MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1051 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-9

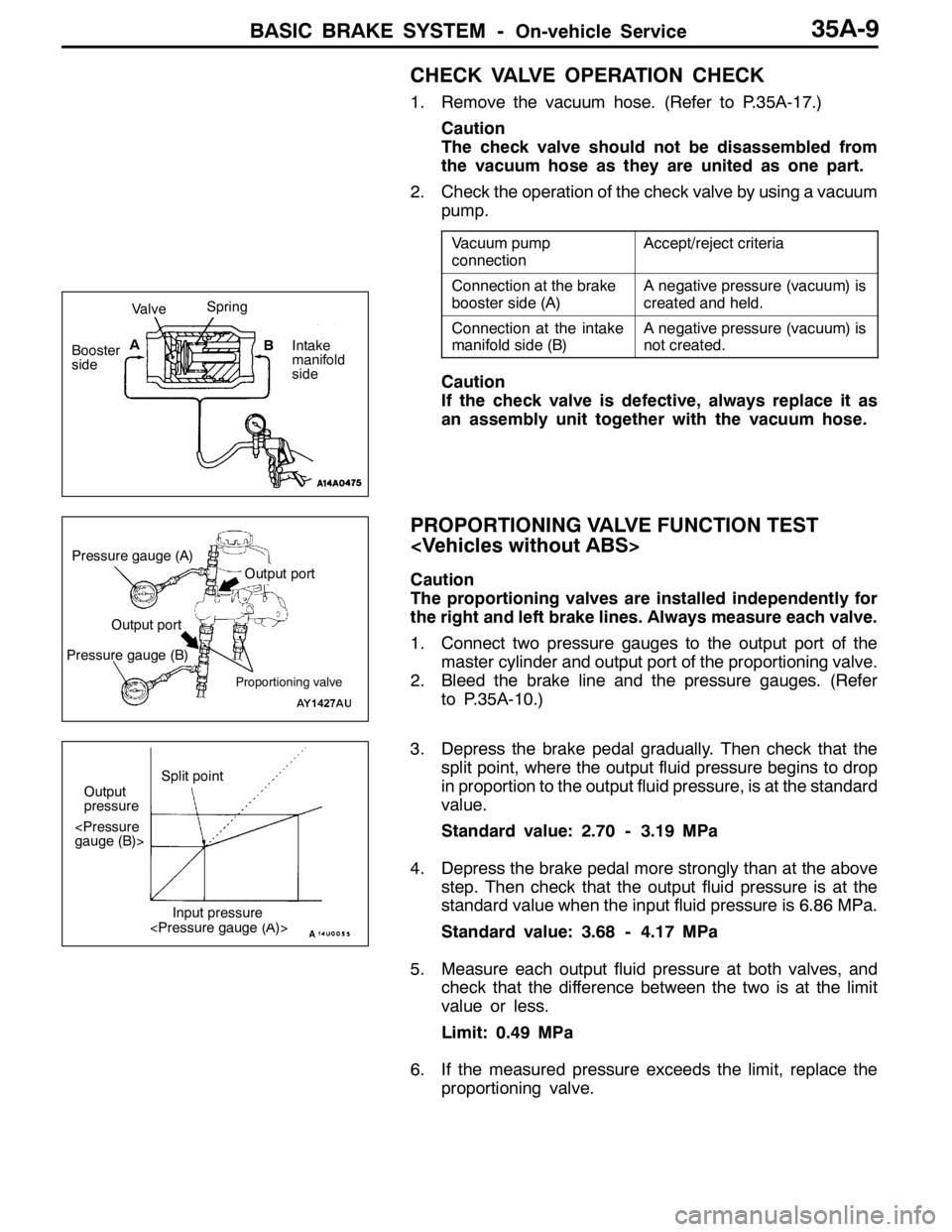

CHECK VALVE OPERATION CHECK

1. Remove the vacuum hose. (Refer to P.35A-17.)

Caution

The check valve should not be disassembled from

the vacuum hose as they are united as one part.

2. Check the operation of the check valve by using a vacuum

pump.

Vacuum pump

connectionAccept/reject criteria

Connection at the brake

booster side (A)A negative pressure (vacuum) is

created and held.

Connection at the intake

manifold side (B)A negative pressure (vacuum) is

not created.

Caution

If the check valve is defective, always replace it as

an assembly unit together with the vacuum hose.

