sensor MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1103 of 1449

ABS <4WD> -Wheel Speed Sensor35B-33

WHEEL SPEED SENSOR

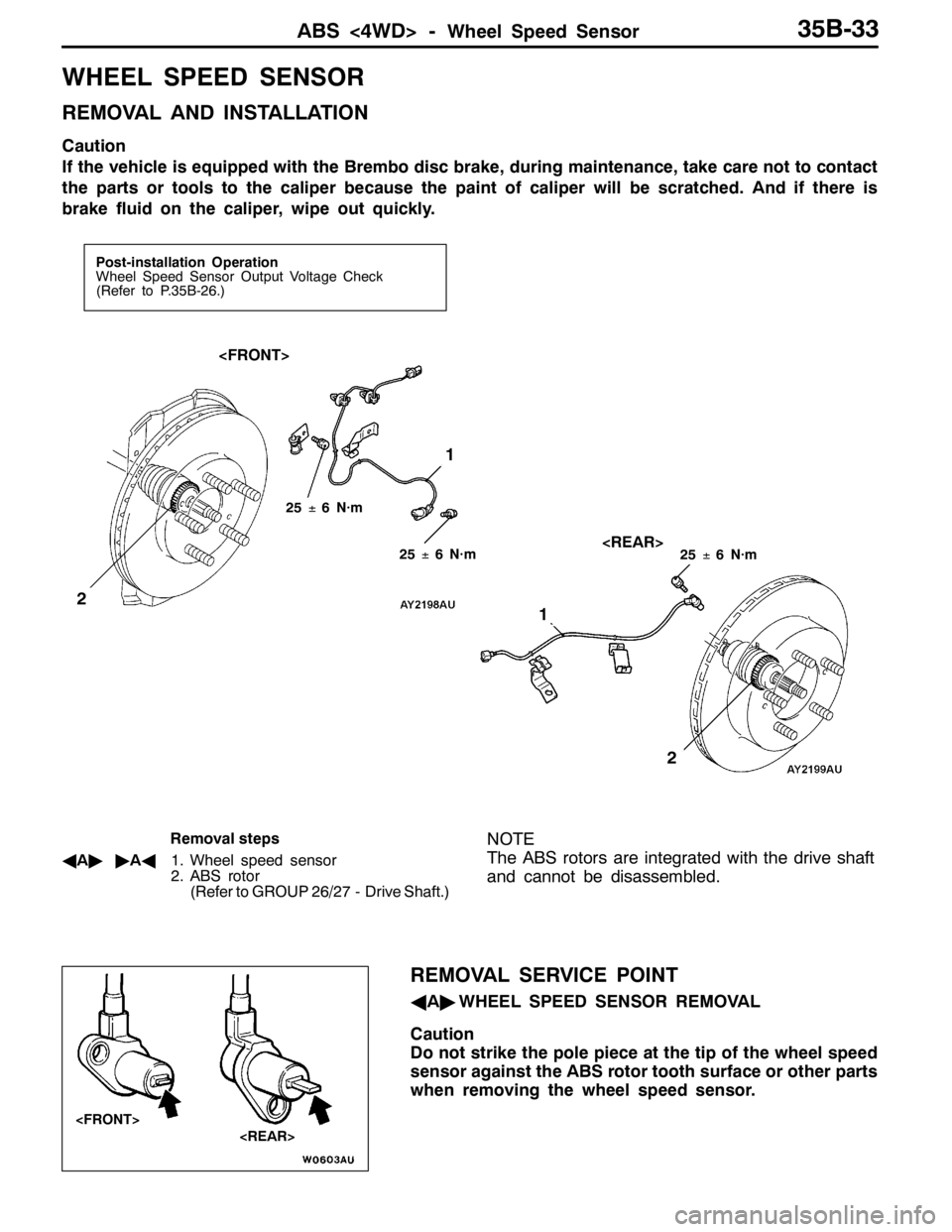

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched. And if there is

brake fluid on the caliper, wipe out quickly.

Post-installation Operation

Wheel Speed Sensor Output Voltage Check

(Refer to P.35B-26.)

1

2

1

2

25±6 N·m

25±6 N·m25±6 N·m

Removal steps

AA""AA1. Wheel speed sensor

2. ABS rotor

(Refer to GROUP 26/27 - Drive Shaft.)NOTE

The ABS rotors are integrated with the drive shaft

and cannot be disassembled.

REMOVAL SERVICE POINT

AA"WHEEL SPEED SENSOR REMOVAL

Caution

Do not strike the pole piece at the tip of the wheel speed

sensor against the ABS rotor tooth surface or other parts

when removing the wheel speed sensor.

