relay MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 459 of 788

FOG LAMP

CHASSIS ELECTRICAL54A-71

FOG LAMP

SERVICE SPECIFICATIONM1542000300343

SPECIAL TOOLM1542000600894

TROUBLESHOOTINGM1542000701292

When the front fog lamp switch is turned to ON with

the tail lamp or the headlamp on (the tail lamp switch

or the headlamp switch is ON), the fog lamp relay

turns on, and the fog lamps will illuminate.

If the tail lamps or the headlamps are turned off with

the lighting switch OFF while the fog lamps are on,

the front fog lamps turn off at the same time to

prevent unattended operation.

If the tail lamps are turned off by the headlamp

automatic shutdown function, the fog lamps turn off

at the same time. However, if the tail lamps illuminate

again, the fog lamps do not.

The front fog lamps are controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

ON-VEHICLE SERVICE

FRONT FOG LAMP AIMING CHECKM1542001100438

After setting the vehicles to the following condition,

adjust the front fog lamp aiming.

•Check that the tyre inflation pressure is at the

value indicated on the tyre pressure labels.

•Set the vehicle to the unladen condition and park

it on a level surface.

•Have a single person (approximately 75 kg) sit in

the driver’s seat.•Run the engine at a speed of 2000 r/min to fully

charge the battery.

Turn on the front fog lamps and check that the

illumination is within the standard value range.

Standard value: Illuminates to within 40

metres

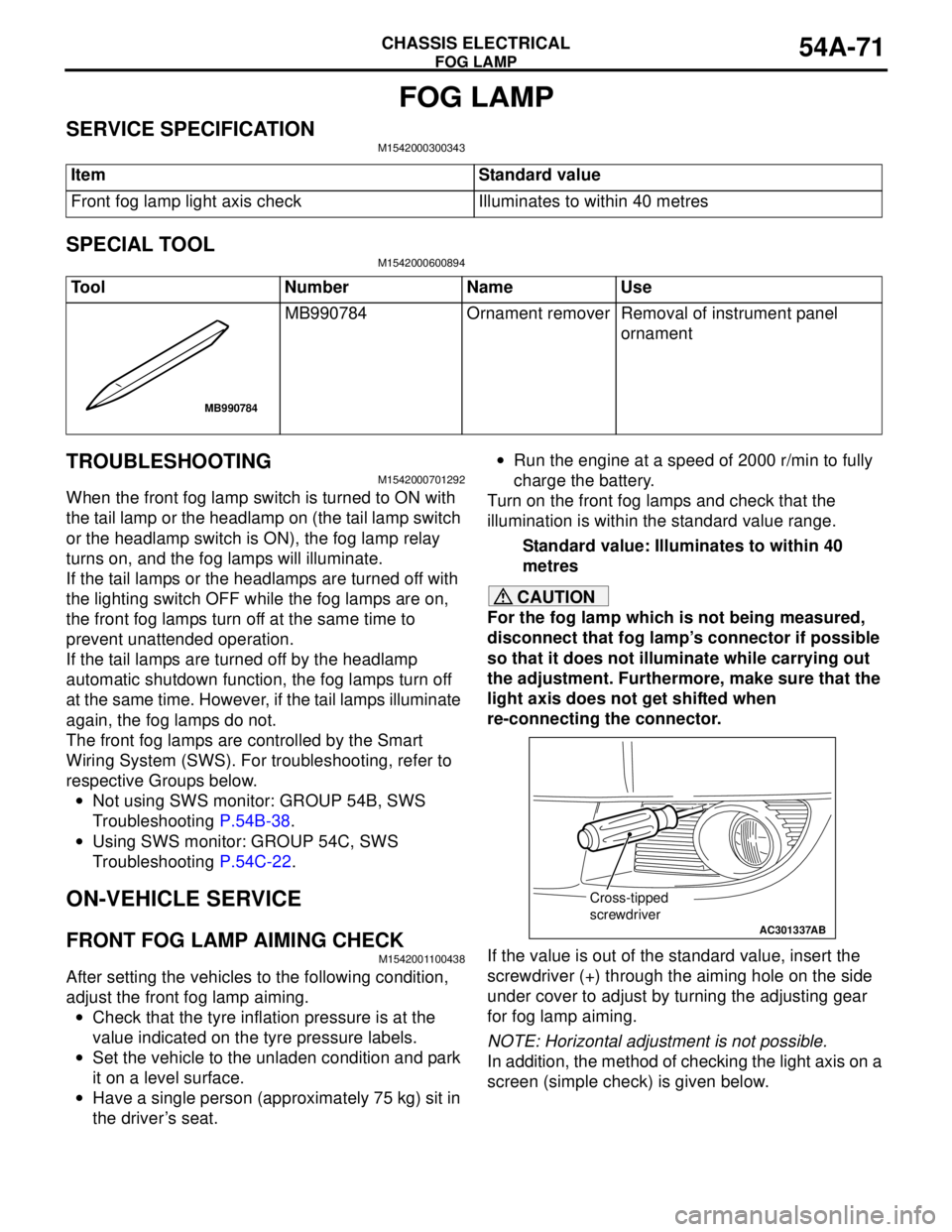

CAUTION

For the fog lamp which is not being measured,

disconnect that fog lamp’s connector if possible

so that it does not illuminate while carrying out

the adjustment. Furthermore, make sure that the

light axis does not get shifted when

re-connecting the connector.

If the value is out of the standard value, insert the

screwdriver (+) through the aiming hole on the side

under cover to adjust by turning the adjusting gear

for fog lamp aiming.

NOTE: Horizontal adjustment is not possible.

