Engine electrical MITSUBISHI LANCER 2005 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 74 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

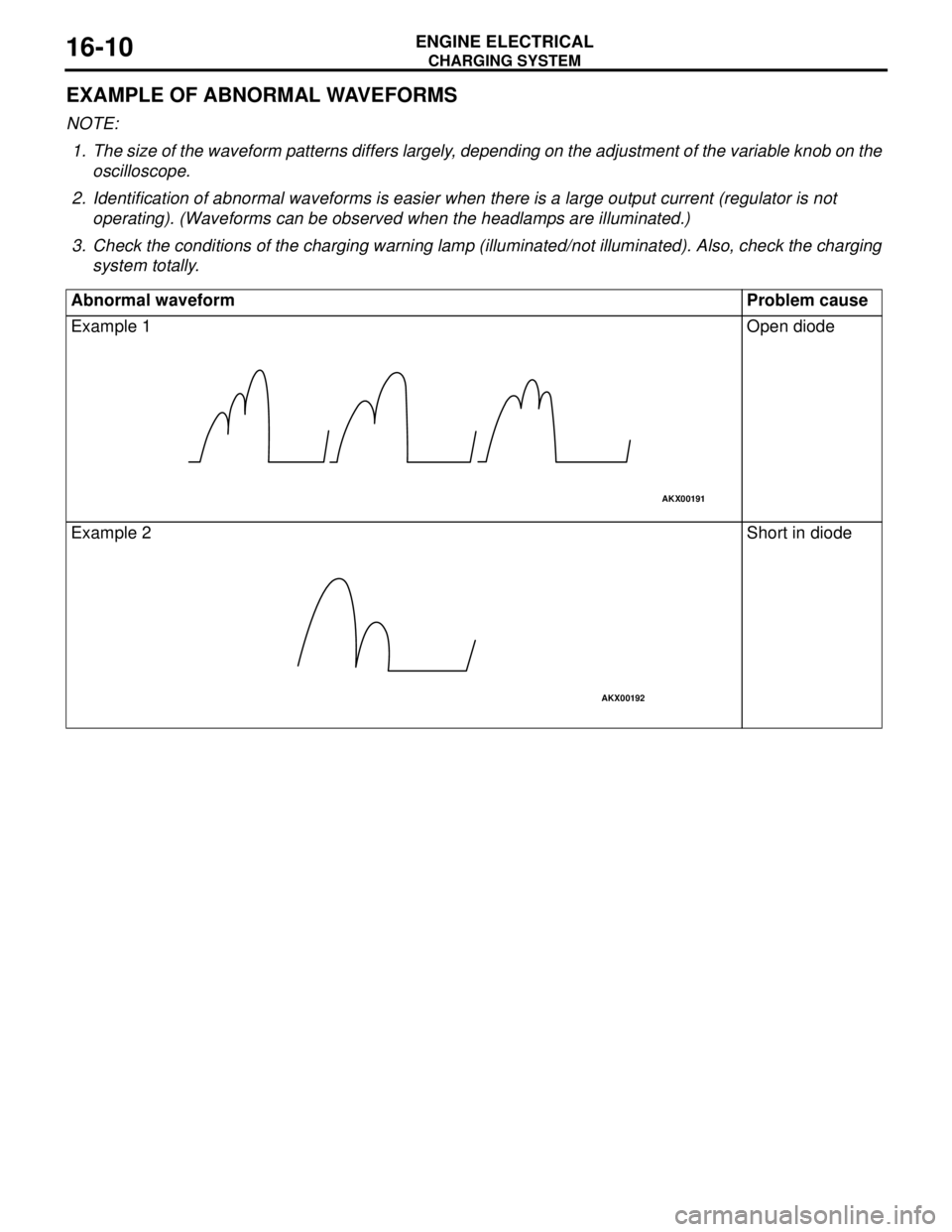

EXAMPLE OF ABNORMAL WAVEFORMS

NOTE: .

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob on the

oscilloscope.

2. Identification of abnormal waveforms is easier when there is a large output current (regulator is not

operating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illuminated). Also, check the charging

system totally.

