light MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 210 of 1449

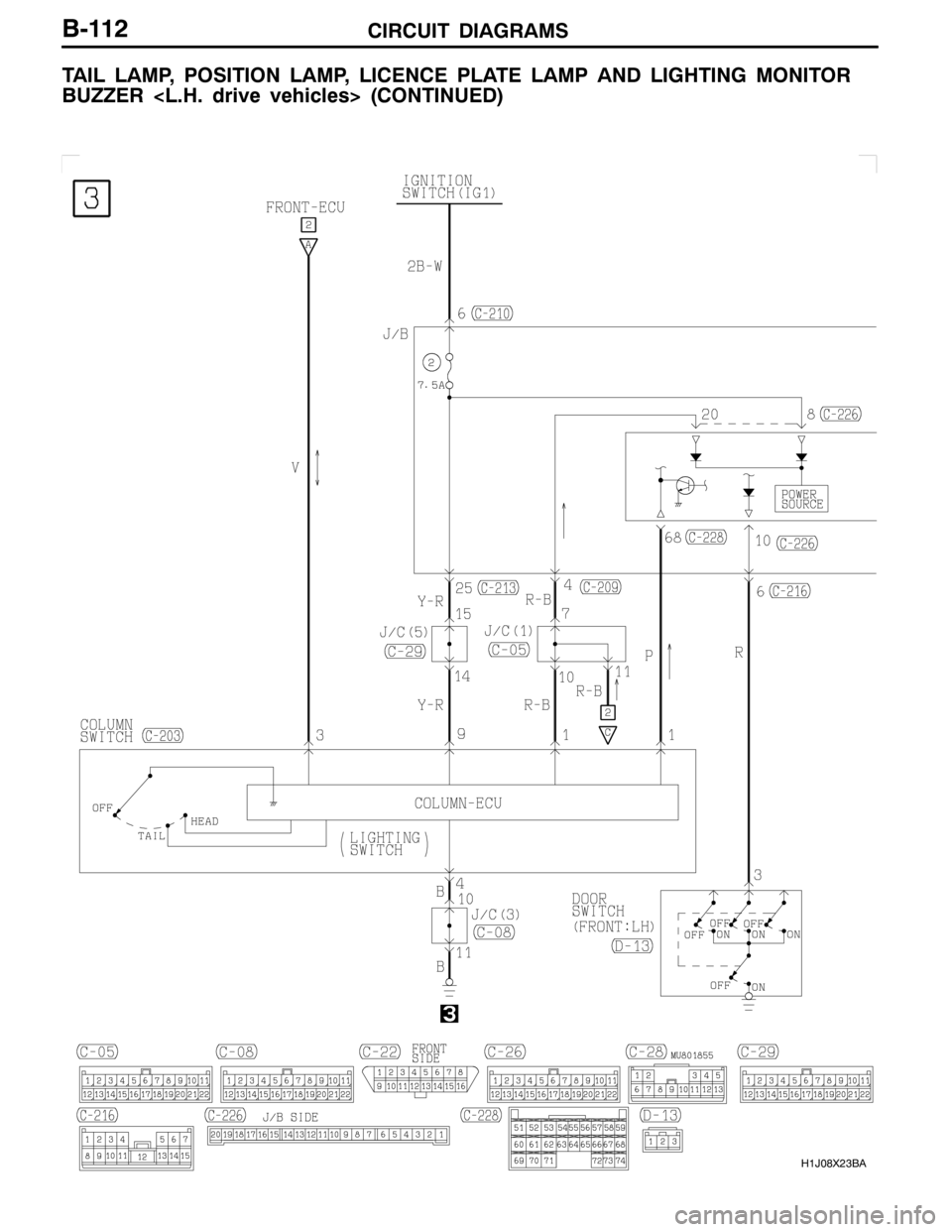

CIRCUIT DIAGRAMS

H1J08X23BA

B-112

TAIL LAMP, POSITION LAMP, LICENCE PLATE LAMP AND LIGHTING MONITOR

BUZZER

Page 212 of 1449

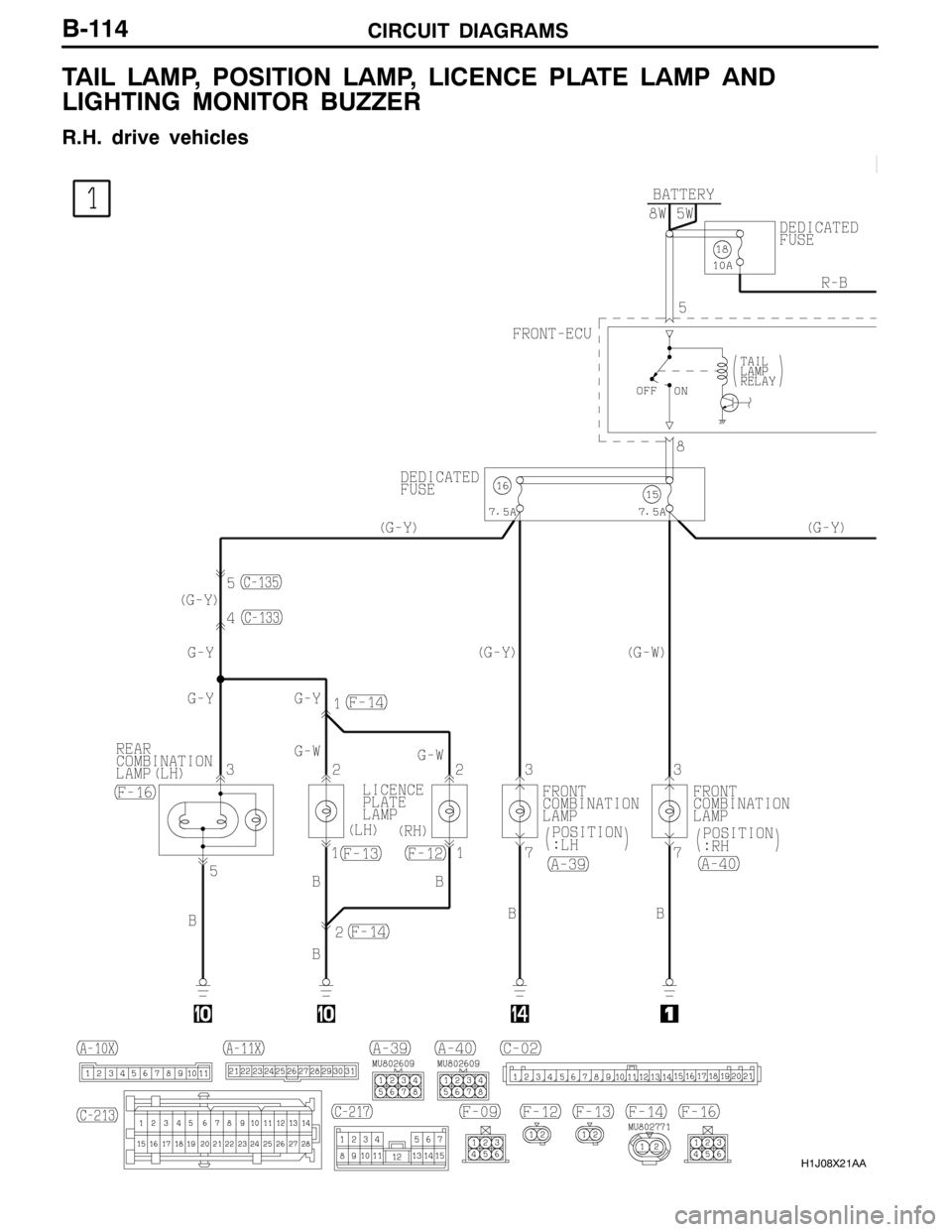

CIRCUIT DIAGRAMS

H1J08X21AA

B-114

TAIL LAMP, POSITION LAMP, LICENCE PLATE LAMP AND

LIGHTING MONITOR BUZZER

R.H. drive vehicles

Page 214 of 1449

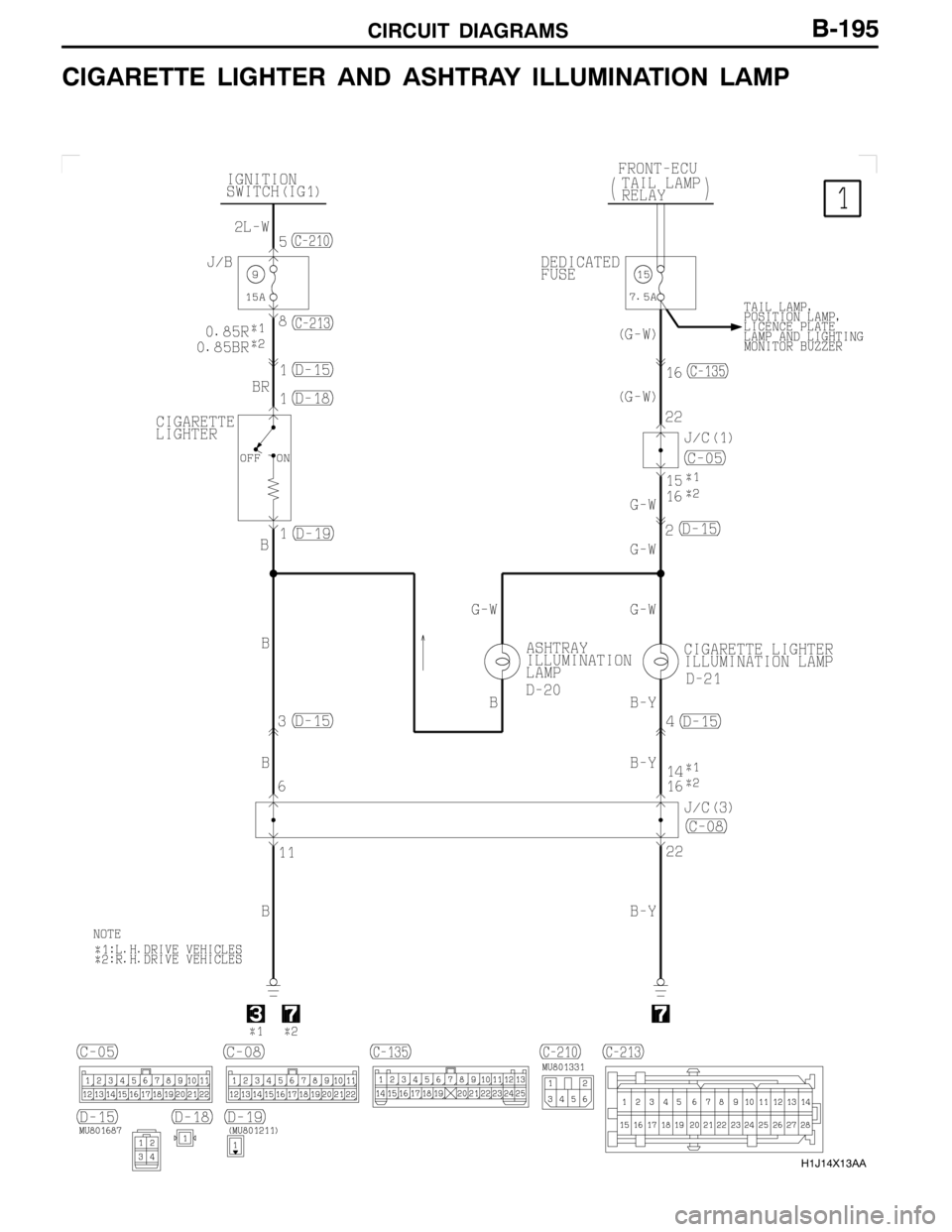

CIRCUIT DIAGRAMS

H1J08X21BA

B-116

TAIL LAMP, POSITION LAMP, LICENCE PLATE LAMP AND LIGHTING MONITOR

BUZZER

Page 293 of 1449

