service MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 503 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-49

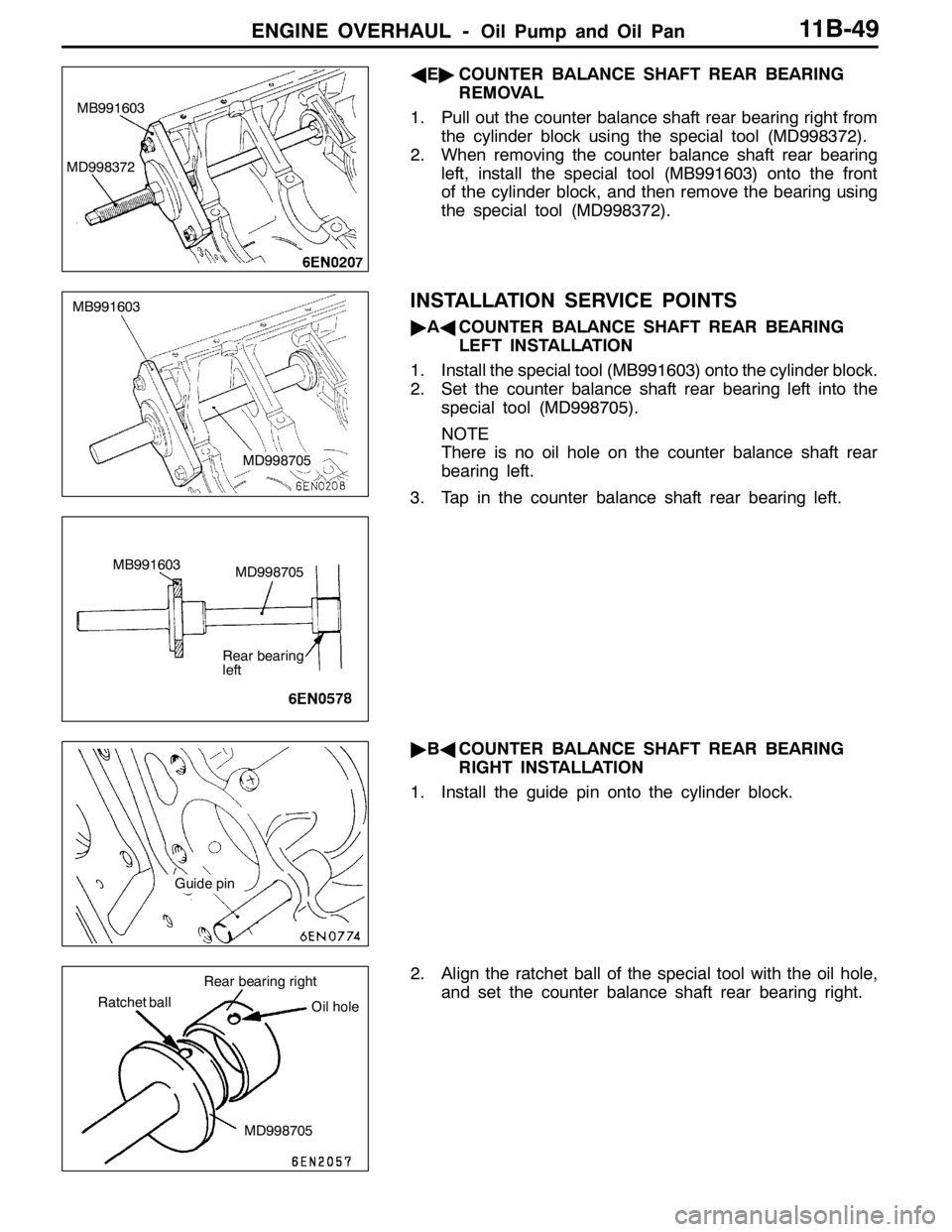

AE"COUNTER BALANCE SHAFT REAR BEARING

REMOVAL

1. Pull out the counter balance shaft rear bearing right from

the cylinder block using the special tool (MD998372).

2. When removing the counter balance shaft rear bearing

left, install the special tool (MB991603) onto the front

of the cylinder block, and then remove the bearing using

the special tool (MD998372).

INSTALLATION SERVICE POINTS

"AACOUNTER BALANCE SHAFT REAR BEARING

LEFT INSTALLATION

1. Install the special tool (MB991603) onto the cylinder block.

2. Set the counter balance shaft rear bearing left into the

special tool (MD998705).

NOTE

There is no oil hole on the counter balance shaft rear

bearing left.

3. Tap in the counter balance shaft rear bearing left.

"BACOUNTER BALANCE SHAFT REAR BEARING

RIGHT INSTALLATION

1. Install the guide pin onto the cylinder block.

2. Align the ratchet ball of the special tool with the oil hole,

and set the counter balance shaft rear bearing right.

