relay MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 38 of 788

ON-VEHICLE SERVICE

ENGINE COOLING14-24

3. Connect the cooling fan motor drive control unit

connector, and disconnect the cooling fan motor

(L.H.) connector.

4. Ensure that the A/C switch is off, and start the

engine and run it at idle.

5. Measure the voltage between the cooling fan

motor drive control unit side connector terminal 1

and 2.

Standard value: 1V or less

WARNING

Stay clear of the fan when the fan starts

running.

6. Turn the A/C switch to the "ON" position.

7. Measure the voltage between the cooling fan

motor drive control unit side connector terminal 1

and 2 while the fan is running. The voltage should

repeat the values below.

Standard value:

1. 1 V or less

2. 8.2 ± 0.7 V

3. System voltage ± 2.6 V

8. If the voltage does not repeatedly change as

indicated, replace the cooling fan motor drive

control unit. (Refer to P.14-35).

FAN CONTROL RELAY CONTINUITY

CHECK

M1141006200280

AC303496AB

Cooling fan motor

drive control unit

Battery

voltageTerminal No.to

be connected to

testerContinuity test

results

Not applied 4 − 2 Open circuit

Connect

terminal

No.1 and

battery (−)

terminal.

Connect

terminal

No.3 and

battery (+)

terminal.4 − 2 Less than 2 ohms

AC211776

13

4 2

3 4

1 2

AC301712

Fan control relay

AB

Page 65 of 788

16-1

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM . . . . . . . .

16-2

GENERAL INFORMATION . . . . . .

16-2

SERVICE SPECIFICATIONS. . . . .16-3

SPECIAL TOOL . . . . . . . . . . . . . . .16-3

ON-VEHICLE SERVICE. . . . . . . . .16-3

ALTERNATOR OUTPUT LINE VOLTAGE

DROP TEST . . . . . . . . . . . . . . . . . . . . . 16-3

OUTPUT CURRENT TEST . . . . . . . . . . 16-5

REGULATED VOLTAGE TEST . . . . . . . 16-7

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-9

ALTERNATOR ASSEMBLY . . . . .16-12

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-12

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-13

DISASSEMBLY AND REASSEMBLY . . 16-15

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-17

STARTING SYSTEM . . . . . . . . .16-19

GENERAL INFORMATION . . . . . .

16-19

SERVICE SPECIFICATIONS. . . . .16-20

STARTER MOTOR ASSEMBLY . .16-21

REMOVAL AND INSTALLATION

<4G1> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-21

REMOVAL AND INSTALLATION

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . 16-22

STARTER MOTOR ASSEMBLY

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-23

DISASSEMBLY AND REASSEMBLY . . 16-26

INSPECTION . . . . . . . . . . . . . . . . . . . . . 16-27

IGNITION SYSTEM . . . . . . . . . 16-30

GENERAL INFORMATION . . . . . .