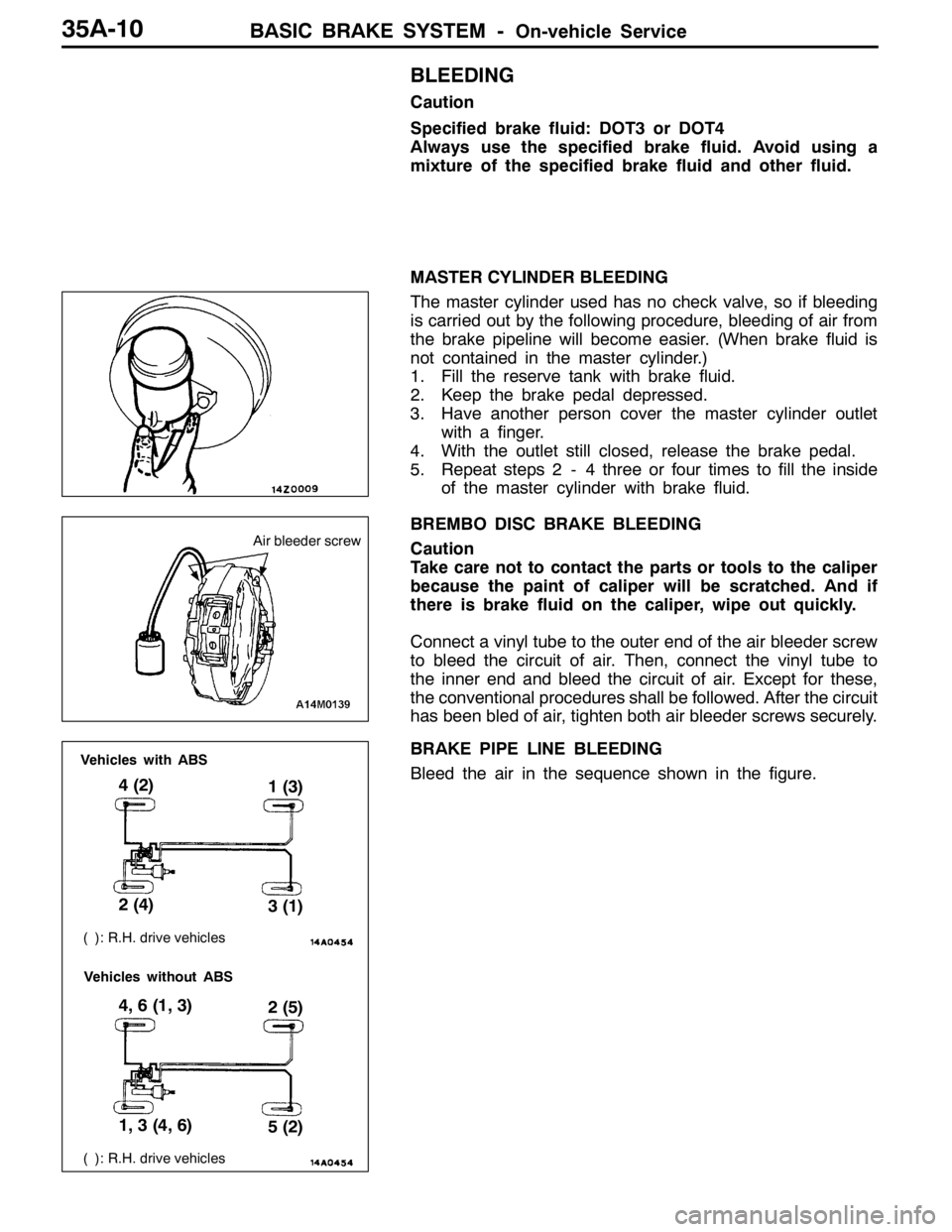

PROPORTIONING VALVE FUNCTION TEST

Caution

The proportioning valves are installed independently for

the right and left brake lines. Always measure each valve.

1. Connect two pressure gauges to the output port of the

master cylinder and output port of the proportioning valve.

2. Bleed the brake line and the pressure gauges. (Refer

to P.35A-10.)

3. Depress the brake pedal gradually. Then check that the

split point, where the output fluid pressure begins to drop

in proportion to the output fluid pressure, is at the standard

value.

Standard value: 2.70 - 3.19 MPa

4. Depress the brake pedal more strongly than at the above

step. Then check that the output fluid pressure is at the

standard value when the input fluid pressure is 6.86 MPa.

Standard value: 3.68 - 4.17 MPa

5. Measure each output fluid pressure at both valves, and

check that the difference between the two is at the limit

value or less.

Limit: 0.49 MPa

6. If the measured pressure exceeds the limit, replace the

proportioning valve.

ValveSpring

Booster

sideA

B

Intake

manifold

side

Pressure gauge (A)

Proportioning valve

Output port

Output port

Pressure gauge (B)

Output

pressureSplit point

Page 1052 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-10

BLEEDING

Caution

Specified brake fluid: DOT3 or DOT4

Always use the specified brake fluid. Avoid using a

mixture of the specified brake fluid and other fluid.

MASTER CYLINDER BLEEDING

The master cylinder used has no check valve, so if bleeding

is carried out by the following procedure, bleeding of air from

the brake pipeline will become easier. (When brake fluid is

not contained in the master cylinder.)

1. Fill the reserve tank with brake fluid.

2. Keep the brake pedal depressed.

3. Have another person cover the master cylinder outlet

with a finger.

4. With the outlet still closed, release the brake pedal.

5. Repeat steps 2 - 4 three or four times to fill the inside

of the master cylinder with brake fluid.

BREMBO DISC BRAKE BLEEDING

Caution

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

Connect a vinyl tube to the outer end of the air bleeder screw

to bleed the circuit of air. Then, connect the vinyl tube to

the inner end and bleed the circuit of air. Except for these,

the conventional procedures shall be followed. After the circuit

has been bled of air, tighten both air bleeder screws securely.