MB991603

MD998372

MB991603

MD998705

MB991603

MD998705

Rear bearing

left

Guide pin

Ratchet ball

MD998705 Rear bearing right

Oil hole

Page 511 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-57

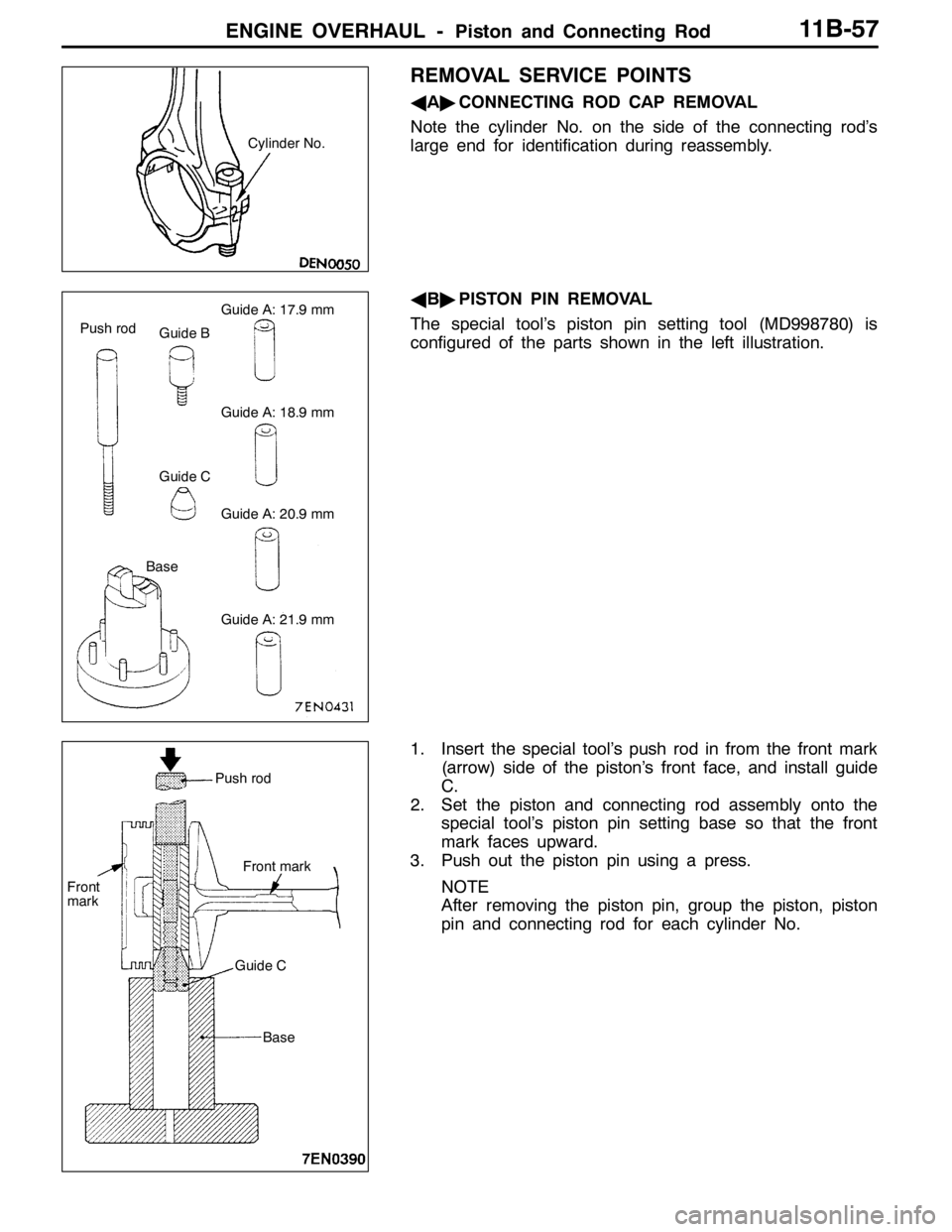

REMOVAL SERVICE POINTS

AA"CONNECTING ROD CAP REMOVAL

Note the cylinder No. on the side of the connecting rod’s

large end for identification during reassembly.

AB"PISTON PIN REMOVAL

The special tool’s piston pin setting tool (MD998780) is

configured of the parts shown in the left illustration.

1. Insert the special tool’s push rod in from the front mark

(arrow) side of the piston’s front face, and install guide

C.

2. Set the piston and connecting rod assembly onto the

special tool’s piston pin setting base so that the front

mark faces upward.

3. Push out the piston pin using a press.

NOTE

After removing the piston pin, group the piston, piston

pin and connecting rod for each cylinder No.

Cylinder No.