16-30

SERVICE SPECIFICATIONS . . . . .16-31

SPECIAL TOOL . . . . . . . . . . . . . . .16-31

ON-VEHICLE SERVICE . . . . . . . . .16-32

IGNITION COIL (WITH BUILT-IN

POWER TRANSISTOR) CHECK . . . . . . 16-32

RESISTIVE CORD CHECK . . . . . . . . . . 16-32

SPARK PLUG CHECK AND

CLEANING <4G1> . . . . . . . . . . . . . . . . . 16-32

SPARK PLUG CHECK AND

CLEANING <4G6> . . . . . . . . . . . . . . . . . 16-33

CAMSHAFT POSITION SENSOR

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 16-33

CRANK ANGLE SENSOR CHECK . . . . 16-33

DETONATION SENSOR CHECK . . . . . 16-33

IGNITION SECONDARY VOLTAGE

WAVEFORM CHECK USING AN

OSCILLOSCOPE . . . . . . . . . . . . . . . . . . 16-33

IGNITION COIL RELAY CHECK . . . . . . 16-37

IGNITION COIL . . . . . . . . . . . . . . . .16-38

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-38

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-39

CAMSHAFT POSITION SENSOR .16-40

REMOVAL AND INSTALLATION . . . . . . 16-40

CRANKSHAFT POSITION SENSOR16-41

REMOVAL AND INSTALLATION

<4G1>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-41

REMOVAL AND INSTALLATION

<4G6>. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-42

DETONATION SENSOR . . . . . . . .16-43

REMOVAL AND INSTALLATION . . . . . . 16-43

Page 101 of 788

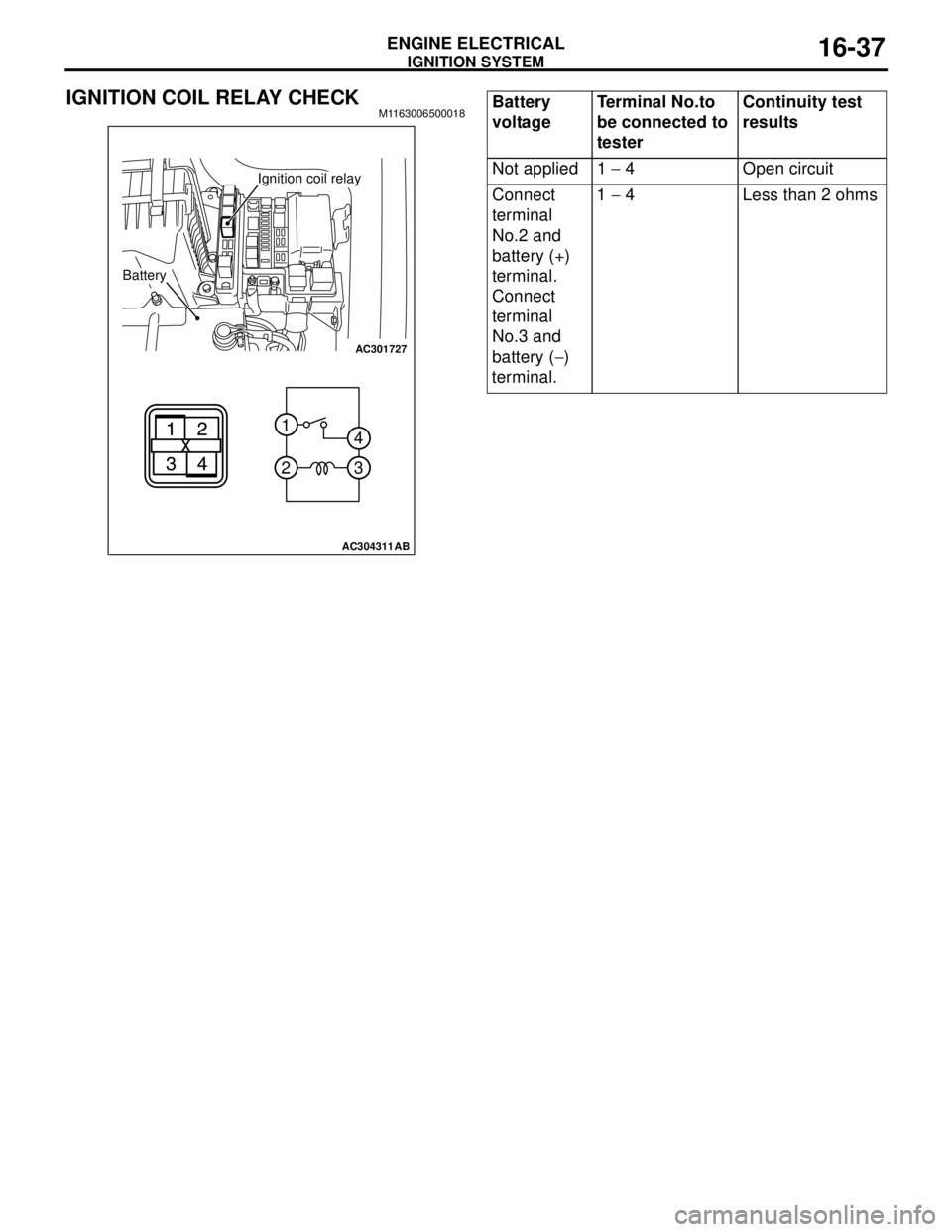

IGNITION SYSTEM

ENGINE ELECTRICAL16-37

IGNITION COIL RELAY CHECKM1163006500018

AC301727

2 1

3 4

AC304311AB

Battery

Ignition coil relay

Battery

voltageTerminal No.to

be connected to

testerContinuity test

results

Not applied 1 − 4 Open circuit

Connect

terminal

No.2 and

battery (+)

terminal.

Connect

terminal

No.3 and

battery (−)

