Engine electrical MITSUBISHI LANCER 2005 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 84 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-20

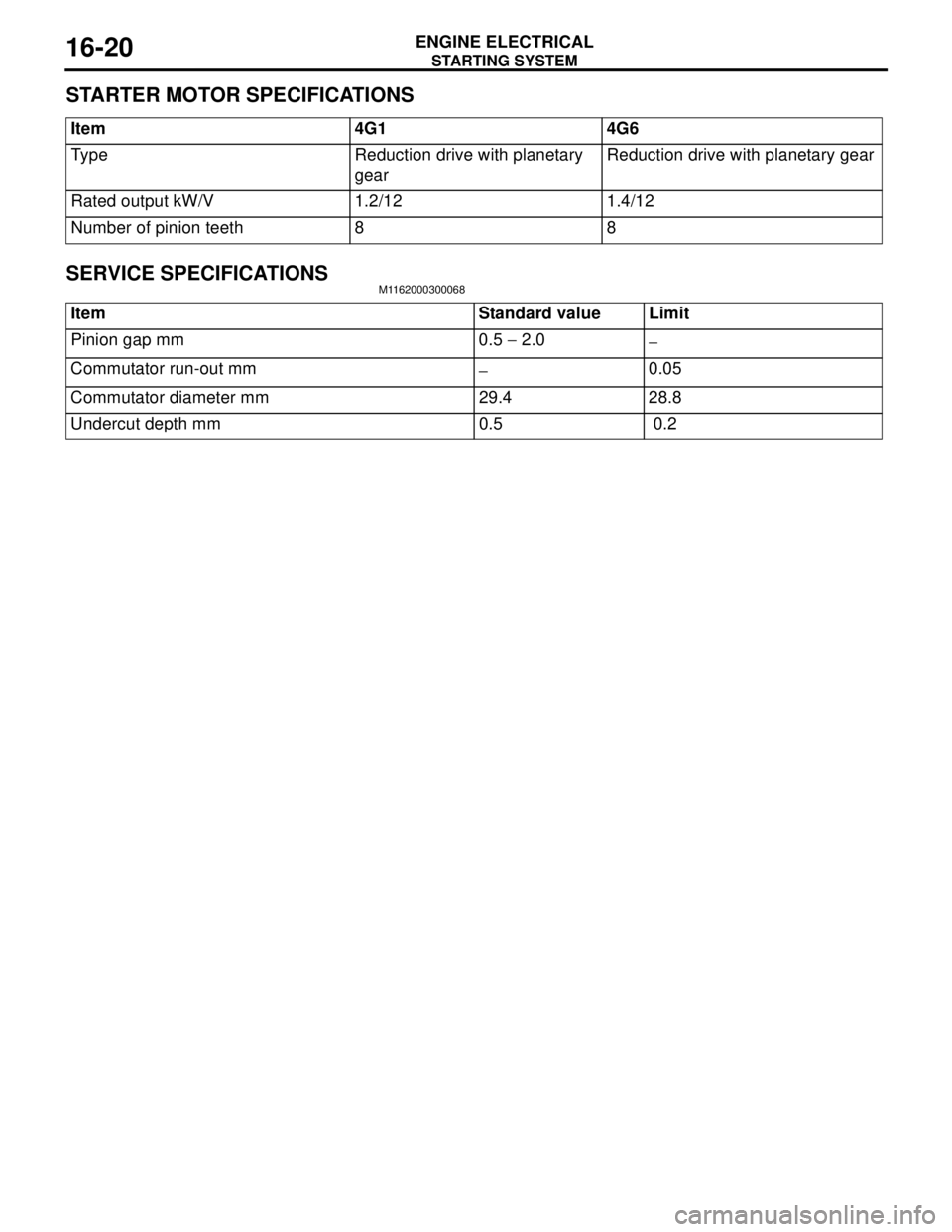

STARTER MOTOR SPECIFICATIONS

SERVICE SPECIFICATIONS

M1162000300068

Item 4G1 4G6

Type Reduction drive with planetary

gearReduction drive with planetary gear

Rated output kW/V 1.2/12 1.4/12

Number of pinion teeth 8 8

Item Standard value Limit

Pinion gap mm 0.5 − 2.0

−

Commutator run-out mm

−0.05

Commutator diameter mm 29.4 28.8

Undercut depth mm 0.5 0.2

Page 85 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-21

STARTER MOTOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>M1162001000628

REMOVAL SERVICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBLY

Remove the shift cable bracket installation bolt with

the shift cable installed on the shift cable bracket,

and remove the shift cable and shift cable bracket

assembly from the transmission.

<> SHIFT CABLE CONNECTION

REMOVAL

Disengage the transmission, and remove the shift

cable assembly from the transmission.

<

Remove the starter assembly from above the

vehicle.

