height MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 320 of 788

TRUNK LID

BODY42-42

3. If there is a difference in height between the side

outer panels and the side edges of the trunk lid

panel assembly, check the trunk lid hinges and, if

necessary, replace them

4. If the clearance around the trunk lid panel

assembly is not uniform, and the trunk lid can be

locked and unlocked smoothly, make adjustments

to the trunk lid bumpers (refer to P.42-42) and

trunk lid hinges (Refer to P.42-42).

5. If the locking and unlocking of the trunk lid still is

difficult after making the above adjustments,

adjust the trunk lid striker (Refer to P.42-42).

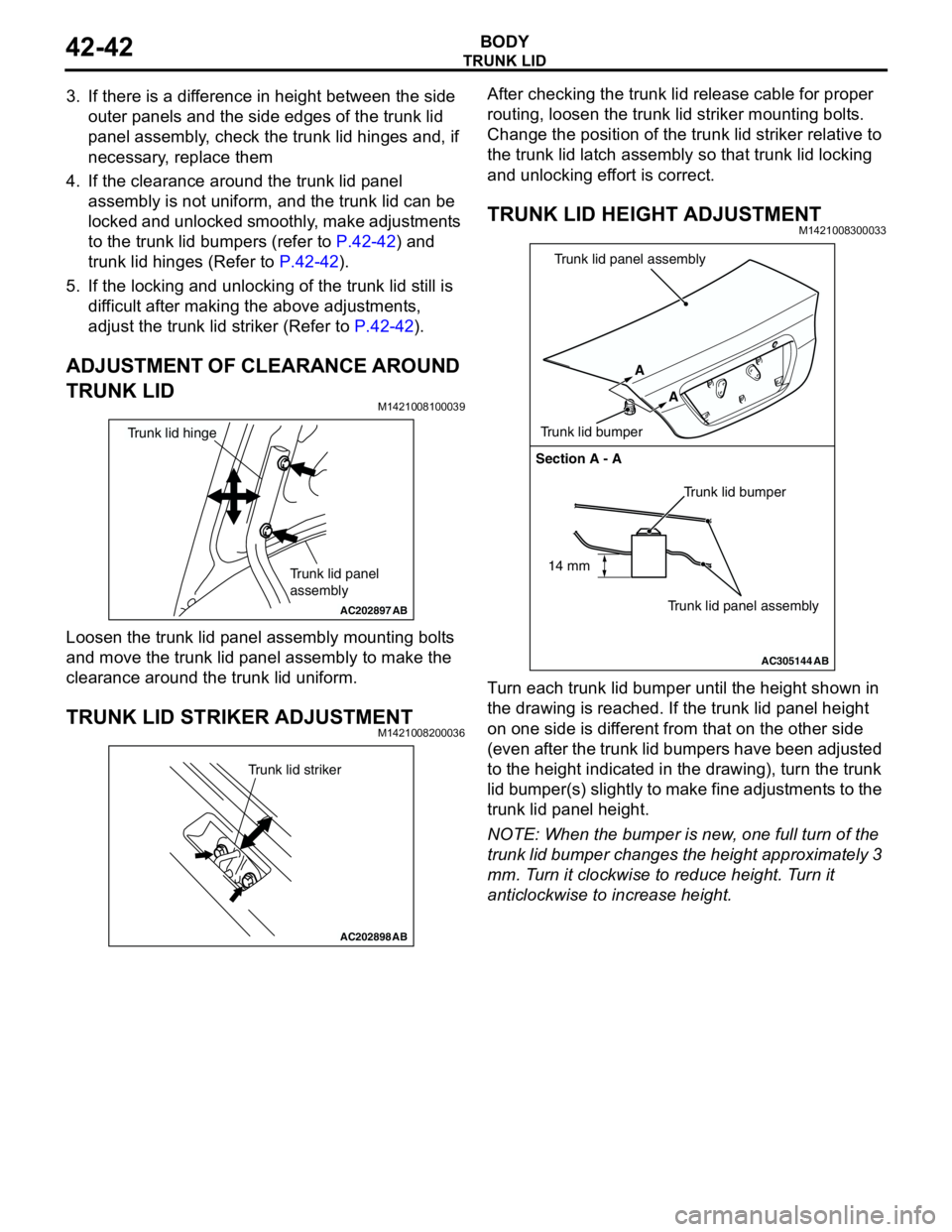

ADJUSTMENT OF CLEARANCE AROUND

TRUNK LID

M1421008100039

Loosen the trunk lid panel assembly mounting bolts

and move the trunk lid panel assembly to make the

clearance around the trunk lid uniform.

