Air con MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 31 of 788

TROUBLESHOOTING

ENGINE COOLING14-17

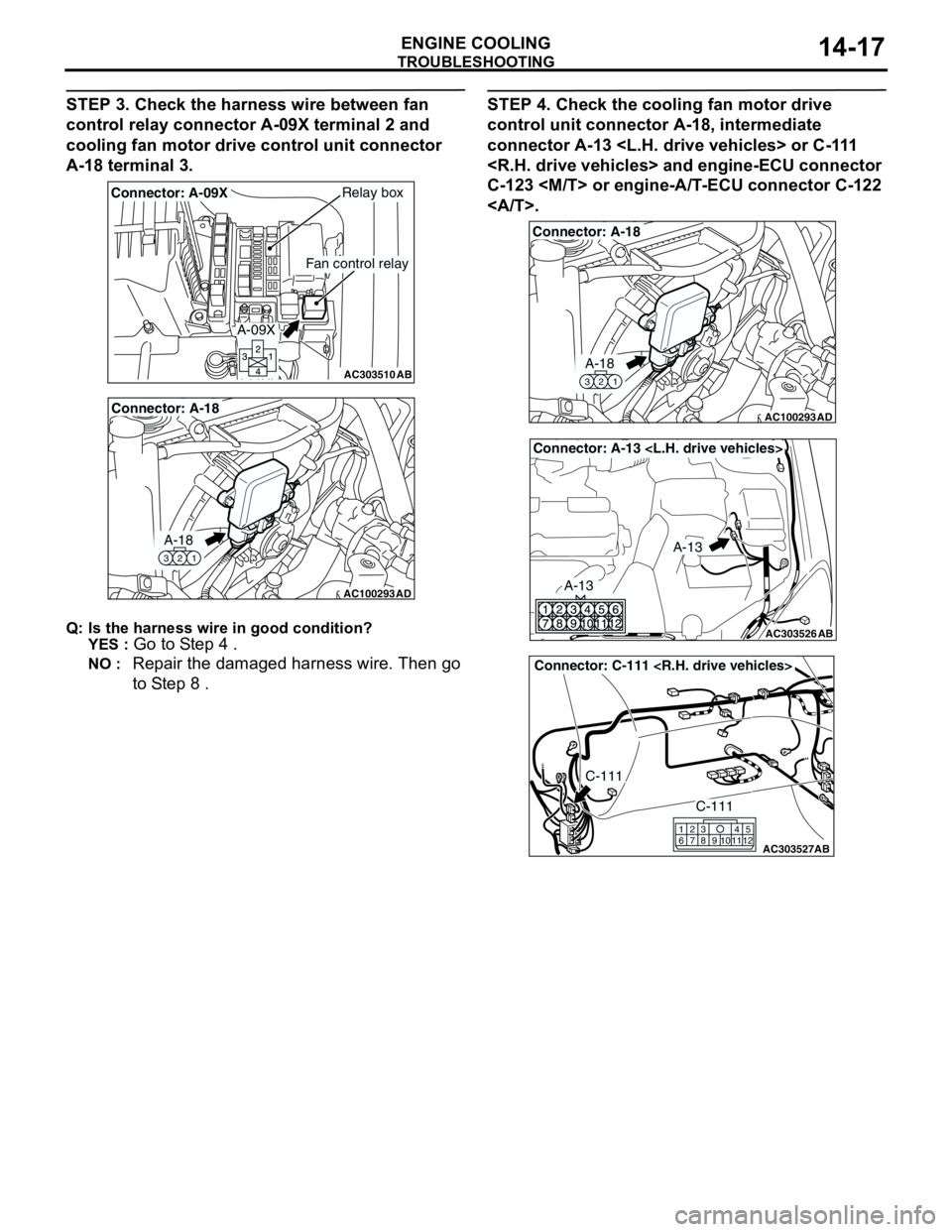

STEP 3. Check the harness wire between fan

control relay connector A-09X terminal 2 and

cooling fan motor drive control unit connector

A-18 terminal 3.

Q: Is the harness wire in good condition?

YES :

Go to Step 4 .

NO : Repair the damaged harness wire. Then go

to Step 8 .