Abnormal waveform Problem cause

Example 1 Open diode

Example 2 Short in diode

AKX00191

AKX00192

Page 75 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-11

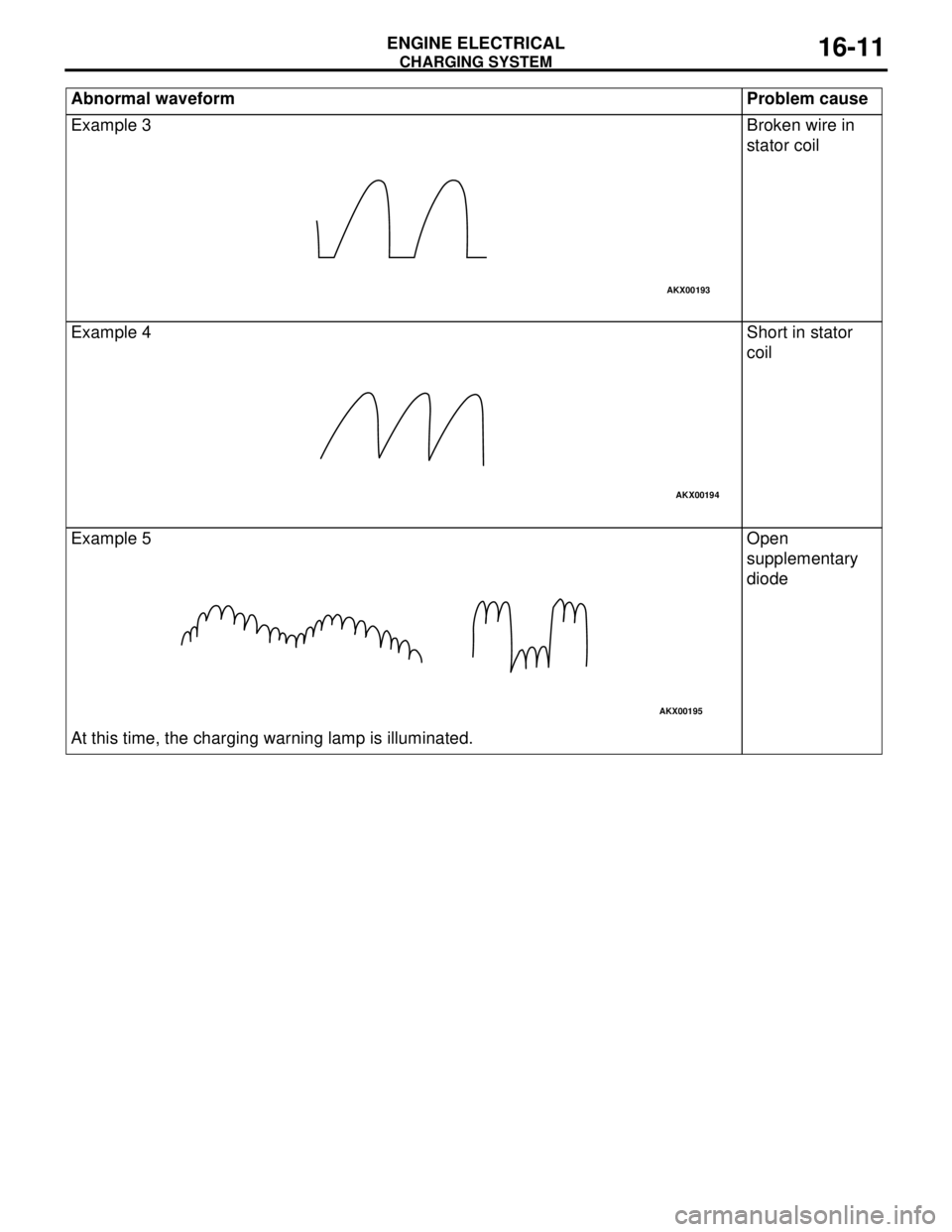

Example 3 Broken wire in

stator coil

Example 4 Short in stator

coil

Example 5

At this time, the charging warning lamp is illuminated.Open

supplementary

diode Abnormal waveform Problem cause

AKX00193

AKX00194

AKX00195

Page 76 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-12

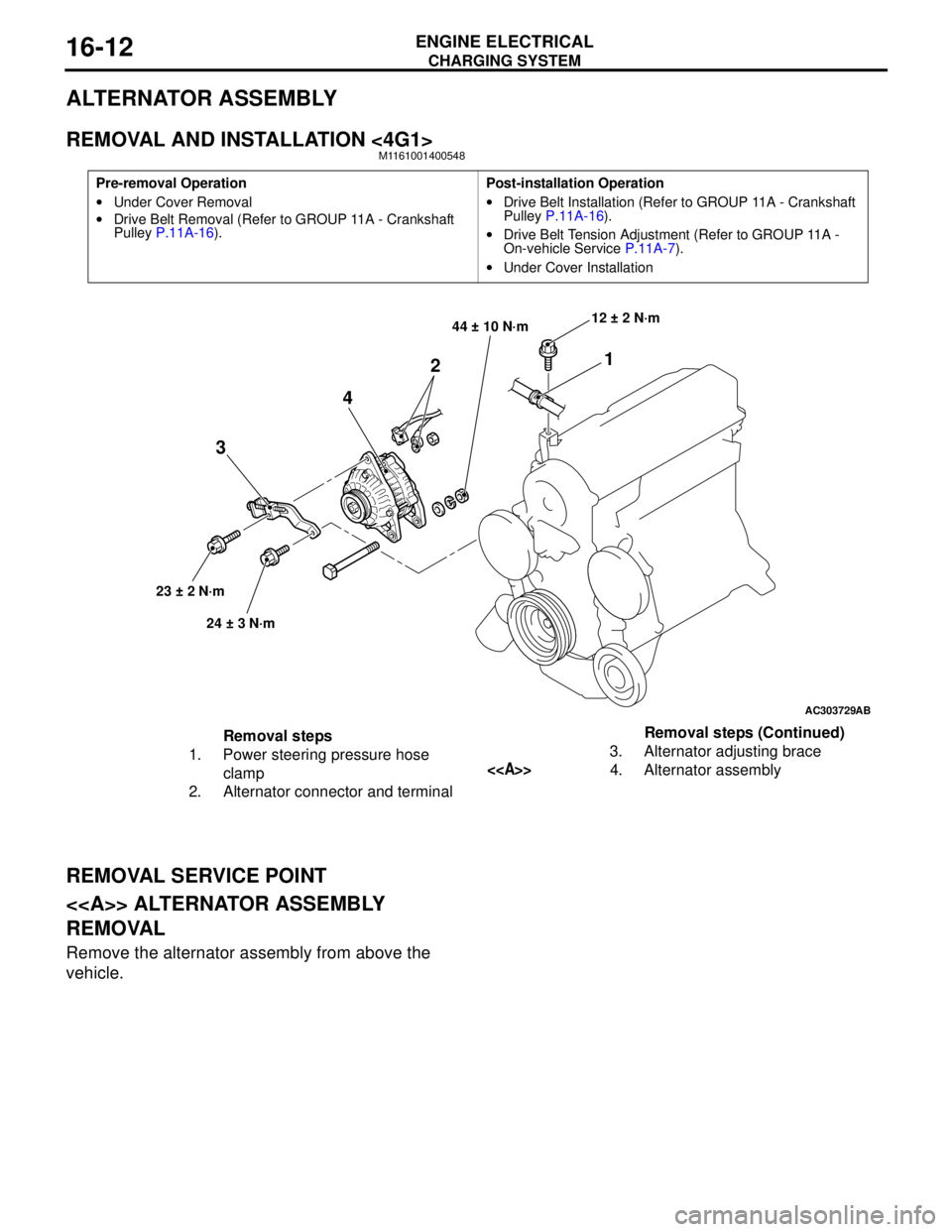

ALTERNATOR ASSEMBLY

REMOVAL AND INSTALLATION <4G1>M1161001400548

REMOVAL SERVICE POINT

<> ALTERNATOR ASSEMBLY

REMOVAL

Remove the alternator assembly from above the

vehicle.

Pre-removal Operation

•Under Cover Removal

•Drive Belt Removal (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).Post-installation Operation

•Drive Belt Installation (Refer to GROUP 11A - Crankshaft

Pulley P.11A-16).

•Drive Belt Tension Adjustment (Refer to GROUP 11A -

On-vehicle Service P.11A-7).

•Under Cover Installation

AC303729

1

2

4

3

44 ± 10 N·m

23 ± 2 N·m

24 ± 3 N·m12 ± 2 N·m

AB

Removal steps

1. Power steering pressure hose

clamp

2. Alternator connector and terminal3. Alternator adjusting brace

<>4. Alternator assemblyRemoval steps (Continued)

