seat adjustment MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 160 of 788

ON-VEHICLE SERVICE

REAR AXLE27-4

ON-VEHICLE SERVICE

WHEEL BEARING AXIAL PLAY CHECKM1271000900452

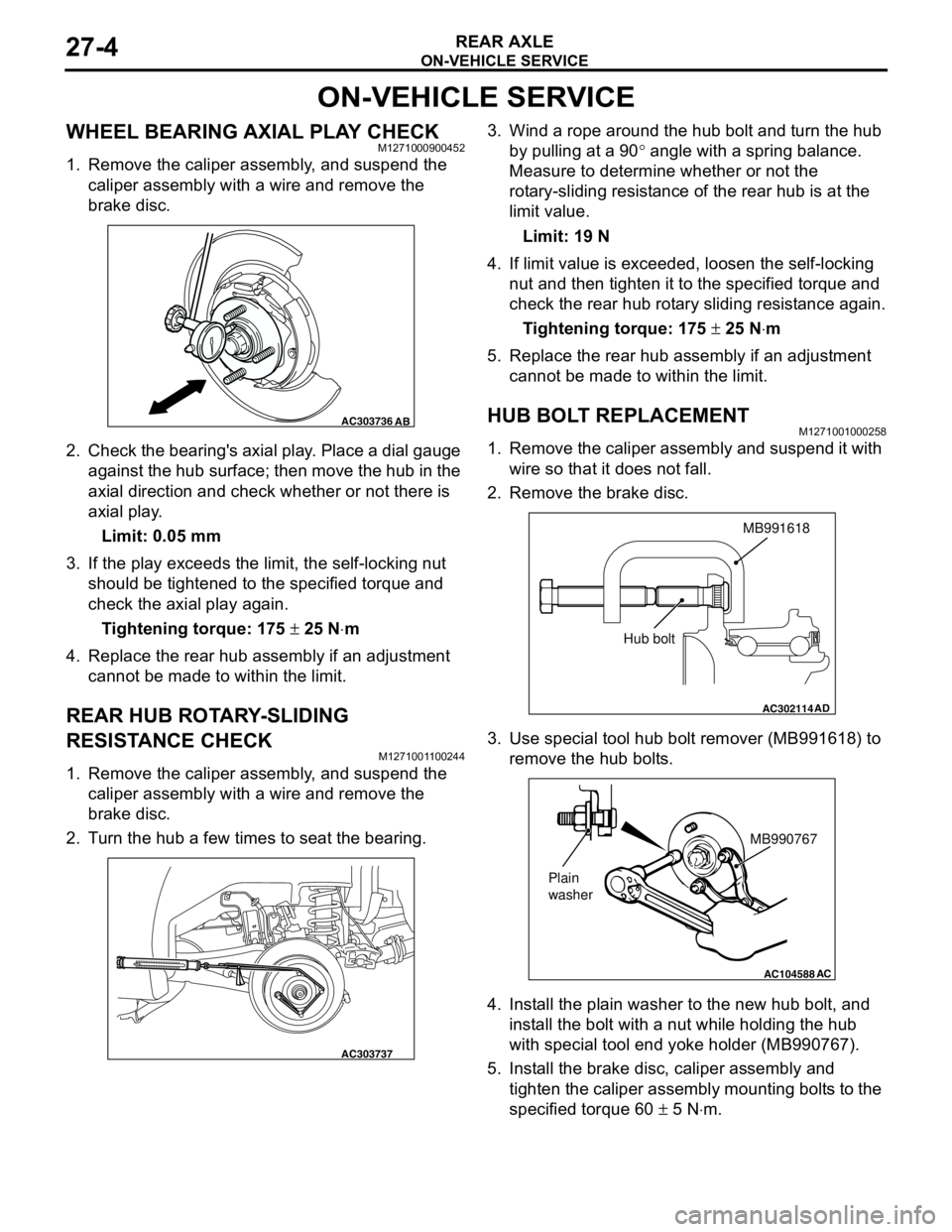

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Check the bearing's axial play. Place a dial gauge

against the hub surface; then move the hub in the

axial direction and check whether or not there is

axial play.

Limit: 0.05 mm

3. If the play exceeds the limit, the self-locking nut

should be tightened to the specified torque and

check the axial play again.