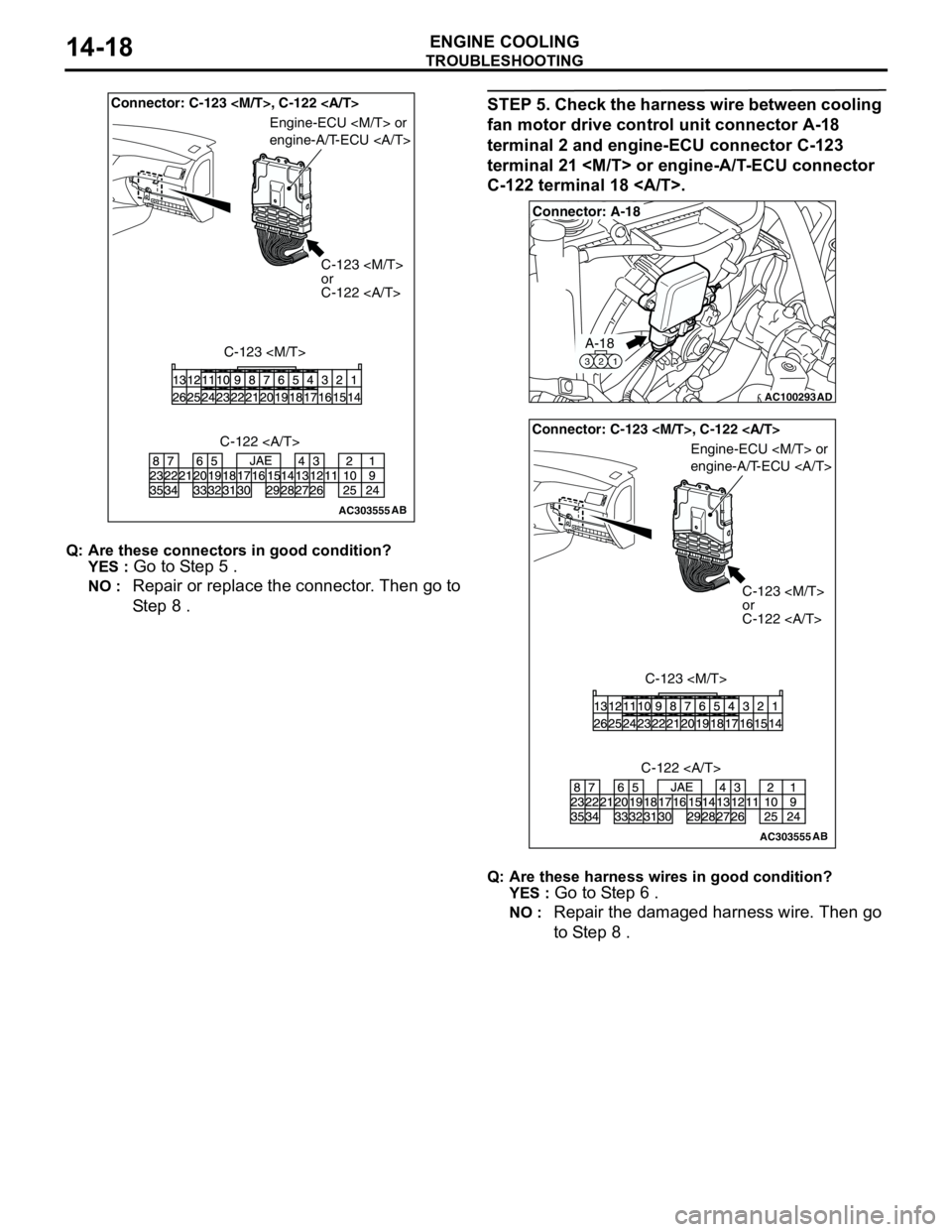

STEP 4. Check the cooling fan motor drive

control unit connector A-18, intermediate

connector A-13

C-123

.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

AC100293

A-18

321

Connector: A-18

AD

AC100293

A-18

321

Connector: A-18

AD

AC303526

Connector: A-13

AB

A-13

A-13

AC303527

Connector: C-111

AB

C-111

C-111

615

121179

810234

Page 32 of 788

TROUBLESHOOTING

ENGINE COOLING14-18

Q: Are these connectors in good condition?

YES :

Go to Step 5 .

NO : Repair or replace the connector. Then go to

Step 8 .

STEP 5. Check the harness wire between cooling

fan motor drive control unit connector A-18

terminal 2 and engine-ECU connector C-123

terminal 21

C-122 terminal 18 .

Q: Are these harness wires in good condition?

YES :

Go to Step 6 .

NO : Repair the damaged harness wire. Then go

to Step 8 .