Page 1104 of 1449

ABS <4WD> -Wheel Speed Sensor35B-34

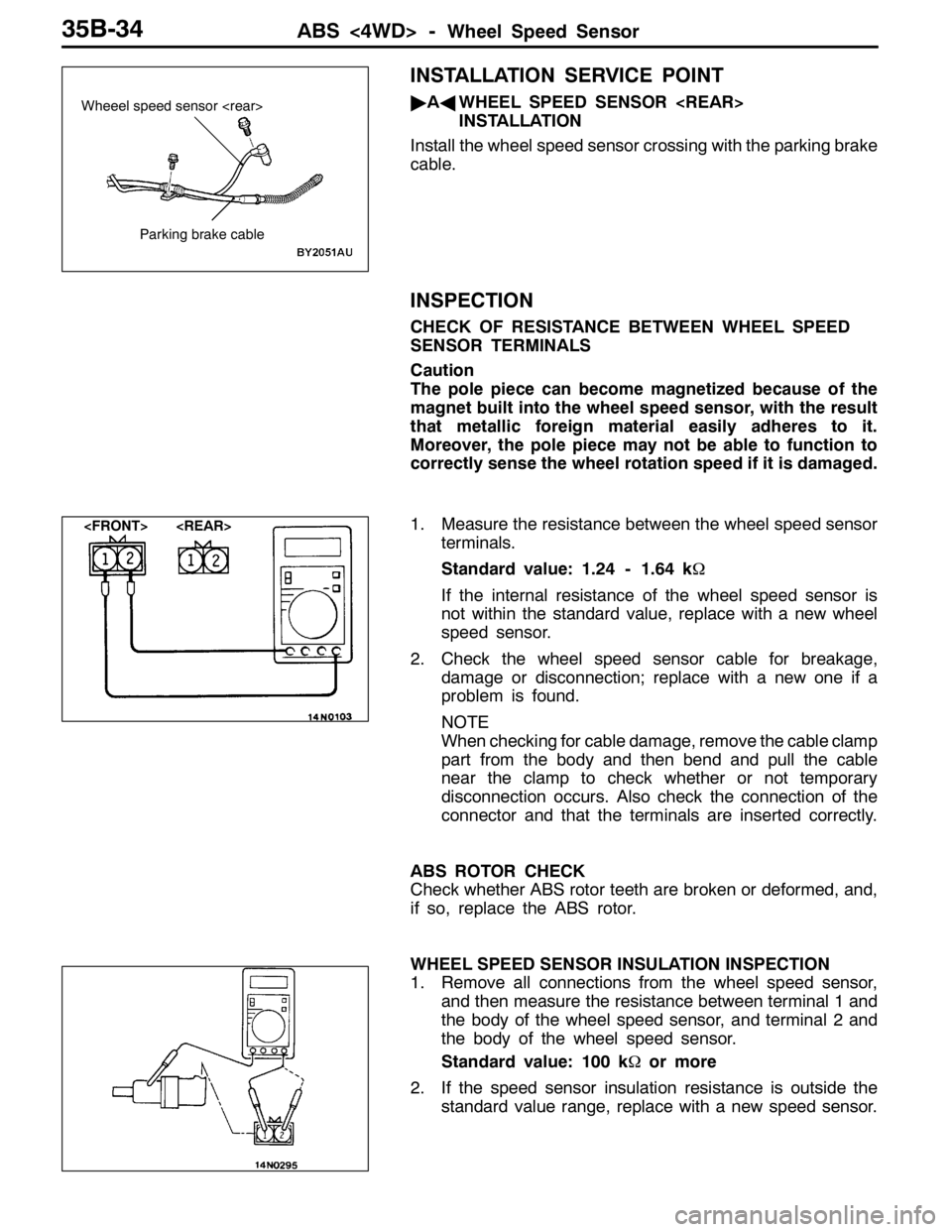

INSTALLATION SERVICE POINT

"AAWHEEL SPEED SENSOR

INSTALLATION

Install the wheel speed sensor crossing with the parking brake

cable.

INSPECTION

CHECK OF RESISTANCE BETWEEN WHEEL SPEED

SENSOR TERMINALS

Caution

The pole piece can become magnetized because of the

magnet built into the wheel speed sensor, with the result

that metallic foreign material easily adheres to it.

Moreover, the pole piece may not be able to function to

correctly sense the wheel rotation speed if it is damaged.

1. Measure the resistance between the wheel speed sensor

terminals.

Standard value: 1.24 - 1.64 kΩ

If the internal resistance of the wheel speed sensor is

not within the standard value, replace with a new wheel

speed sensor.

2. Check the wheel speed sensor cable for breakage,

damage or disconnection; replace with a new one if a

problem is found.

NOTE

When checking for cable damage, remove the cable clamp

part from the body and then bend and pull the cable

near the clamp to check whether or not temporary

disconnection occurs. Also check the connection of the

connector and that the terminals are inserted correctly.

ABS ROTOR CHECK

Check whether ABS rotor teeth are broken or deformed, and,

if so, replace the ABS rotor.

WHEEL SPEED SENSOR INSULATION INSPECTION

1. Remove all connections from the wheel speed sensor,

and then measure the resistance between terminal 1 and

the body of the wheel speed sensor, and terminal 2 and

the body of the wheel speed sensor.

Standard value: 100 kΩor more

2. If the speed sensor insulation resistance is outside the

standard value range, replace with a new speed sensor.

