service MITSUBISHI LANCER EVOLUTION 2007 Service Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 619 of 1449

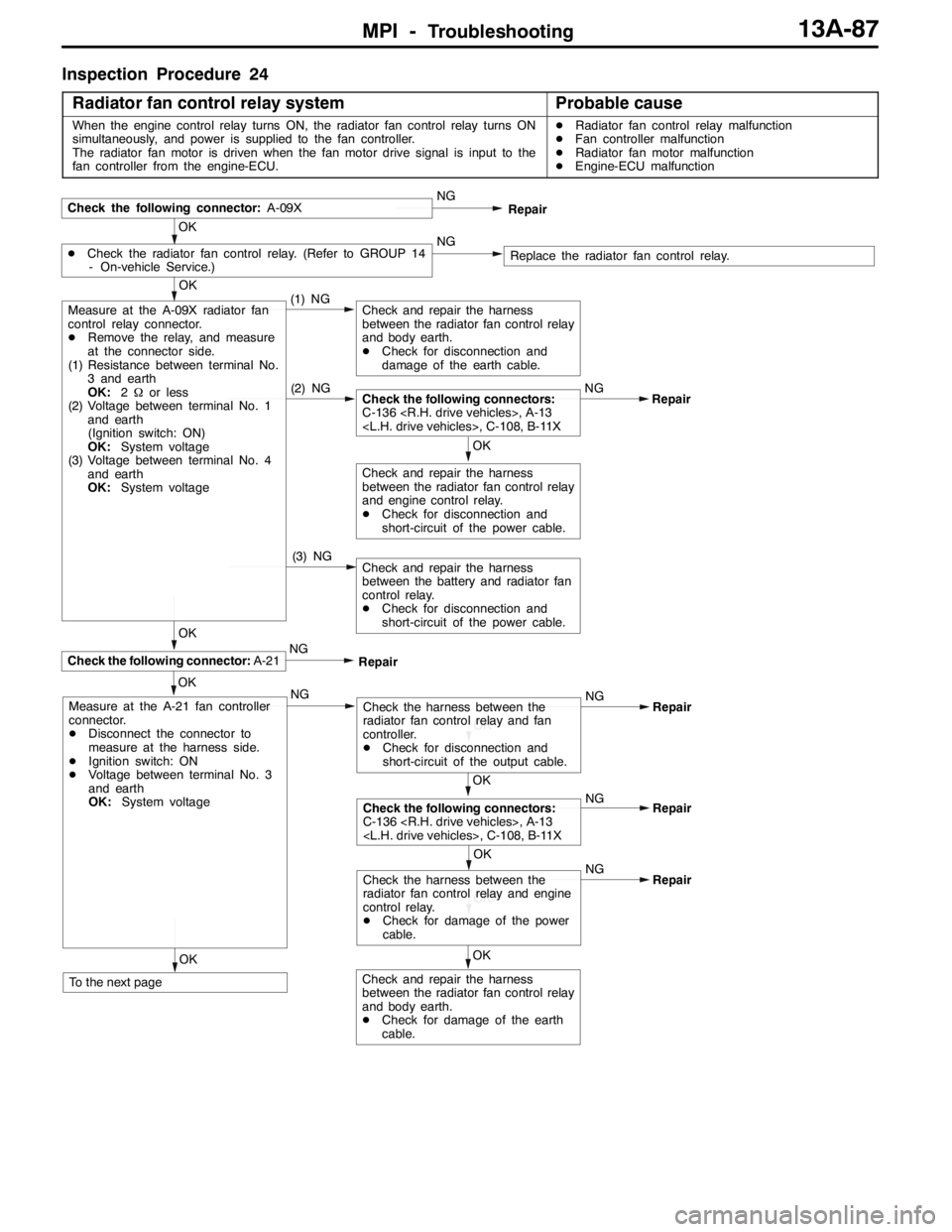

MPI -Troubleshooting13A-87

Inspection Procedure 24

Radiator fan control relay system

Probable cause

When the engine control relay turns ON, the radiator fan control relay turns ON

simultaneously, and power is supplied to the fan controller.

The radiator fan motor is driven when the fan motor drive signal is input to the

fan controller from the engine-ECU.DRadiator fan control relay malfunction

DFan controller malfunction

DRadiator fan motor malfunction

DEngine-ECU malfunction

OK

(1) NG

OK

DCheck the radiator fan control relay. (Refer to GROUP 14

- On-vehicle Service.)NGReplace the radiator fan control relay.