Page 77 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-13

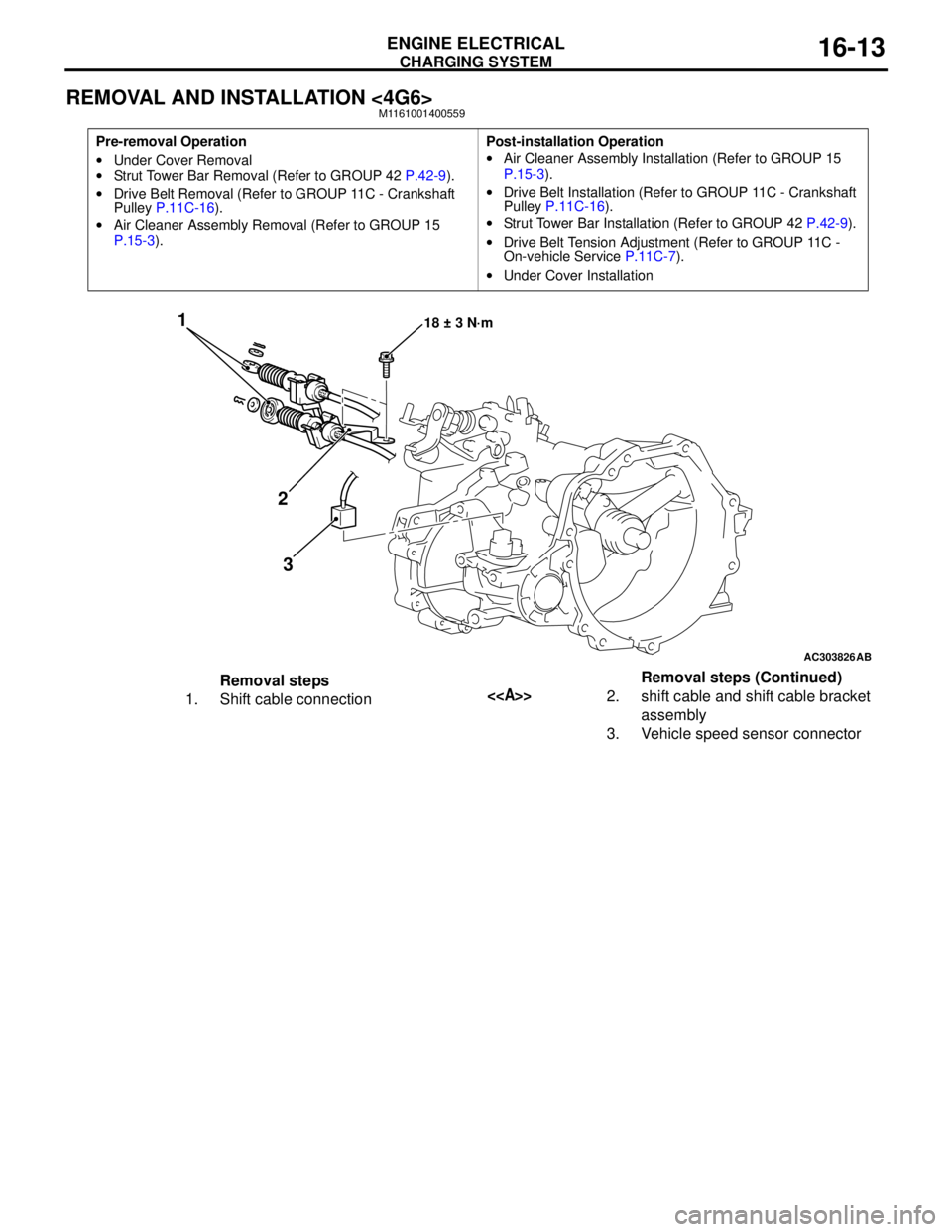

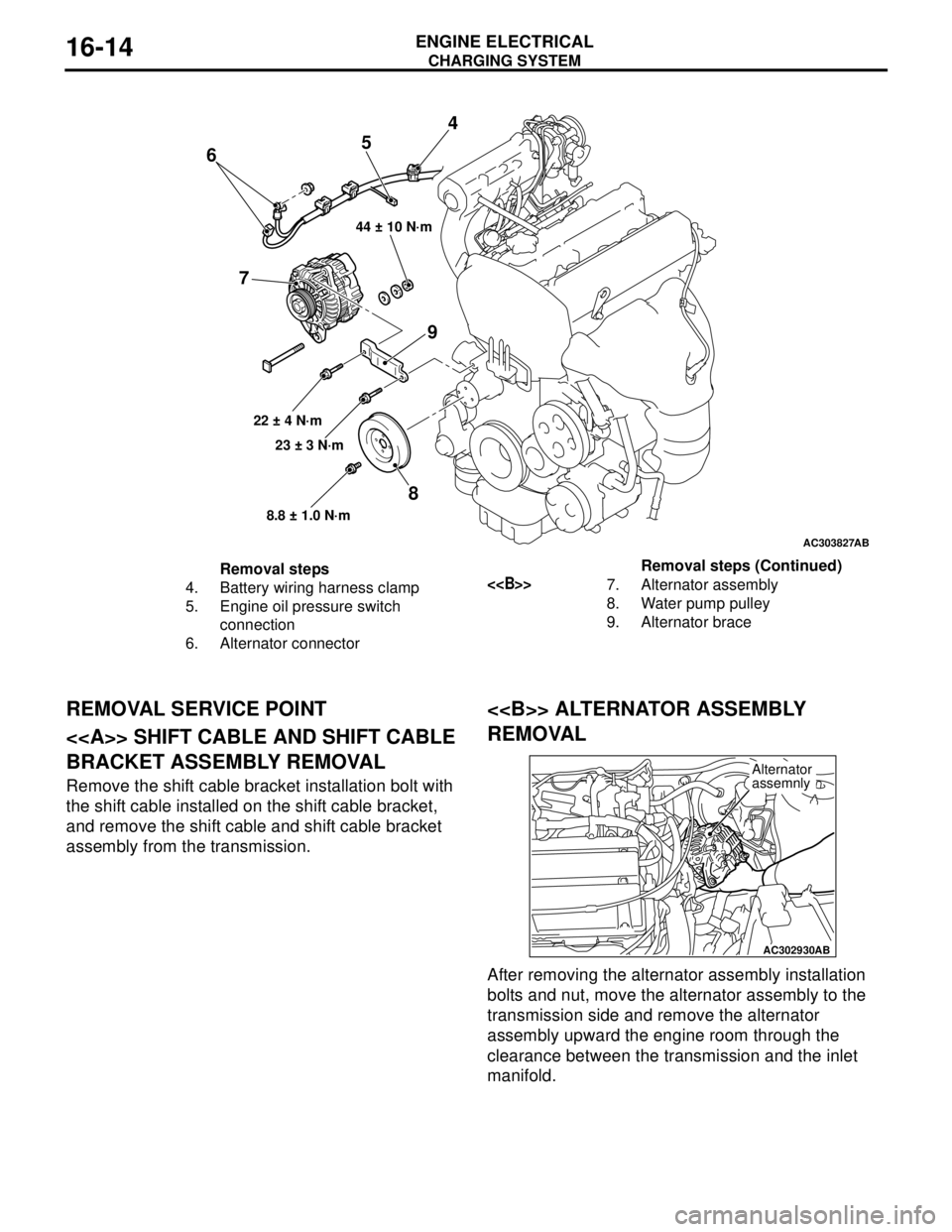

REMOVAL AND INSTALLATION <4G6>M1161001400559

Pre-removal Operation

•Under Cover Removal

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Drive Belt Removal (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Air Cleaner Assembly Removal (Refer to GROUP 15

P.15-3).Post-installation Operation

•Air Cleaner Assembly Installation (Refer to GROUP 15

P.15-3).

•Drive Belt Installation (Refer to GROUP 11C - Crankshaft

Pulley P.11C-16).

•Strut Tower Bar Installation (Refer to GROUP 42 P.42-9).

•Drive Belt Tension Adjustment (Refer to GROUP 11C -

On-vehicle Service P.11C-7).