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Battery and Battery Tray Removal and Installation

AC303962AB

1

1 2

3

56

7

4

30 ± 3 N·m18 ± 3 N·m

12 ± 2 N·m

Removal steps

1. Shift cable connection

<>2. shift cable and shift cable bracket

assembly

<>3. Shift cable connection 4. Starter connector and terminal

5. Harness bracket

6. Harness bracket <

Page 86 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-22

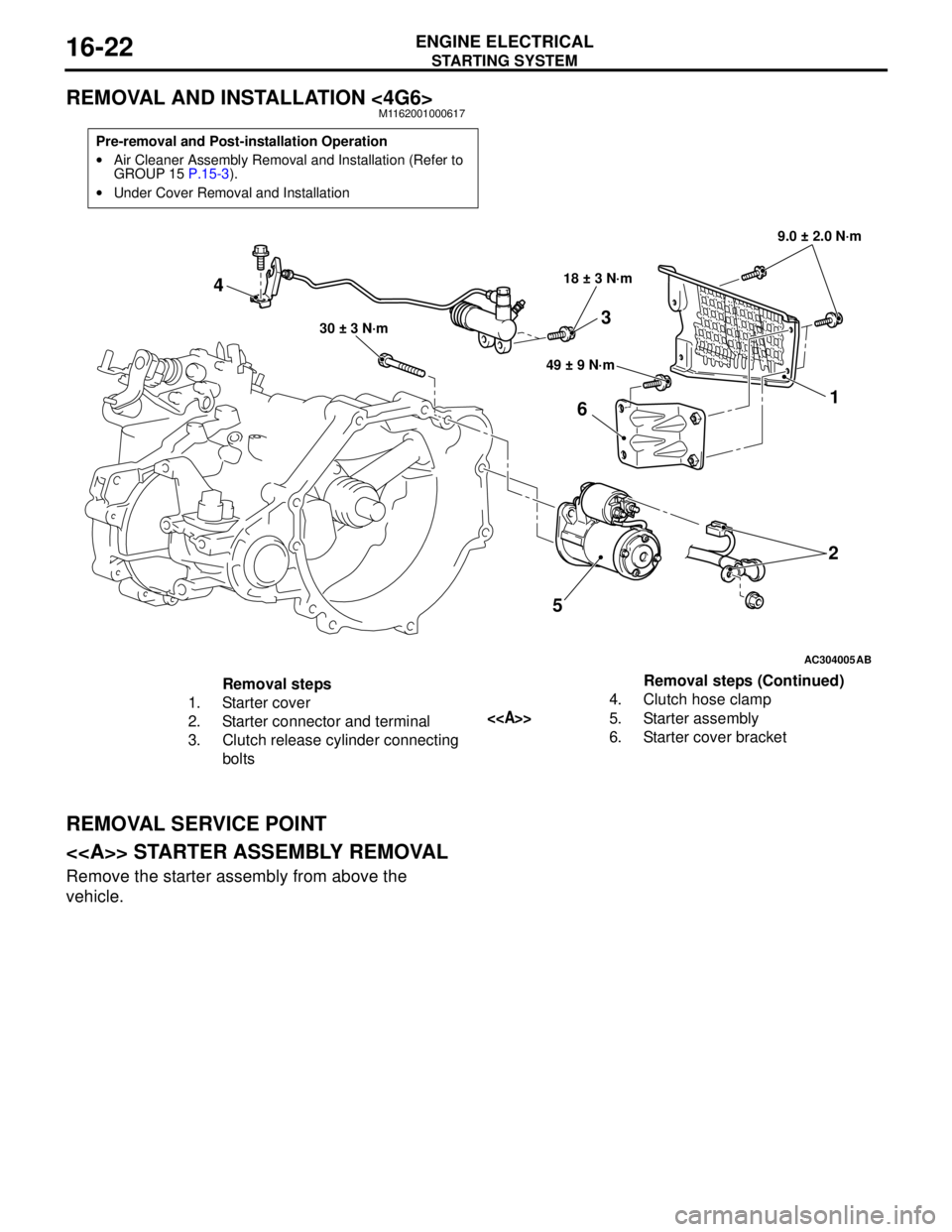

REMOVAL AND INSTALLATION <4G6>M1162001000617

REMOVAL SERVICE POINT

<> STARTER ASSEMBLY REMOVAL

Remove the starter assembly from above the

vehicle.

Pre-removal and Post-installation Operation

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Under Cover Removal and Installation

