sensor MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1060 of 1449

BASIC BRAKE SYSTEM -ProportioningValve,MasterCylinder

and Brake Booster35A-18

Master cylinder removal steps

1. Clutch hose connection

2. Brake fluid level sensor connector

3. Reservoir cap assembly

4. Brake fluid level sensor

5. Brake pipe connection

6. Proportioning valve

7. O ring

8. Master cylinder

Proportioning valve removal steps

5. Brake pipe connection

6. Proportioning valve

7. O ring

Brake booster removal steps

1. Clutch hose connection

2. Brake fluid level sensor connector5. Brake pipe connection

8. Master cylinder

"BADPush rod protrusion amount check and

adjustment

"AA9. Vacuum hose

(With built-in check valve)

10. Snap pin

11. Pin assembly

12. Clevis

DRemove A/C liquid pipe B

from the

retaining clip.(Refer to GROUP 55A

- Refrigerant Line.)

13. Brake booster

14. Sealer

Fitting removal steps

"AA9. Vacuum hose

(With built-in check valve)

15. Fitting

INSTALLATION SERVICE POINTS

"AAVACUUM HOSE CONNECTION

Insert the vacuum hose to the brake booster with its paint

mark facing upward, and then secure the hose by using the

hose clip.

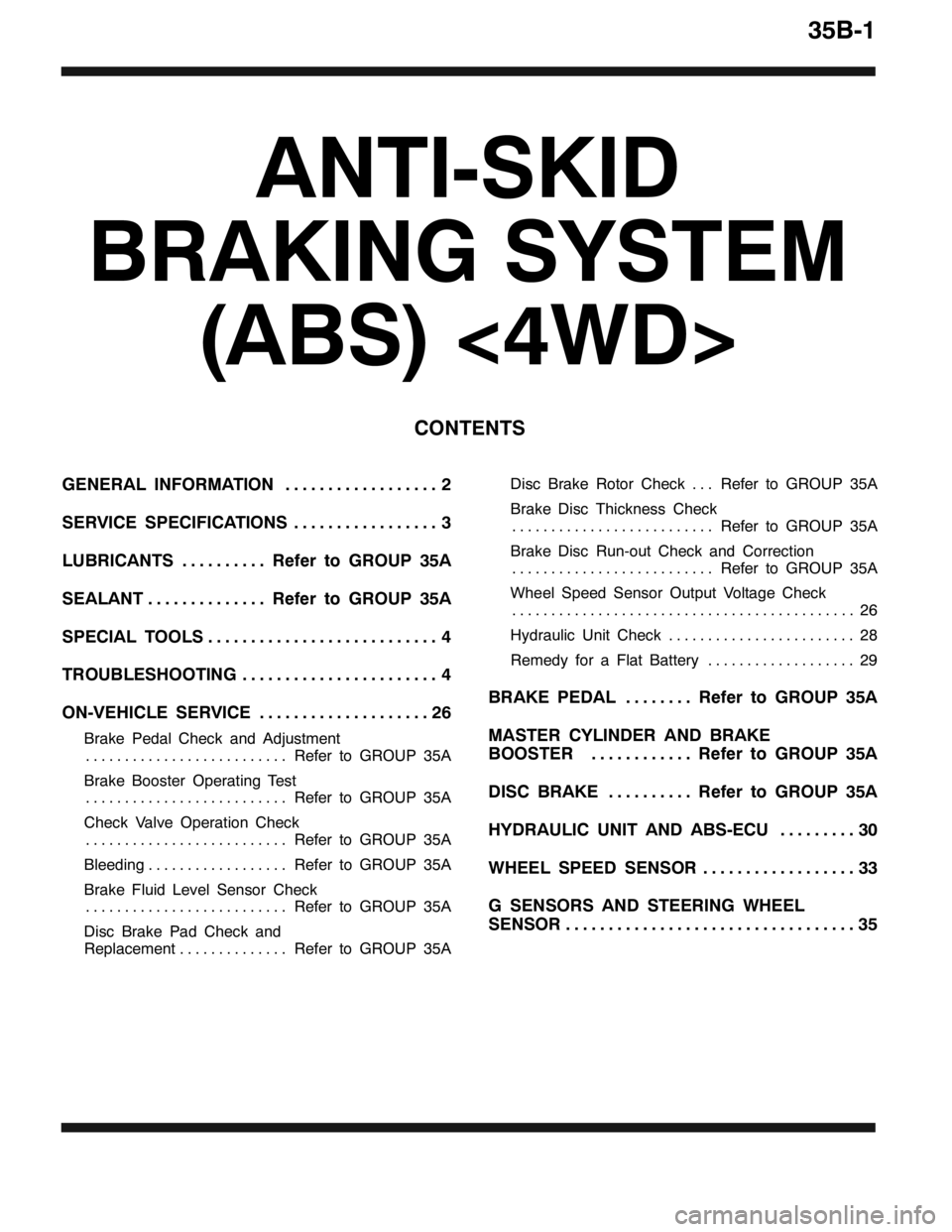

"BAPUSH ROD PROTRUSION AMOUNT CHECK AND

ADJUSTMENT

1. Measure dimension (A).

Standard value (A) : 8.98 - 9.23 mm

NOTE

When a negative pressure of 66.7 kPa is applied to the

brake booster, the push rod should protrude 10.27 – 10.53

mm.

Block gauge Measuring distance A

A

Page 1071 of 1449

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS Refer to GROUP 35A..........

SEALANT Refer to GROUP 35A..............

SPECIAL TOOLS 4...........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 26....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Brake Booster Operating Test

Refer to GROUP 35A ..........................

Check Valve Operation Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and

Replacement Refer to GROUP 35A..............Disc Brake Rotor Check Refer to GROUP 35A...

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Run-out Check and Correction

Refer to GROUP 35A ..........................

Wheel Speed Sensor Output Voltage Check

26 ............................................

Hydraulic Unit Check 28........................

Remedy for a Flat Battery 29...................

BRAKE PEDAL Refer to GROUP 35A........

MASTER CYLINDER AND BRAKE

BOOSTER Refer to GROUP 35A............

DISC BRAKE Refer to GROUP 35A..........

HYDRAULIC UNIT AND ABS-ECU 30.........

WHEEL SPEED SENSOR 33..................

G SENSORS AND STEERING WHEEL

SENSOR 35..................................

Page 1072 of 1449

ABS <4WD> -General Information35B-2

GENERAL INFORMATION

ABS has been adopted as optional equipment in

RS-IIto maintain directional stability and steering

performance during sudden braking or braking on

slippery road surfaces.

