low oil pressure MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 249 of 788

ON-VEHICLE SERVICE

POWER STEERING37-15

7. If it is not within the standard value, the probable

cause is a malfunction of the oil line or steering

gear, so check these parts and repair as

necessary.

8. Turn the steering wheel all the way to the left or

right; then check whether or not the retention

hydraulic pressure is the standard value.

Standard value: 8.8 − 9.5 MPa

9. If not the standard value, overhaul the steering

gear. Remeasure fluid pressure.

10. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

11. Bleed the system (Refer to P.37-13).

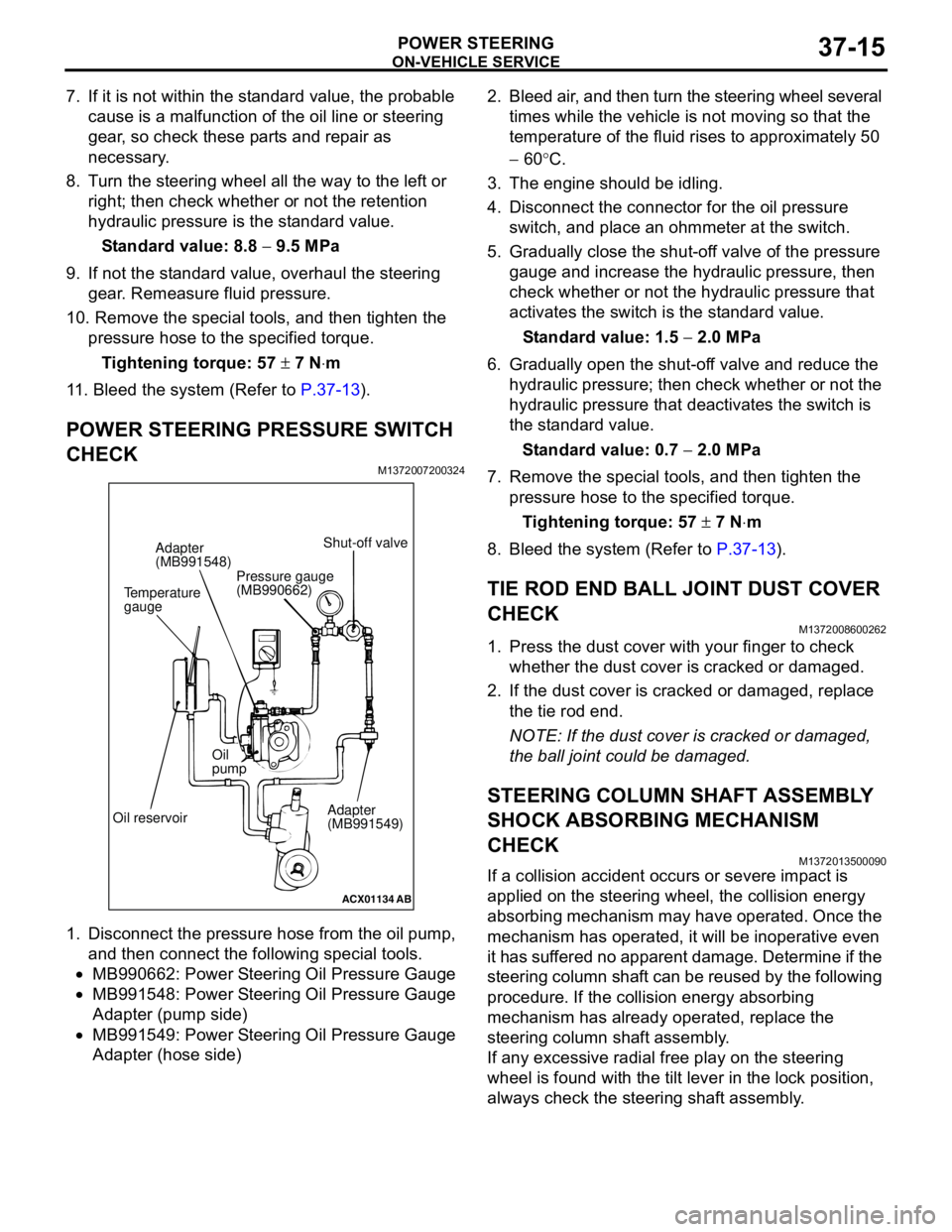

POWER STEERING PRESSURE SWITCH

CHECK

M1372007200324

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•MB990662: Power Steering Oil Pressure Gauge

•MB991548: Power Steering Oil Pressure Gauge

Adapter (pump side)

•MB991549: Power Steering Oil Pressure Gauge

Adapter (hose side)2. Bleed air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

− 60°C.

3. The engine should be idling.

4. Disconnect the connector for the oil pressure

switch, and place an ohmmeter at the switch.

5. Gradually close the shut-off valve of the pressure

gauge and increase the hydraulic pressure, then

check whether or not the hydraulic pressure that

activates the switch is the standard value.

Standard value: 1.5 − 2.0 MPa

6. Gradually open the shut-off valve and reduce the

hydraulic pressure; then check whether or not the

hydraulic pressure that deactivates the switch is

the standard value.

Standard value: 0.7 − 2.0 MPa

7. Remove the special tools, and then tighten the

pressure hose to the specified torque.

Tightening torque: 57 ± 7 N⋅m

8. Bleed the system (Refer to P.37-13).

TIE ROD END BALL JOINT DUST COVER

CHECK

M1372008600262

1. Press the dust cover with your finger to check

whether the dust cover is cracked or damaged.

2. If the dust cover is cracked or damaged, replace

the tie rod end.