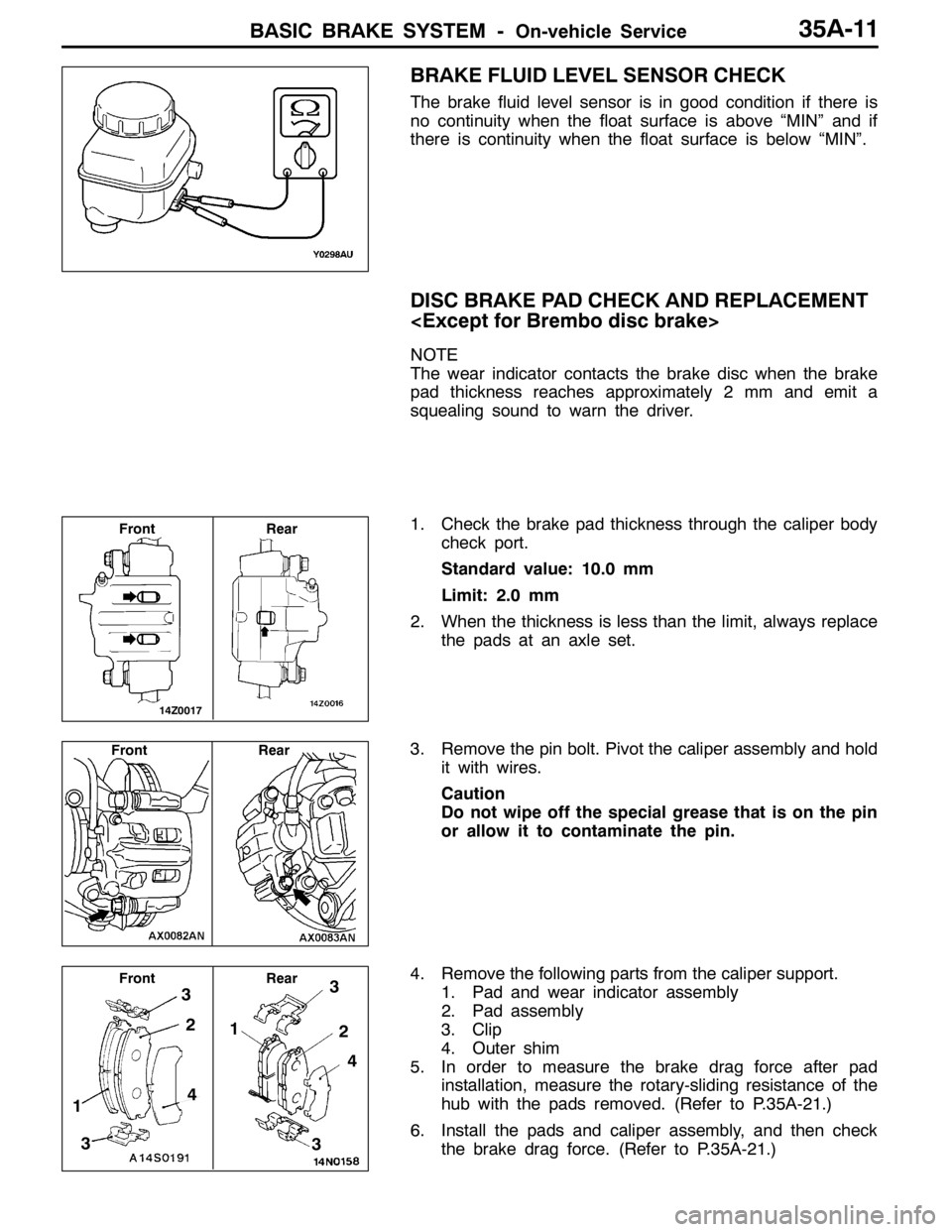

BRAKE PIPE LINE BLEEDING

Bleed the air in the sequence shown in the figure.

Air bleeder screw

( ): R.H. drive vehicles

4 (2)

1 (3)

2 (4)

3 (1)

( ): R.H. drive vehicles

4, 6 (1, 3)

2 (5)

1, 3 (4, 6)

5 (2)

Vehicles with ABS

Vehicles without ABS

Page 1053 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-11

BRAKE FLUID LEVEL SENSOR CHECK

The brake fluid level sensor is in good condition if there is

no continuity when the float surface is above “MIN” and if

there is continuity when the float surface is below “MIN”.

DISC BRAKE PAD CHECK AND REPLACEMENT

NOTE

The wear indicator contacts the brake disc when the brake

pad thickness reaches approximately 2 mm and emit a

squealing sound to warn the driver.

1. Check the brake pad thickness through the caliper body

check port.

Standard value: 10.0 mm

Limit: 2.0 mm

2. When the thickness is less than the limit, always replace

the pads at an axle set.

3. Remove the pin bolt. Pivot the caliper assembly and hold

it with wires.

Caution

Do not wipe off the special grease that is on the pin

or allow it to contaminate the pin.

4. Remove the following parts from the caliper support.

1. Pad and wear indicator assembly

2. Pad assembly

3. Clip

4. Outer shim

5. In order to measure the brake drag force after pad

installation, measure the rotary-sliding resistance of the

hub with the pads removed. (Refer to P.35A-21.)

6. Install the pads and caliper assembly, and then check

the brake drag force. (Refer to P.35A-21.)

14Z0017

Front Rear

Front Rear

Front Rear

12 34

3

1

2 3

4

3

Page 1054 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-12

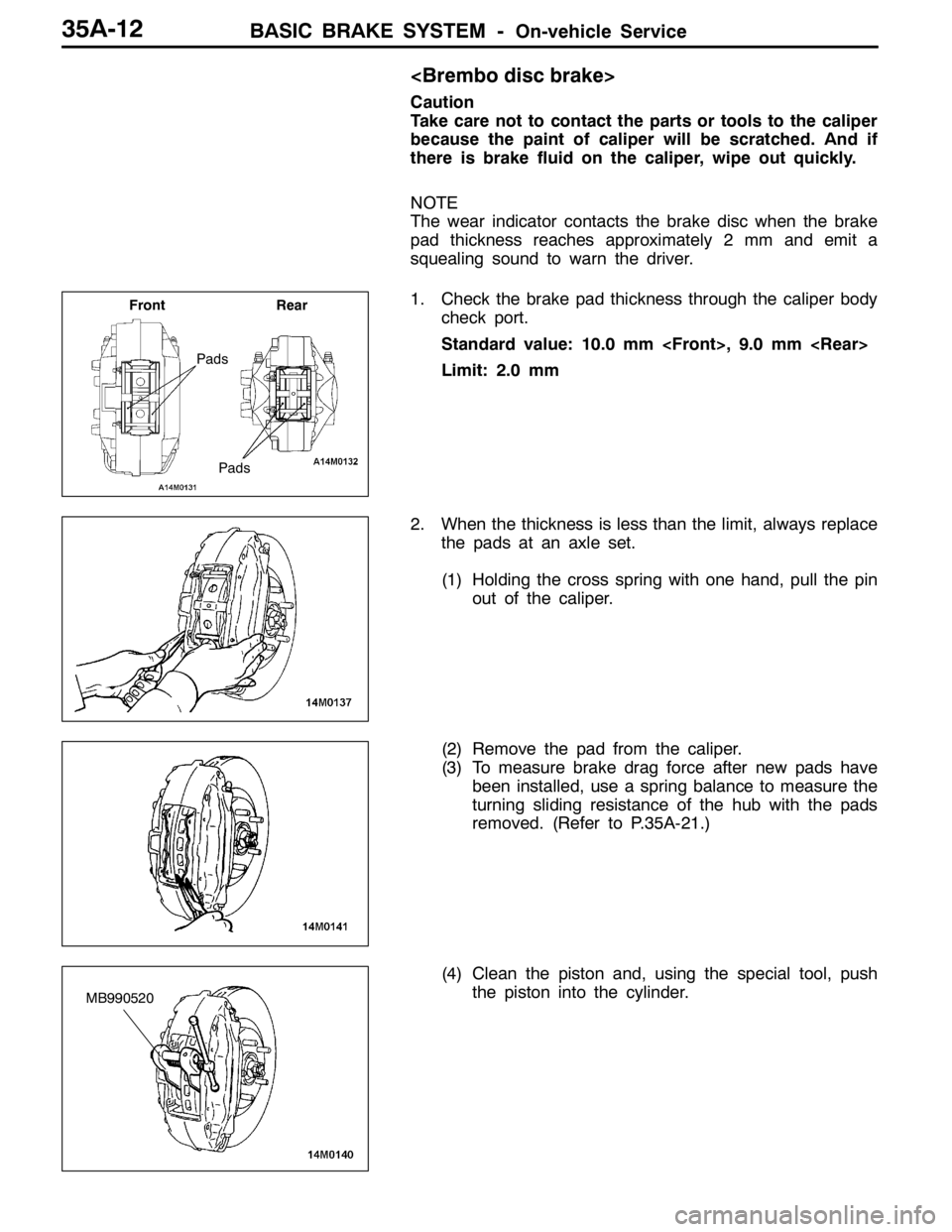

Caution

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

NOTE

The wear indicator contacts the brake disc when the brake

pad thickness reaches approximately 2 mm and emit a

squealing sound to warn the driver.

