light MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 416 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-10

Standard value: 5_BTDC±3_

5. Run the engine at idle for 2 minutes.

6. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Curb idle speed: 850±100 r/min

NOTE

The idle speed is controlled automatically by the idle speed

control (ISC) system.

7. If the idle speed is outside the standard value, check

the MPI components by referring to GROUP 13A -

Troubleshooting.

8. Remove the timing light.

9. Turn the ignition switch to the “LOCK” (OFF) position

and then remove the MUT-II.

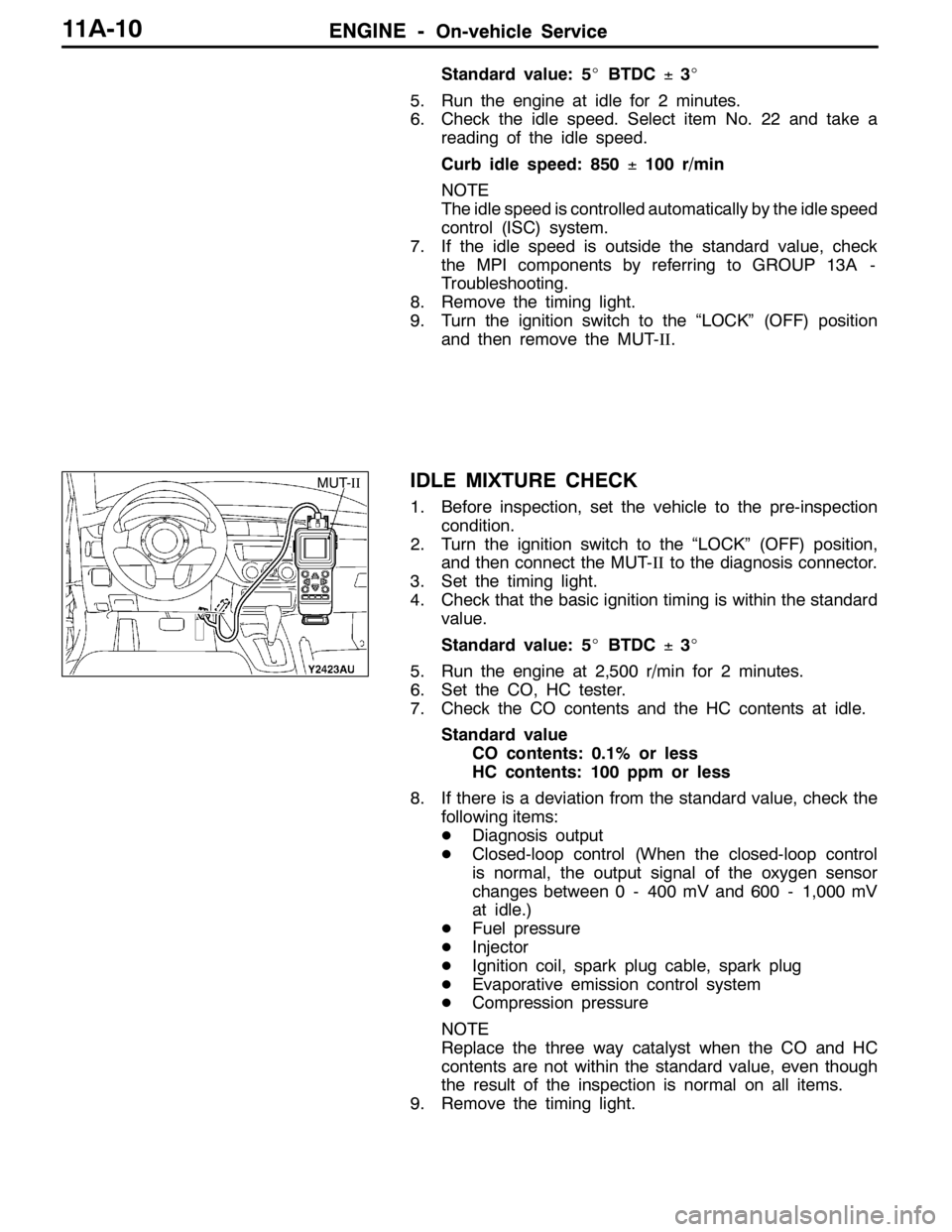

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to the “LOCK” (OFF) position,

and then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

5. Run the engine at 2,500 r/min for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents at idle.

Standard value

CO contents: 0.1% or less

HC contents: 100 ppm or less

8. If there is a deviation from the standard value, check the

following items:

DDiagnosis output

DClosed-loop control (When the closed-loop control

is normal, the output signal of the oxygen sensor

changes between 0 - 400 mV and 600 - 1,000 mV

at idle.)

DFuel pressure

DInjector

DIgnition coil, spark plug cable, spark plug

DEvaporative emission control system

DCompression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

9. Remove the timing light.

MUT-II

Page 449 of 1449

ENGINE -Engine Assembly11A-43

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Caution

1. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper because the paint of caliper will be scratched.

2. Tightening sections indicated in the mark (*) should be finally tightened with engine weight

applied on the body after lightly tightening.

Pre-removal and Post-installation Operation

DFuel Outflow Preventive Operation (Refer to GROUP 13A - On-vehicle Service.)

DFuel Leak Check

DRemoval and Installation of Hood (Refer to GROUP 42.)

DRemoval and Installation of Strut Tower Bar (Refer to GROUP 42.)

DRemoval and Installation of Under Cover (Refer to GROUP 51 - Front Bumper.)

DRemoval and Installation of Side Cover.

DDrive Belt Tension Check (Refer to P.11A - 7.)

DAccelerator Cable Adjustment (Refer to GROUP 17 - On-vehicle Service.)

DDrainage and Refilling Engine Oil(Refer to GROUP 12 - On-vehicle Service.)

DDrainage and Refilling of Engine Coolant (Refer to GROUP 14 - On-vehicle Service.)

DAir Cleaner Removal and Installation (Refer to GROUP 15)

DRemoval and Installation of Air Pipe C, Air Pipe B and Air Hose A (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

DRemoval and Installation of Center Cover (Refer to P.11A - 17.)