CIRCUIT DIAGRAMS

H1J14X13AA

B-195

CIGARETTE LIGHTER AND ASHTRAY ILLUMINATION LAMP

Page 364 of 1449

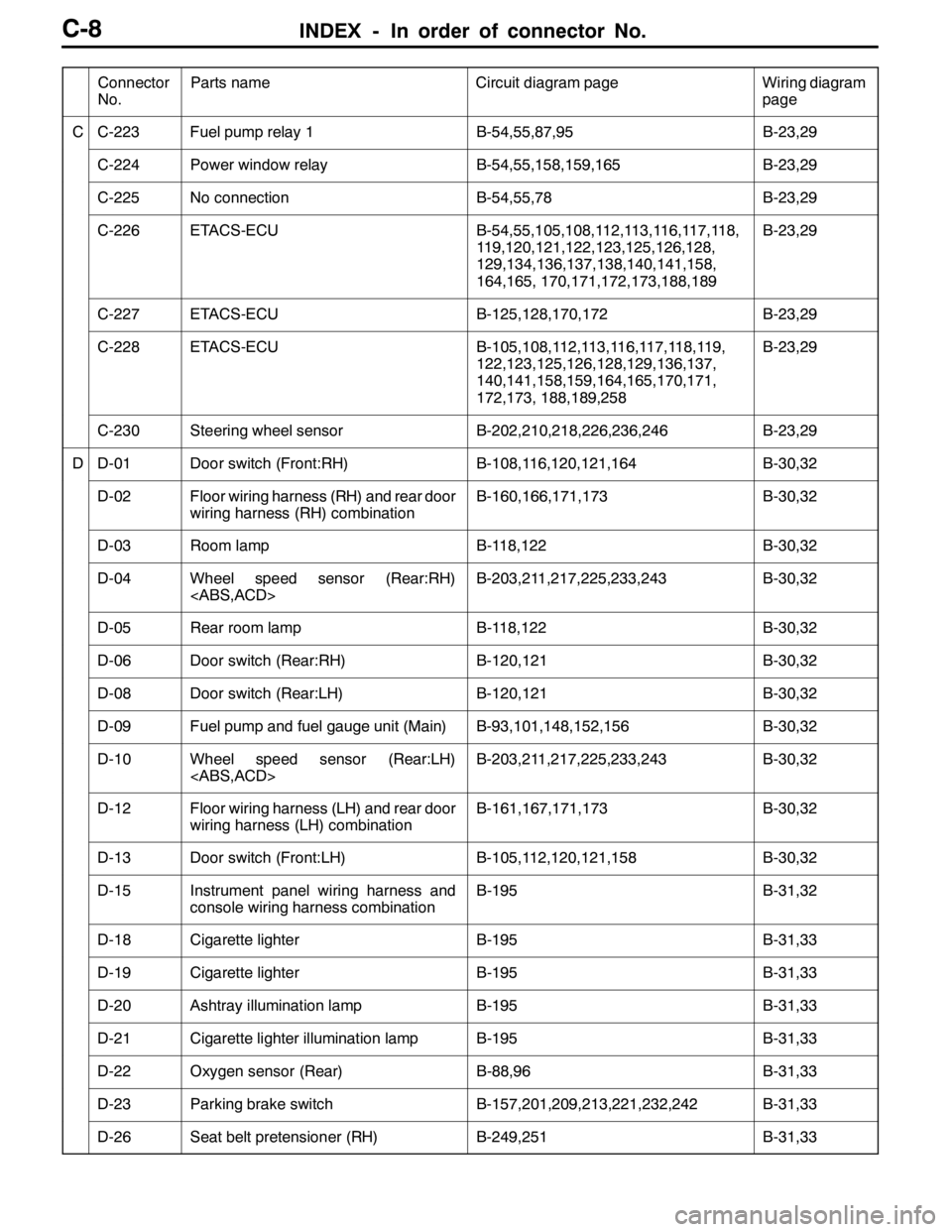

INDEX - In order of connector No.C-8

Wiring diagram

page Circuit diagram page Parts name Connector

No.

CC-223Fuel pump relay 1B-54,55,87,95B-23,29

C-224Power window relayB-54,55,158,159,165B-23,29

C-225No connectionB-54,55,78B-23,29

C-226ETACS-ECUB-54,55,105,108,112,113,116,117,118,

119,120,121,122,123,125,126,128,

129,134,136,137,138,140,141,158,

164,165, 170,171,172,173,188,189B-23,29

C-227ETACS-ECUB-125,128,170,172B-23,29

C-228ETACS-ECUB-105,108,112,113,116,117,118,119,

122,123,125,126,128,129,136,137,

140,141,158,159,164,165,170,171,

172,173, 188,189,258B-23,29

C-230Steering wheel sensorB-202,210,218,226,236,246B-23,29

DD-01Door switch (Front:RH)B-108,116,120,121,164B-30,32

D-02Floor wiring harness (RH) and rear door

wiring harness (RH) combinationB-160,166,171,173B-30,32

D-03Room lampB-118,122B-30,32

D-04Wheel speed sensor (Rear:RH)

D-05Rear room lampB-118,122B-30,32

D-06Door switch (Rear:RH)B-120,121B-30,32

D-08Door switch (Rear:LH)B-120,121B-30,32

D-09Fuel pump and fuel gauge unit (Main)B-93,101,148,152,156B-30,32

D-10Wheel speed sensor (Rear:LH)

