headlamp MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1347 of 1449

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-27

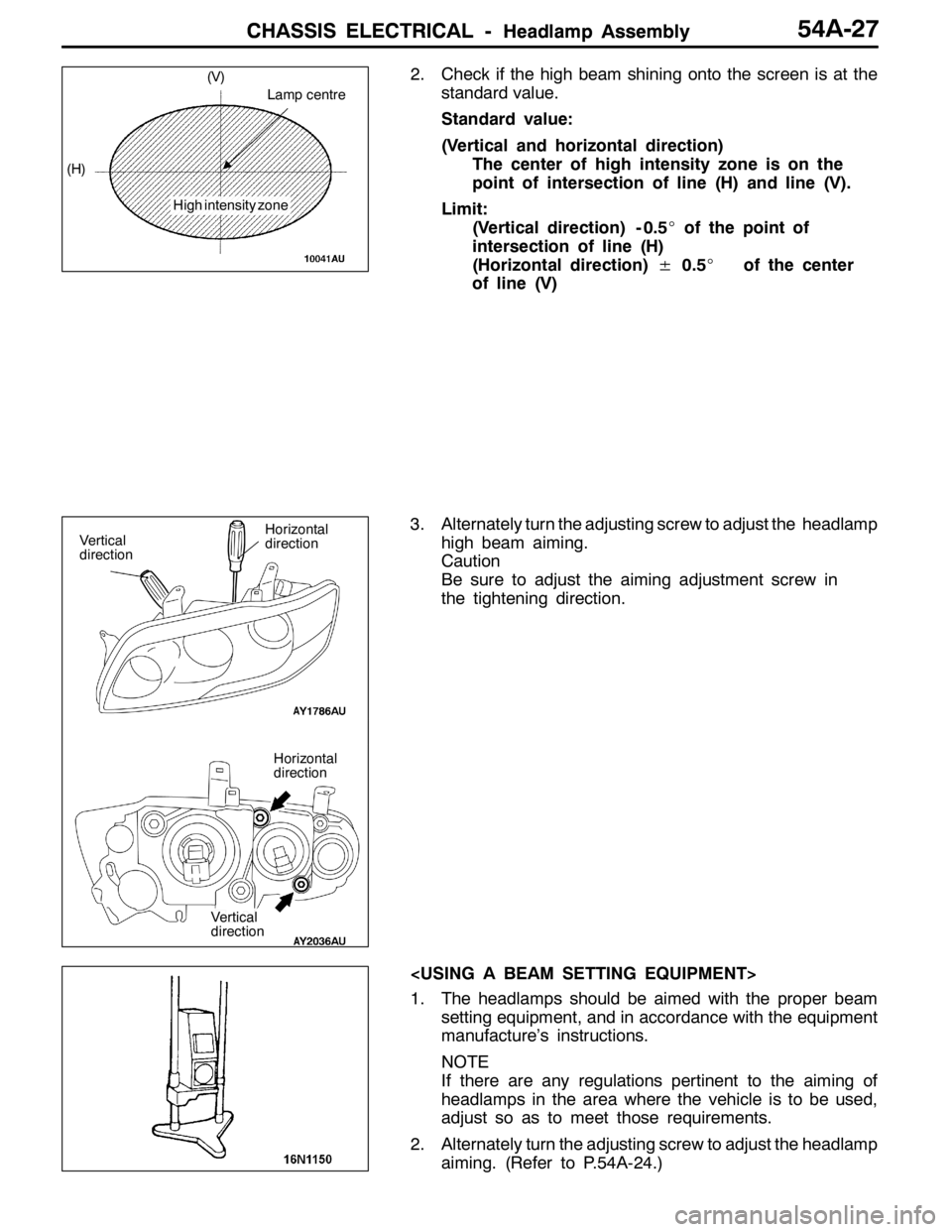

2. Check if the high beam shining onto the screen is at the

standard value.

Standard value:

(Vertical and horizontal direction)

The center of high intensity zone is on the

point of intersection of line (H) and line (V).

Limit:

(Vertical direction) - 0.5_of the point of

intersection of line (H)

(Horizontal direction)±0.5_of the center

of line (V)