DRemoval and Installation of Accelerator Cable (Refer to GROUP 17.)

DRemoval and Installation of Radiator (Refer to GROUP 14.)

DRemoval and Installation of Crossmember Bar (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DRemoval and Installation of Front Exhaust Pipe (Refer to GROUP 15.)

DRemoval and Installation of Air Outlet Fitting (Refer to GROUP 15 - Exhaust manifold.)

Page 462 of 1449

ENGINE OVERHAUL -Specifications11B-8

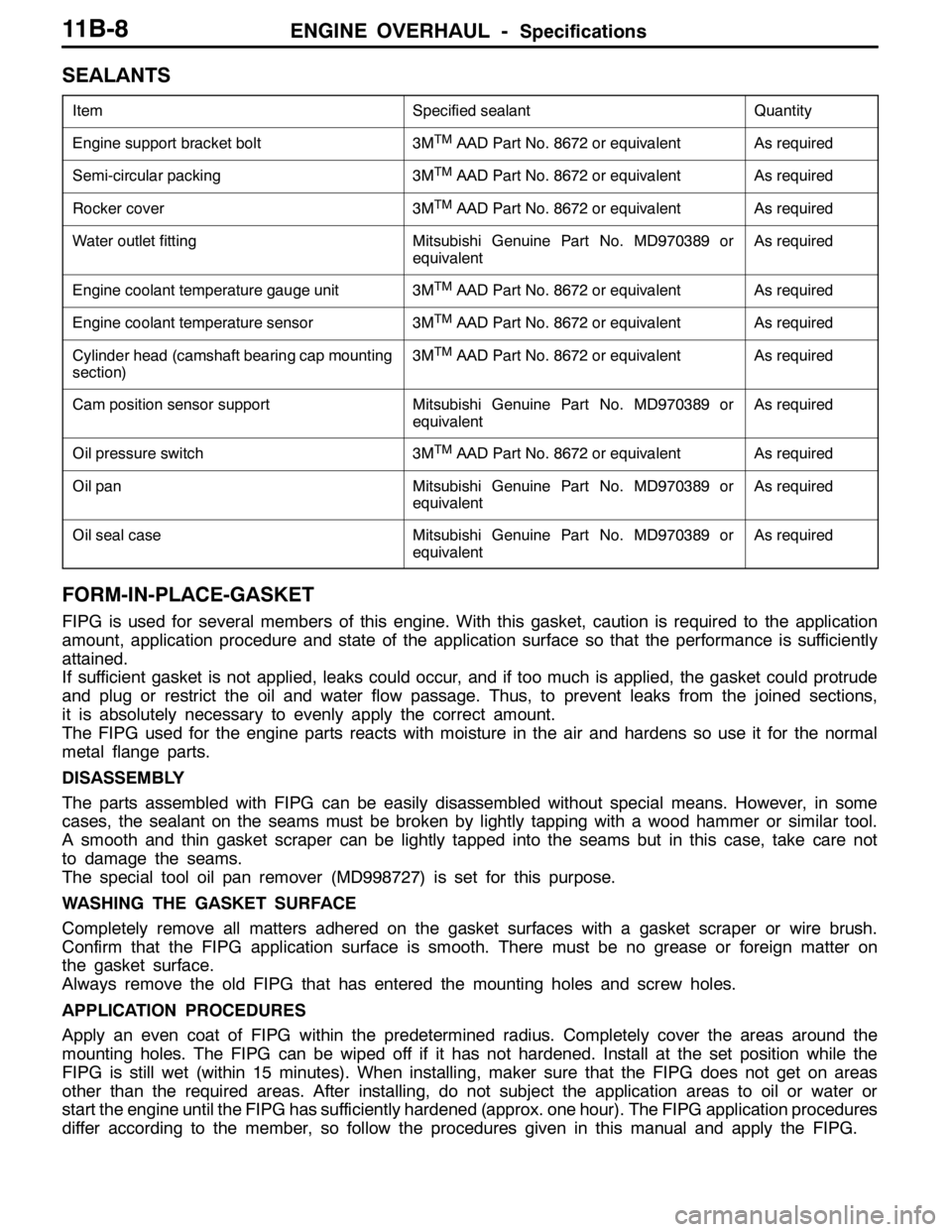

SEALANTS

ItemSpecified sealantQuantity

Engine support bracket bolt3MTMAAD Part No. 8672 or equivalentAs required

Semi-circular packing3MTMAAD Part No. 8672 or equivalentAs required

Rocker cover3MTMAAD Part No. 8672 or equivalentAs required

Water outlet fittingMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Engine coolant temperature gauge unit3MTMAAD Part No. 8672 or equivalentAs required

Engine coolant temperature sensor3MTMAAD Part No. 8672 or equivalentAs required

Cylinder head (camshaft bearing cap mounting

section)3MTMAAD Part No. 8672 or equivalentAs required

Cam position sensor supportMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil pressure switch3MTMAAD Part No. 8672 or equivalentAs required

Oil panMitsubishi Genuine Part No. MD970389 or

equivalentAs required

Oil seal caseMitsubishi Genuine Part No. MD970389 or

equivalentAs required

FORM-IN-PLACE-GASKET

FIPG is used for several members of this engine. With this gasket, caution is required to the application

amount, application procedure and state of the application surface so that the performance is sufficiently

attained.

If sufficient gasket is not applied, leaks could occur, and if too much is applied, the gasket could protrude

and plug or restrict the oil and water flow passage. Thus, to prevent leaks from the joined sections,

it is absolutely necessary to evenly apply the correct amount.

The FIPG used for the engine parts reacts with moisture in the air and hardens so use it for the normal

metal flange parts.

DISASSEMBLY

The parts assembled with FIPG can be easily disassembled without special means. However, in some

cases, the sealant on the seams must be broken by lightly tapping with a wood hammer or similar tool.

A smooth and thin gasket scraper can be lightly tapped into the seams but in this case, take care not

to damage the seams.

The special tool oil pan remover (MD998727) is set for this purpose.

WASHING THE GASKET SURFACE

Completely remove all matters adhered on the gasket surfaces with a gasket scraper or wire brush.