AC304005

521

6

49 ± 9 N·m 18 ± 3 N·m9.0 ± 2.0 N·m

30 ± 3 N·m

AB

4

3

Removal steps

1. Starter cover

2. Starter connector and terminal

3. Clutch release cylinder connecting

bolts4. Clutch hose clamp

<>5. Starter assembly

6. Starter cover bracketRemoval steps (Continued)

Page 87 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-23

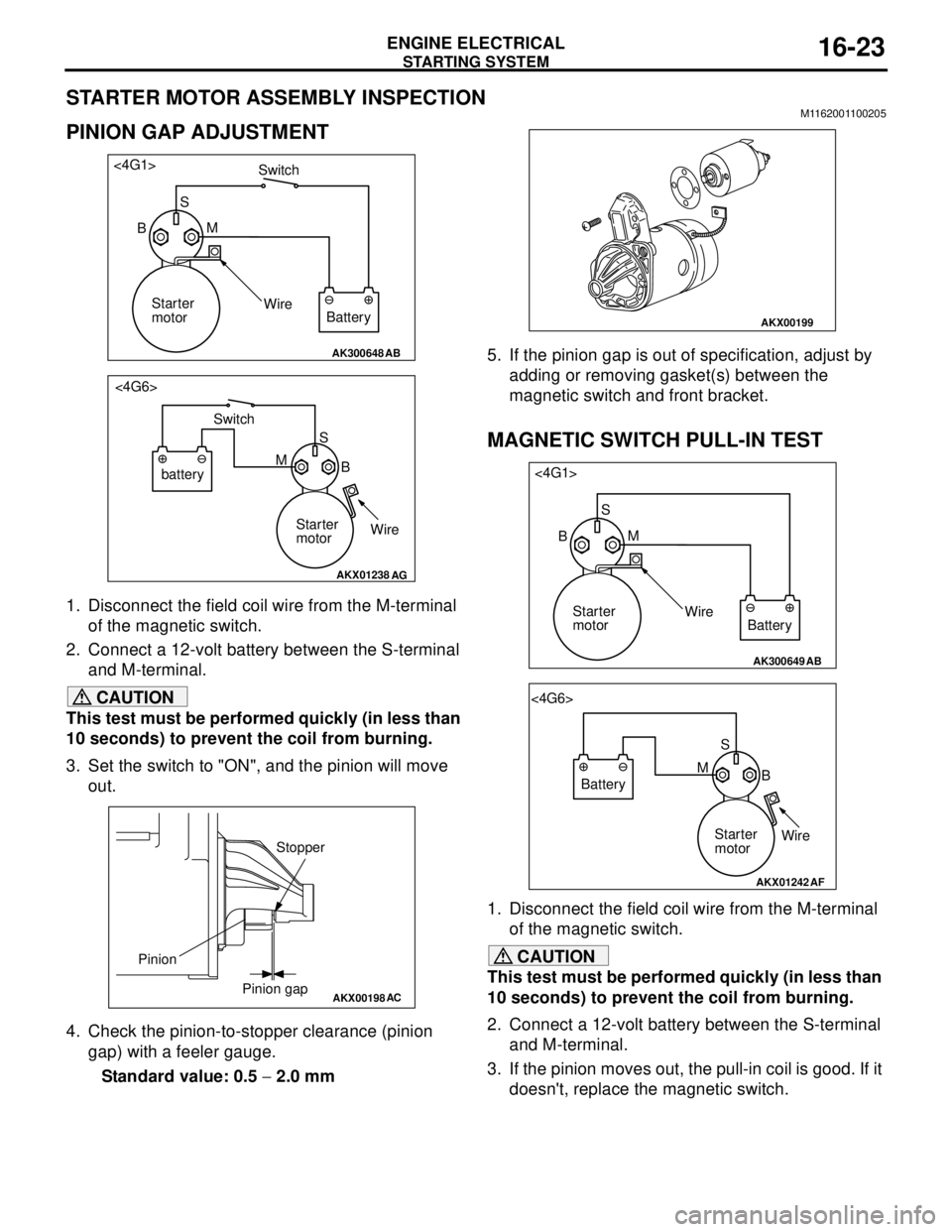

STARTER MOTOR ASSEMBLY INSPECTIONM1162001100205

PINION GAP ADJUSTMENT

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

3. Set the switch to "ON", and the pinion will move

out.

4. Check the pinion-to-stopper clearance (pinion

gap) with a feeler gauge.

Standard value: 0.5 − 2.0 mm5. If the pinion gap is out of specification, adjust by

adding or removing gasket(s) between the

magnetic switch and front bracket.

MAGNETIC SWITCH PULL-IN TEST

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and M-terminal.

3. If the pinion moves out, the pull-in coil is good. If it

doesn't, replace the magnetic switch.