In addition, the method of checking the light axis on a

screen (simple check) is given below. Item Standard value

Front fog lamp light axis check Illuminates to within 40 metres

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

AC301337

Cross-tipped

screwdriver

AB

Page 463 of 788

REAR FOG LAMP

CHASSIS ELECTRICAL54A-75

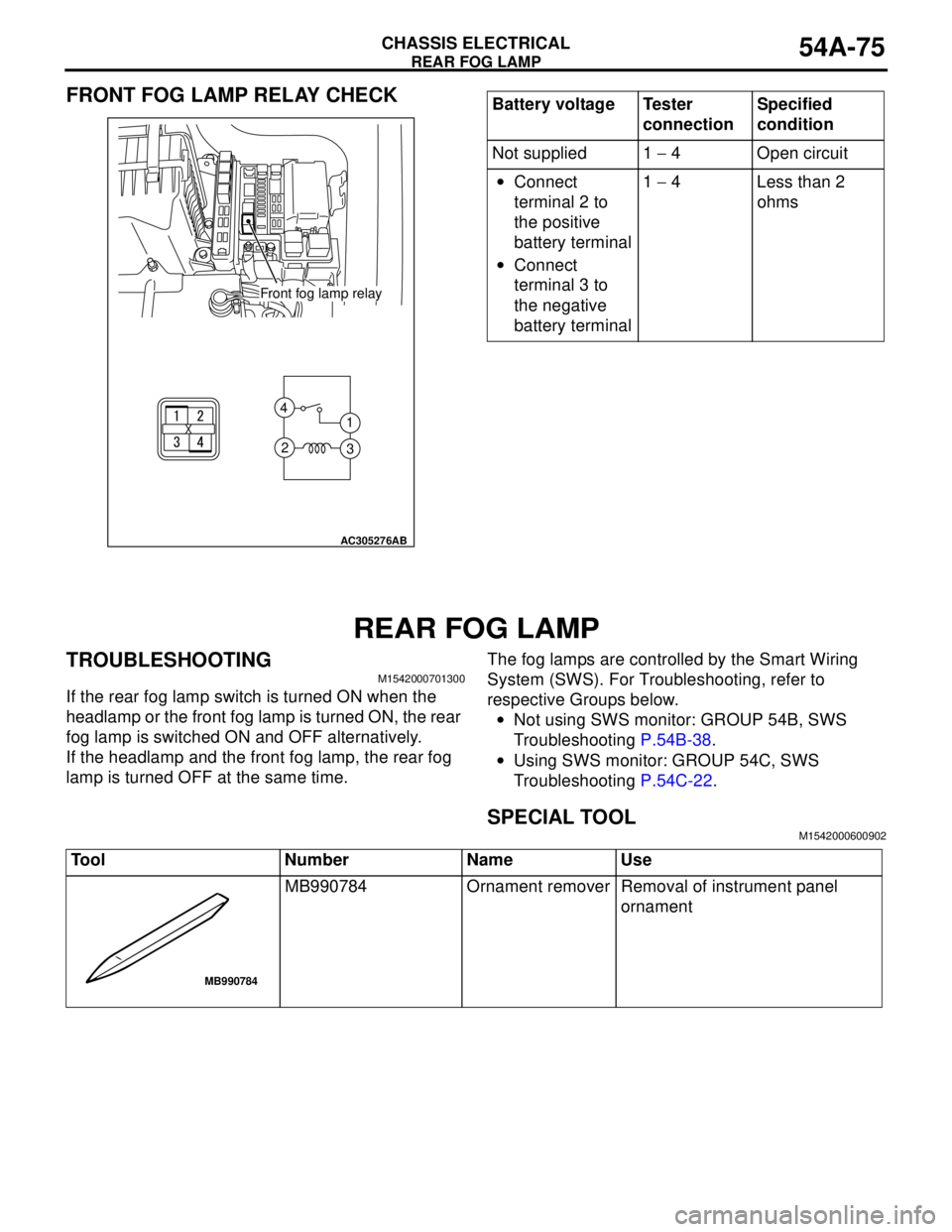

FRONT FOG LAMP RELAY CHECK

REAR FOG LAMP

TROUBLESHOOTINGM1542000701300

If the rear fog lamp switch is turned ON when the

headlamp or the front fog lamp is turned ON, the rear

fog lamp is switched ON and OFF alternatively.

If the headlamp and the front fog lamp, the rear fog

lamp is turned OFF at the same time.The fog lamps are controlled by the Smart Wiring