terminal.1 − 4 Less than 2 ohms

Page 118 of 788

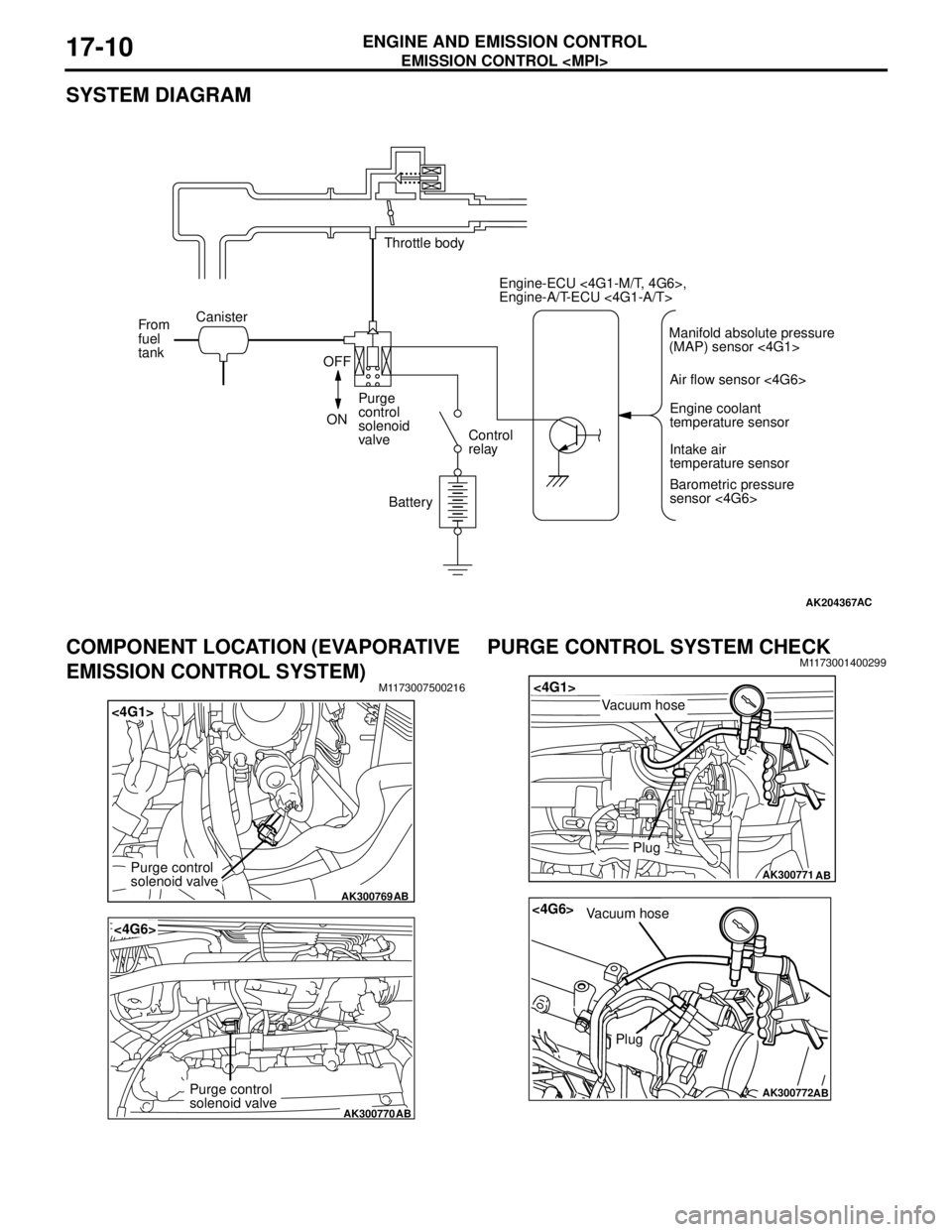

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

SYSTEM DIAGRAM

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173007500216

PURGE CONTROL SYSTEM CHECKM1173001400299

AK204367AC

Throttle body

Canister

From

fuel

tank

OFF

ONPurge

control

solenoid

valveControl

relay

BatteryEngine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

Air flow sensor <4G6>

Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6> Manifold absolute pressure