D-12Floor wiring harness (LH) and rear door

wiring harness (LH) combinationB-161,167,171,173B-30,32

D-13Door switch (Front:LH)B-105,112,120,121,158B-30,32

D-15Instrument panel wiring harness and

console wiring harness combinationB-195B-31,32

D-18Cigarette lighterB-195B-31,33

D-19Cigarette lighterB-195B-31,33

D-20Ashtray illumination lampB-195B-31,33

D-21Cigarette lighter illumination lampB-195B-31,33

D-22Oxygen sensor (Rear)B-88,96B-31,33

D-23Parking brake switchB-157,201,209,213,221,232,242B-31,33

D-26Seat belt pretensioner (RH)B-249,251B-31,33

Page 367 of 1449

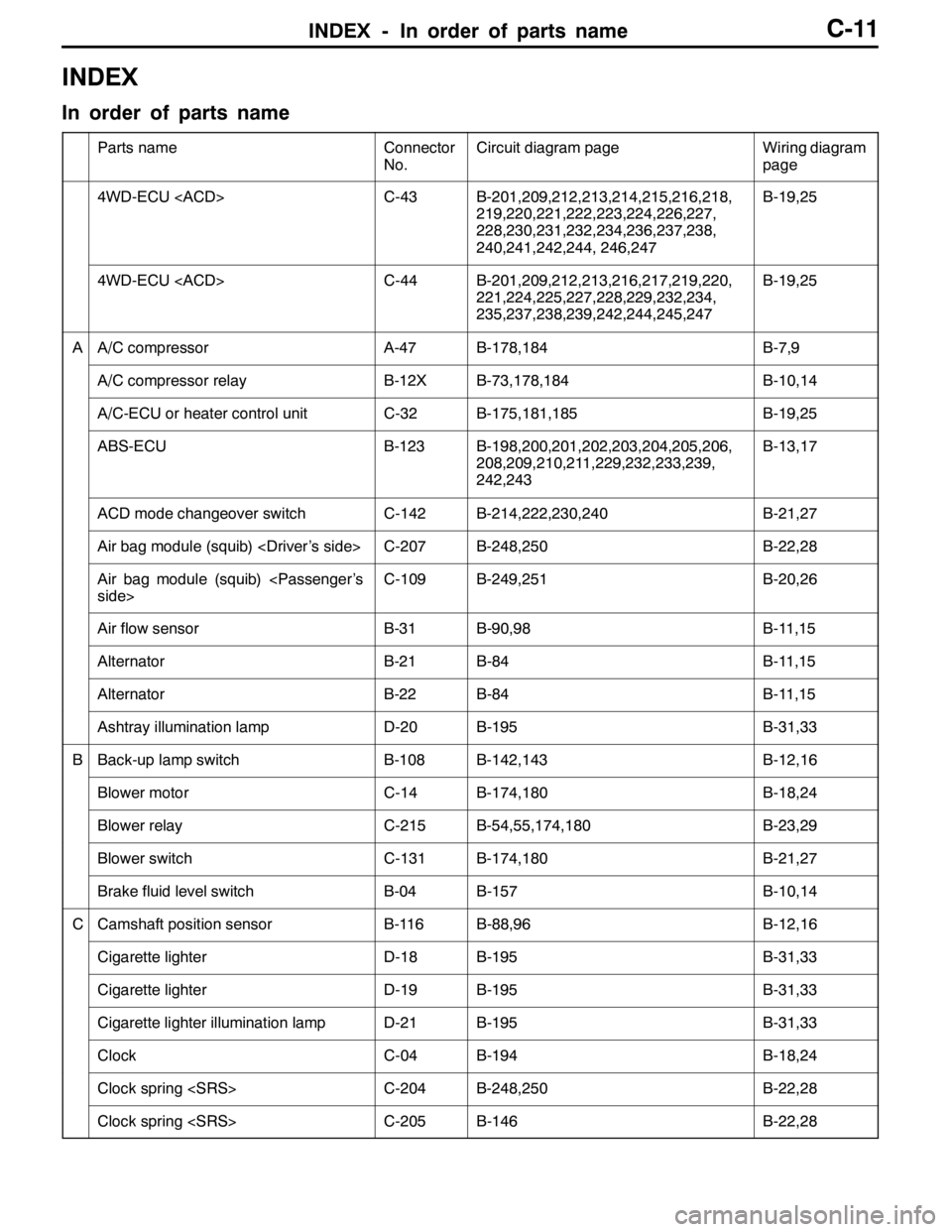

INDEX - In order of parts nameC-11

INDEX

In order of parts name

Parts nameConnector

No.Circuit diagram pageWiring diagram

page

4WD-ECU

219,220,221,222,223,224,226,227,

228,230,231,232,234,236,237,238,

240,241,242,244, 246,247B-19,25

4WD-ECU

221,224,225,227,228,229,232,234,

235,237,238,239,242,244,245,247B-19,25

AA/C compressorA-47B-178,184B-7,9

A/C compressor relayB-12XB-73,178,184B-10,14

A/C-ECU or heater control unitC-32B-175,181,185B-19,25

ABS-ECUB-123B-198,200,201,202,203,204,205,206,

208,209,210,211,229,232,233,239,

242,243B-13,17

ACD mode changeover switchC-142B-214,222,230,240B-21,27

Air bag module (squib)

Air bag module (squib)