Tightening torque: 175 ± 25 N⋅m

4. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK

M1271001100244

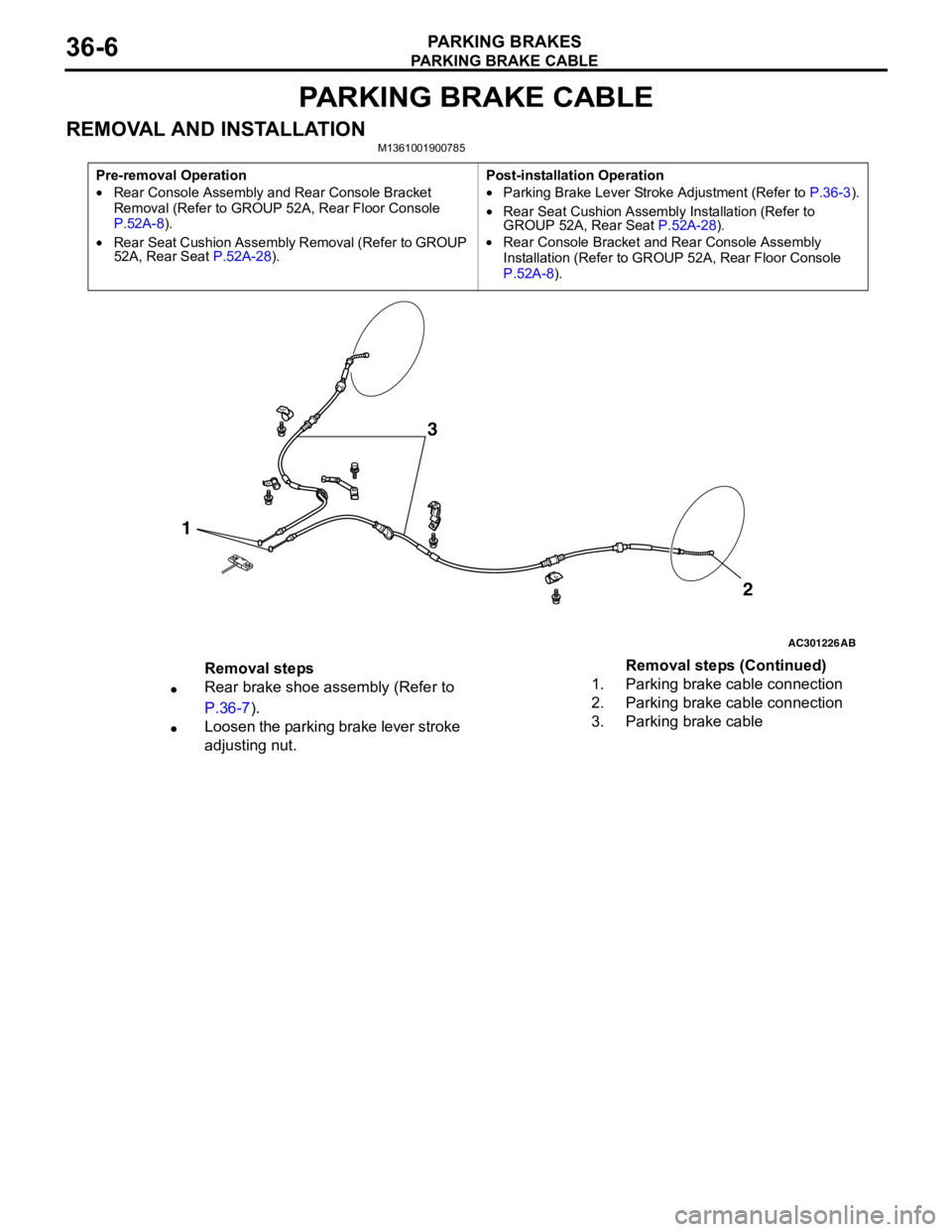

1. Remove the caliper assembly, and suspend the

caliper assembly with a wire and remove the

brake disc.

2. Turn the hub a few times to seat the bearing.3. Wind a rope around the hub bolt and turn the hub

by pulling at a 90° angle with a spring balance.

Measure to determine whether or not the

rotary-sliding resistance of the rear hub is at the

limit value.

Limit: 19 N

4. If limit value is exceeded, loosen the self-locking

nut and then tighten it to the specified torque and

check the rear hub rotary sliding resistance again.

Tightening torque: 175 ± 25 N⋅m

5. Replace the rear hub assembly if an adjustment

cannot be made to within the limit.

HUB BOLT REPLACEMENTM1271001000258

1. Remove the caliper assembly and suspend it with

wire so that it does not fall.

2. Remove the brake disc.

3. Use special tool hub bolt remover (MB991618) to

remove the hub bolts.

4. Install the plain washer to the new hub bolt, and

install the bolt with a nut while holding the hub

with special tool end yoke holder (MB990767).

5. Install the brake disc, caliper assembly and

tighten the caliper assembly mounting bolts to the

specified torque 60 ± 5 N⋅m.