Push rod

Guide BGuide A: 17.9 mm

Guide A: 18.9 mm

Guide A: 20.9 mm

Guide A: 21.9 mm BaseGuide C

Push rod

Front mark

Guide C

Base Front

mark

Page 512 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-58

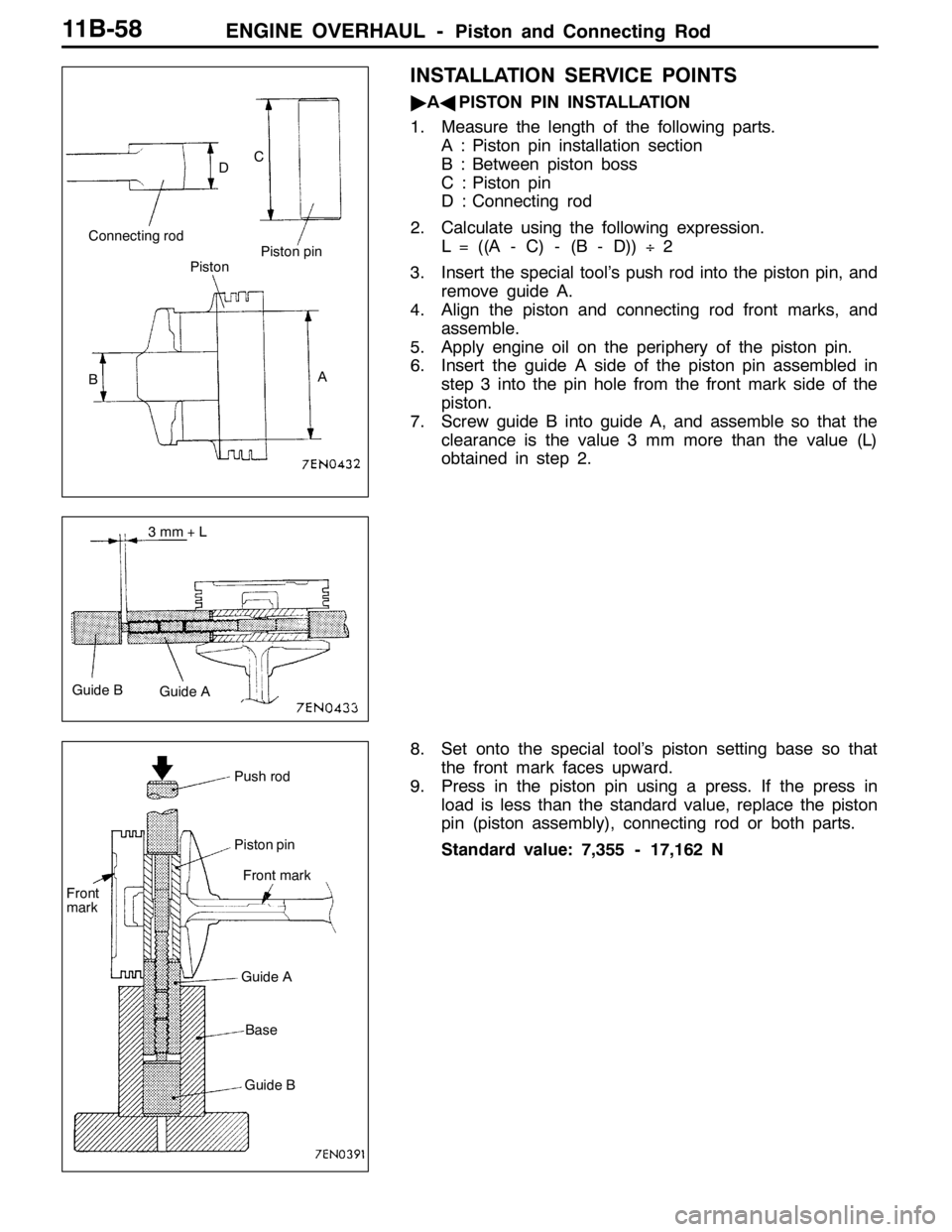

INSTALLATION SERVICE POINTS

"AAPISTON PIN INSTALLATION

1. Measure the length of the following parts.

A : Piston pin installation section

B : Between piston boss

C : Piston pin

D : Connecting rod

2. Calculate using the following expression.

L = ((A - C) - (B - D))÷2

3. Insert the special tool’s push rod into the piston pin, and

remove guide A.

4. Align the piston and connecting rod front marks, and

assemble.

5. Apply engine oil on the periphery of the piston pin.

6. Insert the guide A side of the piston pin assembled in

step 3 into the pin hole from the front mark side of the

piston.

7. Screw guide B into guide A, and assemble so that the

clearance is the value 3 mm more than the value (L)

obtained in step 2.

8. Set onto the special tool’s piston setting base so that

the front mark faces upward.

9. Press in the piston pin using a press. If the press in

load is less than the standard value, replace the piston

pin (piston assembly), connecting rod or both parts.