Confirm that the FIPG application surface is smooth. There must be no grease or foreign matter on

the gasket surface.

Always remove the old FIPG that has entered the mounting holes and screw holes.

APPLICATION PROCEDURES

Apply an even coat of FIPG within the predetermined radius. Completely cover the areas around the

mounting holes. The FIPG can be wiped off if it has not hardened. Install at the set position while the

FIPG is still wet (within 15 minutes). When installing, maker sure that the FIPG does not get on areas

other than the required areas. After installing, do not subject the application areas to oil or water or

start the engine until the FIPG has sufficiently hardened (approx. one hour). The FIPG application procedures

differ according to the member, so follow the procedures given in this manual and apply the FIPG.

Page 471 of 1449

ENGINE OVERHAUL -Timing Belt11B-17

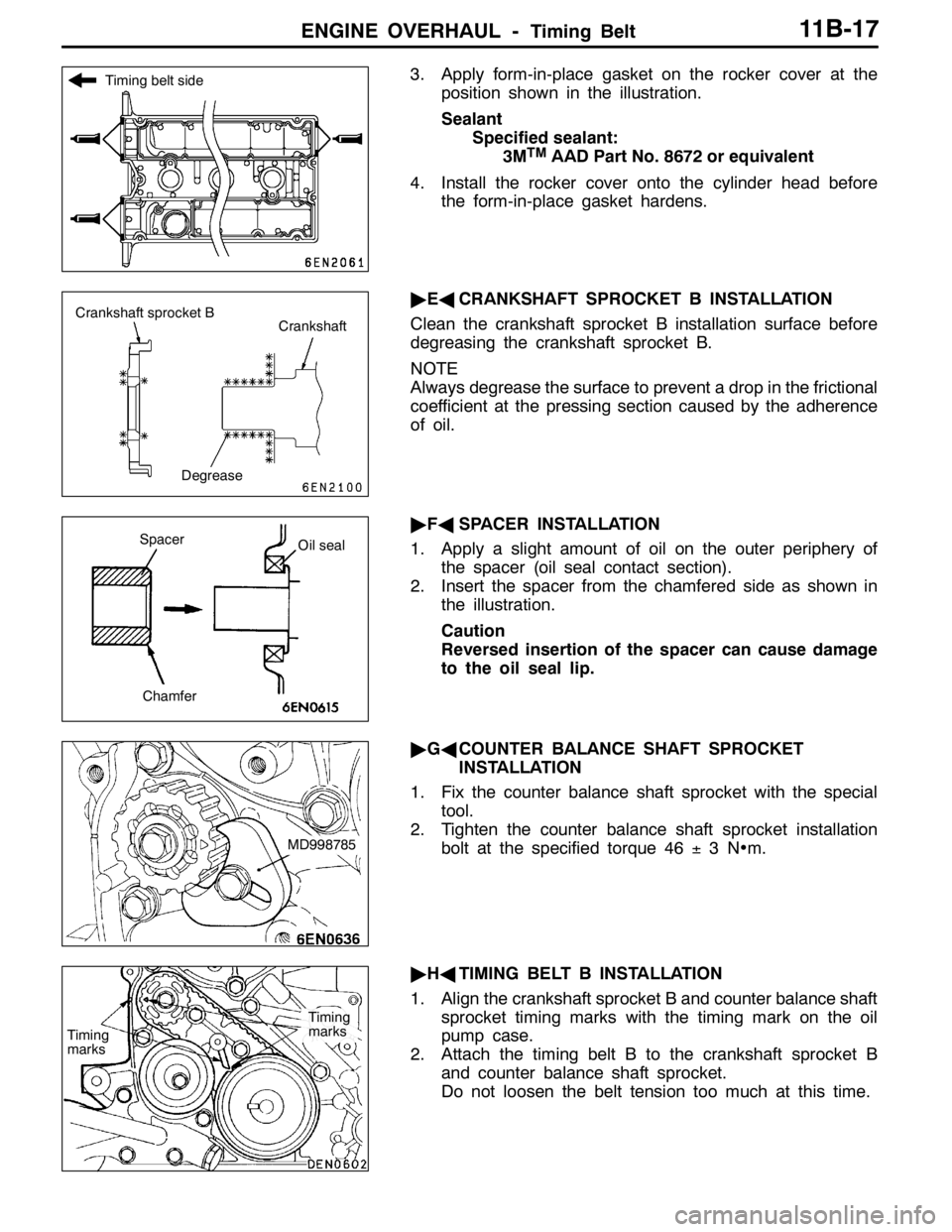

3. Apply form-in-place gasket on the rocker cover at the

position shown in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the rocker cover onto the cylinder head before

the form-in-place gasket hardens.

"EACRANKSHAFT SPROCKET B INSTALLATION

Clean the crankshaft sprocket B installation surface before

degreasing the crankshaft sprocket B.

NOTE

Always degrease the surface to prevent a drop in the frictional

coefficient at the pressing section caused by the adherence

of oil.

"FASPACER INSTALLATION

1. Apply a slight amount of oil on the outer periphery of

the spacer (oil seal contact section).

2. Insert the spacer from the chamfered side as shown in

the illustration.

Caution

Reversed insertion of the spacer can cause damage

to the oil seal lip.

"GACOUNTER BALANCE SHAFT SPROCKET

INSTALLATION

1. Fix the counter balance shaft sprocket with the special

tool.

2. Tighten the counter balance shaft sprocket installation

bolt at the specified torque 46±3N•m.

"HATIMING BELT B INSTALLATION

1. Align the crankshaft sprocket B and counter balance shaft

sprocket timing marks with the timing mark on the oil

pump case.

2. Attach the timing belt B to the crankshaft sprocket B

and counter balance shaft sprocket.

Do not loosen the belt tension too much at this time.

Timing belt side

Crankshaft sprocket B

Crankshaft

Degrease

Spacer

Oil seal

Chamfer

MD998785

Timing

marks

Timing

marks

Page 472 of 1449

ENGINE OVERHAUL -Timing Belt11B-18

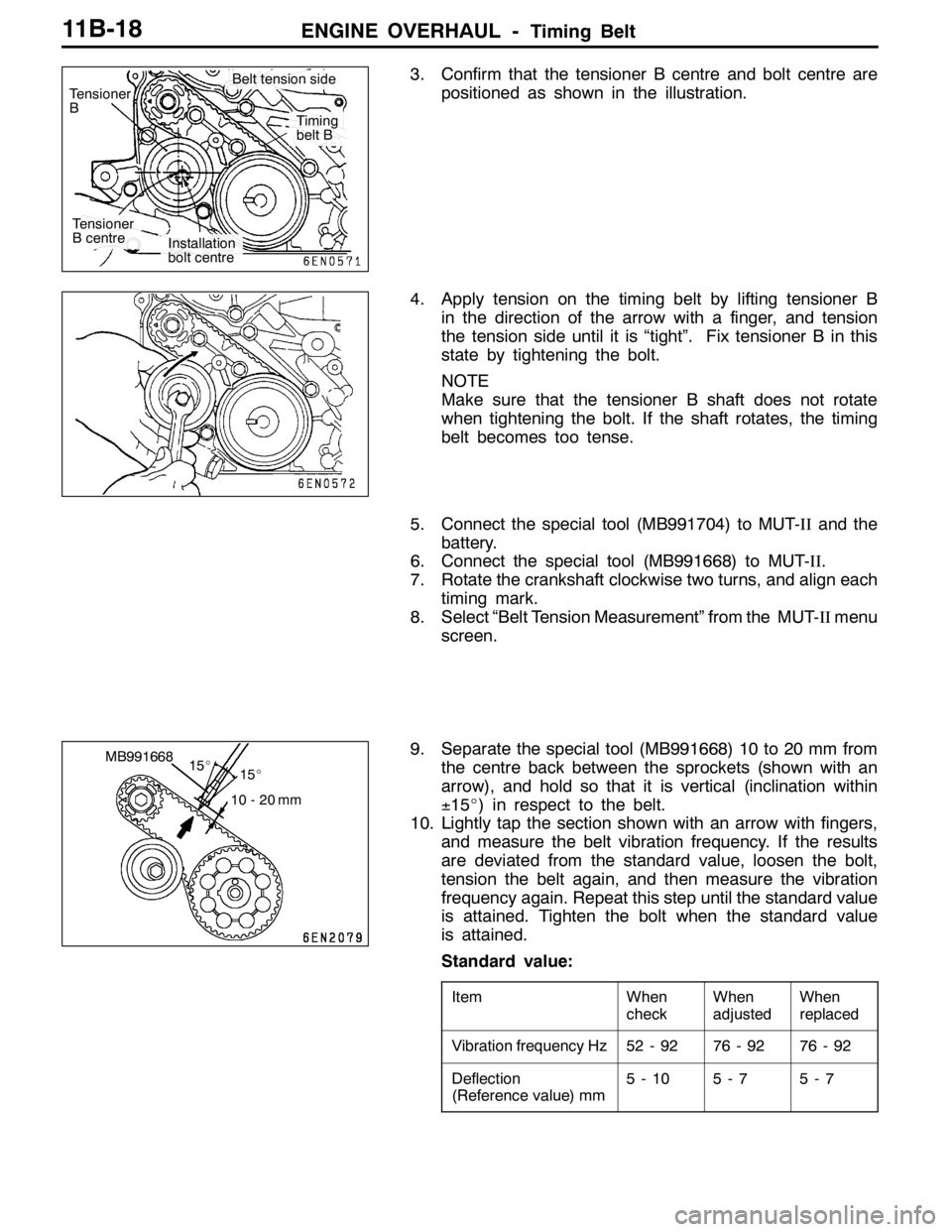

3. Confirm that the tensioner B centre and bolt centre are

positioned as shown in the illustration.

4. Apply tension on the timing belt by lifting tensioner B

in the direction of the arrow with a finger, and tension

the tension side until it is “tight”. Fix tensioner B in this

state by tightening the bolt.

NOTE

Make sure that the tensioner B shaft does not rotate

when tightening the bolt. If the shaft rotates, the timing

belt becomes too tense.

5. Connect the special tool (MB991704) to MUT-IIand the

battery.

6. Connect the special tool (MB991668) to MUT-II.

7. Rotate the crankshaft clockwise two turns, and align each

timing mark.

8. Select “Belt Tension Measurement” from the MUT-IImenu

screen.

9. Separate the special tool (MB991668) 10 to 20 mm from

the centre back between the sprockets (shown with an

arrow), and hold so that it is vertical (inclination within

±15_) in respect to the belt.

10. Lightly tap the section shown with an arrow with fingers,

and measure the belt vibration frequency. If the results

are deviated from the standard value, loosen the bolt,

tension the belt again, and then measure the vibration

frequency again. Repeat this step until the standard value

is attained. Tighten the bolt when the standard value

is attained.

Standard value:

ItemWhen

checkWhen

adjustedWhen

replaced

Vibration frequency Hz52 - 9276 - 9276 - 92

Deflection

(Reference value) mm5-105-75-7

Tensioner

B centre

Installation

bolt centre

Timing

belt B

Belt tension side

Tensioner

B

MB991668

15_ 15_

10 - 20 mm

Page 475 of 1449

ENGINE OVERHAUL -Timing Belt11B-21

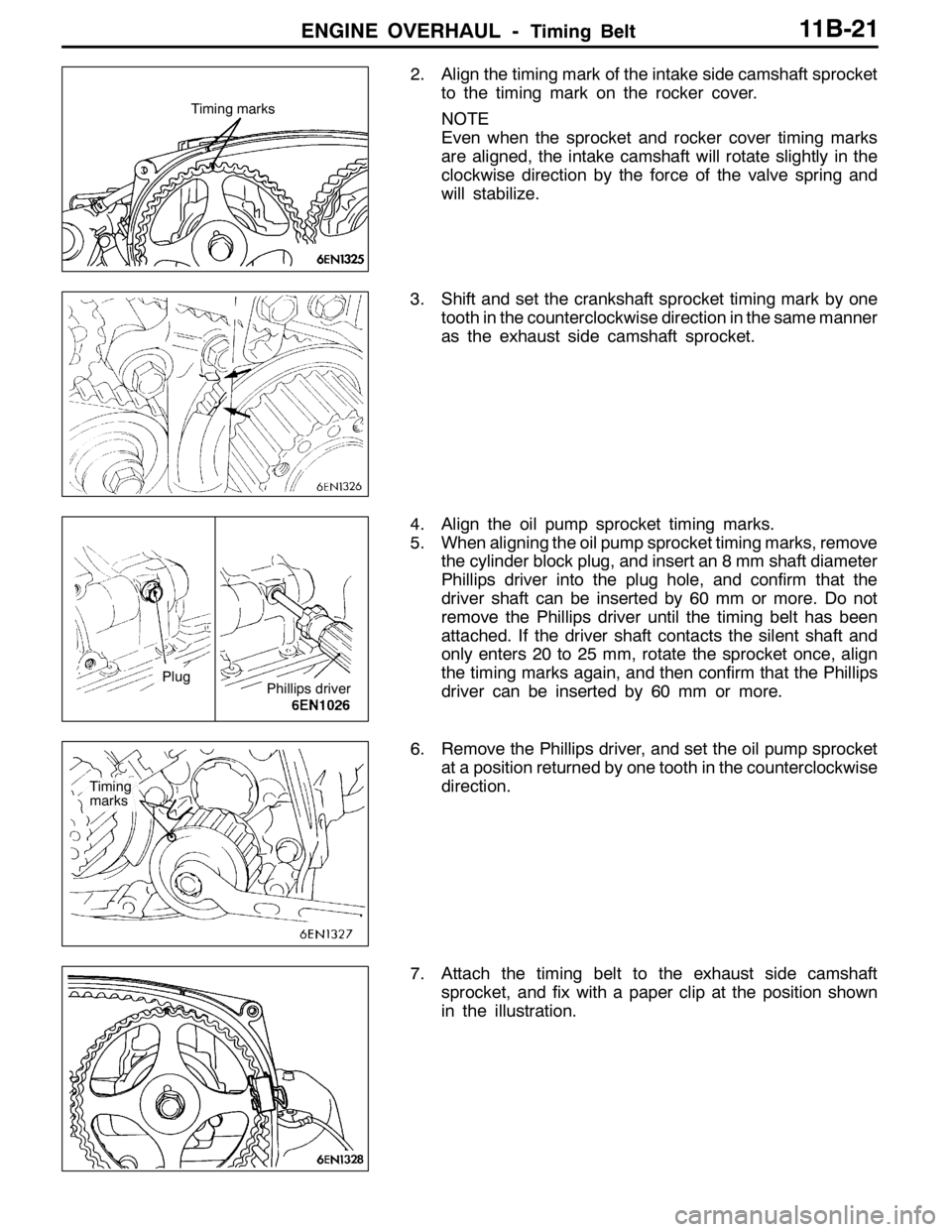

2. Align the timing mark of the intake side camshaft sprocket

to the timing mark on the rocker cover.

NOTE

Even when the sprocket and rocker cover timing marks

are aligned, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

3. Shift and set the crankshaft sprocket timing mark by one

tooth in the counterclockwise direction in the same manner

as the exhaust side camshaft sprocket.

4. Align the oil pump sprocket timing marks.

5. When aligning the oil pump sprocket timing marks, remove

the cylinder block plug, and insert an 8 mm shaft diameter

Phillips driver into the plug hole, and confirm that the

driver shaft can be inserted by 60 mm or more. Do not

remove the Phillips driver until the timing belt has been

attached. If the driver shaft contacts the silent shaft and

only enters 20 to 25 mm, rotate the sprocket once, align

the timing marks again, and then confirm that the Phillips

driver can be inserted by 60 mm or more.

6. Remove the Phillips driver, and set the oil pump sprocket

at a position returned by one tooth in the counterclockwise

direction.

7. Attach the timing belt to the exhaust side camshaft

sprocket, and fix with a paper clip at the position shown

in the illustration.

Timing marks

Phillips driverPlug

Timing

marks

Page 476 of 1449

ENGINE OVERHAUL -Timing Belt11B-22

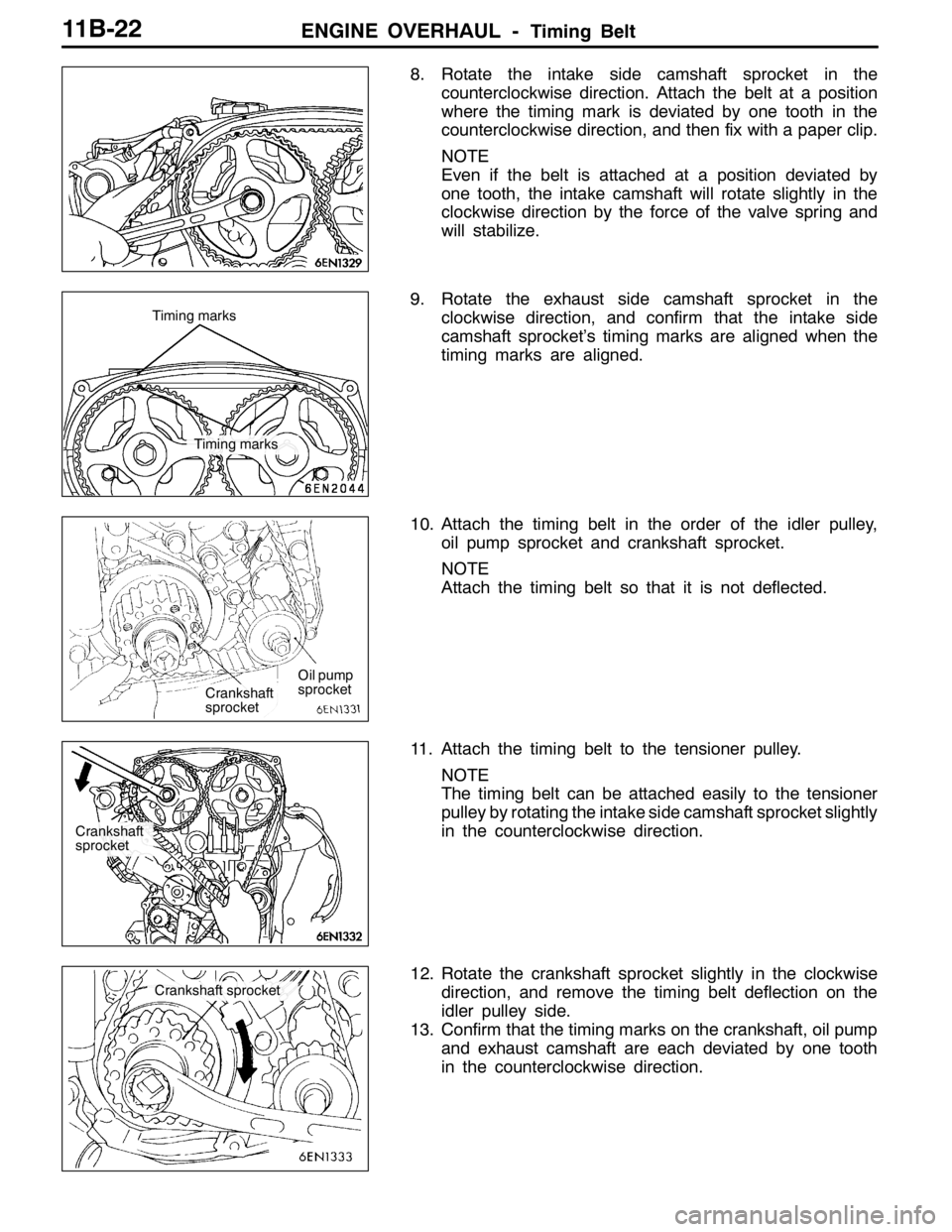

8. Rotate the intake side camshaft sprocket in the

counterclockwise direction. Attach the belt at a position

where the timing mark is deviated by one tooth in the

counterclockwise direction, and then fix with a paper clip.

NOTE

Even if the belt is attached at a position deviated by

one tooth, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

9. Rotate the exhaust side camshaft sprocket in the

clockwise direction, and confirm that the intake side

camshaft sprocket’s timing marks are aligned when the

timing marks are aligned.

10. Attach the timing belt in the order of the idler pulley,

oil pump sprocket and crankshaft sprocket.

NOTE

Attach the timing belt so that it is not deflected.

11. Attach the timing belt to the tensioner pulley.

NOTE

The timing belt can be attached easily to the tensioner

pulley by rotating the intake side camshaft sprocket slightly

in the counterclockwise direction.

12. Rotate the crankshaft sprocket slightly in the clockwise

direction, and remove the timing belt deflection on the

idler pulley side.

13. Confirm that the timing marks on the crankshaft, oil pump

and exhaust camshaft are each deviated by one tooth

in the counterclockwise direction.

Timing marks Timing marks

Crankshaft

sprocketOil pump

sprocket

Crankshaft

sprocket

Crankshaft sprocket

Page 477 of 1449

ENGINE OVERHAUL -Timing Belt11B-23

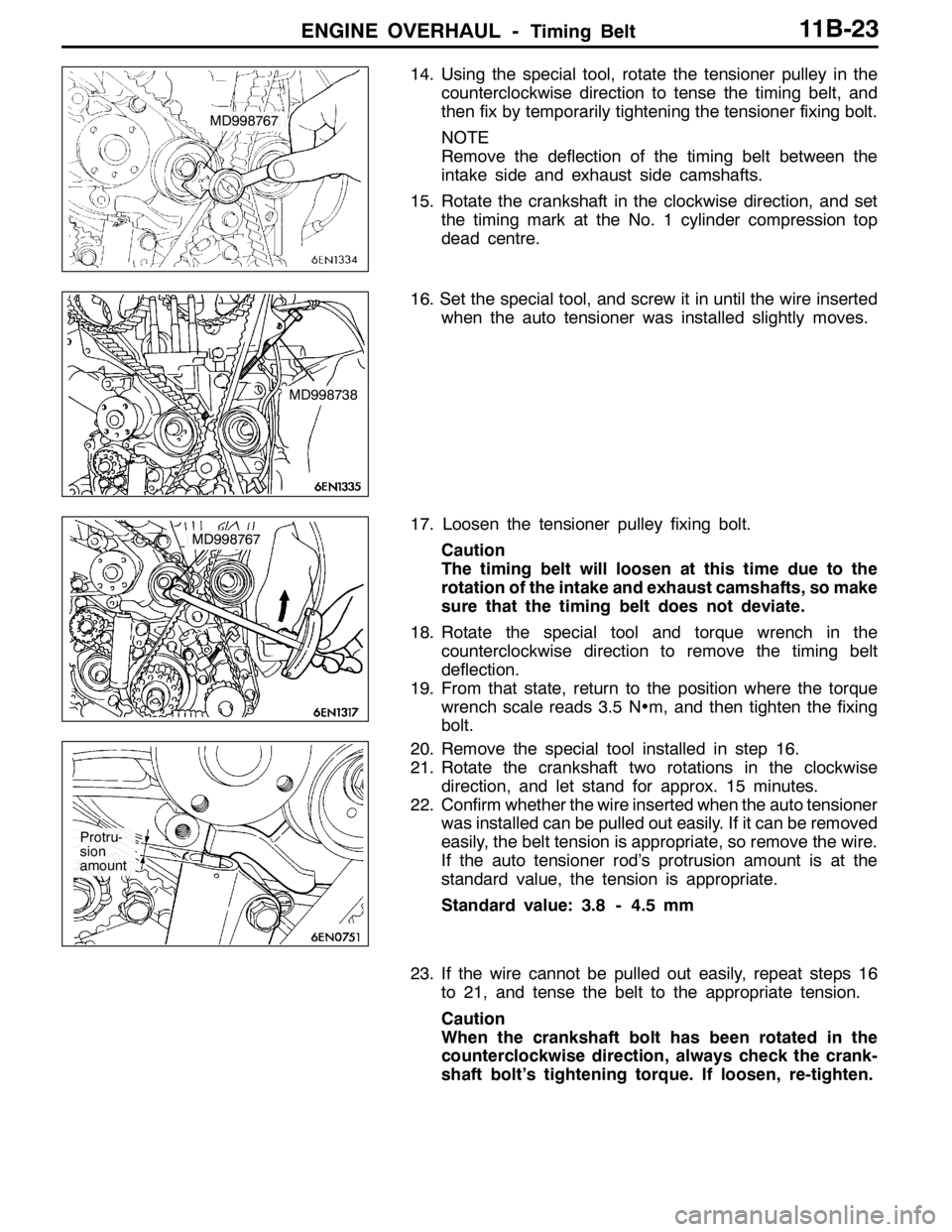

14. Using the special tool, rotate the tensioner pulley in the

counterclockwise direction to tense the timing belt, and

then fix by temporarily tightening the tensioner fixing bolt.

NOTE

Remove the deflection of the timing belt between the

intake side and exhaust side camshafts.

15. Rotate the crankshaft in the clockwise direction, and set

the timing mark at the No. 1 cylinder compression top

dead centre.

16. Set the special tool, and screw it in until the wire inserted

when the auto tensioner was installed slightly moves.

17. Loosen the tensioner pulley fixing bolt.

Caution

The timing belt will loosen at this time due to the

rotation of the intake and exhaust camshafts, so make

sure that the timing belt does not deviate.

18. Rotate the special tool and torque wrench in the

counterclockwise direction to remove the timing belt

deflection.

19. From that state, return to the position where the torque

wrench scale reads 3.5 N•m, and then tighten the fixing

bolt.

20. Remove the special tool installed in step 16.

21. Rotate the crankshaft two rotations in the clockwise

direction, and let stand for approx. 15 minutes.

22. Confirm whether the wire inserted when the auto tensioner

was installed can be pulled out easily. If it can be removed

easily, the belt tension is appropriate, so remove the wire.

If the auto tensioner rod’s protrusion amount is at the

standard value, the tension is appropriate.

Standard value: 3.8 - 4.5 mm

23. If the wire cannot be pulled out easily, repeat steps 16

to 21, and tense the belt to the appropriate tension.

Caution

When the crankshaft bolt has been rotated in the

counterclockwise direction, always check the crank-

shaft bolt’s tightening torque. If loosen, re-tighten.

MD998767

MD998738

MD998767

Protru-

sion

amount

Page 485 of 1449

ENGINE OVERHAUL -Exhaust Manifold11B-31

INSTALLATION SERVICE POINTS

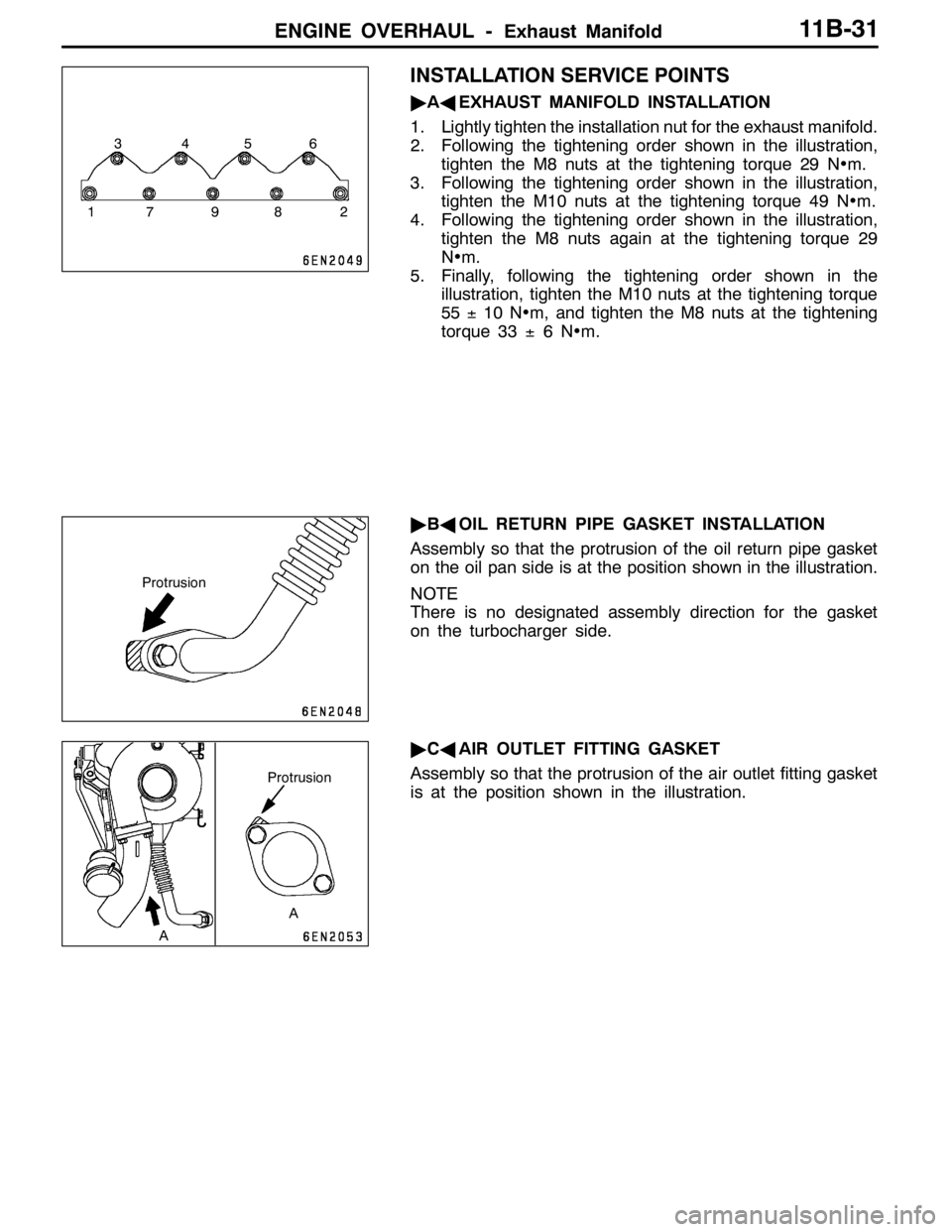

"AAEXHAUST MANIFOLD INSTALLATION

1. Lightly tighten the installation nut for the exhaust manifold.

2. Following the tightening order shown in the illustration,

tighten the M8 nuts at the tightening torque 29 N•m.