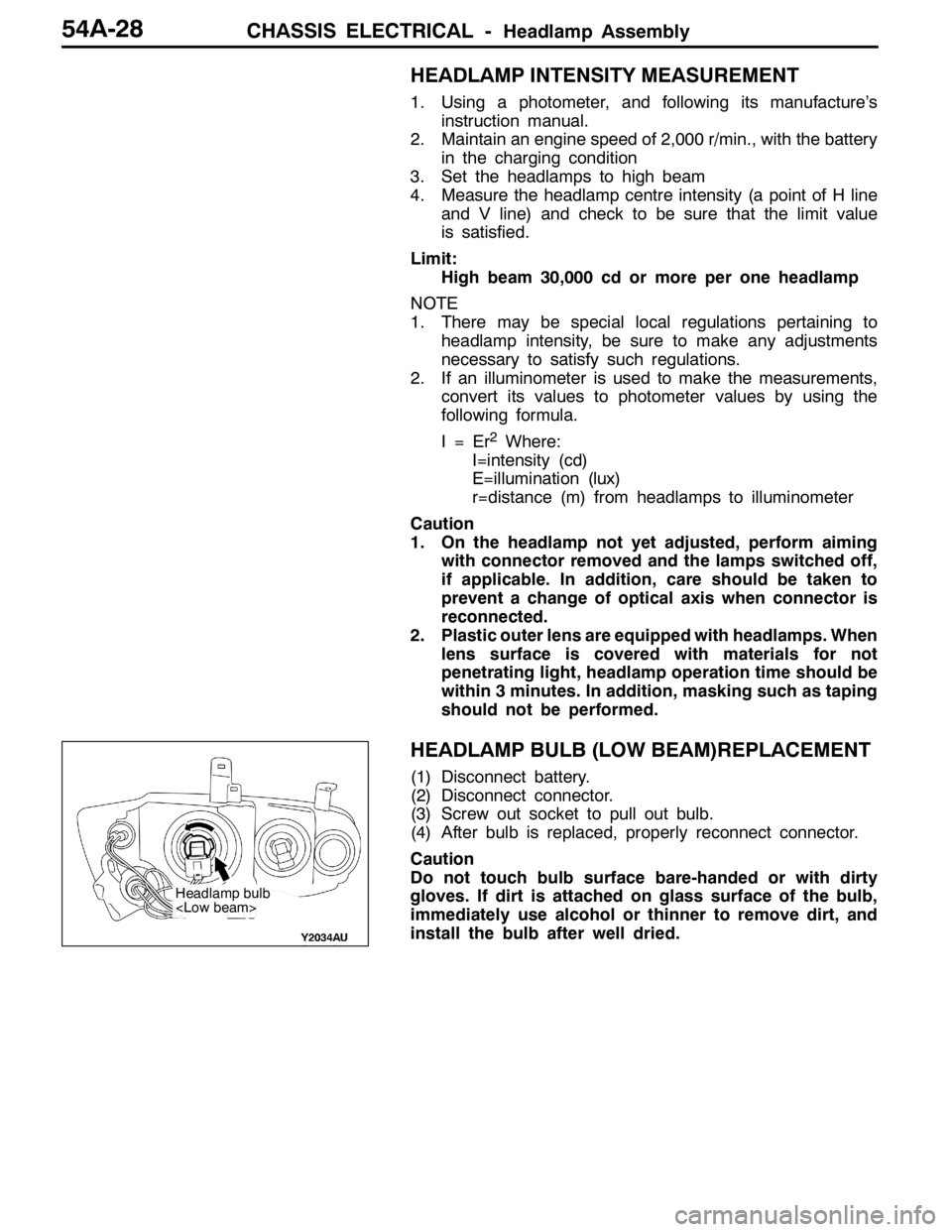

3. Alternately turn the adjusting screw to adjust the headlamp

high beam aiming.

Caution

Be sure to adjust the aiming adjustment screw in

the tightening direction.

1. The headlamps should be aimed with the proper beam

setting equipment, and in accordance with the equipment

manufacture’s instructions.

NOTE

If there are any regulations pertinent to the aiming of

headlamps in the area where the vehicle is to be used,

adjust so as to meet those requirements.

2. Alternately turn the adjusting screw to adjust the headlamp

aiming. (Refer to P.54A-24.)

Lamp centre

High intensity zone (H)(V)

Vertical

direction

Vertical

direction

Horizontal

direction

Horizontal

direction

Page 1348 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-28

HEADLAMP INTENSITY MEASUREMENT

1. Using a photometer, and following its manufacture’s

instruction manual.

2. Maintain an engine speed of 2,000 r/min., with the battery

in the charging condition

3. Set the headlamps to high beam

4. Measure the headlamp centre intensity (a point of H line

and V line) and check to be sure that the limit value

is satisfied.

Limit:

High beam 30,000 cd or more per one headlamp

NOTE

1. There may be special local regulations pertaining to

headlamp intensity, be sure to make any adjustments

necessary to satisfy such regulations.

2. If an illuminometer is used to make the measurements,

convert its values to photometer values by using the

following formula.

I=Er

2Where:

I=intensity (cd)

E=illumination (lux)

r=distance (m) from headlamps to illuminometer

Caution

1. On the headlamp not yet adjusted, perform aiming

with connector removed and the lamps switched off,

if applicable. In addition, care should be taken to

prevent a change of optical axis when connector is

reconnected.

2. Plastic outer lens are equipped with headlamps. When

lens surface is covered with materials for not

penetrating light, headlamp operation time should be

within 3 minutes. In addition, masking such as taping

should not be performed.