NOTE: If the dust cover is cracked or damaged,

the ball joint could be damaged.

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK

M1372013500090

If a collision accident occurs or severe impact is

applied on the steering wheel, the collision energy

absorbing mechanism may have operated. Once the

mechanism has operated, it will be inoperative even

it has suffered no apparent damage. Determine if the

steering column shaft can be reused by the following

procedure. If the collision energy absorbing

mechanism has already operated, replace the

steering column shaft assembly.

If any excessive radial free play on the steering

wheel is found with the tilt lever in the lock position,

always check the steering shaft assembly.

ACX01134

AB

Temperature

gaugeAdapter

(MB991548)

Oil reservoirOil

pump

Adapter

(MB991549) Shut-off valve

Pressure gauge

(MB990662)

Page 272 of 788

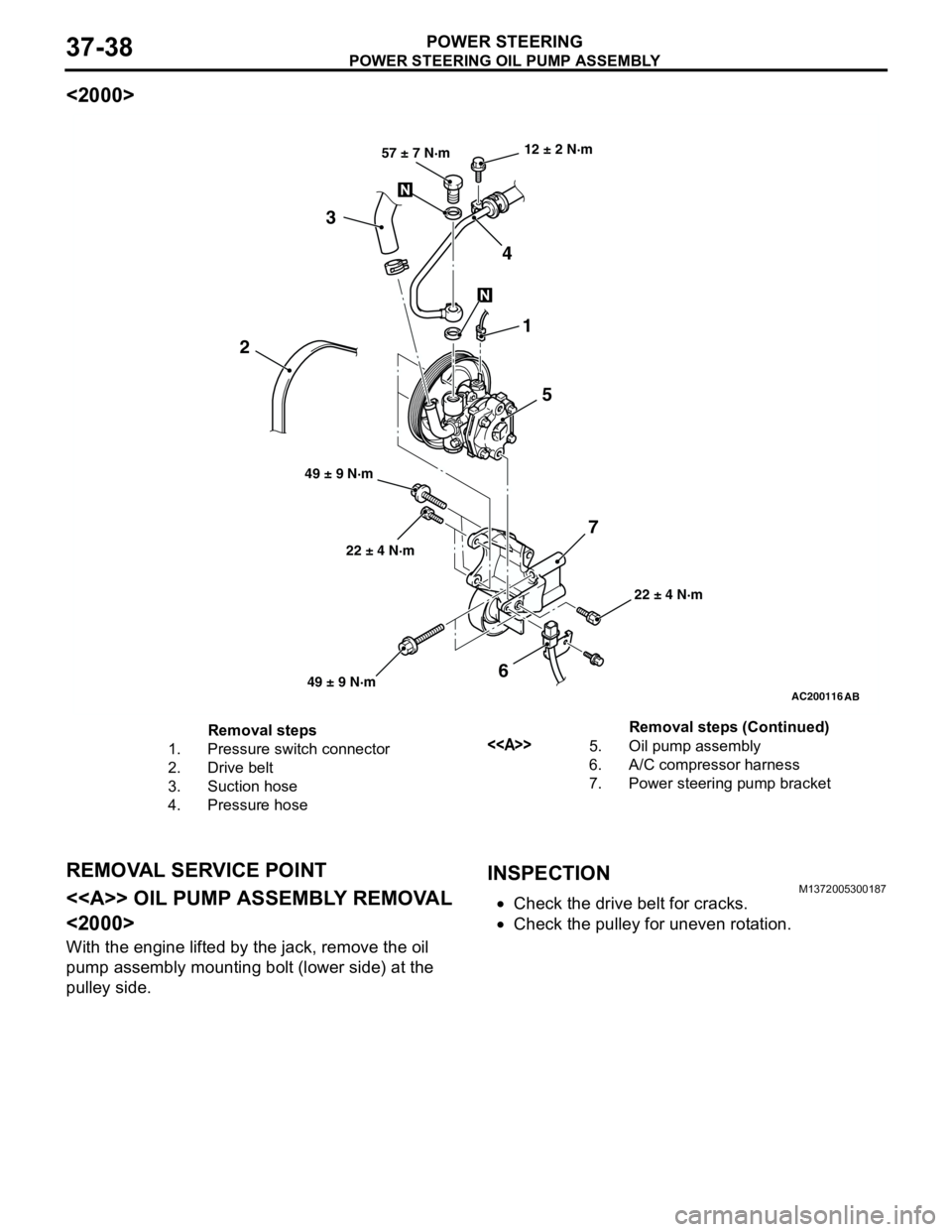

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-38

<2000>

REMOVAL SERVICE POINT

<> OIL PUMP ASSEMBLY REMOVAL

<2000>

With the engine lifted by the jack, remove the oil

pump assembly mounting bolt (lower side) at the

pulley side.

INSPECTIONM1372005300187

•Check the drive belt for cracks.

•Check the pulley for uneven rotation.

AC200116

AB

22 ± 4 N·m 12 ± 2 N·m

22 ± 4 N·m 49 ± 9 N·m57 ± 7 N·m

1

5 4 3

6 2

7

49 ± 9 N·m

Removal steps

1. Pressure switch connector

2. Drive belt

3. Suction hose

4. Pressure hose<>5. Oil pump assembly

6. A/C compressor harness

7. Power steering pump bracketRemoval steps (Continued)

Page 278 of 788

POWER STEERING HOSES

POWER STEERING37-44

REMOVAL SERVICE POINT

<> EYE BOLT/RETURN TUBE

REMOVAL

CAUTION

If the joint cover grommet has been removed,

install it properly as follows.