System (SWS). For Troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

SPECIAL TOOLM1542000600902

1 4

3 2

AC305276

AB

Front fog lamp relay

Battery voltage Tester

connectionSpecified

condition

Not supplied 1 − 4 Open circuit

•Connect

terminal 2 to

the positive

battery terminal

•Connect

terminal 3 to

the negative

battery terminal1 − 4 Less than 2

ohms

Tool Number Name Use

MB990784 Ornament remover Removal of instrument panel

ornament

MB990784

Page 465 of 788

SIDE TURN-SIGNAL LAMP

CHASSIS ELECTRICAL54A-77

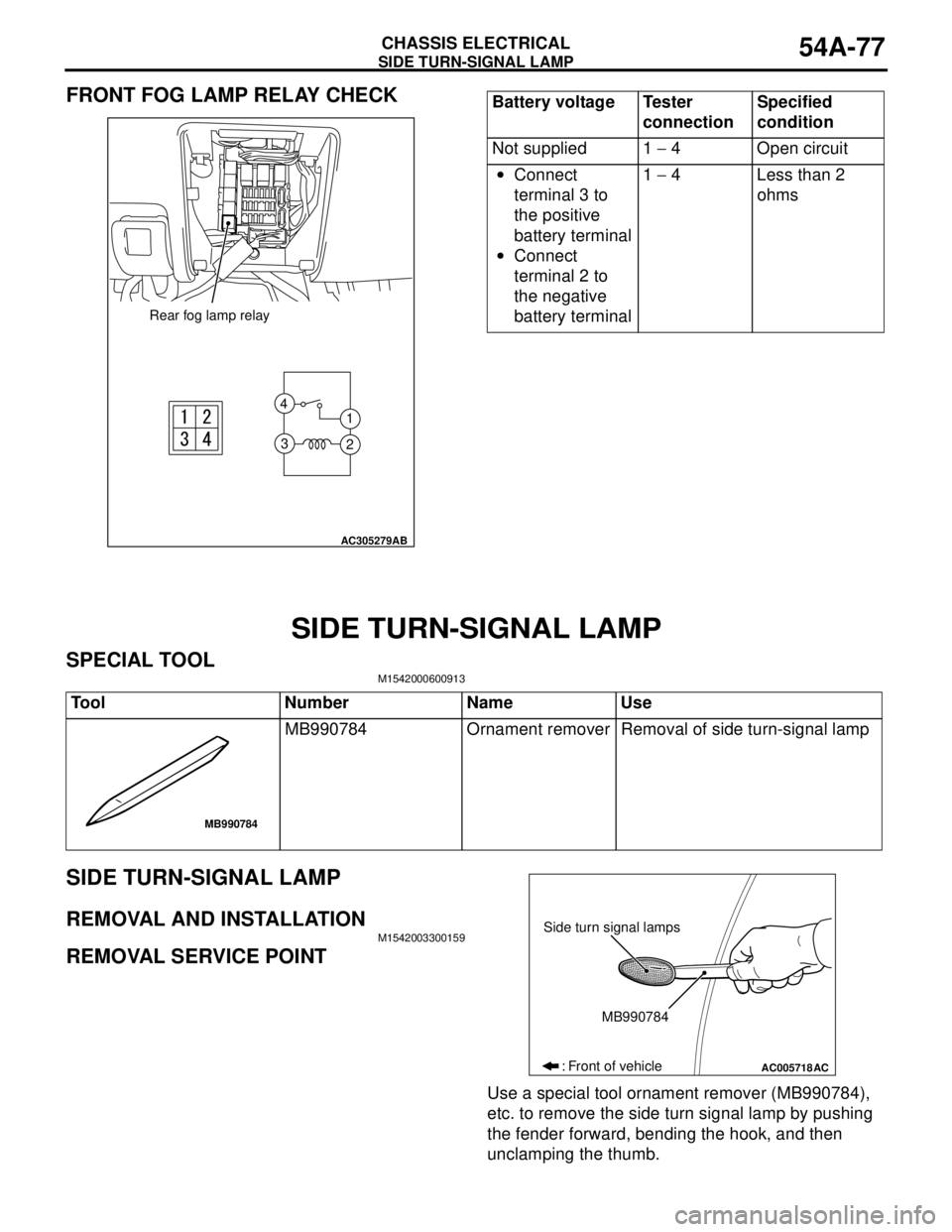

FRONT FOG LAMP RELAY CHECK

SIDE TURN-SIGNAL LAMP

SPECIAL TOOLM1542000600913

SIDE TURN-SIGNAL LAMP

REMOVAL AND INSTALLATIONM1542003300159

REMOVAL SERVICE POINT

Use a special tool ornament remover (MB990784),

etc. to remove the side turn signal lamp by pushing

the fender forward, bending the hook, and then

unclamping the thumb.

AC305279

1 4

3

2

AB

Rear fog lamp relay

Battery voltage Tester

connectionSpecified

condition

Not supplied 1 − 4 Open circuit

•Connect

terminal 3 to

the positive

battery terminal

•Connect

terminal 2 to

the negative

battery terminal1 − 4 Less than 2

ohms

Tool Number Name Use

MB990784 Ornament remover Removal of side turn-signal lamp

MB990784

AC005718

Side turn signal lamps

MB990784

: Front of vehicle

AC

Page 466 of 788

ROOM LAMP

CHASSIS ELECTRICAL54A-78

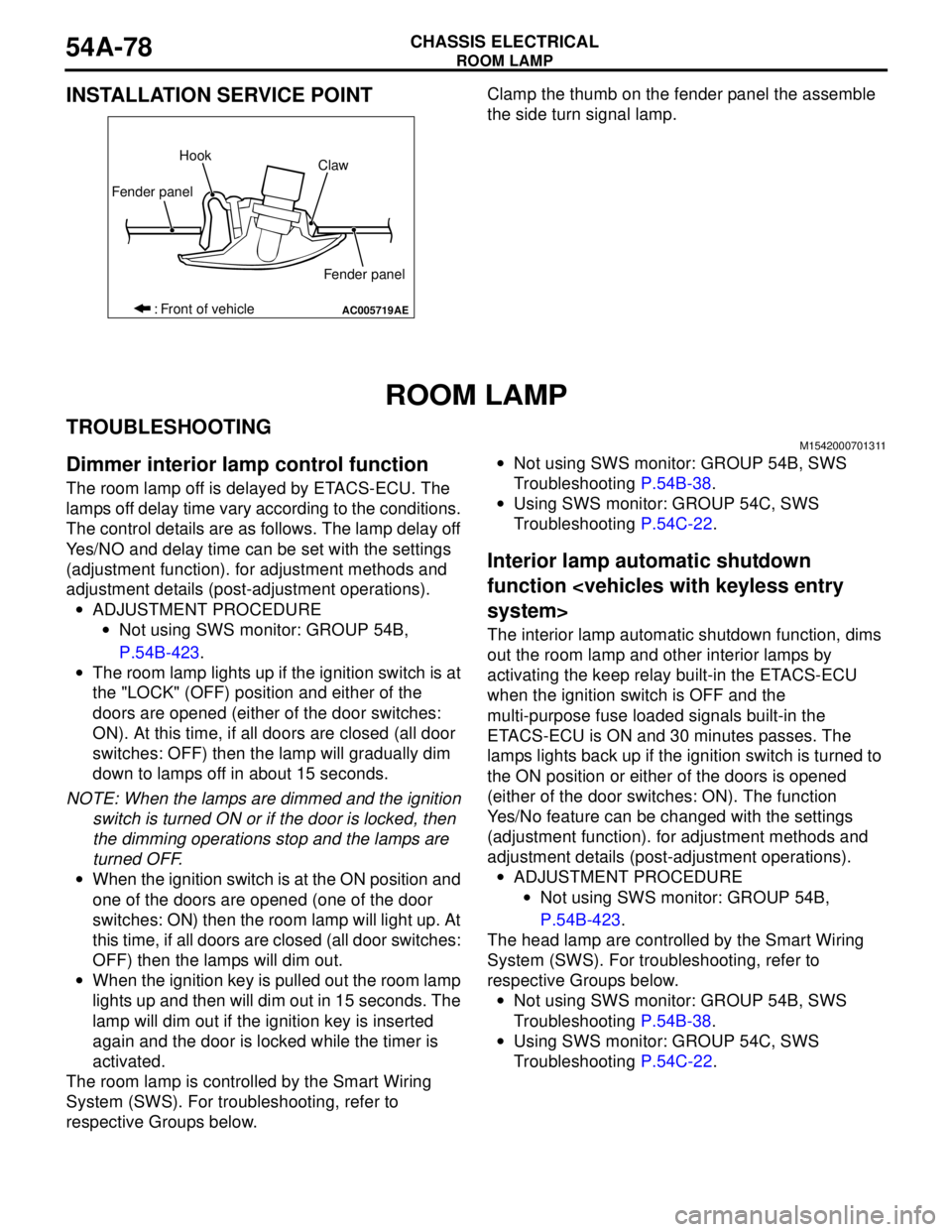

INSTALLATION SERVICE POINTClamp the thumb on the fender panel the assemble

the side turn signal lamp.

ROOM LAMP

TROUBLESHOOTINGM1542000701311

Dimmer interior lamp control function

The room lamp off is delayed by ETACS-ECU. The

lamps off delay time vary according to the conditions.