AC303555AB

Connector: C-123

C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

AC100293

A-18

321

Connector: A-18

AD

AC303555AB

Connector: C-123

C-123

or

C-122

C-123

Engine-ECU

engine-A/T-ECU

C-122

Page 36 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-22

ON-VEHICLE SERVICE

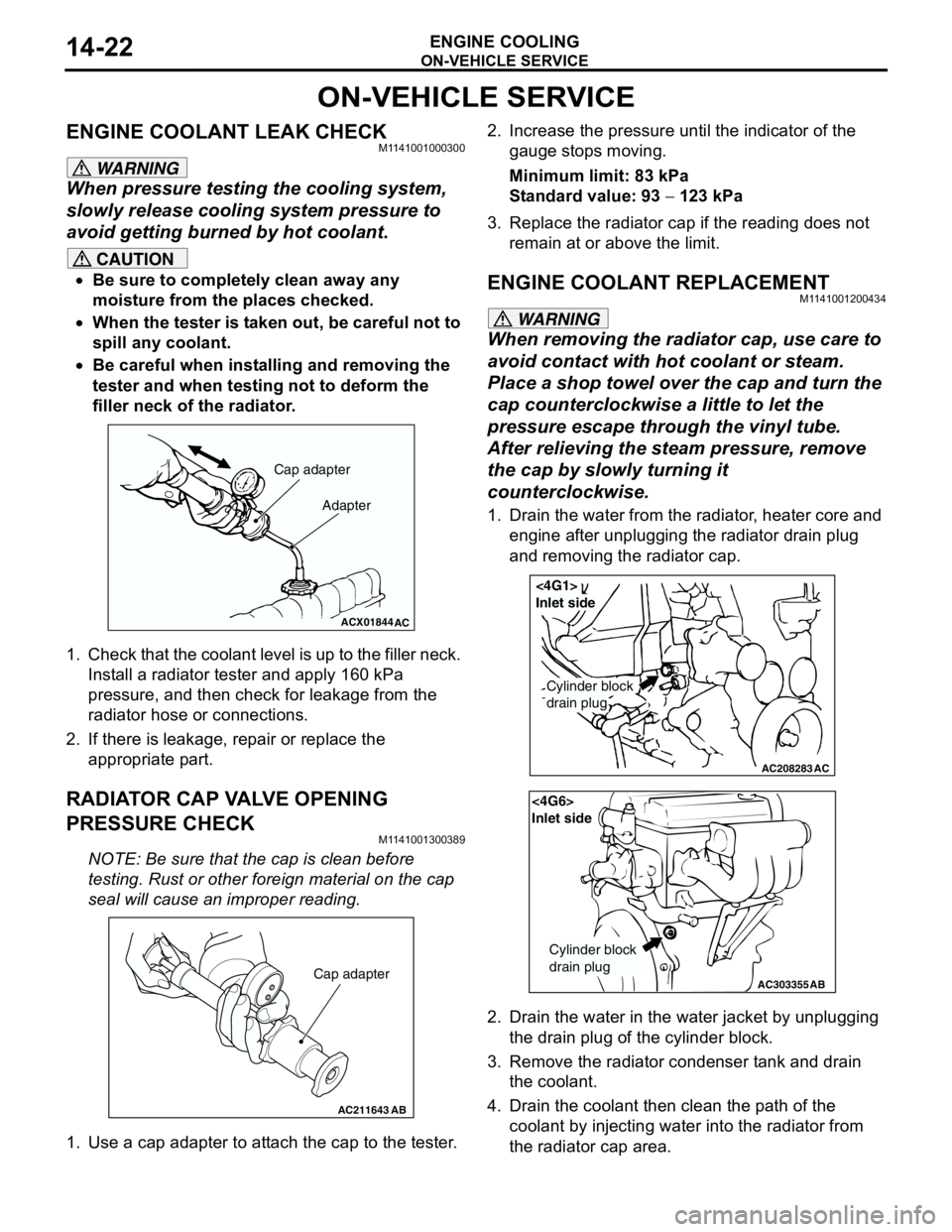

ENGINE COOLANT LEAK CHECKM1141001000300

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

•Be sure to completely clean away any

moisture from the places checked.

•When the tester is taken out, be careful not to

spill any coolant.

•Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

1. Check that the coolant level is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP VALVE OPENING

PRESSURE CHECK

M1141001300389

NOTE: Be sure that the cap is clean before

testing. Rust or other foreign material on the cap

seal will cause an improper reading.

1. Use a cap adapter to attach the cap to the tester.2. Increase the pressure until the indicator of the

gauge stops moving.

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not

remain at or above the limit.

ENGINE COOLANT REPLACEMENTM1141001200434

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap counterclockwise a little to let the

pressure escape through the vinyl tube.

After relieving the steam pressure, remove

the cap by slowly turning it

counterclockwise.

1. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

2. Drain the water in the water jacket by unplugging

the drain plug of the cylinder block.

3. Remove the radiator condenser tank and drain

the coolant.

4. Drain the coolant then clean the path of the

coolant by injecting water into the radiator from

the radiator cap area.