Align the joint cover grommet notch (arrow A)

with the steering gear lug (arrow B), and then

install the steering joint cover to the steering

gear.

1. Loosen the crossmember mounting bolts and

nuts, and lower the crossmember to a position so

that the eye bolts or return tube at the steering

gear side can be removed.

NOTE: In this case, do not remove the

crossmember mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

>>A<< RETURN HOSE INSTALLATION

Install the return hose so that the marking is

positioned as shown in the illustration.

>>B<< RETURN HOSE INSTALLATION

Install the return hose so that the markings are

positioned as shown in the illustration.

>>C<< SUCTION HOSE INSTALLATION

Install the suction hose (oil pump side) so that the

marking is positioned forward.

•Centermember (Refer to GROUP 32,

Engine Roll Stopper Centermember

P.32-7).

•Front exhaust pipe (Refer to GROUP

15, Exhaust Pipe and Main Muffler

P.15-11).

4. Steering gear and joint connecting

bolt

5. Rear roll stopper connecting bolt

<>6. Eye bolt

7. Gasket

8. Pressure hose assembly

<>9. Return tube

10. O-ringRemoval steps (Continued)

AC304922AB

A

B Joint cover

grommet

Steering gear

AC100277

ABReturn hose

AC305132AB

Return hose

Return tubeReturn hose

Page 486 of 788

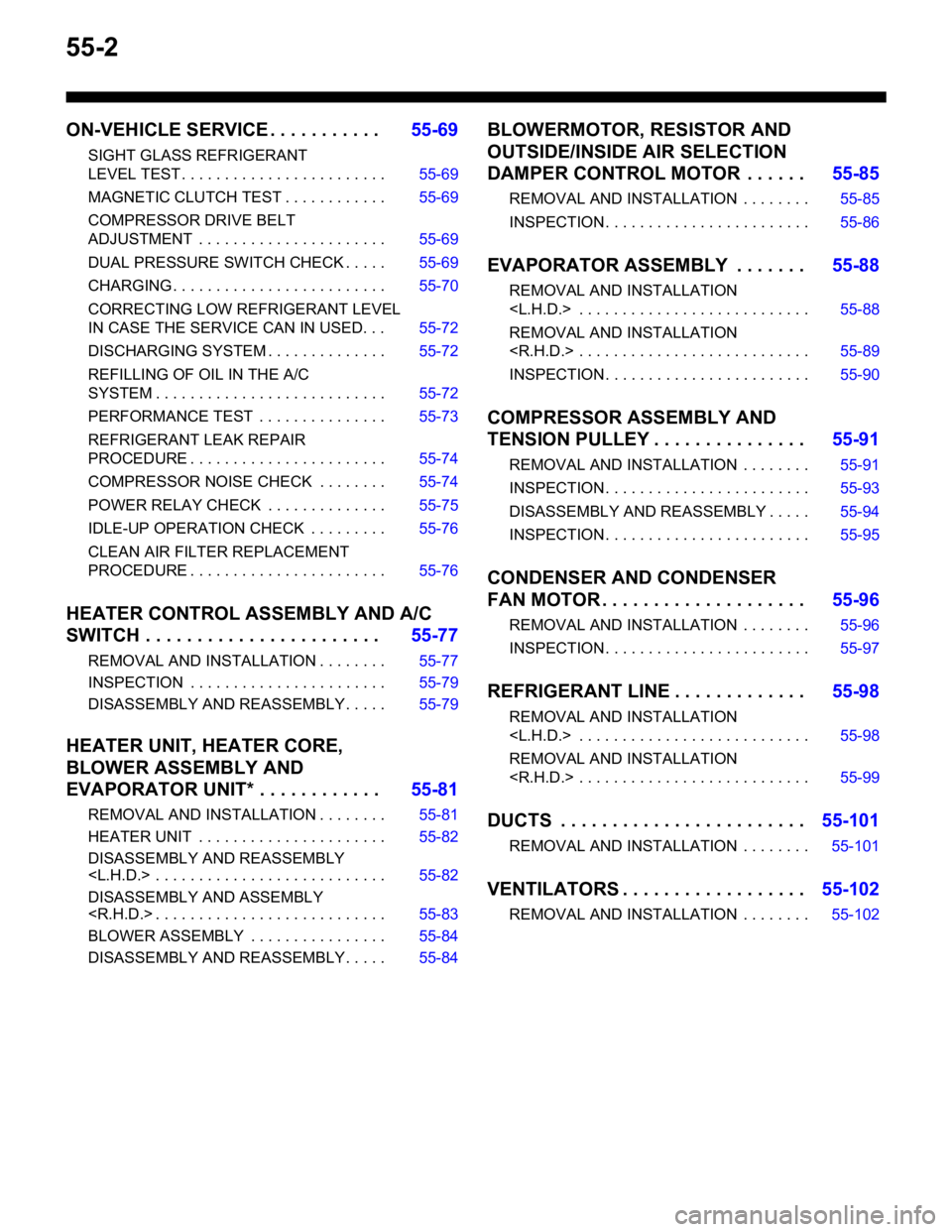

55-2

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102

Page 496 of 788

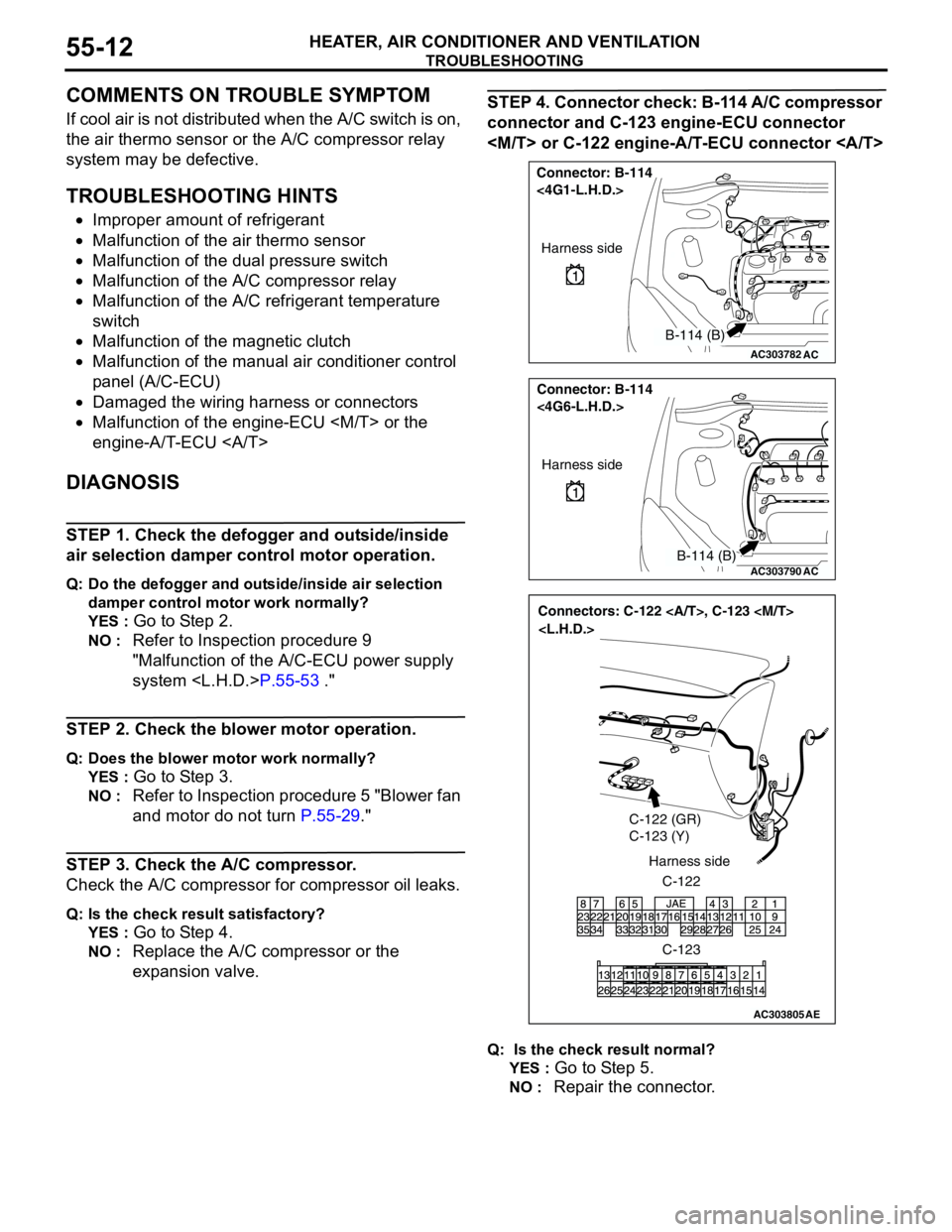

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-12

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 9

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

AC303805

Connectors: C-122 , C-123

C-122 (GR)

C-123 (Y)