The ABS control method is a 4-sensor, 4-channel

method which provides independent control for all

wheels.

Following system for Lancer EVOLUTION-VII has

been modified from Lancer EVOLUTION-VI Tommi

Makinen Edition.DBy adding lateral G sensor, longitudinal G

sensor and steering wheel sensor, optimized

ABS control at the time of cornering.

DBy inputting parking brake switch signal to

ABS-ECU with pulling parking brake lever, ABS

control has been optimized.

DABS-ECU outputs ABS signal to 4WD-ECU.

DG sensor (lateral), steering wheel sensor and

parking brake switch have been added to the

diagnosis and service data.

DABS-ECU connector has been changed.

EBD CONTROL

In ABS, electronic control method is used by which

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the each wheel speed

sensor’s signal. EBD control is a control system

which provides a high level of control for both vehicle

braking force and vehicle stability. The system has

the following features:

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicleladen condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.

DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled to improve the

wear resistance characteristics of the pad,

during front brakes applying.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront43

Rear43

ABS speed sensorTypeMagnet coil typep

Gap between sensor and rotor mm0.85

Page 1073 of 1449

ABS <4WD> -General Information/Service Specifications35B-3

CONSTRUCTION DIAGRAM

Stop lamp

switch*Parking brake

switch

Diagnosis

connector*

Wheel speed sensorWheel speed sensor Hydraulic unit

assembly*

(integrated with

the ABS-ECU) ABS warning lamp

Lateral G sensor

Longitudinal G sensor Steering

wheel

sensor*

NOTE

For R.H. drive vehicles, only the position indicated by the * is symmetrical.

SERVICE SPECIFICATIONS

ItemsStandard value

Wheel speed sensor internal resistance kΩ1.24 - 1.64

Wheel speed sensor insulation resistance kΩ100 or more

Lateral G sensor/Longitudinal G

sensoroutputvoltageV

On stationary vehicle2.4 - 2.6

sensor outputvoltageV

With front mark downward3.4 - 3.6

Page 1074 of 1449

ABS <4WD> -Special Tools/Troubleshooting35B-4

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IIsub

assemblyFor checking of ABS

(Diagnosis code display when using the

MUT-II)

MB991529Diagnosis code

check harnessFor checking of ABS

(Diagnosis code display when using the ABS

warning lamp)

MB991348Test harness setFor checking of G sensor

TROUBLESHOOTING

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

NOTES WITH REGARD TO DIAGNOSIS

1. The phenomena listed in the following table are not abnormal.

PhenomenonExplanation of phenomenon

System check soundWhen starting the engine, a thudding sound can sometimes be heard coming from inside

the engine compartment, but this is because the system operation check is being

performed, and is not an abnormality.