3. Following the tightening order shown in the illustration,

tighten the M10 nuts at the tightening torque 49 N•m.

4. Following the tightening order shown in the illustration,

tighten the M8 nuts again at the tightening torque 29

N•m.

5. Finally, following the tightening order shown in the

illustration, tighten the M10 nuts at the tightening torque

55±10 N•m, and tighten the M8 nuts at the tightening

torque 33±6N•m.

"BAOIL RETURN PIPE GASKET INSTALLATION

Assembly so that the protrusion of the oil return pipe gasket

on the oil pan side is at the position shown in the illustration.

NOTE

There is no designated assembly direction for the gasket

on the turbocharger side.

"CAAIR OUTLET FITTING GASKET

Assembly so that the protrusion of the air outlet fitting gasket

is at the position shown in the illustration.

7982 13456

Protrusion

Protrusion

AA

Page 490 of 1449

ENGINE OVERHAUL -Rocker Arm and Camshaft11B-36

3. Apply sealant on the contact surfaces with the head shown

in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the bearing caps onto the cylinder head, and in

two to three steps tighten strongly.

5. Finally, tighten at the specified torque 20±1N•m.

6. Confirm that the rocker arm is correctly installed.

NOTE

Wipe off all excessive sealant.

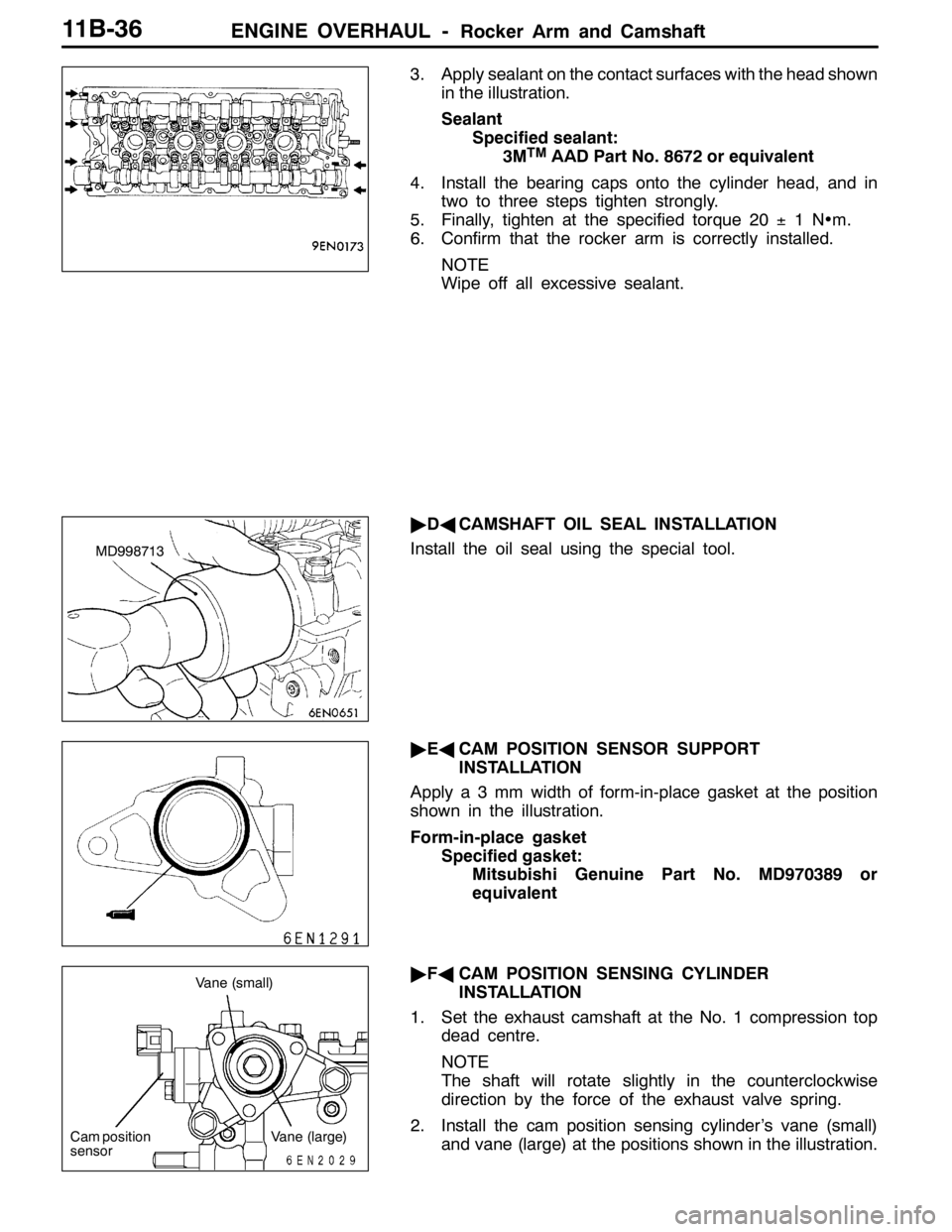

"DACAMSHAFT OIL SEAL INSTALLATION

Install the oil seal using the special tool.

"EACAM POSITION SENSOR SUPPORT

INSTALLATION

Apply a 3 mm width of form-in-place gasket at the position

shown in the illustration.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

"FACAM POSITION SENSING CYLINDER

INSTALLATION

1. Set the exhaust camshaft at the No. 1 compression top

dead centre.

NOTE

The shaft will rotate slightly in the counterclockwise

direction by the force of the exhaust valve spring.

2. Install the cam position sensing cylinder’s vane (small)

and vane (large) at the positions shown in the illustration.

MD998713

Vane (small)

Cam position

sensorVane (large)