ac compressor MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 556 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-72

25.After charging with refrigerant, turn the handle of

the adaptor valve back all the way (valve closed).

26.Tighten the charging valve handle (valve closed).

Remove the quick joint (for low-pressure) from the

low-pressure service valve.

27.Remove the service can.

NOTE: If the service can is not emptied

completely, keep the handles of the charging

valve and adaptor valve closed for the next

charging.

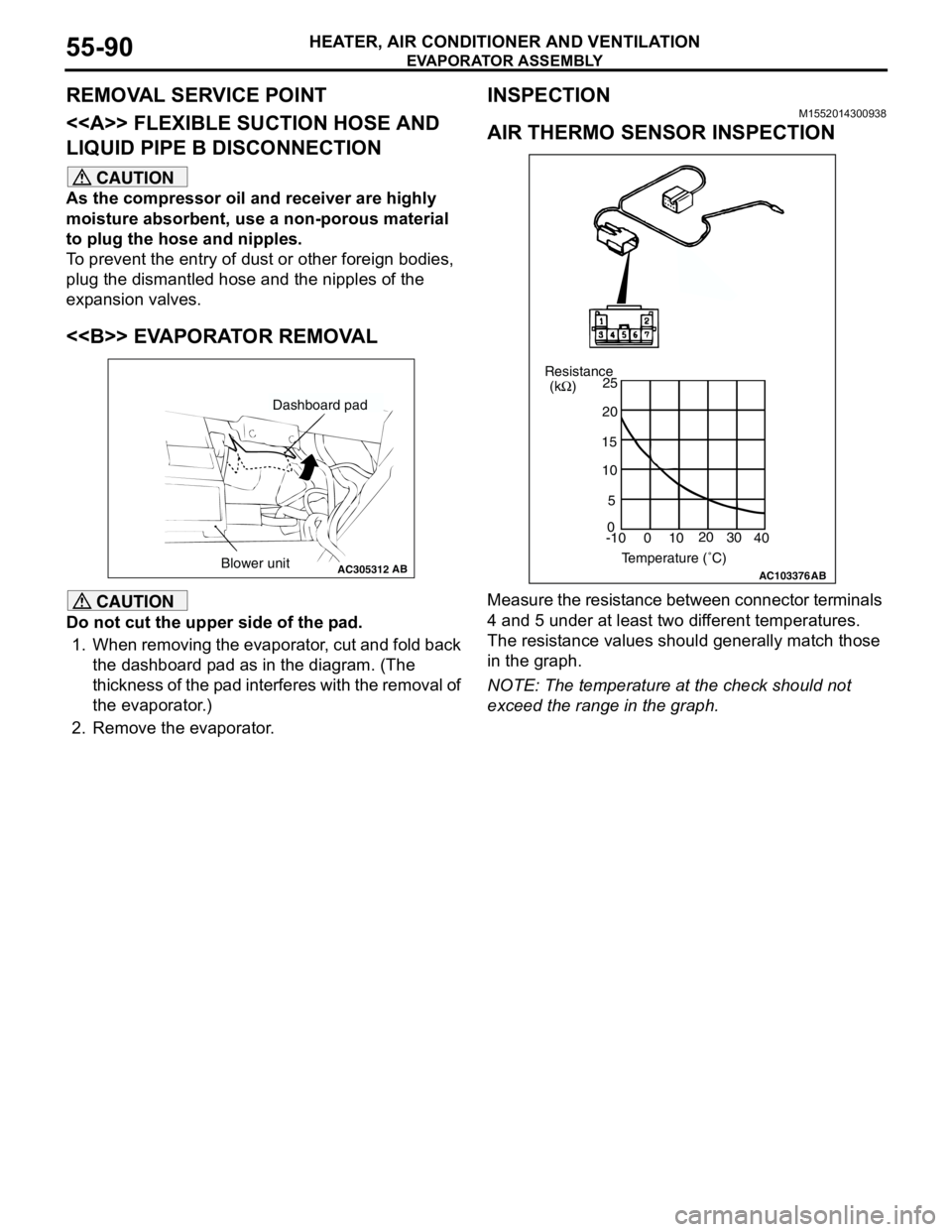

CORRECTING LOW REFRIGERANT

LEVEL IN CASE THE SERVICE CAN IN

USED

M1552014600100

1. Install the charge valve with the handle turned all

the way back (valve open) to the service can.

2. Install the adaptor valve with the handle turned all

the way back (valve close) to the charging valve.

3. Connect the charging hose (blue) to the adaptor

valve.

4. Connect the charging hose (blue) to the quick

joint (for low-pressure).

5. Tighten the handle of the charge valve (valve

close), and pierce the service can.

6. Turn the handle of the adaptor valve to bleed the

air.7. Install the quick joint (for low-pressure) to the

low-pressure service valve.

NOTE: The low-pressure service valve should be

connected to the suction hose.

8. Start the engine.

9. Operate the air conditioner and set at the lowest

temperature (MAX. COOL).

10.Fix the engine speed at 1,500 r/min.

11.Tighten the handle of the adaptor valve (valve

open), and replenish refrigerant while checking

the quantity through the sight glass.

12.After replenishing is completed, turn the handle of

the adaptor valve all the way back (valve close),

and remove the quick joint.

NOTE: When there is remainder of refrigerant in

the service can, keep it for next use with the

charge value and the valve of the adaptor valve

being closed.

DISCHARGING SYSTEMM1552013000105

Use the refrigerant recovery unit to discharge

refrigerant gas from the system.

NOTE: Refer to the Refrigerant Recovery and

Recycling Unit instruction Manual for operation of the

unit.

REFILLING OF OIL IN THE A/C SYSTEMM1552020000033

Too little oil will provide inadequate compressor

lubrication and cause a compressor failure. Too

much oil will increase discharge air temperature.

When a compressor is installed at the factory, it

contains 140mL <1300, 1600> or 120 mL <2000> of

compressor oil. While the A/C system is in operation,

the oil is carried through the entire system by the

refrigerant. Some of this oil will be trapped and

retained in various parts of the system.

