Changes MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 677 of 1449

MPI -Throttle Body13A-145

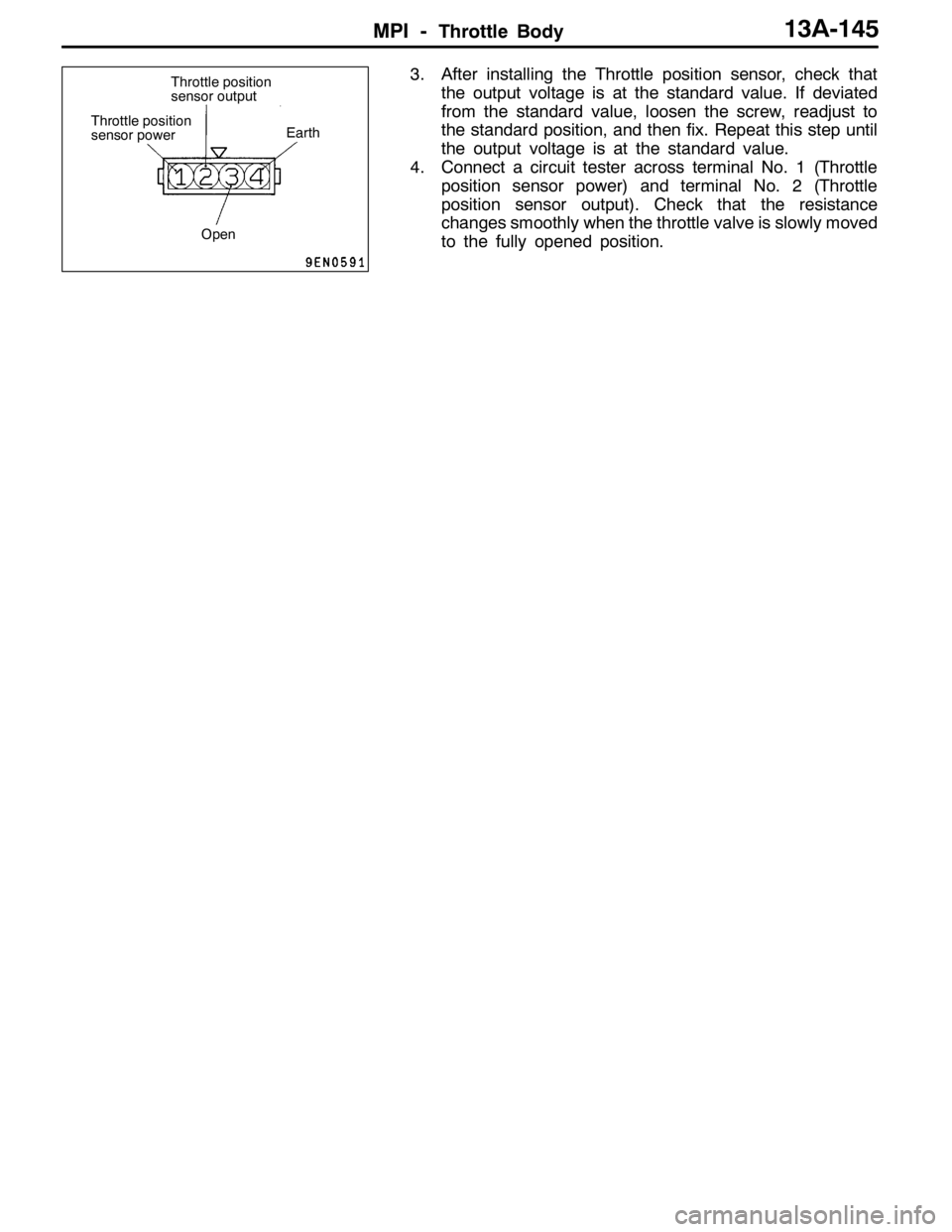

3. After installing the Throttle position sensor, check that

the output voltage is at the standard value. If deviated

from the standard value, loosen the screw, readjust to

the standard position, and then fix. Repeat this step until

the output voltage is at the standard value.