(MAP) sensor <4G1>

AK300769

<4G1>

AB

Purge control

solenoid valve

AK300770

<4G6>

AB

Purge control

solenoid valve

AK300771

<4G1>

AB

Plug

Vacuum hose

AK300772

<4G6>

AB

Plug

Vacuum hose

Page 121 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-13

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM

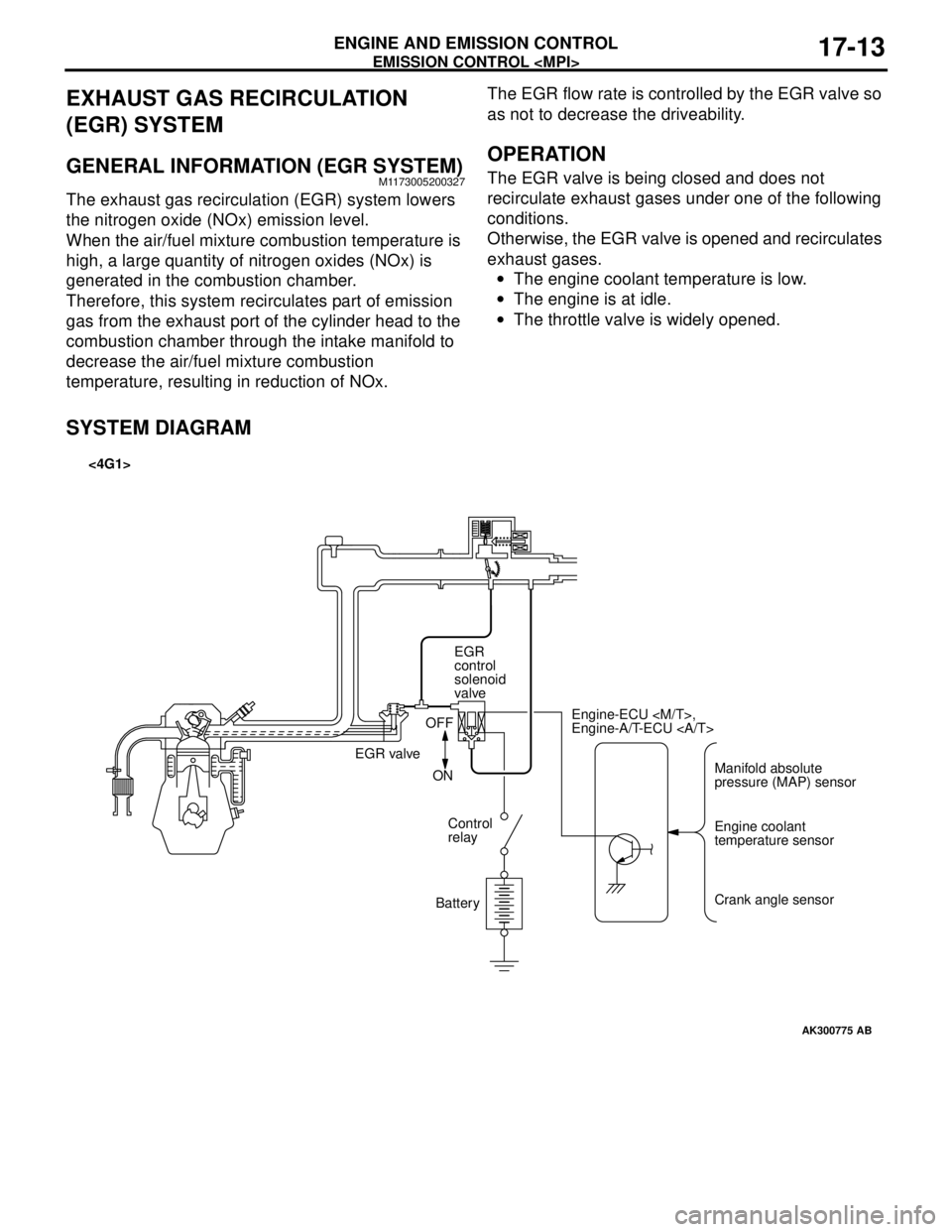

GENERAL INFORMATION (EGR SYSTEM)M1173005200327

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level.

When the air/fuel mixture combustion temperature is

high, a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber.

Therefore, this system recirculates part of emission

gas from the exhaust port of the cylinder head to the

combustion chamber through the intake manifold to

decrease the air/fuel mixture combustion

temperature, resulting in reduction of NOx.The EGR flow rate is controlled by the EGR valve so

as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not

recirculate exhaust gases under one of the following

conditions.

Otherwise, the EGR valve is opened and recirculates

exhaust gases.

•The engine coolant temperature is low.

•The engine is at idle.

•The throttle valve is widely opened.