Check the following connector:A-09XNG

Repair

OK

OK

(2) NGCheck the following connectors:

C-136

OK

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for disconnection and

damage of the earth cable.

Repair

OK

Check the following connector:A-21

Check and repair the harness

between the radiator fan control relay

and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

(3) NGCheck and repair the harness

between the battery and radiator fan

control relay.

DCheck for disconnection and

short-circuit of the power cable.

Measure at the A-09X radiator fan

control relay connector.

DRemove the relay, and measure

at the connector side.

(1) Resistance between terminal No.

3 and earth

OK:2Ωor less

(2) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK:System voltage

(3) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair

OK

Measure at the A-21 fan controller

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltage

To the next pageNG

OK

Check the harness between the

radiator fan control relay and fan

controller.

DCheck for disconnection and

short-circuit of the output cable.NG

Repair

OK

Check the following connectors:

C-136

Repair

OK

OK

Check the harness between the

radiator fan control relay and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for damage of the earth

cable.

Page 621 of 1449

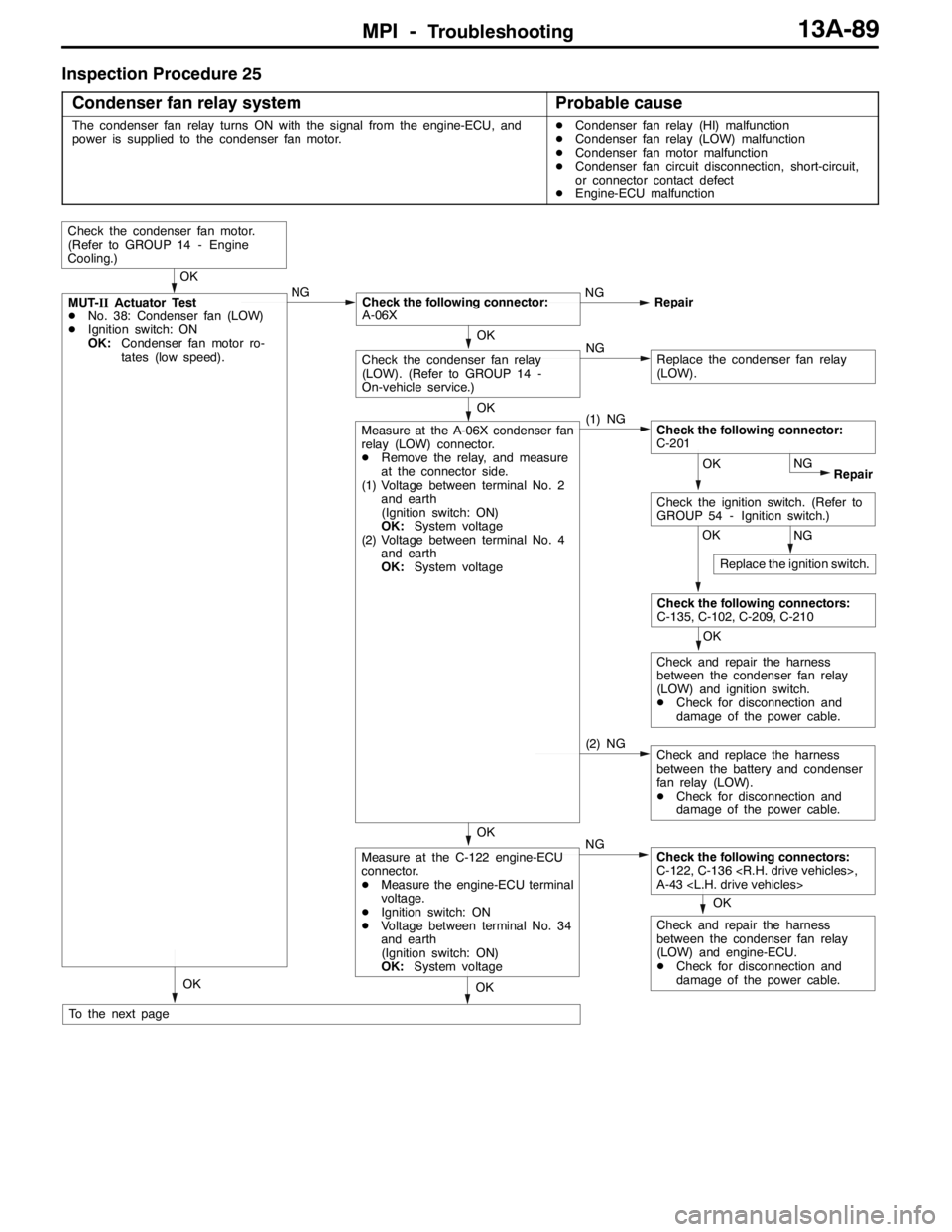

MPI -Troubleshooting13A-89

Inspection Procedure 25

Condenser fan relay system

Probable cause

The condenser fan relay turns ON with the signal from the engine-ECU, and

power is supplied to the condenser fan motor.DCondenser fan relay (HI) malfunction