C-122 Harness side

C-123

AE

Page 505 of 788

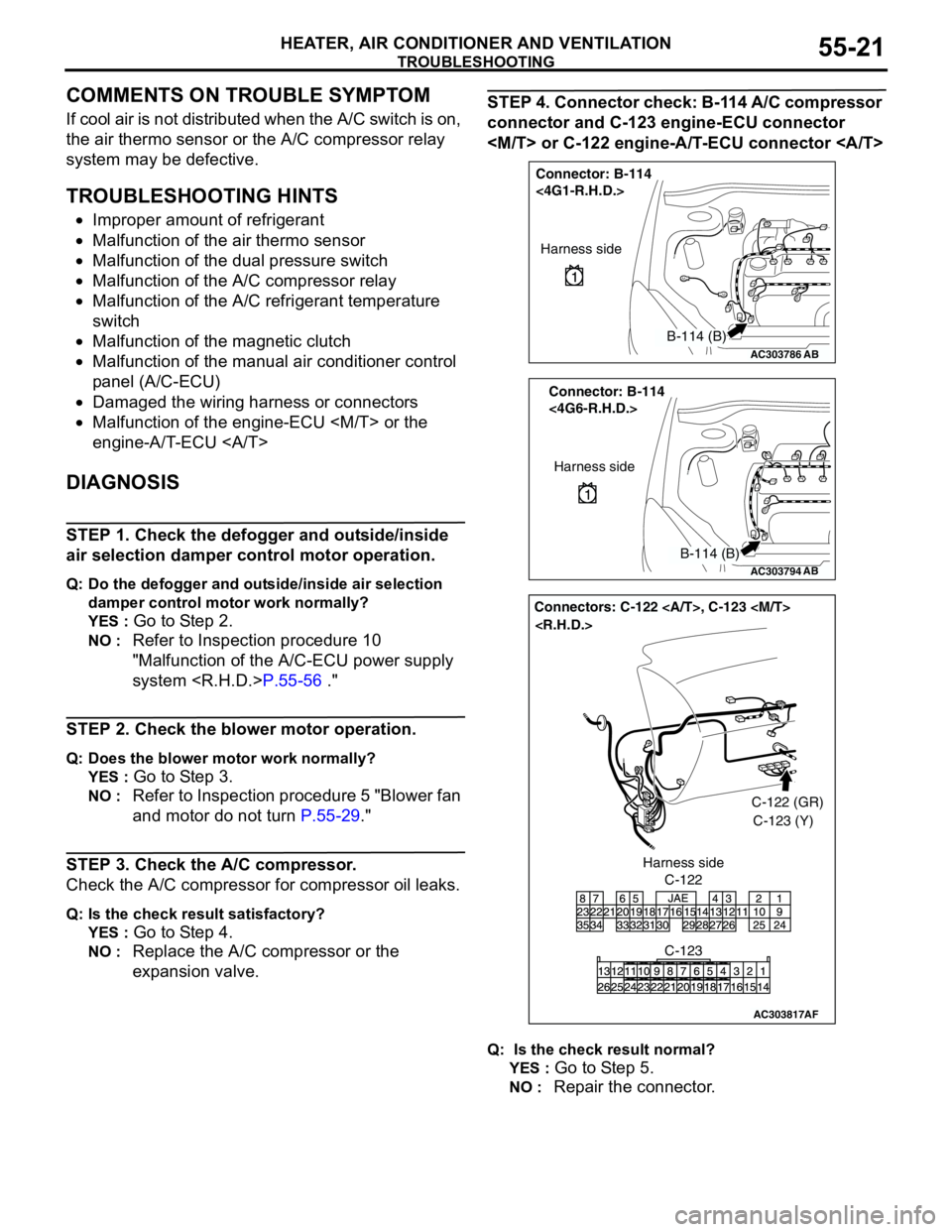

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-21

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 10

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC303817

Connectors: C-122 , C-123

AF

C-122C-122 (GR)

C-123 (Y)

C-123 Harness side

Page 556 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-72

25.After charging with refrigerant, turn the handle of

the adaptor valve back all the way (valve closed).

26.Tighten the charging valve handle (valve closed).

Remove the quick joint (for low-pressure) from the

low-pressure service valve.

27.Remove the service can.

NOTE: If the service can is not emptied

completely, keep the handles of the charging

valve and adaptor valve closed for the next

charging.

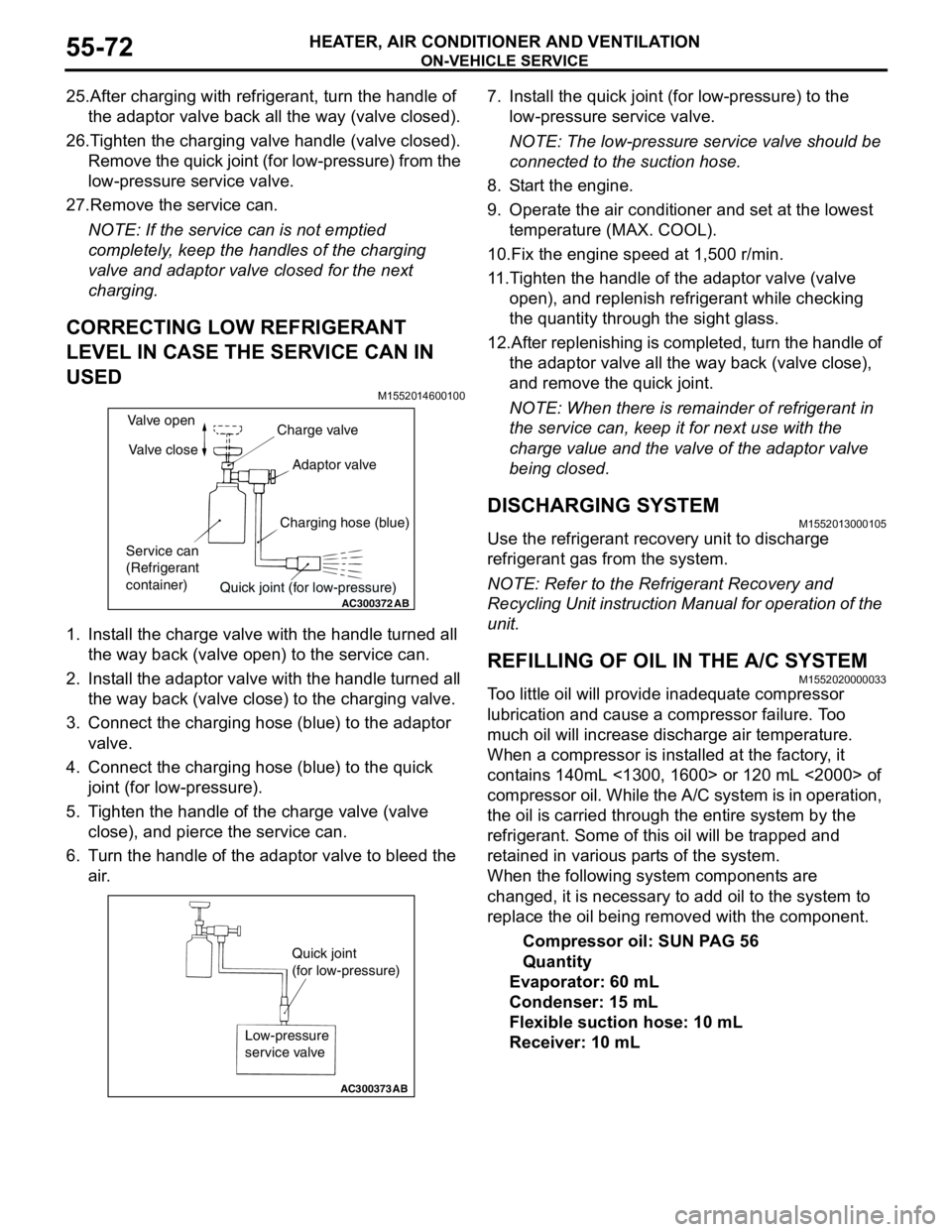

CORRECTING LOW REFRIGERANT

LEVEL IN CASE THE SERVICE CAN IN

USED

M1552014600100

1. Install the charge valve with the handle turned all

the way back (valve open) to the service can.