The control details are as follows. The lamp delay off

Yes/NO and delay time can be set with the settings

(adjustment function). for adjustment methods and

adjustment details (post-adjustment operations).

•ADJUSTMENT PROCEDURE

•Not using SWS monitor: GROUP 54B,

P.54B-423.

•The room lamp lights up if the ignition switch is at

the "LOCK" (OFF) position and either of the

doors are opened (either of the door switches:

ON). At this time, if all doors are closed (all door

switches: OFF) then the lamp will gradually dim

down to lamps off in about 15 seconds.

NOTE: When the lamps are dimmed and the ignition

switch is turned ON or if the door is locked, then

the dimming operations stop and the lamps are

turned OFF.

•When the ignition switch is at the ON position and

one of the doors are opened (one of the door

switches: ON) then the room lamp will light up. At

this time, if all doors are closed (all door switches:

OFF) then the lamps will dim out.

•When the ignition key is pulled out the room lamp

lights up and then will dim out in 15 seconds. The

lamp will dim out if the ignition key is inserted

again and the door is locked while the timer is

activated.

The room lamp is controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

Interior lamp automatic shutdown

function

The interior lamp automatic shutdown function, dims

out the room lamp and other interior lamps by

activating the keep relay built-in the ETACS-ECU

when the ignition switch is OFF and the

multi-purpose fuse loaded signals built-in the

ETACS-ECU is ON and 30 minutes passes. The

lamps lights back up if the ignition switch is turned to

the ON position or either of the doors is opened

(either of the door switches: ON). The function

Yes/No feature can be changed with the settings

(adjustment function). for adjustment methods and

adjustment details (post-adjustment operations).

•ADJUSTMENT PROCEDURE

•Not using SWS monitor: GROUP 54B,

P.54B-423.

The head lamp are controlled by the Smart Wiring

System (SWS). For troubleshooting, refer to

respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Troubleshooting P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Troubleshooting P.54C-22.