DCondenser fan relay (LOW) malfunction

DCondenser fan motor malfunction

DCondenser fan circuit disconnection, short-circuit,

or connector contact defect

DEngine-ECU malfunction

OK

Check and repair the harness

between the condenser fan relay

(LOW) and engine-ECU.

DCheck for disconnection and

damage of the power cable.

(2) NG

OK

OK

Check the condenser fan motor.

(Refer to GROUP 14 - Engine

Cooling.)

OK

NG

OK

Check the following connector:

A-06X

OK

MUT-IIActuator Test

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan motor ro-

tates (low speed).NG

OK

Measure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 34

and earth

(Ignition switch: ON)

OK:System voltageRepair

NG

To the next page

NGReplace the condenser fan relay

(LOW).

OK

Check the condenser fan relay

(LOW). (Refer to GROUP 14 -

On-vehicle service.)

(1) NGMeasure at the A-06X condenser fan

relay (LOW) connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair OK

OK

Check the following connectors:

C-135, C-102, C-209, C-210

Check and repair the harness

between the condenser fan relay

(LOW) and ignition switch.

DCheck for disconnection and

damage of the power cable.

Check the following connectors:

C-122, C-136

A-43

Check the following connector:

C-201

NG

Check the ignition switch. (Refer to

GROUP 54 - Ignition switch.)

Replace the ignition switch.

Check and replace the harness

between the battery and condenser

fan relay (LOW).

DCheck for disconnection and

damage of the power cable.