1. Check the brake pad thickness through the caliper body

check port.

Standard value: 10.0 mm

Limit: 2.0 mm

2. When the thickness is less than the limit, always replace

the pads at an axle set.

(1) Holding the cross spring with one hand, pull the pin

out of the caliper.

(2) Remove the pad from the caliper.

(3) To measure brake drag force after new pads have

been installed, use a spring balance to measure the

turning sliding resistance of the hub with the pads

removed. (Refer to P.35A-21.)

(4) Clean the piston and, using the special tool, push

the piston into the cylinder.

Pads

Front Rear

Pads

MB990520

Page 1055 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-13

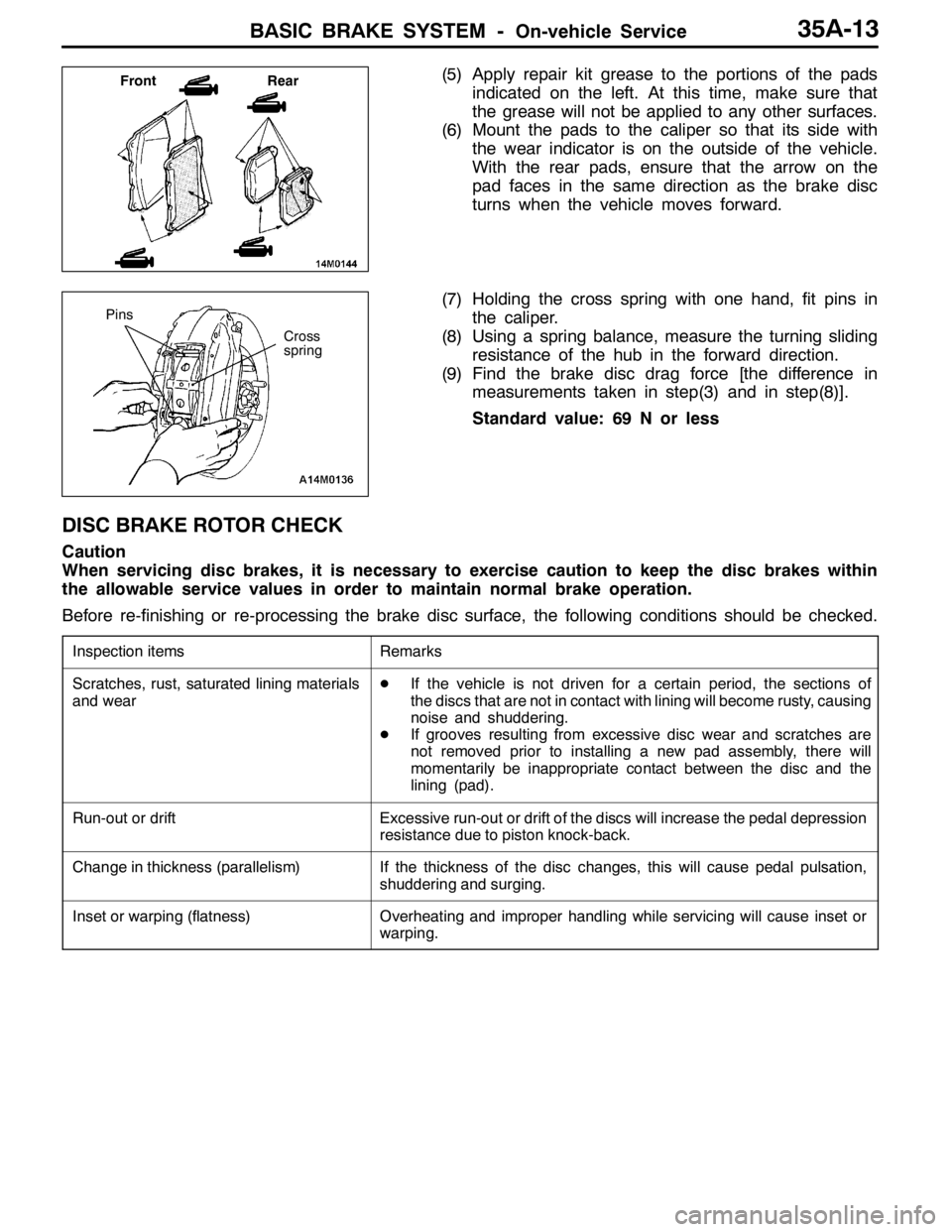

(5) Apply repair kit grease to the portions of the pads

indicated on the left. At this time, make sure that

the grease will not be applied to any other surfaces.

(6) Mount the pads to the caliper so that its side with

the wear indicator is on the outside of the vehicle.

With the rear pads, ensure that the arrow on the

pad faces in the same direction as the brake disc

turns when the vehicle moves forward.

(7) Holding the cross spring with one hand, fit pins in

the caliper.

(8) Using a spring balance, measure the turning sliding

resistance of the hub in the forward direction.

(9) Find the brake disc drag force [the difference in

measurements taken in step(3) and in step(8)].

Standard value: 69 N or less

DISC BRAKE ROTOR CHECK

Caution

When servicing disc brakes, it is necessary to exercise caution to keep the disc brakes within

the allowable service values in order to maintain normal brake operation.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checked.

Inspection itemsRemarks

Scratches, rust, saturated lining materials

and wearDIf the vehicle is not driven for a certain period, the sections of

the discs that are not in contact with lining will become rusty, causing

noise and shuddering.

DIf grooves resulting from excessive disc wear and scratches are

not removed prior to installing a new pad assembly, there will

momentarily be inappropriate contact between the disc and the

lining (pad).

Run-out or driftExcessive run-out or drift of the discs will increase the pedal depression

resistance due to piston knock-back.

Change in thickness (parallelism)If the thickness of the disc changes, this will cause pedal pulsation,

shuddering and surging.

Inset or warping (flatness)Overheating and improper handling while servicing will cause inset or

warping.