•Under Cover Installation

AC303826

1

2

318 ± 3 N·m

AB

Removal steps

1. Shift cable connection<>2. shift cable and shift cable bracket

assembly

3. Vehicle speed sensor connectorRemoval steps (Continued)

Page 78 of 788

Page 79 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-15

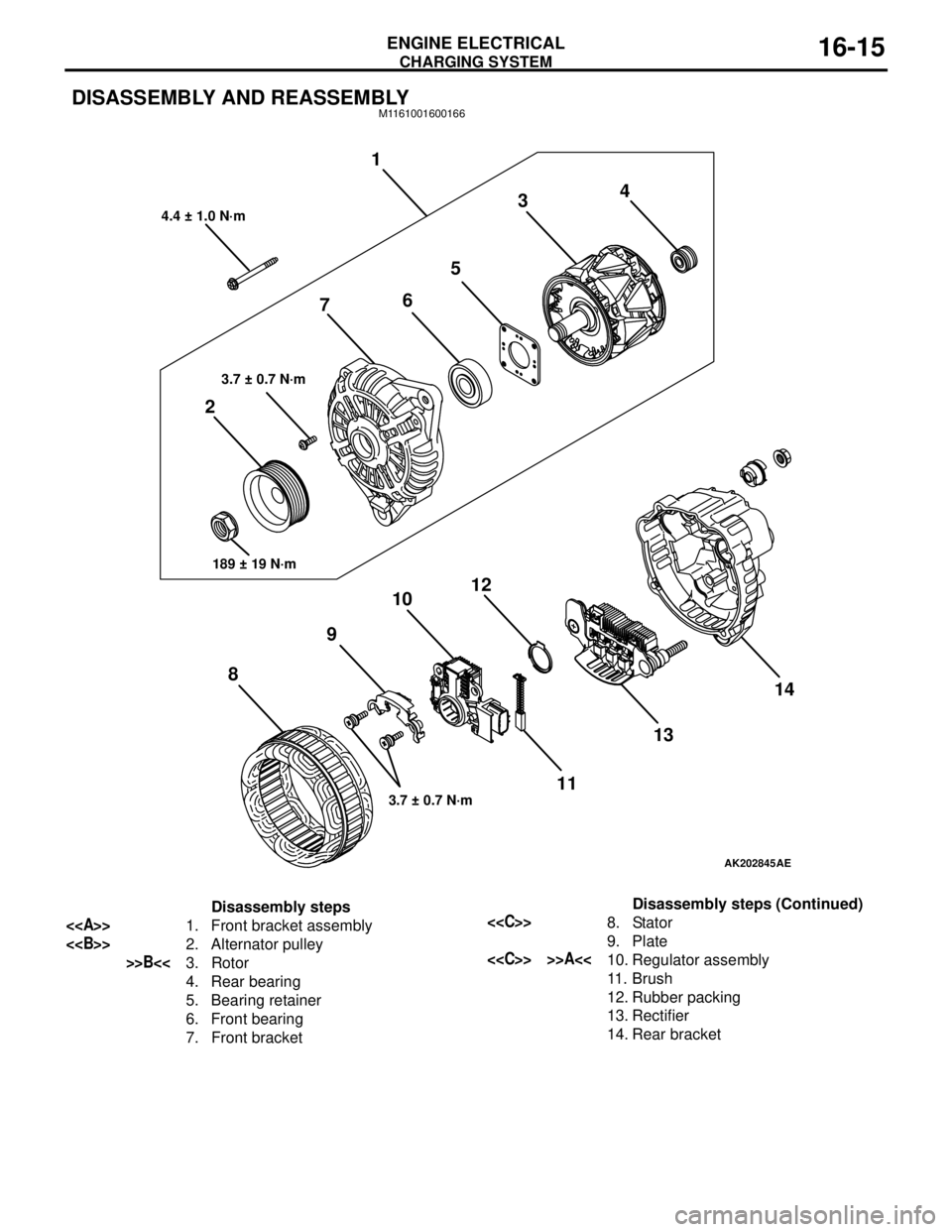

DISASSEMBLY AND REASSEMBLYM1161001600166

AK202845

1

234

5

6

7

8910

11 12

1314

AE

4.4 ± 1.0 N·m

3.7 ± 0.7 N·m

189 ± 19 N·m

3.7 ± 0.7 N·m

Disassembly steps

<>1. Front bracket assembly

<>2. Alternator pulley

>>B<<3. Rotor

4. Rear bearing

5. Bearing retainer

6. Front bearing

7. Front bracket

<

9. Plate

<

11 . B r u s h

12. Rubber packing

13. Rectifier

14. Rear bracketDisassembly steps (Continued)