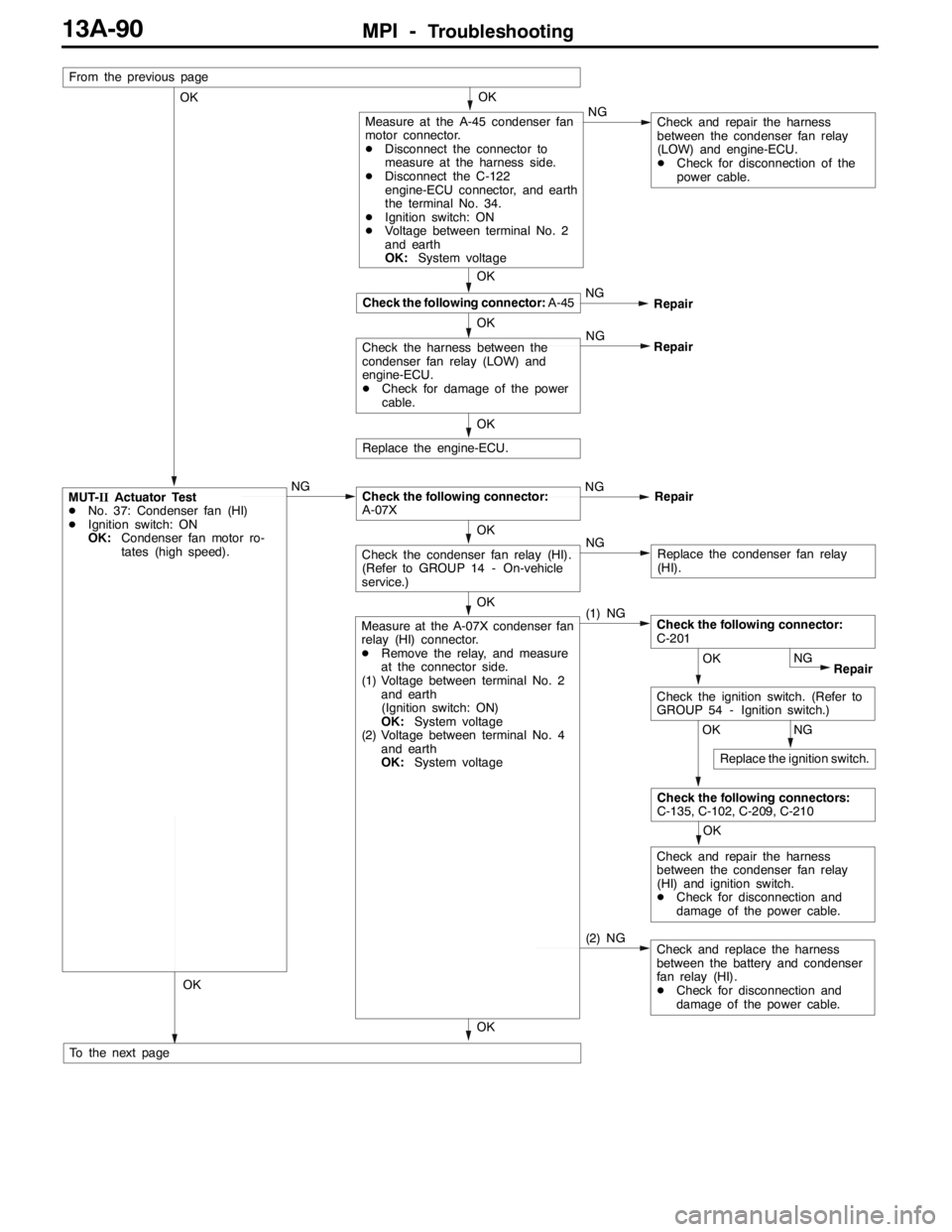

Page 622 of 1449

MPI -Troubleshooting13A-90

(2) NG

OK

OK

OK

NG

OK

Check the following connector:

A-07X

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DIgnition switch: ON

OK:Condenser fan motor ro-

tates (high speed).NG

Repair

NGReplace the condenser fan relay

(HI).

OK

Check the condenser fan relay (HI).

(Refer to GROUP 14 - On-vehicle

service.)

(1) NGMeasure at the A-07X condenser fan

relay (HI) connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair OK

OK

Check the following connectors:

C-135, C-102, C-209, C-210

Check and repair the harness

between the condenser fan relay

(HI) and ignition switch.

DCheck for disconnection and

damage of the power cable.

Check the following connector:

C-201

NG

Check the ignition switch. (Refer to

GROUP 54 - Ignition switch.)

Replace the ignition switch.

Check and replace the harness

between the battery and condenser

fan relay (HI).

DCheck for disconnection and

damage of the power cable.

NGCheck the following connector:A-45

OK

Replace the engine-ECU.

OK

To the next page

NG

OK

Check the harness between the

condenser fan relay (LOW) and

engine-ECU.

DCheck for damage of the power

cable.Repair Repair

NGOK

Measure at the A-45 condenser fan

motor connector.

DDisconnect the connector to

measure at the harness side.

DDisconnect the C-122

engine-ECU connector, and earth

the terminal No. 34.

DIgnition switch: ON

DVoltage between terminal No. 2

and earth

OK:System voltageCheck and repair the harness

between the condenser fan relay

(LOW) and engine-ECU.

DCheck for disconnection of the

power cable.