When the following system components are

changed, it is necessary to add oil to the system to

replace the oil being removed with the component.

Compressor oil: SUN PAG 56

Quantity

Evaporator: 60 mL

Condenser: 15 mL

Flexible suction hose: 10 mL

Receiver: 10 mL

AC300372

AB

Valve open

Valve close

Service can

(Refrigerant

container)Charge valve

Adaptor valve

Charging hose (blue)

Quick joint (for low-pressure)

AC300373

Quick joint

(for low-pressure)

Low-pressure

service valve

AB

Page 557 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-73

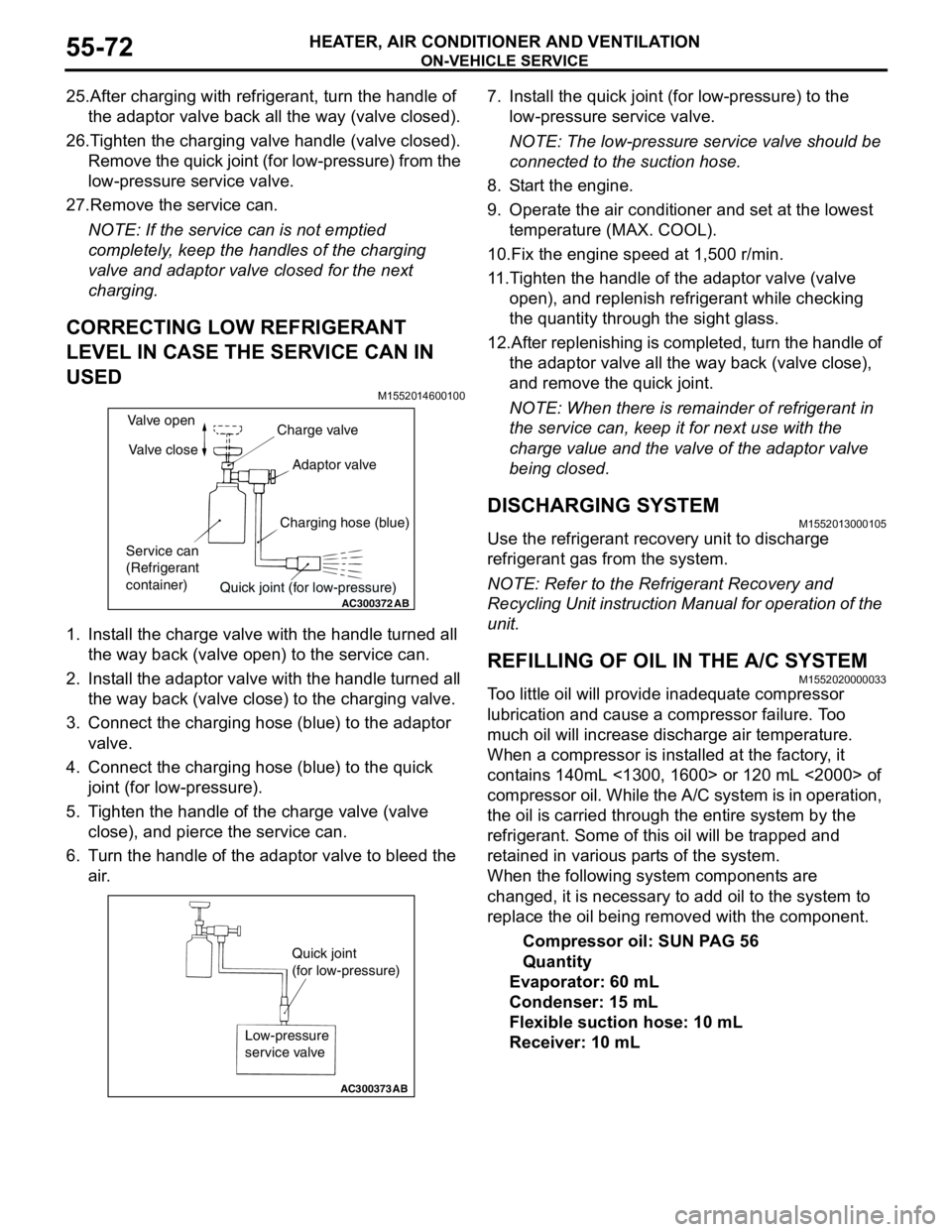

PERFORMANCE TEST M1552001400355

1. The vehicles to be tested should be in a place that

is not in direct sunlight.

2. Close the high and low-pressure valve of the

gauge manifold.

3. Connect the charging hose (blue) to the

low-pressure valve and connect the charging

hose (red) to the high-pressure valve of the gauge

manifold.

CAUTION

•To connect the quick joint, press section A

firmly against the service valve until a click is

heard.

•When connecting, run your hand along the

hose while pressing to ensure that there are

no bends in the hose.

4. Install the quick joint (for low-pressure) to the

charging hose (blue), and connect the quick joint

(for high-pressure) to the charging hose (red).NOTE: The high-pressure service valve is on the

A/C pipe and the low-pressure service valve is on

the suction hose.

5. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick

joint (for high-pressure) to the high-pressure

service valve.

6. Start the engine.

7. Set the A/C controls as follows:

•A/C switch: A/C − ON position

•Mode selection: FACE position

•Temperature control: MAXIMUM COOLING

position

•Air selection: RECIRCULATION position

•Blower switch: "4" (Fast) position

8. Keep engine speed to idling speed with A/C clutch

engaged.

9. Engine should be warmed up with doors and all

windows opened.

10.Insert a thermometer in the centre air outlet and

operate the engine for 20 minutes.

NOTE: If the clutch cycles, take the reading before

the clutch disengages.

11.Note the discharge air temperature.