Standard value: 7,355 - 17,162 N

Connecting rod

PistonPiston pin

BA DC

3mm+L

Guide B

Guide A

Push rod

Piston pin

Front mark

Front

mark

Guide A

Guide BBase

Page 519 of 1449

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-65

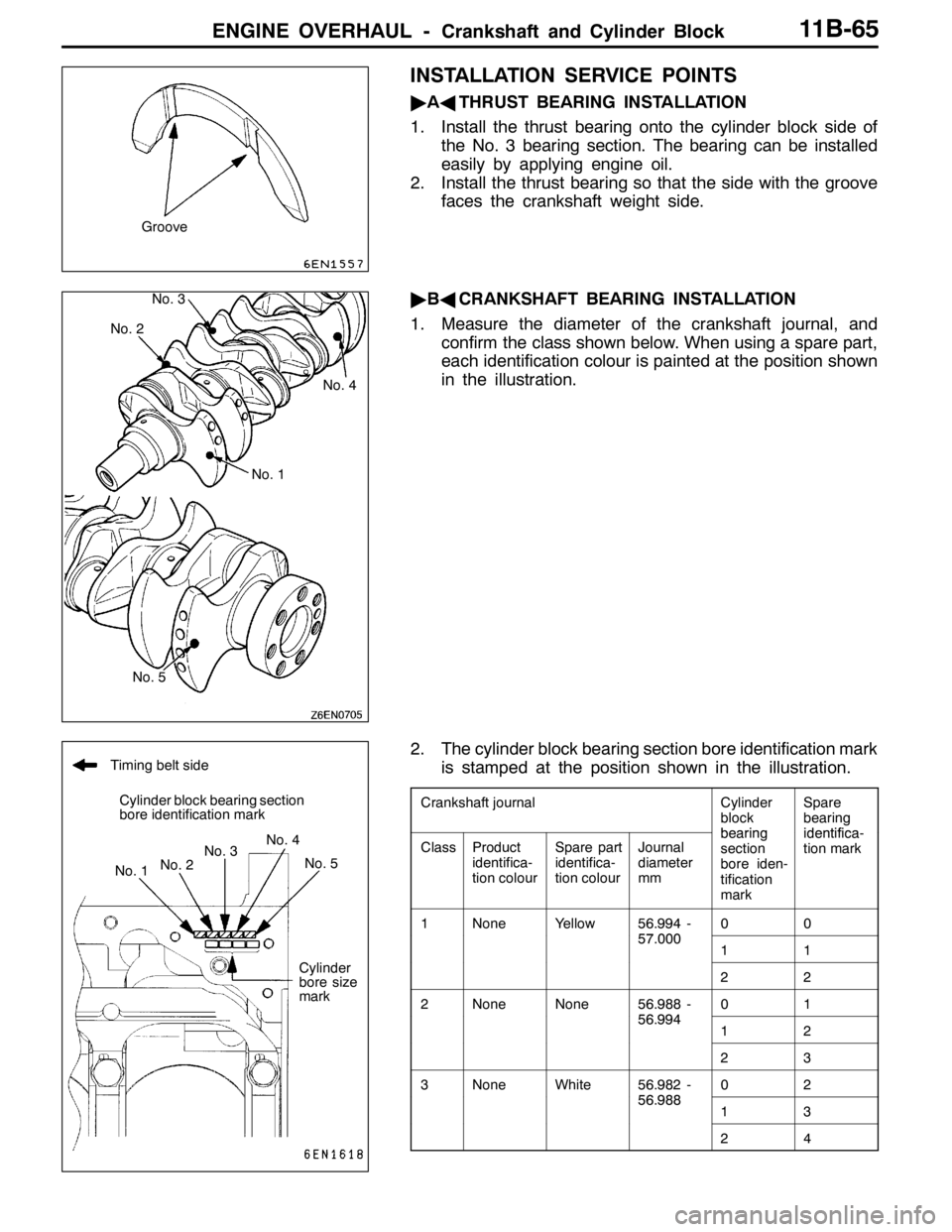

INSTALLATION SERVICE POINTS

"AATHRUST BEARING INSTALLATION

1. Install the thrust bearing onto the cylinder block side of

the No. 3 bearing section. The bearing can be installed

easily by applying engine oil.

2. Install the thrust bearing so that the side with the groove

faces the crankshaft weight side.

"BACRANKSHAFT BEARING INSTALLATION

1. Measure the diameter of the crankshaft journal, and

confirm the class shown below. When using a spare part,

each identification colour is painted at the position shown

in the illustration.

2. The cylinder block bearing section bore identification mark

is stamped at the position shown in the illustration.

Crankshaft journalCylinder

block

bearing

Spare

bearing

identificaClassProduct

identifica-

tion colourSpare part

identifica-

tion colourJournal

diameter

mmbearing

section

bore iden-

tification

markidentifica-

tion mark

1NoneYellow56.994 -57 0000057.00011

22

2NoneNone56.988 -56 9940156.99412

23

3NoneWhite56.982 -56 9880256.98813

24

Groove

No. 2

No. 1No. 4

No. 5No. 3

Timing belt side

Cylinder block bearing section

bore identification mark

No. 1No. 2No. 3No. 4

No. 5

Cylinder

bore size

mark

Page 525 of 1449

12-1

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

LUBRICANTS 3..............................

SPECIAL TOOL 3............................ON-VEHICLE SERVICE 4.....................

Engine Oil Check 4............................

Engine Oil Replacement 4.......................

Oil Filter Replacement 5........................

Oil Pressure Check 5..........................

ENGINE OIL COOLER 7......................