Wheeel speed sensor

Parking brake cable

Page 1105 of 1449

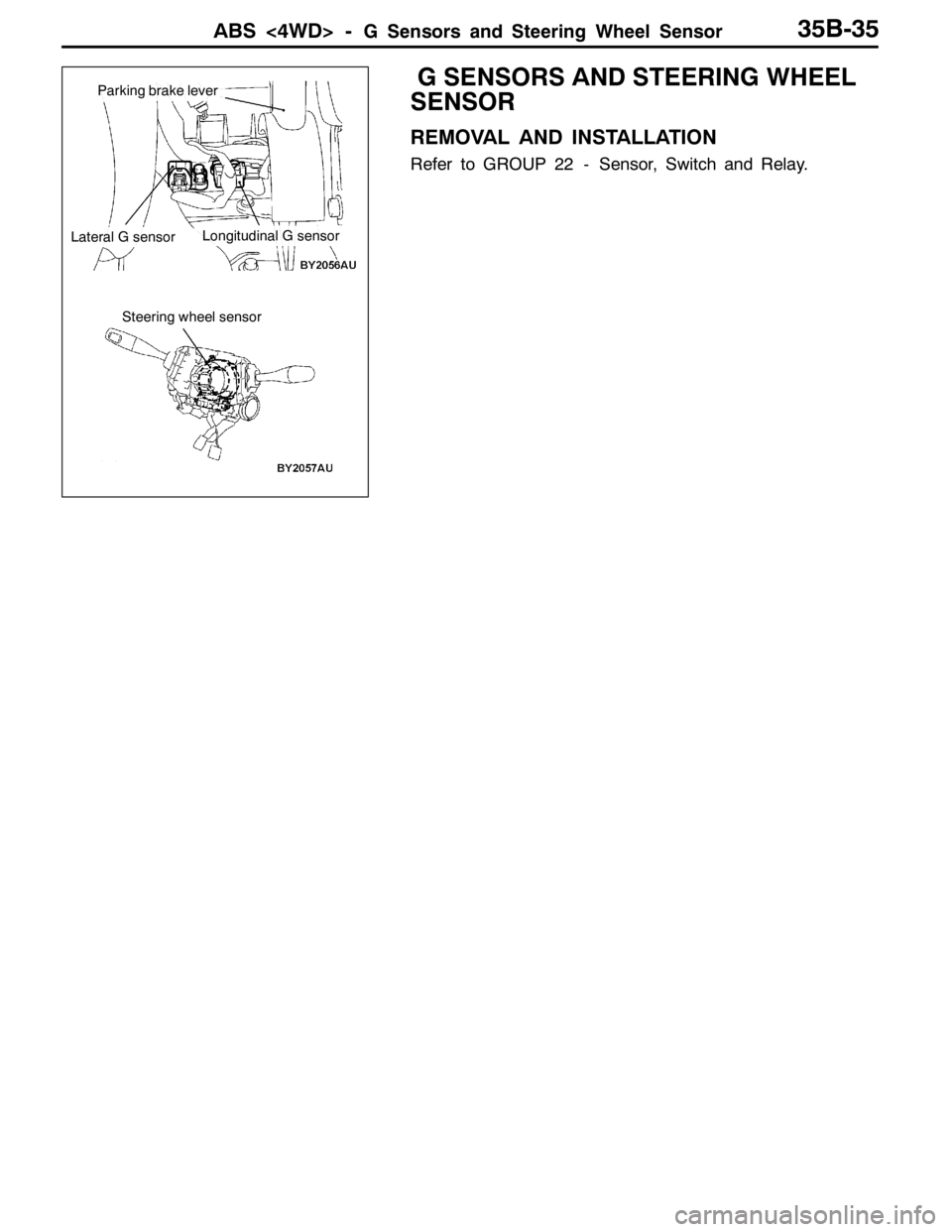

ABS <4WD> -G Sensors and Steering Wheel Sensor35B-35

G SENSORS AND STEERING WHEEL

SENSOR

REMOVAL AND INSTALLATION

Refer to GROUP 22 - Sensor, Switch and Relay.

Parking brake lever

Lateral G sensorLongitudinal G sensor

Steering wheel sensor

Page 1246 of 1449

SRS -General InformationSRS -General Information52B-2

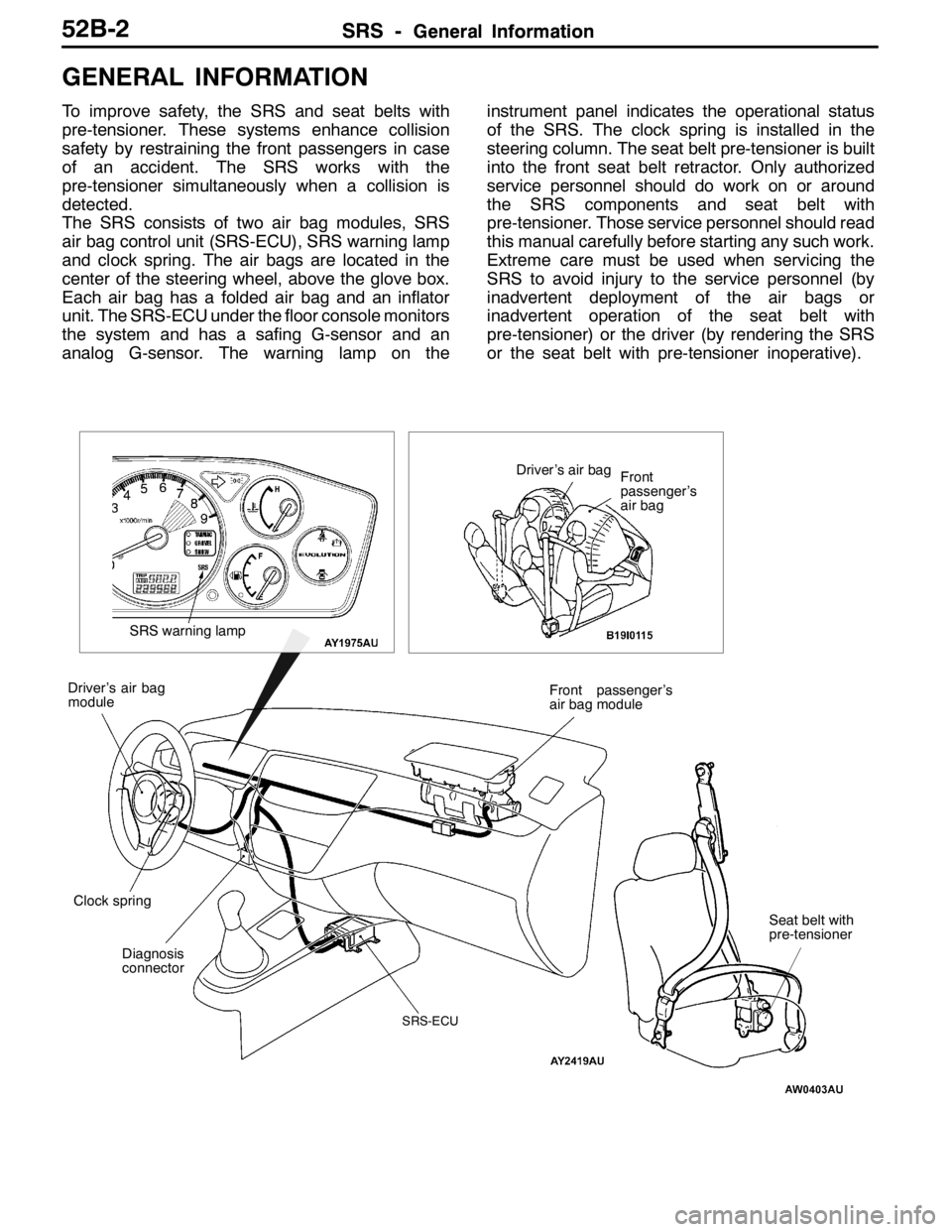

GENERAL INFORMATION

To improve safety, the SRS and seat belts with

pre-tensioner. These systems enhance collision

safety by restraining the front passengers in case

of an accident. The SRS works with the

pre-tensioner simultaneously when a collision is

detected.

The SRS consists of two air bag modules, SRS

air bag control unit (SRS-ECU), SRS warning lamp

and clock spring. The air bags are located in the

center of the steering wheel, above the glove box.

Each air bag has a folded air bag and an inflator

unit. The SRS-ECU under the floor console monitors

the system and has a safing G-sensor and an

analog G-sensor. The warning lamp on theinstrument panel indicates the operational status

of the SRS. The clock spring is installed in the

steering column. The seat belt pre-tensioner is built

into the front seat belt retractor. Only authorized

service personnel should do work on or around

the SRS components and seat belt with

pre-tensioner. Those service personnel should read

this manual carefully before starting any such work.

