ac compressor MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 544 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-60

COMMENTS ON TROUBLE SYMPTOM

If the power is not supplied to the A/C compressor,

the A/C compressor circuit system may be

defective..

TROUBLESHOOTING HINTS

•Malfunction of the A/C compressor relay

•Damaged the wiring harness or connectors

DIAGNOSIS

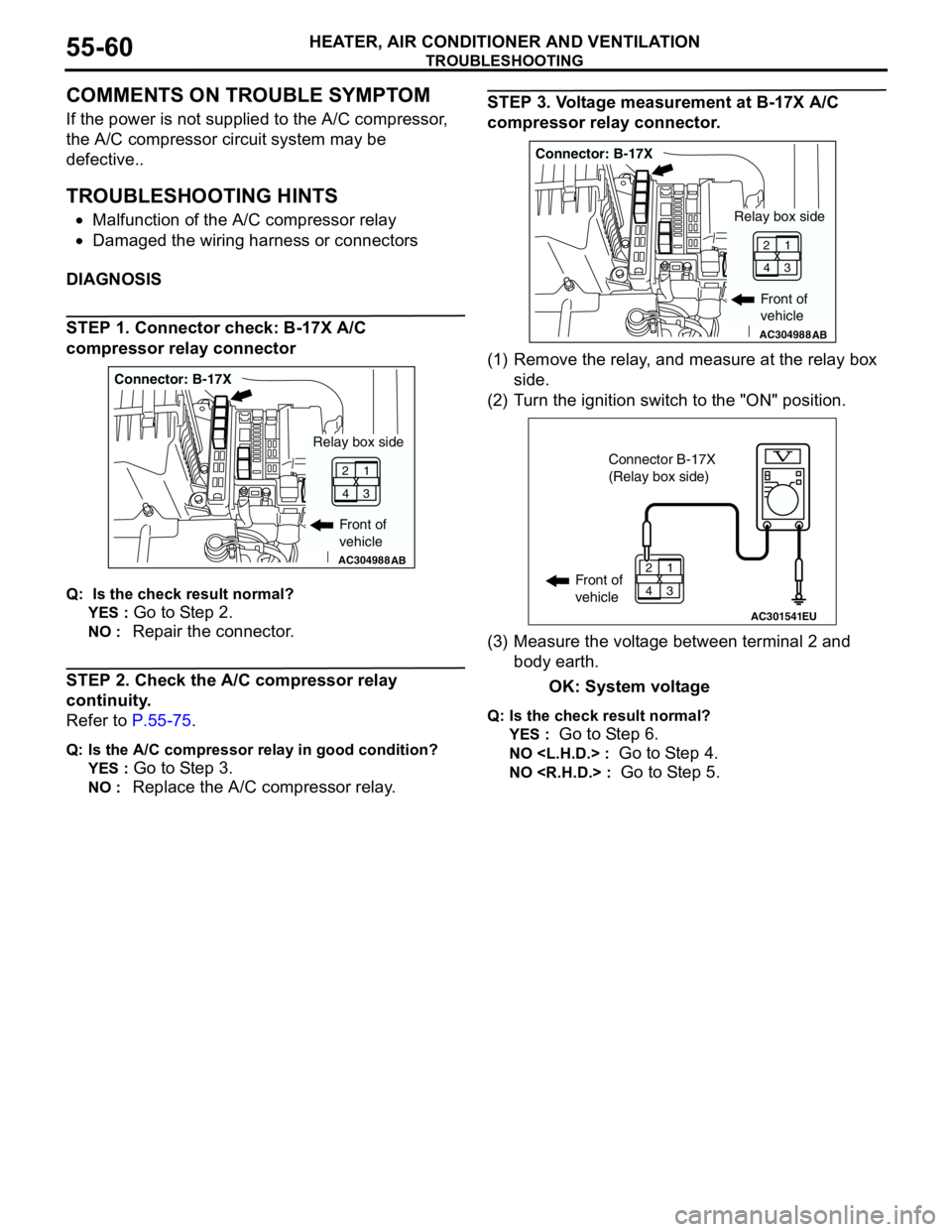

STEP 1. Connector check: B-17X A/C

compressor relay connector

Q: Is the check result normal?

YES :

Go to Step 2.

NO : Repair the connector.

STEP 2. Check the A/C compressor relay

continuity.

Refer to P.55-75.

Q: Is the A/C compressor relay in good condition?

YES :

Go to Step 3.

NO : Replace the A/C compressor relay.

STEP 3. Voltage measurement at B-17X A/C

compressor relay connector.

(1) Remove the relay, and measure at the relay box

side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 2 and

body earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 6.

NO

NO

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC301541EU

Connector B-17X

(Relay box side)

Front of

vehicle1

3 2

4

Page 545 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-61

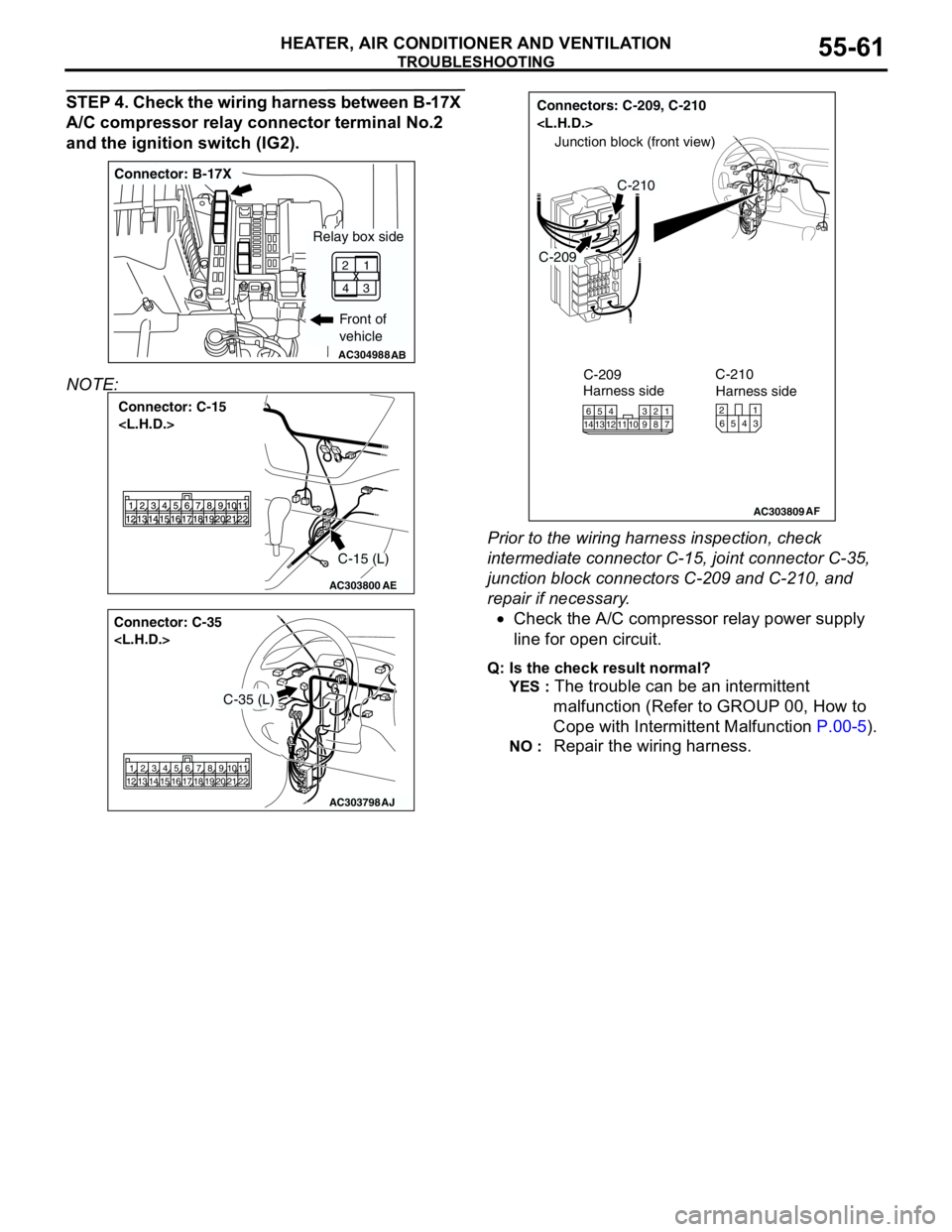

STEP 4. Check the wiring harness between B-17X

A/C compressor relay connector terminal No.2

and the ignition switch (IG2).

NOTE:

Prior to the wiring harness inspection, check

intermediate connector C-15, joint connector C-35,

junction block connectors C-209 and C-210, and

repair if necessary.

•Check the A/C compressor relay power supply

line for open circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303800

Connector: C-15

AE

C-15 (L)

AC303798

Connector: C-35

AJ

2 1313 12 1421 105 4616 15 17789

19 18 2011

22

C-35 (L)

AC303809

Connectors: C-209, C-210

AF

C-209

C-210

Junction block (front view)

C-209

Harness side

1016

145

12134117 238 9

C-210

Harness side

4 65321

Page 546 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-62

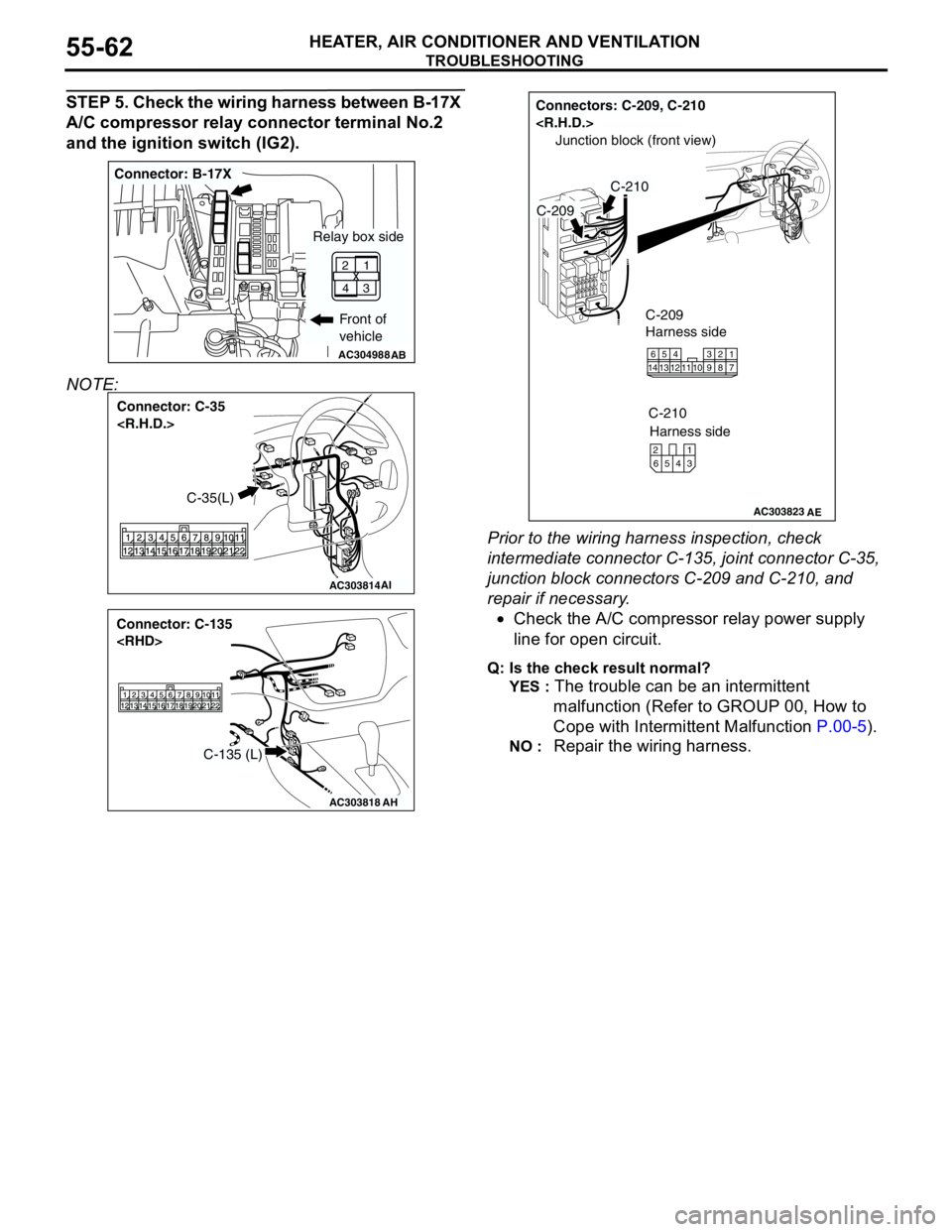

STEP 5. Check the wiring harness between B-17X

A/C compressor relay connector terminal No.2

and the ignition switch (IG2).

NOTE:

Prior to the wiring harness inspection, check

intermediate connector C-135, joint connector C-35,

junction block connectors C-209 and C-210, and

repair if necessary.

•Check the A/C compressor relay power supply

line for open circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303814

Connector: C-35

AI

C-35(L)

AC303818

Connector: C-135

AH

C-135 (L)

AC303823

Connectors: C-209, C-210

AE

C-210

Junction block (front view)

C-209

C-209

Harness side

1016

145

12134117 238 9

C-210

Harness side

4 65321

Page 547 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-63

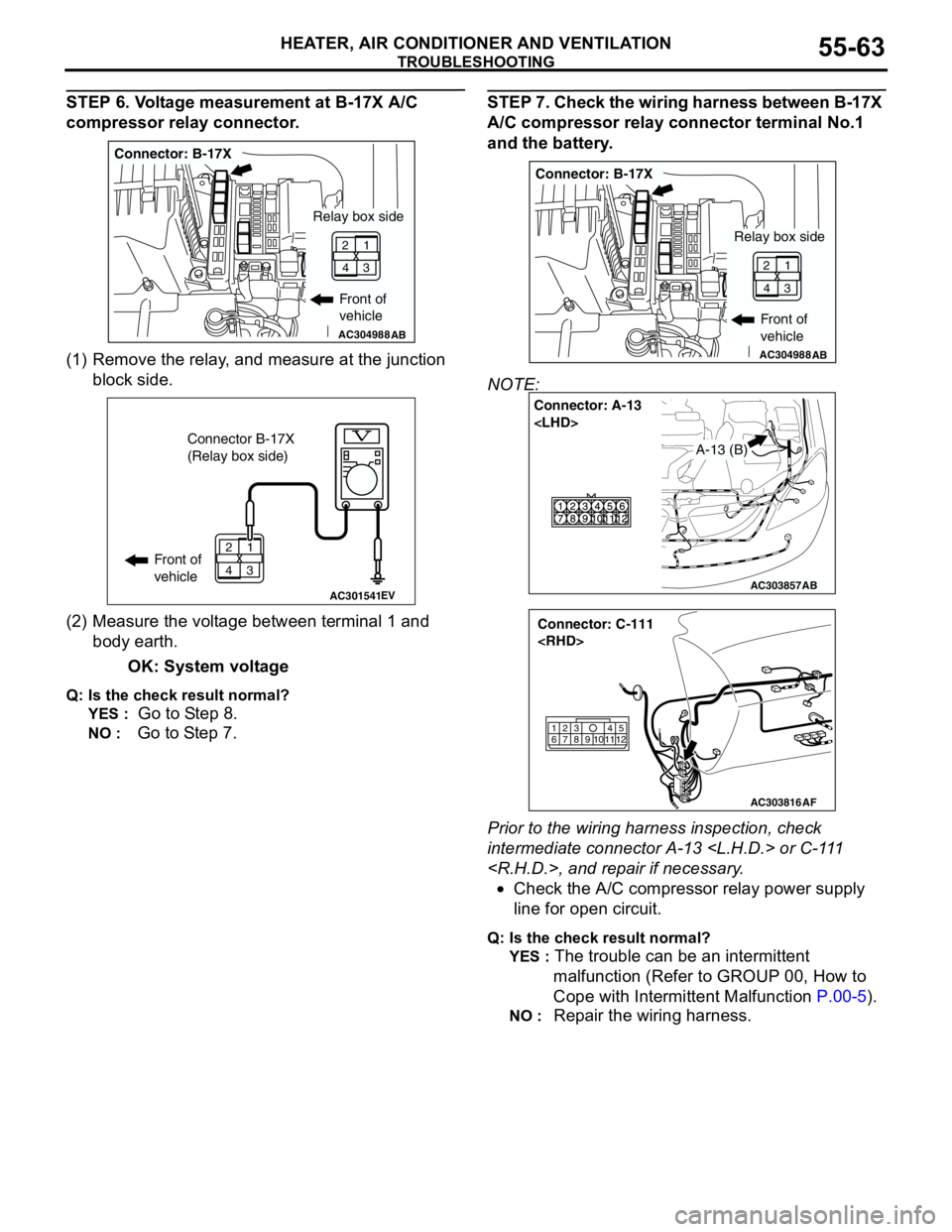

STEP 6. Voltage measurement at B-17X A/C

compressor relay connector.

(1) Remove the relay, and measure at the junction

block side.

(2) Measure the voltage between terminal 1 and

body earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 8.

NO : Go to Step 7.

STEP 7. Check the wiring harness between B-17X

A/C compressor relay connector terminal No.1

and the battery.

NOTE:

Prior to the wiring harness inspection, check

intermediate connector A-13

•Check the A/C compressor relay power supply

line for open circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC301541EV

Connector B-17X

(Relay box side)

Front of

vehicle1

3 2

4

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303857

Connector: A-13

AB

A-13 (B)

AC303816

Connector: C-111

AF

615

121179

810234

Page 548 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-64

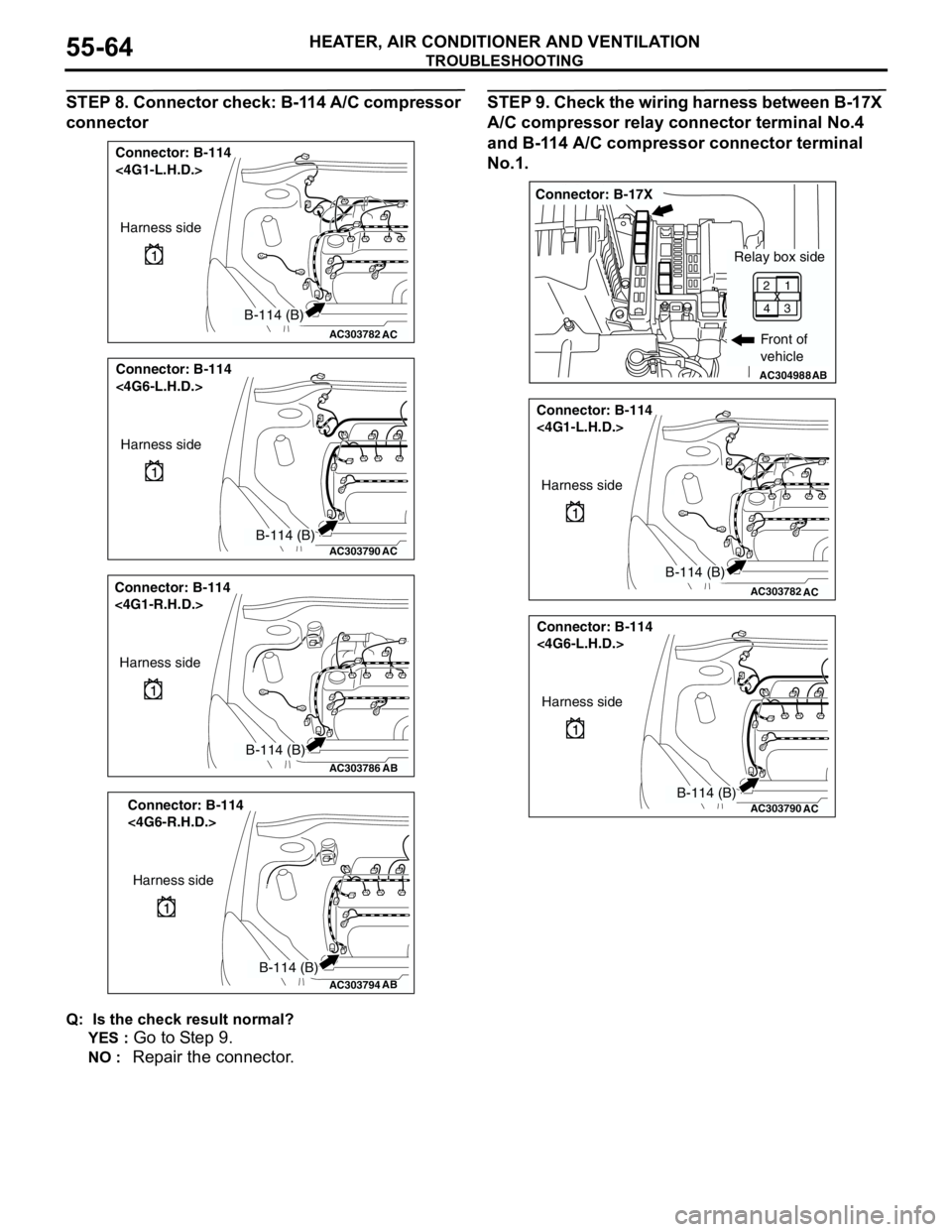

STEP 8. Connector check: B-114 A/C compressor

connector

Q: Is the check result normal?

YES :

Go to Step 9.

NO : Repair the connector.

STEP 9. Check the wiring harness between B-17X

A/C compressor relay connector terminal No.4

and B-114 A/C compressor connector terminal

No.1.

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303782

Connector: B-114

<4G1-L.H.D.>

AC

Harness side

B-114 (B)

AC303790

Connector: B-114

<4G6-L.H.D.>

AC

Harness side

B-114 (B)

Page 549 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-65

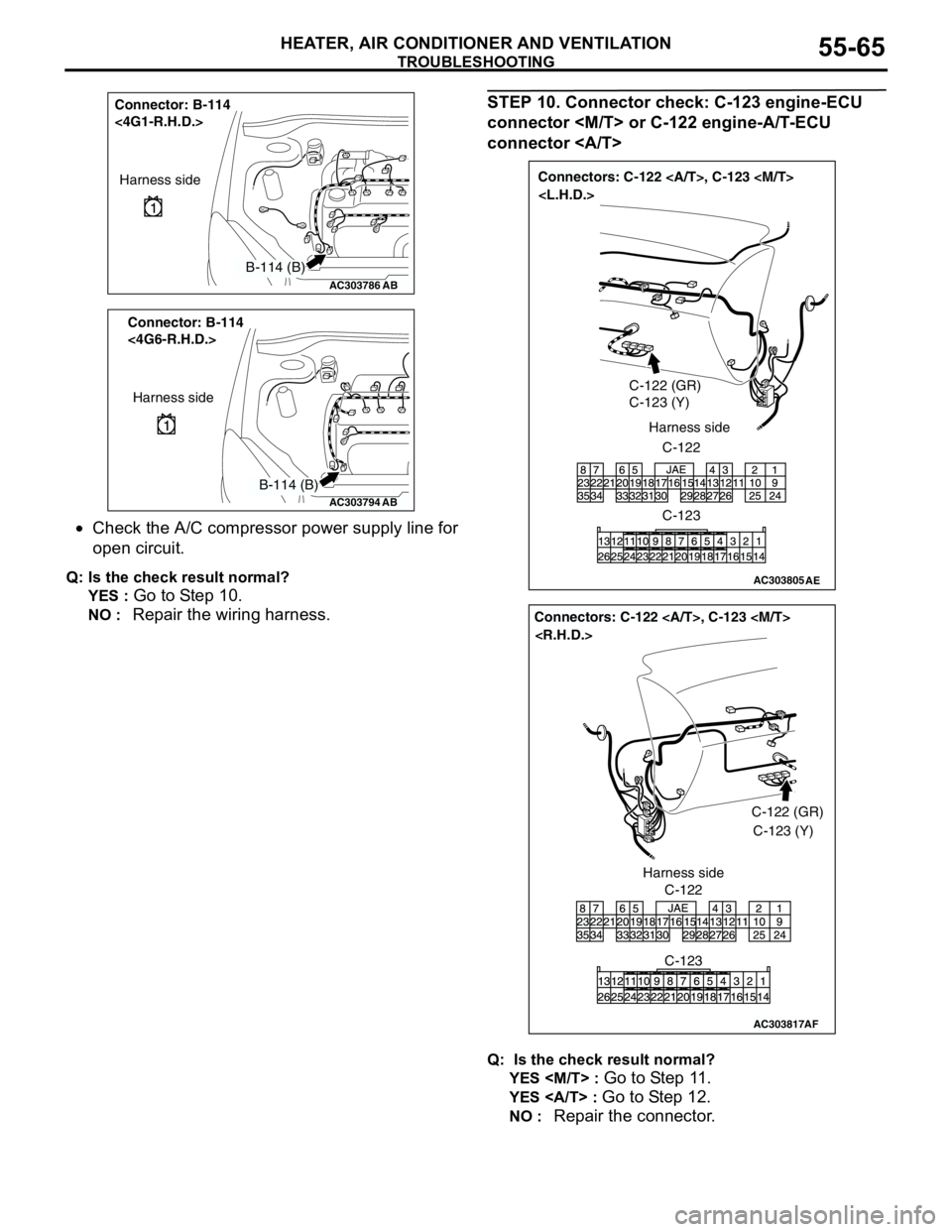

•Check the A/C compressor power supply line for

open circuit.

Q: Is the check result normal?

YES :

Go to Step 10.

NO : Repair the wiring harness.

STEP 10. Connector check: C-123 engine-ECU

connector

connector

Q: Is the check result normal?

YES

Go to Step 11.

YES : Go to Step 12.

NO : Repair the connector.

AC303786

Connector: B-114

<4G1-R.H.D.>

AB

Harness side

B-114 (B)

AC303794

Connector: B-114

<4G6-R.H.D.>

AB

Harness side

B-114 (B)

AC303805

Connectors: C-122 , C-123

C-122 (GR)

C-123 (Y)

C-122 Harness side

C-123

AE

AC303817

Connectors: C-122 , C-123

AF

C-122C-122 (GR)

C-123 (Y)

C-123 Harness side

Page 550 of 788

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION55-66

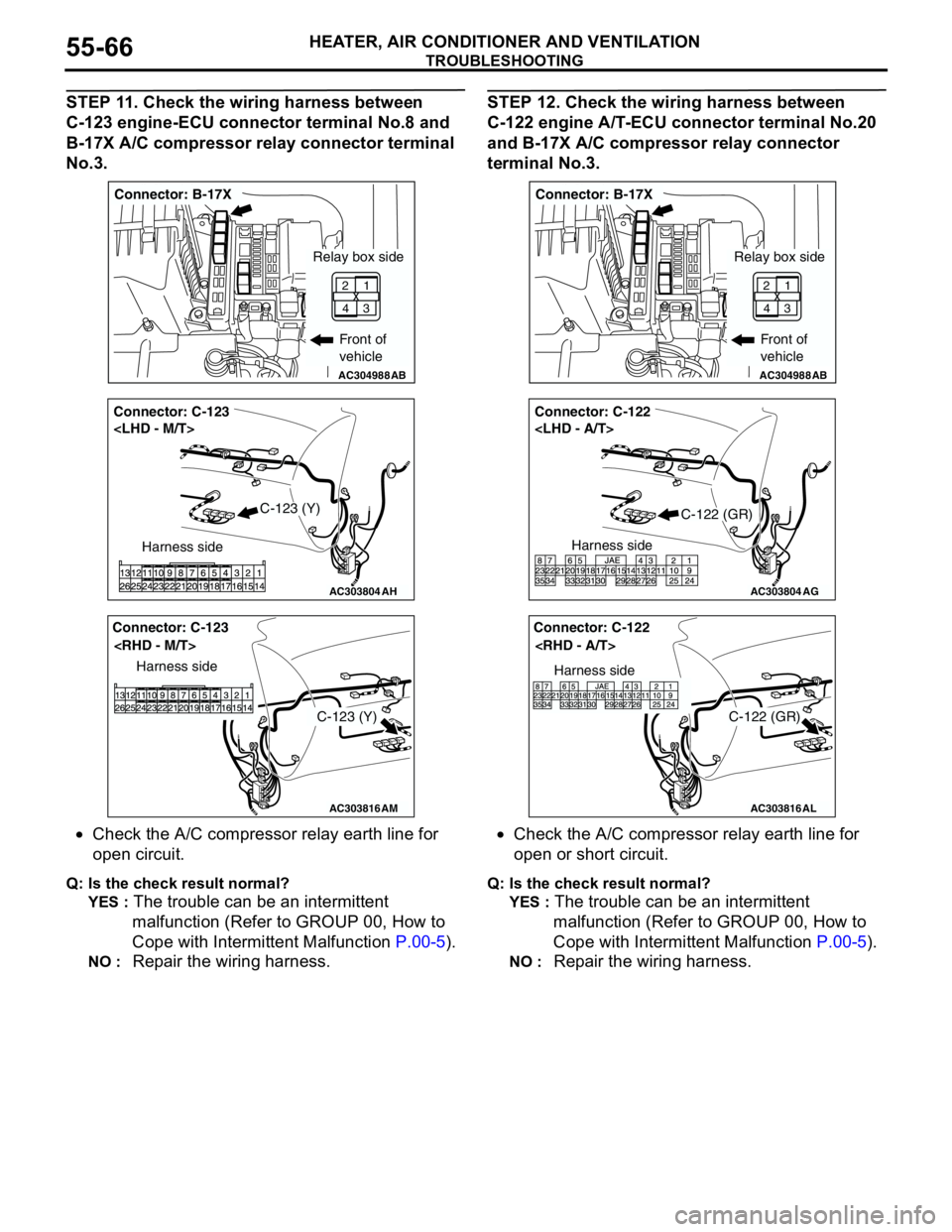

STEP 11. Check the wiring harness between

C-123 engine-ECU connector terminal No.8 and

B-17X A/C compressor relay connector terminal

No.3.

•Check the A/C compressor relay earth line for

open circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

STEP 12. Check the wiring harness between

C-122 engine A/T-ECU connector terminal No.20

and B-17X A/C compressor relay connector

terminal No.3.

•Check the A/C compressor relay earth line for

open or short circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00, How to

Cope with Intermittent Malfunction P.00-5).

NO : Repair the wiring harness.

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303804

Connector: C-123

AH

Harness side

C-123 (Y)

AC303816

Connector: C-123

AM

Harness side

C-123 (Y)

AC304988AB

Connector: B-17X

Front of

vehicle

1

3 2

4

Relay box side

AC303804

Connector: C-122

AG

Harness side

C-122 (GR)

AC303816

Connector: C-122

AL

Harness side

C-122 (GR)

Page 553 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-69

ON-VEHICLE SERVICE

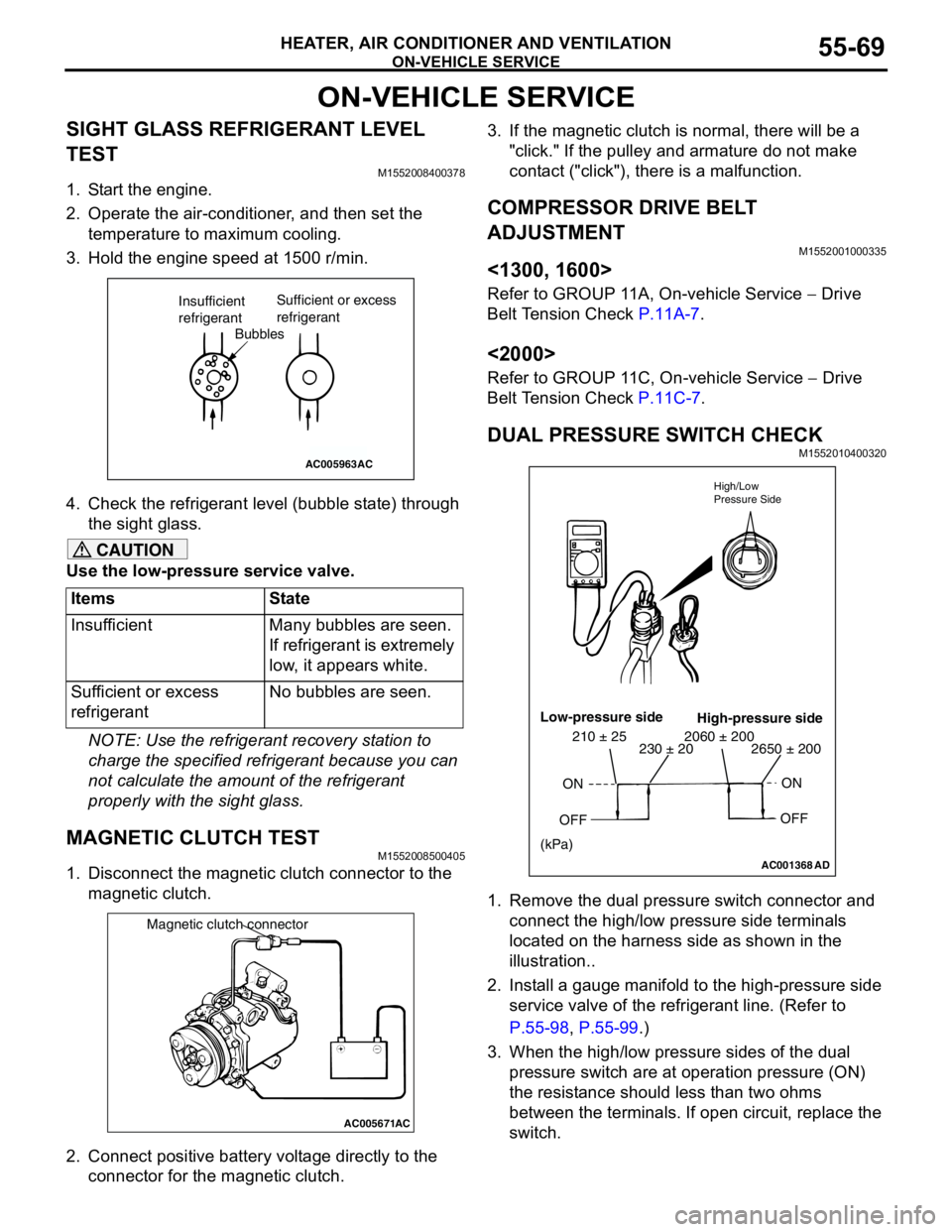

SIGHT GLASS REFRIGERANT LEVEL

TEST

M1552008400378

1. Start the engine.

2. Operate the air-conditioner, and then set the

temperature to maximum cooling.

3. Hold the engine speed at 1500 r/min.

4. Check the refrigerant level (bubble state) through

the sight glass.

CAUTION

Use the low-pressure service valve.

NOTE: Use the refrigerant recovery station to

charge the specified refrigerant because you can

not calculate the amount of the refrigerant

properly with the sight glass.

MAGNETIC CLUTCH TESTM1552008500405

1. Disconnect the magnetic clutch connector to the

magnetic clutch.

2. Connect positive battery voltage directly to the

connector for the magnetic clutch.3. If the magnetic clutch is normal, there will be a

"click." If the pulley and armature do not make

contact ("click"), there is a malfunction.

COMPRESSOR DRIVE BELT

ADJUSTMENT

M1552001000335

<1300, 1600>

Refer to GROUP 11A, On-vehicle Service − Drive

Belt Tension Check P.11A-7.

<2000>

Refer to GROUP 11C, On-vehicle Service − Drive

Belt Tension Check P.11C-7.

DUAL PRESSURE SWITCH CHECKM1552010400320

1. Remove the dual pressure switch connector and

connect the high/low pressure side terminals

located on the harness side as shown in the

illustration..

2. Install a gauge manifold to the high-pressure side

service valve of the refrigerant line. (Refer to

P.55-98, P.55-99.)

3. When the high/low pressure sides of the dual

pressure switch are at operation pressure (ON)

the resistance should less than two ohms

between the terminals. If open circuit, replace the

switch. Items State

Insufficient Many bubbles are seen.

If refrigerant is extremely

low, it appears white.

Sufficient or excess

refrigerantNo bubbles are seen.

AC005963

Bubbles Insufficient

refrigerantSufficient or excess

refrigerant

AC

AC005671

Magnetic clutch connector

AC

AC001368AD High/Low

Pressure Side

Low-pressure side

High-pressure side

ON

OFFON

OFF

2650 ± 200 2060 ± 200230 ± 20 210 ± 25

(kPa)

Page 554 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-70

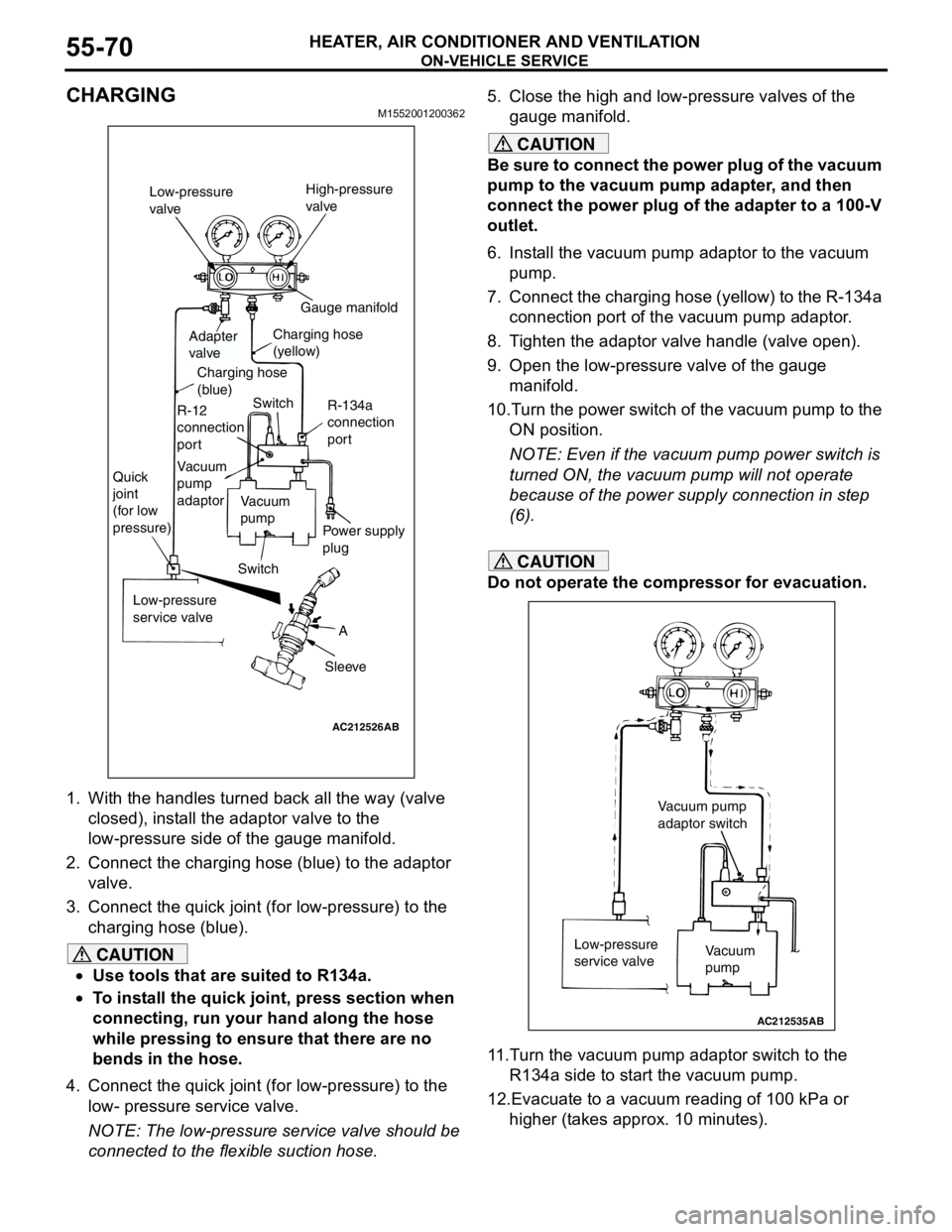

CHARGING M1552001200362

1. With the handles turned back all the way (valve

closed), install the adaptor valve to the

low-pressure side of the gauge manifold.

2. Connect the charging hose (blue) to the adaptor

valve.

3. Connect the quick joint (for low-pressure) to the

charging hose (blue).

CAUTION

•Use tools that are suited to R134a.

•To install the quick joint, press section when

connecting, run your hand along the hose

while pressing to ensure that there are no

bends in the hose.

4. Connect the quick joint (for low-pressure) to the

low- pressure service valve.

NOTE: The low-pressure service valve should be

connected to the flexible suction hose.5. Close the high and low-pressure valves of the

gauge manifold.

CAUTION

Be sure to connect the power plug of the vacuum

pump to the vacuum pump adapter, and then

connect the power plug of the adapter to a 100-V

outlet.

6. Install the vacuum pump adaptor to the vacuum

pump.

7. Connect the charging hose (yellow) to the R-134a

connection port of the vacuum pump adaptor.

8. Tighten the adaptor valve handle (valve open).

9. Open the low-pressure valve of the gauge

manifold.

10.Turn the power switch of the vacuum pump to the

ON position.

NOTE: Even if the vacuum pump power switch is

turned ON, the vacuum pump will not operate

because of the power supply connection in step

(6).

CAUTION

Do not operate the compressor for evacuation.

11.Turn the vacuum pump adaptor switch to the

R134a side to start the vacuum pump.

12.Evacuate to a vacuum reading of 100 kPa or

higher (takes approx. 10 minutes).

AC212526

AB

A

Sleeve Low-pressure

service valve Quick

joint

(for low

pressure)

SwitchVacuum

pump

Power supply

plug Vacuum

pump

adaptor R-12

connection

portCharging hose

(blue)

Adapter

valveCharging hose

(yellow)Gauge manifold

Switch

R-134a

connection

port Low-pressure

valveHigh-pressure

valve

AC212535

Vacuum

pump Low-pressure

service valve

AB

Vacuum pump

adaptor switch

Page 555 of 788

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-71

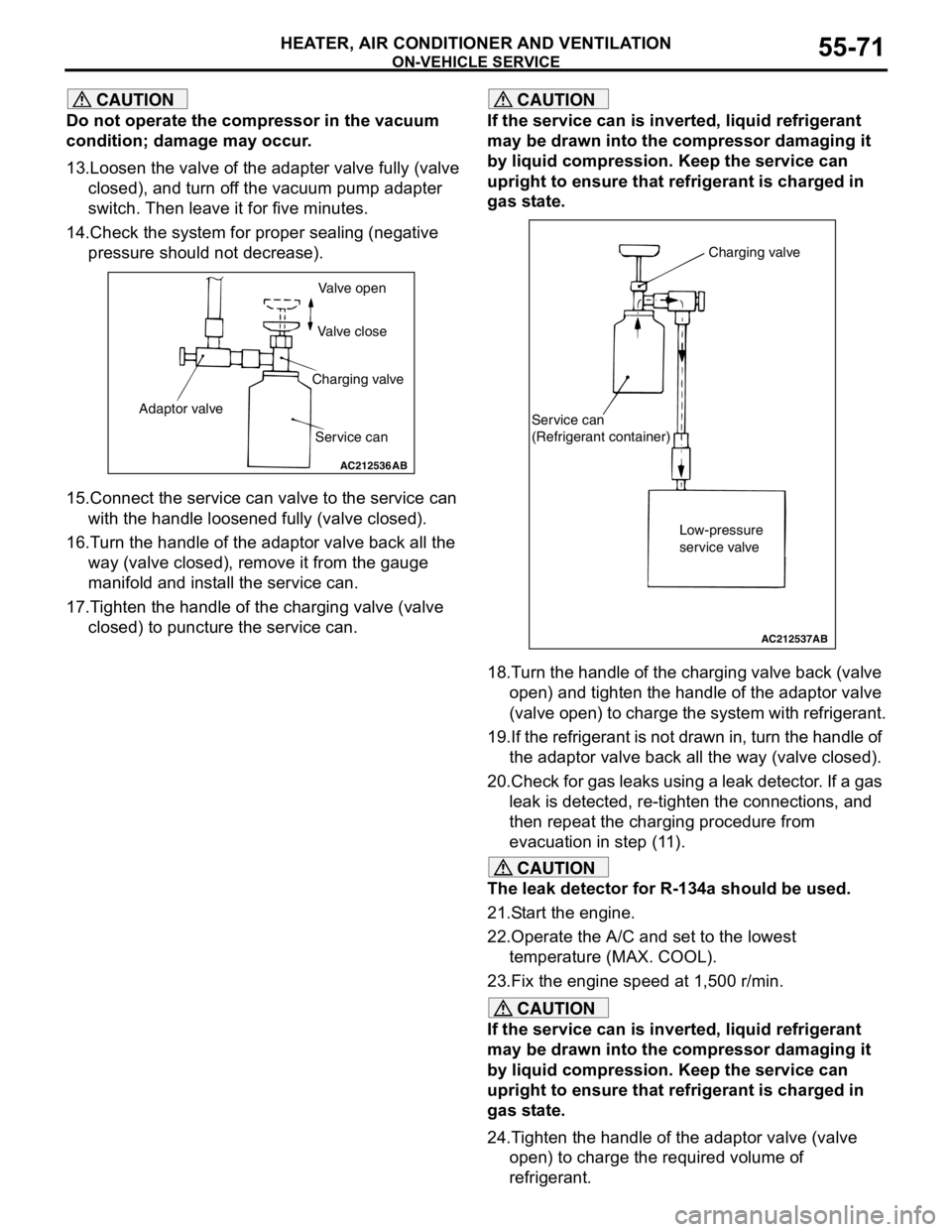

CAUTION

Do not operate the compressor in the vacuum

condition; damage may occur.

13.Loosen the valve of the adapter valve fully (valve

closed), and turn off the vacuum pump adapter

switch. Then leave it for five minutes.

14.Check the system for proper sealing (negative

pressure should not decrease).

15.Connect the service can valve to the service can

with the handle loosened fully (valve closed).

16.Turn the handle of the adaptor valve back all the

way (valve closed), remove it from the gauge

manifold and install the service can.

17.Tighten the handle of the charging valve (valve

closed) to puncture the service can.

CAUTION

If the service can is inverted, liquid refrigerant

may be drawn into the compressor damaging it

by liquid compression. Keep the service can

upright to ensure that refrigerant is charged in

gas state.

18.Turn the handle of the charging valve back (valve

open) and tighten the handle of the adaptor valve

(valve open) to charge the system with refrigerant.

19.If the refrigerant is not drawn in, turn the handle of

the adaptor valve back all the way (valve closed).

20.Check for gas leaks using a leak detector. If a gas

leak is detected, re-tighten the connections, and

then repeat the charging procedure from

evacuation in step (11).

CAUTION

The leak detector for R-134a should be used.

21.Start the engine.

22.Operate the A/C and set to the lowest

temperature (MAX. COOL).

23.Fix the engine speed at 1,500 r/min.

CAUTION

If the service can is inverted, liquid refrigerant

may be drawn into the compressor damaging it

by liquid compression. Keep the service can

upright to ensure that refrigerant is charged in

gas state.

24.Tighten the handle of the adaptor valve (valve

open) to charge the required volume of

refrigerant.

AC212536

Valve open

Valve close

Charging valve

Service can Adaptor valve

AB

AC212537

Charging valve

Service can

(Refrigerant container)

Low-pressure

service valve

AB