AC005719

Fender panelHook

Claw

Fender panel

: Front of vehicle

AE

Page 477 of 788

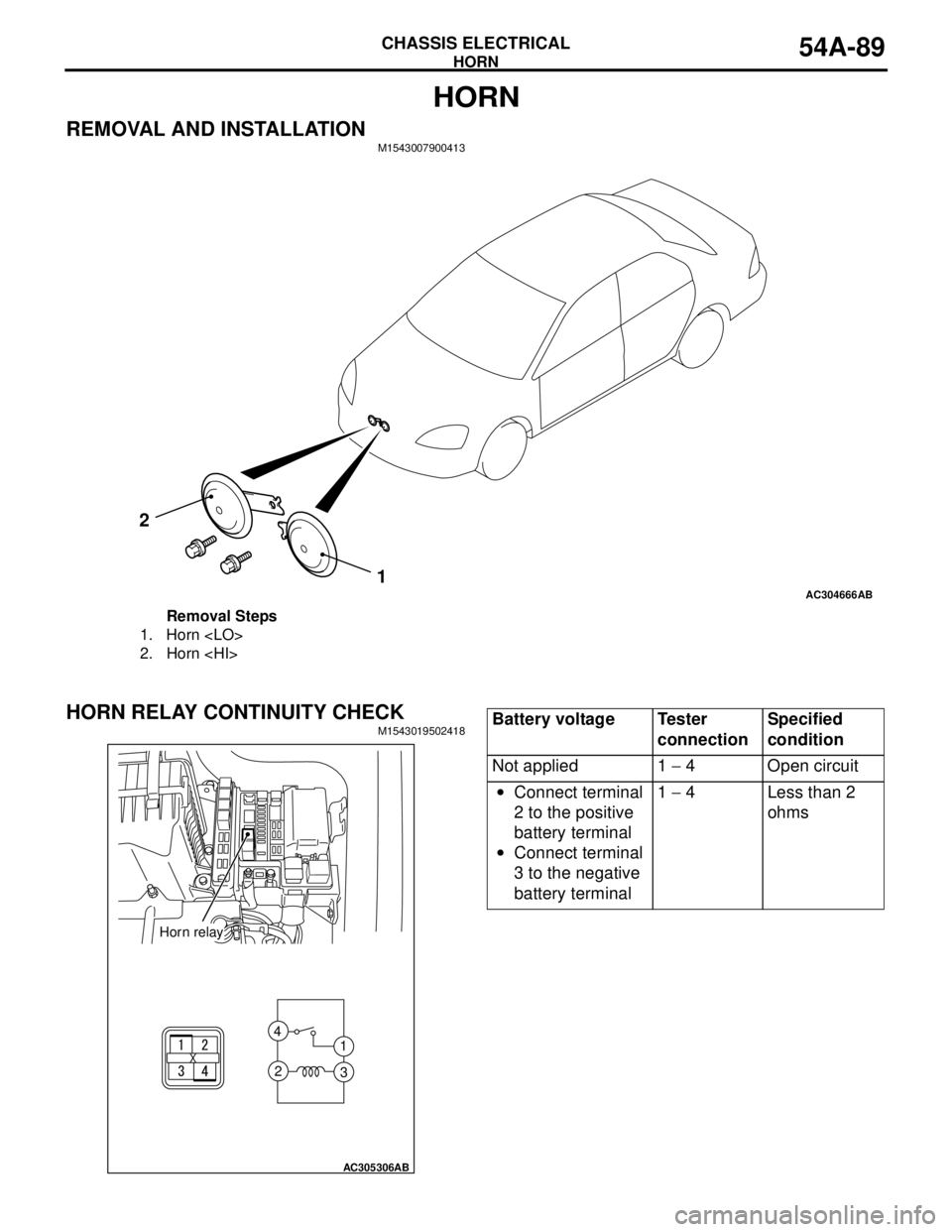

HORN

CHASSIS ELECTRICAL54A-89

HORN

REMOVAL AND INSTALLATIONM1543007900413

HORN RELAY CONTINUITY CHECKM1543019502418

AC304666AB

1 2

Removal Steps

1. Horn

2. Horn

AC305306

1 4

3 2

AB

Horn relay

Battery voltage Tester

connectionSpecified

condition

Not applied 1 − 4 Open circuit

•Connect terminal

2 to the positive

battery terminal

•Connect terminal

3 to the negative

battery terminal1 − 4 Less than 2

ohms

Page 483 of 788

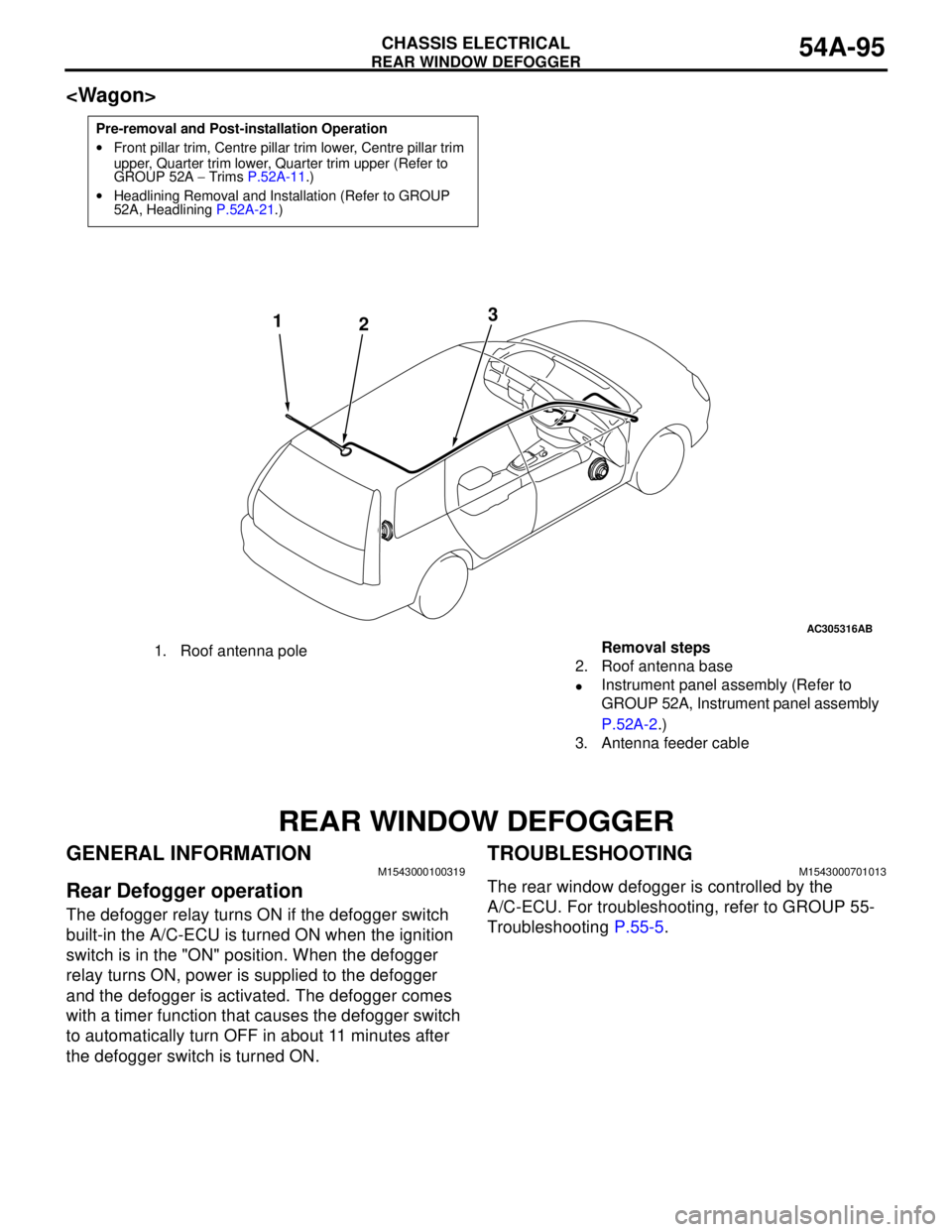

REAR WINDOW DEFOGGER

CHASSIS ELECTRICAL54A-95

REAR WINDOW DEFOGGER

GENERAL INFORMATIONM1543000100319

Rear Defogger operation

The defogger relay turns ON if the defogger switch

built-in the A/C-ECU is turned ON when the ignition

switch is in the "ON" position. When the defogger

relay turns ON, power is supplied to the defogger

and the defogger is activated. The defogger comes

with a timer function that causes the defogger switch

to automatically turn OFF in about 11 minutes after

the defogger switch is turned ON.

TROUBLESHOOTINGM1543000701013

The rear window defogger is controlled by the

A/C-ECU. For troubleshooting, refer to GROUP 55-

Troubleshooting P.55-5.

Pre-removal and Post-installation Operation

•Front pillar trim, Centre pillar trim lower, Centre pillar trim

upper, Quarter trim lower, Quarter trim upper (Refer to

GROUP 52A − Trims P.52A-11.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-21.)

AC305316

AB

1

23

1. Roof antenna poleRemoval steps

2. Roof antenna base

•Instrument panel assembly (Refer to

GROUP 52A, Instrument panel assembly

P.52A-2.)