2. Install the adaptor valve with the handle turned all

the way back (valve close) to the charging valve.

3. Connect the charging hose (blue) to the adaptor

valve.

4. Connect the charging hose (blue) to the quick

joint (for low-pressure).

5. Tighten the handle of the charge valve (valve

close), and pierce the service can.

6. Turn the handle of the adaptor valve to bleed the

air.7. Install the quick joint (for low-pressure) to the

low-pressure service valve.

NOTE: The low-pressure service valve should be

connected to the suction hose.

8. Start the engine.

9. Operate the air conditioner and set at the lowest

temperature (MAX. COOL).

10.Fix the engine speed at 1,500 r/min.

11.Tighten the handle of the adaptor valve (valve

open), and replenish refrigerant while checking

the quantity through the sight glass.

12.After replenishing is completed, turn the handle of

the adaptor valve all the way back (valve close),

and remove the quick joint.

NOTE: When there is remainder of refrigerant in

the service can, keep it for next use with the

charge value and the valve of the adaptor valve

being closed.

DISCHARGING SYSTEMM1552013000105

Use the refrigerant recovery unit to discharge

refrigerant gas from the system.

NOTE: Refer to the Refrigerant Recovery and

Recycling Unit instruction Manual for operation of the

unit.

REFILLING OF OIL IN THE A/C SYSTEMM1552020000033

Too little oil will provide inadequate compressor

lubrication and cause a compressor failure. Too

much oil will increase discharge air temperature.

When a compressor is installed at the factory, it

contains 140mL <1300, 1600> or 120 mL <2000> of

compressor oil. While the A/C system is in operation,

the oil is carried through the entire system by the

refrigerant. Some of this oil will be trapped and

retained in various parts of the system.

When the following system components are

changed, it is necessary to add oil to the system to

replace the oil being removed with the component.

Compressor oil: SUN PAG 56

Quantity

Evaporator: 60 mL

Condenser: 15 mL

Flexible suction hose: 10 mL

Receiver: 10 mL

AC300372

AB

Valve open

Valve close

Service can

(Refrigerant

container)Charge valve

Adaptor valve

Charging hose (blue)

Quick joint (for low-pressure)

AC300373

Quick joint

(for low-pressure)