SYSTEM DIAGRAM

AK300775

Manifold absolute

pressure (MAP) sensor Engine-ECU

Engine-A/T-ECU

Engine coolant

temperature sensor

Crank angle sensor EGR

control

solenoid

valve

EGR valveOFF

ON

Control

relay

Battery

AB

<4G1>

Page 122 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-14

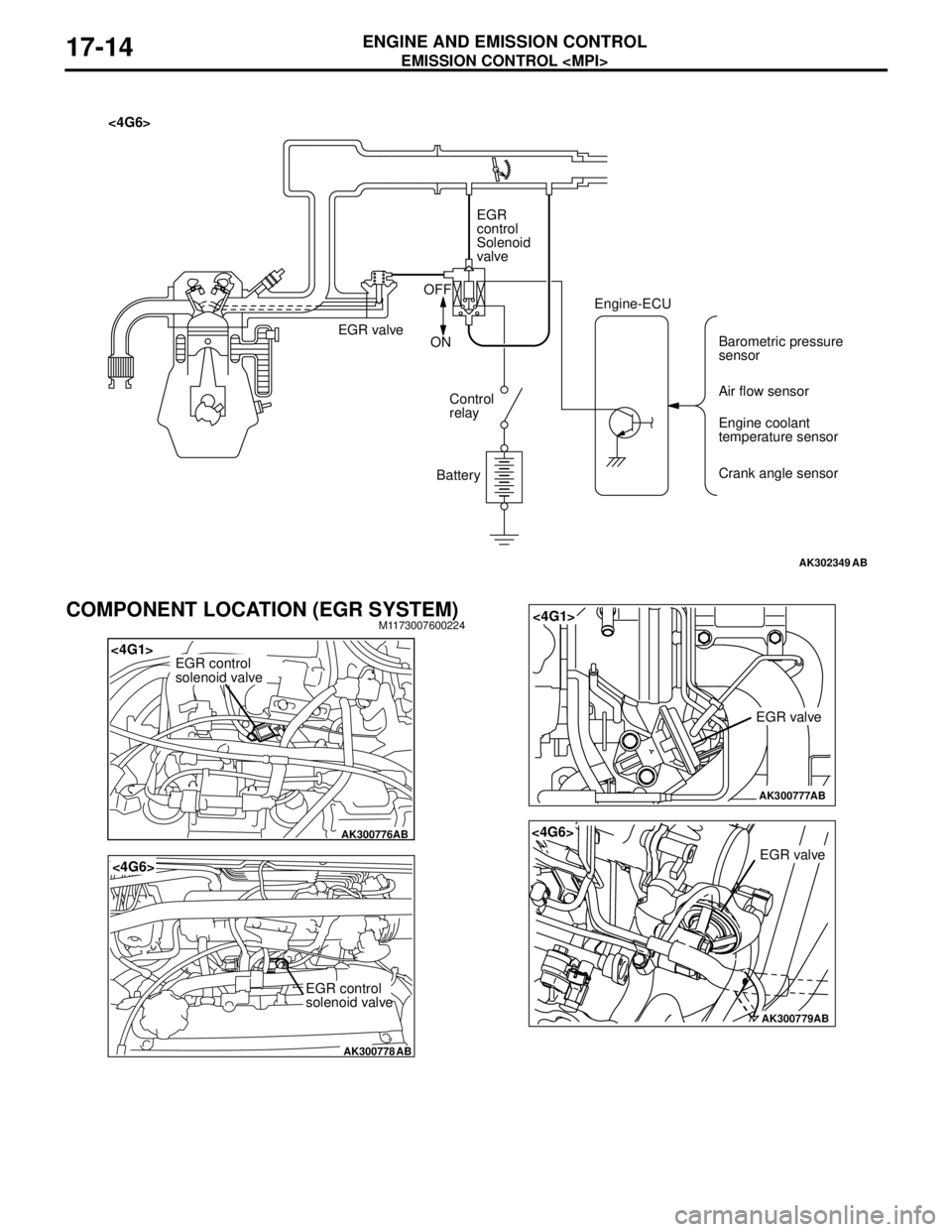

COMPONENT LOCATION (EGR SYSTEM)M1173007600224

AK302349AB

<4G6>

EGR

control

Solenoid

valve

EGR valveOFF

ON

Control

relay

BatteryEngine-ECU

Barometric pressure

sensor

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

AK300776

<4G1>

AB

EGR control

solenoid valve

AK300778

<4G6>

AB

EGR control

solenoid valve

AK300777

<4G1>

AB

EGR valve

AK300779AB

<4G6>

EGR valve

Page 280 of 788

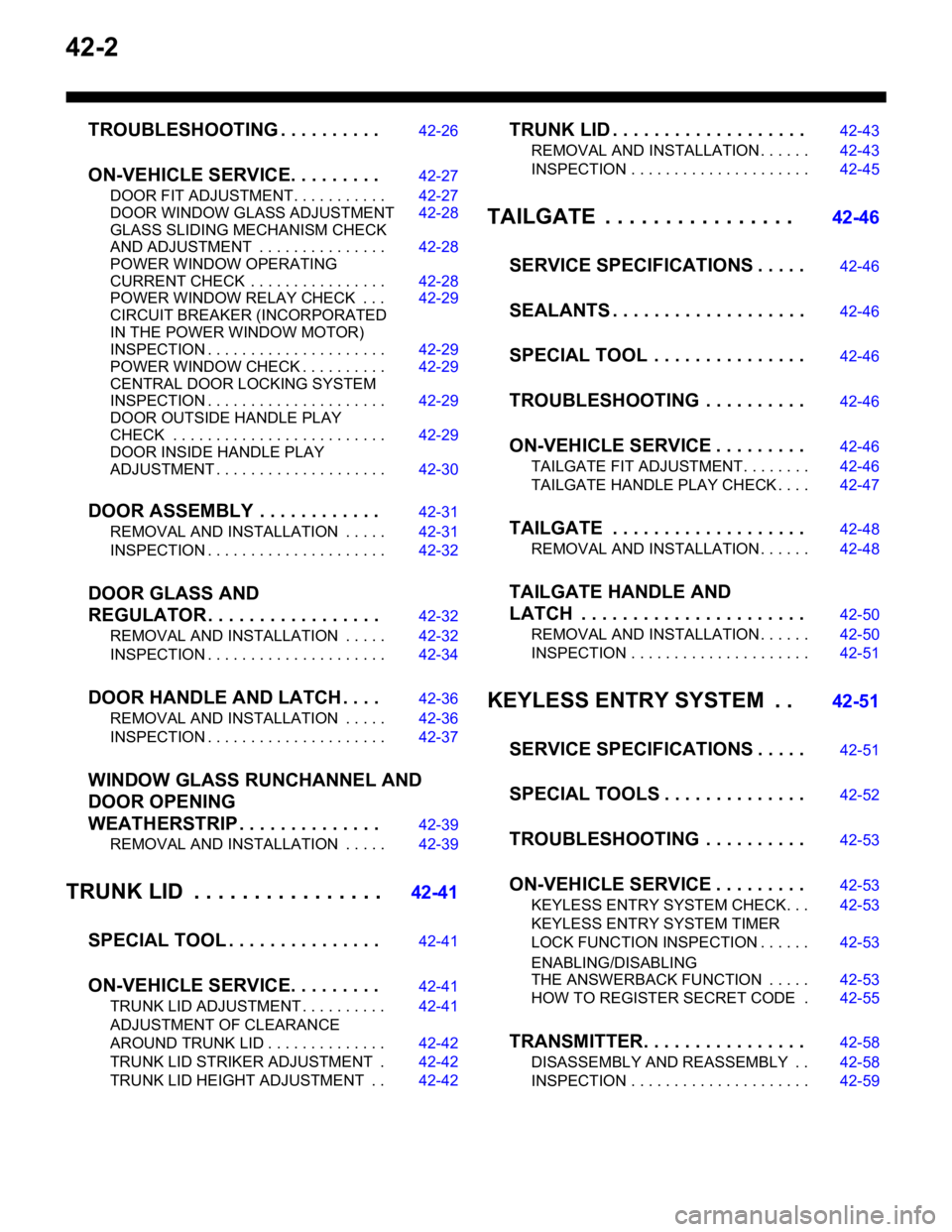

42-2

TROUBLESHOOTING . . . . . . . . . .42-26

ON-VEHICLE SERVICE. . . . . . . . .42-27

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-27

DOOR WINDOW GLASS ADJUSTMENT42-28

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-28

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-28

POWER WINDOW RELAY CHECK . . . 42-29

CIRCUIT BREAKER (INCORPORATED

IN THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

POWER WINDOW CHECK . . . . . . . . . . 42-29

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR OUTSIDE HANDLE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR INSIDE HANDLE PLAY

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-30

DOOR ASSEMBLY . . . . . . . . . . . .42-31

REMOVAL AND INSTALLATION . . . . . 42-31

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-32