Air flow sensorB-31B-90,98B-11,15

AlternatorB-21B-84B-11,15

AlternatorB-22B-84B-11,15

Ashtray illumination lampD-20B-195B-31,33

BBack-up lamp switchB-108B-142,143B-12,16

Blower motorC-14B-174,180B-18,24

Blower relayC-215B-54,55,174,180B-23,29

Blower switchC-131B-174,180B-21,27

Brake fluid level switchB-04B-157B-10,14

CCamshaft position sensorB-116B-88,96B-12,16

Cigarette lighterD-18B-195B-31,33

Cigarette lighterD-19B-195B-31,33

Cigarette lighter illumination lampD-21B-195B-31,33

ClockC-04B-194B-18,24

Clock spring

Clock spring

Page 391 of 1449

GENERAL -How to Use Troubleshooting/Inspection Service Points00-13

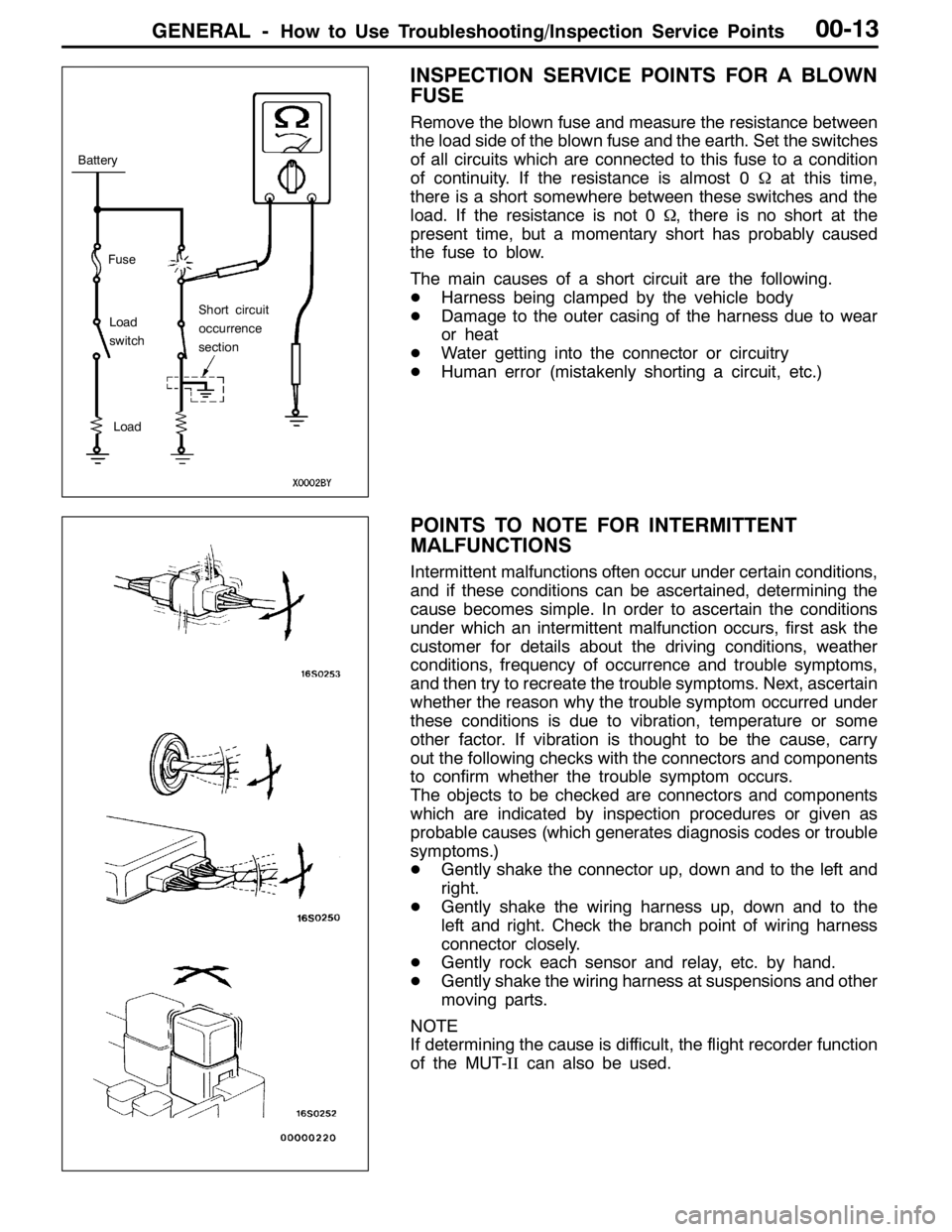

INSPECTION SERVICE POINTS FOR A BLOWN

FUSE

Remove the blown fuse and measure the resistance between

the load side of the blown fuse and the earth. Set the switches

of all circuits which are connected to this fuse to a condition

of continuity. If the resistance is almost 0Ωat this time,

there is a short somewhere between these switches and the

load. If the resistance is not 0Ω, there is no short at the

present time, but a momentary short has probably caused

the fuse to blow.

The main causes of a short circuit are the following.

DHarness being clamped by the vehicle body

DDamage to the outer casing of the harness due to wear

or heat

DWater getting into the connector or circuitry

DHuman error (mistakenly shorting a circuit, etc.)

POINTS TO NOTE FOR INTERMITTENT

MALFUNCTIONS

Intermittent malfunctions often occur under certain conditions,

and if these conditions can be ascertained, determining the

cause becomes simple. In order to ascertain the conditions

under which an intermittent malfunction occurs, first ask the

customer for details about the driving conditions, weather

conditions, frequency of occurrence and trouble symptoms,

and then try to recreate the trouble symptoms. Next, ascertain

whether the reason why the trouble symptom occurred under

these conditions is due to vibration, temperature or some

other factor. If vibration is thought to be the cause, carry

out the following checks with the connectors and components

to confirm whether the trouble symptom occurs.

The objects to be checked are connectors and components

which are indicated by inspection procedures or given as

probable causes (which generates diagnosis codes or trouble

symptoms.)

DGently shake the connector up, down and to the left and

right.

DGently shake the wiring harness up, down and to the

left and right. Check the branch point of wiring harness

connector closely.

DGently rock each sensor and relay, etc. by hand.

DGently shake the wiring harness at suspensions and other

moving parts.

NOTE

If determining the cause is difficult, the flight recorder function

of the MUT-IIcan also be used.

Fuse

Battery

Load

switch

Load

Short circuit

occurrence

section

Page 397 of 1449

GENERAL -Precautions Before ServiceGENERAL -Precautions Before Service00-19

SERVICING THE ELECTRICAL SYSTEM

Before replacing a component related to the electrical system

and before undertaking any repair procedures involving the

electrical system, be sure to first disconnect the negative

( - ) cable from the battery in order to avoid damage caused

by short-circuiting.

Caution

Before connecting or disconnecting the negative ( - ) cable,

be sure to turn off the ignition switch and the lighting

switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

APPLICATION OF ANTI-CORROSION AGENTS

AND UNDERCOATS

If oil or grease gets onto the oxygen sensor, it will cause

a drop in the performance of the sensor.

Cover the oxygen sensor with a protective cover when applying

anti-corrosion agents and undercoats.

PRE-INSPECTION CONDITION

“Pre-inspection condition” refers to the condition that the

vehicle must be in before proper engine inspection can be

carried out. If you see the words “Set the vehicle to the

pre-inspection condition”. in this manual, it means to set the

vehicle to the following condition.

DEngine coolant temperature: 80 to 90_C

DLamps, electric cooling fan and all accessories: OFF

DM/T: Neutral

DA/T: P range

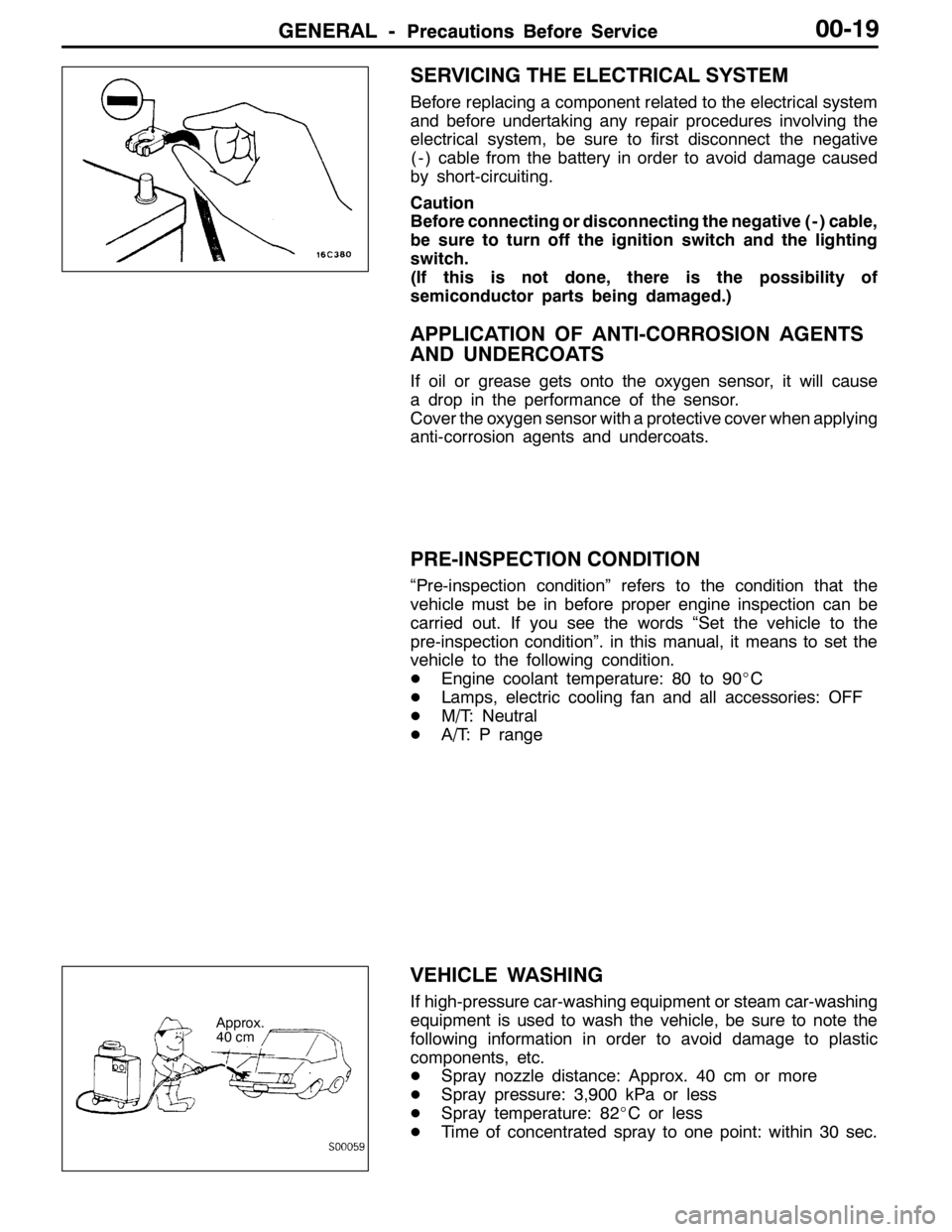

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to note the

following information in order to avoid damage to plastic

components, etc.

DSpray nozzle distance: Approx. 40 cm or more

DSpray pressure: 3,900 kPa or less

DSpray temperature: 82_C or less

DTime of concentrated spray to one point: within 30 sec.

Approx.