Extreme care must be used when servicing the

SRS to avoid injury to the service personnel (by

inadvertent deployment of the air bags or

inadvertent operation of the seat belt with

pre-tensioner) or the driver (by rendering the SRS

or the seat belt with pre-tensioner inoperative).

Diagnosis

connectorFront passenger’s

air bag module

Clock spring Driver’s air bag

module

SRS-ECU

SRS warning lamp

Driver’s air bag

Front

passenger’s

air bag

Seat belt with

pre-tensioner

Page 1253 of 1449

SRS -Troubleshooting52B-9

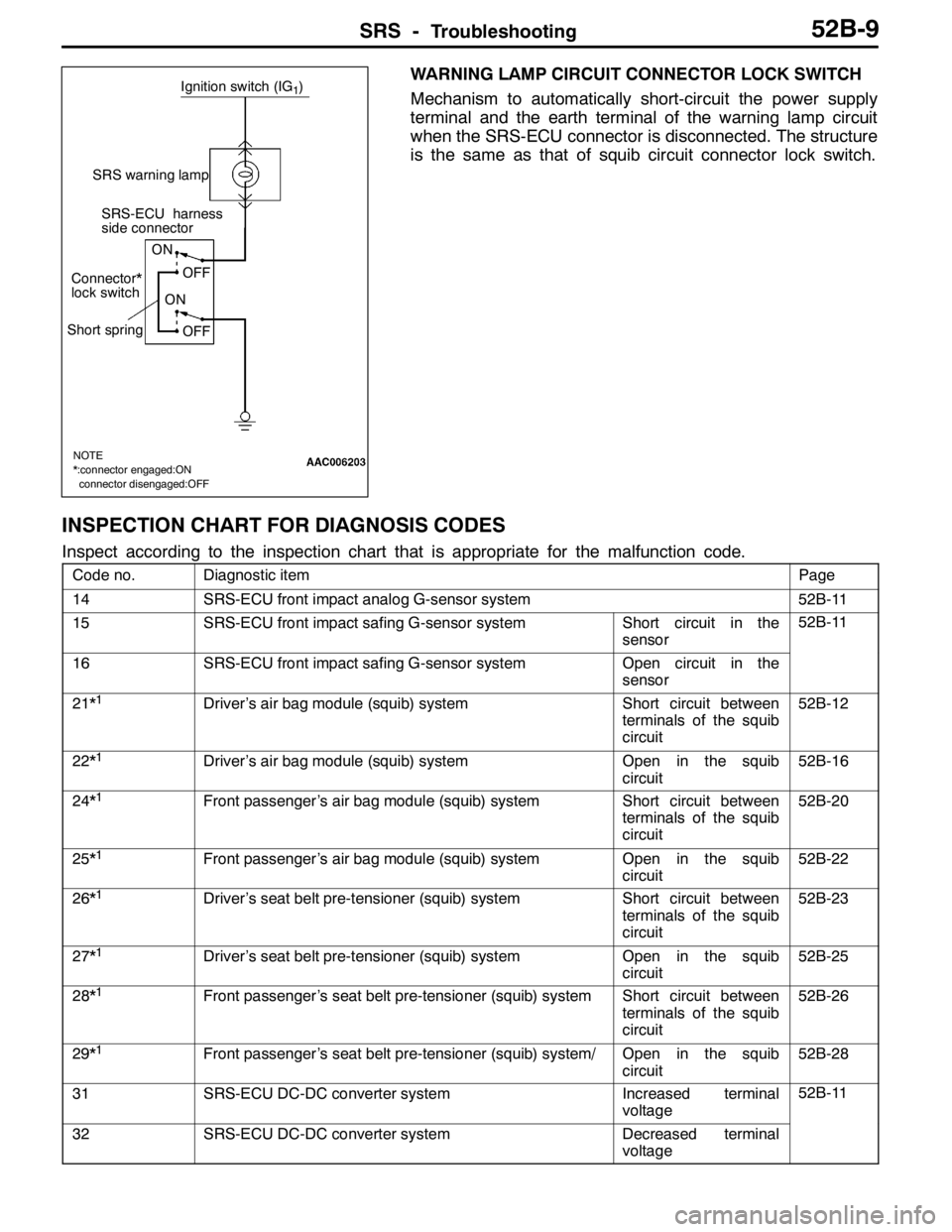

WARNING LAMP CIRCUIT CONNECTOR LOCK SWITCH

Mechanism to automatically short-circuit the power supply

terminal and the earth terminal of the warning lamp circuit

when the SRS-ECU connector is disconnected. The structure

is the same as that of squib circuit connector lock switch.

INSPECTION CHART FOR DIAGNOSIS CODES

Inspect according to the inspection chart that is appropriate for the malfunction code.

Code no.Diagnostic itemPage

14SRS-ECU front impact analog G-sensor system52B-11

15SRS-ECU front impact safing G-sensor systemShort circuit in the

sensor52B-11

16SRS-ECU front impact safing G-sensor systemOpen circuit in the

sensor

21*1Driver’s air bag module (squib) systemShort circuit between

terminals of the squib

circuit52B-12

22*1Driver’s air bag module (squib) systemOpen in the squib

circuit52B-16

24*1Front passenger’s air bag module (squib) systemShort circuit between

terminals of the squib

circuit52B-20

25*1Front passenger’s air bag module (squib) systemOpen in the squib

circuit52B-22

26*1Driver’s seat belt pre-tensioner (squib) systemShort circuit between

terminals of the squib

circuit52B-23

27*1Driver’s seat belt pre-tensioner (squib) systemOpen in the squib

circuit52B-25

28*1Front passenger’s seat belt pre-tensioner (squib) systemShort circuit between

terminals of the squib

circuit52B-26

29*1Front passenger’s seat belt pre-tensioner (squib) system/Open in the squib

circuit52B-28

31SRS-ECU DC-DC converter systemIncreased terminal

voltage52B-11

32SRS-ECU DC-DC converter systemDecreased terminal

voltage

Ignition switch (IG1)