DOOR GLASS AND

REGULATOR . . . . . . . . . . . . . . . . .

42-32

REMOVAL AND INSTALLATION . . . . . 42-32

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR HANDLE AND LATCH . . . .42-36

REMOVAL AND INSTALLATION . . . . . 42-36

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-37

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-39

REMOVAL AND INSTALLATION . . . . . 42-39

TRUNK LID . . . . . . . . . . . . . . . .42-41

SPECIAL TOOL . . . . . . . . . . . . . . .

42-41

ON-VEHICLE SERVICE. . . . . . . . .42-41

TRUNK LID ADJUSTMENT . . . . . . . . . . 42-41

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-42

TRUNK LID STRIKER ADJUSTMENT . 42-42

TRUNK LID HEIGHT ADJUSTMENT . . 42-42

TRUNK LID . . . . . . . . . . . . . . . . . . .42-43

REMOVAL AND INSTALLATION . . . . . . 42-43

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-45

TAILGATE . . . . . . . . . . . . . . . . 42-46

SERVICE SPECIFICATIONS . . . . .

42-46

SEALANTS . . . . . . . . . . . . . . . . . . .42-46

SPECIAL TOOL . . . . . . . . . . . . . . .42-46

TROUBLESHOOTING . . . . . . . . . .42-46

ON-VEHICLE SERVICE . . . . . . . . .42-46

TAILGATE FIT ADJUSTMENT. . . . . . . . 42-46

TAILGATE HANDLE PLAY CHECK . . . . 42-47

TAILGATE . . . . . . . . . . . . . . . . . . .42-48

REMOVAL AND INSTALLATION . . . . . . 42-48

TAILGATE HANDLE AND

LATCH . . . . . . . . . . . . . . . . . . . . . .

42-50

REMOVAL AND INSTALLATION . . . . . . 42-50

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-51

KEYLESS ENTRY SYSTEM . . 42-51

SERVICE SPECIFICATIONS . . . . .