ACX01844

Cap adapter

Adapter

AC

AC211643AB

Cap adapter

AC208283AC

Cylinder block

drain plug

<4G1>

Inlet side

AC303355

<4G6>

Inlet side

Cylinder block

drain plug

AB

Page 37 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-23

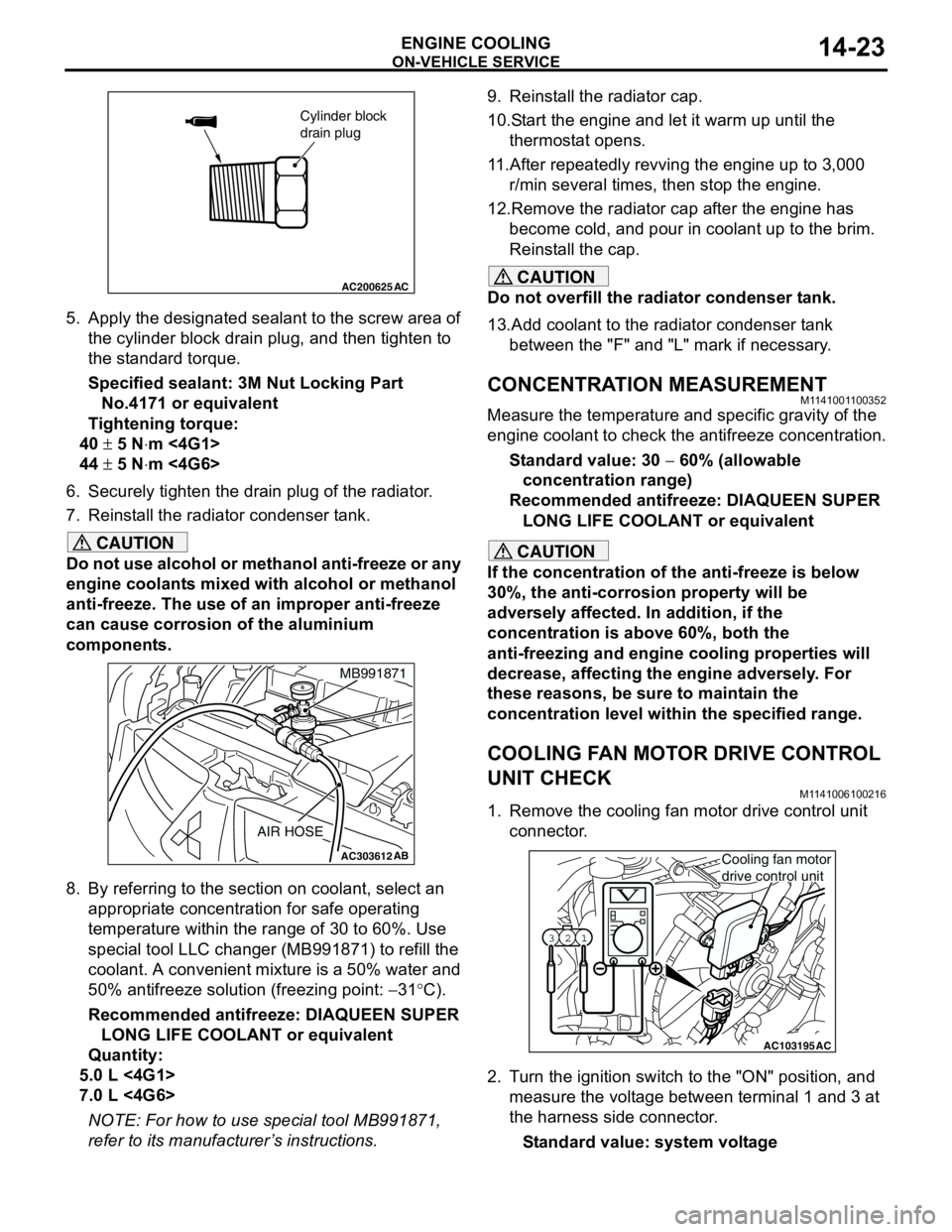

5. Apply the designated sealant to the screw area of

the cylinder block drain plug, and then tighten to

the standard torque.

Specified sealant: 3M Nut Locking Part

No.4171 or equivalent

Tightening torque:

40 ± 5 N⋅m <4G1>

44 ± 5 N⋅m <4G6>

6. Securely tighten the drain plug of the radiator.

7. Reinstall the radiator condenser tank.

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause corrosion of the aluminium

components.

8. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60%. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50% water and

50% antifreeze solution (freezing point: −31°C).

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

Quantity:

5.0 L <4G1>

7.0 L <4G6>

NOTE: For how to use special tool MB991871,

refer to its manufacturer’s instructions.9. Reinstall the radiator cap.

10.Start the engine and let it warm up until the

thermostat opens.

11.After repeatedly revving the engine up to 3,000

r/min several times, then stop the engine.

12.Remove the radiator cap after the engine has

become cold, and pour in coolant up to the brim.

Reinstall the cap.

CAUTION

Do not overfill the radiator condenser tank.

13.Add coolant to the radiator condenser tank

between the "F" and "L" mark if necessary.

CONCENTRATION MEASUREMENTM1141001100352

Measure the temperature and specific gravity of the

engine coolant to check the antifreeze concentration.

Standard value: 30 − 60% (allowable

concentration range)

Recommended antifreeze: DIAQUEEN SUPER

LONG LIFE COOLANT or equivalent

CAUTION

If the concentration of the anti-freeze is below

30%, the anti-corrosion property will be

adversely affected. In addition, if the

concentration is above 60%, both the

anti-freezing and engine cooling properties will

decrease, affecting the engine adversely. For

these reasons, be sure to maintain the

concentration level within the specified range.

COOLING FAN MOTOR DRIVE CONTROL

UNIT CHECK

M1141006100216

1. Remove the cooling fan motor drive control unit

connector.

2. Turn the ignition switch to the "ON" position, and

measure the voltage between terminal 1 and 3 at

the harness side connector.