ABS operation sound1. Sound of the motor inside the ABS hydraulic unit operation. (whine)

2. Sound is the generated along with vibration of the brake pedal. (scraping)

3. When ABS operates, sound is generated from the vehicle chassis due to repeated

brake application and release.

(Thump: suspension; squeak: tyres)

System check soundWhen depressing the brake pedal during driving, a shock is sometime felt.

2. For road surfaces such as snow-covered roads and gravel roads, the braking distance for vehicles

with ABS can sometimes be longer than that for other vehicles. Accordingly, advise the customer

to drive safely on such roads by lowering the vehicle speed and not being too overconfident.

3. Diagnosis detection condition can vary depending on the diagnosis code.

Make sure that checking requirements listed in the “Comment” are satisfied when checking the trouble

symptom again.

Page 1077 of 1449

ABS <4WD> -Troubleshooting35B-7

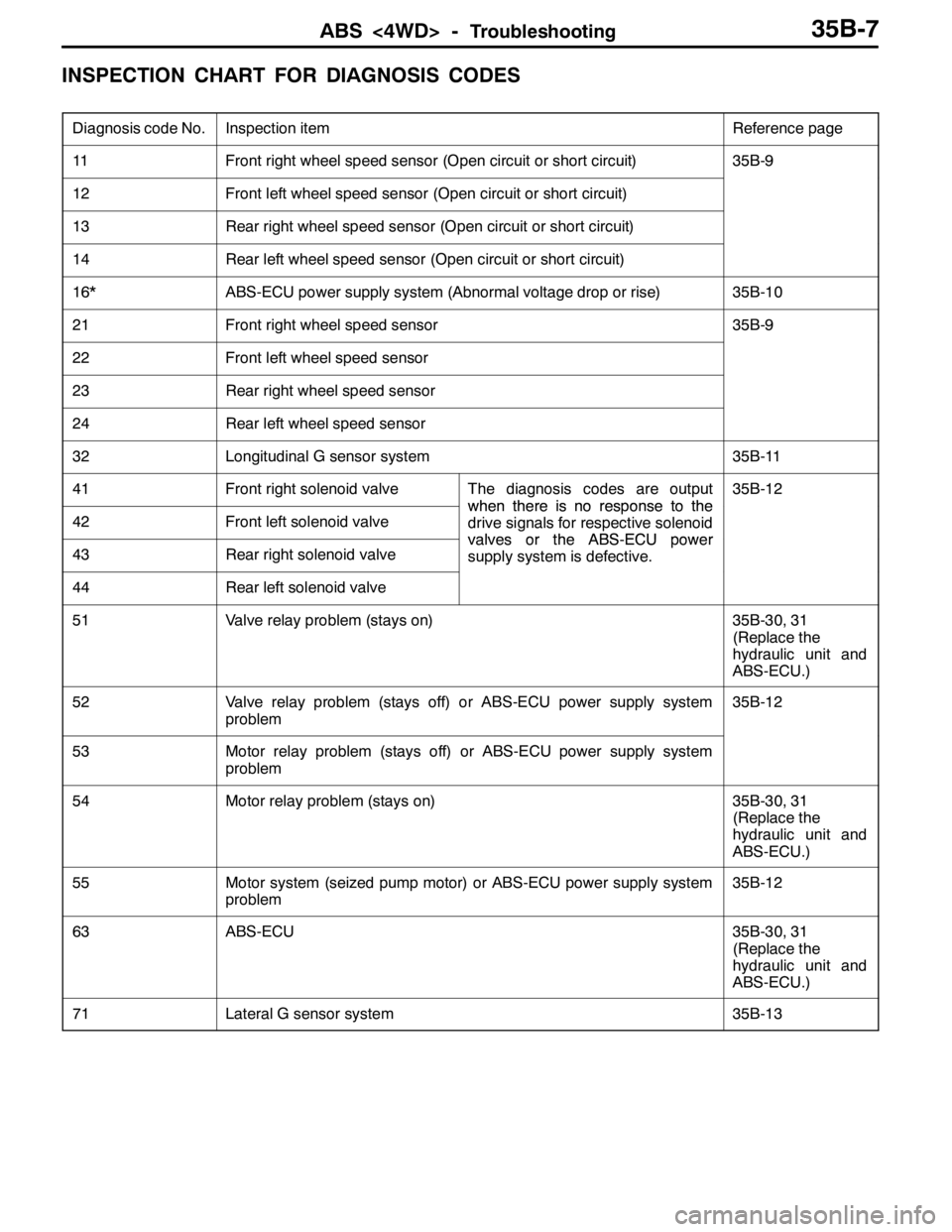

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis code No.Inspection itemReference page