4. Connect a circuit tester across terminal No. 1 (Throttle

position sensor power) and terminal No. 2 (Throttle

position sensor output). Check that the resistance

changes smoothly when the throttle valve is slowly moved

to the fully opened position.Throttle position

sensor output

Throttle position

sensor powerEarth

Open

Page 781 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-11

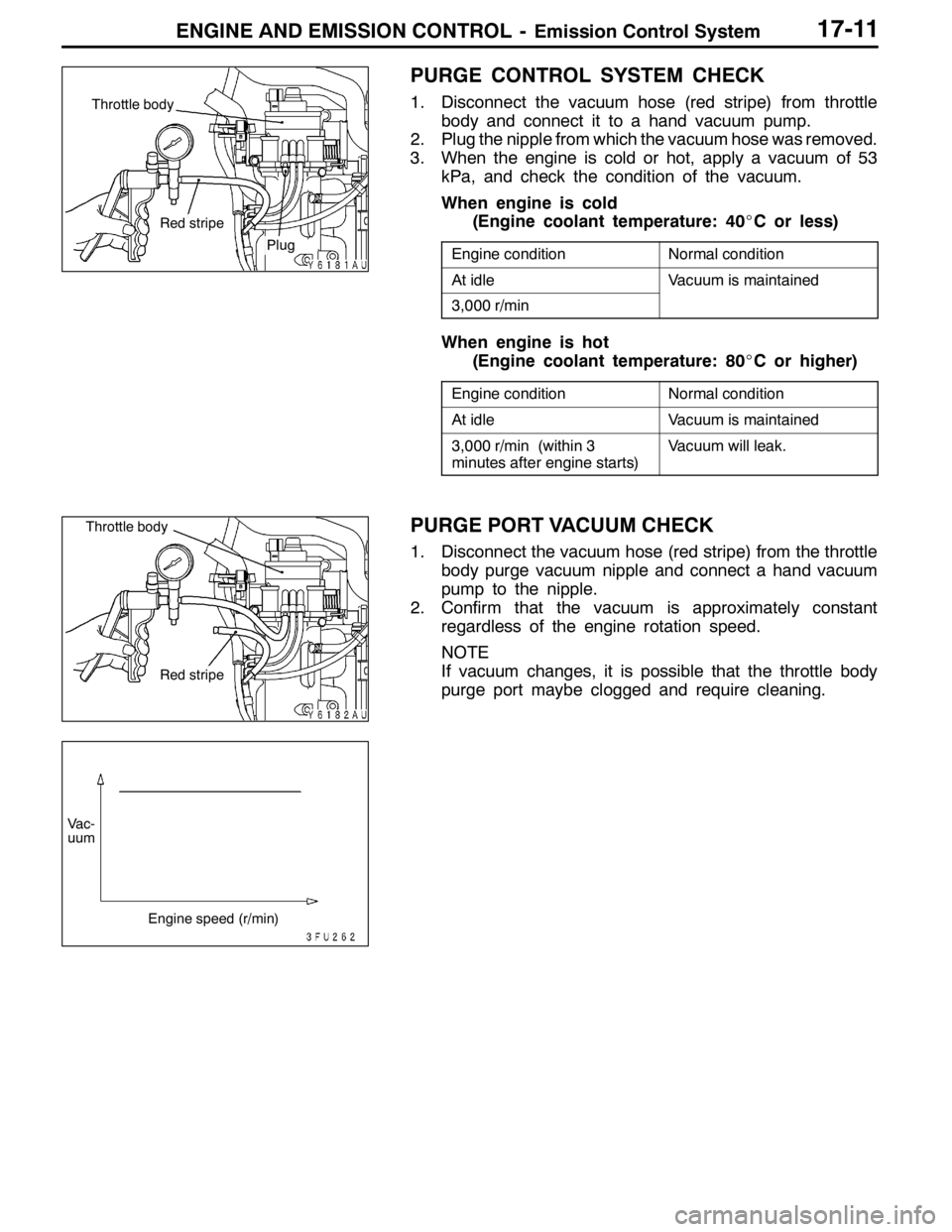

PURGE CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (red stripe) from throttle

body and connect it to a hand vacuum pump.

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53

kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40_C or less)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min

When engine is hot

(Engine coolant temperature: 80_C or higher)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min (within 3

minutes after engine starts)Vacuum will leak.

PURGE PORT VACUUM CHECK

1. Disconnect the vacuum hose (red stripe) from the throttle

body purge vacuum nipple and connect a hand vacuum

pump to the nipple.

2. Confirm that the vacuum is approximately constant

regardless of the engine rotation speed.

NOTE

If vacuum changes, it is possible that the throttle body

purge port maybe clogged and require cleaning.

Red stripe

Plug

Throttle body

Red stripe

Throttle body

Vac-

uum

Engine speed (r/min)

Page 810 of 1449

22A-2

MANUAL

TRANSMISSION

CONTENTS

GENERAL 3.................................

Outline of Changes 3...........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATION 3..................

LUBRICANTS 3..............................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 40....................

Transmission Oil Check 40......................

Transmission Oil Replacement 40................

Transfer Oil Check 40..........................

Transfer Oil Replacement 40....................

Fluid Check

Bleeding

Hydraulic Pressure Check

Wheel Speed Sensor Output Voltage

Measurement

TRANSMISSION CONTROL* 46...............

TRANSFER ASSEMBLY 49...................

TRANSMISSION ASSEMBLY 52...............

4WD-ECU

SENSOR, SWITCH AND RELAY

AYC> 56.....................................

HYDRAULIC UNIT Refer to GROUP27B.......