Standard value: system voltage

AC200625

Cylinder block

drain plug

AC

AC303612AB

MB991871

AIR HOSE

AC103195

Y1716AU

1 23

AC

Cooling fan motor

drive control unit

Page 45 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

WATER HOSE AND WATER PIPE

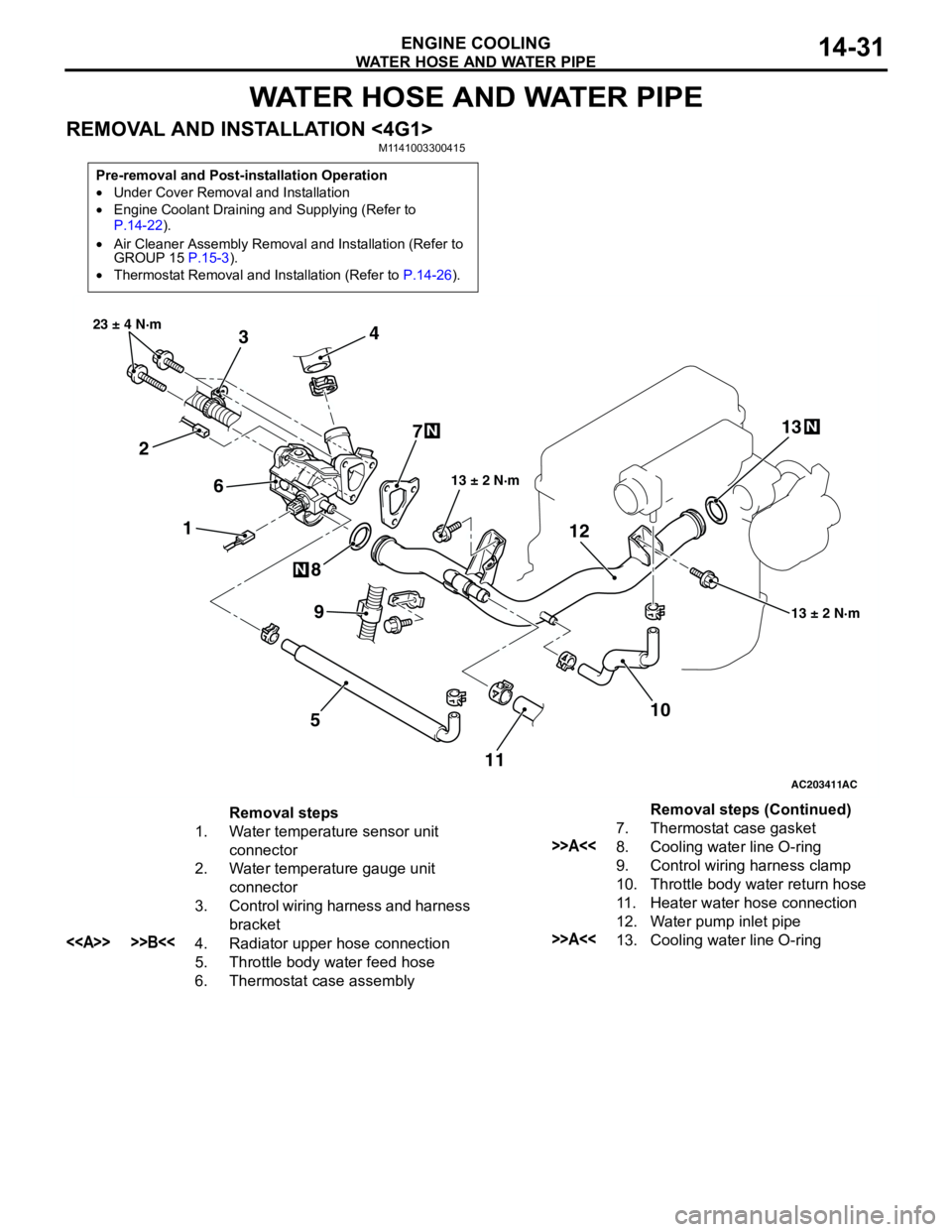

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC203411

1 234

5 67

8

10 9

13 ± 2 N·m 23 ± 4 N·m

13 ± 2 N·m

N

N

AC

111213

N

Removal steps

1. Water temperature sensor unit

connector

2. Water temperature gauge unit

connector

3. Control wiring harness and harness

bracket

<> >>B<<4. Radiator upper hose connection

5. Throttle body water feed hose

6. Thermostat case assembly7. Thermostat case gasket

>>A<<8. Cooling water line O-ring

9. Control wiring harness clamp

10. Throttle body water return hose

11. Heater water hose connection

12. Water pump inlet pipe

>>A<<13. Cooling water line O-ringRemoval steps (Continued)