Front Rear

Cross

spring

Pins

Page 1056 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-14

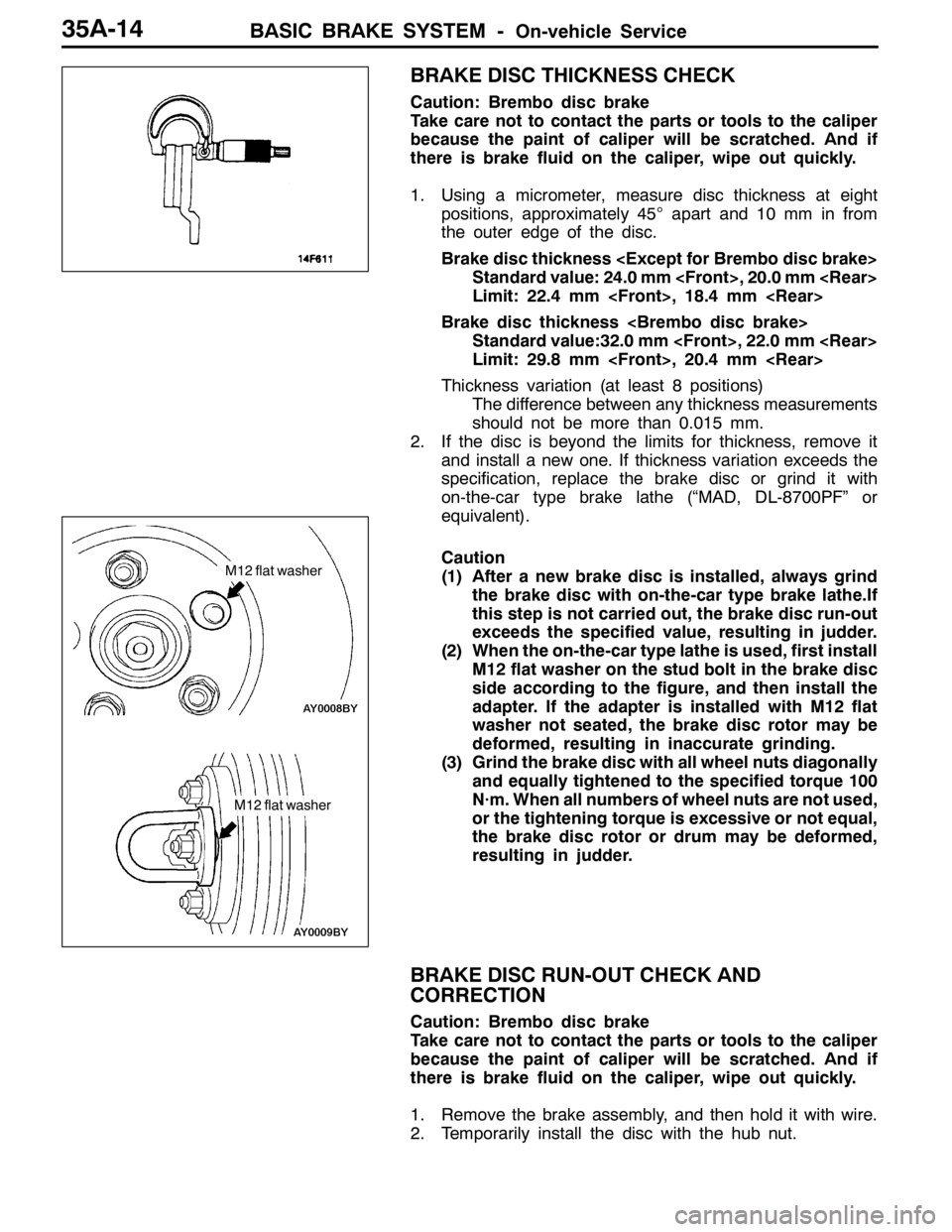

BRAKE DISC THICKNESS CHECK

Caution: Brembo disc brake

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

1. Using a micrometer, measure disc thickness at eight

positions, approximately 45°apart and 10 mm in from

the outer edge of the disc.

Brake disc thickness

Standard value: 24.0 mm

Limit: 22.4 mm

Brake disc thickness

Standard value:32.0 mm

Limit: 29.8 mm

Thickness variation (at least 8 positions)

The difference between any thickness measurements

should not be more than 0.015 mm.

2. If the disc is beyond the limits for thickness, remove it

and install a new one. If thickness variation exceeds the

specification, replace the brake disc or grind it with

on-the-car type brake lathe (“MAD, DL-8700PF” or

equivalent).

Caution

(1) After a new brake disc is installed, always grind

the brake disc with on-the-car type brake lathe.If

this step is not carried out, the brake disc run-out

exceeds the specified value, resulting in judder.

(2) When the on-the-car type lathe is used, first install

M12 flat washer on the stud bolt in the brake disc

side according to the figure, and then install the

adapter. If the adapter is installed with M12 flat

washer not seated, the brake disc rotor may be

deformed, resulting in inaccurate grinding.

(3) Grind the brake disc with all wheel nuts diagonally

and equally tightened to the specified torque 100

N·m. When all numbers of wheel nuts are not used,

or the tightening torque is excessive or not equal,

the brake disc rotor or drum may be deformed,

resulting in judder.

BRAKE DISC RUN-OUT CHECK AND

CORRECTION

Caution: Brembo disc brake

Take care not to contact the parts or tools to the caliper

because the paint of caliper will be scratched. And if

there is brake fluid on the caliper, wipe out quickly.