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 817 of 1449

MANUAL TRANSMISSION - Troubleshooting

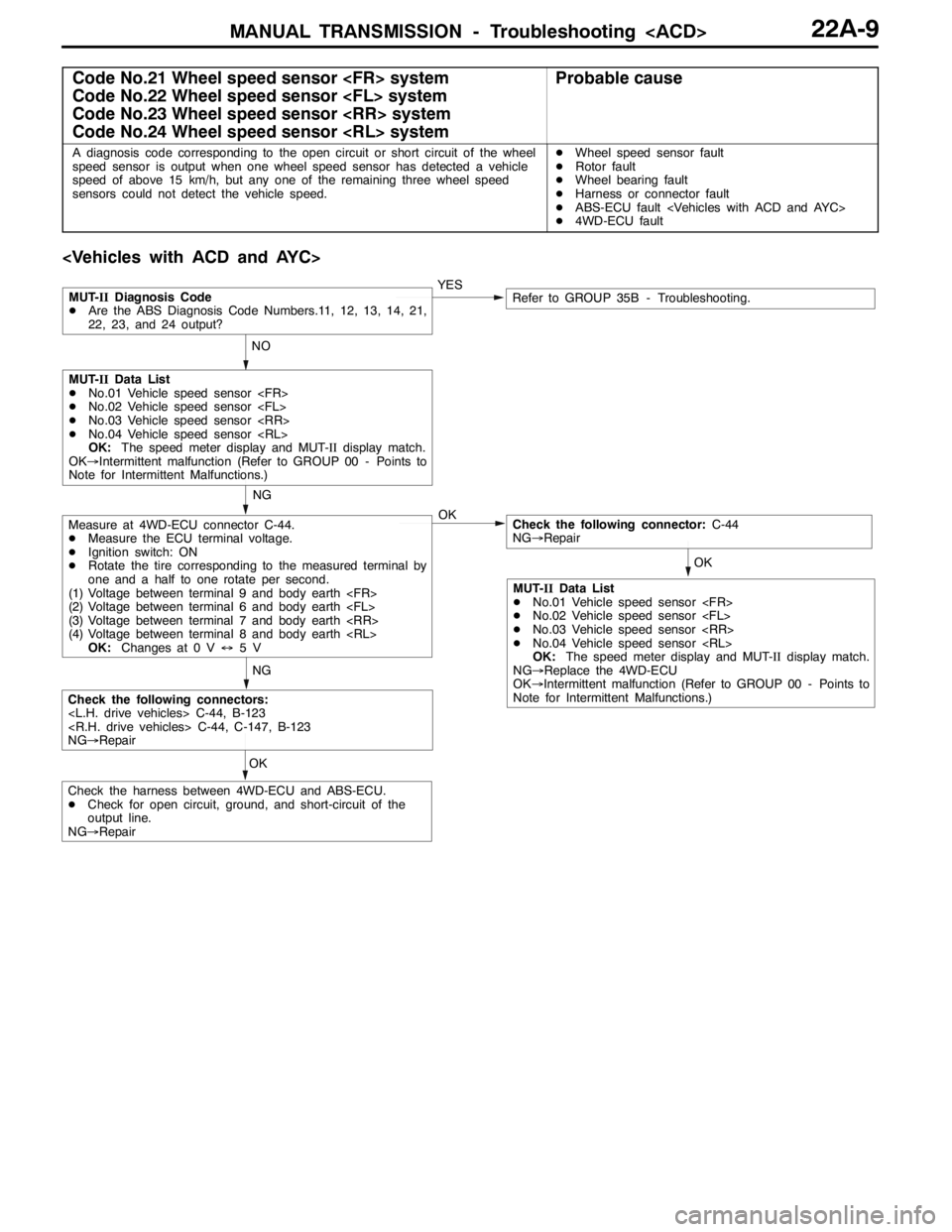

Code No.21 Wheel speed sensor

Code No.22 Wheel speed sensor

Code No.23 Wheel speed sensor

Code No.24 Wheel speed sensor

A diagnosis code corresponding to the open circuit or short circuit of the wheel

speed sensor is output when one wheel speed sensor has detected a vehicle

speed of above 15 km/h, but any one of the remaining three wheel speed

sensors could not detect the vehicle speed.DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OKNGYES

NO

OK

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5VCheck the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair

MUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Numbers.11, 12, 13, 14, 21,

22, 23, and 24 output?Refer to GROUP 35B - Troubleshooting.

NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

OK

Check the harness between 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground, and short-circuit of the

output line.