11Front right wheel speed sensor (Open circuit or short circuit)35B-9

12Front left wheel speed sensor (Open circuit or short circuit)

13Rear right wheel speed sensor (Open circuit or short circuit)

14Rear left wheel speed sensor (Open circuit or short circuit)

16*ABS-ECU power supply system (Abnormal voltage drop or rise)35B-10

21Front right wheel speed sensor35B-9

22Front left wheel speed sensor

23Rear right wheel speed sensor

24Rear left wheel speed sensor

32Longitudinal G sensor system35B-11

41Front right solenoid valveThe diagnosis codes are output

whenthereisnoresponsetothe

35B-12

42Front left solenoid valve

whenthereis no responsetothe

drive signals for respective solenoid

valvesortheABS ECUpower43Rear right solenoid valvevalves or theABS-ECUpower

supply system is defective.

44Rear left solenoid valve

51Valve relay problem (stays on)35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

52Valve relay problem (stays off) or ABS-ECU power supply system

problem35B-12

53Motor relay problem (stays off) or ABS-ECU power supply system

problem

54Motor relay problem (stays on)35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

55Motor system (seized pump motor) or ABS-ECU power supply system

problem35B-12

63ABS-ECU35B-30, 31

(Replace the

hydraulic unit and

ABS-ECU.)