SRS warning lamp

SRS-ECU harness

side connector

Short spring

ON

ONOFF

OFF Connector*

lock switch

NOTE

*:connector engaged:ON

connector disengaged:OFF

Page 1255 of 1449

SRS -Troubleshooting52B-11

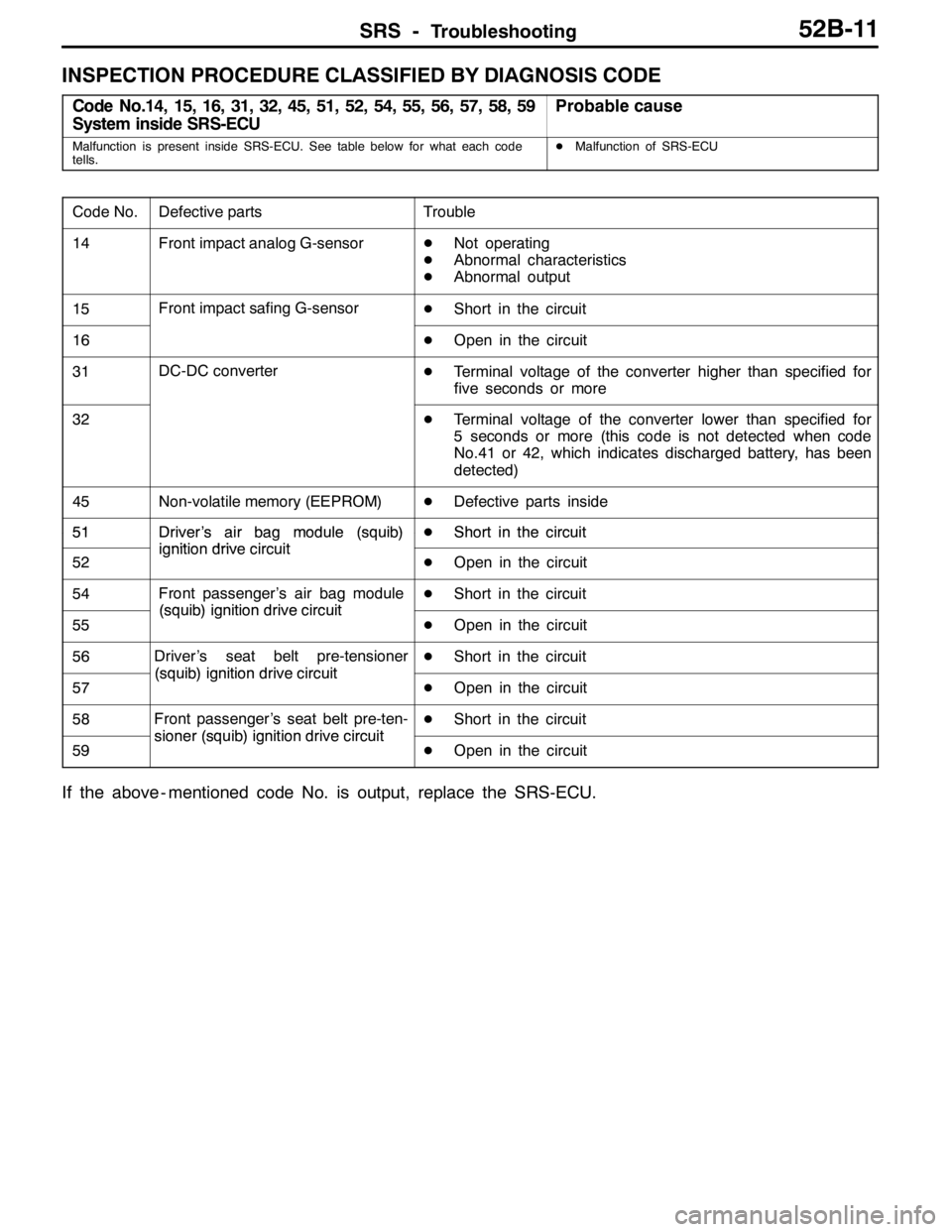

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No.14, 15, 16, 31, 32, 45, 51, 52, 54, 55, 56, 57, 58, 59

System inside SRS-ECUProbable cause

Malfunction is present inside SRS-ECU. See table below for what each code

tells.DMalfunction of SRS-ECU

Code No.Defective partsTrouble

14Front impact analog G-sensorDNot operating

DAbnormal characteristics

DAbnormal output

15Front impact safing G-sensorDShort in the circuit

16DOpen in the circuit

31DC-DC converterDTerminal voltage of the converter higher than specified for

five seconds or more

32DTerminal voltage of the converter lower than specified for

5 seconds or more (this code is not detected when code

No.41 or 42, which indicates discharged battery, has been

detected)

45Non-volatile memory (EEPROM)DDefective parts inside

51Driver’sairbagmodule(squib)DShortinthecircuit51Driver’sairbag module(squib)

ignitiondrivecircuit

DShortinthecircuit

52ignition drive circuitDOpen in the circuit

54Front passenger’s air bag module

(squib)ignitiondrivecircuit

DShort in the circuit

55(squib)ignitiondrive circuitDOpen in the circuit

56Driver’s seat belt pre-tensioner

(squib)ignitiondrivecircuit

DShort in the circuit

57(squib)ignitiondrive circuitDOpen in the circuit

58Front passenger’s seat belt pre-ten-

sioner(squib)ignitiondrivecircuit

DShort in the circuit

59sioner(squib)ignitiondrive circuitDOpen in the circuit

If the above - mentioned code No. is output, replace the SRS-ECU.