AK300648AB

<4G1>

Switch

S

M

Wire

Battery Starter

motor B

AKX01238

<4G6>

B MS

batterySwitch

Starter

motorWire

AG

AKX00198

Stopper

Pinion gap Pinion

AC

AKX00199

AK300649AB

<4G1>

S

M

Wire

Battery Starter

motor B

AKX01242

<4G6>

S

B M

Battery

Starter

motorWire

AF

Page 88 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-24

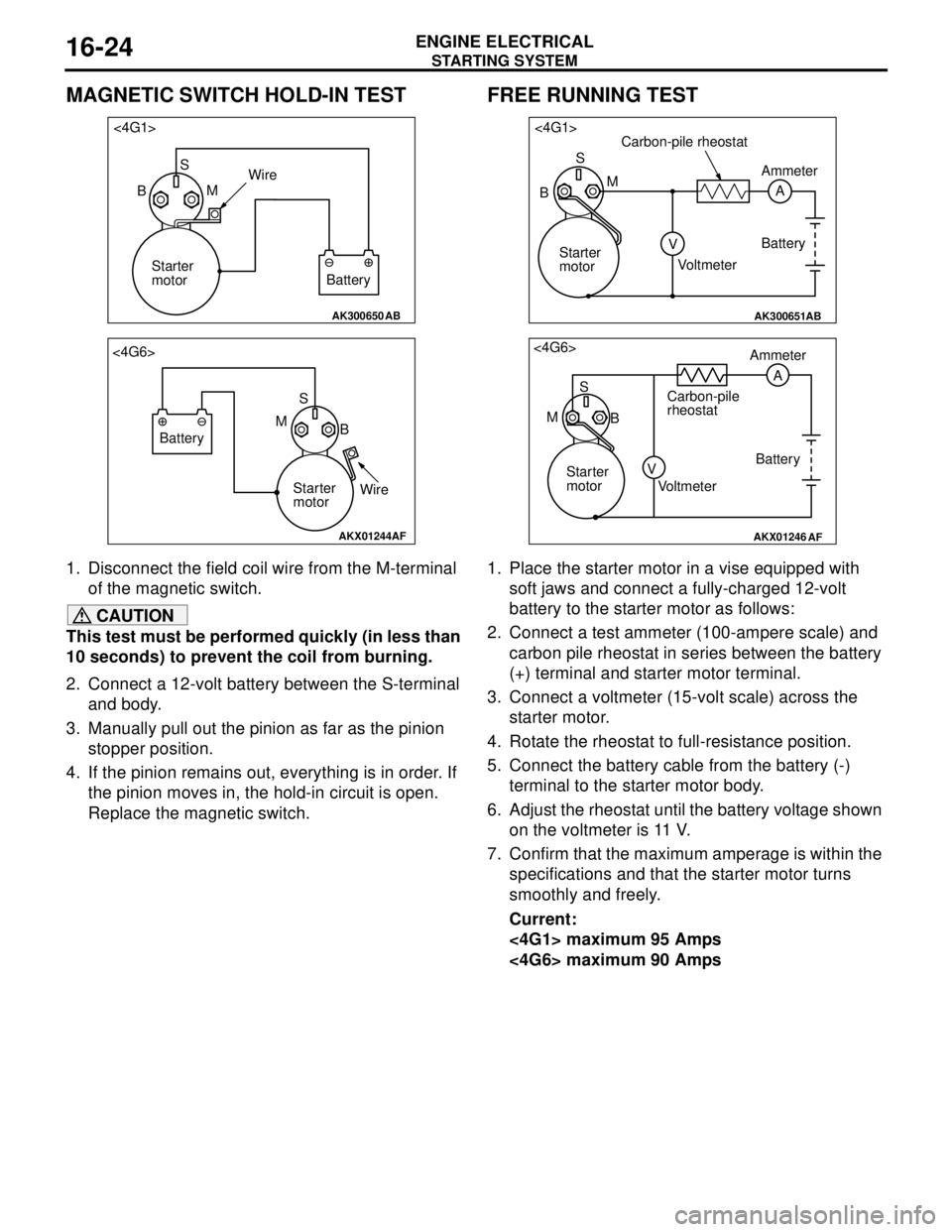

MAGNETIC SWITCH HOLD-IN TEST

1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the S-terminal

and body.

3. Manually pull out the pinion as far as the pinion

stopper position.

4. If the pinion remains out, everything is in order. If

the pinion moves in, the hold-in circuit is open.

Replace the magnetic switch.

FREE RUNNING TEST

1. Place the starter motor in a vise equipped with

soft jaws and connect a fully-charged 12-volt

battery to the starter motor as follows:

2. Connect a test ammeter (100-ampere scale) and

carbon pile rheostat in series between the battery

(+) terminal and starter motor terminal.

3. Connect a voltmeter (15-volt scale) across the

starter motor.

4. Rotate the rheostat to full-resistance position.

5. Connect the battery cable from the battery (-)

terminal to the starter motor body.

6. Adjust the rheostat until the battery voltage shown

on the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the

specifications and that the starter motor turns

smoothly and freely.

Current:

<4G1> maximum 95 Amps

<4G6> maximum 90 Amps

AK300650AB

<4G1>

S

BMWire

Battery Starter

motor

AKX01244

<4G6>

S

B M

Battery

Starter

motorWire

AF

AK300651AB

<4G1>

S

A M

V BCarbon-pile rheostat

Battery

VoltmeterAmmeter

Starter

motor

AKX01246

<4G6>

S

M

BAmmeter

Carbon-pile

rheostat

Battery

Starter

motor

Voltmeter

AF

A

V

Page 89 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-25

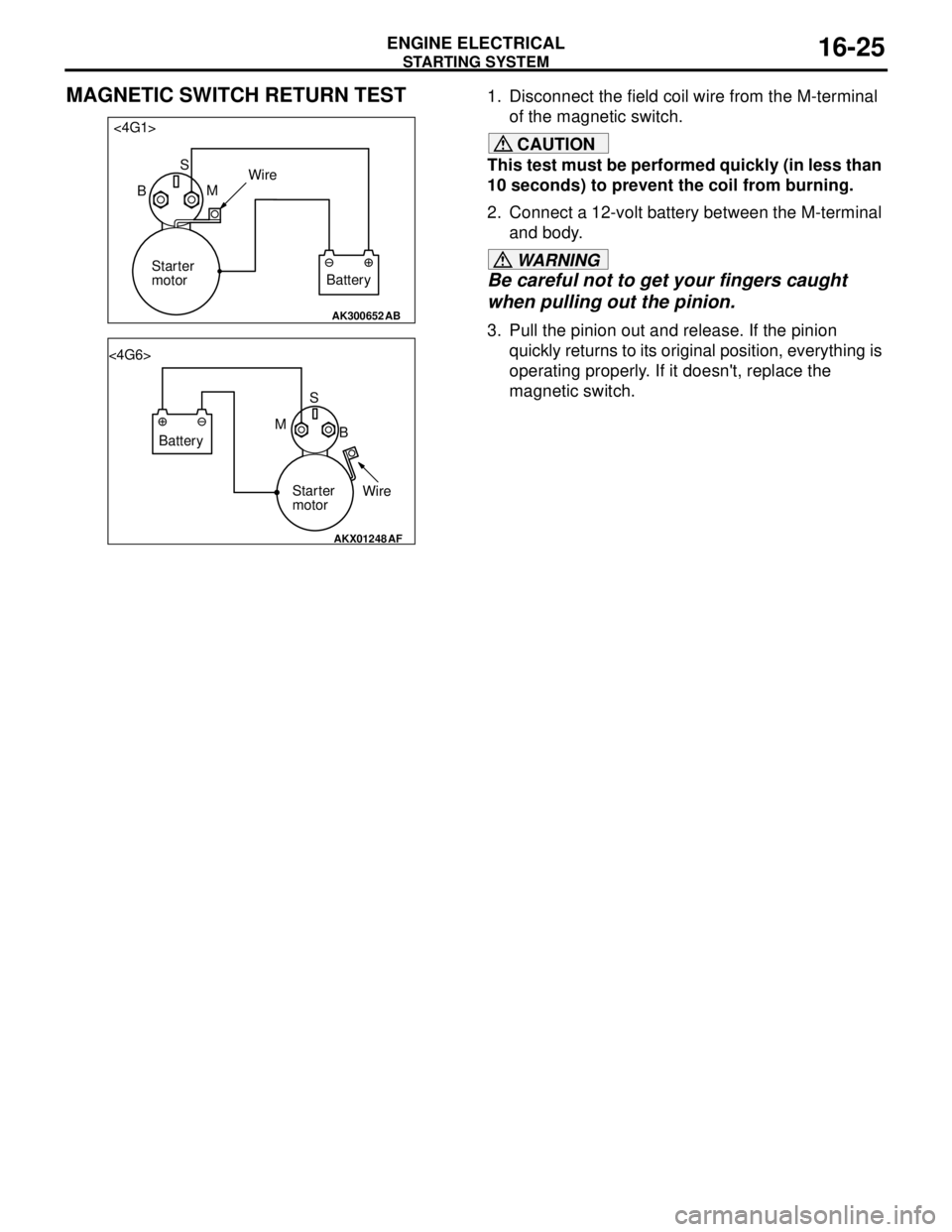

MAGNETIC SWITCH RETURN TEST1. Disconnect the field coil wire from the M-terminal

of the magnetic switch.

CAUTION

This test must be performed quickly (in less than

10 seconds) to prevent the coil from burning.

2. Connect a 12-volt battery between the M-terminal

and body.

WARNING

Be careful not to get your fingers caught

when pulling out the pinion.

3. Pull the pinion out and release. If the pinion

quickly returns to its original position, everything is

operating properly. If it doesn't, replace the

magnetic switch.