Low-pressure

service valve

AB

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

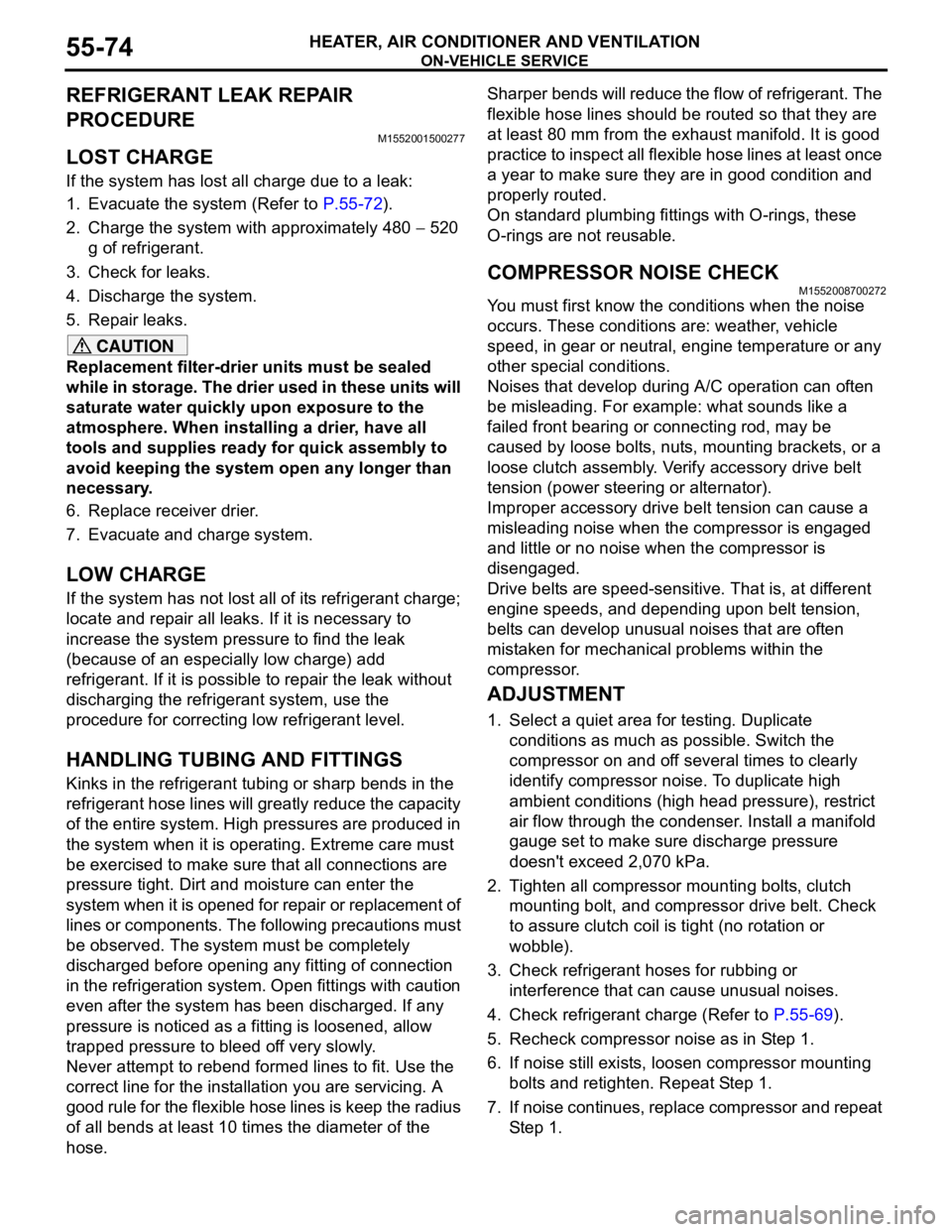

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

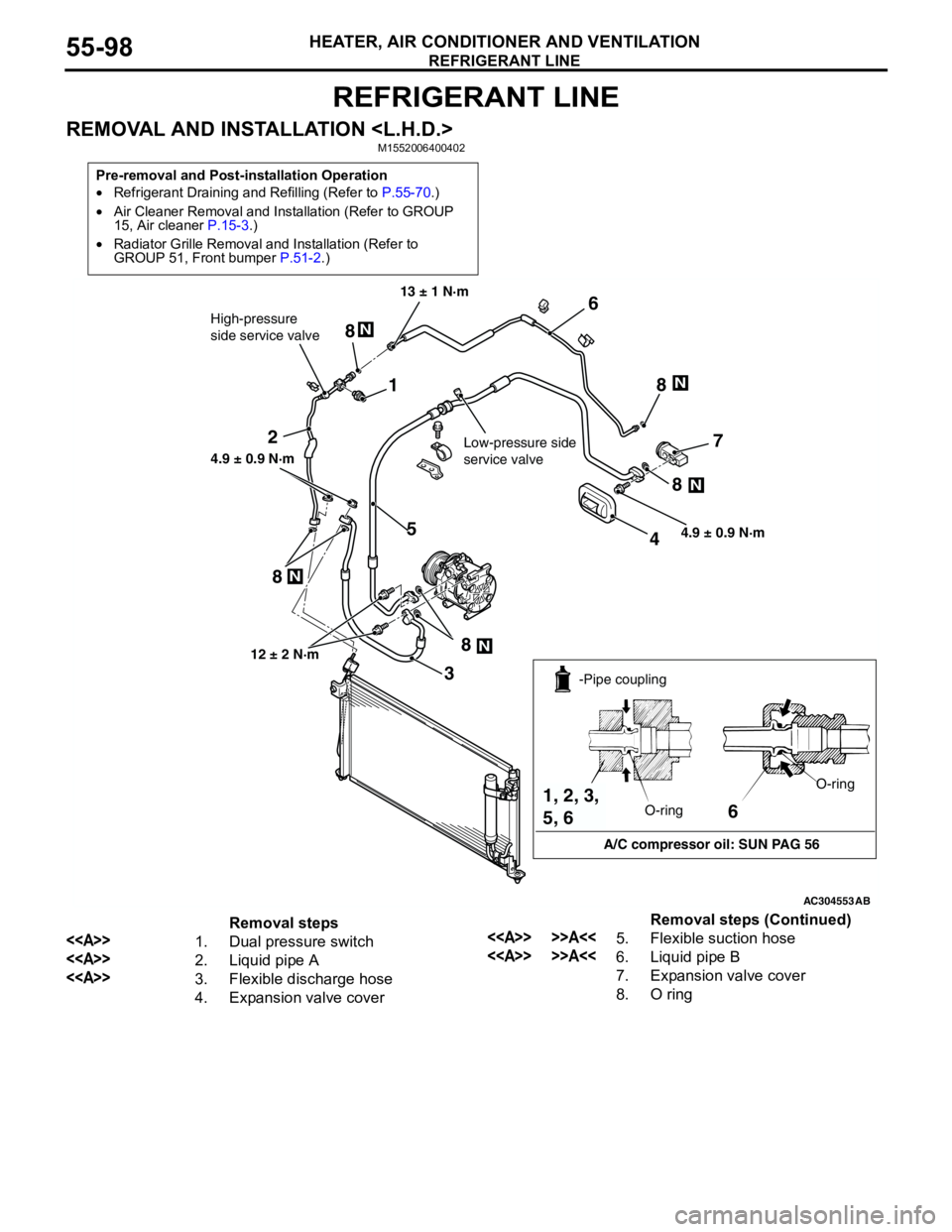

Page 582 of 788

REFRIGERANT LINE

HEATER, AIR CONDITIONER AND VENTILATION55-98

REFRIGERANT LINE

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant Draining and Refilling (Refer to P.55-70.)

•Air Cleaner Removal and Installation (Refer to GROUP

15, Air cleaner P.15-3.)

•Radiator Grille Removal and Installation (Refer to

GROUP 51, Front bumper P.51-2.)