Performance Temperature Chart

AC001388

Low-pressure

valveHigh-pressure

valve

Gauge manifold

Charging

hose (red)

A

Sleeve Charging

hose (blue)

Adaptor valve

(for low-

pressure)

Low-

pressure

service

valveHigh-

pressure

service

valve

AB

Adaptor valve

(for high-

pressure)

AC304576

Thermometer

AB

Garage ambient temperature °C20 25 30 35

Discharge air temperature °C8.0 − 11.0 12.0 − 16.0 17.0 − 21.0 22.5 − 27.5

Compressor high pressure kPa 740 − 840 950 − 1,050 1,160 − 1,300 1,360 − 1,550

Compressor low pressure kPa 150 − 190 190 − 240 240 − 300 300 − 375

Page 558 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-74

REFRIGERANT LEAK REPAIR

PROCEDURE

M1552001500277

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system (Refer to P.55-72).

2. Charge the system with approximately 480 − 520

g of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

CAUTION

Replacement filter-drier units must be sealed

while in storage. The drier used in these units will

saturate water quickly upon exposure to the

atmosphere. When installing a drier, have all

tools and supplies ready for quick assembly to

avoid keeping the system open any longer than

necessary.

6. Replace receiver drier.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capacity

of the entire system. High pressures are produced in

the system when it is operating. Extreme care must

be exercised to make sure that all connections are

pressure tight. Dirt and moisture can enter the

system when it is opened for repair or replacement of

lines or components. The following precautions must

be observed. The system must be completely

discharged before opening any fitting of connection

in the refrigeration system. Open fittings with caution

even after the system has been discharged. If any

pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing. A

good rule for the flexible hose lines is keep the radius

of all bends at least 10 times the diameter of the

hose.Sharper bends will reduce the flow of refrigerant. The

flexible hose lines should be routed so that they are

at least 80 mm from the exhaust manifold. It is good

practice to inspect all flexible hose lines at least once

a year to make sure they are in good condition and

properly routed.

On standard plumbing fittings with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE CHECKM1552008700272

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or any

other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt

tension (power steering or alternator).

Improper accessory drive belt tension can cause a

misleading noise when the compressor is engaged

and little or no noise when the compressor is

disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.

ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch the

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure), restrict

air flow through the condenser. Install a manifold

gauge set to make sure discharge pressure

doesn't exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt. Check

to assure clutch coil is tight (no rotation or

wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge (Refer to P.55-69).

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retighten. Repeat Step 1.

7. If noise continues, replace compressor and repeat

Step 1.

Page 559 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-75

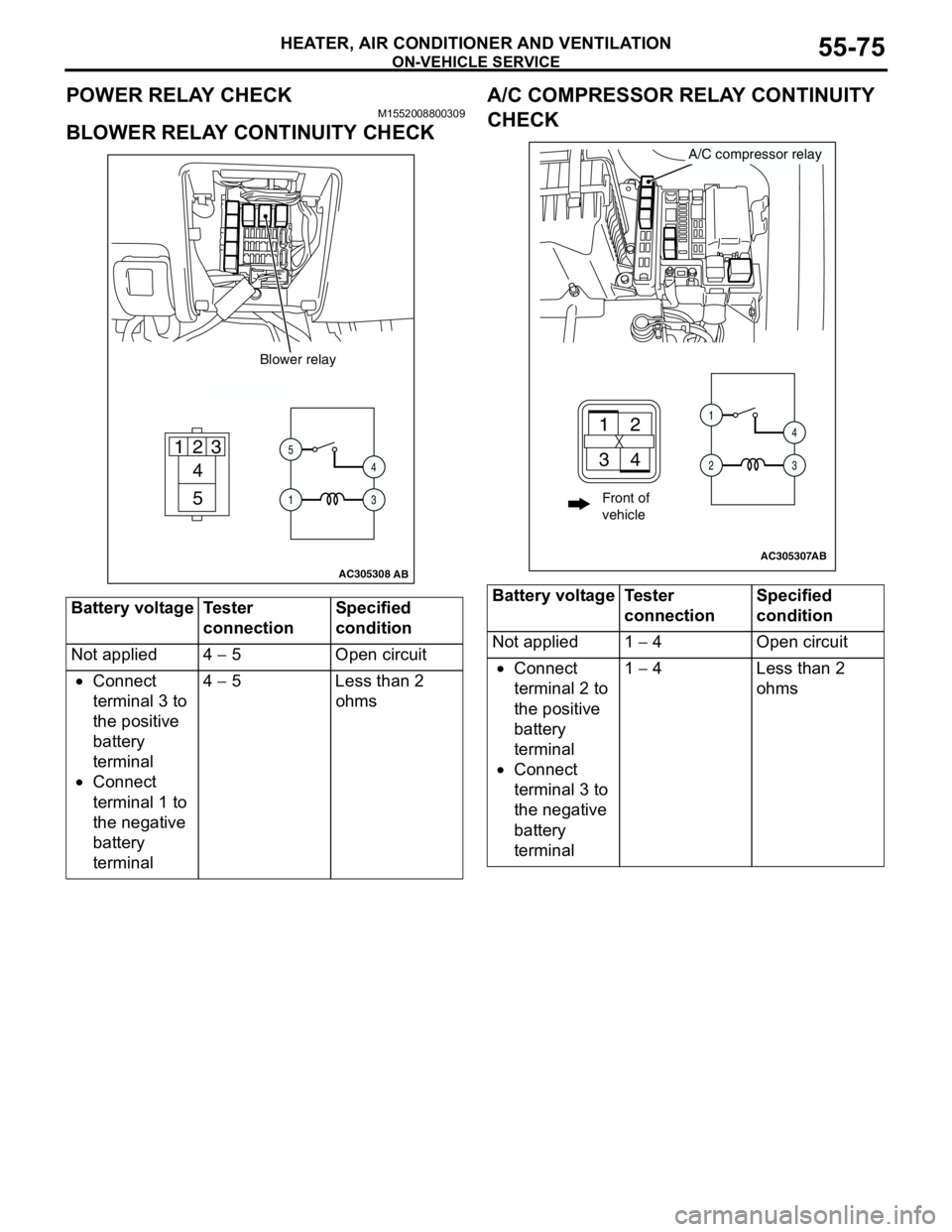

POWER RELAY CHECKM1552008800309

BLOWER RELAY CONTINUITY CHECKA/C COMPRESSOR RELAY CONTINUITY

CHECK

Battery voltage Tester

connectionSpecified

condition

Not applied 4 − 5 Open circuit

•Connect

terminal 3 to

the positive

battery

terminal

•Connect

terminal 1 to

the negative

battery

terminal4 − 5 Less than 2

ohms

AC305308

4

5 1

235

14

3

Blower relay

AB

Battery voltage Tester

connectionSpecified

condition

Not applied 1 − 4 Open circuit

•Connect

terminal 2 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal1 − 4 Less than 2