AK300652AB

<4G1>

S

BMWire

Battery Starter

motor

AKX01248

<4G6>

S

B M

Battery

Starter

motorWire

AF

Page 90 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-26

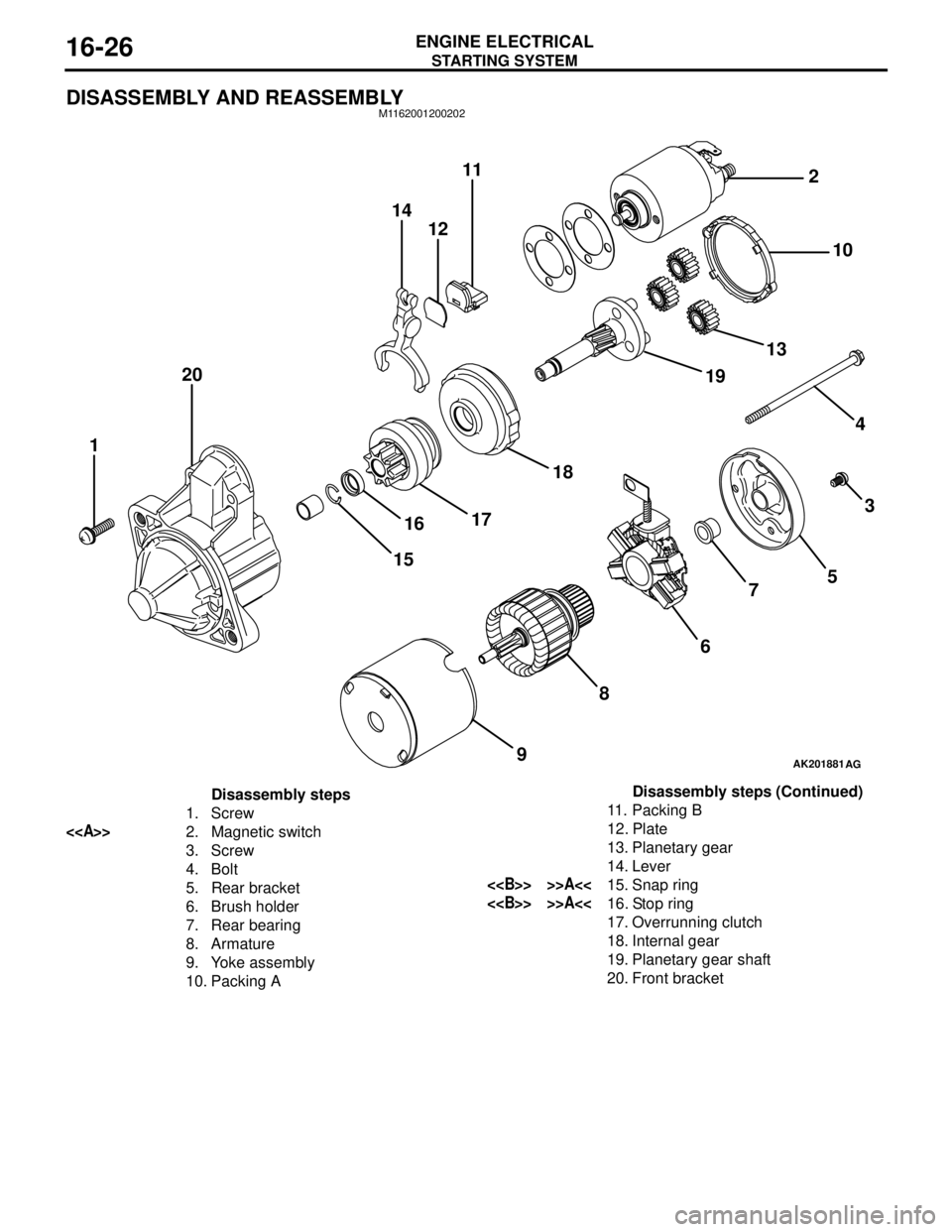

DISASSEMBLY AND REASSEMBLYM1162001200202

AK201881

14

1211

20

1

15161718191310 2

4

3

5

7

6

8

9

AG

Disassembly steps

1. Screw

<>2. Magnetic switch

3. Screw

4. Bolt

5. Rear bracket

6. Brush holder

7. Rear bearing

8. Armature

9. Yoke assembly

10. Packing A11. Packing B

12. Plate

13. Planetary gear

14. Lever

<> >>A<<15. Snap ring

<> >>A<<16. Stop ring

17. Overrunning clutch

18. Internal gear

19. Planetary gear shaft

20. Front bracketDisassembly steps (Continued)

Page 91 of 788

Page 92 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-28

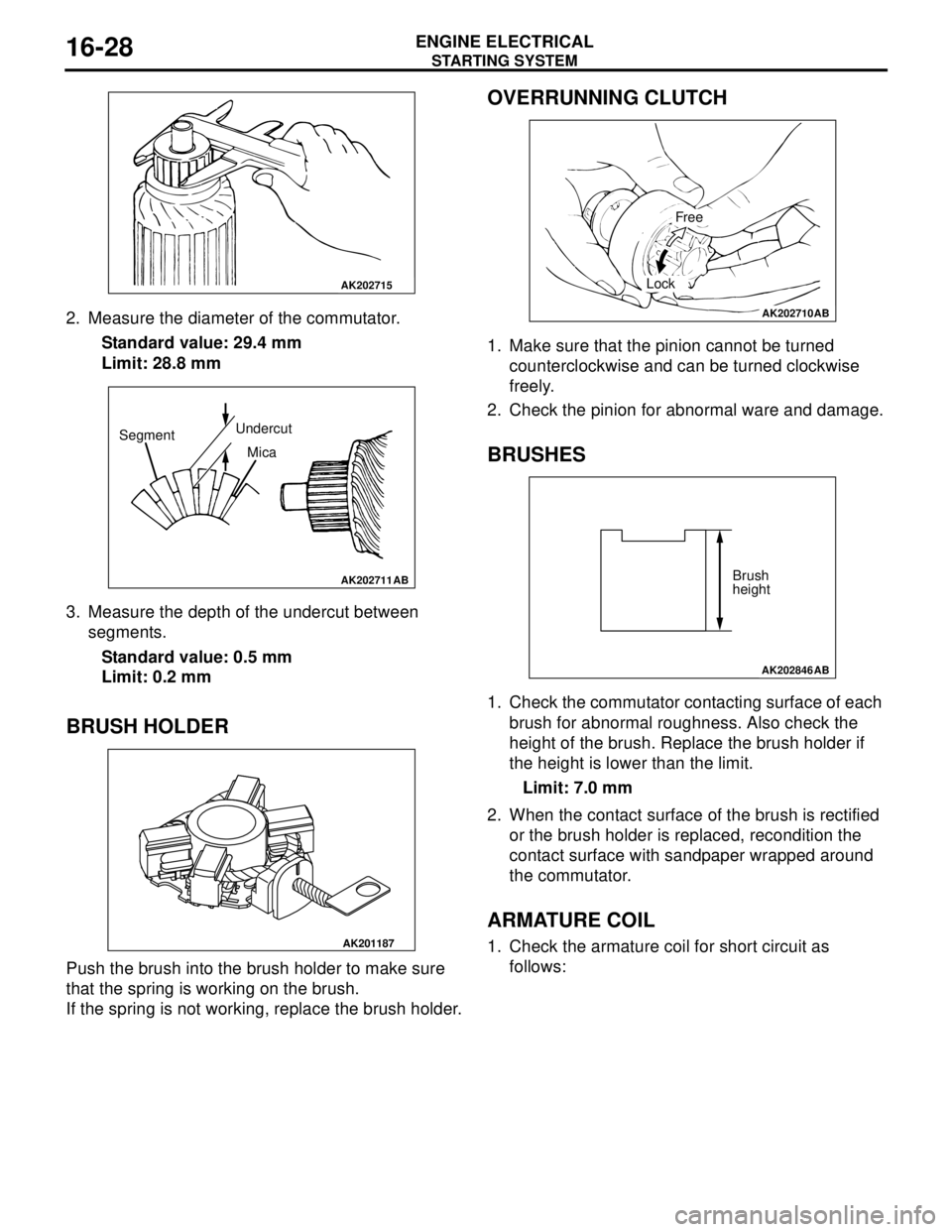

2. Measure the diameter of the commutator.