AC303736AB

AC303737

AC302114

MB991618

AD

Hub bolt

AC104588

MB990767

Plain

washer

AC

Page 230 of 788

PARKING BRAKE CABLE

PARKING BRAKES36-6

PARKING BRAKE CABLE

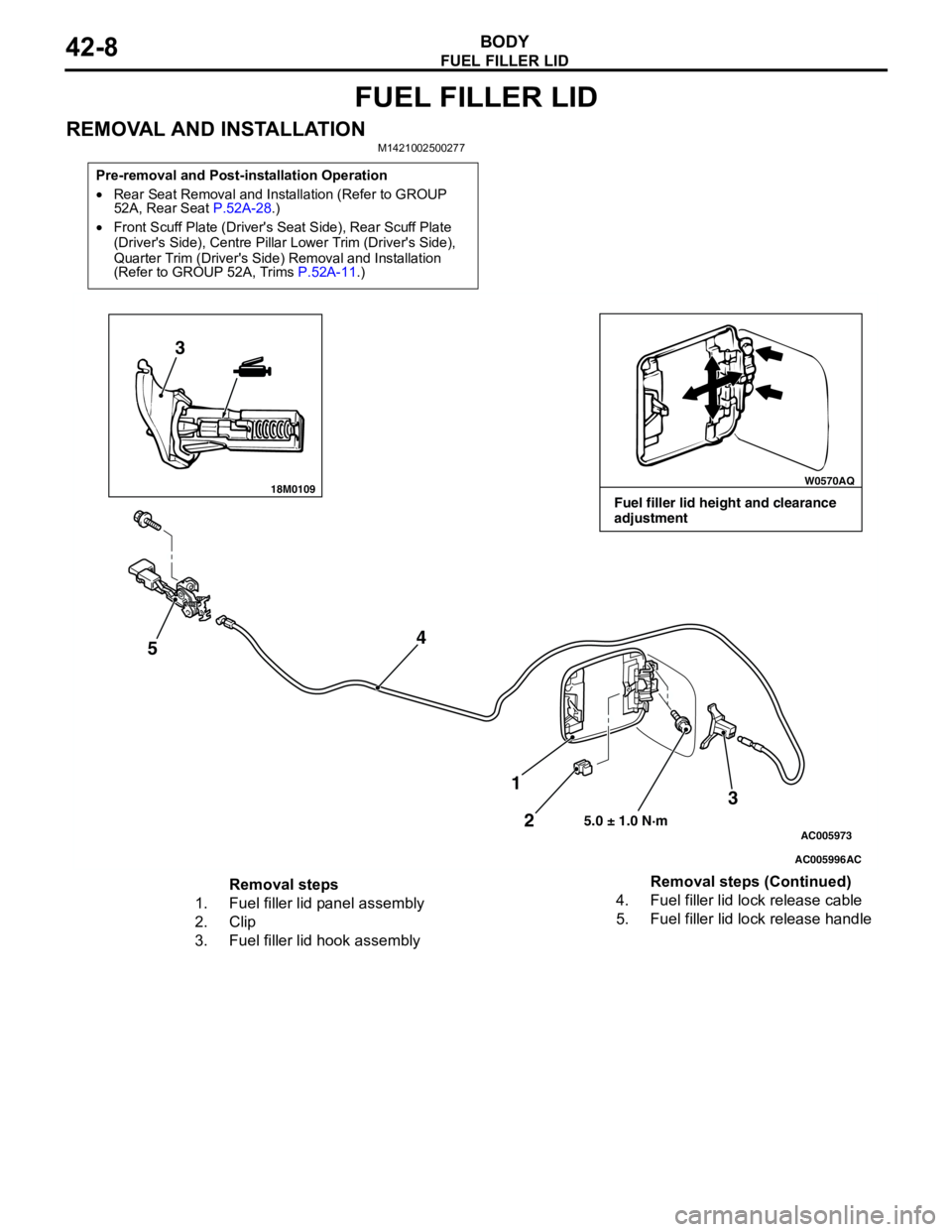

REMOVAL AND INSTALLATIONM1361001900785

Pre-removal Operation

•Rear Console Assembly and Rear Console Bracket

Removal (Refer to GROUP 52A, Rear Floor Console

P.52A-8).

•Rear Seat Cushion Assembly Removal (Refer to GROUP

52A, Rear Seat P.52A-28).Post-installation Operation

•Parking Brake Lever Stroke Adjustment (Refer to P.36-3).

•Rear Seat Cushion Assembly Installation (Refer to

GROUP 52A, Rear Seat P.52A-28).

•Rear Console Bracket and Rear Console Assembly

Installation (Refer to GROUP 52A, Rear Floor Console

P.52A-8).

AC301226

1

AB

2

3

Removal steps

•Rear brake shoe assembly (Refer to

P.36-7).