71Lateral G sensor system35B-13

Page 1078 of 1449

ABS <4WD> -Troubleshooting35B-8

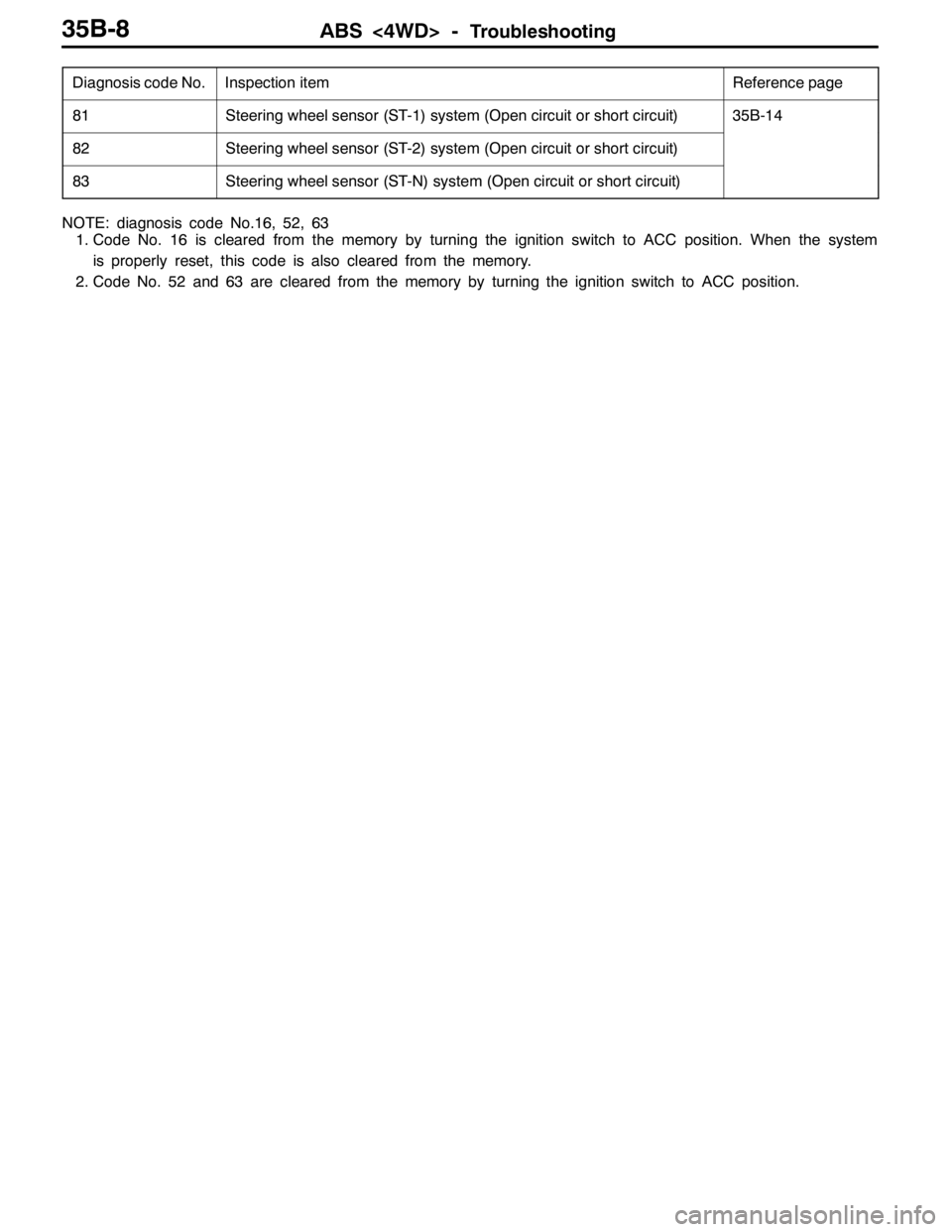

Diagnosis code No.Reference page Inspection item

81Steering wheel sensor (ST-1) system (Open circuit or short circuit)35B-14

82Steering wheel sensor (ST-2) system (Open circuit or short circuit)

83Steering wheel sensor (ST-N) system (Open circuit or short circuit)

NOTE: diagnosis code No.16, 52, 63

1. Code No. 16 is cleared from the memory by turning the ignition switch to ACC position. When the system

is properly reset, this code is also cleared from the memory.