Page 527 of 1449

ENGINE LUBRICATION -Service Specifications/Sealant/Lubricants/Special Tool12-3

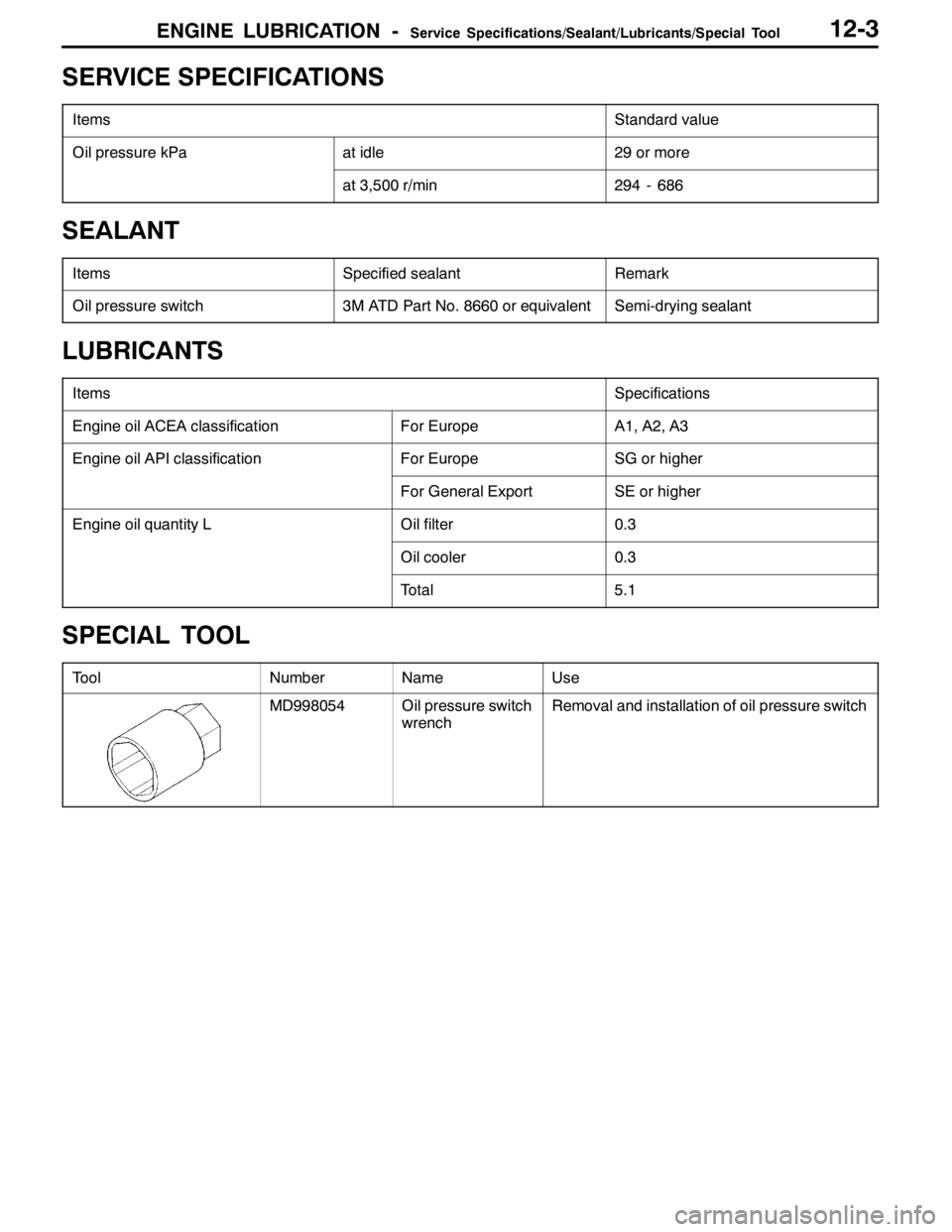

SERVICE SPECIFICATIONS

ItemsStandard value

Oil pressure kPaat idle29 or more

at 3,500 r/min294 - 686

SEALANT

ItemsSpecified sealantRemark

Oil pressure switch3M ATD Part No. 8660 or equivalentSemi-drying sealant

LUBRICANTS

ItemsSpecifications

Engine oil ACEA classificationFor EuropeA1, A2, A3

Engine oil API classificationFor EuropeSG or higher

For General ExportSE or higher

Engine oil quantity LOil filter0.3

Oil cooler0.3

Total5.1

SPECIAL TOOL

ToolNumberNameUse

MD998054Oil pressure switch

wrenchRemoval and installation of oil pressure switch

Page 528 of 1449

ENGINE LUBRICATION -On-vehicle Service12-4

ON-VEHICLE SERVICE

ENGINE OIL CHECK

1. Pull out the level gauge slowly and check that the oil

level is in the illustrated range.

2. Check that the oil is not excessively dirty, that there is

no coolant or petrol mixed in, and that it has sufficient

viscosity.