NG→Repair

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Page 819 of 1449

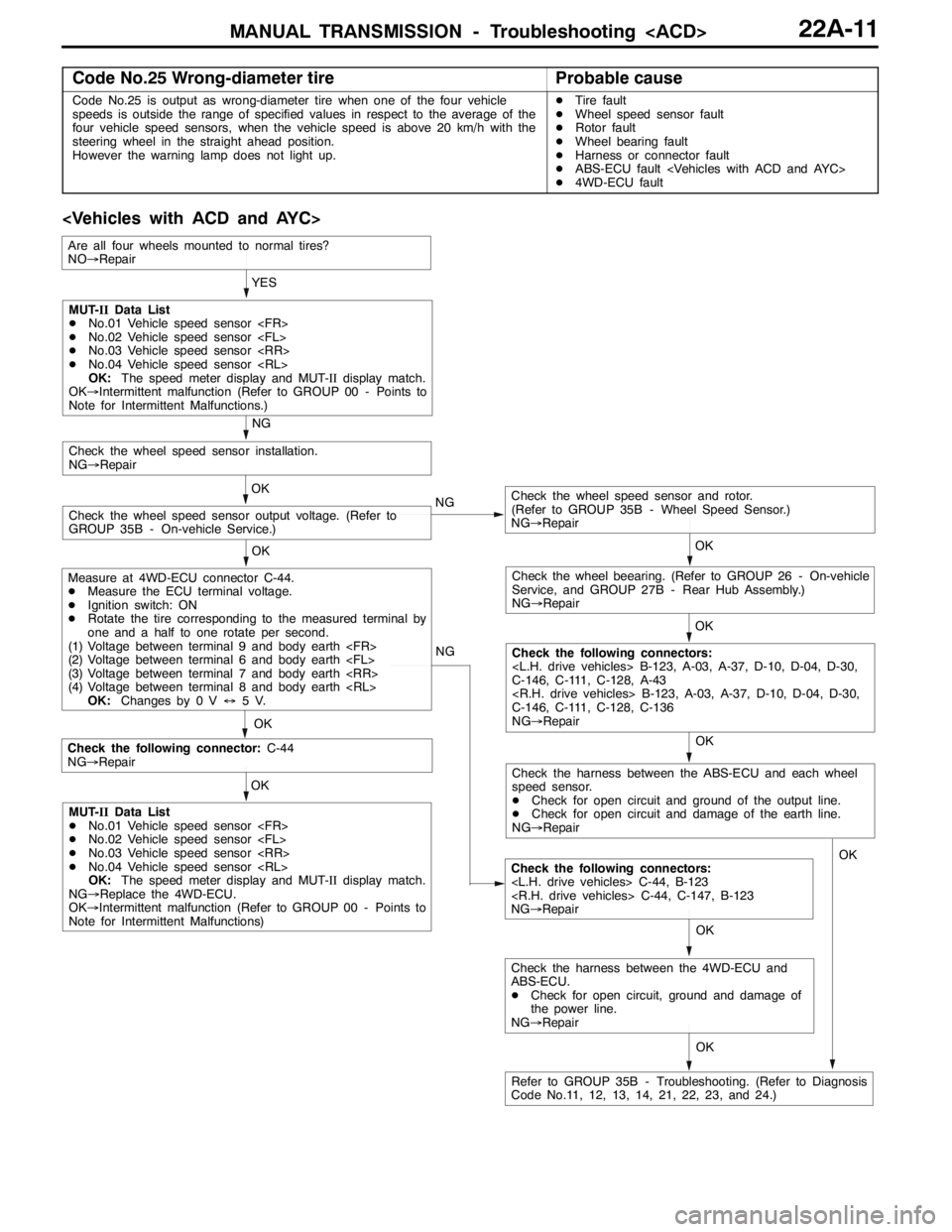

MANUAL TRANSMISSION - Troubleshooting

Code No.25 Wrong-diameter tireProbable cause

Code No.25 is output as wrong-diameter tire when one of the four vehicle

speeds is outside the range of specified values in respect to the average of the

four vehicle speed sensors, when the vehicle speed is above 20 km/h with the

steering wheel in the straight ahead position.

However the warning lamp does not light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OKYES

OK

OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→Repair

Check the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the wheel speed sensor installation.

NG→Repair

NG

OK

Check the wheel beearing. (Refer to GROUP 26 - On-vehicle

Service, and GROUP 27B - Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes by 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Refer to GROUP 35B - Troubleshooting. (Refer to Diagnosis

Code No.11, 12, 13, 14, 21, 22, 23, and 24.)

Are all four wheels mounted to normal tires?

NO→Repair

Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit and ground of the output line.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Check the harness between the 4WD-ECU and

ABS-ECU.

DCheck for open circuit, ground and damage of

the power line.

NG→RepairOK

Page 821 of 1449

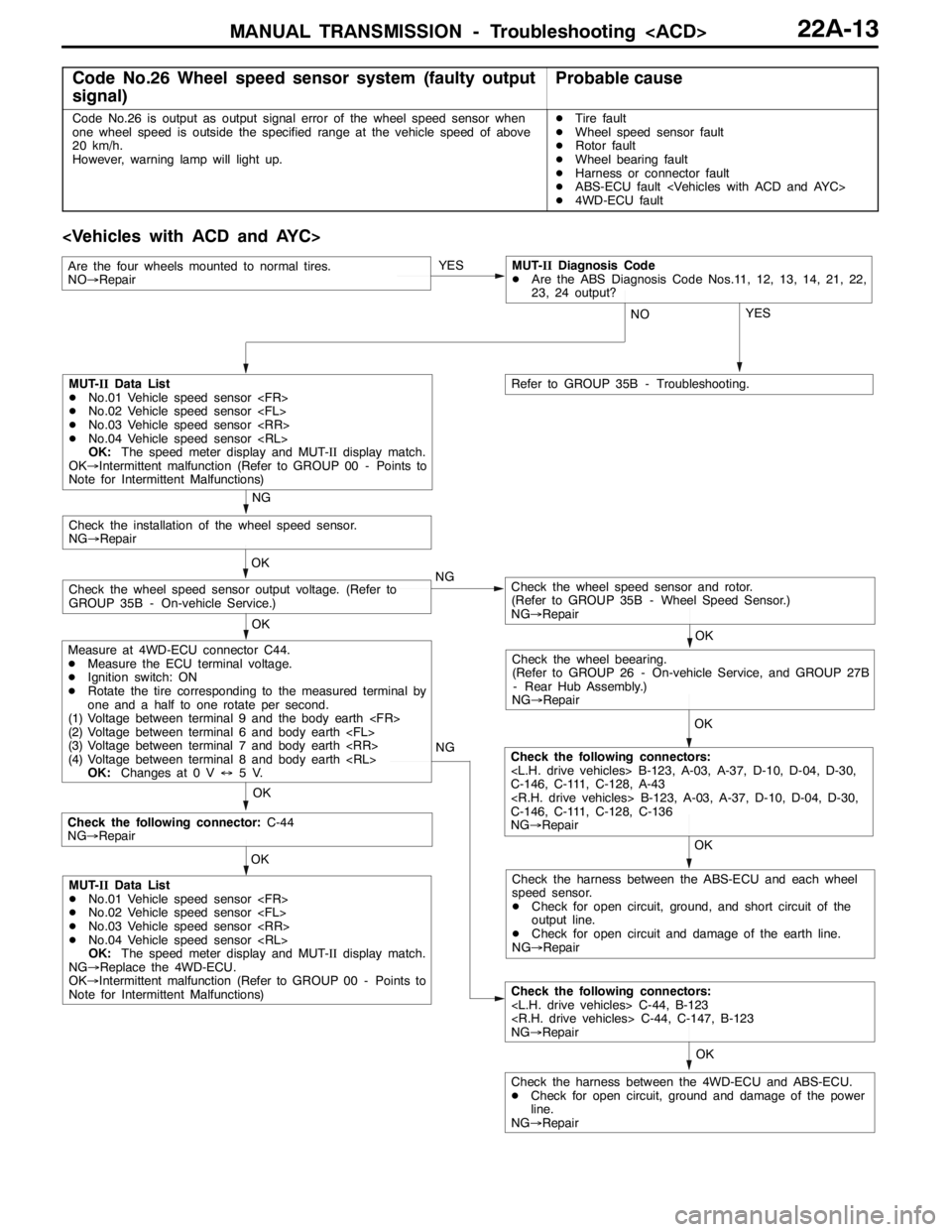

MANUAL TRANSMISSION - Troubleshooting

Code No.26 Wheel speed sensor system (faulty output

signal)Probable cause

Code No.26 is output as output signal error of the wheel speed sensor when

one wheel speed is outside the specified range at the vehicle speed of above

20 km/h.

However, warning lamp will light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OK

Check the harness between the 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground and damage of the power

line.

NG→RepairYES

OK OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→RepairCheck the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the installation of the wheel speed sensor.

NG→Repair

NG

OK

Check the wheel beearing.