1. Remove the brake assembly, and then hold it with wire.

2. Temporarily install the disc with the hub nut.

M12 flat washer

M12 flat washer

Page 1057 of 1449

BASIC BRAKE SYSTEM -On-vehicle Service35A-15

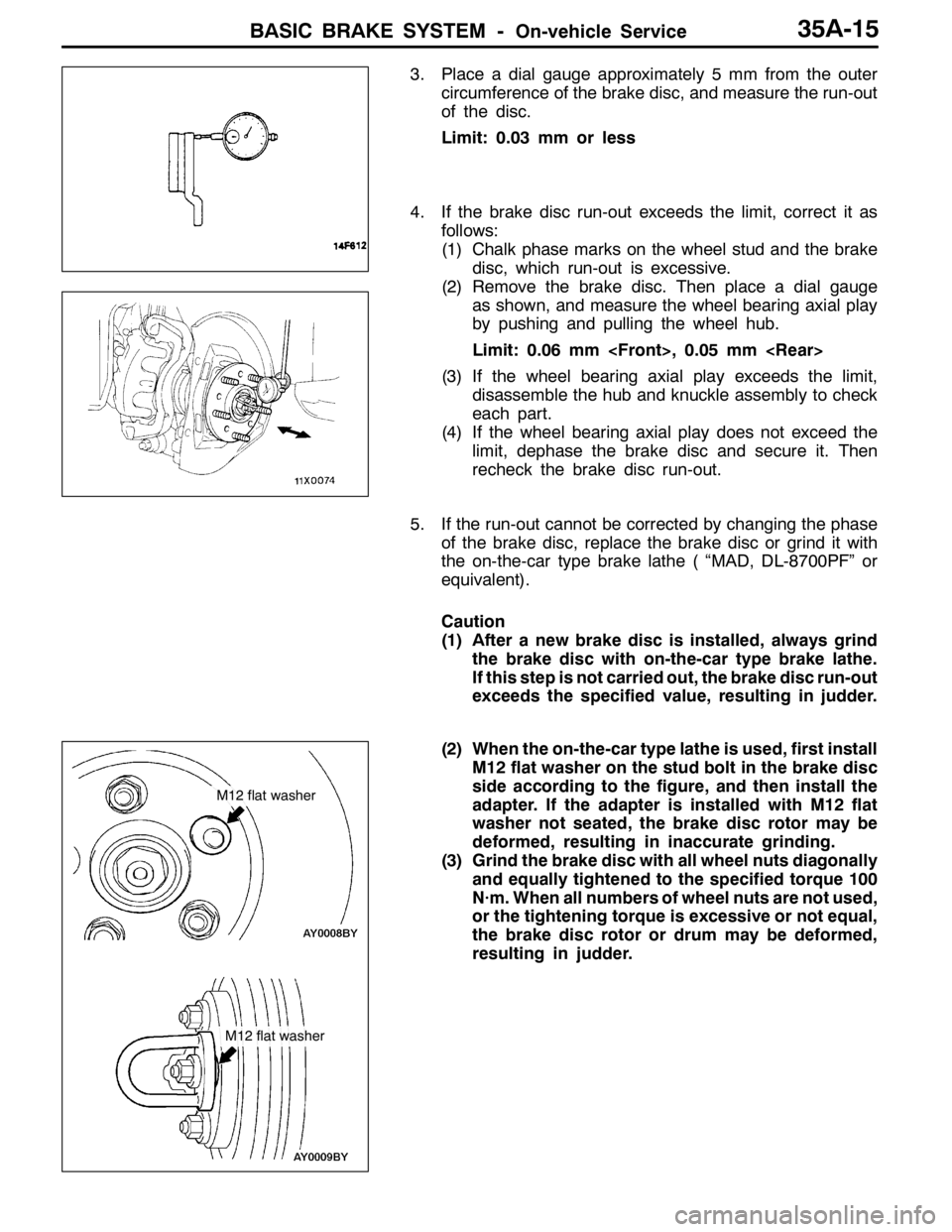

3. Place a dial gauge approximately 5 mm from the outer

circumference of the brake disc, and measure the run-out

of the disc.

Limit: 0.03 mm or less

4. If the brake disc run-out exceeds the limit, correct it as

follows:

(1) Chalk phase marks on the wheel stud and the brake

disc, which run-out is excessive.

(2) Remove the brake disc. Then place a dial gauge

as shown, and measure the wheel bearing axial play

by pushing and pulling the wheel hub.

Limit: 0.06 mm

(3) If the wheel bearing axial play exceeds the limit,

disassemble the hub and knuckle assembly to check

each part.

(4) If the wheel bearing axial play does not exceed the

limit, dephase the brake disc and secure it. Then

recheck the brake disc run-out.

5. If the run-out cannot be corrected by changing the phase

of the brake disc, replace the brake disc or grind it with

the on-the-car type brake lathe ( “MAD, DL-8700PF” or

equivalent).

Caution

(1) After a new brake disc is installed, always grind

the brake disc with on-the-car type brake lathe.

If this step is not carried out, the brake disc run-out

exceeds the specified value, resulting in judder.

(2) When the on-the-car type lathe is used, first install

M12 flat washer on the stud bolt in the brake disc

side according to the figure, and then install the

adapter. If the adapter is installed with M12 flat

washer not seated, the brake disc rotor may be

deformed, resulting in inaccurate grinding.

(3) Grind the brake disc with all wheel nuts diagonally

and equally tightened to the specified torque 100

N·m. When all numbers of wheel nuts are not used,

or the tightening torque is excessive or not equal,

the brake disc rotor or drum may be deformed,

resulting in judder.