From the previous page

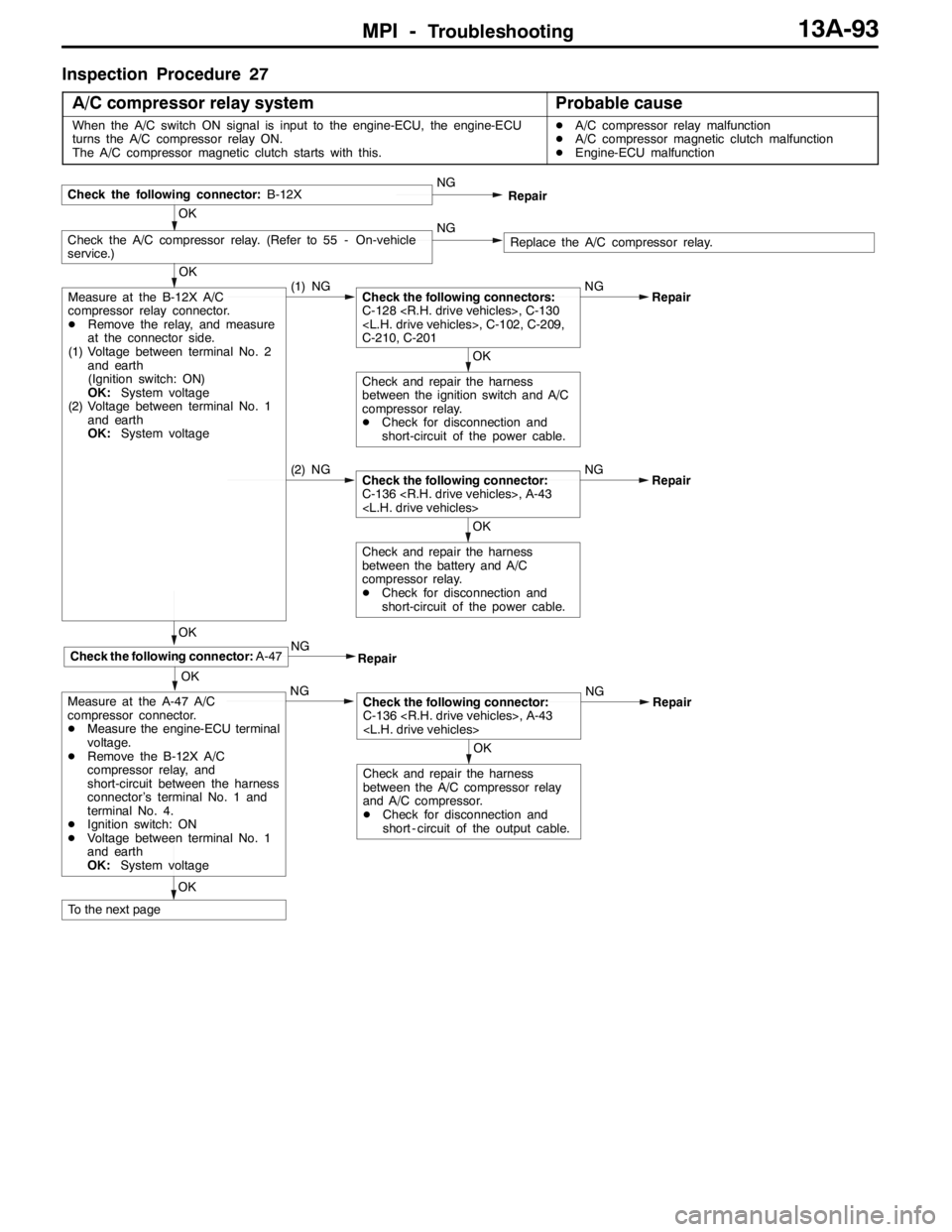

Page 625 of 1449

MPI -Troubleshooting13A-93

Inspection Procedure 27

A/C compressor relay system

Probable cause

When the A/C switch ON signal is input to the engine-ECU, the engine-ECU

turns the A/C compressor relay ON.

The A/C compressor magnetic clutch starts with this.DA/C compressor relay malfunction

DA/C compressor magnetic clutch malfunction

DEngine-ECU malfunction

OK

(2) NGCheck the following connector:

C-136

Check and repair the harness

between the battery and A/C

compressor relay.

DCheck for disconnection and

short-circuit of the power cable.

OK

Check the A/C compressor relay. (Refer to 55 - On-vehicle

service.)NGReplace the A/C compressor relay.

Check the following connector:B-12XNG

Repair

OK

OK

Measure at the B-12X A/C

compressor relay connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 1

and earth

OK:System voltage(1) NGCheck the following connectors:

C-128

C-210, C-201NG

OK

Check and repair the harness

between the ignition switch and A/C

compressor relay.

DCheck for disconnection and

short-circuit of the power cable.Repair

OKNG

Measure at the A-47 A/C

compressor connector.

DMeasure the engine-ECU terminal

voltage.

DRemove the B-12X A/C

compressor relay, and

short-circuit between the harness

connector’s terminal No. 1 and

terminal No. 4.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltage

To the next pageRepair

NG

OK

Check the following connector:A-47

Repair

OK

Check the following connector:

C-136

Check and repair the harness

between the A/C compressor relay

and A/C compressor.