(Refer to GROUP 26 - On-vehicle Service, and GROUP 27B

- Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Measure at 4WD-ECU connector C44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and the body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit, ground, and short circuit of the

output line.

DCheck for open circuit and damage of the earth line.

NG→Repair YES

NO

Refer to GROUP 35B - Troubleshooting.

Are the four wheels mounted to normal tires.

NO→RepairMUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Nos.11, 12, 13, 14, 21, 22,

23, 24 output?

Page 823 of 1449

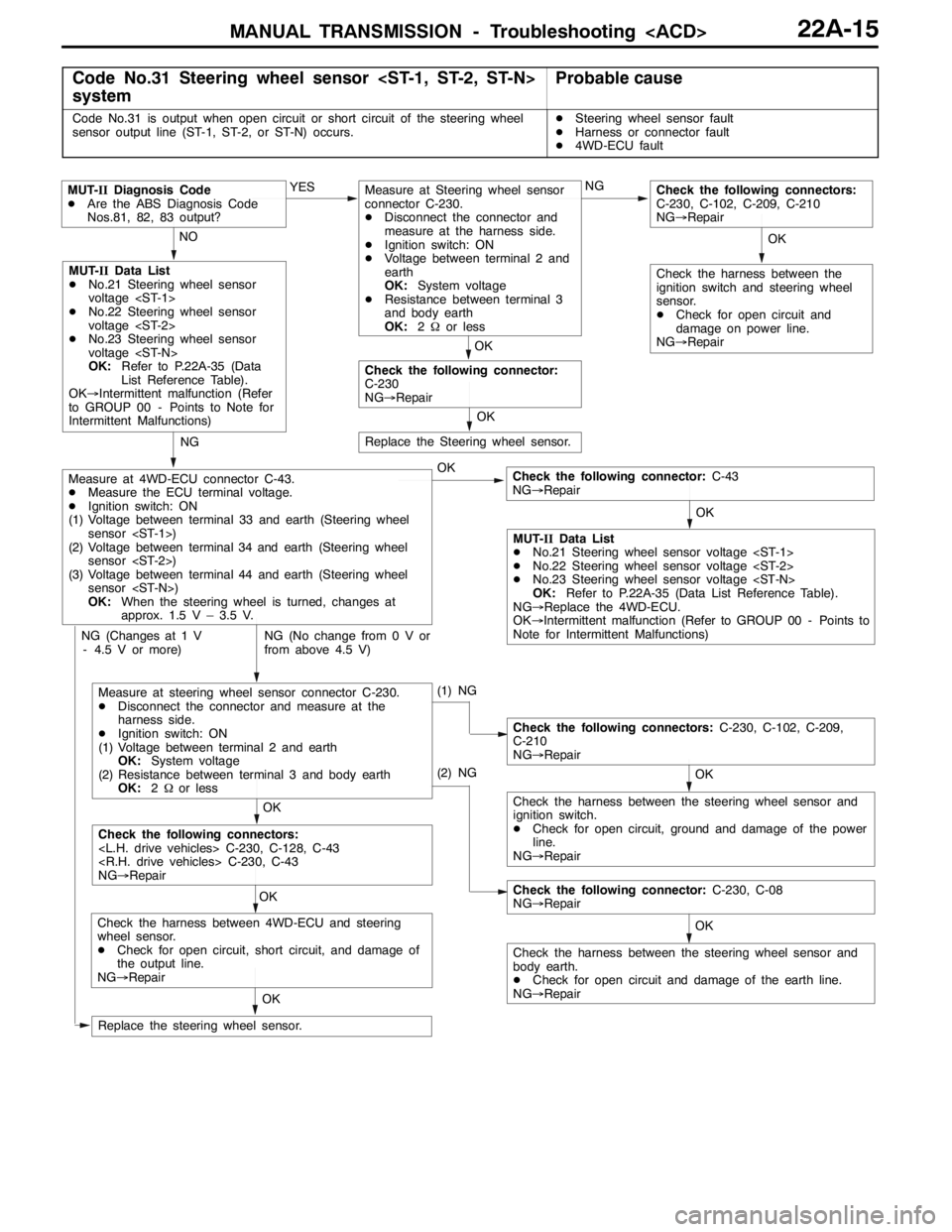

MANUAL TRANSMISSION - Troubleshooting

Code No.31 Steering wheel sensor

systemProbable cause

Code No.31 is output when open circuit or short circuit of the steering wheel

sensor output line (ST-1, ST-2, or ST-N) occurs.DSteering wheel sensor fault

DHarness or connector fault

D4WD-ECU fault

OK NG NO

OK

MUT-IIData List

DNo.21 Steering wheel sensor

voltage

DNo.22 Steering wheel sensor

voltage

DNo.23 Steering wheel sensor

voltage

OK:Refer to P.22A-35 (Data

List Reference Table).

OK→Intermittent malfunction (Refer

to GROUP 00 - Points to Note for

Intermittent Malfunctions)

Check the following connector:C-43

NG→Repair YES

MUT-IIDiagnosis Code

DAre the ABS Diagnosis Code

Nos.81, 82, 83 output?

MUT-IIData List

DNo.21 Steering wheel sensor voltage

DNo.22 Steering wheel sensor voltage

DNo.23 Steering wheel sensor voltage

OK:Refer to P.22A-35 (Data List Reference Table).

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

NG (No change from 0 V or

from above 4.5 V)

Measure at 4WD-ECU connector C-43.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

(1) Voltage between terminal 33 and earth (Steering wheel

sensor

(2) Voltage between terminal34and earth (Steering wheel

sensor

(3) Voltage between terminal44 andearth (Steering wheel

sensor

OK:When the steering wheel is turned, changes at

approx. 1.5 V – 3.5 V.