M12 flat washer

M12 flat washer

Page 1058 of 1449

BASIC BRAKE SYSTEM -Brake Pedal35A-16

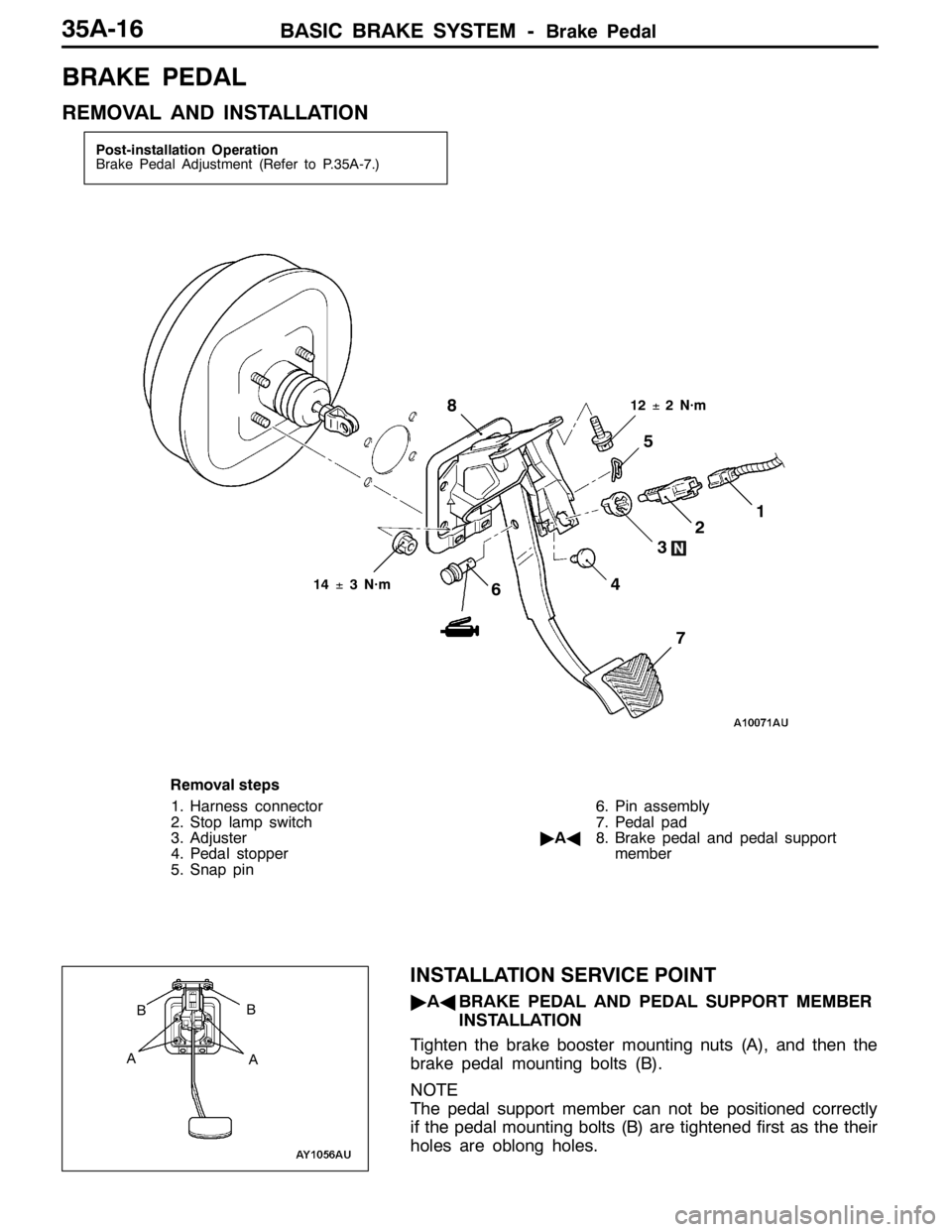

BRAKE PEDAL

REMOVAL AND INSTALLATION

Post-installation Operation

Brake Pedal Adjustment (Refer to P.35A-7.)

1

2

3

64 8

7 5

12±2 N·m

14±3 N·m

Removal steps

1. Harness connector

2. Stop lamp switch

3. Adjuster

4. Pedal stopper

5. Snap pin6. Pin assembly

7. Pedal pad

"AA8. Brake pedal and pedal support

member

INSTALLATION SERVICE POINT

"AABRAKE PEDAL AND PEDAL SUPPORT MEMBER

INSTALLATION

Tighten the brake booster mounting nuts (A), and then the

brake pedal mounting bolts (B).

NOTE

The pedal support member can not be positioned correctly

if the pedal mounting bolts (B) are tightened first as the their

holes are oblong holes.

AA

BB

Page 1059 of 1449

BASIC BRAKE SYSTEM -Brake Pedal/Proportioning Valve,

Master Cylinder and Brake Booster35A-17

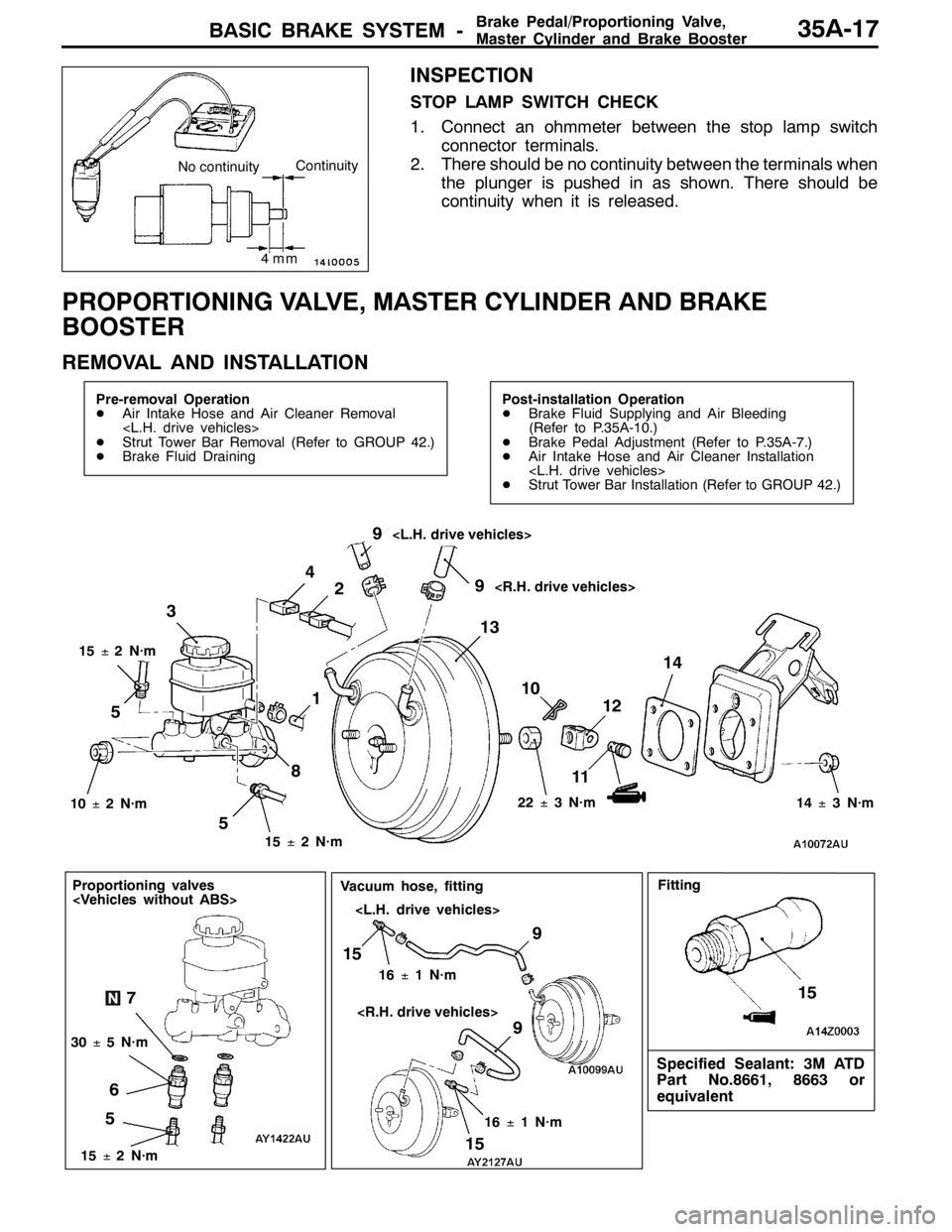

INSPECTION

STOP LAMP SWITCH CHECK

1. Connect an ohmmeter between the stop lamp switch

connector terminals.