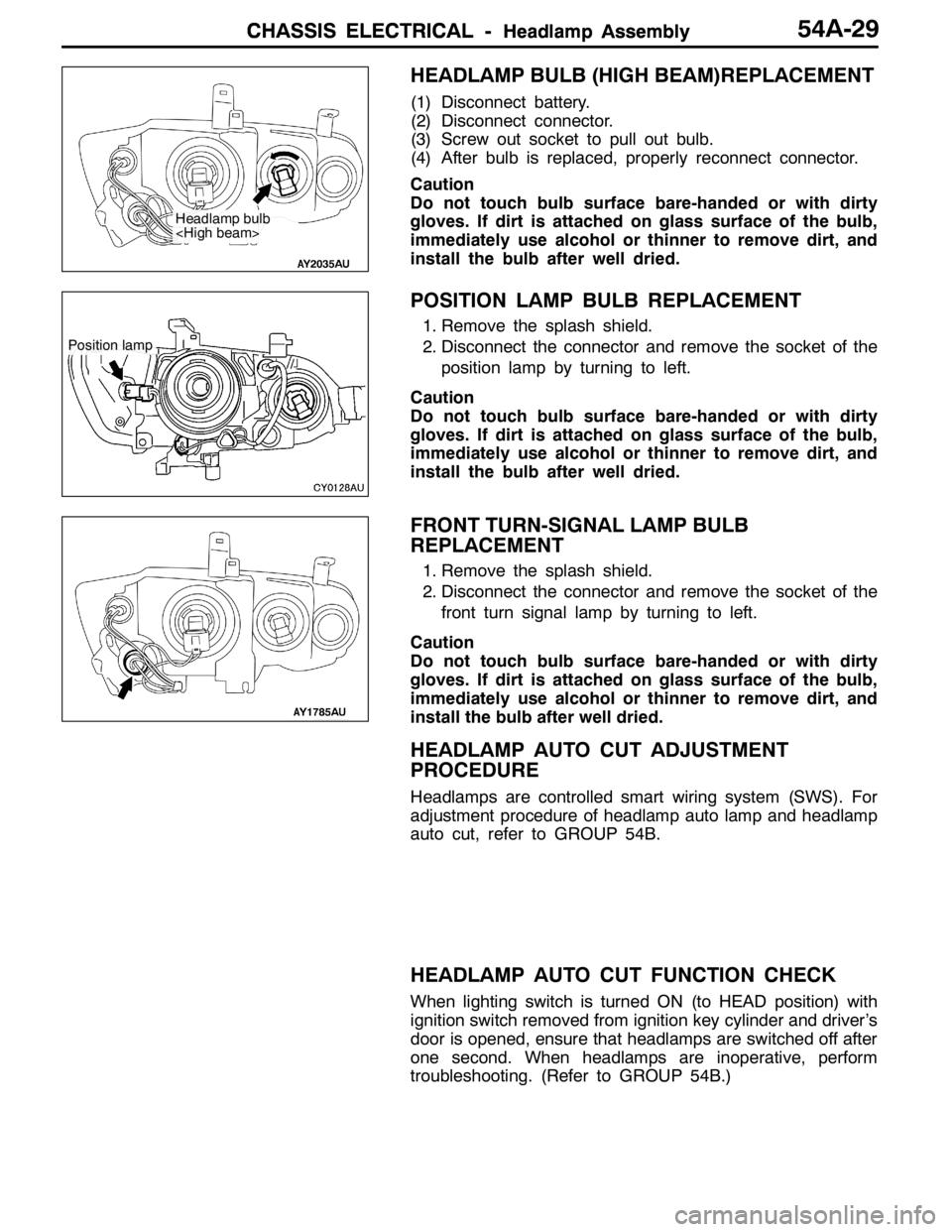

HEADLAMP BULB (LOW BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

Headlamp bulb

Page 1349 of 1449

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-29

HEADLAMP BULB (HIGH BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

POSITION LAMP BULB REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

position lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

FRONT TURN-SIGNAL LAMP BULB

REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

front turn signal lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HEADLAMP AUTO CUT ADJUSTMENT

PROCEDURE

Headlamps are controlled smart wiring system (SWS). For

adjustment procedure of headlamp auto lamp and headlamp

auto cut, refer to GROUP 54B.

HEADLAMP AUTO CUT FUNCTION CHECK

When lighting switch is turned ON (to HEAD position) with

ignition switch removed from ignition key cylinder and driver’s

door is opened, ensure that headlamps are switched off after

one second. When headlamps are inoperative, perform

troubleshooting. (Refer to GROUP 54B.)

Headlamp bulb

Position lamp

Page 1350 of 1449

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-30

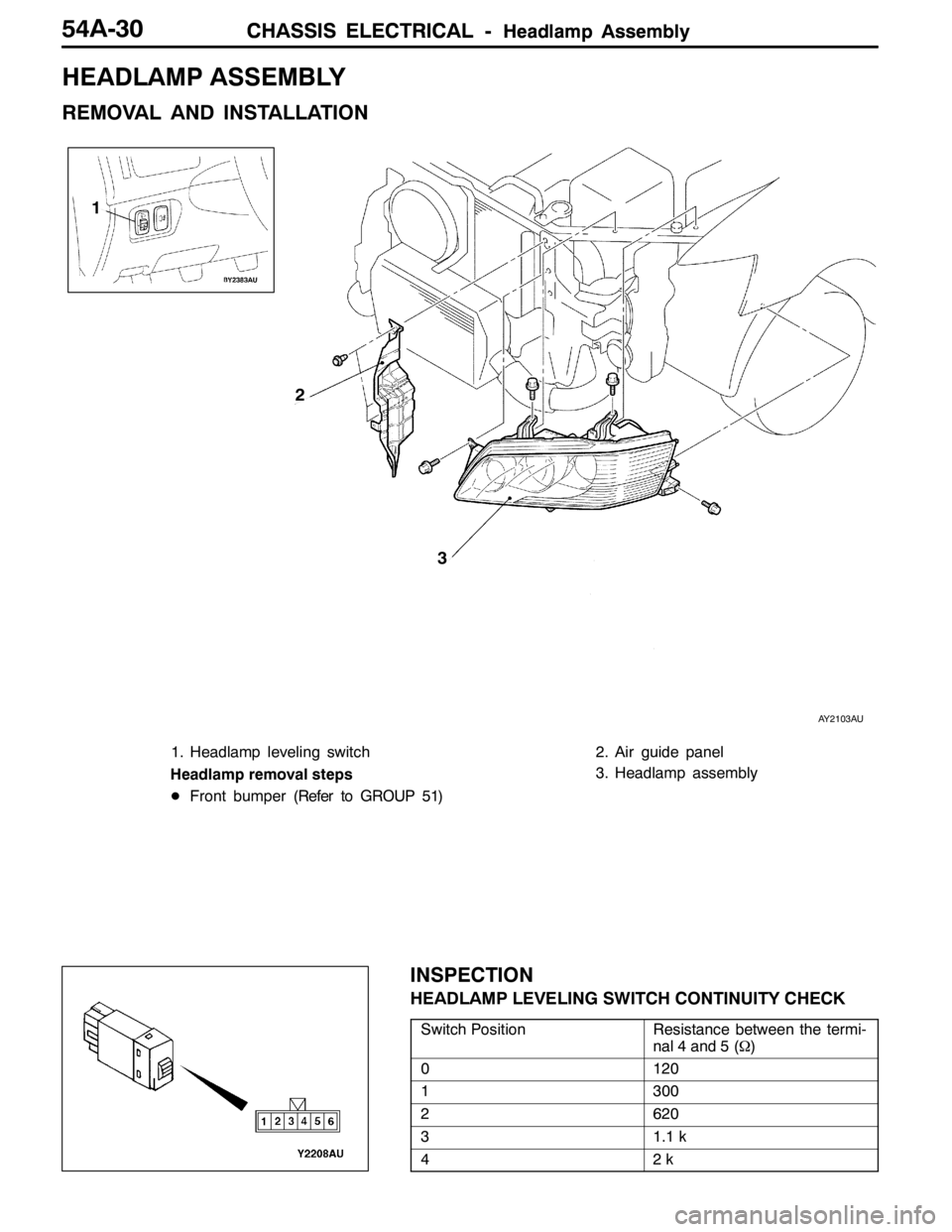

HEADLAMP ASSEMBLY

REMOVAL AND INSTALLATION

2

3

1

AY2103AU

1. Headlamp leveling switch

Headlamp removal steps

DFront bumper (Refer to GROUP 51)2. Air guide panel

3. Headlamp assembly

INSPECTION

HEADLAMP LEVELING SWITCH CONTINUITY CHECK

Switch PositionResistance between the termi-

nal 4 and 5 (Ω)