3. Antenna feeder cable

Page 484 of 788

REAR WINDOW DEFOGGER

CHASSIS ELECTRICAL54A-96

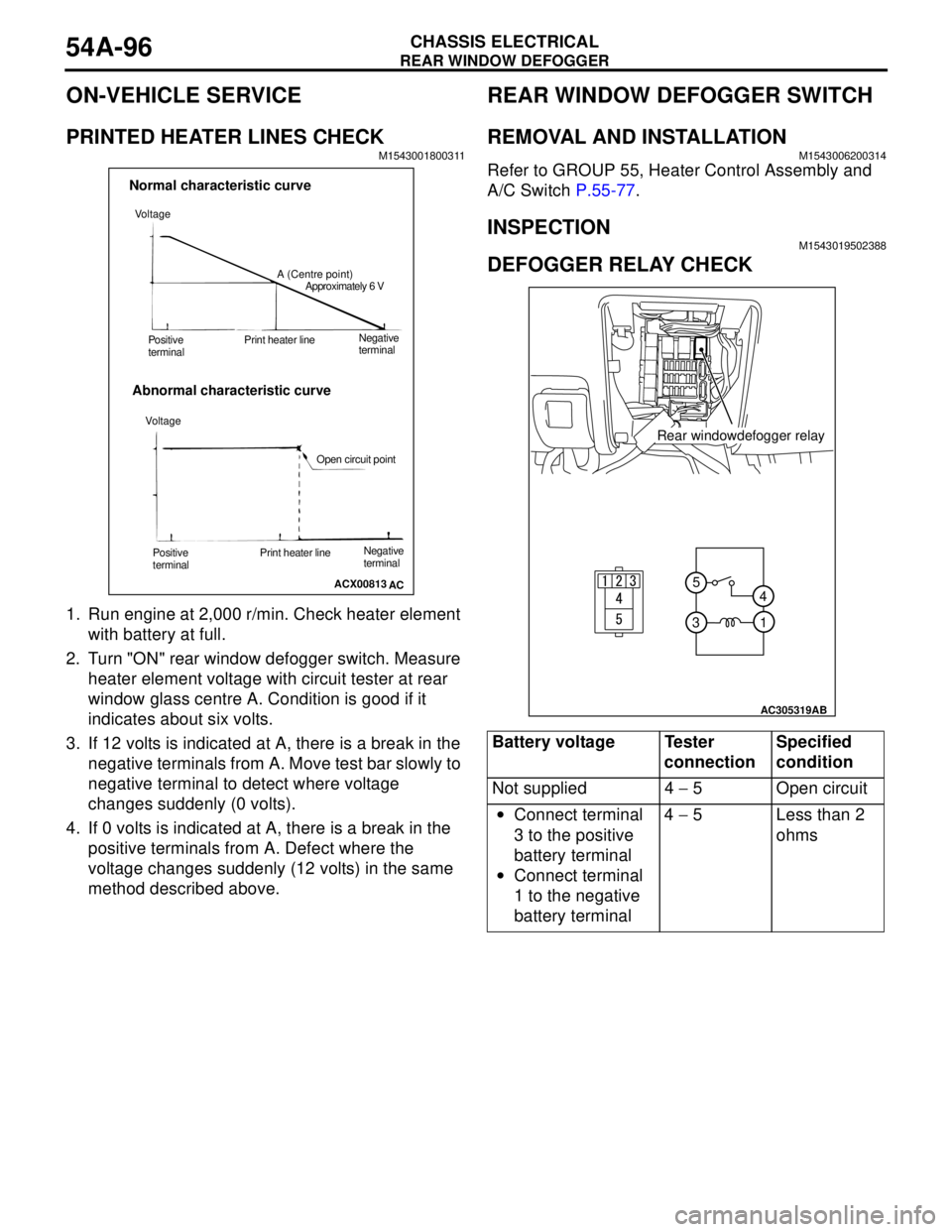

ON-VEHICLE SERVICE

PRINTED HEATER LINES CHECKM1543001800311

1. Run engine at 2,000 r/min. Check heater element

with battery at full.

2. Turn "ON" rear window defogger switch. Measure

heater element voltage with circuit tester at rear

window glass centre A. Condition is good if it

indicates about six volts.

3. If 12 volts is indicated at A, there is a break in the

negative terminals from A. Move test bar slowly to

negative terminal to detect where voltage

changes suddenly (0 volts).

4. If 0 volts is indicated at A, there is a break in the

positive terminals from A. Defect where the

voltage changes suddenly (12 volts) in the same

method described above.

REAR WINDOW DEFOGGER SWITCH

REMOVAL AND INSTALLATIONM1543006200314

Refer to GROUP 55, Heater Control Assembly and

A/C Switch P.55-77.

INSPECTIONM1543019502388

DEFOGGER RELAY CHECK

ACX00813

Normal characteristic curve

Abnormal characteristic curve

A (Centre point)