ohms

AC305307

A/C compressor relay

AB

21

34

1

24

3

Front of

vehicle

Page 565 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-81

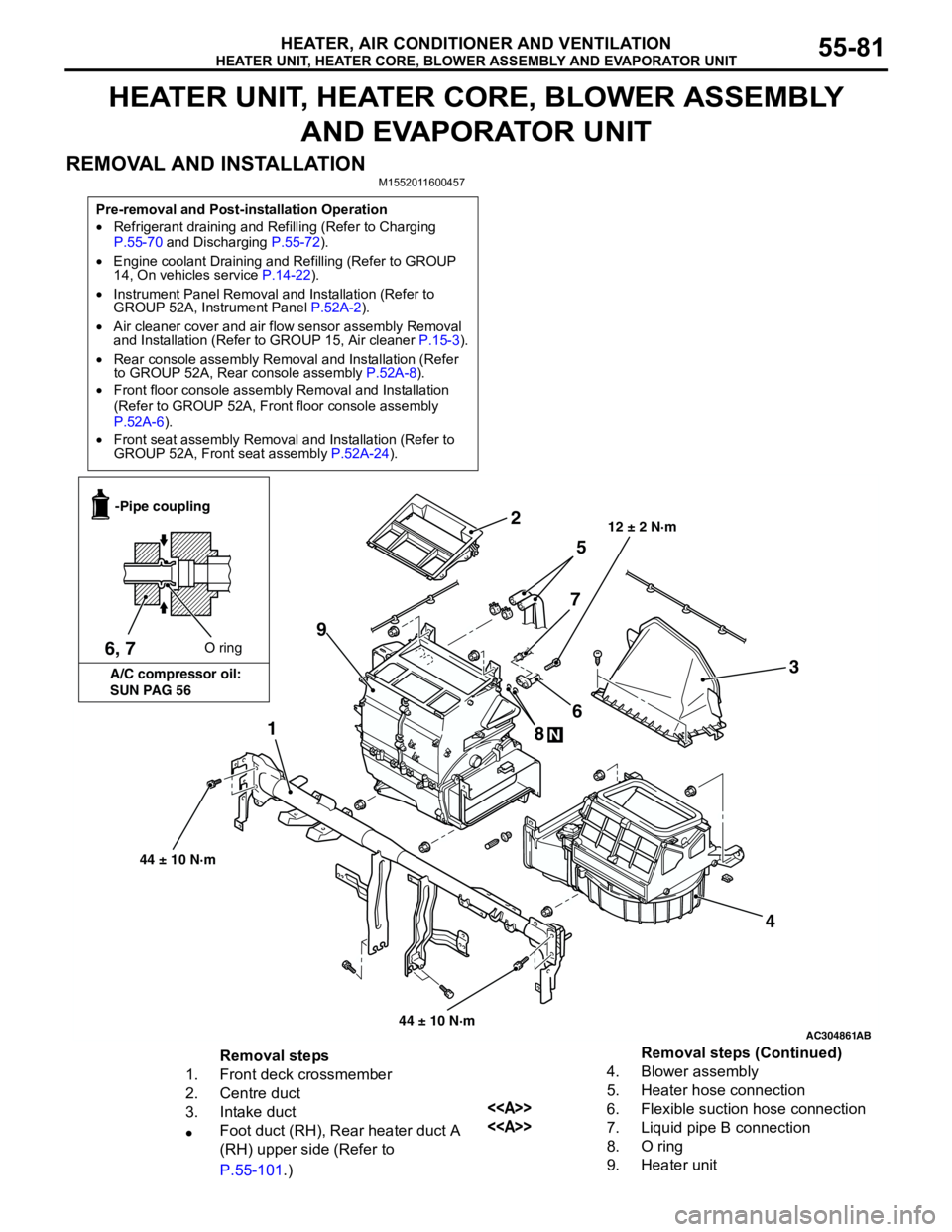

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY

AND EVAPORATOR UNIT

REMOVAL AND INSTALLATION

M1552011600457

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Engine coolant Draining and Refilling (Refer to GROUP

14, On vehicles service P.14-22).

•Instrument Panel Removal and Installation (Refer to

GROUP 52A, Instrument Panel P.52A-2).

•Air cleaner cover and air flow sensor assembly Removal

and Installation (Refer to GROUP 15, Air cleaner P.15-3).

•Rear console assembly Removal and Installation (Refer

to GROUP 52A, Rear console assembly P.52A-8).

•Front floor console assembly Removal and Installation

(Refer to GROUP 52A, Front floor console assembly

P.52A-6).

•Front seat assembly Removal and Installation (Refer to

GROUP 52A, Front seat assembly P.52A-24).

