Page 325 of 788

TA I L G AT E

BODY42-47

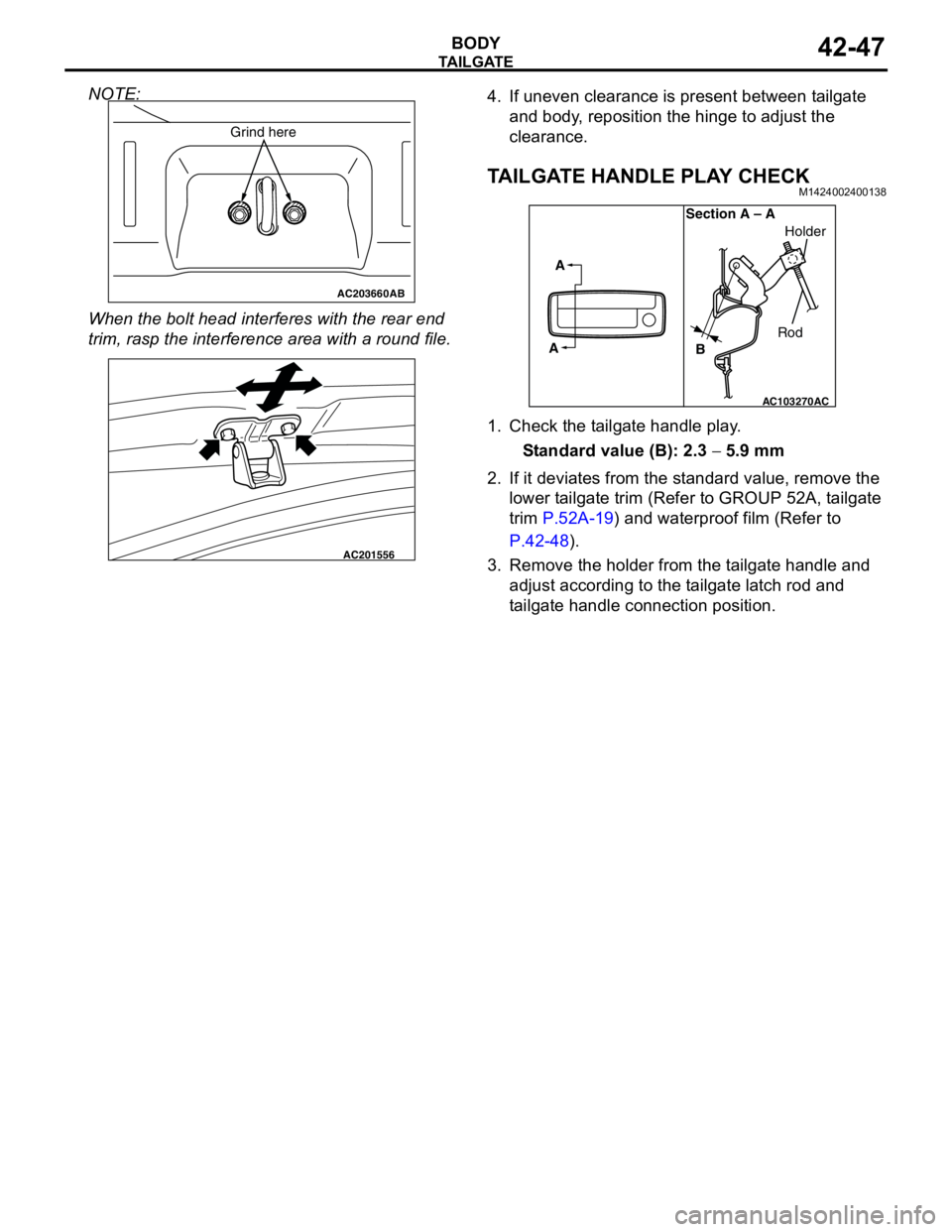

NOTE:

When the bolt head interferes with the rear end

trim, rasp the interference area with a round file.4. If uneven clearance is present between tailgate

and body, reposition the hinge to adjust the

clearance.

TAILGATE HANDLE PLAY CHECKM1424002400138

1. Check the tailgate handle play.

Standard value (B): 2.3 − 5.9 mm

2. If it deviates from the standard value, remove the

lower tailgate trim (Refer to GROUP 52A, tailgate

trim P.52A-19) and waterproof film (Refer to

P.42-48).

3. Remove the holder from the tailgate handle and

adjust according to the tailgate latch rod and

tailgate handle connection position.

AC203660AB

Grind here

AC201556

AC103270

A

ASection A – A

RodHolder

B

AC