40 cm

Page 404 of 1449

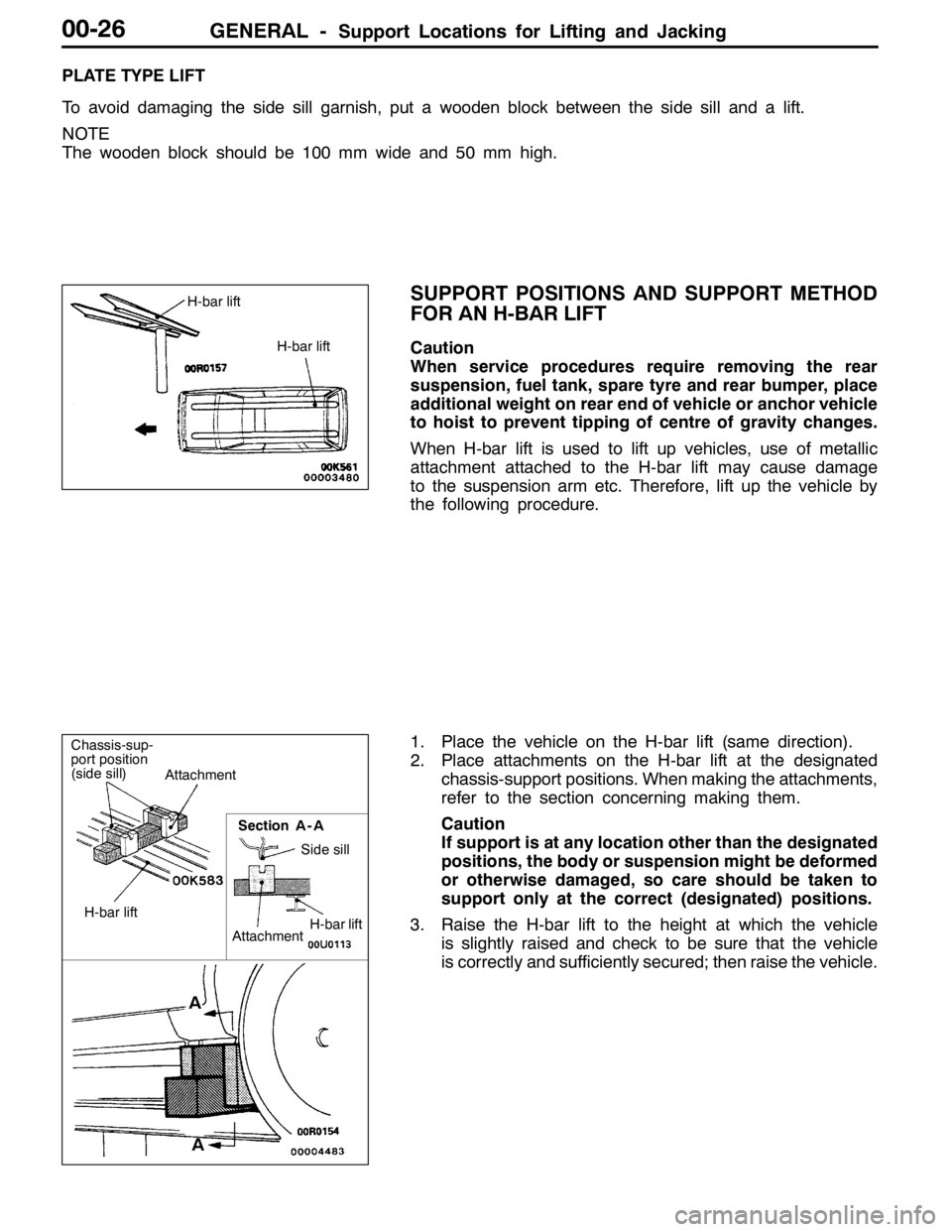

GENERAL -Support Locations for Lifting and Jacking00-26

PLATE TYPE LIFT

To avoid damaging the side sill garnish, put a wooden block between the side sill and a lift.

NOTE

The wooden block should be 100 mm wide and 50 mm high.

SUPPORT POSITIONS AND SUPPORT METHOD

FOR AN H-BAR LIFT

Caution

When service procedures require removing the rear

suspension, fuel tank, spare tyre and rear bumper, place

additional weight on rear end of vehicle or anchor vehicle

to hoist to prevent tipping of centre of gravity changes.

When H-bar lift is used to lift up vehicles, use of metallic

attachment attached to the H-bar lift may cause damage

to the suspension arm etc. Therefore, lift up the vehicle by

the following procedure.

1. Place the vehicle on the H-bar lift (same direction).

2. Place attachments on the H-bar lift at the designated

chassis-support positions. When making the attachments,

refer to the section concerning making them.

Caution

If support is at any location other than the designated

positions, the body or suspension might be deformed

or otherwise damaged, so care should be taken to

support only at the correct (designated) positions.

3. Raise the H-bar lift to the height at which the vehicle

is slightly raised and check to be sure that the vehicle

is correctly and sufficiently secured; then raise the vehicle.

H-bar lift

H-bar lift

A

Chassis-sup-

port position

(side sill)

Attachment

H-bar liftSection A - A

Side sill

AttachmentH-bar lift

A

Page 415 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-9

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position and

then connect the MUT-IIto the diagnosis connector.

3. Set up a timing light.

4. Start the engine and run at idle.

5. Check that engine idle speed is within the standard value.

Standard value: 850±100 r/min

6. Select No.17 of the MUT-IIActuator test.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

8. If the basic ignition timing is outside the standard value,

inspect the MPI system while referring to GROUP 13A

- Troubleshooting.

9. Press the MUT-IIclear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

10. Check that ignition timing is at the standard value.

Standard value: approximately 5_BTDC

NOTE

(1) Ignition timing is variable within about±7, even under

normal operating.

(2) And it is automatically further advanced by

approximately 5_from standard value at higher

altitudes.

11. Remove the timing light.

12. Turn the ignition switch to “LOCK” (OFF) position and

then remove the MUT-II.

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position, and

then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

MUT-II

MUT-II