Page 1293 of 1449

SRS - Individual Component Service/Warning/Caution Labels52B-49

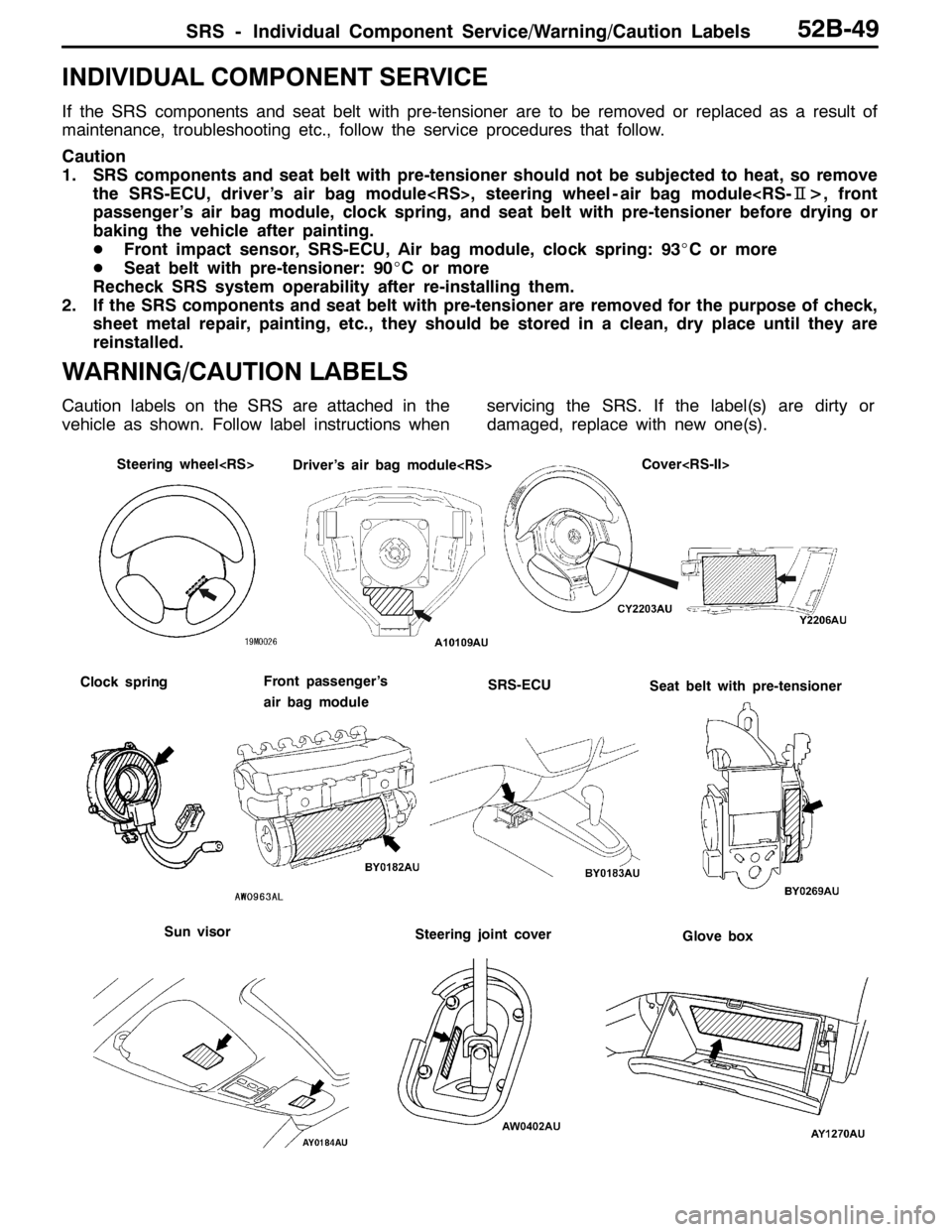

INDIVIDUAL COMPONENT SERVICE

If the SRS components and seat belt with pre-tensioner are to be removed or replaced as a result of

maintenance, troubleshooting etc., follow the service procedures that follow.

Caution

1. SRS components and seat belt with pre-tensioner should not be subjected to heat, so remove

the SRS-ECU, driver’s air bag module

passenger’s air bag module, clock spring, and seat belt with pre-tensioner before drying or

baking the vehicle after painting.

DFront impact sensor, SRS-ECU, Air bag module, clock spring: 93_C or more

DSeat belt with pre-tensioner: 90_C or more

Recheck SRS system operability after re-installing them.

2. If the SRS components and seat belt with pre-tensioner are removed for the purpose of check,

sheet metal repair, painting, etc., they should be stored in a clean, dry place until they are

reinstalled.

WARNING/CAUTION LABELS

Caution labels on the SRS are attached in the

vehicle as shown. Follow label instructions whenservicing the SRS. If the label(s) are dirty or

damaged, replace with new one(s).

Steering wheel

Driver’s air bag module

Clock springFront passenger’s

air bag moduleSRS-ECU

Sun visor

Steering joint cover

Glove boxCover

Seat belt with pre-tensioner

Page 1380 of 1449

SWS -Troubleshooting54B-16

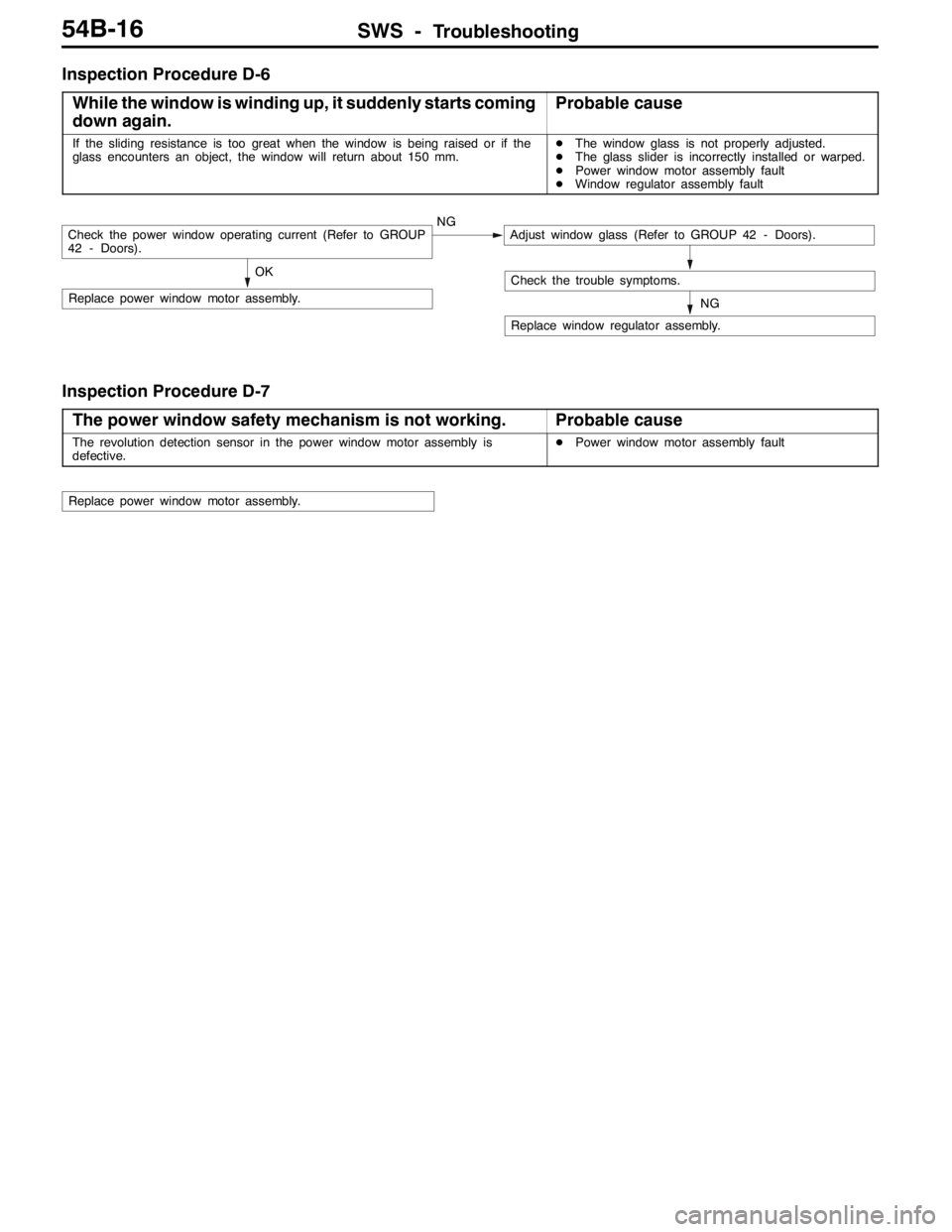

Inspection Procedure D-6

While the window is winding up, it suddenly starts coming

down again.

Probable cause

If the sliding resistance is too great when the window is being raised or if the

glass encounters an object, the window will return about 150 mm.DThe window glass is not properly adjusted.

DThe glass slider is incorrectly installed or warped.

DPower window motor assembly fault

DWindow regulator assembly fault

NG

Replace window regulator assembly.

OK

Replace power window motor assembly.

Check the trouble symptoms.

Check the power window operating current (Refer to GROUP

42 - Doors).NGAdjust window glass (Refer to GROUP 42 - Doors).

Inspection Procedure D-7

The power window safety mechanism is not working.

Probable cause

The revolution detection sensor in the power window motor assembly is

defective.DPower window motor assembly fault

Replace power window motor assembly.

Page 1399 of 1449

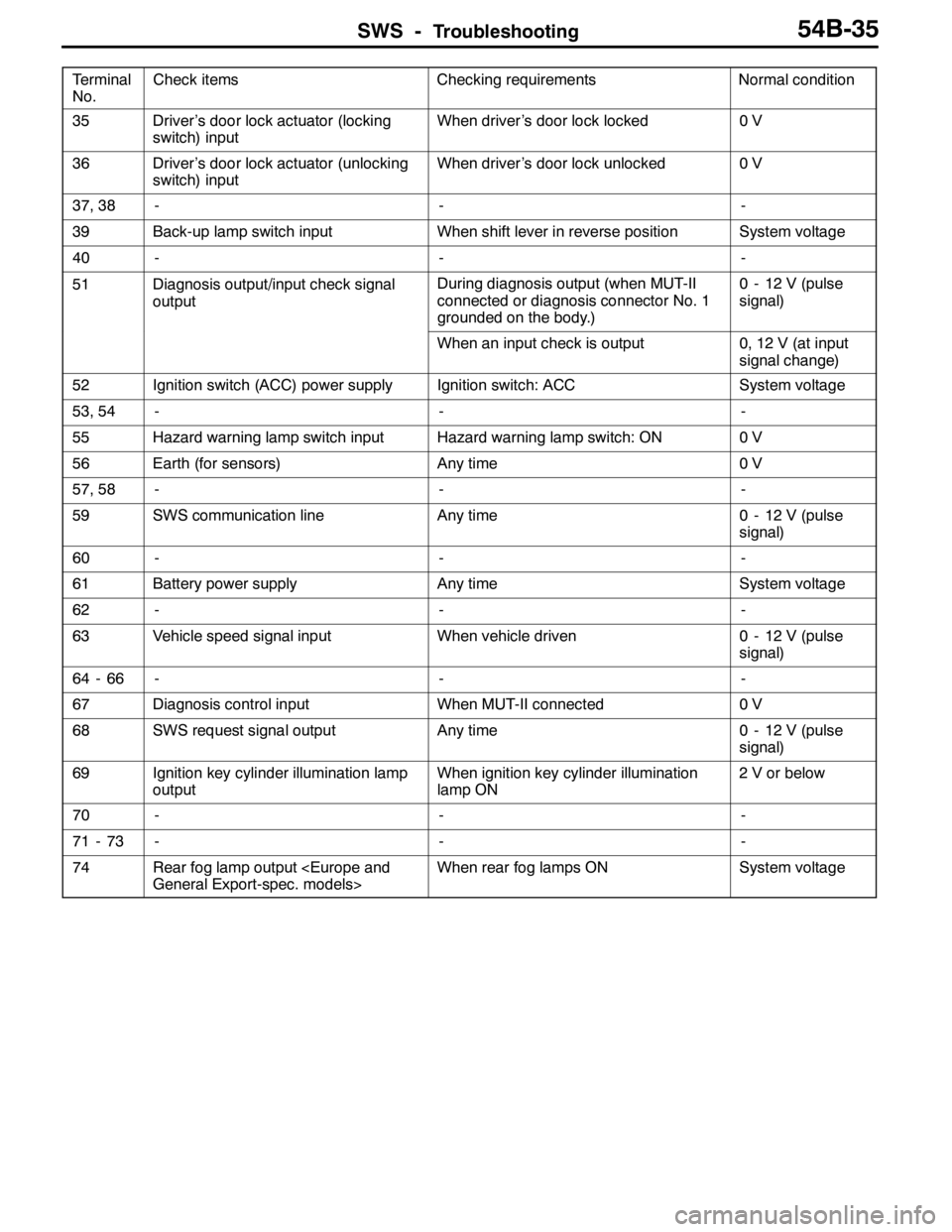

SWS -Troubleshooting54B-35

Terminal

No.Normal condition Checking requirements Check items

35Driver’s door lock actuator (locking

switch) inputWhen driver’s door lock locked0V

36Driver’s door lock actuator (unlocking

switch) inputWhen driver’s door lock unlocked0V

37, 38---

39Back-up lamp switch inputWhen shift lever in reverse positionSystem voltage

40---

51Diagnosis output/input check signal

outputDuring diagnosis output (when MUT-II

connected or diagnosis connector No. 1

grounded on the body.)0 - 12 V (pulse

signal)