(1) NG

NG (Changes at 1 V

- 4.5 V or more)

OK

Check the harness between the steering wheel sensor and

ignition switch.

DCheck for open circuit, ground and damage of the power

line.

NG→Repair

Check the following connectors:C-230, C-102, C-209,

C-210

NG→Repair

OKOK

Check the following connectors:

NG→Repair

OK

Check the harness between 4WD-ECU and steering

wheel sensor.

DCheck for open circuit, short circuit, and damage of

the output line.

NG→Repair

Replace the steering wheel sensor.

Replace the Steering wheel sensor.

OK

OK

Check the following connector:

C-230

NG→RepairNG

Measure at Steering wheel sensor

connector C-230.

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal 2 and

earth

OK:System voltage

DResistance between terminal 3

and body earth

OK:2Ωor less

OK

Check the following connectors:

C-230, C-102, C-209, C-210

NG→Repair

Check the harness between the

ignition switch and steering wheel

sensor.

DCheck for open circuit and

damage on power line.

NG→Repair

(2) NG

OK

Check the harness between the steering wheel sensor and

body earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Check the following connector:C-230, C-08

NG→Repair

Measure at steering wheel sensor connector C-230.

DDisconnect the connector and measure at the

harness side.

DIgnition switch: ON

(1) Voltage between terminal 2 and earth

OK:System voltage

(2) Resistance between terminal 3 and body earth

OK:2Ωor less

Page 824 of 1449

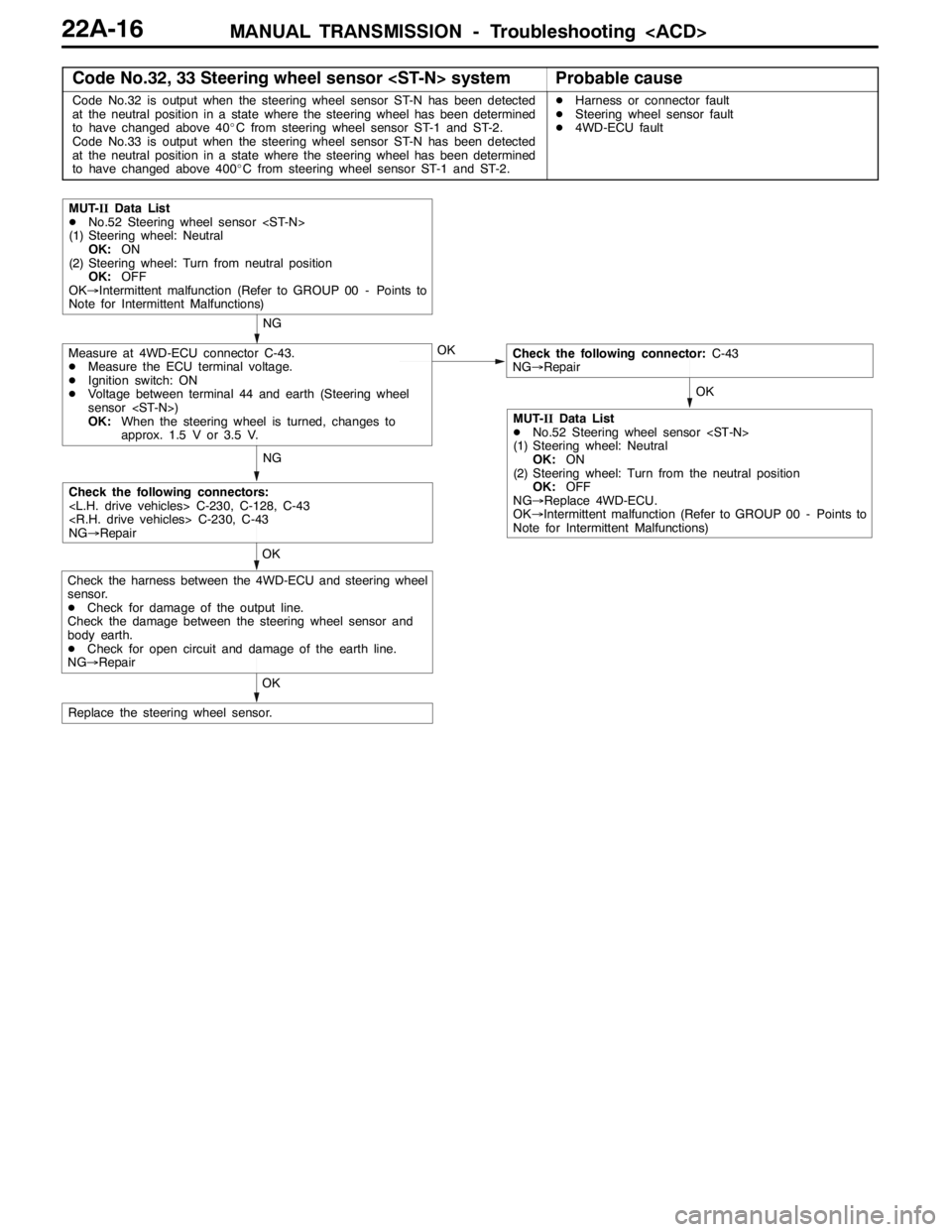

MANUAL TRANSMISSION - Troubleshooting

Code No.32, 33 Steering wheel sensor

Code No.32 is output when the steering wheel sensor ST-N has been detected

at the neutral position in a state where the steering wheel has been determined

to have changed above 40_C from steering wheel sensor ST-1 and ST-2.