2. There should be no continuity between the terminals when

the plunger is pushed in as shown. There should be

continuity when it is released.

PROPORTIONING VALVE, MASTER CYLINDER AND BRAKE

BOOSTER

REMOVAL AND INSTALLATION

Pre-removal Operation

DAir Intake Hose and Air Cleaner Removal

DStrut Tower Bar Removal (Refer to GROUP 42.)

DBrake Fluid DrainingPost-installation Operation

DBrake Fluid Supplying and Air Bleeding

(Refer to P.35A-10.)

DBrake Pedal Adjustment (Refer to P.35A-7.)

DAir Intake Hose and Air Cleaner Installation

DStrut Tower Bar Installation (Refer to GROUP 42.)

510

11 3

12 4

14

15±2N·m 15±2N·m

22±3N·m

10±2N·m

13 2

8

14±3N·m

519

9

15±2N·m

5

Proportioning valves

67

30±5N·m

9

15

16±1N·m

9

15

16±1N·m

Vacuum hose, fitting

Specified Sealant: 3M ATD

Part No.8661, 8663 or

equivalent

15

Fitting

4mm

No continuityContinuity

Page 1060 of 1449

BASIC BRAKE SYSTEM -ProportioningValve,MasterCylinder

and Brake Booster35A-18

Master cylinder removal steps

1. Clutch hose connection

2. Brake fluid level sensor connector

3. Reservoir cap assembly

4. Brake fluid level sensor

5. Brake pipe connection

6. Proportioning valve

7. O ring

8. Master cylinder

Proportioning valve removal steps

5. Brake pipe connection

6. Proportioning valve

7. O ring

Brake booster removal steps

1. Clutch hose connection

2. Brake fluid level sensor connector5. Brake pipe connection

8. Master cylinder

"BADPush rod protrusion amount check and

adjustment

"AA9. Vacuum hose

(With built-in check valve)

10. Snap pin

11. Pin assembly

12. Clevis

DRemove A/C liquid pipe B

from the

retaining clip.(Refer to GROUP 55A

- Refrigerant Line.)

13. Brake booster

14. Sealer

Fitting removal steps

"AA9. Vacuum hose

(With built-in check valve)

15. Fitting

INSTALLATION SERVICE POINTS

"AAVACUUM HOSE CONNECTION

Insert the vacuum hose to the brake booster with its paint

mark facing upward, and then secure the hose by using the

hose clip.

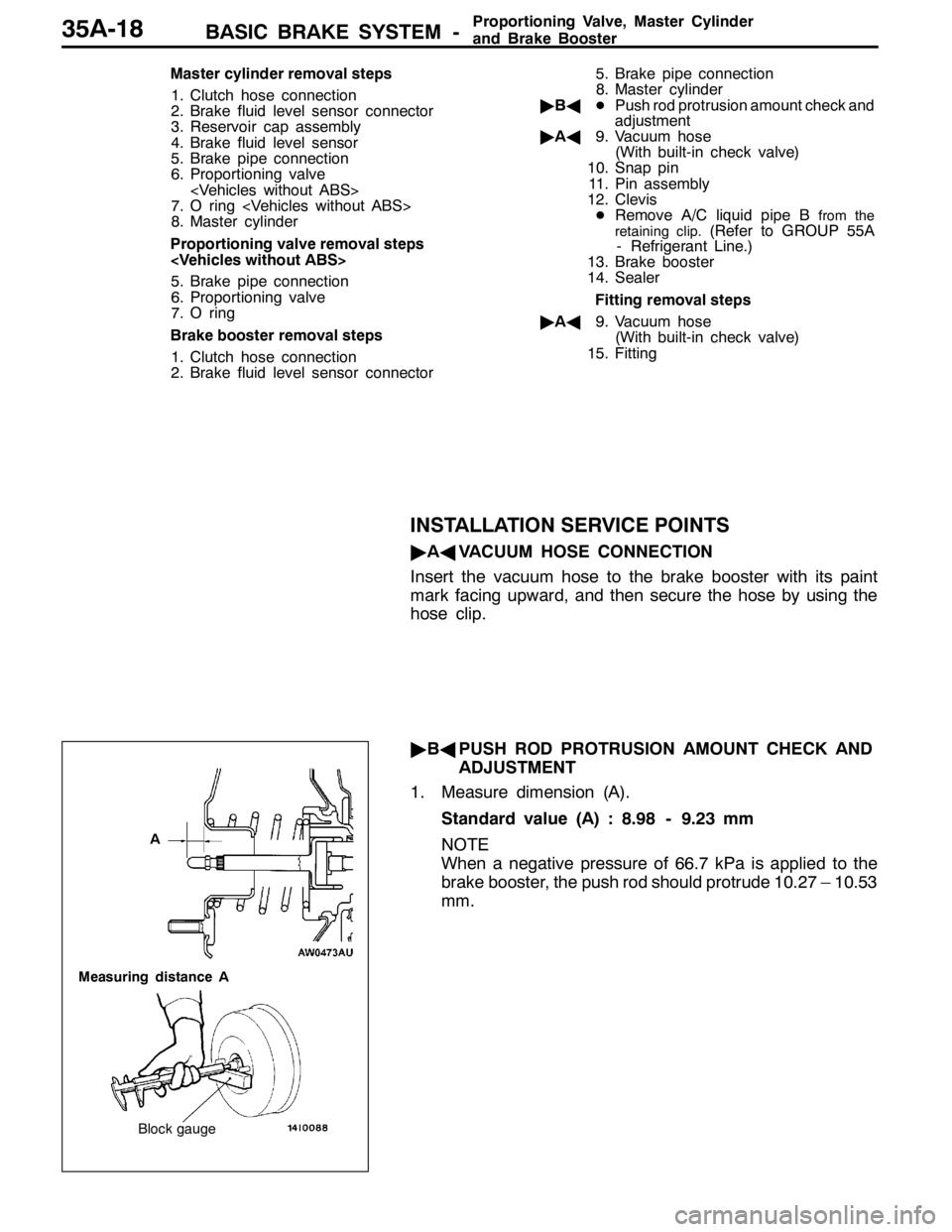

"BAPUSH ROD PROTRUSION AMOUNT CHECK AND

ADJUSTMENT

1. Measure dimension (A).

Standard value (A) : 8.98 - 9.23 mm

NOTE

When a negative pressure of 66.7 kPa is applied to the

brake booster, the push rod should protrude 10.27 – 10.53

mm.

Block gauge Measuring distance A

A