0120

1300

2620

31.1 k

42k

Page 1359 of 1449

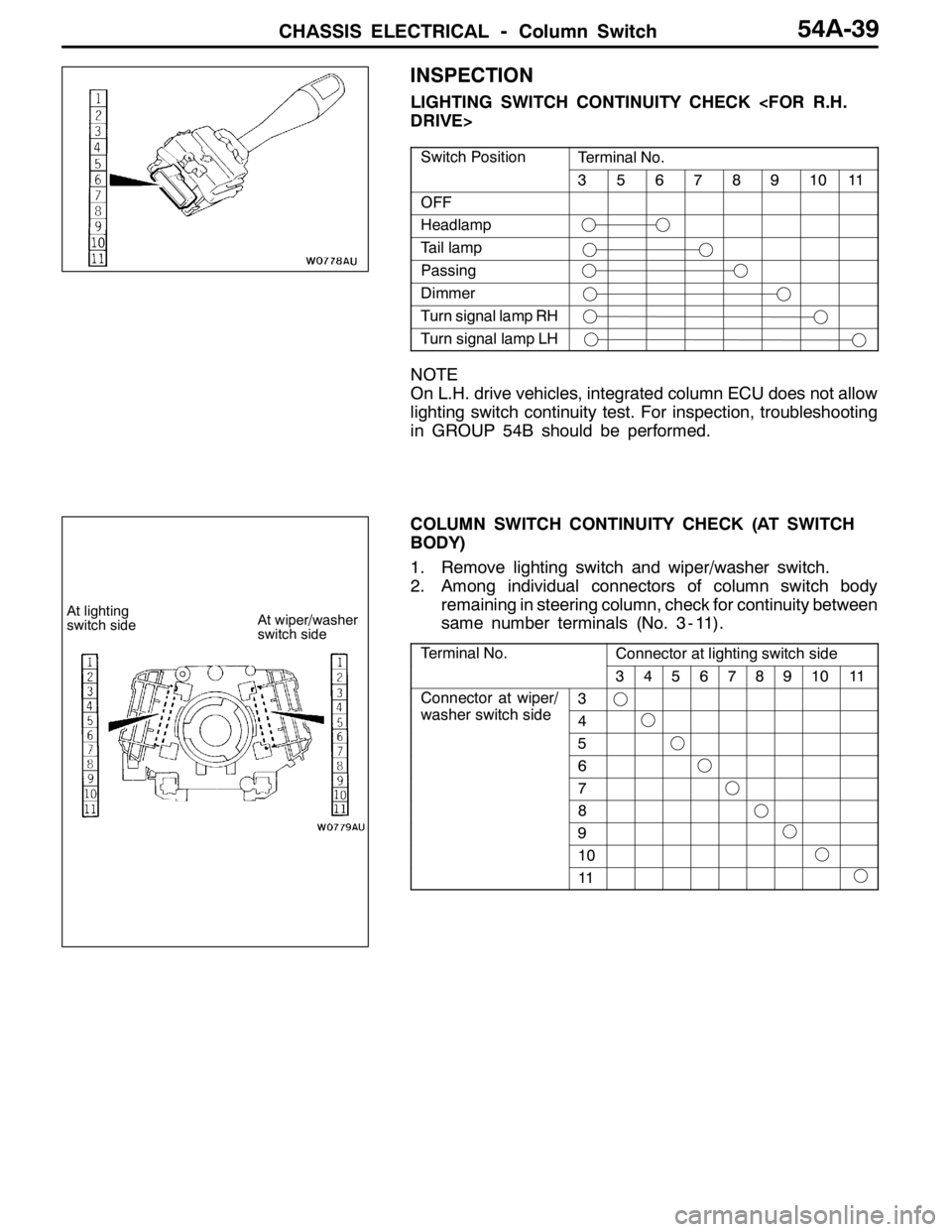

CHASSIS ELECTRICAL-Column Switch54A-39

INSPECTION

LIGHTING SWITCH CONTINUITY CHECK

Switch PositionTerminal No.

3567891011

OFF

Headlamp

Tail lamp

Passing

Dimmer

Turn signal lamp RH

Turn signal lamp LH

NOTE

On L.H. drive vehicles, integrated column ECU does not allow

lighting switch continuity test. For inspection, troubleshooting

in GROUP 54B should be performed.