42-51

SPECIAL TOOLS . . . . . . . . . . . . . .42-52

TROUBLESHOOTING . . . . . . . . . .42-53

ON-VEHICLE SERVICE . . . . . . . . .42-53

KEYLESS ENTRY SYSTEM CHECK. . . 42-53

KEYLESS ENTRY SYSTEM TIMER

LOCK FUNCTION INSPECTION . . . . . . 42-53

ENABLING/DISABLING

THE ANSWERBACK FUNCTION . . . . . 42-53

HOW TO REGISTER SECRET CODE . 42-55

TRANSMITTER. . . . . . . . . . . . . . . .42-58

DISASSEMBLY AND REASSEMBLY . . 42-58

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-59

Page 307 of 788

DOOR

BODY42-29

3. If the operation current is outside the standard

value, refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

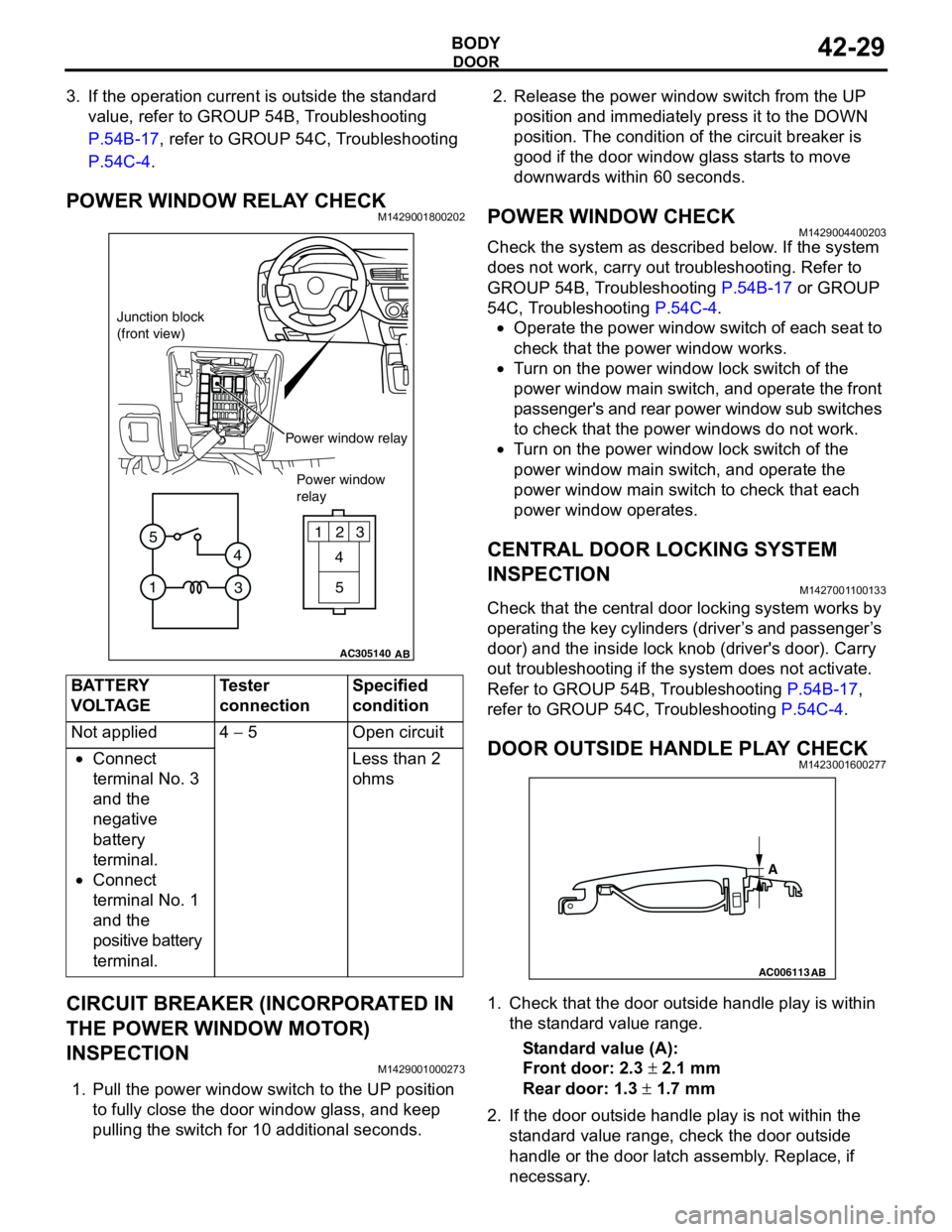

POWER WINDOW RELAY CHECKM1429001800202

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION

M1429001000273

1. Pull the power window switch to the UP position

to fully close the door window glass, and keep

pulling the switch for 10 additional seconds.2. Release the power window switch from the UP

position and immediately press it to the DOWN

position. The condition of the circuit breaker is

good if the door window glass starts to move

downwards within 60 seconds.

POWER WINDOW CHECKM1429004400203

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

•Operate the power window switch of each seat to

check that the power window works.

•Turn on the power window lock switch of the

power window main switch, and operate the front

passenger's and rear power window sub switches

to check that the power windows do not work.

•Turn on the power window lock switch of the

power window main switch, and operate the

power window main switch to check that each

power window operates.

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M1427001100133

Check that the central door locking system works by

operating the key cylinders (driver’s and passenger’s

door) and the inside lock knob (driver's door). Carry

out troubleshooting if the system does not activate.

Refer to GROUP 54B, Troubleshooting P.54B-17,

refer to GROUP 54C, Troubleshooting P.54C-4.

DOOR OUTSIDE HANDLE PLAY CHECKM1423001600277

1. Check that the door outside handle play is within

the standard value range.

Standard value (A):

Front door: 2.3 ± 2.1 mm

Rear door: 1.3 ± 1.7 mm

2. If the door outside handle play is not within the

standard value range, check the door outside

handle or the door latch assembly. Replace, if

necessary. BATTERY

VOLTAGETester

connectionSpecified

condition

Not applied 4 − 5 Open circuit

•Connect

terminal No. 3

and the

negative

battery

terminal.