Standard value: 29.4 mm

Limit: 28.8 mm

3. Measure the depth of the undercut between

segments.

Standard value: 0.5 mm

Limit: 0.2 mm

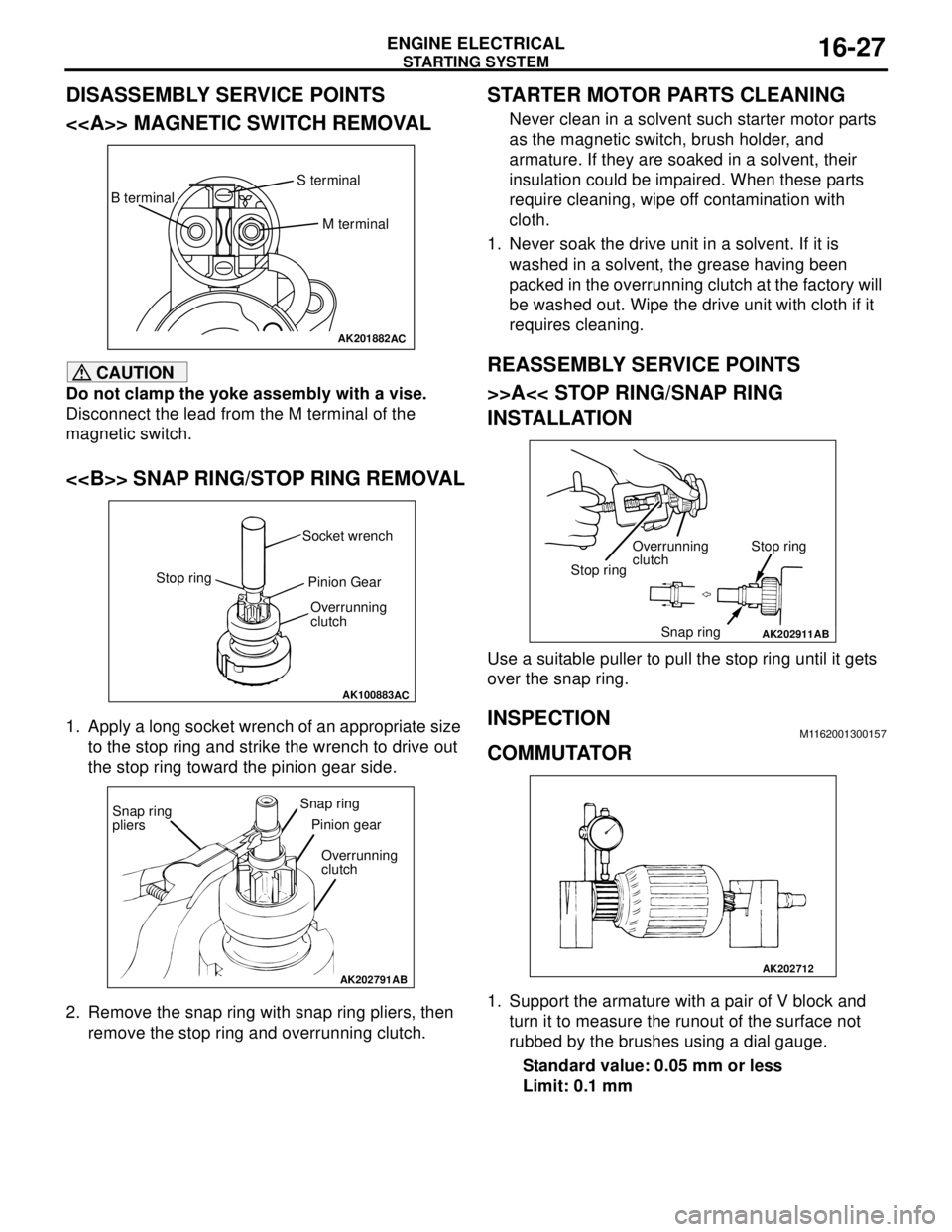

BRUSH HOLDER

Push the brush into the brush holder to make sure

that the spring is working on the brush.

If the spring is not working, replace the brush holder.

OVERRUNNING CLUTCH

1. Make sure that the pinion cannot be turned

counterclockwise and can be turned clockwise

freely.

2. Check the pinion for abnormal ware and damage.

BRUSHES

1. Check the commutator contacting surface of each

brush for abnormal roughness. Also check the

height of the brush. Replace the brush holder if

the height is lower than the limit.

Limit: 7.0 mm

2. When the contact surface of the brush is rectified

or the brush holder is replaced, recondition the

contact surface with sandpaper wrapped around

the commutator.