Approximately 6 V

Negative

terminal Print heater line

Positive

terminal

Open circuit point Voltage

AC Voltage

Negative

terminal Print heater line

Positive

terminal

Battery voltage Tester

connectionSpecified

condition

Not supplied 4 − 5 Open circuit

•Connect terminal

3 to the positive

battery terminal

•Connect terminal

1 to the negative

battery terminal4 − 5 Less than 2

ohms

1 5

4

3

AC305319

AB

Rear windowdefogger relay

Page 486 of 788

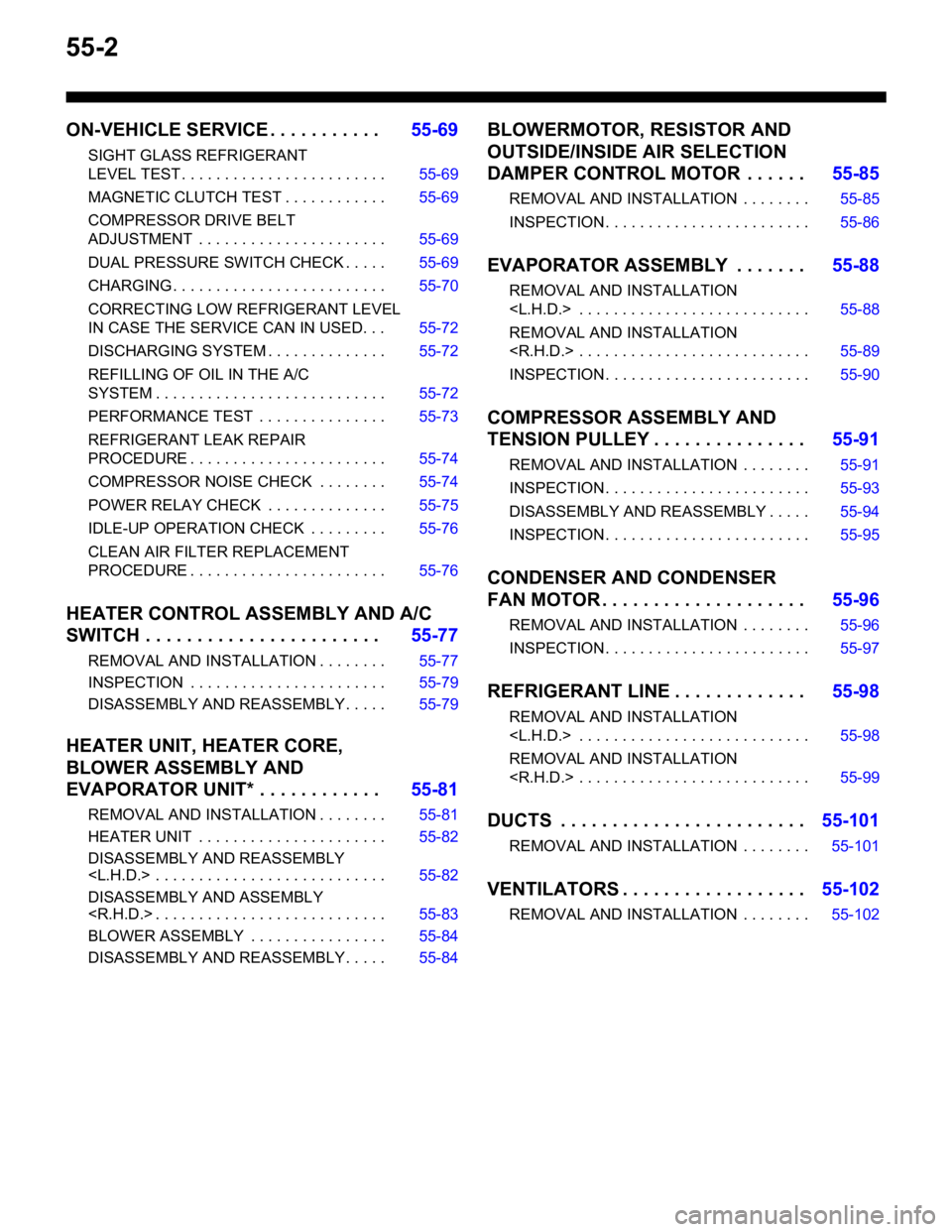

55-2

ON-VEHICLE SERVICE . . . . . . . . . . .55-69

SIGHT GLASS REFRIGERANT

LEVEL TEST . . . . . . . . . . . . . . . . . . . . . . . . 55-69

MAGNETIC CLUTCH TEST . . . . . . . . . . . . 55-69

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 55-69

DUAL PRESSURE SWITCH CHECK . . . . . 55-69

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 55-70

CORRECTING LOW REFRIGERANT LEVEL

IN CASE THE SERVICE CAN IN USED. . . 55-72

DISCHARGING SYSTEM . . . . . . . . . . . . . . 55-72

REFILLING OF OIL IN THE A/C

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-72

PERFORMANCE TEST . . . . . . . . . . . . . . . 55-73

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-74

COMPRESSOR NOISE CHECK . . . . . . . . 55-74

POWER RELAY CHECK . . . . . . . . . . . . . . 55-75

IDLE-UP OPERATION CHECK . . . . . . . . . 55-76

CLEAN AIR FILTER REPLACEMENT

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 55-76

HEATER CONTROL ASSEMBLY AND A/C

SWITCH . . . . . . . . . . . . . . . . . . . . . . .55-77

REMOVAL AND INSTALLATION . . . . . . . . 55-77

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 55-79

DISASSEMBLY AND REASSEMBLY . . . . . 55-79

HEATER UNIT, HEATER CORE,

BLOWER ASSEMBLY AND

EVAPORATOR UNIT* . . . . . . . . . . . .55-81

REMOVAL AND INSTALLATION . . . . . . . . 55-81

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . 55-82

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY AND ASSEMBLY

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . 55-84

DISASSEMBLY AND REASSEMBLY . . . . . 55-84

BLOWERMOTOR, RESISTOR AND

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR . . . . . .55-85

REMOVAL AND INSTALLATION . . . . . . . . 55-85

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-86

EVAPORATOR ASSEMBLY . . . . . . .55-88

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-90

COMPRESSOR ASSEMBLY AND

TENSION PULLEY . . . . . . . . . . . . . . .55-91

REMOVAL AND INSTALLATION . . . . . . . . 55-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-93

DISASSEMBLY AND REASSEMBLY . . . . . 55-94

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-95

CONDENSER AND CONDENSER

FAN MOTOR . . . . . . . . . . . . . . . . . . . .55-96

REMOVAL AND INSTALLATION . . . . . . . . 55-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 55-97