•Connect

terminal No. 1

and the

positive battery

terminal.Less than 2

ohms

AC305140

123

4

5

1

3 4 5

AB

Junction block

(front view)

Power window relay

Power window

relay

AC006113

AB

A

Page 359 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-21

WINDSHIELD WIPER AND WASHER

GENERAL INFORMATIONM1511000100514

WINDSHIELD WIPER AND WASHER

OPERATION

Windshield Low-speed (and High-speed)

Wiper Operation

•If the windshield low-speed wiper switch is turned

to the ON position with the ignition switch at the

"ACC" or "ON" position, the column switch sends

a low-speed wiper ON and high-speed wiper OFF

signals to the front-ECU. This turns the wiper

signal on and the wiper speed control relay off

(low-speed), causing the wipers to operate at

low-speed.

•If the windshield high-speed wiper switch is

turned to the ON position, the column switch

sends a low-speed wiper OFF and high-speed

wiper ON signals to the front-ECU. This turns

both the wiper signal and the wiper speed control

relay on (high-speed), causing the wipers to

operate at high-speed.

NOTE: The windshield wiper speed is switchable

with the built-in wiper speed control relay.

High-speed operations take place when the wiper

speed control relay is set to "ON" and low-speed

operations take place when the wiper speed control

relay is set to "OFF".

Windshield Intermittent Wiper Operation

The ETACS-ECU calculates the wiper operation

interval according to the voltage signal sent from the

column switch. Then the ETACS-ECU sends a signal

to the front-ECU. The front-ECU determines the

wiper operation interval and turns on the wiper relay

signal relay. This causes the wiper auto stop relay to

turn on. Then the wiper auto stop relay will turn off

after the wipers reach the park position. This causes

the wiper signal relay and then the wipers to turn off.

If the wiper signal relay remains off for the wiper

operation interval, the relay turns on again, causing

the wipers to operate in intermittent mode.

Windshield Mist Wiper Operation

•If the windshield mist wiper switch is turned to the

ON position with the ignition switch at the "ACC"

or "ON" position, the mist wiper high-speed

operation signal is sent to the front-ECU. This

signal turns on the wiper speed control relay,

causing the wipers to work at high-speed while

the mist switch is on.

•While the windshield mist wiper switch remains

turned on when the intermittent mode is still

working, the wipers work as the mist wiper.

However, the wipers return to the intermittent

mode again when the switch is changed back to

"INT" position.

•To prevent the windshield mist wiper from

operating when the windshield wiper switch is

turned OFF, the windshield mist wiper does not

work for 0.5 second after the windshield

intermittent wiper switch, the windshield

low-speed wiper switch and the windshield

high-speed wiper switch are turned OFF.

Windshield Washer Operation

•If the windshield washer switch is turned to ON

position with the ignition switch at "ACC" or "ON"

position, the windshield washer ON signal is sent

to the front-ECU. After 0.3 second, the windshield

wiper signal turns on. After the windshield washer

switch signal turns off, the windshield wiper signal

turns off in three seconds.

•If the windshield washer switch is turned on while

the windshield wiper is at intermittent mode,

when the windshield washer switch is turned OFF

within 0.2 second, the wiper works only once to

perform mist operation by the windshield washer

switch. When the ON condition of the windshield

washer switch continues more than 0.2 second,

the wiper performs the same movement as

normal condition from the time when 0.2 second

has elapsed and then returns to the intermittent

motion.

Page 374 of 788

DOOR MIRROR

EXTERIOR51-36

DOOR MIRROR

GENERAL INFORMATIONM1511000100536

DOOR MIRROR OPERATION

Remote Controlled Mirror Operation

•The mirror on the door mirror moves up/down

and left/right by operating the remote controlled

door mirror switch when the ignition switch is in

the "ON" or "ACC" position.Heated Door Mirror operation

•The defogger relay switch is activated (ON) by

turning on the A/C-ECU built-in defogger switch

when the ignition switch is in the "ON" position.

When the defogger relay is turned ON, power is

supplied to the defogger and door mirror, and the

heater of the door mirror (heated door mirror)

starts operations. The defogger comes with a

timer function and will automatically turn OFF the

switch approximately 11 minutes after the

defogger switch is turned ON. The heated door

mirror operations are also terminated along with

the defogger, at this time.

SERVICE SPECIFICATIONM1511000300347

SPECIAL TOOLM1511000601103

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOWM1511014600169

Refer to GROUP 00 − How to Use

Troubleshooting/Inspection Service Points P.00-5.

TROUBLE SYMPTOM CHARTM1511015000160

ItemStandard value

Heated door mirror operation current Ω5.9 − 7.8

Tool Number Name Application

MB990784 Ornament remover Removal of remote controlled

mirror switch

MB990784

Symptom Inspection

procedureReference

page

All heated door mirrors do not operate 1

P.51-37

The right or left heated door mirror does not operate 2

P.51-39