ARMATURE COIL

1. Check the armature coil for short circuit as

follows:

AK202715

AK202711

SegmentUndercut

Mica

AB

AK201187

AK202710

Free

Lock

AB

AK202846

Brush

height

AB

Page 93 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-29

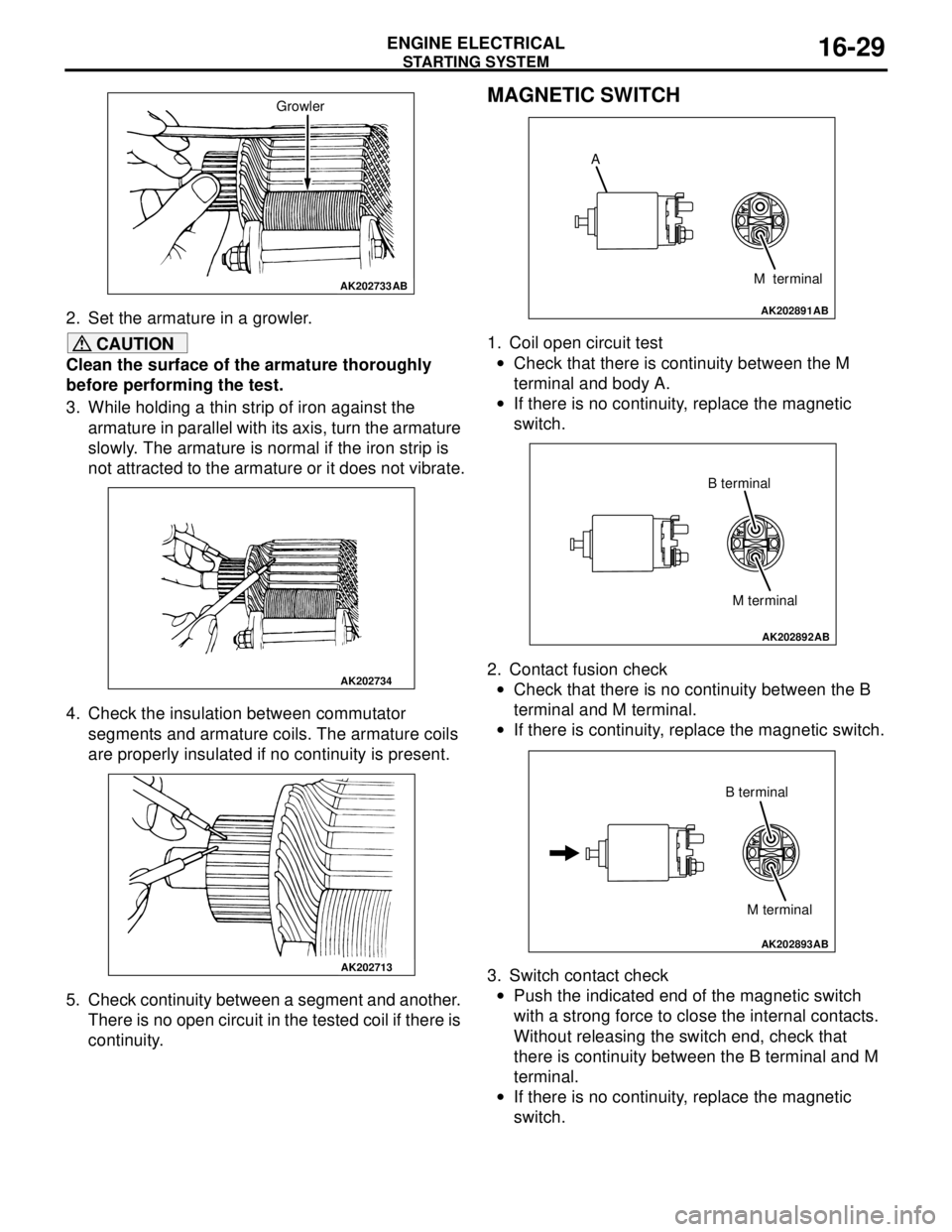

2. Set the armature in a growler.

CAUTION

Clean the surface of the armature thoroughly

before performing the test.

3. While holding a thin strip of iron against the

armature in parallel with its axis, turn the armature

slowly. The armature is normal if the iron strip is

not attracted to the armature or it does not vibrate.

4. Check the insulation between commutator

segments and armature coils. The armature coils

are properly insulated if no continuity is present.

5. Check continuity between a segment and another.

There is no open circuit in the tested coil if there is

continuity.

MAGNETIC SWITCH

1. Coil open circuit test

•Check that there is continuity between the M

terminal and body A.

•If there is no continuity, replace the magnetic

switch.

2. Contact fusion check

•Check that there is no continuity between the B

terminal and M terminal.

•If there is continuity, replace the magnetic switch.

3. Switch contact check

•Push the indicated end of the magnetic switch

with a strong force to close the internal contacts.

Without releasing the switch end, check that

there is continuity between the B terminal and M

terminal.

•If there is no continuity, replace the magnetic

switch.

AK202733

Growler

AB

AK202734

AK202713

AK202891

A

M terminal

AB

AK202892

M terminal B terminal

AB

AK202893

M terminal B terminal

AB