AC304861

1

2

3

4 5

6

7

8

N

9

AB

12 ± 2 N·m

6, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

44 ± 10 N·m

44 ± 10 N·m

Removal steps

1. Front deck crossmember

2. Centre duct

3. Intake duct

•Foot duct (RH), Rear heater duct A

(RH) upper side (Refer to

P.55-101.)4. Blower assembly

5. Heater hose connection

<>6. Flexible suction hose connection

<>7. Liquid pipe B connection

8. O ring

9. Heater unitRemoval steps (Continued)

Page 566 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-82

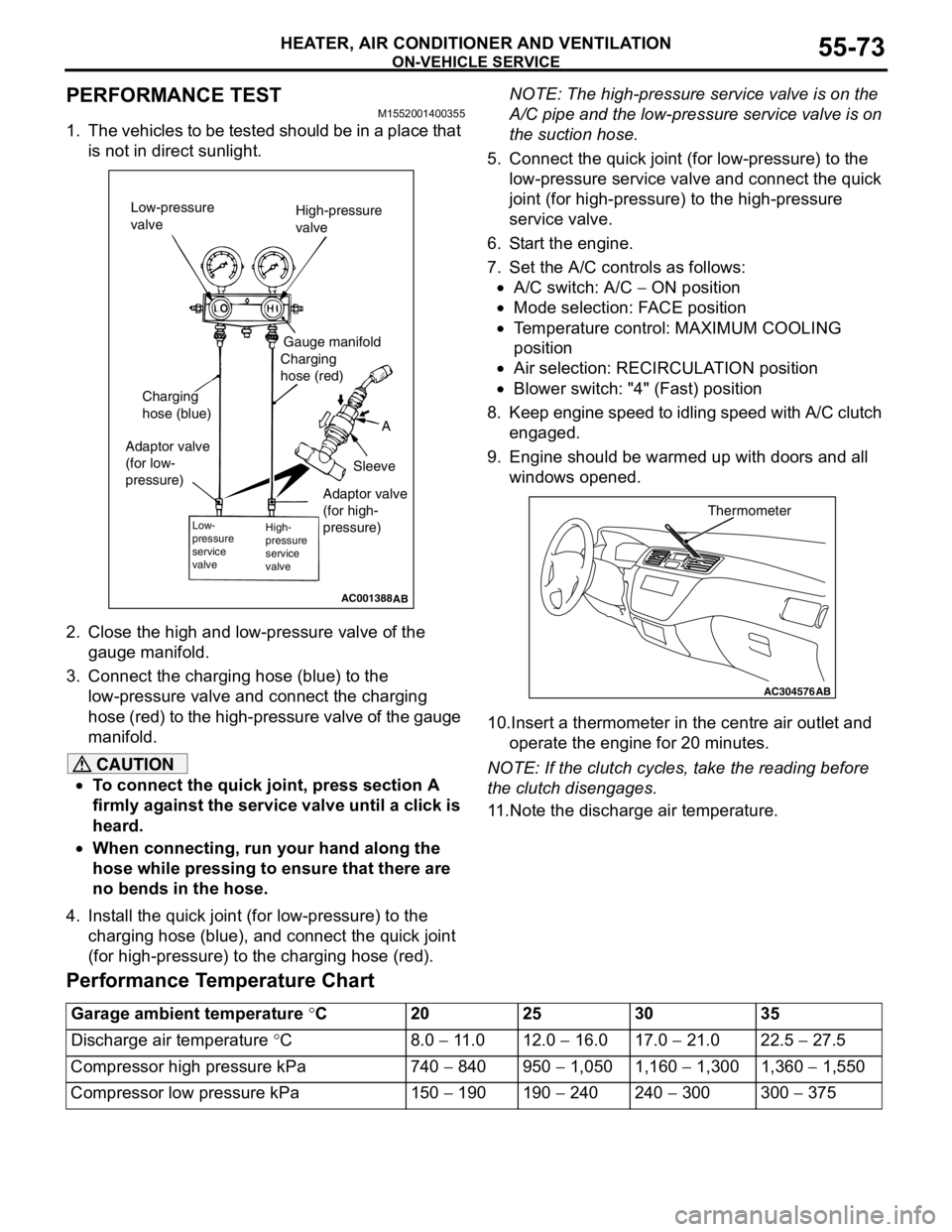

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

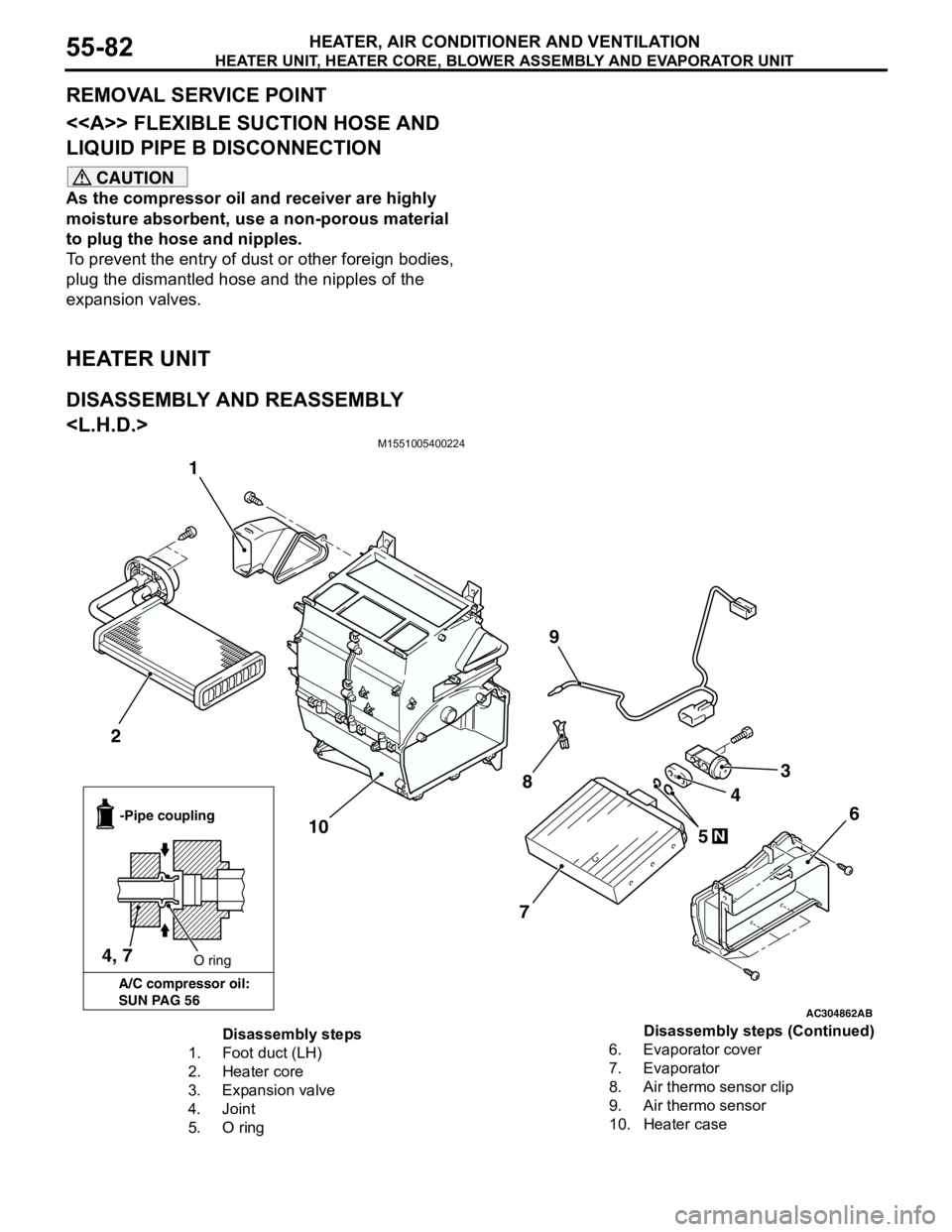