Page 80 of 788

Page 81 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-17

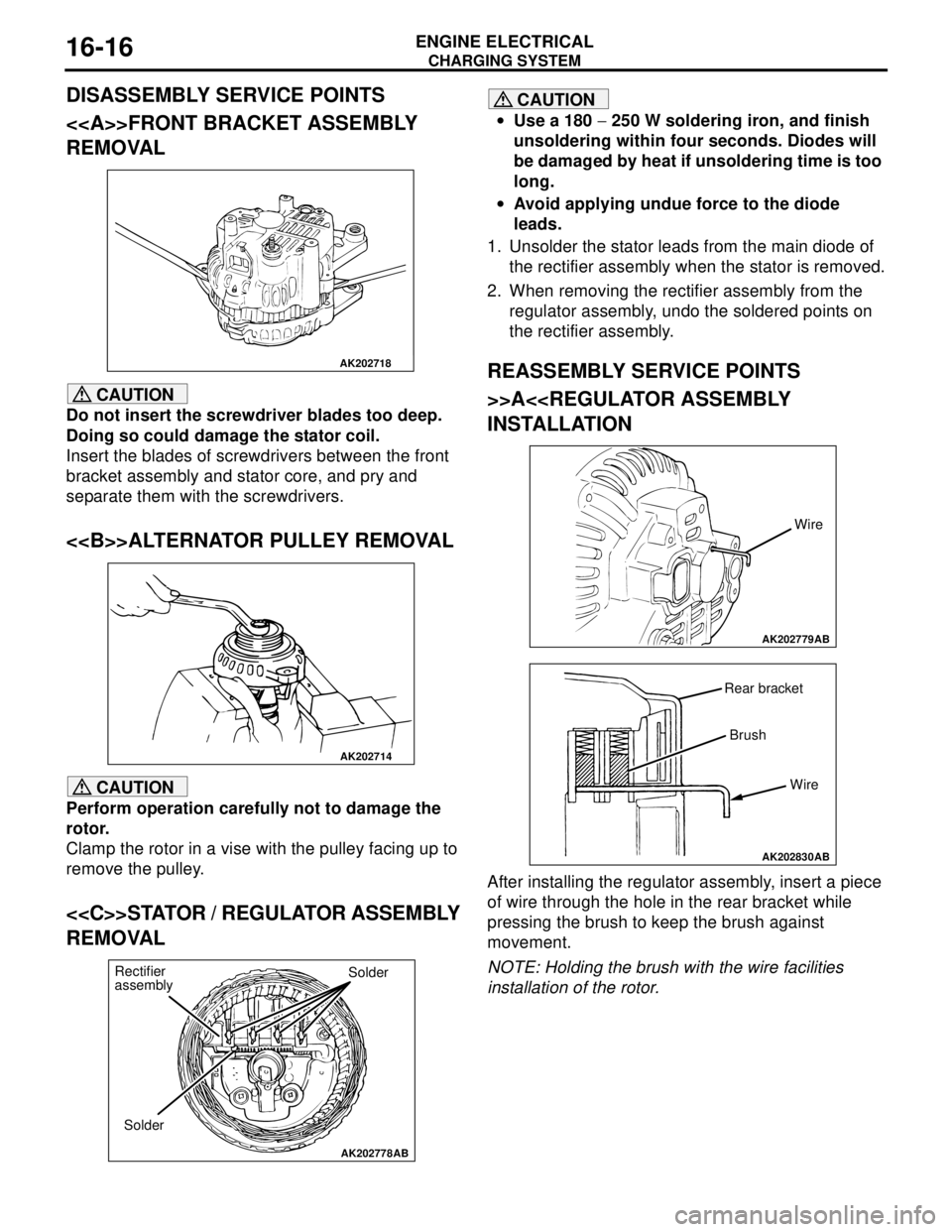

>>B<< ROTOR INSTALLATION

Remove the brush holding wire after the rotor has

been installed.

INSPECTION M1161001700152

ROTOR

1. Measure the resistance between the two slip rings

of the rotor coil to check the continuity between

them.

Replace the rotor if the resistance is not within the

standard value range.

Standard value: 3 − 5 Ω

2. Check the continuity between the slip rings and

core.

3. If continuity is present, replace the rotor.

STATOR

1. Check the continuity between coil leads.

If there is no continuity, replace the stator.

2. Check the continuity between coil and core.

If there is no continuity, replace the stator.

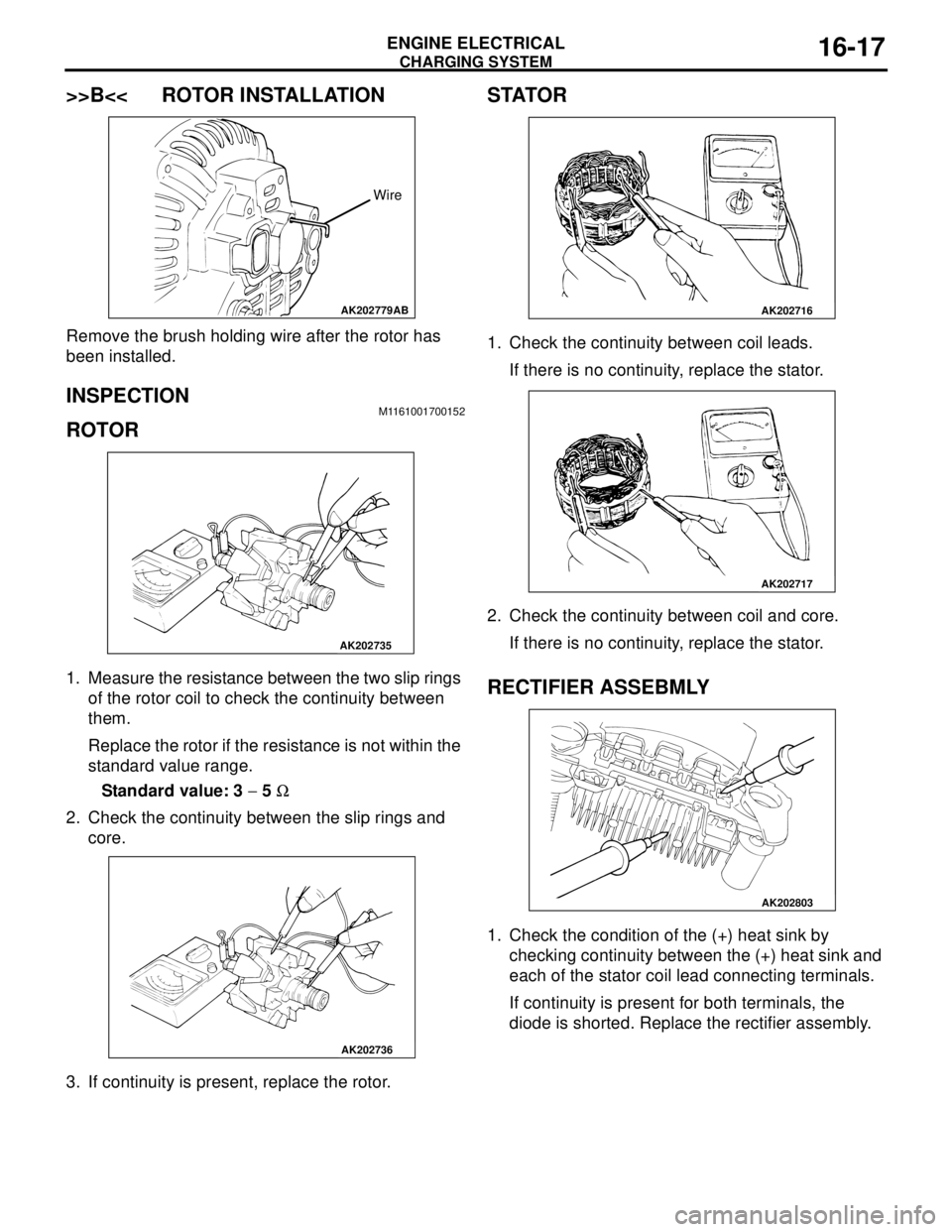

RECTIFIER ASSEBMLY

1. Check the condition of the (+) heat sink by

checking continuity between the (+) heat sink and

each of the stator coil lead connecting terminals.

If continuity is present for both terminals, the

diode is shorted. Replace the rectifier assembly.

AK202779

Wire

AB

AK202735

AK202736

AK202716

AK202717

AK202803

Page 82 of 788

CHARGING SYSTEM

ENGINE ELECTRICAL16-18

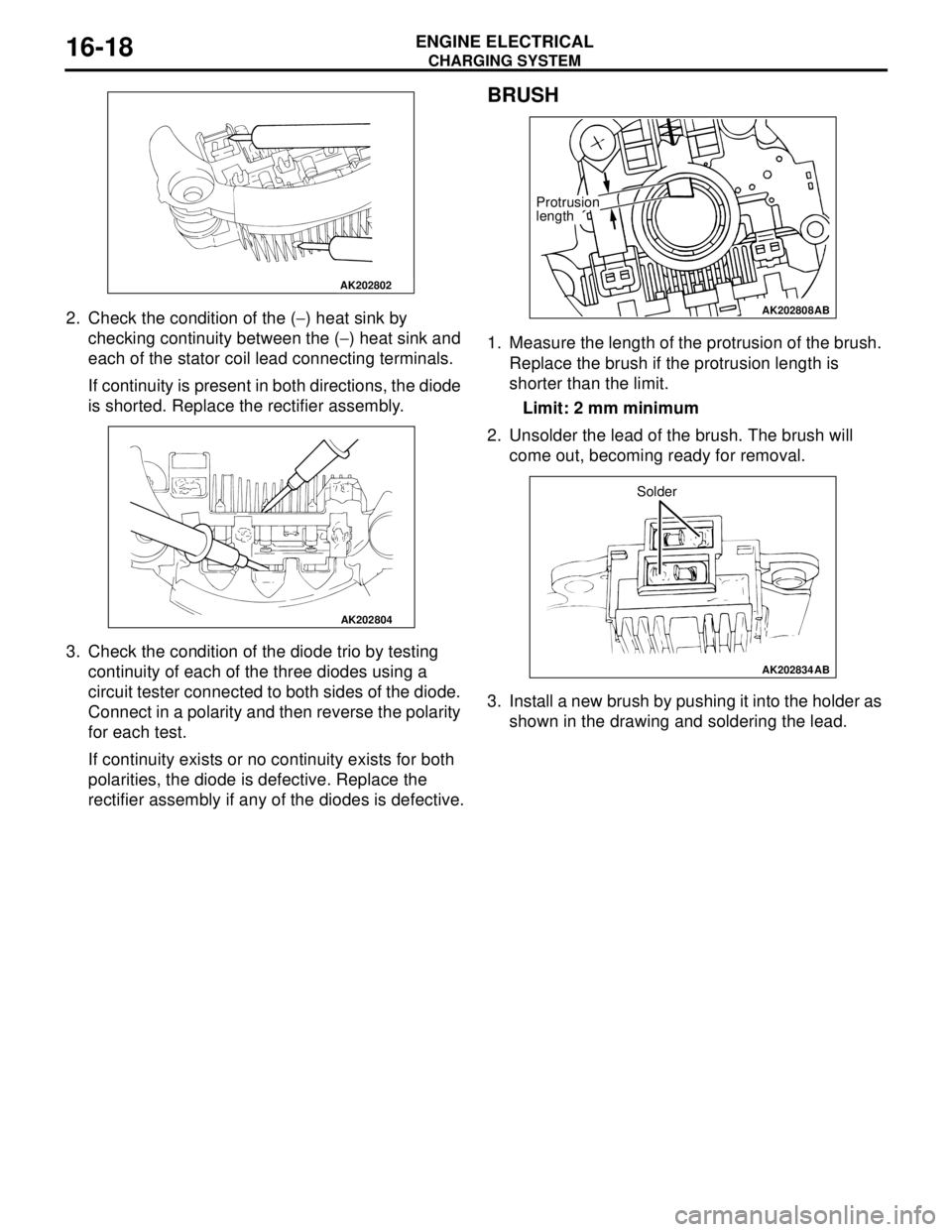

2. Check the condition of the (−) heat sink by

checking continuity between the (−) heat sink and

each of the stator coil lead connecting terminals.

If continuity is present in both directions, the diode

is shorted. Replace the rectifier assembly.

3. Check the condition of the diode trio by testing

continuity of each of the three diodes using a

circuit tester connected to both sides of the diode.

Connect in a polarity and then reverse the polarity

for each test.

If continuity exists or no continuity exists for both

polarities, the diode is defective. Replace the

rectifier assembly if any of the diodes is defective.

BRUSH

1. Measure the length of the protrusion of the brush.

Replace the brush if the protrusion length is

shorter than the limit.

Limit: 2 mm minimum

2. Unsolder the lead of the brush. The brush will

come out, becoming ready for removal.

3. Install a new brush by pushing it into the holder as

shown in the drawing and soldering the lead.

AK202802

AK202804

AK202808

Protrusion

length

AB

AK202834

Solder

AB

Page 83 of 788

STARTING SYSTEM

ENGINE ELECTRICAL16-19

STARTING SYSTEM

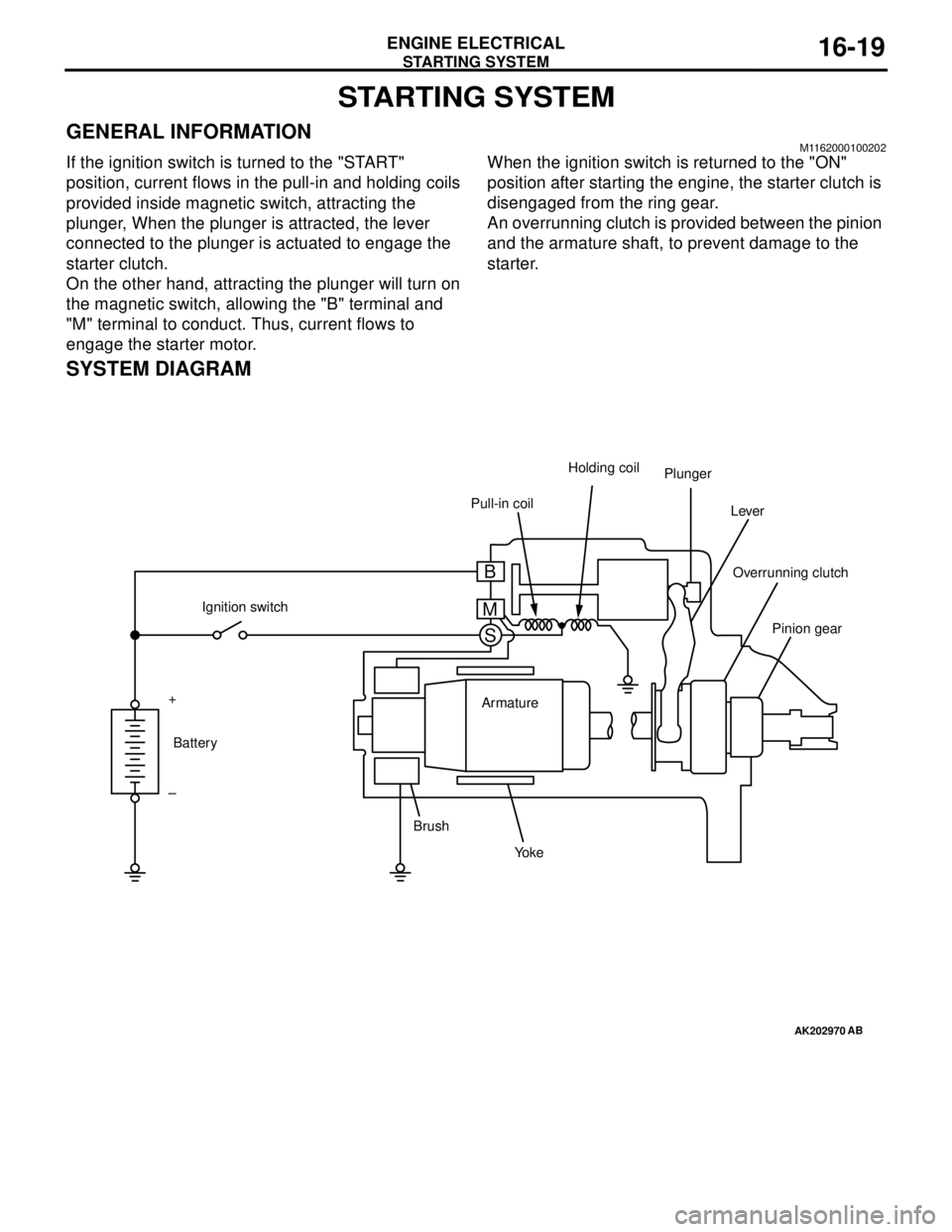

GENERAL INFORMATIONM1162000100202

If the ignition switch is turned to the "START"

position, current flows in the pull-in and holding coils

provided inside magnetic switch, attracting the

plunger, When the plunger is attracted, the lever

connected to the plunger is actuated to engage the

starter clutch.

On the other hand, attracting the plunger will turn on

the magnetic switch, allowing the "B" terminal and

"M" terminal to conduct. Thus, current flows to

engage the starter motor.When the ignition switch is returned to the "ON"

position after starting the engine, the starter clutch is

disengaged from the ring gear.

An overrunning clutch is provided between the pinion

and the armature shaft, to prevent damage to the

starter.

SYSTEM DIAGRAM

AK202970

Pull-in coilHolding coil

Plunger

Lever

Pinion gear Overrunning clutch

Yo k e BrushArmature Ignition switch

Battery +

–

AB

B

M

S