Page 47 of 788

WATER HOSE AND WATER PIPE

ENGINE COOLING14-33

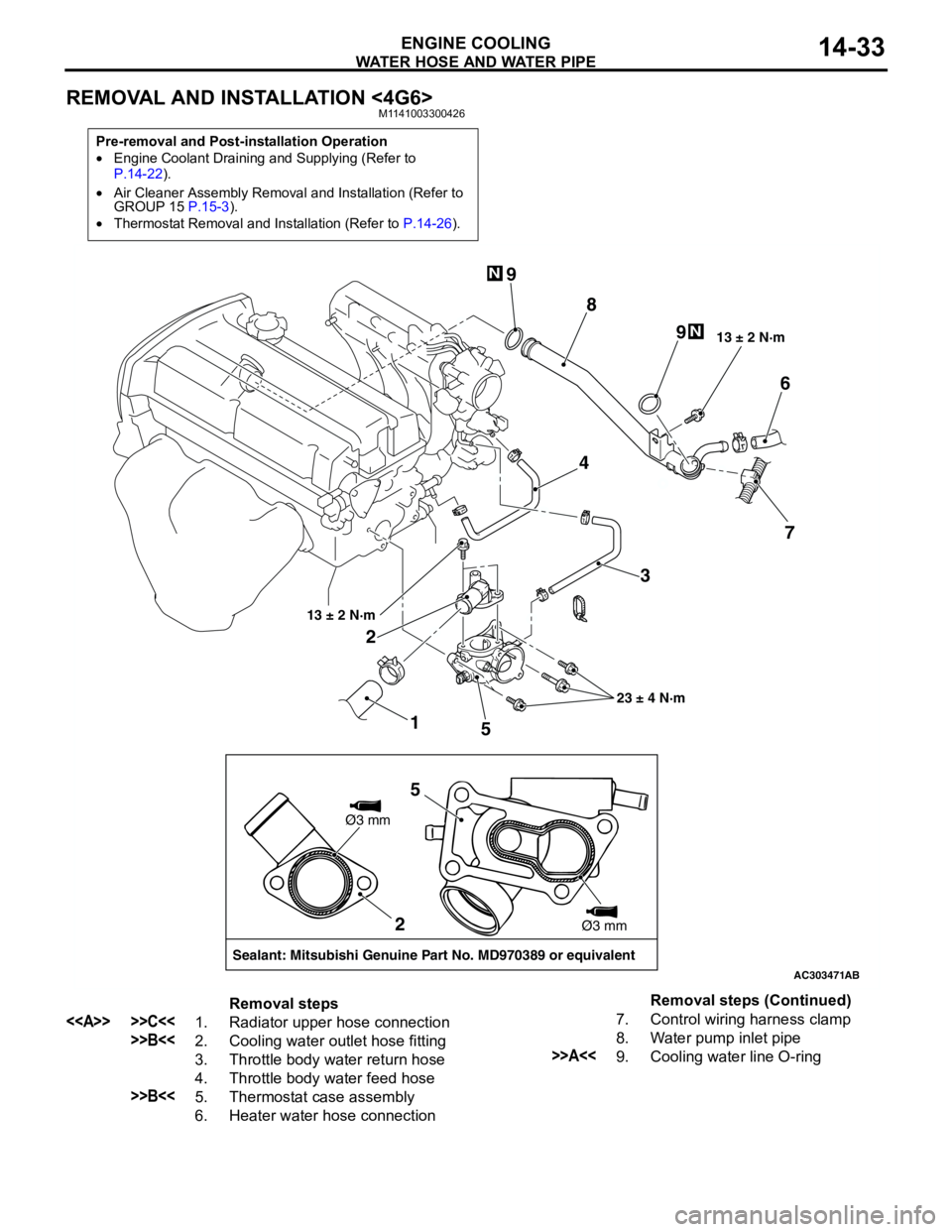

REMOVAL AND INSTALLATION <4G6>M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to

P.14-22).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-26).

AC303471

1 23 4

56

7 8 9

9

13 ± 2 N·m

23 ± 4 N·m 13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalentØ3 mm

Ø3 mm

5

Removal steps

<> >>C<<1. Radiator upper hose connection

>>B<<2. Cooling water outlet hose fitting

3. Throttle body water return hose

4. Throttle body water feed hose

>>B<<5. Thermostat case assembly

6. Heater water hose connection7. Control wiring harness clamp

8. Water pump inlet pipe

>>A<<9. Cooling water line O-ringRemoval steps (Continued)