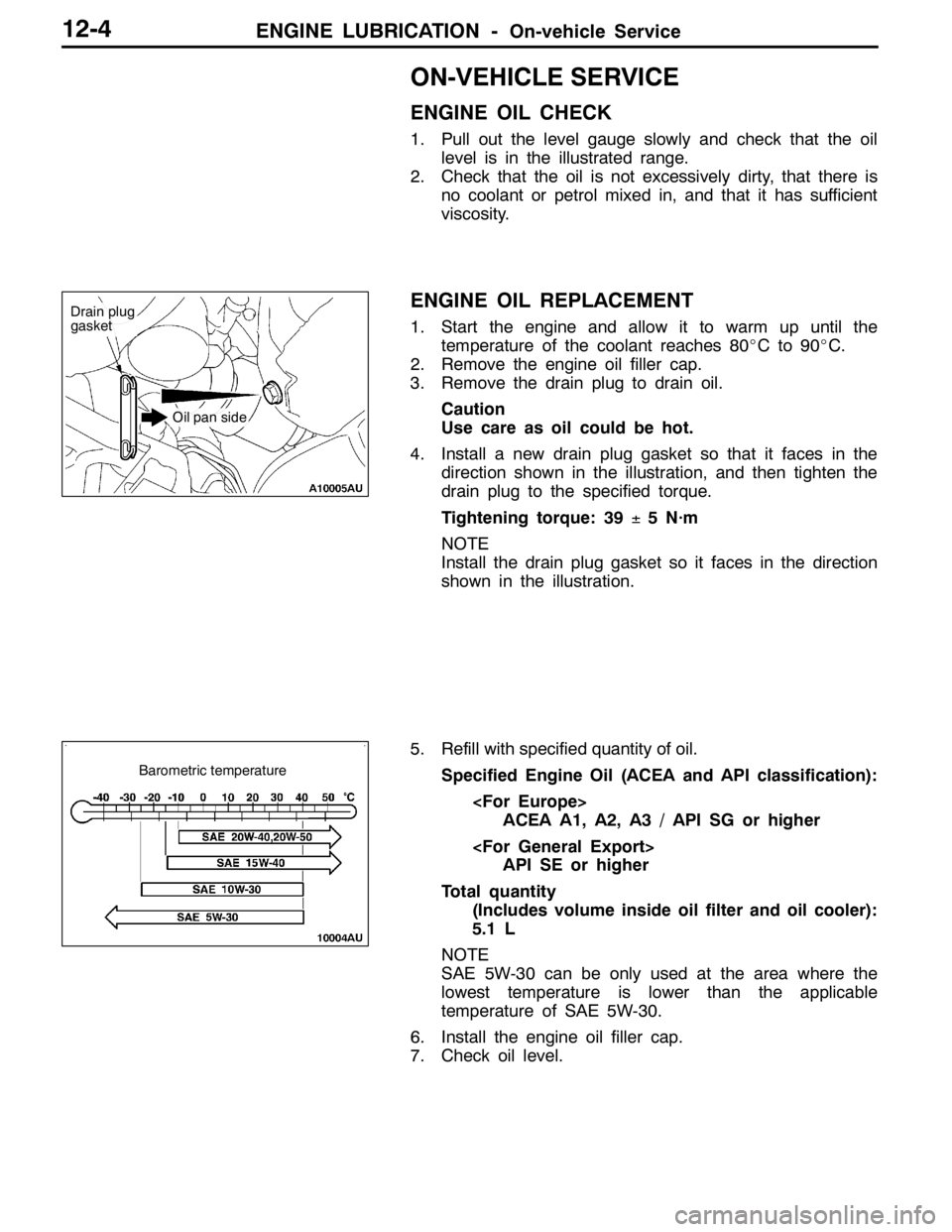

ENGINE OIL REPLACEMENT

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

4. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the

drain plug to the specified torque.

Tightening torque: 39±5 N·m

NOTE

Install the drain plug gasket so it faces in the direction

shown in the illustration.

5. Refill with specified quantity of oil.

Specified Engine Oil (ACEA and API classification):

ACEA A1, A2, A3 / API SG or higher

API SE or higher

Total quantity

(Includes volume inside oil filter and oil cooler):

5.1 L

NOTE

SAE 5W-30 can be only used at the area where the

lowest temperature is lower than the applicable

temperature of SAE 5W-30.