HEATER UNIT

DISASSEMBLY AND REASSEMBLY

M1551005400224

AC304862

1

2

3

4

5

6

7

8

9

10

AB

4, 7O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

N

Disassembly steps

1. Foot duct (LH)

2. Heater core

3. Expansion valve

4. Joint

5. O ring6. Evaporator cover

7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

10. Heater caseDisassembly steps (Continued)

Page 567 of 788

HEATER UNIT, HEATER CORE, BLOWER ASSEMBLY AND EVAPORATOR UNIT

HEATER, AIR CONDITIONER AND VENTILATION55-83

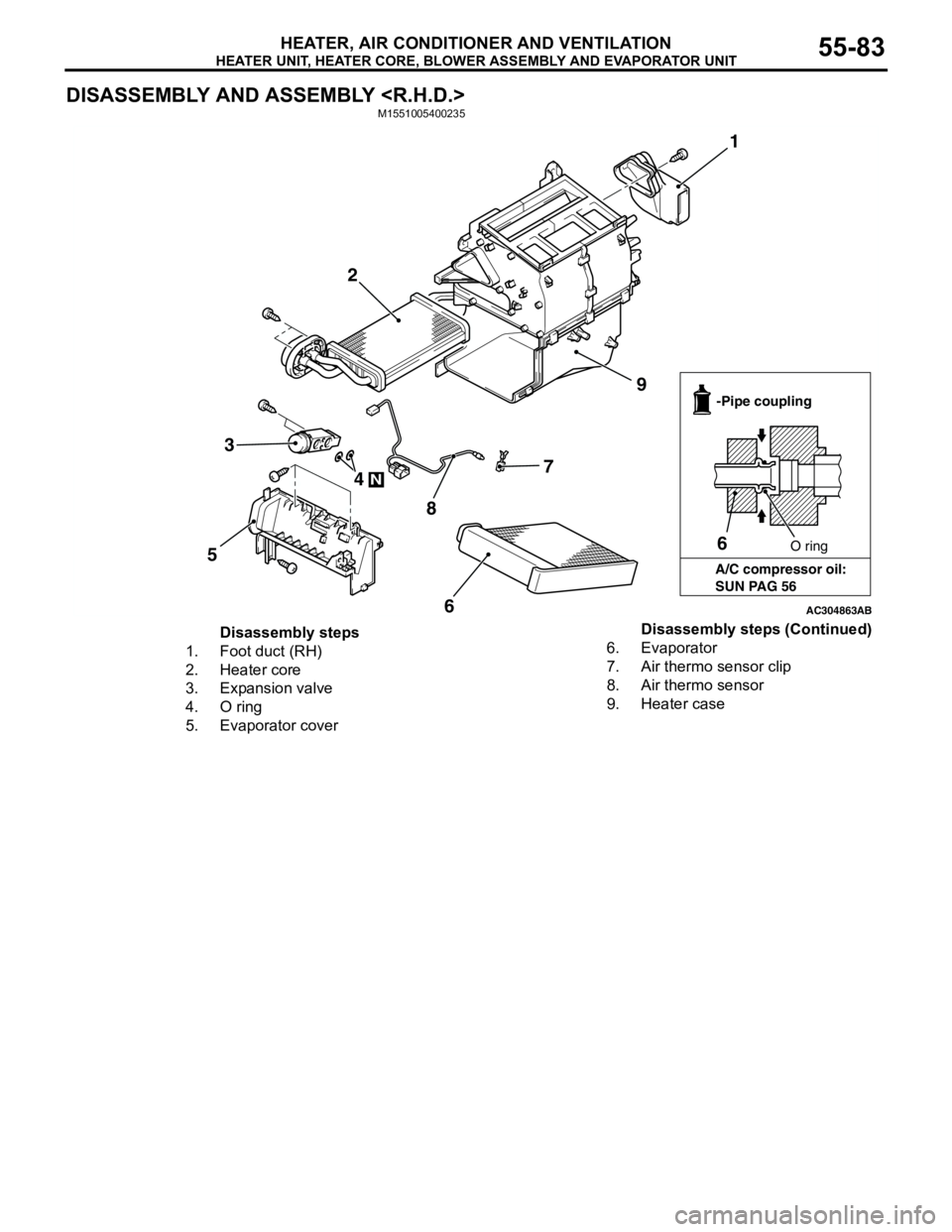

DISASSEMBLY AND ASSEMBLY

AC304863

1

2

3

4

5

N

6

7

8

9

AB

6O ring -Pipe coupling

A/C compressor oil:

SUN PAG 56

Disassembly steps

1. Foot duct (RH)

2. Heater core

3. Expansion valve

4. O ring

5. Evaporator cover6. Evaporator

7. Air thermo sensor clip

8. Air thermo sensor

9. Heater caseDisassembly steps (Continued)

Page 572 of 788

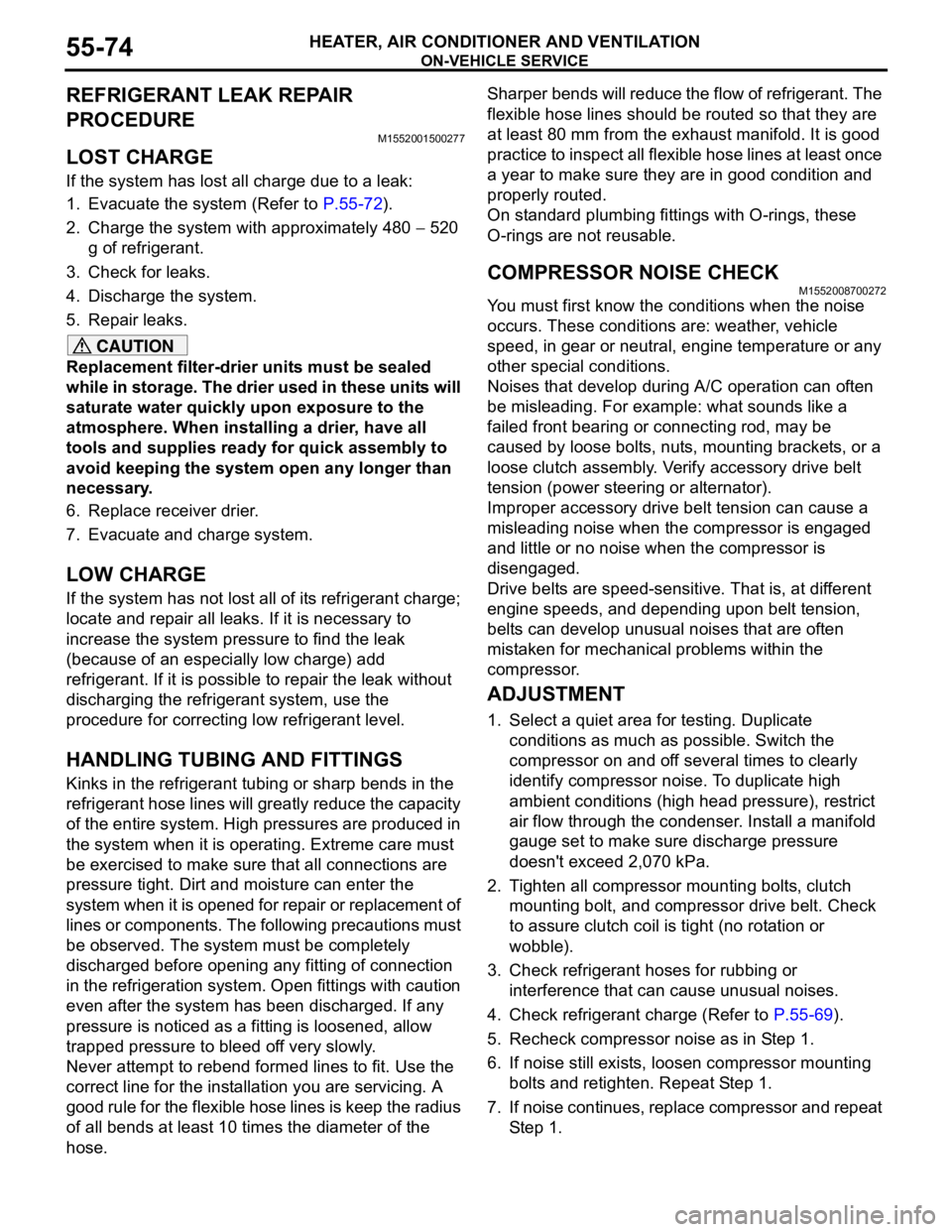

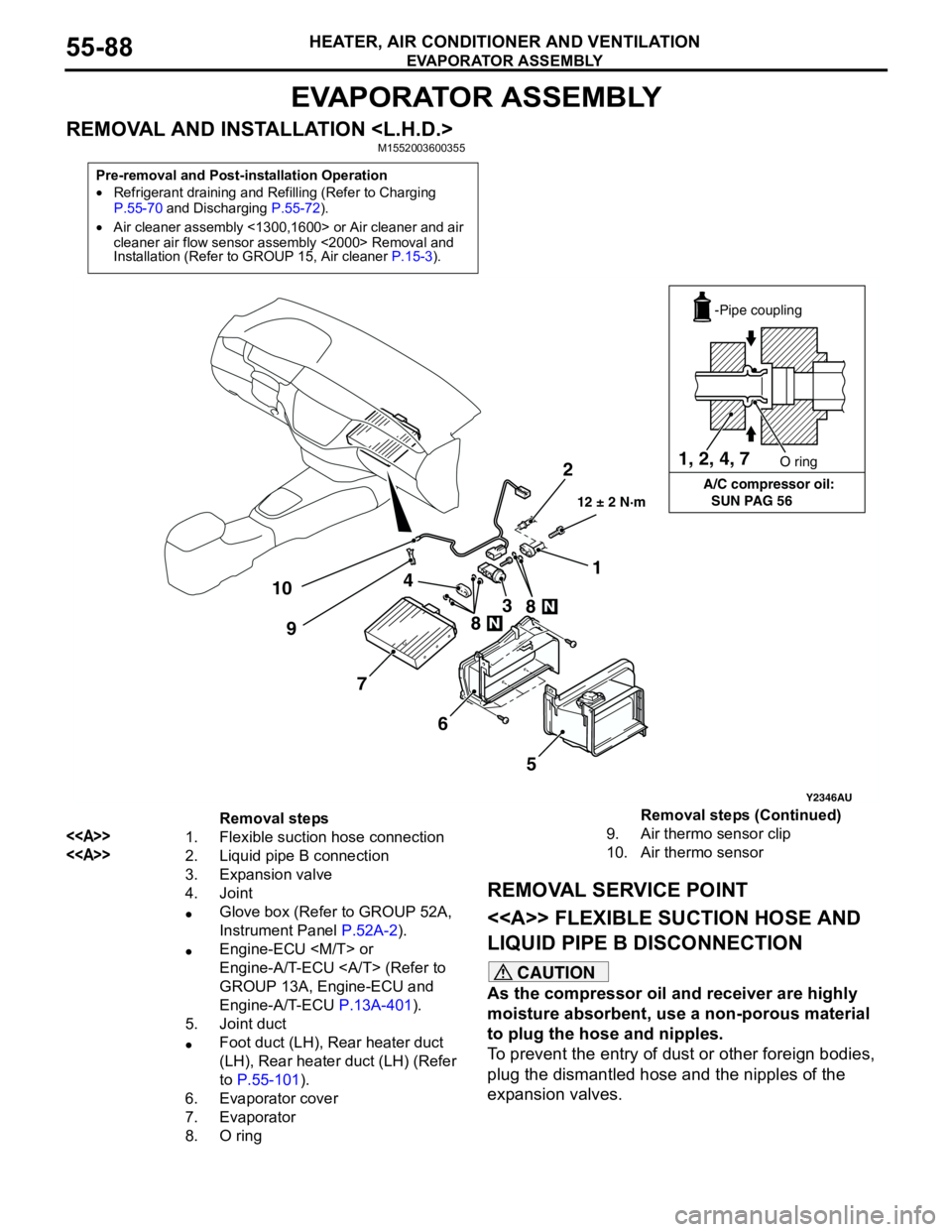

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-88

EVAPORATOR ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

Y2346AU

1, 2, 4, 7

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

2

101

3 4

7

6

5 98

8

12 ± 2 N·m

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

4. Joint

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

5. Joint duct