•Loosen the parking brake lever stroke

adjusting nut.1. Parking brake cable connection

2. Parking brake cable connection

3. Parking brake cableRemoval steps (Continued)

Page 286 of 788

FUEL FILLER LID

BODY42-8

FUEL FILLER LID

REMOVAL AND INSTALLATIONM1421002500277

Pre-removal and Post-installation Operation

•Rear Seat Removal and Installation (Refer to GROUP

52A, Rear Seat P.52A-28.)

•Front Scuff Plate (Driver's Seat Side), Rear Scuff Plate

(Driver's Side), Centre Pillar Lower Trim (Driver's Side),

Quarter Trim (Driver's Side) Removal and Installation

(Refer to GROUP 52A, Trims P.52A-11.)

18M0109W0570AQ

AC005996

AC005973

3

54

3

2 1

5.0 ± 1.0 N·m

AC

Fuel filler lid height and clearance

adjustment

Removal steps

1. Fuel filler lid panel assembly

2. Clip

3. Fuel filler lid hook assembly4. Fuel filler lid lock release cable

5. Fuel filler lid lock release handleRemoval steps (Continued)

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

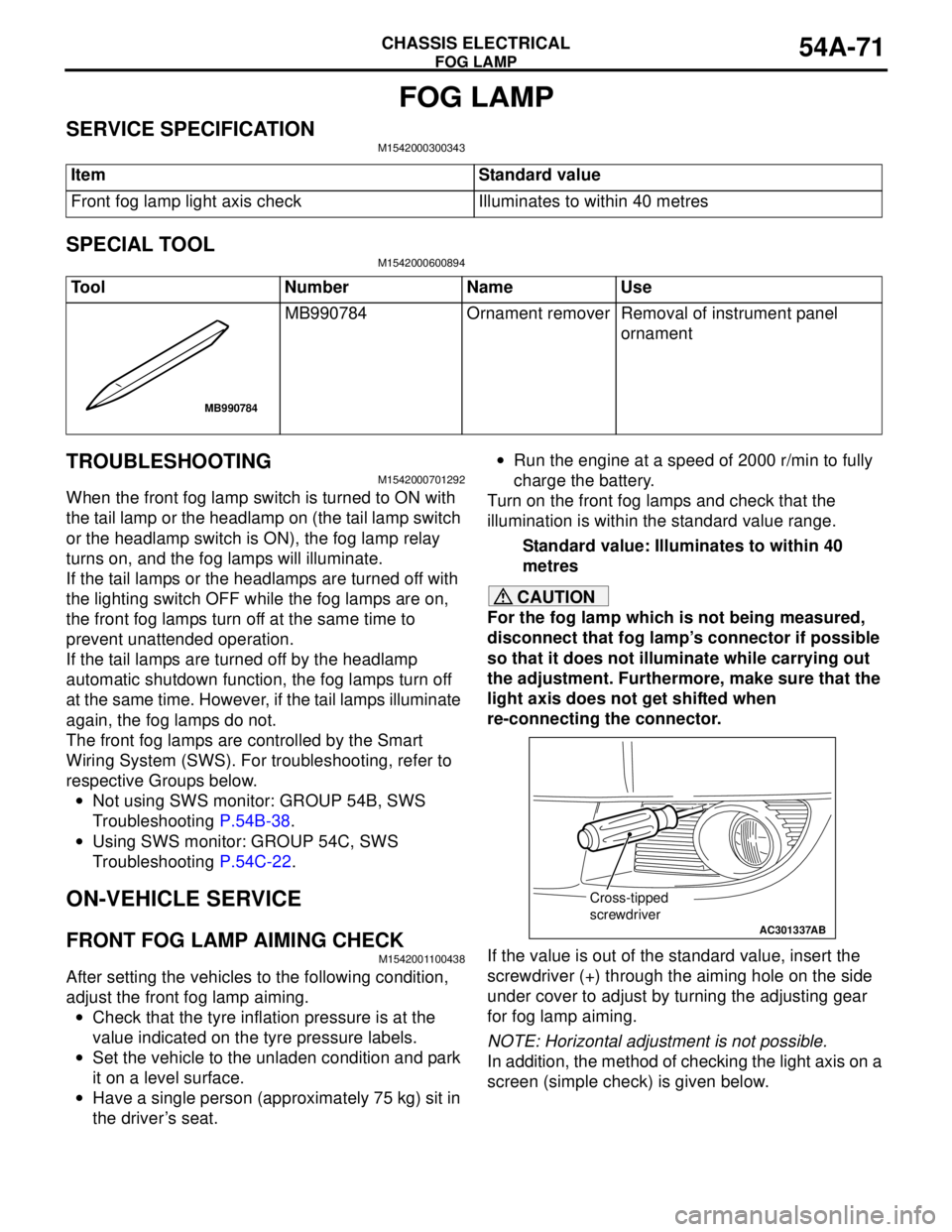

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB