wiper MITSUBISHI LANCER 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 364 of 800

Wiper blade assembly removal steps

>>B<<1.Wiper blade assembly

>>A<<2.Wiper blade

Windshield wiper motor and link

assembly removal steps

3.Cover

4.Wiper arm

5.Hood weather strip

6.Front deck garnish (passenger's side)

7.Front deck garnish (driver's side)

<>8.Windshield wiper motor assembly

9.Link assembly

Washer hose removal steps

•Front splash shield (Refer to GROUP

42, Fender

P.42-6)

10.Rear washer hose

11 .Front washer hose

Windshield washer nozzle removal

steps

•Connection of front washer hose

11 .Washer nozzle

Washer tank and washer motor

removal steps

•Side undercover (RH)

•Front splash shield (Refer to GROUP

42, Fender

P.42-6)

•Connection of front washer hose and

rear washer hose

12.Washer tank assembly

13.Front washer motor

14.Rear washer motor

WINDSHIELD W I PER AND W A SHER

EXTERIOR51-32

NOTE: For re moval a nd in st allation of the wiper an d

washer switch, refer to GROUP 54A, Colu mn switch

P.5 4 A - 89.

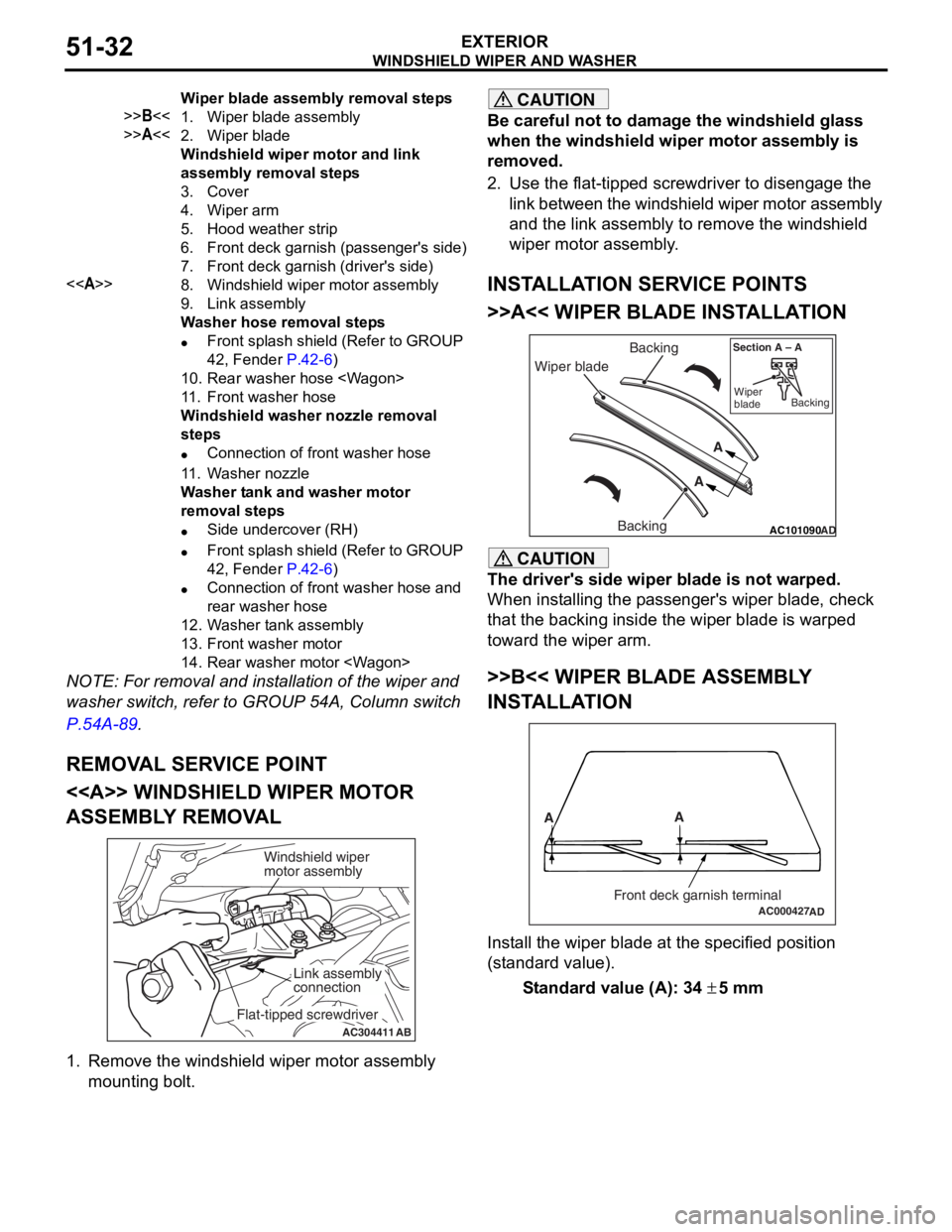

REMOV A L SER V ICE POINT

<> WI NDSHIELD W I PER MOT O R

ASSEMBL

Y REMOV A L

AC304411AB

Windshield wiper

motor assembly

Link assembly

connection

Flat-tipped screwdriver

1.

Remove the win d shield wiper motor asse mbly

mounting bo lt.

CAUTION

Be careful not to damage the windshield glass

when the windshield wiper motor assembly is

removed.

2. Use the flat-tipped screwdriver to disengage the link between the windshield wiper motor assembly

and the link assembly to remove the windshield

wiper motor assembly.

INSTALLATION SERVICE POINTS

>>A<< WIPER BLADE INSTALLATION

AC101090 AD

Wiper blade Backing

Backing A

A

Section A – A

Wiper

blade Backing

CAUTION

The driver's side wiper blade is not warped.

When installing the passenger's wiper blade, check

that the backing inside the wiper blade is warped

toward the wiper arm.

>>B<< WIPER BLADE ASSEMBLY

INSTALLATION

AC000427

A

A

Front deck garnish terminalAD

Install the wiper blade at the specified position

(standard value).

Standard value (A): 34 ± 5 mm

Page 365 of 800

WINDSHIELD WIPER AND WASHER

EXTERIOR51-33

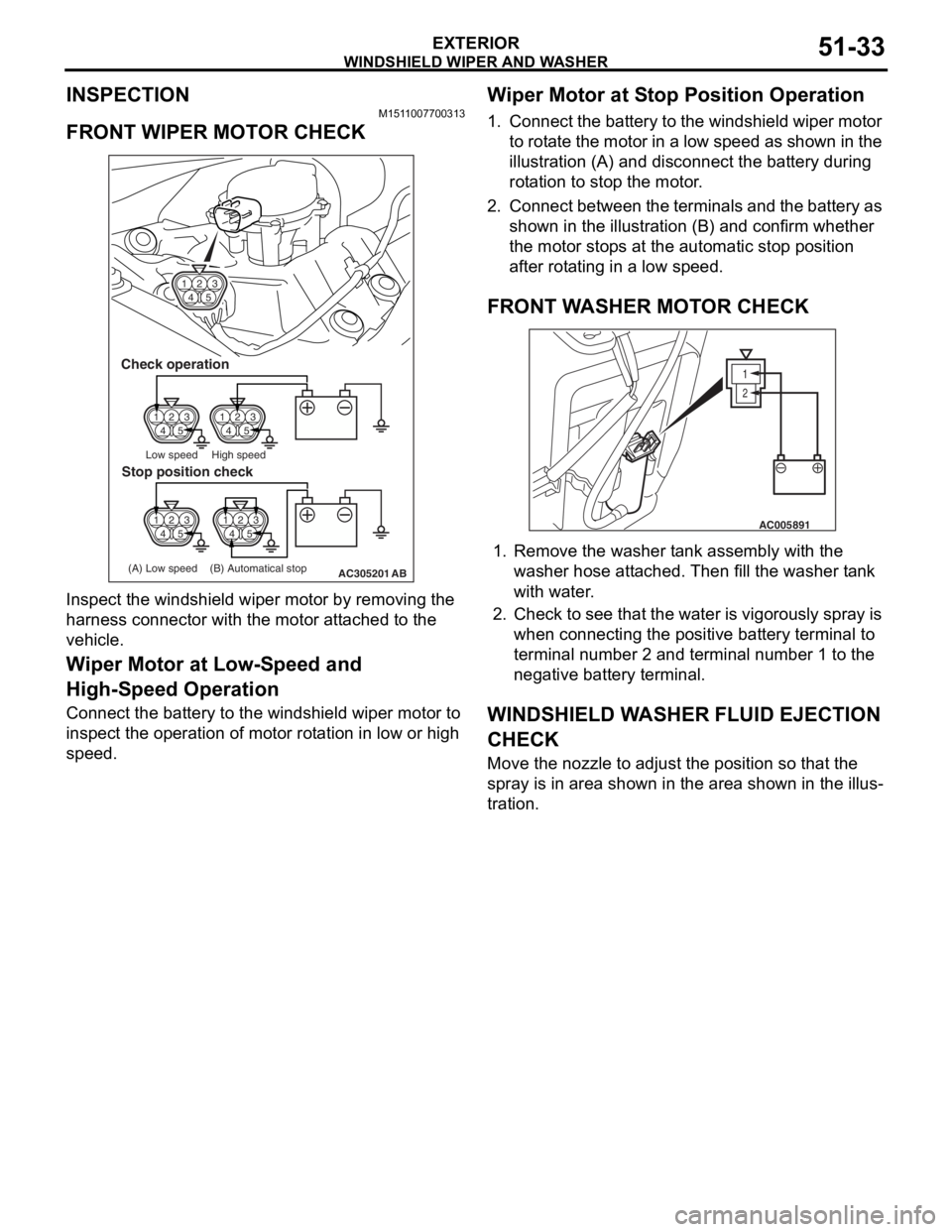

INSPECTION

M1511007700313

FRONT WIPER MOTOR CHECK

14 23

5

14 23

514 23

5

14 23

5

AC305201

14 23

5

Check operation

Low speed High speed

(A) Low speed (B) Automatical stop

Stop position check

AB

Inspe c t th e windshie l d wipe r mot o r by removing the

harness connector wit

h the motor a t t a ched to the

vehicle

.

Wiper Motor at Low-S peed and

High-S

peed Operation

Connect the ba ttery to the windsh i eld wiper motor to

insp

ect the ope ration of motor rot a tion in low or high

spee

d.

Wiper Motor at S t op Position Operation

1.Conn ect t he batt e ry to the wind shield wip e r mot o r

to rot a te th e motor in a low sp eed a s shown in the

illu stration (A) an d disco nnect the ba ttery durin g

ro t a tion to stop the motor .

2.Co nn ect b e t w ee n t h e te rmin als an d the b a tt ery as

shown in the illu strat i on (B) a nd co nfirm whether

th e mo tor sto p s at th e auto m atic stop po sition

a f ter rot a ting in a low sp eed.

FRONT WA SHER MOT O R CHECK

1

2

AC005891

1.Remove t he wash er t ank assembly wit h the

washer hose att a ched. T hen fill t he wash er t ank

with wa ter .

2.Check to see that th e wa ter is vigo rously sp ray is

when conn ecting the positive batt e ry te rmin al to

termina l number 2 and te rmin al nu mber 1 to th e

neg ative batt e ry te rmin al.

WI NDSHIELD W A SHER FLUID EJECTION

CHECK

Move the nozzle to adjust th e position so that th e

spray is in a

r ea shown in the are a sh own in t he illus

-

tration.

Page 366 of 800

AC304420

305

70

25

55 140

100

120 115

305 300

600

3002525

25

25

25

25

25

55

6560

50

60

50

AB

Windshield washer

nozzle perpendicular

Windshield washer

nozzle perpendicular

Windshield washer nozzle

Ceramic line terminal

UNITS: mm

WINDSHIELD WI PER AND W A SHER

EXTERIOR51-34

WI NDSHIELD W I PER AND WINDSHIELD

W

A SHER SWIT CH CHECK

1

6

8

11 10 9 7

5 4

3

2

AC000417

Che

c k cont inuity be tween th e switch ter m in als.

Switch positionTester

connectionSpecified

condition

OFF6 − 11 , 6 − 10,

6 − 9, 6 − 8, 6 −

7

Open circuit

Windshield mist

wiper switch6 − 11Less than 2

ohms

Windshield

intermittent wiper

switch6 − 10

Windshield

low-speed wiper

switch6 − 9

Windshield

high-speed wiper

switch6 − 8

Windshield

washer switch6 − 7

Page 367 of 800

REAR WIPER AND WASHER

EXTERIOR51-35

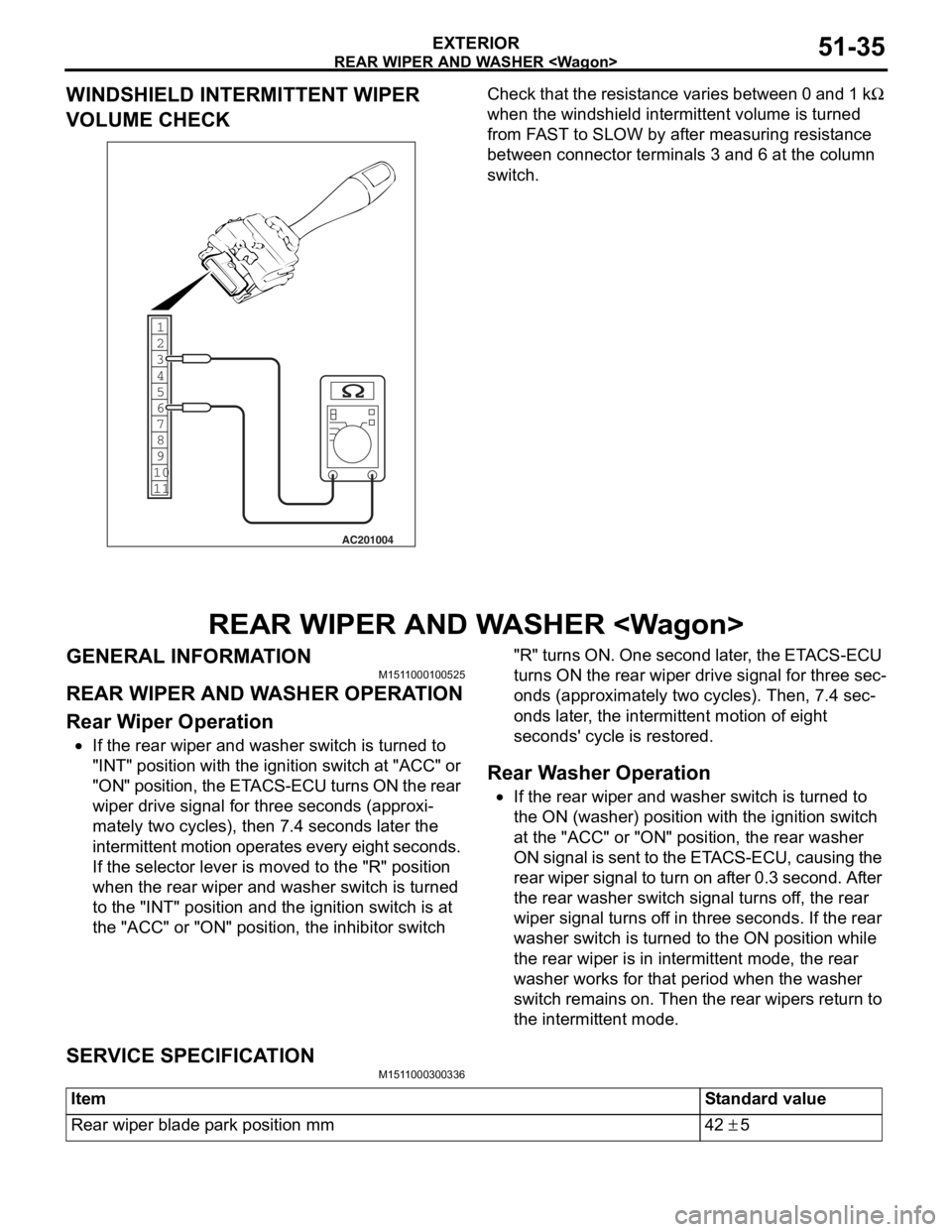

WINDSHIELD INTERMITTENT WIPER

VOLUME CHECK

1

6

8

11 10 9 7 5 4 3

2

AC201004

Ch

eck tha t the resist ance varie s between 0 a nd 1 kΩ

wh

en the

windshield int

e

rmittent volume is turn

ed

from F

A

ST

to SLOW by a

f

te

r mea

s

uring resist

an

ce

between conne

ctor

terminals 3 an

d 6 at

the column

switc

h

.

REAR WIPER AND W A SHER

GENERAL INFORMAT IONM151 1 0001 0052 5

REAR WIPER AND W A SHER OPERA T ION

Rear W i p e r O p eration

•If the rear wiper and washe r switch is turne d to

"INT" position

wit h th e ignition switch at "ACC" or

"ON" po

siti on, t he ET ACS-ECU t u rn s ON t he re ar

wipe

r drive signal for thre e se cond s (ap p roxi

-

mately two cycles), then 7 . 4 se cond s la ter the

int

e rmit tent mot i on o perates every eigh t seco nds.

If th

e se lector lever is moved to the "R" p o sition

when t

he rear wiper an d washe r switch is turn ed

to t

he "INT" position an d the ignit i on switch is at

the

"ACC" or "ON" positio n, the inhibito r switch "R" tu rns ON. One second late r , the ET ACS-ECU

turn s ON th e rear wip e r drive signal for thre e sec

-

ond

s (ap p roximat e ly two cycle s ). Th en, 7.4 sec-

onds later , th e inte rmittent motio n of eight

sec

o nds ' cy cle is restored.

Rear W a sher Operatio n

•If the rear wiper and washe r switch is turne d to

the

ON (washer) position wi th the ignition switch

at t

he "ACC" or "ON" po sit i on, t he rear wa sher

ON signal is sent to the ET

ACS-ECU, causing the

re

ar wipe r sign al to tu rn on a f ter 0 . 3 seco nd . Af te r

the

rear washer switch sign al tu rns o f f, the rear

wipe

r signa l t u rns of f in thre e seco nds. If the rear

washer switch is tu

rned to the ON position while

the

rear wipe r is in intermitten t mod e , the rear

washer works for th

at period when the washer

switch

rema ins on. Then the rea r wipe rs ret u rn to

the

intermitte nt mode.

SERV ICE SPECIFICA T ION

M151 1 0003 0033 6

ItemStandard value

Rear wiper blade park position mm42 ± 5

Page 368 of 800

REAR WIPER AND WASHER

EXTERIOR51-36

TROUBLESHOOTING

M1511000700334

The rear wiper and washer are controlled by the

Smart Wiring System (SWS). For troubleshooting,

refer to GROUP 54B, Troubleshooting

P.54B-15 or

GROUP 54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

M1511000800472

CHECK OF REAR WIPER OPERATION

WHEN SELECTOR LEVER IS AT THE "R"

POSITION

1. When the selector lever is moved to the "R" position with the rear wiper switch at the "INT"

position, the wiper should operate twice or three

times at low speed after approximately one

second.

2. If not, carry out the troubleshooting (Refer to GROUP 54B, Troubleshooting

P.54B-15 or

GROUP 54C, Troubleshooting P.54C-4).

REAR WIPER AND WASHER

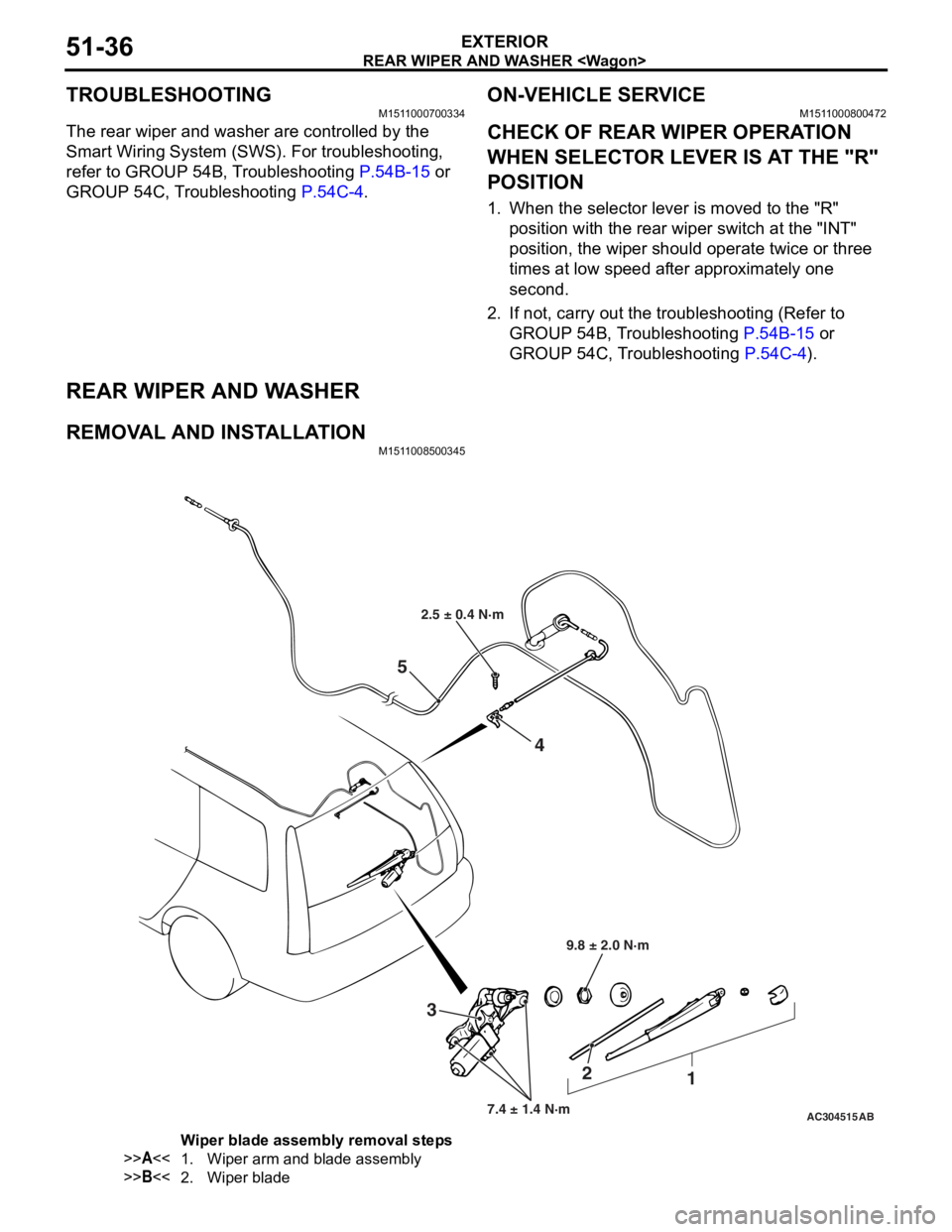

REMOVAL AND INSTALLATIONM1511008500345

AC304515

2.5 ± 0.4 N·m

9.8 ± 2.0 N·m

7.4 ± 1.4 N·m

3 2

1

4

5

AB

Wiper blade assembly removal steps

>>A<<1.Wiper arm and blade assembly

>>B<<2.Wiper blade

Page 369 of 800

Rear wiper motor removal steps

•Tailgate trim lower (Refer to GROUP

52A, Tailgate trim

P.52A-21.)

•Tailgate waterproof film (Refer to

GROUP 42, Tailgate

P.42-48.)

3.Rear wiper motor assembly

Rear washer nozzle removal steps

•High-mounted stop lamp assembly

(Refer to GROUP 54A, High-mounted

stop lamp

P.54A-84.)

4.Rear washer nozzle

Washer hose removal steps

•Front scuff plate, rear scuff plate, cowl

side trim and quarter trim (Refer to

GROUP 52A, Trims

P.52A-13.)

•Tailgate lower trim, tailgate proof film

(Refer to GROUP 52A, Tailgate trim

P.52A-21.)

•High-mounted stop lamp assembly

(Refer to GROUP 54A, High-mounted

stop lamp

P.54A-84.)

5.Rear washer hose

REAR WIPE R AN D W A SHER

EXTERIOR51-37

NOTE: For re moval a nd in st allation of the wiper an d

washer switch, refer to GROUP 54A, Colu mn switch

P.5 4 A - 89.

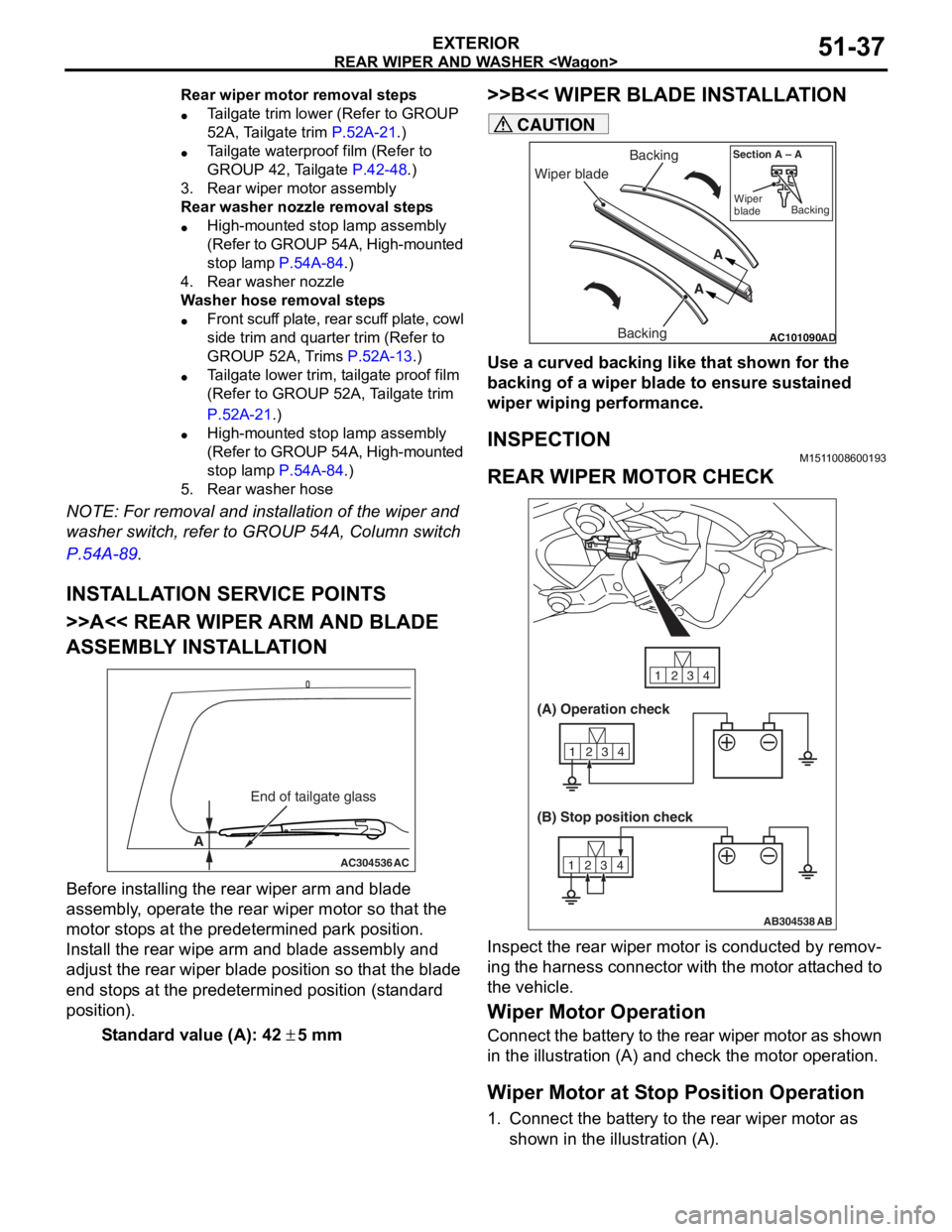

INSTALLA T ION SER VICE POINT S

>>A<< REAR WIPER ARM AND BLADE

ASSEMBL

Y INST ALLA TION

AC304536

A

AC

End of tailgate glass

Before inst alling the rear wiper arm and blad e

assembly

, ope rate the rear wip e r mo tor so that th e

motor stop

s at the predete r min ed p a rk position .

Inst

all the re ar wipe arm a nd blade assembly and

adjust the

rear wipe r blad e positio n so t hat the blad e

end stop

s at the pre determined positio n (st anda rd

position

) .

St andard va lue (A): 42 ± 5 mm

>>B<< W I PER BLADE INST ALLA TION

AC101090AD

Wiper blade Backing

Backing A

A

Section A – A

Wiper

blade Backing

CAUTION

Use a curved backing like that shown for the

backing of a wiper blade to ensure sustained

wiper wiping performance.

INSPECTION

M1511008600193

REAR WIPER MOTOR CHECK

AB304538

1234

1234

1234

AB

(A) Operation check

(B) Stop position check

Inspect the rear wiper motor is conducted by remov-

ing the harness connector with the motor attached to

the vehicle.

Wiper Motor Operation

Connect the battery to the rear wiper motor as shown

in the illustration (A) and check the motor operation.

Wiper Motor at Stop Position Operation

1. Connect the battery to the rear wiper motor as

shown in the illustration (A).

Page 370 of 800

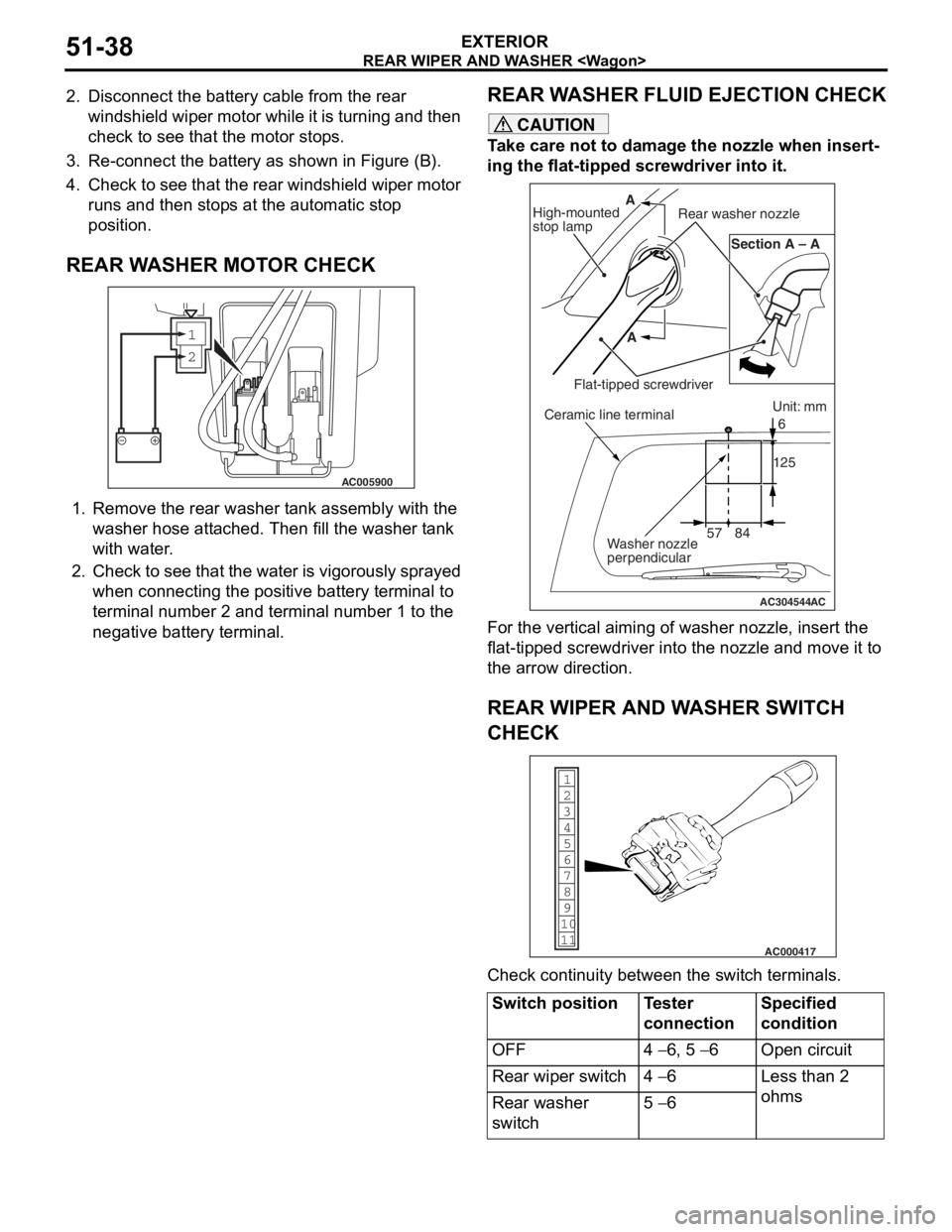

REAR WIPER AND WASHER

EXTERIOR51-38

2. Disconnect the battery cable from the rear windshield wiper motor while it is turning and then

check to see that the motor stops.

3. Re-connect the battery as shown in Figure (B).

4. Check to see that the rear windshield wiper motor runs and then stops at the automatic stop

position.

REAR WASHER MOTOR CHECK

1

2

AC005900

1.Remo ve th e rear washer t ank assembly with th e

wash er hose att a ched. T hen fill t he wash er t ank

with wa ter .

2.Check to see t hat t he wate r is vigor ously spra yed

when conn ecting the positive batt e ry te rmin al to

termina l number 2 and te rmin al nu mber 1 to th e

neg ative batt e ry te rmin al.

REAR WA SHER FLUI D EJECTION CHECK

CAUTION

Take care not to damage the nozzle when insert-

ing the flat-tipped screwdriver into it.

AC304544AC

Unit: mm

57 84 125

6

Section A – A

A

A

High-mounted

stop lamp Rear washer nozzle

Flat-tipped screwdriverCeramic line terminal

Washer nozzle

perpendicular

For the vertical aiming of washer nozzle, insert the

flat-tipped screwdriver into the nozzle and move it to

the arrow direction.

REAR WIPER AND WASHER SWITCH

CHECK

1

6

8

11 10 9 7

5 4

3

2

AC000417

Check continuity between the switch terminals.

Switch positionTester

connectionSpecified

condition

OFF4 − 6, 5 − 6Open circuit

Rear wiper switch4 − 6Less than 2

ohms

Rear washer

switch5 − 6

Page 407 of 800

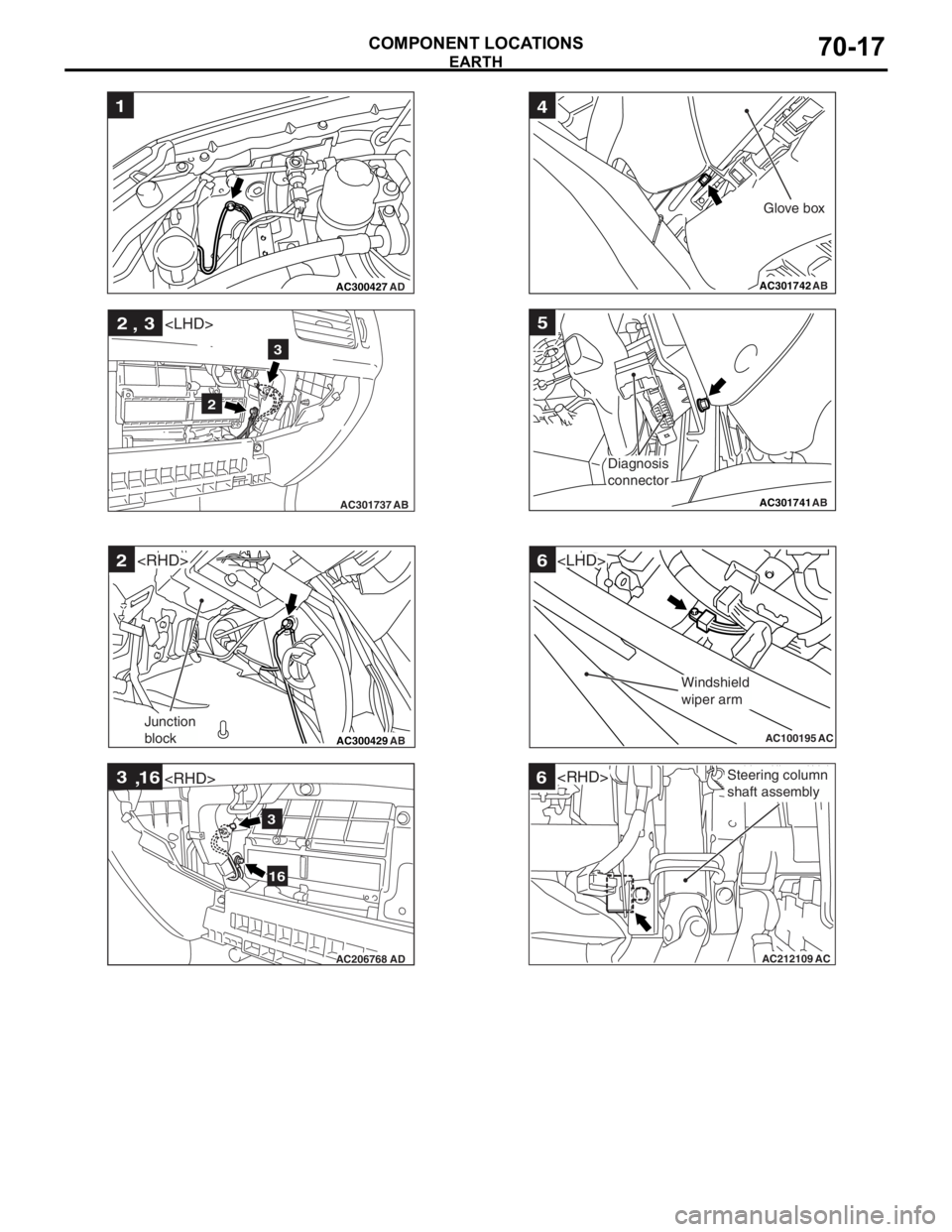

AC300427

1

AD

AC301737AB

2 3

,

2

3

AC300429 AB

2

Junction

block

AC206768 AD

3

16

,

3

16

AC301742 AB

4

Glove box

AC301741AB

5

Diagnosis

connector

AC100195

6

AC

Windshield

wiper arm

AC212109AC

6Steering column

shaft assembly

EARTH

COMPONENT LOCA

TIONS70-17

Page 408 of 800

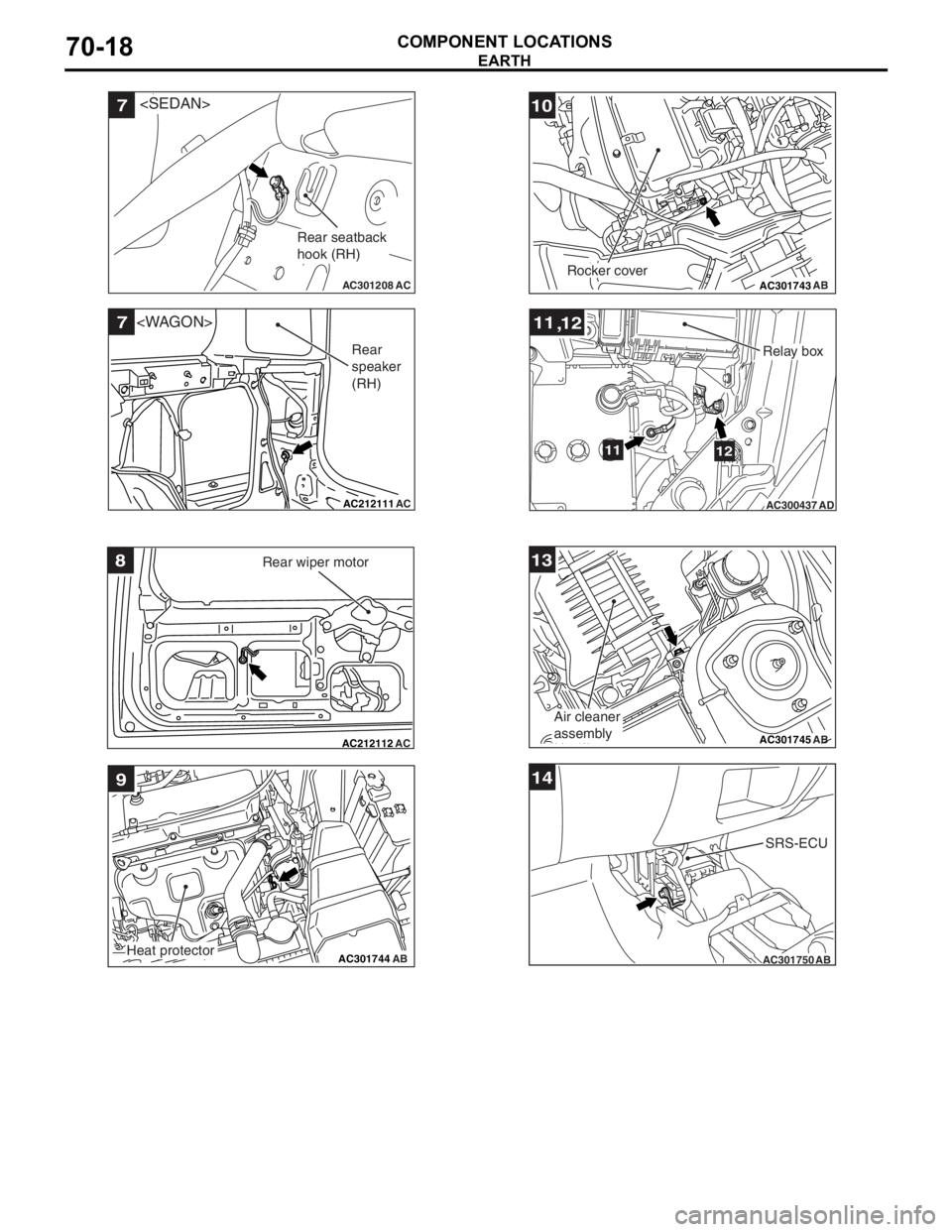

AC301208

7

AC

Rear seatback

hook (RH)

AC212111

7

AC

Rear

speaker

(RH)

AC212112AC

8Rear wiper motor

AC301744AB

9

Heat protector

AC301743AB

10

Rocker cover

AC300437

1112

,

1112

AD

Relay box

AC301745

13

AB

Air cleaner

assembly

AC301750AB

14

SRS-ECU

EARTH

COMPONENT LOCA TIONS70-18

Page 420 of 800

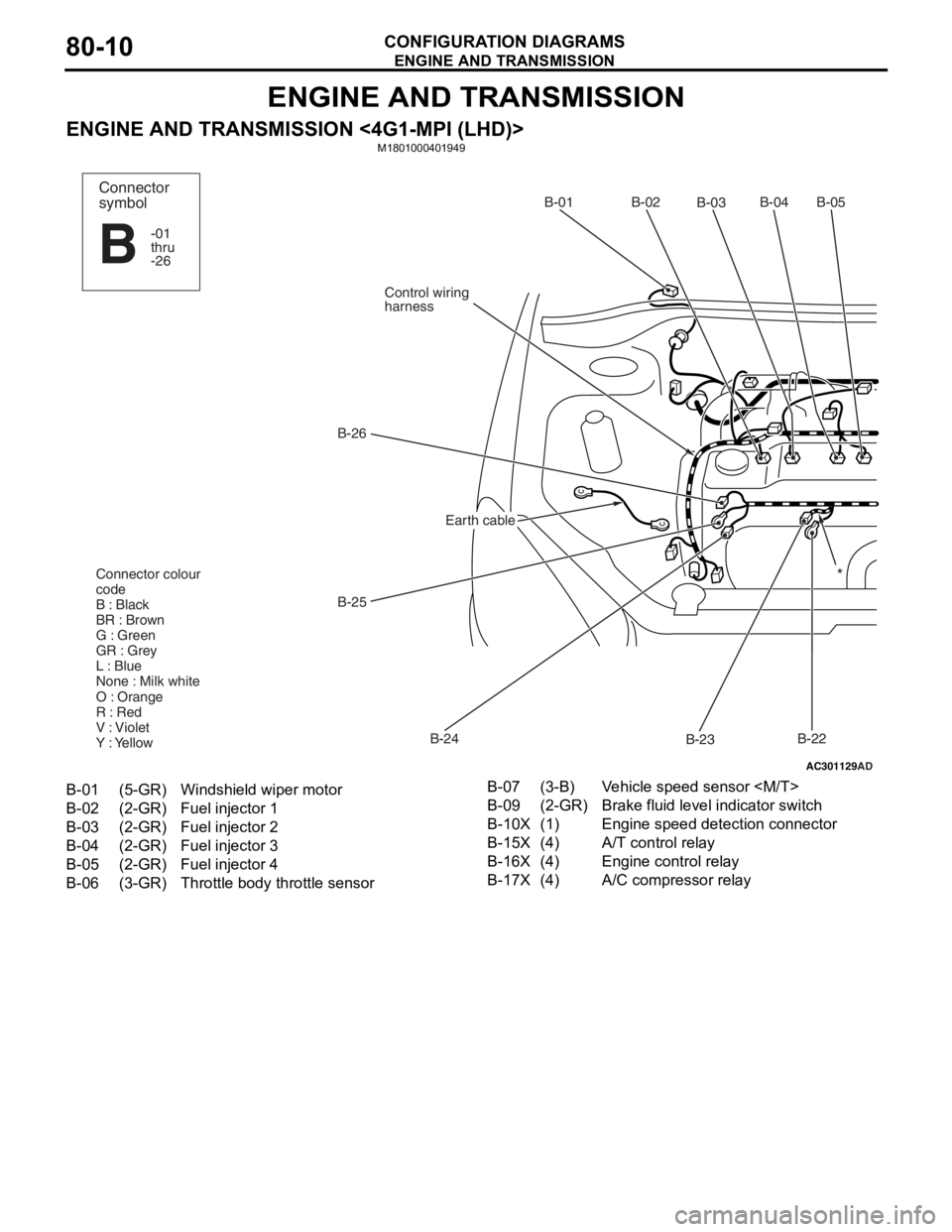

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-10

ENGINE AND TRANSMISSION

ENGINE AND TRANSMISSION <4G1-MPI (LHD)>M1801000401949

AC301129

AD

B-02

B-03B-04B-05

B-22

B-23

B-24

B-25

B-26

Control wiring

harnessB-01

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow*

Connector

symbol

-01

thru

-26

B

Earth cable

B-01(5-GR)Windshield wiper motor

B-02(2-GR)Fuel injector 1

B-03(2-GR)Fuel injector 2

B-04(2-GR)Fuel injector 3

B-05(2-GR)Fuel injector 4

B-06(3-GR)Throttle body throttle sensor

B-07(3-B)Vehicle speed sensor

B-09(2-GR)Brake fluid level indicator switch

B-10X(1)Engine speed detection connector

B-15X(4)A/T control relay

B-16X(4)Engine control relay

B-17X(4)A/C compressor relay