AC304553

1

2

3

45

6

7

8N

N

N

N

N

8 8

8

8

High-pressure

side service valve

Low-pressure side

service valve

4.9 ± 0.9 N·m 13 ± 1 N·m

4.9 ± 0.9 N·m

12 ± 2 N·m

AB

6

A/C compressor oil: SUN PAG 56 -Pipe coupling

O-ringO-ring

1, 2, 3,

5, 6

Removal steps

<>1. Dual pressure switch

<>2. Liquid pipe A

<>3. Flexible discharge hose

4. Expansion valve cover

<> >>A<<5. Flexible suction hose

<> >>A<<6. Liquid pipe B

7. Expansion valve cover

8. O ringRemoval steps (Continued)

Page 583 of 788

REFRIGERANT LINE

HEATER, AIR CONDITIONER AND VENTILATION55-99

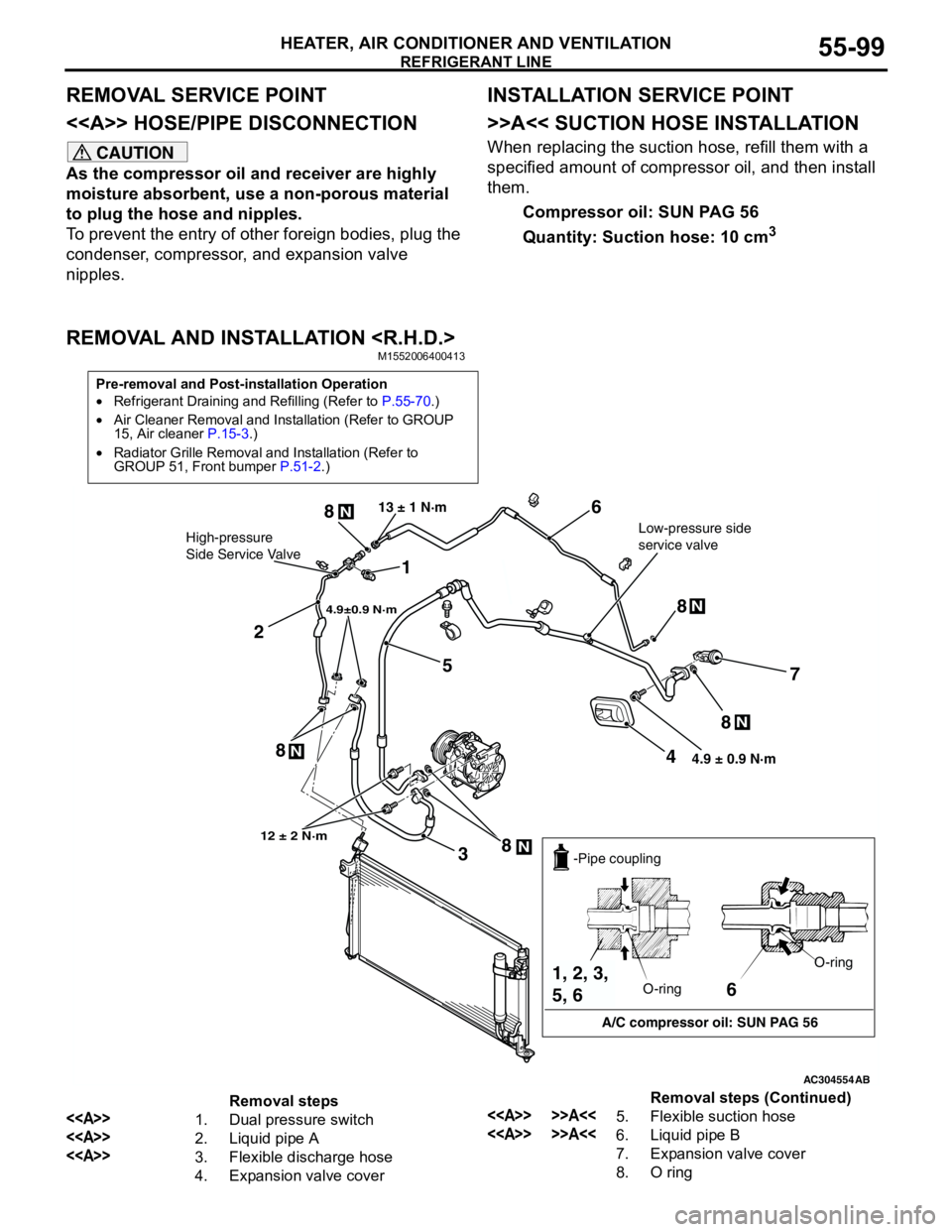

REMOVAL SERVICE POINT

<> HOSE/PIPE DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of other foreign bodies, plug the

condenser, compressor, and expansion valve

nipples.

INSTALLATION SERVICE POINT

>>A<< SUCTION HOSE INSTALLATION

When replacing the suction hose, refill them with a

specified amount of compressor oil, and then install

them.

Compressor oil: SUN PAG 56

Quantity: Suction hose: 10 cm

3

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant Draining and Refilling (Refer to P.55-70.)

•Air Cleaner Removal and Installation (Refer to GROUP

15, Air cleaner P.15-3.)

•Radiator Grille Removal and Installation (Refer to

GROUP 51, Front bumper P.51-2.)

AC304554

1

2

3

4

5

6

7

8N

8N

8N

N8 8

N

4.9±0.9 N·m

Low-pressure side

service valve 13 ± 1 N·mHigh-pressure

Side Service Valve

12 ± 2 N·m

4.9 ± 0.9 N·m

AB

6

A/C compressor oil: SUN PAG 56 -Pipe coupling

O-ringO-ring

1, 2, 3,

5, 6

Removal steps

<>1. Dual pressure switch

<>2. Liquid pipe A

<>3. Flexible discharge hose

4. Expansion valve cover

<> >>A<<5. Flexible suction hose

<> >>A<<6. Liquid pipe B

7. Expansion valve cover

8. O ringRemoval steps (Continued)