•Foot duct (LH), Rear heater duct

(LH), Rear heater duct (LH) (Refer

to P.55-101).

6. Evaporator cover

7. Evaporator

8. O ring 9. Air thermo sensor clip

10. Air thermo sensorRemoval steps (Continued)

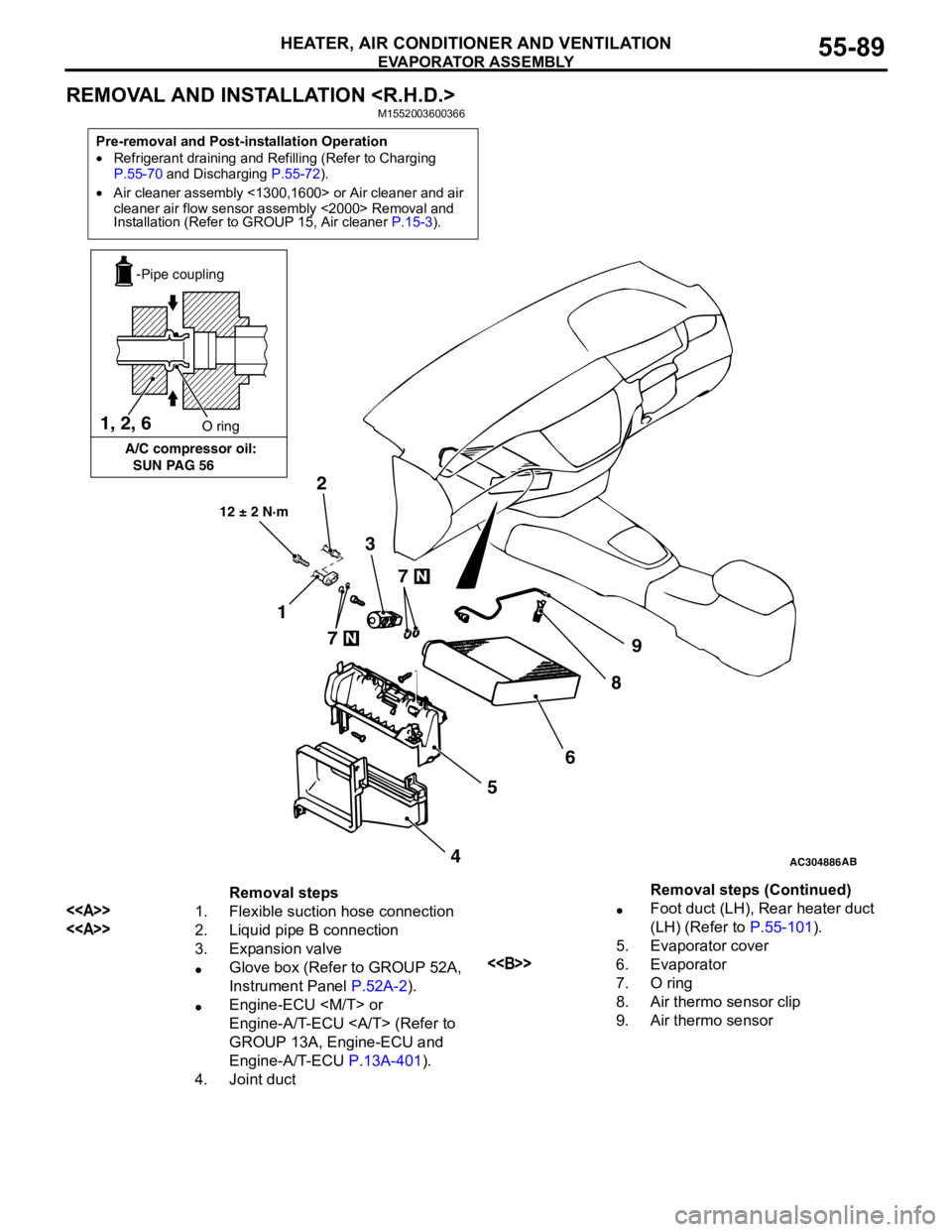

Page 573 of 788

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-89

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

AC304886AB

12 ± 2 N·m

7

7

2

1

9

8

6

5

4 3 1, 2, 6

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

4. Joint duct•Foot duct (LH), Rear heater duct

(LH) (Refer to P.55-101).

5. Evaporator cover

<>6. Evaporator

7. O ring

8. Air thermo sensor clip

9. Air thermo sensorRemoval steps (Continued)

Page 574 of 788