Code No.33 is output when the steering wheel sensor ST-N has been detected

at the neutral position in a state where the steering wheel has been determined

to have changed above 400_C from steering wheel sensor ST-1 and ST-2.DHarness or connector fault

DSteering wheel sensor fault

D4WD-ECU fault

NG

OK

MUT-IIData List

DNo.52 Steering wheel sensor

(1) Steering wheel: Neutral

OK:ON

(2) Steering wheel: Turn from neutral position

OK:OFF

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Check the following connector:C-43

NG→Repair

NG

Check the following connectors:

NG→Repair

OK

Replace the steering wheel sensor.OK

Measure at 4WD-ECU connector C-43.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DVoltage between terminal 44 and earth (Steering wheel

sensor

OK:When the steering wheel is turned, changes to

approx. 1.5 V or 3.5 V.

MUT-IIData List

DNo.52 Steering wheel sensor

(1) Steering wheel: Neutral

OK:ON

(2) Steering wheel: Turn from the neutral position

OK:OFF

NG→Replace 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

OK

Check the harness between the 4WD-ECU and steering wheel

sensor.

DCheck for damage of the output line.

Check the damage between the steering wheel sensor and

body earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Page 825 of 1449

MANUAL TRANSMISSION - Troubleshooting

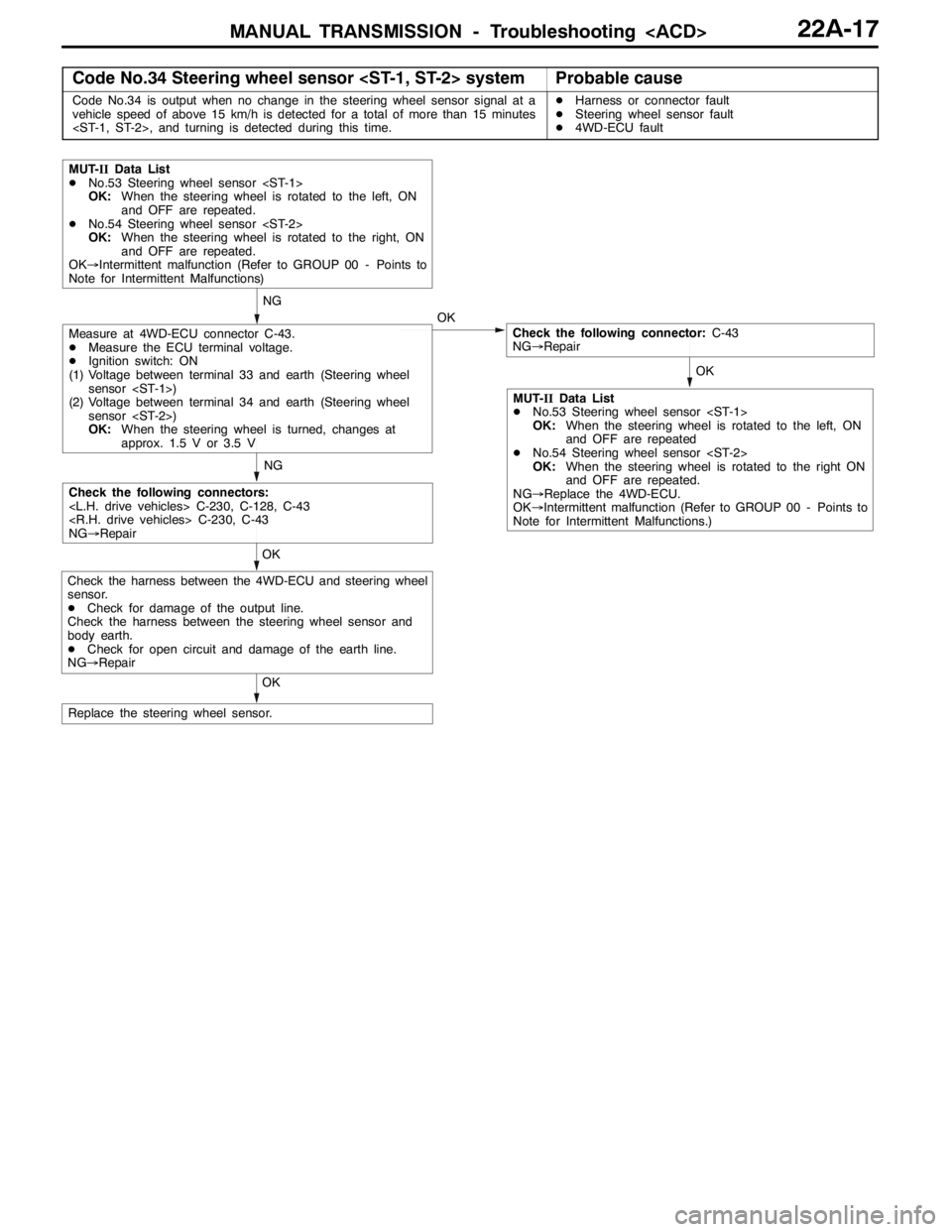

Code No.34 Steering wheel sensor

Code No.34 is output when no change in the steering wheel sensor signal at a

vehicle speed of above 15 km/h is detected for a total of more than 15 minutes

DSteering wheel sensor fault

D4WD-ECU fault

NG

OK

MUT-IIData List

DNo.53 Steering wheel sensor

OK:When the steering wheel is rotated to the left, ON

and OFF are repeated.

DNo.54 Steering wheel sensor

OK:When the steering wheel is rotated to the right, ON

and OFF are repeated.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Check the following connector:C-43

NG→Repair

NG

Check the following connectors:

NG→Repair

OK

Replace the steering wheel sensor.OK

OK

Check the harness between the 4WD-ECU and steering wheel

sensor.

DCheck for damage of the output line.

Check the harness between the steering wheel sensor and

body earth.

DCheck for open circuit and damage of the earth line.