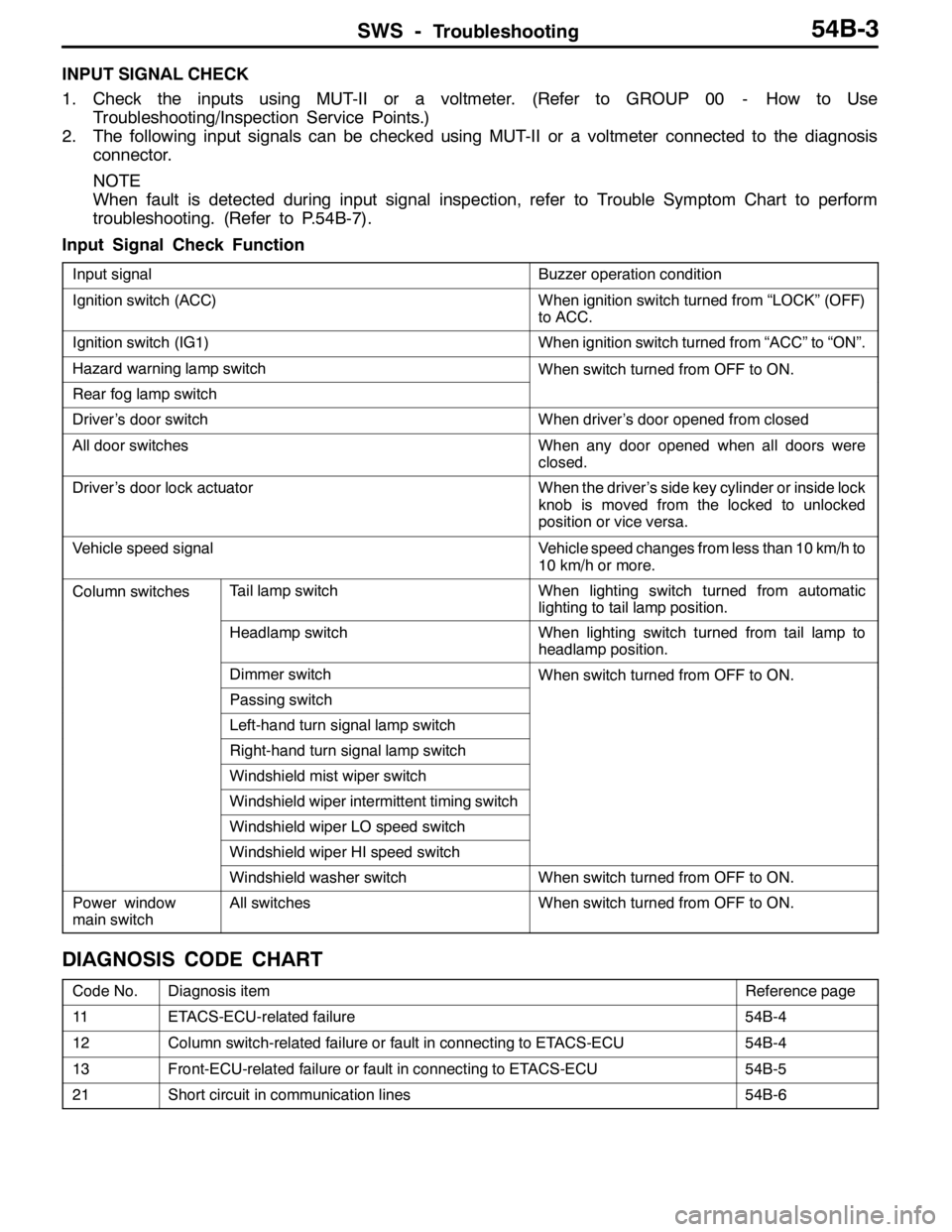

COLUMN SWITCH CONTINUITY CHECK (AT SWITCH

BODY)

1. Remove lighting switch and wiper/washer switch.

2. Among individual connectors of column switch body

remaining in steering column, check for continuity between

same number terminals (No. 3 - 11).

Terminal No.Connector at lighting switch side

34567891011

Connector at wiper/

hit hid

3p

washer switch side4

5

6

7

8

9

10

11

At lighting

switch sideAt wiper/washer

switch side

Page 1367 of 1449

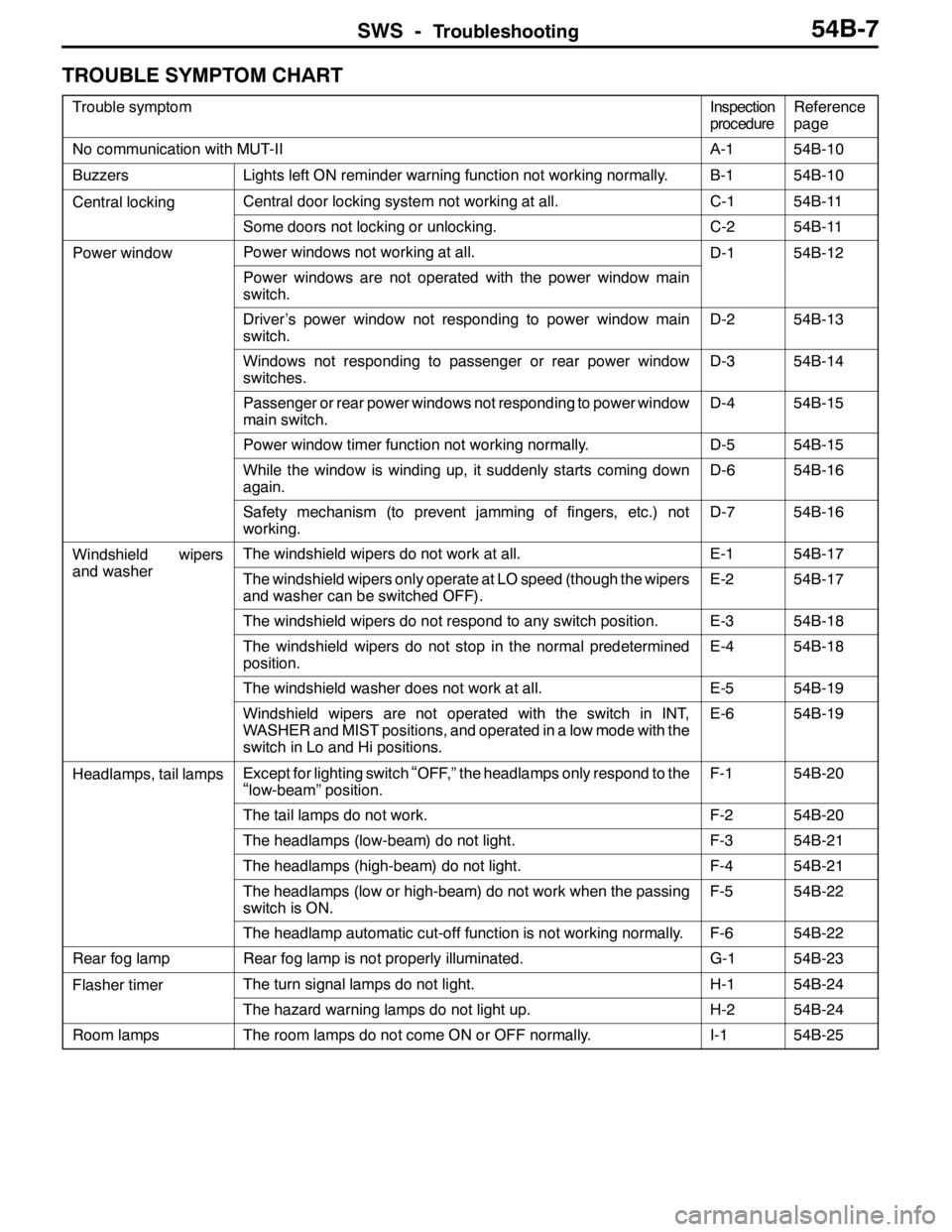

SWS -Troubleshooting54B-3

INPUT SIGNAL CHECK

1. Check the inputs using MUT-II or a voltmeter. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

2. The following input signals can be checked using MUT-II or a voltmeter connected to the diagnosis

connector.

NOTE

When fault is detected during input signal inspection, refer to Trouble Symptom Chart to perform

troubleshooting. (Refer to P.54B-7).

Input Signal Check Function

Input signalBuzzer operation condition

Ignition switch (ACC)When ignition switch turned from “LOCK” (OFF)

to ACC.

Ignition switch (IG1)When ignition switch turned from “ACC” to “ON”.

Hazard warning lamp switchWhen switch turned from OFF to ON.