2. Code No. 52 and 63 are cleared from the memory by turning the ignition switch to ACC position.

Page 1079 of 1449

ABS <4WD> -Troubleshooting35B-9

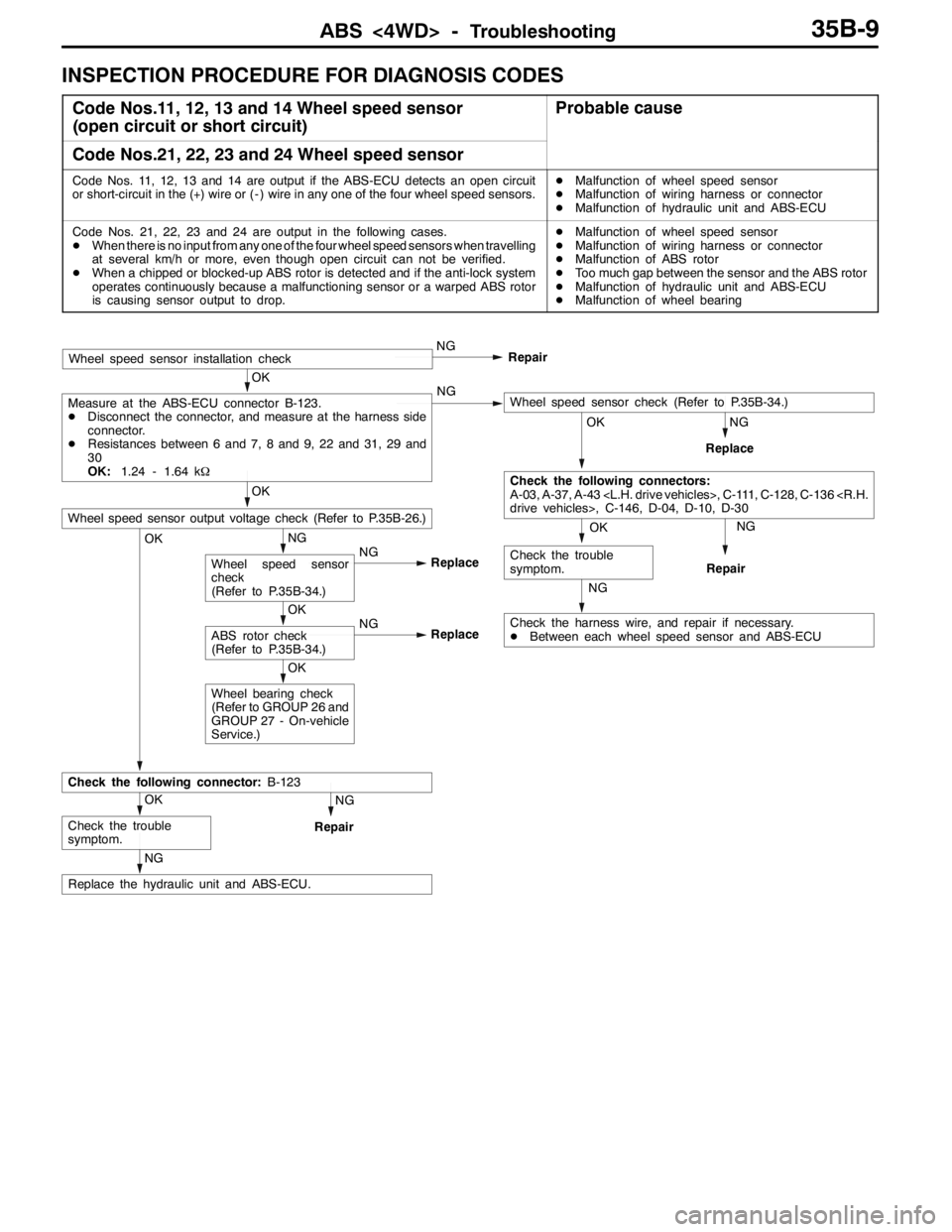

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code Nos.11, 12, 13 and 14 Wheel speed sensor

(open circuit or short circuit)Probable cause

Code Nos.21, 22, 23 and 24 Wheel speed sensor

Code Nos. 11, 12, 13 and 14 are output if the ABS-ECU detects an open circuit

or short-circuit in the (+) wire or ( - ) wire in any one of the four wheel speed sensors.DMalfunction of wheel speed sensor

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

Code Nos. 21, 22, 23 and 24 are output in the following cases.

DWhen there is no input from any one of the four wheel speed sensors when travelling

at several km/h or more, even though open circuit can not be verified.

DWhen a chipped or blocked-up ABS rotor is detected and if the anti-lock system

operates continuously because a malfunctioning sensor or a warped ABS rotor

is causing sensor output to drop.DMalfunction of wheel speed sensor

DMalfunction of wiring harness or connector

DMalfunction of ABS rotor

DToo much gap between the sensor and the ABS rotor

DMalfunction of hydraulic unit and ABS-ECU

DMalfunction of wheel bearing

NG

NG

Replace

OK

Check the harness wire, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU

NG

Repair

OK

Wheel bearing check

(Refer to GROUP 26 and

GROUP 27 - On-vehicle

Service.)

NG

Repair

NG

Replace the hydraulic unit and ABS-ECU.

OK

Check the trouble

symptom.

Check the following connector:B-123

OK

ABS rotor check

(Refer to P.35B-34.)NG

Replace

NG

Wheel speed sensor

check

(Refer to P.35B-34.)NG

Replace

OK

Wheel speed sensor output voltage check (Refer to P.35B-26.)OK

Check the trouble

symptom.

OK

Check the following connectors:

A-03, A-37, A-43

OK

Measure at the ABS-ECU connector B-123.

DDisconnect the connector, and measure at the harness side

connector.

DResistances between 6 and 7, 8 and 9, 22 and 31, 29 and

30

OK:1.24 - 1.64 kΩNGWheel speed sensor check (Refer to P.35B-34.)