NG→Repair

Measure at 4WD-ECU connector C-43.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

(1) Voltage between terminal 33 and earth (Steering wheel

sensor

(2) Voltage between terminal 34 and earth (Steering wheel

sensor

OK:When the steering wheel is turned, changes at

approx. 1.5 V or 3.5 V

MUT-IIData List

DNo.53 Steering wheel sensor

OK:When the steering wheel is rotated to the left, ON

and OFF are repeated

DNo.54 Steering wheel sensor

OK:When the steering wheel is rotated to the right ON

and OFF are repeated.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Page 843 of 1449

MANUAL TRANSMISSION - Troubleshooting

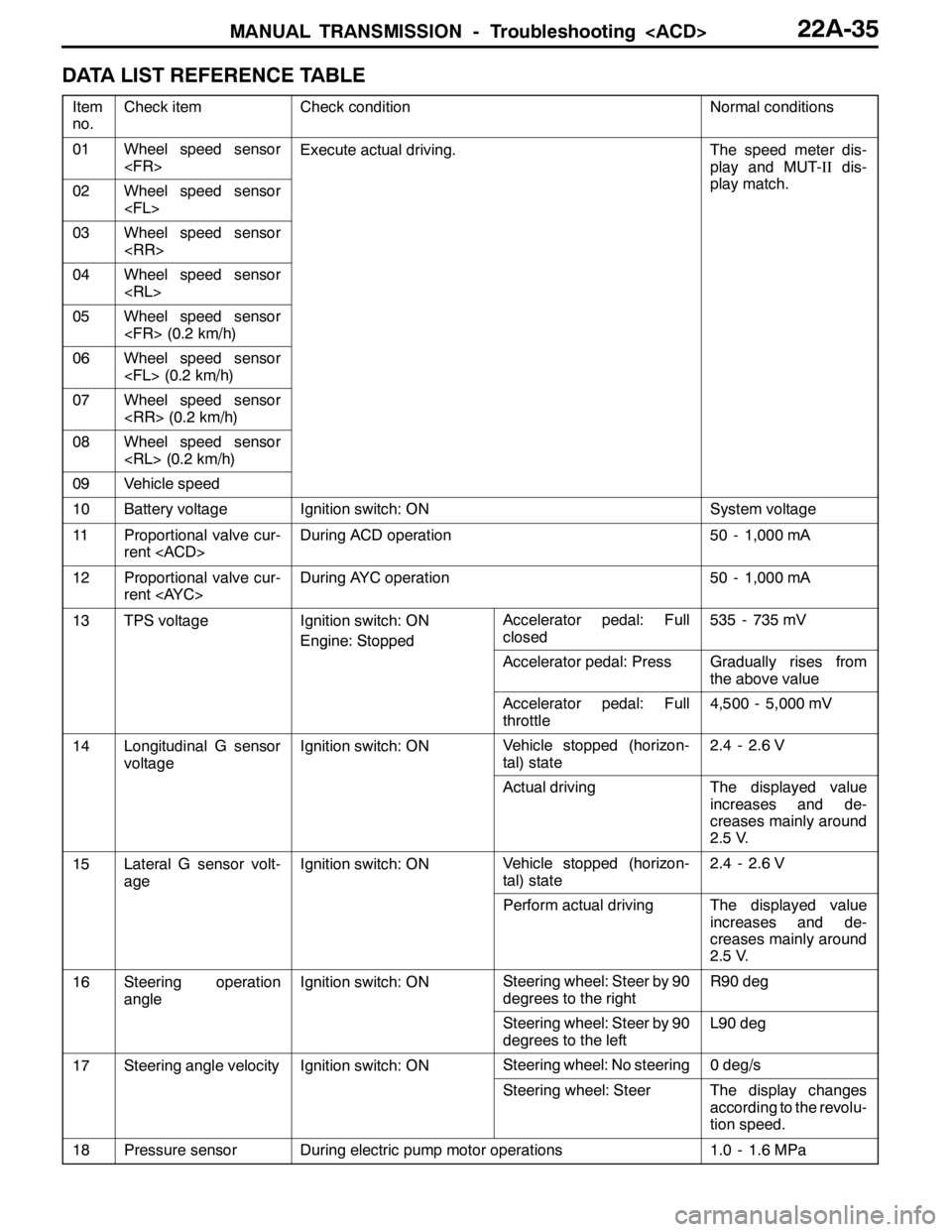

DATA LIST REFERENCE TABLE

Item

no.Check itemCheck conditionNormal conditions

01Wheel speed sensor

play and MUT-IIdis-

lth02Wheel speed sensor

py

play match.

03Wheel speed sensor

04Wheel speed sensor

05Wheel speed sensor

06Wheel speed sensor

07Wheel speed sensor

08Wheel speed sensor

09Vehicle speed

10Battery voltageIgnition switch: ONSystem voltage

11Proportional valve cur-

rent

12Proportional valve cur-

rent

13TPS voltageIgnition switch: ON

Engine: StoppedAccelerator pedal: Full

closed535 - 735 mV

Engine:Stopped

Accelerator pedal: PressGradually rises from

the above value

Accelerator pedal: Full

throttle4,500 - 5,000 mV

14Longitudinal G sensor

voltageIgnition switch: ONVehicle stopped (horizon-

tal) state2.4 - 2.6 V

g

Actual drivingThe displayed value

increases and de-

creases mainly around

2.5 V.

15Lateral G sensor volt-

ageIgnition switch: ONVehicle stopped (horizon-

tal) state2.4 - 2.6 V

g

Perform actual drivingThe displayed value

increases and de-

creases mainly around

2.5 V.

16Steering operation

angleIgnition switch: ONSteering wheel: Steer by 90

degrees to the rightR90 deg

g

Steering wheel: Steer by 90

degrees to the leftL90 deg

17Steering angle velocityIgnition switch: ONSteering wheel: No steering0 deg/sggyg

Steering wheel: SteerThe display changes

according to the revolu-

tion speed.

18Pressure sensorDuring electric pump motor operations1.0 - 1.6 MPa