Rear fog lamp switch

Driver’s door switchWhen driver’s door opened from closed

All door switchesWhen any door opened when all doors were

closed.

Driver’s door lock actuatorWhen the driver’s side key cylinder or inside lock

knob is moved from the locked to unlocked

position or vice versa.

Vehicle speed signalVehicle speed changes from less than 10 km/h to

10 km/h or more.

Column switchesTail lamp switchWhen lighting switch turned from automatic

lighting to tail lamp position.

Headlamp switchWhen lighting switch turned from tail lamp to

headlamp position.

Dimmer switchWhen switch turned from OFF to ON.

Passing switch

Left-hand turn signal lamp switch

Right-hand turn signal lamp switch

Windshield mist wiper switch

Windshield wiper intermittent timing switch

Windshield wiper LO speed switch

Windshield wiper HI speed switch

Windshield washer switchWhen switch turned from OFF to ON.

Power window

main switchAll switchesWhen switch turned from OFF to ON.

DIAGNOSIS CODE CHART

Code No.Diagnosis itemReference page

11ETACS-ECU-related failure54B-4

12Column switch-related failure or fault in connecting to ETACS-ECU54B-4

13Front-ECU-related failure or fault in connecting to ETACS-ECU54B-5

21Short circuit in communication lines54B-6

Page 1371 of 1449

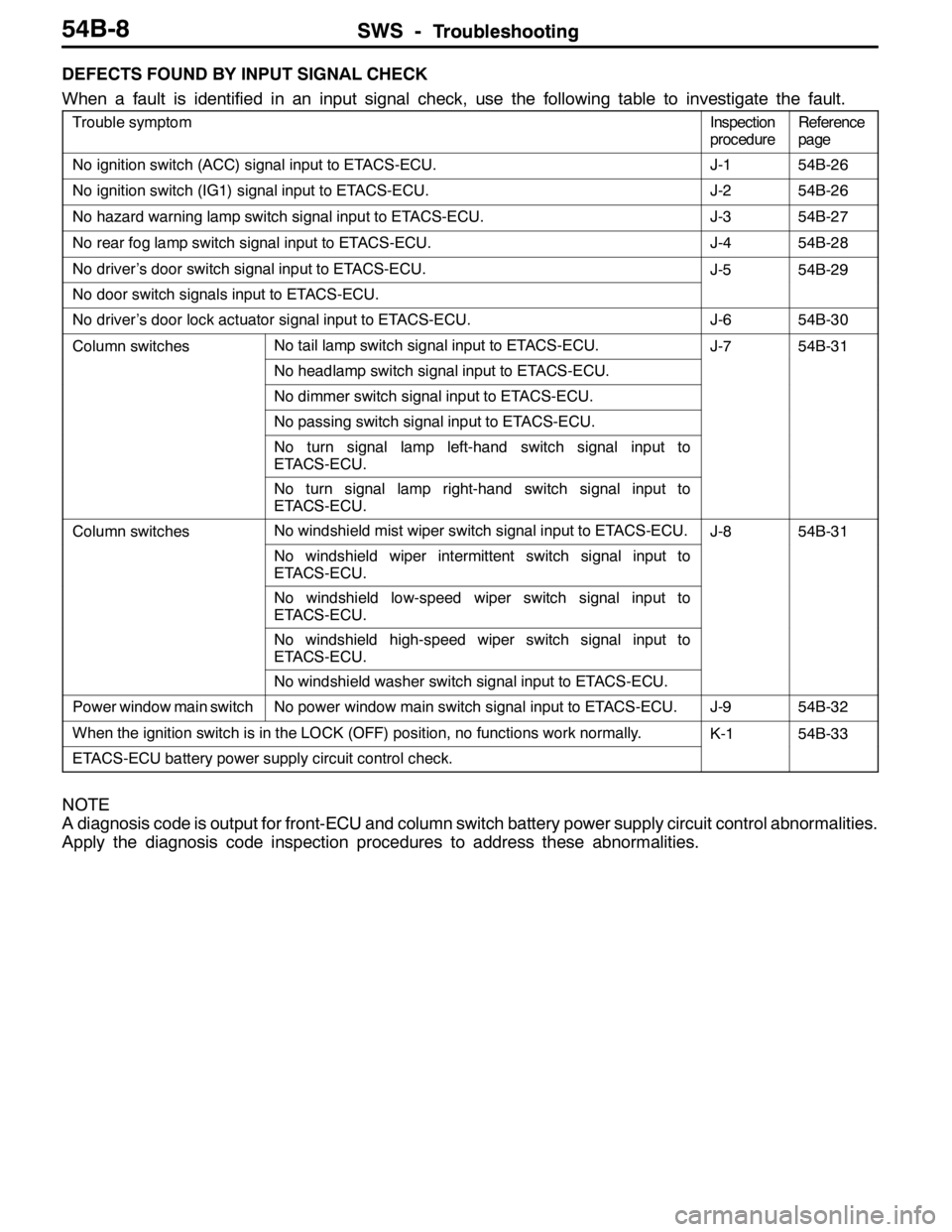

SWS -Troubleshooting54B-7

TROUBLE SYMPTOM CHART

Trouble symptomInspection

procedureReference

page

No communication with MUT-IIA-154B-10

BuzzersLights left ON reminder warning function not working normally.B-154B-10

Central lockingCentral door locking system not working at all.C-154B-11g

Some doors not locking or unlocking.C-254B-11

Power windowPower windows not working at all.D-154B-12

Power windows are not operated with the power window main

switch.

Driver’s power window not responding to power window main

switch.D-254B-13

Windows not responding to passenger or rear power window

switches.D-354B-14

Passenger or rear power windows not responding to power window

main switch.D-454B-15

Power window timer function not working normally.D-554B-15

While the window is winding up, it suddenly starts coming down

again.D-654B-16

Safety mechanism (to prevent jamming of fingers, etc.) not

working.D-754B-16

Windshield wipers

dh

The windshield wipers do not work at all.E-154B-17p

and washerThe windshield wipers only operate at LO speed (though the wipers

and washer can be switched OFF).E-254B-17

The windshield wipers do not respond to any switch position.E-354B-18

The windshield wipers do not stop in the normal predetermined

position.E-454B-18

The windshield washer does not work at all.E-554B-19

Windshield wipers are not operated with the switch in INT,

WASHER and MIST positions, and operated in a low mode with the

switch in Lo and Hi positions.E-654B-19

Headlamps, tail lampsExcept for lighting switch“OFF,” the headlamps only respond to the

“low-beam” position.