Wheel speed sensor installation checkNG

Repair

Page 1081 of 1449

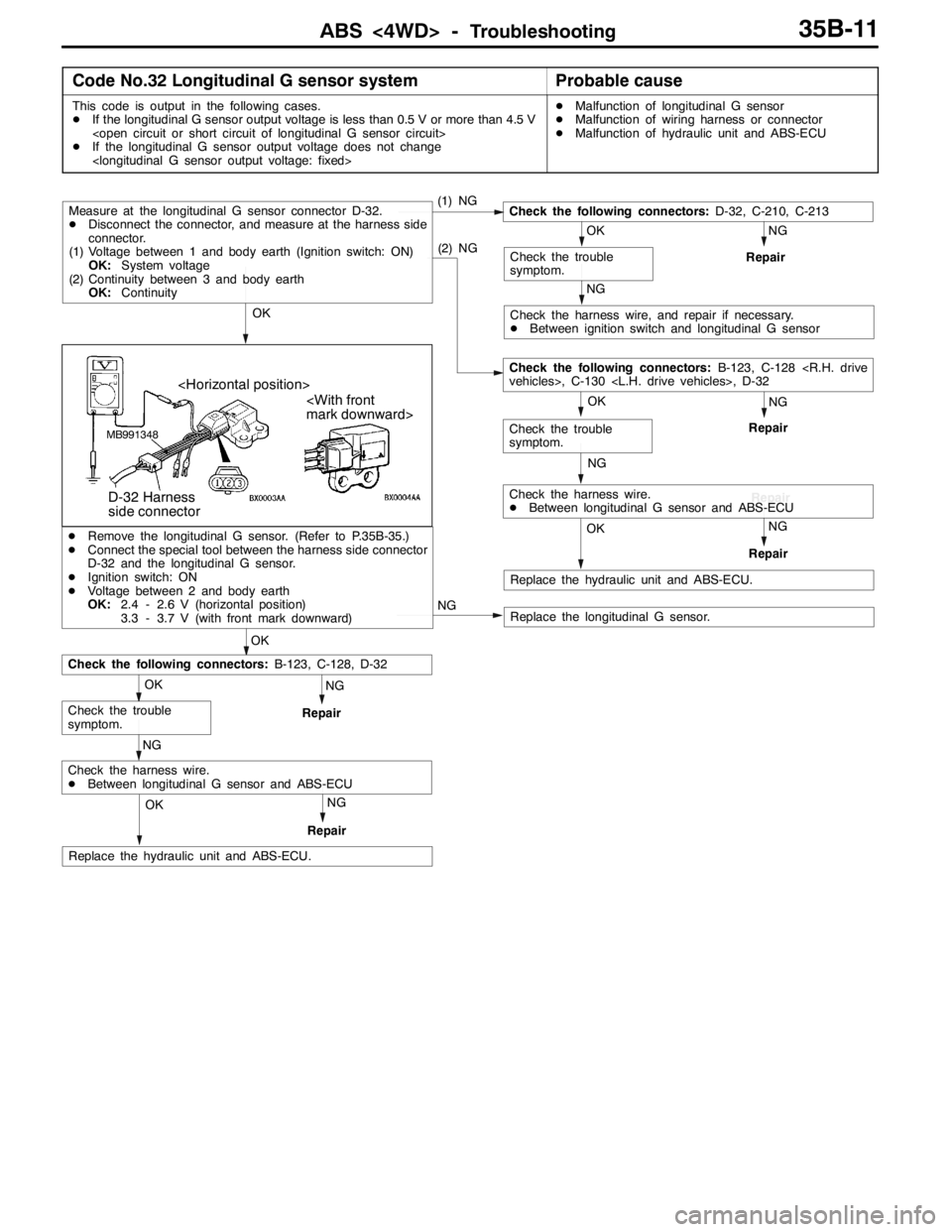

ABS <4WD> -Troubleshooting35B-11

Code No.32 Longitudinal G sensor systemProbable cause

This code is output in the following cases.

DIf the longitudinal G sensor output voltage is less than 0.5 V or more than 4.5 V

DIf the longitudinal G sensor output voltage does not change

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

(1) NG

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween ignition switch and longitudinal G sensor

OK

Check the trouble

symptom.

Check the following connectors:D-32, C-210, C-213

NG

Repair

NG

OK

Check the trouble

symptom. OK

(2) NG

Measure at the longitudinal G sensor connector D-32.

DDisconnect the connector, and measure at the harness side

connector.

(1) Voltage between 1 and body earth (Ignition switch: ON)

OK:System voltage

(2) Continuity between 3 and body earth

OK:Continuity

Repair

Check the following connectors:B-123, C-128

NGOK

Repair

Check the harness wire.

DBetween longitudinal G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

MB991348

D-32 Harness

side connector

NG

OK

NG

Repair

NG

OK

Check the trouble

symptom.

Check the following connectors:B-123, C-128, D-32

DRemove the longitudinal G sensor. (Refer to P.35B-35.)

DConnect the special tool between the harness side connector

D-32 and the longitudinal G sensor.

DIgnition switch: ON

DVoltage between 2 and body earth

OK:2.4 - 2.6 V (horizontal position)

3.3 - 3.7 V (with front mark downward)

NGOK

Repair

Check the harness wire.

DBetween longitudinal G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

Replace the longitudinal G sensor.