When an input check is output0, 12 V (at input

signal change)

52Ignition switch (ACC) power supplyIgnition switch: ACCSystem voltage

53, 54---

55Hazard warning lamp switch inputHazard warning lamp switch: ON0V

56Earth (for sensors)Any time0V

57, 58---

59SWS communication lineAny time0 - 12 V (pulse

signal)

60---

61Battery power supplyAny timeSystem voltage

62---

63Vehicle speed signal inputWhen vehicle driven0 - 12 V (pulse

signal)

64 - 66---

67Diagnosis control inputWhen MUT-II connected0V

68SWS request signal outputAny time0 - 12 V (pulse

signal)

69Ignition key cylinder illumination lamp

outputWhen ignition key cylinder illumination

lamp ON2 V or below

70---

71 - 73---

74Rear fog lamp output

Page 1403 of 1449

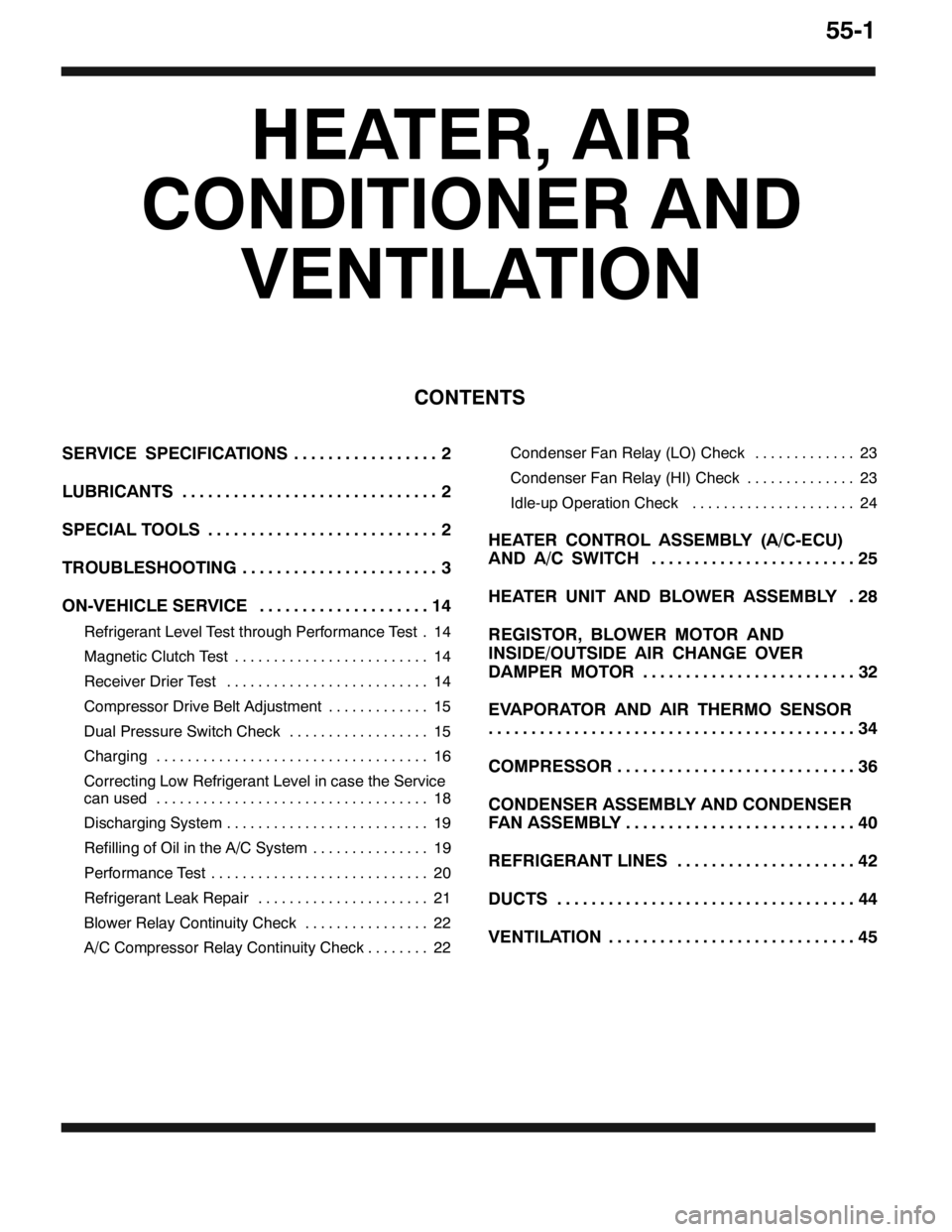

55-1

HEATER, AIR

CONDITIONER AND

VENTILATION

CONTENTS

SERVICE SPECIFICATIONS 2.................

LUBRICANTS 2..............................

SPECIAL TOOLS 2...........................

TROUBLESHOOTING 3.......................

ON-VEHICLE SERVICE 14....................

Refrigerant Level Test through Performance Test 14.

Magnetic Clutch Test 14.........................

Receiver Drier Test 14..........................

Compressor Drive Belt Adjustment 15.............

Dual Pressure Switch Check 15..................

Charging 16...................................

Correcting Low Refrigerant Level in case the Service

can used 18...................................

Discharging System 19..........................

Refilling of Oil in the A/C System 19...............

Performance Test 20............................

Refrigerant Leak Repair 21......................

Blower Relay Continuity Check 22................

A/C Compressor Relay Continuity Check 22........Condenser Fan Relay (LO) Check 23.............

Condenser Fan Relay (HI) Check 23..............

Idle-up Operation Check 24.....................

HEATER CONTROL ASSEMBLY (A/C-ECU)

AND A/C SWITCH 25........................

HEATER UNIT AND BLOWER ASSEMBLY 28.

REGISTOR, BLOWER MOTOR AND

INSIDE/OUTSIDE AIR CHANGE OVER

DAMPER MOTOR 32.........................

EVAPORATOR AND AIR THERMO SENSOR

34 ...........................................

COMPRESSOR 36............................

CONDENSER ASSEMBLY AND CONDENSER

FAN ASSEMBLY 40...........................

REFRIGERANT LINES 42.....................

DUCTS 44...................................

VENTILATION 45.............................