F-154B-20

The tail lamps do not work.F-254B-20

The headlamps (low-beam) do not light.F-354B-21

The headlamps (high-beam) do not light.F-454B-21

The headlamps (low or high-beam) do not work when the passing

switch is ON.F-554B-22

The headlamp automatic cut-off function is not working normally.F-654B-22

Rear fog lampRear fog lamp is not properly illuminated.G-154B-23

Flasher timerThe turn signal lamps do not light.H-154B-24

The hazard warning lamps do not light up.H-254B-24

Room lampsThe room lamps do not come ON or OFF normally.I-154B-25

Page 1372 of 1449

SWS -TroubleshootingSWS -Troubleshooting54B-8

DEFECTS FOUND BY INPUT SIGNAL CHECK

When a fault is identified in an input signal check, use the following table to investigate the fault.

Trouble symptomInspection

procedureReference

page

No ignition switch (ACC) signal input to ETACS-ECU.J-154B-26

No ignition switch (IG1) signal input to ETACS-ECU.J-254B-26

No hazard warning lamp switch signal input to ETACS-ECU.J-354B-27

No rear fog lamp switch signal input to ETACS-ECU.J-454B-28

No driver’s door switch signal input to ETACS-ECU.J-554B-29

No door switch signals input to ETACS-ECU.

No driver’s door lock actuator signal input to ETACS-ECU.J-654B-30

Column switchesNo tail lamp switch signal input to ETACS-ECU.J-754B-31

No headlamp switch signal input to ETACS-ECU.

No dimmer switch signal input to ETACS-ECU.

No passing switch signal input to ETACS-ECU.

No turn signal lamp left-hand switch signal input to

ETACS-ECU.

No turn signal lamp right-hand switch signal input to

ETACS-ECU.

Column switchesNo windshield mist wiper switch signal input to ETACS-ECU.J-854B-31

No windshield wiper intermittent switch signal input to

ETACS-ECU.

No windshield low-speed wiper switch signal input to

ETACS-ECU.

No windshield high-speed wiper switch signal input to

ETACS-ECU.

No windshield washer switch signal input to ETACS-ECU.

Power window main switchNo power window main switch signal input to ETACS-ECU.J-954B-32

When the ignition switch is in the LOCK (OFF) position, no functions work normally.K-154B-33

ETACS-ECU battery power supply circuit control check.

NOTE

A diagnosis code is output for front-ECU and column switch battery power supply circuit control abnormalities.

Apply the diagnosis code inspection procedures to address these abnormalities.

Page 1373 of 1449

SWS -Troubleshooting54B-9

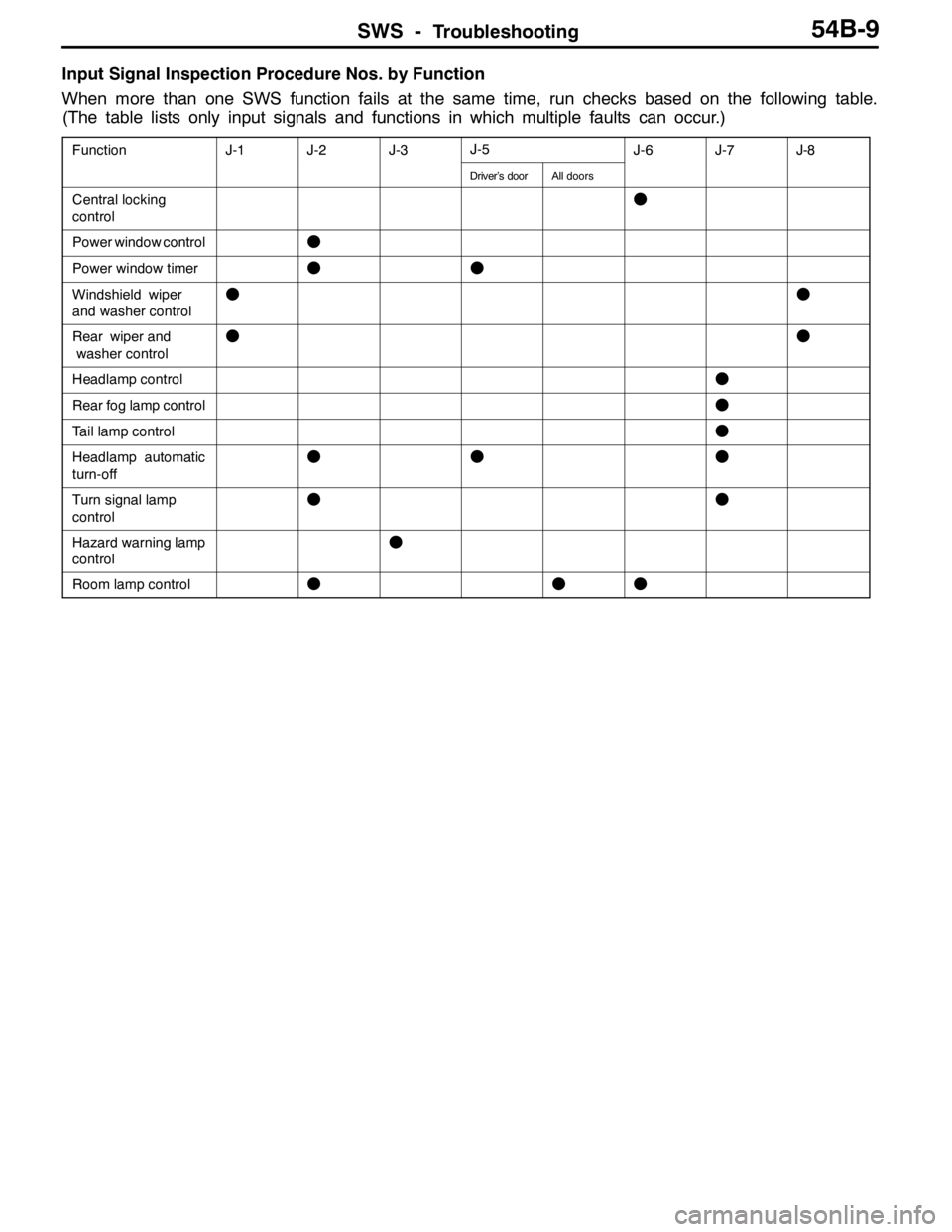

Input Signal Inspection Procedure Nos. by Function

When more than one SWS function fails at the same time, run checks based on the following table.