TRUNK LID STRIKER ADJUSTMENTM1421008200036

After checking the trunk lid release cable for proper

routing, loosen the trunk lid striker mounting bolts.

Change the position of the trunk lid striker relative to

the trunk lid latch assembly so that trunk lid locking

and unlocking effort is correct.

TRUNK LID HEIGHT ADJUSTMENTM1421008300033

Turn each trunk lid bumper until the height shown in

the drawing is reached. If the trunk lid panel height

on one side is different from that on the other side

(even after the trunk lid bumpers have been adjusted

to the height indicated in the drawing), turn the trunk

lid bumper(s) slightly to make fine adjustments to the

trunk lid panel height.

NOTE: When the bumper is new, one full turn of the

trunk lid bumper changes the height approximately 3

mm. Turn it clockwise to reduce height. Turn it

anticlockwise to increase height.

AC202897

Trunk lid panel

assembly

Trunk lid hinge

AB

AC202898

Trunk lid striker

AB

AC305144

Section A - A

Trunk lid bumper

Trunk lid panel assembly A

A

Trunk lid bumperTrunk lid panel assembly

AB

14 mm

Page 417 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-29

COMBINATION METER ASSEMBLY

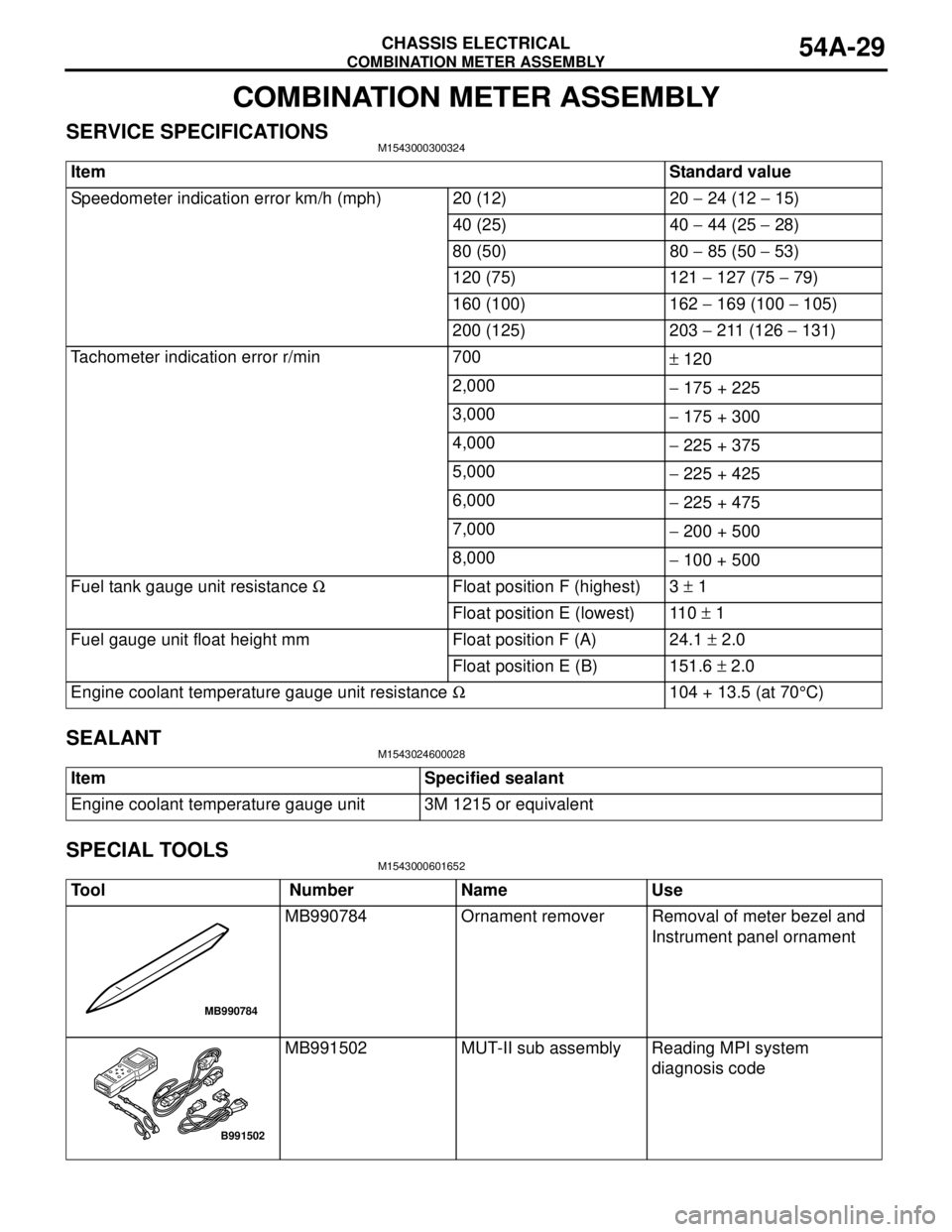

SERVICE SPECIFICATIONSM1543000300324

SEALANTM1543024600028

SPECIAL TOOLSM1543000601652

ItemStandard value

Speedometer indication error km/h (mph) 20 (12) 20 − 24 (12 − 15)

40 (25) 40 − 44 (25 − 28)

80 (50) 80 − 85 (50 − 53)

120 (75) 121 − 127 (75 − 79)

160 (100) 162 − 169 (100 − 105)

200 (125) 203 − 211 (126 − 131)

Tachometer indication error r/min 700

± 120

2,000

− 175 + 225

3,000

− 175 + 300

4,000

− 225 + 375

5,000

− 225 + 425

6,000

− 225 + 475

7,000

− 200 + 500

8,000

− 100 + 500

Fuel tank gauge unit resistance ΩFloat position F (highest) 3 ± 1

Float position E (lowest) 110 ± 1

Fuel gauge unit float height mm Float position F (A) 24.1 ± 2.0

Float position E (B) 151.6 ± 2.0

Engine coolant temperature gauge unit resistance Ω104 + 13.5 (at 70°C)

Item Specified sealant

Engine coolant temperature gauge unit 3M 1215 or equivalent

Tool Number Name Use

MB990784 Ornament remover Removal of meter bezel and

Instrument panel ornament

MB991502 MUT-II sub assembly Reading MPI system

diagnosis code

MB990784

B991502

Page 449 of 788

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL54A-61

NOTE: For tachometer check, use an external

high quality inductive tachometer.

2. Compare the readings of the vehicle tachometer

and the external tachometer at every engine

speed, and check if the variations are within the

standard values.

Standard values:

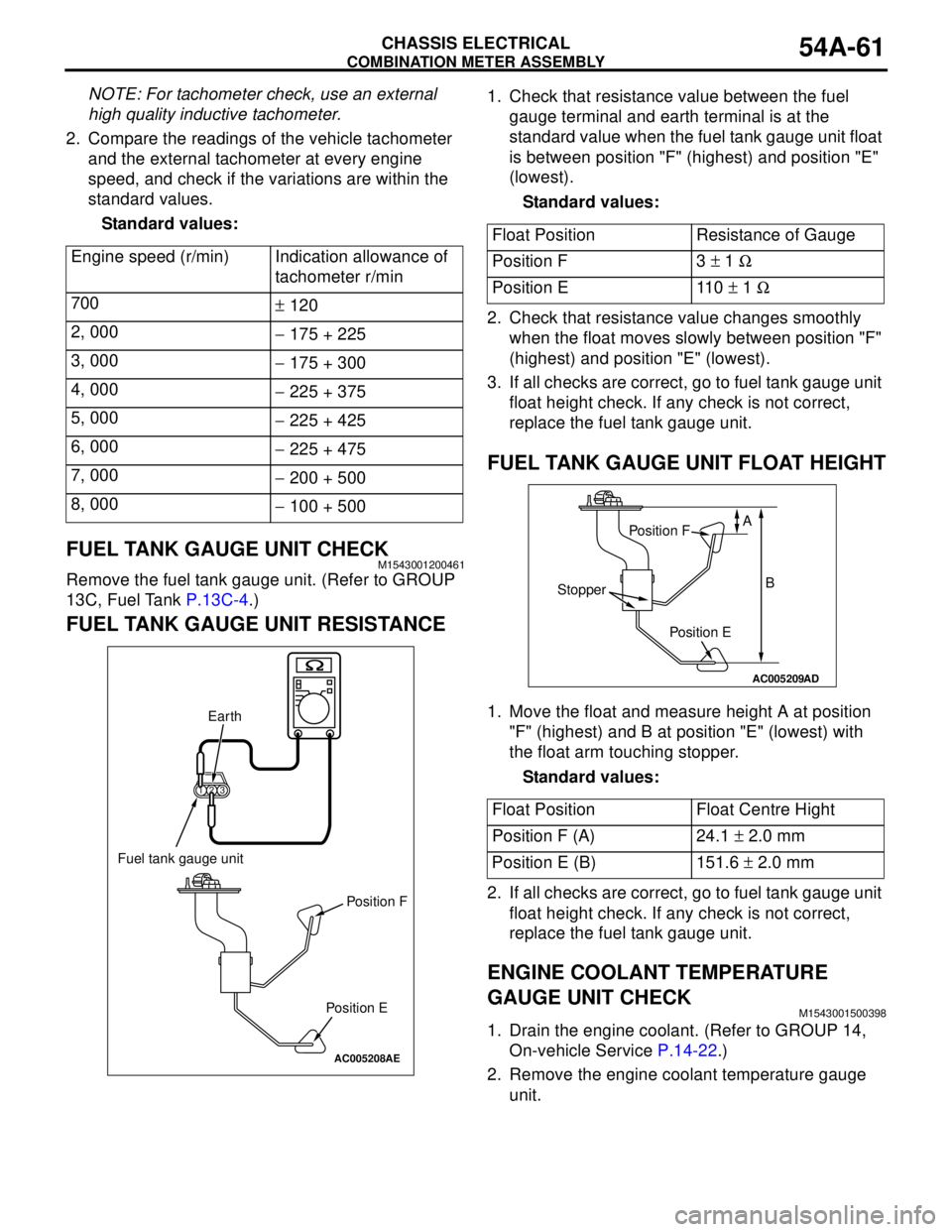

FUEL TANK GAUGE UNIT CHECKM1543001200461

Remove the fuel tank gauge unit. (Refer to GROUP

13C, Fuel Tank P.13C-4.)

FUEL TANK GAUGE UNIT RESISTANCE

1. Check that resistance value between the fuel

gauge terminal and earth terminal is at the

standard value when the fuel tank gauge unit float

is between position "F" (highest) and position "E"

(lowest).

Standard values:

2. Check that resistance value changes smoothly

when the float moves slowly between position "F"

(highest) and position "E" (lowest).

3. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

FUEL TANK GAUGE UNIT FLOAT HEIGHT

1. Move the float and measure height A at position

"F" (highest) and B at position "E" (lowest) with

the float arm touching stopper.

Standard values:

2. If all checks are correct, go to fuel tank gauge unit

float height check. If any check is not correct,

replace the fuel tank gauge unit.

ENGINE COOLANT TEMPERATURE

GAUGE UNIT CHECK

M1543001500398

1. Drain the engine coolant. (Refer to GROUP 14,

On-vehicle Service P.14-22.)

2. Remove the engine coolant temperature gauge

unit. Engine speed (r/min) Indication allowance of

tachometer r/min

700

± 120

2, 000

− 175 + 225

3, 000

− 175 + 300

4, 000

− 225 + 375

5, 000

− 225 + 425

6, 000

− 225 + 475

7, 000

− 200 + 500

8, 000

− 100 + 500

AC005208

123

AE

Fuel tank gauge unit

Earth

Position F

Position E

Float Position Resistance of Gauge

Position F 3 ± 1 Ω

Position E 110 ± 1 Ω

Float Position Float Centre Hight

Position F (A) 24.1 ± 2.0 mm

Position E (B) 151.6 ± 2.0 mm

AC005209

AD

Position F

Position E

Stopper

A

B

Page 455 of 788

HEADLAMP

CHASSIS ELECTRICAL54A-67

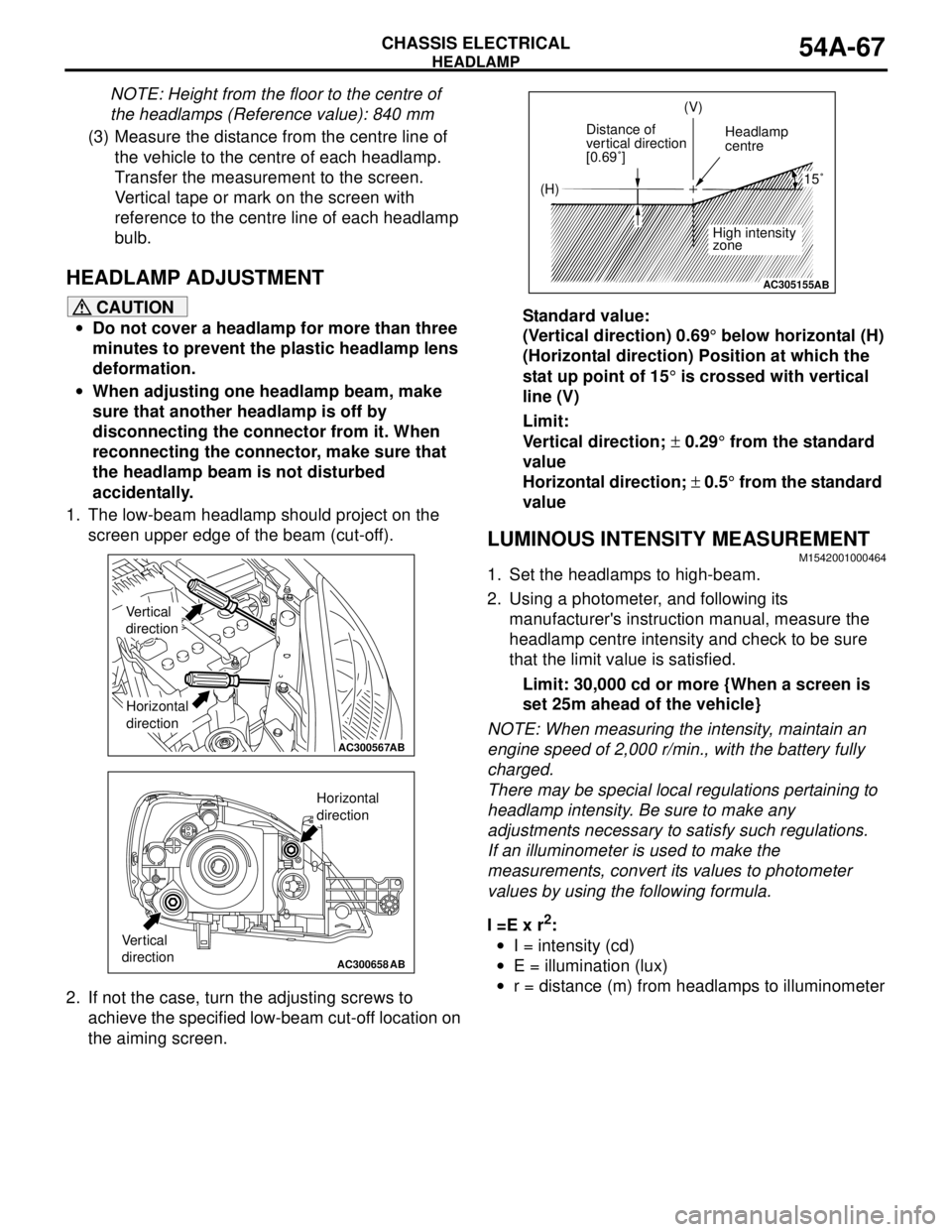

NOTE: Height from the floor to the centre of

the headlamps (Reference value): 840 mm

(3) Measure the distance from the centre line of

the vehicle to the centre of each headlamp.

Transfer the measurement to the screen.

Vertical tape or mark on the screen with

reference to the centre line of each headlamp

bulb.

HEADLAMP ADJUSTMENT

CAUTION

•Do not cover a headlamp for more than three

minutes to prevent the plastic headlamp lens

deformation.

•When adjusting one headlamp beam, make

sure that another headlamp is off by

disconnecting the connector from it. When

reconnecting the connector, make sure that

the headlamp beam is not disturbed

accidentally.

1. The low-beam headlamp should project on the

screen upper edge of the beam (cut-off).

2. If not the case, turn the adjusting screws to

achieve the specified low-beam cut-off location on

the aiming screen.Standard value:

(Vertical direction) 0.69° below horizontal (H)

(Horizontal direction) Position at which the

stat up point of 15° is crossed with vertical

line (V)

Limit:

Vertical direction; ± 0.29° from the standard

value

Horizontal direction; ± 0.5° from the standard

value

LUMINOUS INTENSITY MEASUREMENTM1542001000464

1. Set the headlamps to high-beam.

2. Using a photometer, and following its

manufacturer's instruction manual, measure the

headlamp centre intensity and check to be sure

that the limit value is satisfied.

Limit: 30,000 cd or more {When a screen is

set 25m ahead of the vehicle}

NOTE: When measuring the intensity, maintain an

engine speed of 2,000 r/min., with the battery fully

charged.

There may be special local regulations pertaining to

headlamp intensity. Be sure to make any

adjustments necessary to satisfy such regulations.

If an illuminometer is used to make the

measurements, convert its values to photometer

values by using the following formula.

I =E x r

2:

•I = intensity (cd)

•E = illumination (lux)

•r = distance (m) from headlamps to illuminometer

AC300567AB

Vertical

direction

Horizontal

direction

AC300658AB

Vertical

direction

Horizontal

direction

AC305155

(H)(V)

Distance of

vertical direction

[0.69˚]Headlamp

centre

High intensity

zone

15˚

AB