6. Install the engine oil filler cap.

7. Check oil level.

Drain plug

gasket

Oil pan side

Barometric temperature

Page 529 of 1449

ENGINE LUBRICATION -On-vehicle Service12-5

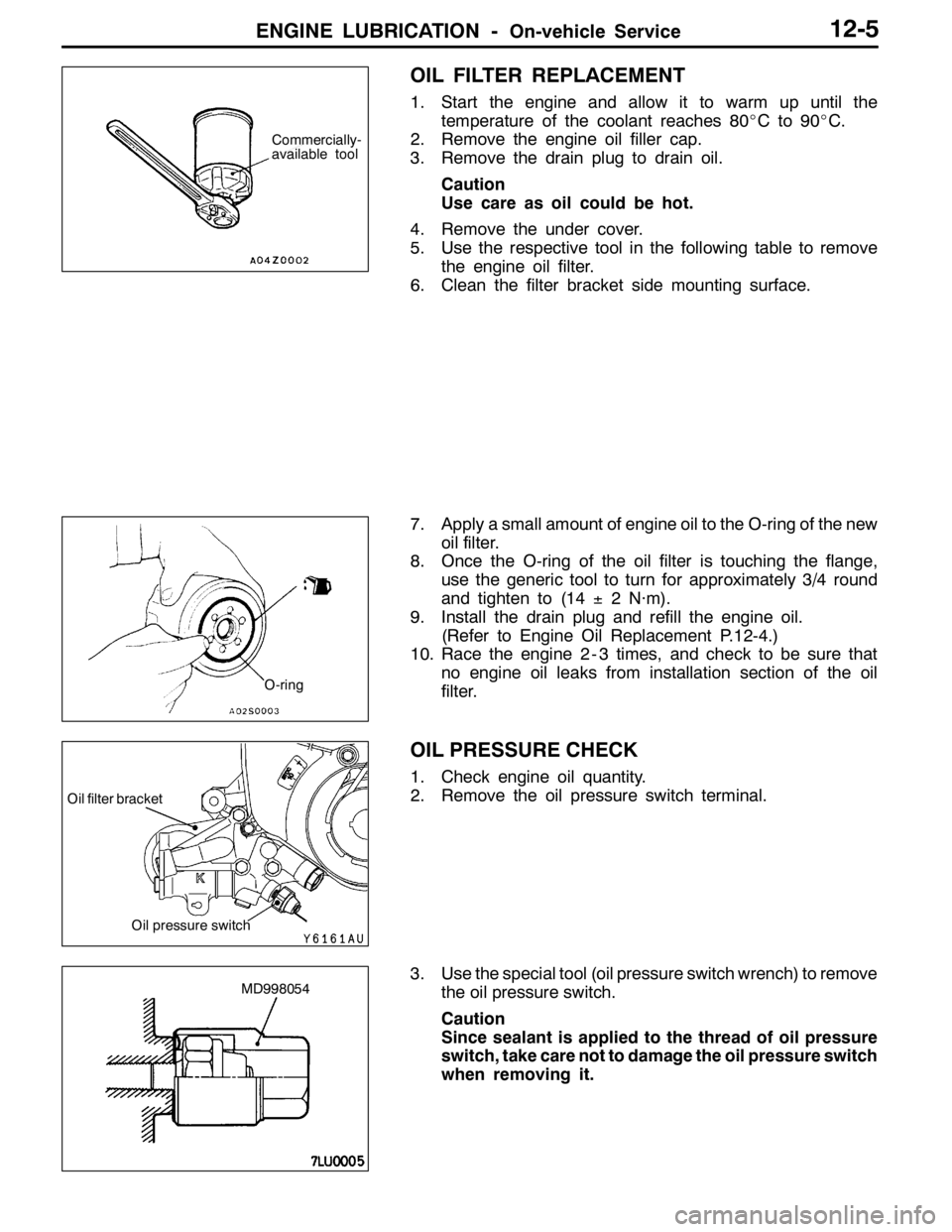

OIL FILTER REPLACEMENT

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

4. Remove the under cover.

5. Use the respective tool in the following table to remove

the engine oil filter.

6. Clean the filter bracket side mounting surface.

7. Apply a small amount of engine oil to the O-ring of the new

oil filter.

8. Once the O-ring of the oil filter is touching the flange,

use the generic tool to turn for approximately 3/4 round

and tighten to (14±2 N·m).

9. Install the drain plug and refill the engine oil.

(Refer to Engine Oil Replacement P.12-4.)

10. Race the engine 2 - 3 times, and check to be sure that

no engine oil leaks from installation section of the oil

filter.

OIL PRESSURE CHECK

1. Check engine oil quantity.

2. Remove the oil pressure switch terminal.

3. Use the special tool (oil pressure switch wrench) to remove

the oil pressure switch.

Caution

Since sealant is applied to the thread of oil pressure

switch, take care not to damage the oil pressure switch

when removing it.

Commercially-

available tool

O-ring

Oil pressure switch

Oil filter bracket

MD998054

Page 530 of 1449

ENGINE LUBRICATION -On-vehicle Service12-6

4. Install the oil pressure gauge.

NOTE

Use a adapter of PT 1/8 thread.

5. Run the engine to warm it.

6. After the engine has been warmed up, check that oil

pressure is within the standard value.

Standard value:

At idle: 29 kPa or more

At 3,500 r/min: 294 - 686 kPa

7. Remove the oil pressure gauge.

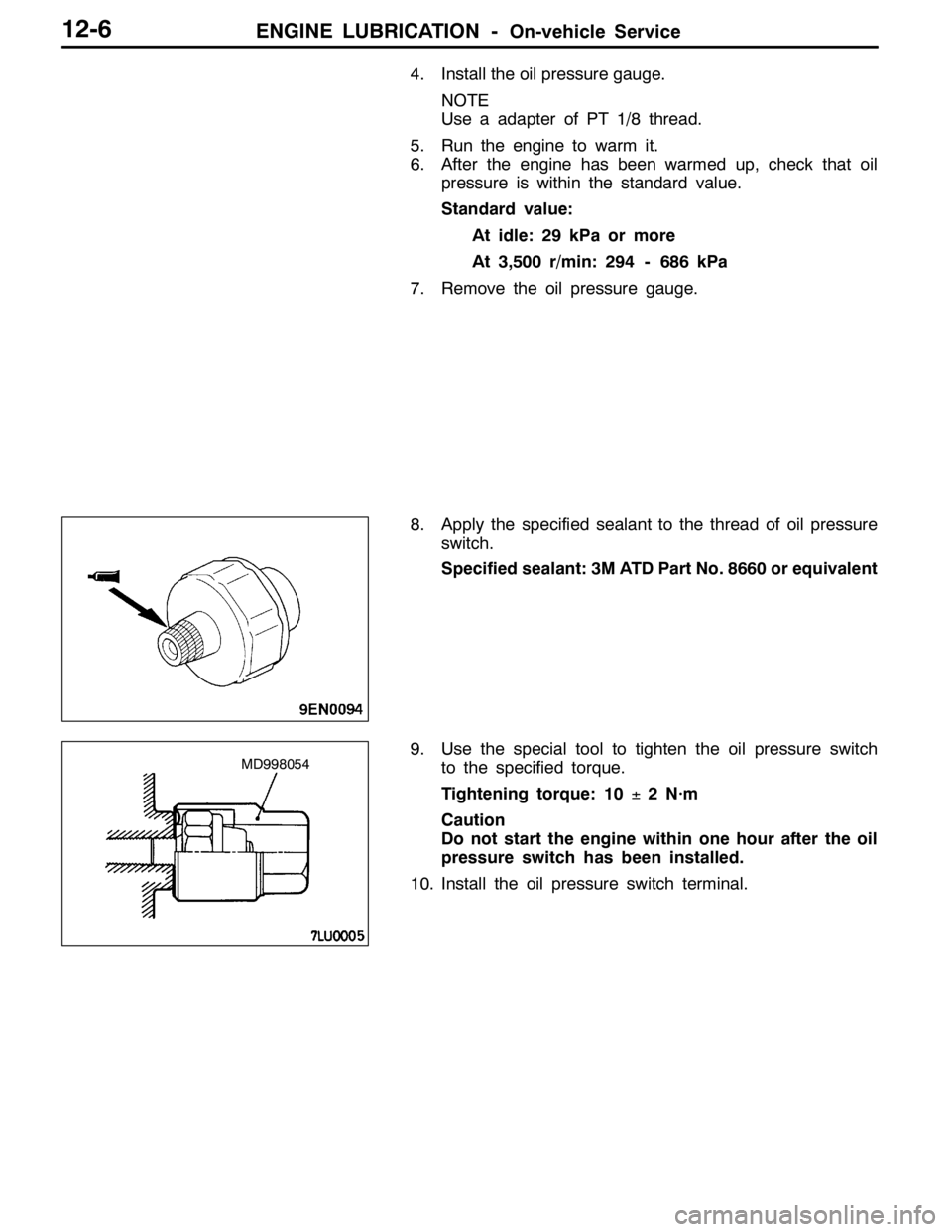

8. Apply the specified sealant to the thread of oil pressure

switch.

Specified sealant: 3M ATD Part No. 8660 or equivalent

9. Use the special tool to tighten the oil pressure switch

to the specified torque.

Tightening torque: 10±2 N·m

Caution

Do not start the engine within one hour after the oil

pressure switch has been installed.

10. Install the oil pressure switch terminal.

MD998054

Page 534 of 1449

13A-2

MULTIPOINT FUEL

INJECTION (MPI)

CONTENTS

GENERAL INFORMATION 3...................

SERVICE SPECIFICATIONS 6.................

SEALANT 6..................................

SPECIAL TOOLS 7...........................

TROUBLESHOOTING 9.......................

ON-VEHICLE SERVICE 125..................

Fuel Pump Connector Disconnection

(How to Reduce the Fuel Pressure) 125...........

Fuel Pump Operation Check 125.................

Throttle Body (Throttle Valve Area)

Cleaning 126..................................

Throttle Position Sensor Adjustment 126...........

Basic Idle Speed Adjustment 127.................

Fuel Pressure Test 128..........................

Component Location 131........................

Engine Control Relay Continuity Check 132........

Fuel Pump Relay 1, 2 Continuity Check 132........Fuel Pump Relay 3 Continuity Check 132..........

Fuel Pump Resistor Check 132...................

Intake Air Temperature Sensor Check 132.........

Engine Coolant Temperature Sensor Check 133....

Throttle Position Sensor Check 134...............

Oxygen Sensor Check 134......................

Injector Check 136..............................

Resistor (for Injector) Check 138..................

Idle Speed Control Servo (Stepper Motor)

Check 138.....................................

Fuel Pressure Control Solenoid Valve Check 140...

Purge Control Solenoid Valve Check 140..........

EGR Control Solenoid Valve Check 140...........

INJECTOR 141..............................

THROTTLE BODY 143.......................

ENGINE CONTROL RESISTOR, RELAY 146....

ENGINE-ECU 147...........................