Page 1083 of 1449

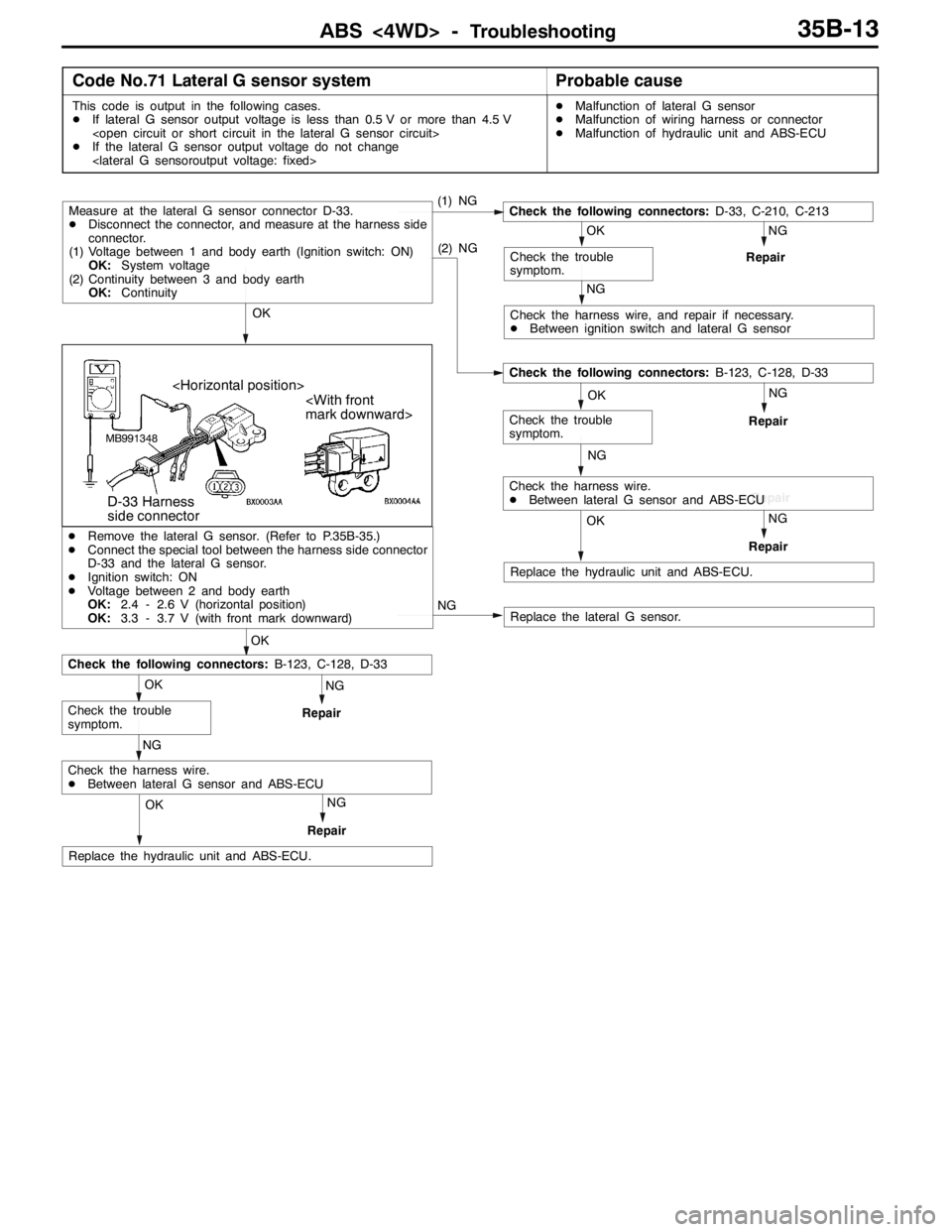

ABS <4WD> -Troubleshooting35B-13

Code No.71 Lateral G sensor systemProbable cause

This code is output in the following cases.

DIf lateral G sensor output voltage is less than 0.5 V or more than 4.5 V

DIf the lateral G sensor output voltage do not change

DMalfunction of wiring harness or connector

DMalfunction of hydraulic unit and ABS-ECU

(1) NG

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween ignition switch and lateral G sensor

OK

Check the trouble

symptom.

Check the following connectors:D-33, C-210, C-213

NG

Repair

NG

OK

Check the trouble

symptom. OK

(2) NG

Measure at the lateral G sensor connector D-33.

DDisconnect the connector, and measure at the harness side

connector.

(1) Voltage between 1 and body earth (Ignition switch: ON)

OK:System voltage

(2) Continuity between 3 and body earth

OK:Continuity

Repair

Check the following connectors:B-123, C-128, D-33

NGOK

Repair

Check the harness wire.

DBetween lateral G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

MB991348

D-33 Harness

side connector

NG

OK

NG

Repair

NG

OK

Check the trouble

symptom.

Check the following connectors:B-123, C-128, D-33

DRemove the lateral G sensor. (Refer to P.35B-35.)

DConnect the special tool between the harness side connector

D-33 and the lateral G sensor.

DIgnition switch: ON

DVoltage between 2 and body earth

OK:2.4 - 2.6 V (horizontal position)

OK:3.3 - 3.7 V (with front mark downward)

NGOK

Repair

Check the harness wire.

DBetween lateral G sensor and ABS-ECU

Replace the hydraulic unit and ABS-ECU.

Replace the lateral G sensor.