(The table lists only input signals and functions in which multiple faults can occur.)

FunctionJ-1J-2J-3J-5J-6J-7J-8

Driver’s doorAll doors

Central locking

controlF

Power window controlF

Power window timerFF

Windshield wiper

and washer controlFF

Rear wiper and

washer controlFF

Headlamp controlF

Rear fog lamp controlF

Tail lamp controlF

Headlamp automatic

turn-offFFF

Turn signal lamp

controlFF

Hazard warning lamp

controlF

Room lamp controlFFF

Page 1374 of 1449

SWS -Troubleshooting54B-10

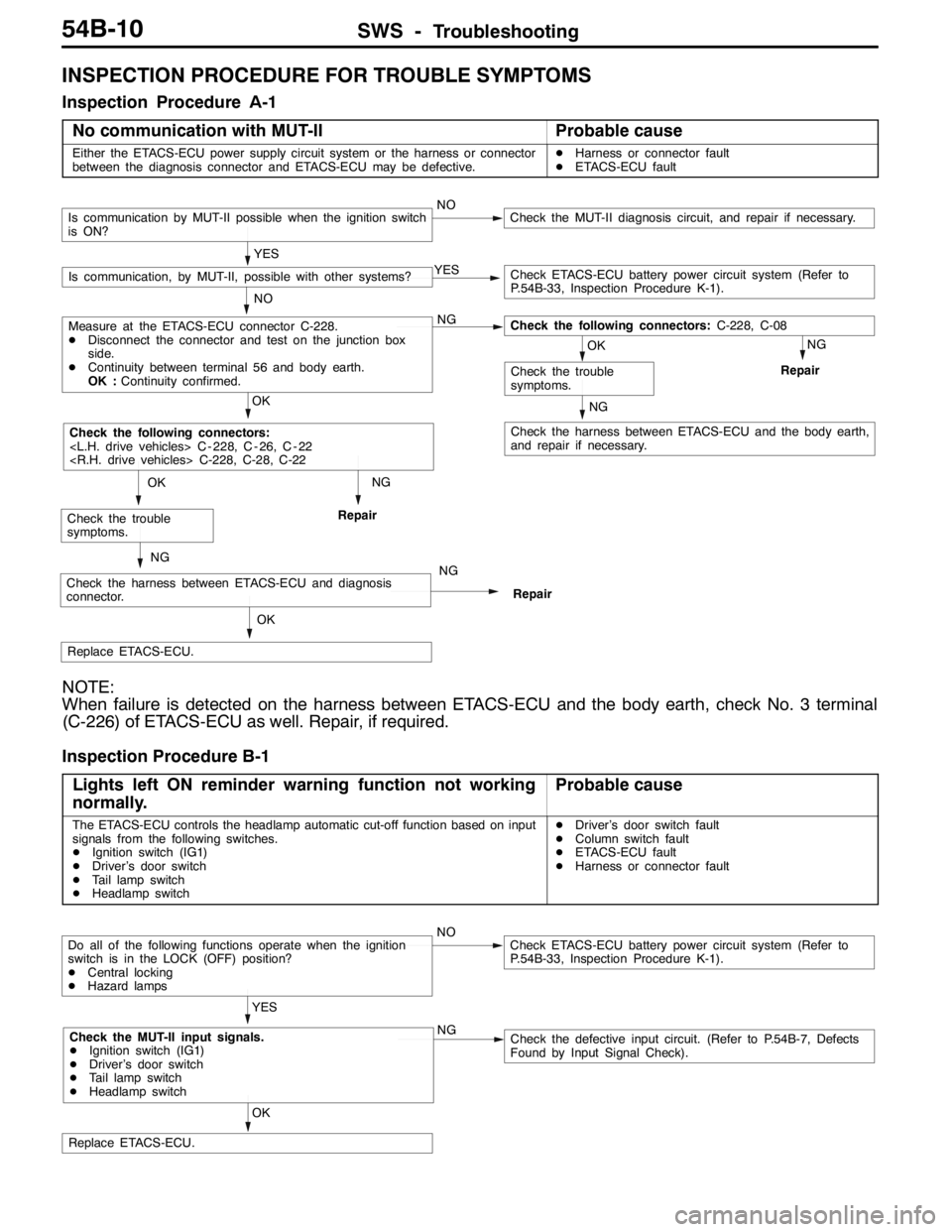

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure A-1

No communication with MUT-II

Probable cause

Either the ETACS-ECU power supply circuit system or the harness or connector

between the diagnosis connector and ETACS-ECU may be defective.DHarness or connector fault

DETACS-ECU fault

NG

Check the harness between ETACS-ECU and the body earth,

and repair if necessary.

NG

Repair

NG

Repair

OK

Replace ETACS-ECU.

NG

Check the harness between ETACS-ECU and diagnosis

connector.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:

OK

Check the trouble

symptoms.

NO

Measure at the ETACS-ECU connector C-228.

DDisconnect the connector and test on the junction box

side.

DContinuity between terminal 56 and body earth.

OK :Continuity confirmed.NGCheck the following connectors:C-228, C-08

YES

Is communication, by MUT-II, possible with other systems?YESCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

Is communication by MUT-II possible when the ignition switch

is ON?NOCheck the MUT-II diagnosis circuit, and repair if necessary.

NOTE:

When failure is detected on the harness between ETACS-ECU and the body earth, check No. 3 terminal

(C-226) of ETACS-ECU as well. Repair, if required.

Inspection Procedure B-1

Lights left ON reminder warning function not working

normally.

Probable cause

The ETACS-ECU controls the headlamp automatic cut-off function based on input

signals from the following switches.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchDDriver’s door switch fault

DColumn switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace ETACS-ECU.

YES

Check the MUT-II input signals.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchNGCheck the defective input circuit. (Refer to P.54B-7, Defects

Found by Input Signal Check).

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DCentral locking

DHazard lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).