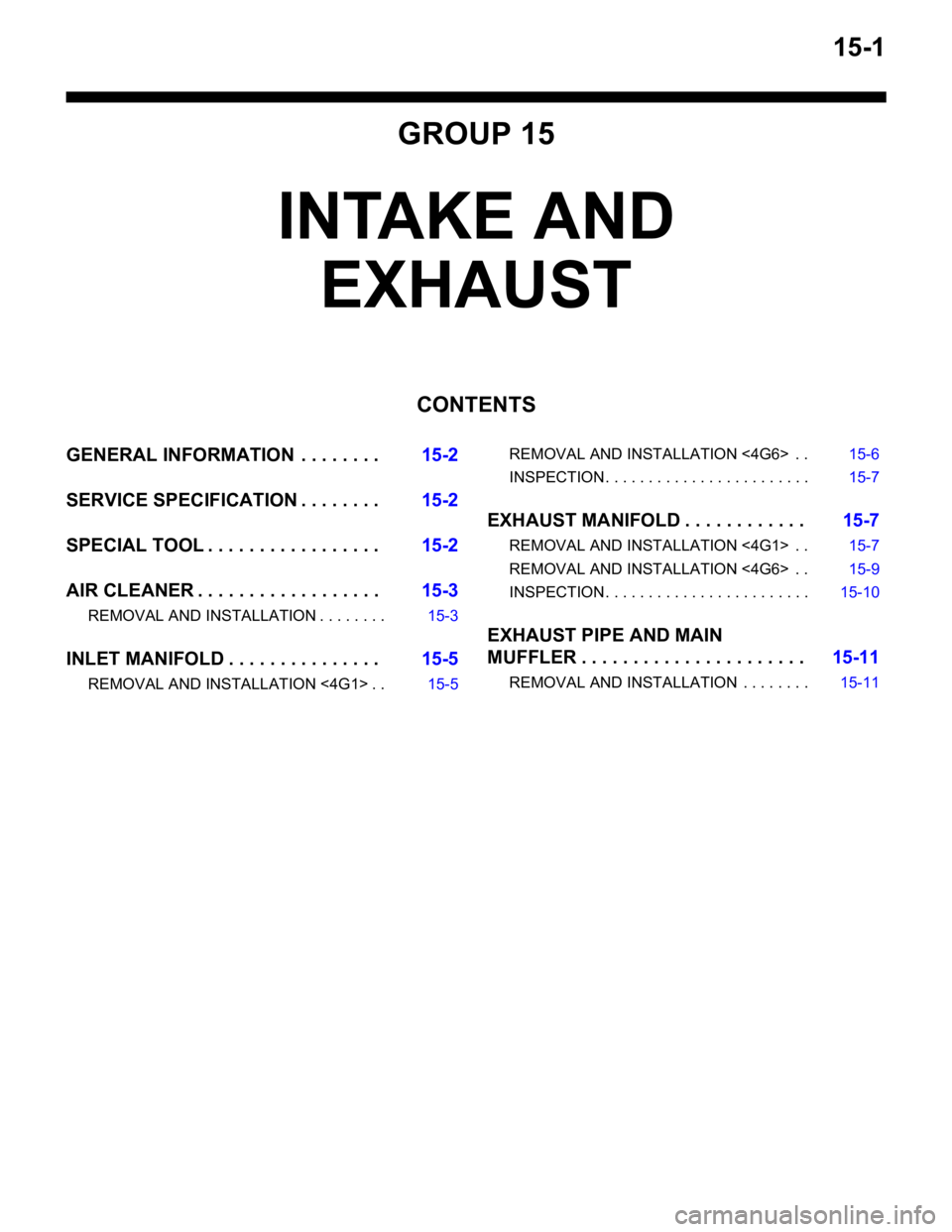

Page 53 of 788

15-1

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATION . . . . . . . .15-2

SERVICE SPECIFICATION . . . . . . . .15-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .15-2