REFRIGERANT LINE . . . . . . . . . . . . .55-98

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

DUCTS . . . . . . . . . . . . . . . . . . . . . . . .55-101

REMOVAL AND INSTALLATION . . . . . . . . 55-101

VENTILATORS . . . . . . . . . . . . . . . . . .55-102

REMOVAL AND INSTALLATION . . . . . . . . 55-102

Page 496 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-12

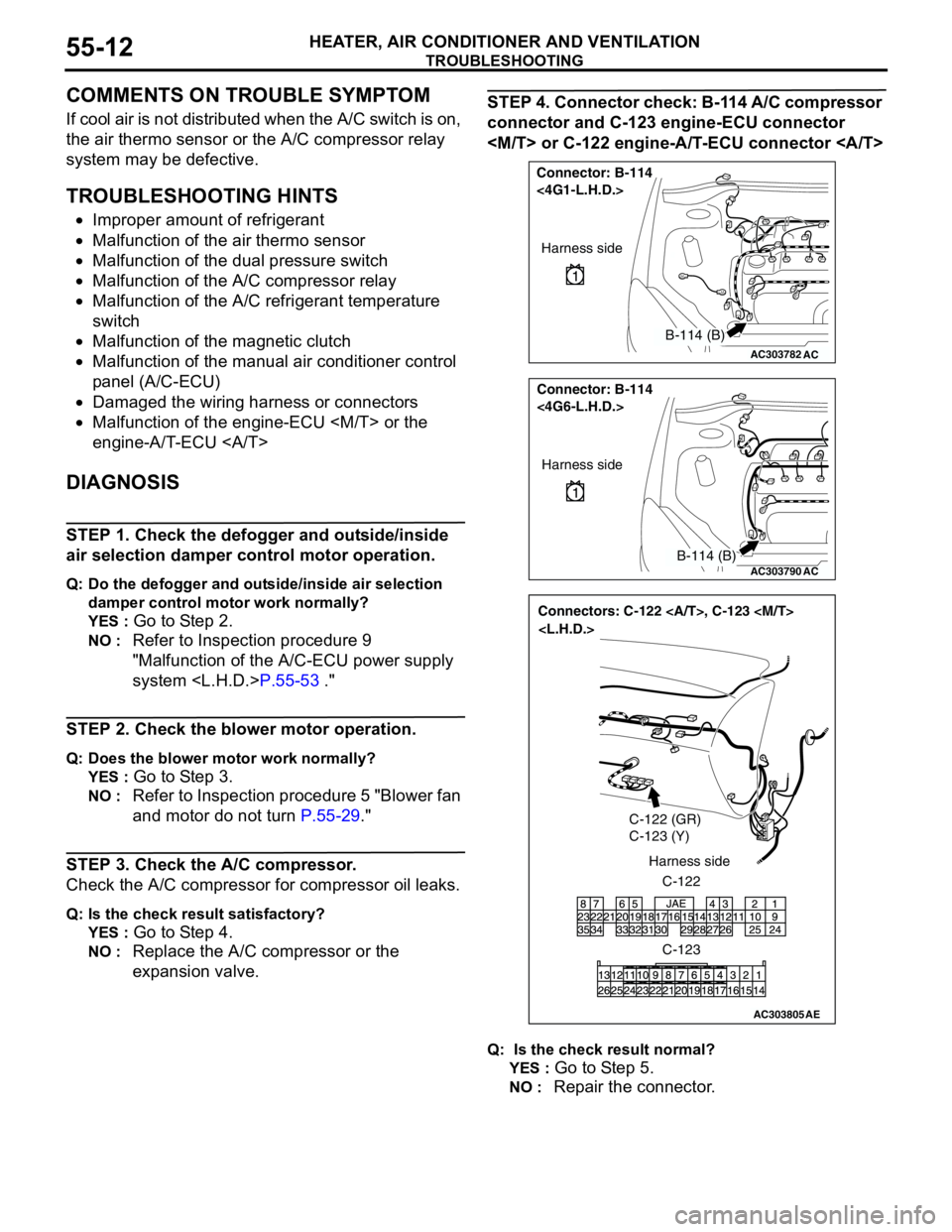

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 9

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

AC303805

Connectors: C-122 , C-123

C-122 (GR)

C-123 (Y)

C-122 Harness side

C-123

AE

Page 505 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-21

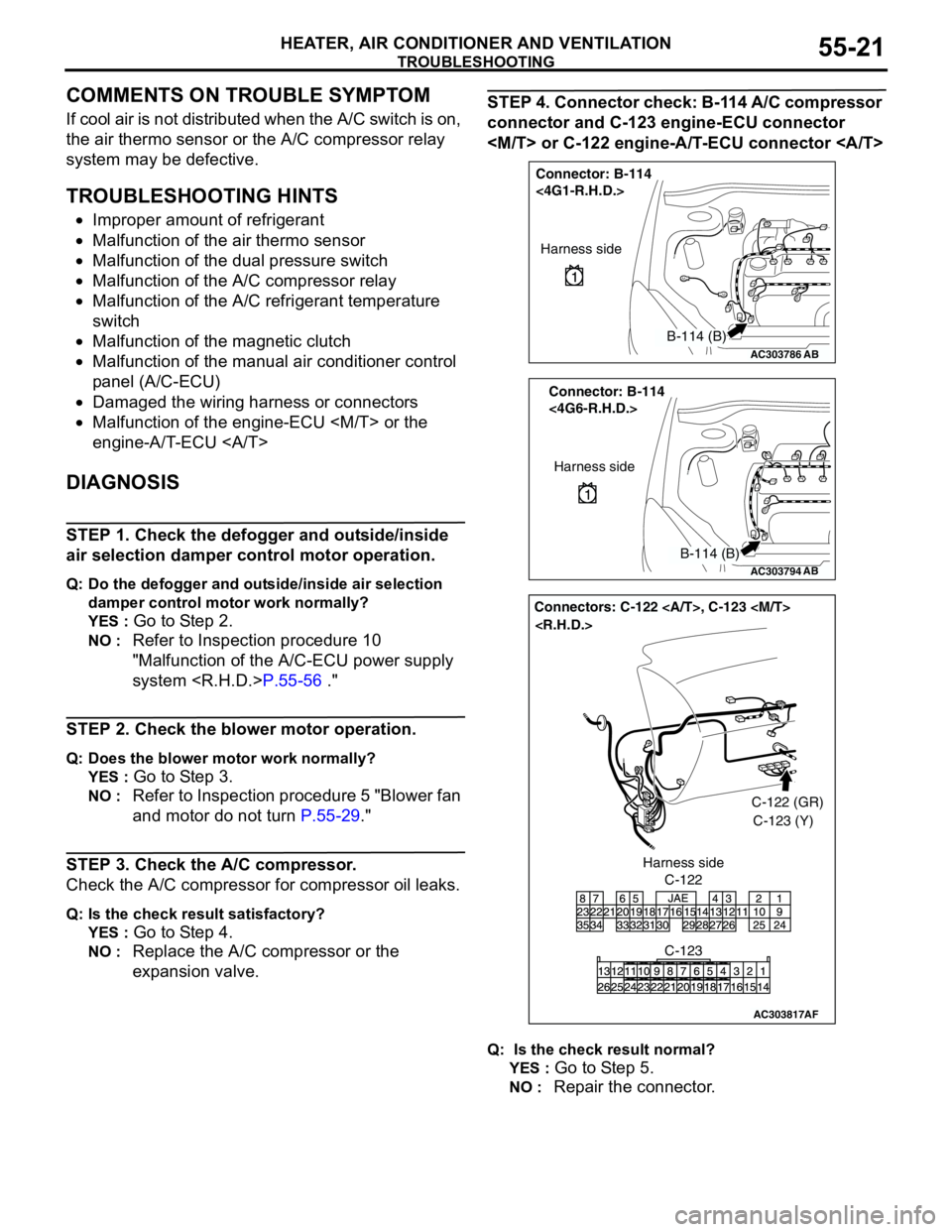

COMMENTS ON TROUBLE SYMPTOM

If cool air is not distributed when the A/C switch is on,

the air thermo sensor or the A/C compressor relay

system may be defective.

TROUBLESHOOTING HINTS

•Improper amount of refrigerant

•Malfunction of the air thermo sensor

•Malfunction of the dual pressure switch

•Malfunction of the A/C compressor relay

•Malfunction of the A/C refrigerant temperature

switch

•Malfunction of the magnetic clutch

•Malfunction of the manual air conditioner control

panel (A/C-ECU)

•Damaged the wiring harness or connectors

•Malfunction of the engine-ECU

engine-A/T-ECU

DIAGNOSIS

STEP 1. Check the defogger and outside/inside

air selection damper control motor operation.

Q: Do the defogger and outside/inside air selection

damper control motor work normally?

YES :

Go to Step 2.

NO : Refer to Inspection procedure 10

"Malfunction of the A/C-ECU power supply

system

STEP 2. Check the blower motor operation.

Q: Does the blower motor work normally?

YES :

Go to Step 3.

NO : Refer to Inspection procedure 5 "Blower fan

and motor do not turn P.55-29."

STEP 3. Check the A/C compressor.

Check the A/C compressor for compressor oil leaks.

Q: Is the check result satisfactory?

YES :

Go to Step 4.

NO : Replace the A/C compressor or the

expansion valve.

STEP 4. Connector check: B-114 A/C compressor

connector and C-123 engine-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5.

NO : Repair the connector.

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC303817

Connectors: C-122 , C-123

AF

C-122C-122 (GR)

C-123 (Y)

C-123 Harness side