AIR CLEANER . . . . . . . . . . . . . . . . . .15-3

REMOVAL AND INSTALLATION . . . . . . . . 15-3

INLET MANIFOLD . . . . . . . . . . . . . . .15-5

REMOVAL AND INSTALLATION <4G1> . . 15-5REMOVAL AND INSTALLATION <4G6> . . 15-6

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 15-7

EXHAUST MANIFOLD . . . . . . . . . . . .15-7

REMOVAL AND INSTALLATION <4G1> . . 15-7

REMOVAL AND INSTALLATION <4G6> . . 15-9

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 15-10

EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . .15-11

REMOVAL AND INSTALLATION . . . . . . . . 15-11

Page 56 of 788

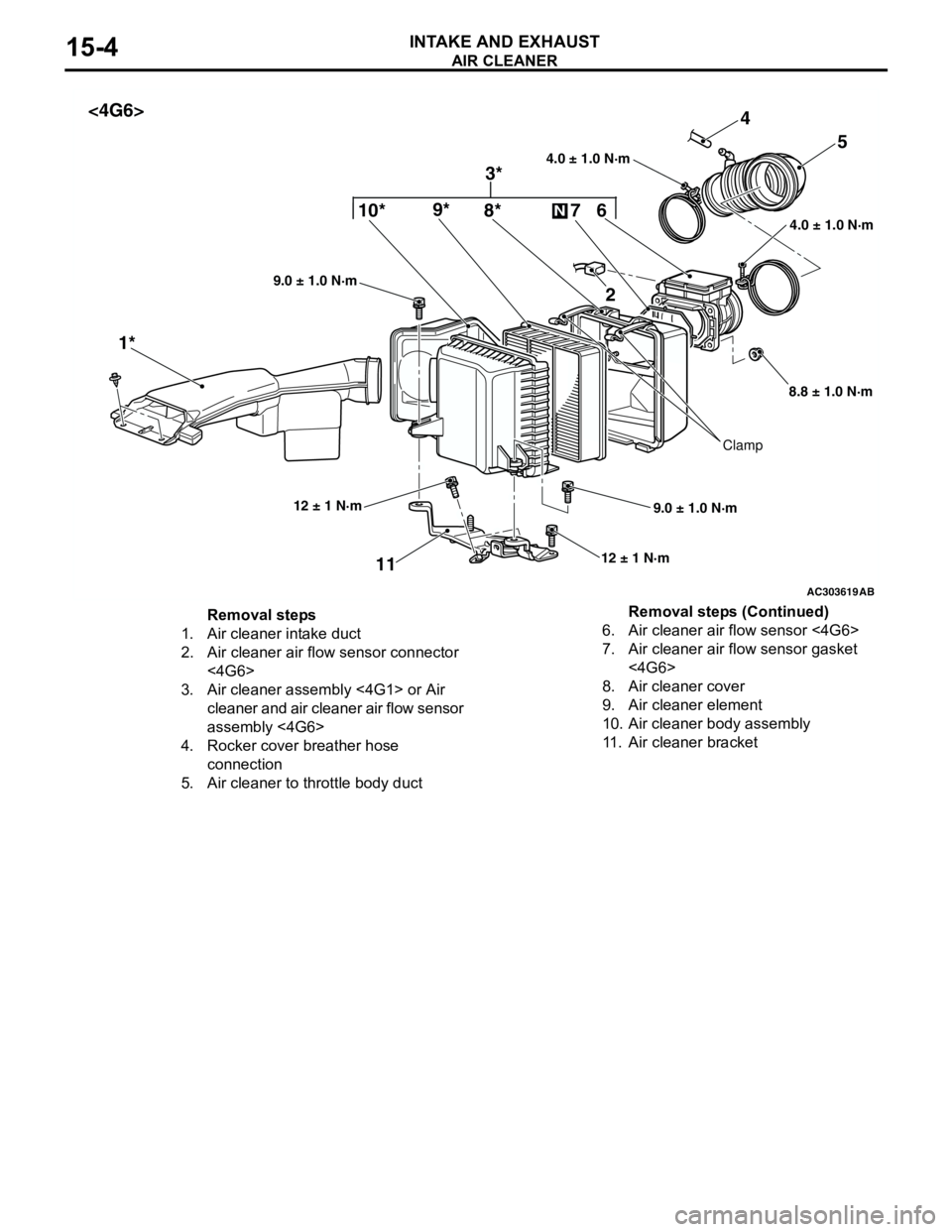

AIR CLEANER

INTAKE AND EXHAUST15-4

AC303619

4.0 ± 1.0 N·m 4.0 ± 1.0 N·m10*9*4

1*5

11

12 ± 1 N·m

9.0 ± 1.0 N·m 9.0 ± 1.0 N·m

AB

12 ± 1 N·m

Clamp

8*

3* <4G6>

6 7

N

2

8.8 ± 1.0 N·m

Removal steps

1. Air cleaner intake duct

2. Air cleaner air flow sensor connector

<4G6>

3. Air cleaner assembly <4G1> or Air

cleaner and air cleaner air flow sensor

assembly <4G6>

4. Rocker cover breather hose

connection

5. Air cleaner to throttle body duct6. Air cleaner air flow sensor <4G6>

7. Air cleaner air flow sensor gasket

<4G6>

8. Air cleaner cover

9. Air cleaner element

10. Air cleaner body assembly

11. Air cleaner bracketRemoval steps (Continued)

Page 68 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0 − 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is

possibly not found the problem that the output

current is dropping due to the insufficient

connection between terminal "B" and the output

wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II/III (Refer to

GROUP 11A − On-vehicle Service − Idle speed

check <4G1> P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is

maximum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the MUT-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 77 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

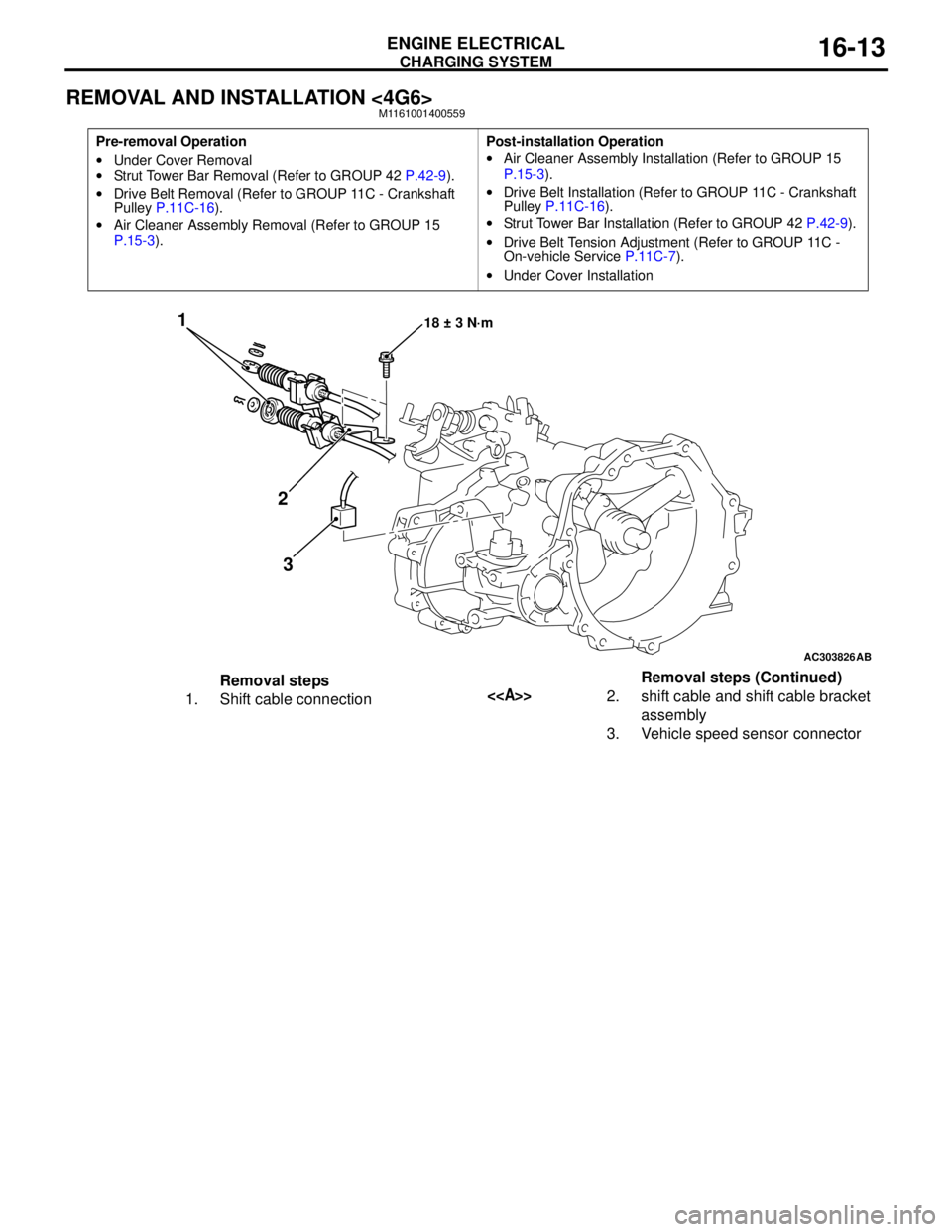

REMOVAL AND INSTALLATION <4G6>M1161001400559

Pre-removal Operation

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Removal (Refer to GROUP 15

P.15-3).Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15

P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service P.11C-7).

•Under Cover Installation

AC303826

1

2

318 ± 3 N·m

AB

Removal steps

1. Shift cable connection<>2. shift cable and shift cable bracket

assembly

3. Vehicle speed sensor connectorRemoval steps (Continued)