DCheck for disconnection and

short - circuit of the output cable.Repair

Page 638 of 1449

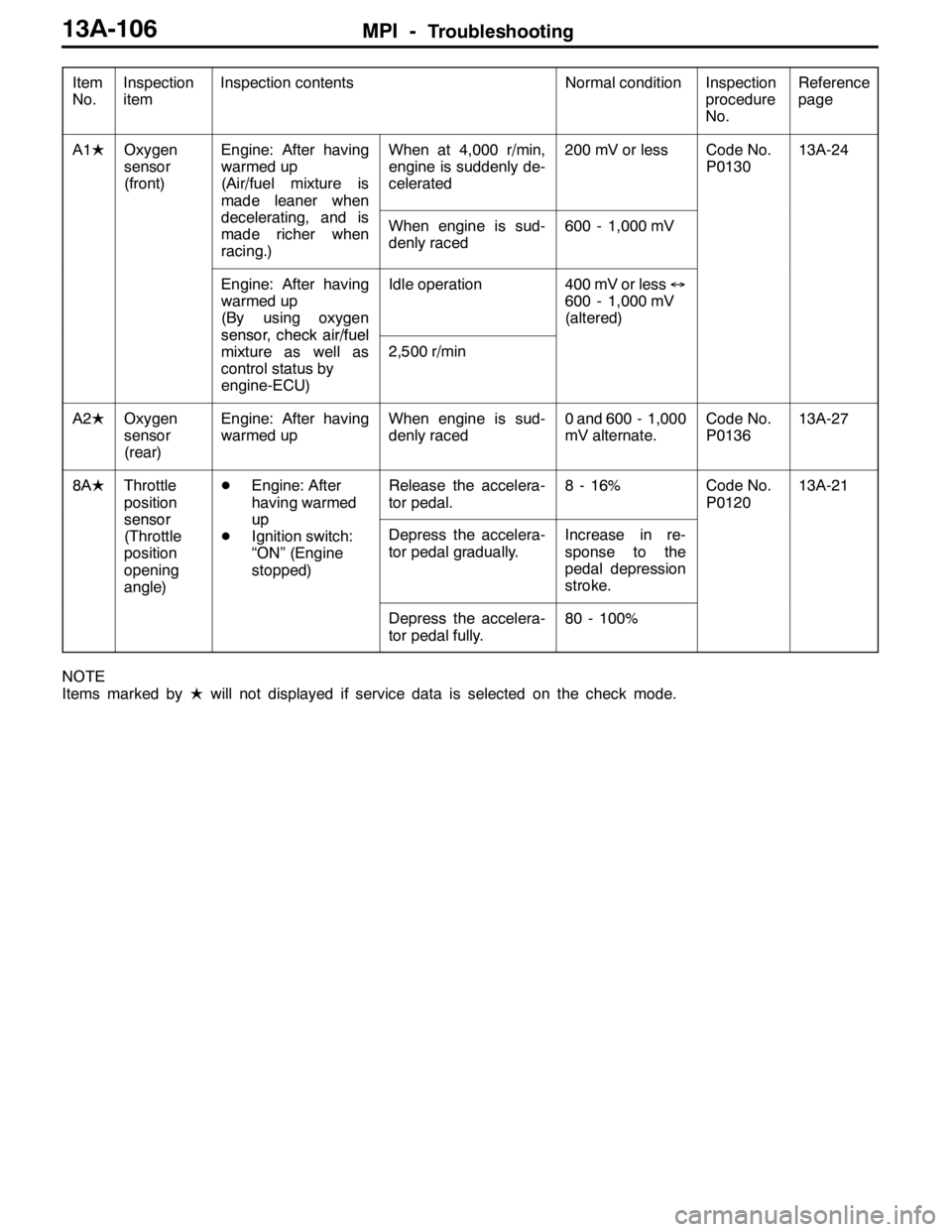

MPI -Troubleshooting13A-106

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

A1LOxygen

sensor

(front)Engine: After having

warmed up

(Air/fuel mixture is

made leaner whenWhen at 4,000 r/min,

engine is suddenly de-

celerated200 mV or lessCode No.

P013013A-24

madeleanerwhen

decelerating, and is

made richer when

racing.)When engine is sud-

denly raced600 - 1,000 mV

Engine: After having

warmed up

(By using oxygen

sensorcheckair/fuel

Idle operation400 mV or less↔

600 - 1,000 mV

(altered)

sensor, checkair/fuel

mixture as well as

control status by

engine-ECU)2,500 r/min

A2LOxygen

sensor

(rear)Engine: After having

warmed upWhen engine is sud-

denly raced0 and 600 - 1,000

mV alternate.Code No.

P013613A-27

8ALThrottle

position

sensor

DEngine: After

having warmed

up

Release the accelera-

tor pedal.8 - 16%Code No.

P012013A-21

sensor

(Throttle

position

opening

angle)up

DIgnition switch:

“ON” (Engine

stopped)Depress the accelera-

tor pedal gradually.Increase in re-

sponse to the

pedal depression

stroke.

Depress the accelera-

tor pedal fully.80 - 100%

NOTE

Items marked byLwill not displayed if service data is selected on the check mode.

Page 657 of 1449

MPI -On-vehicle Service13A-125

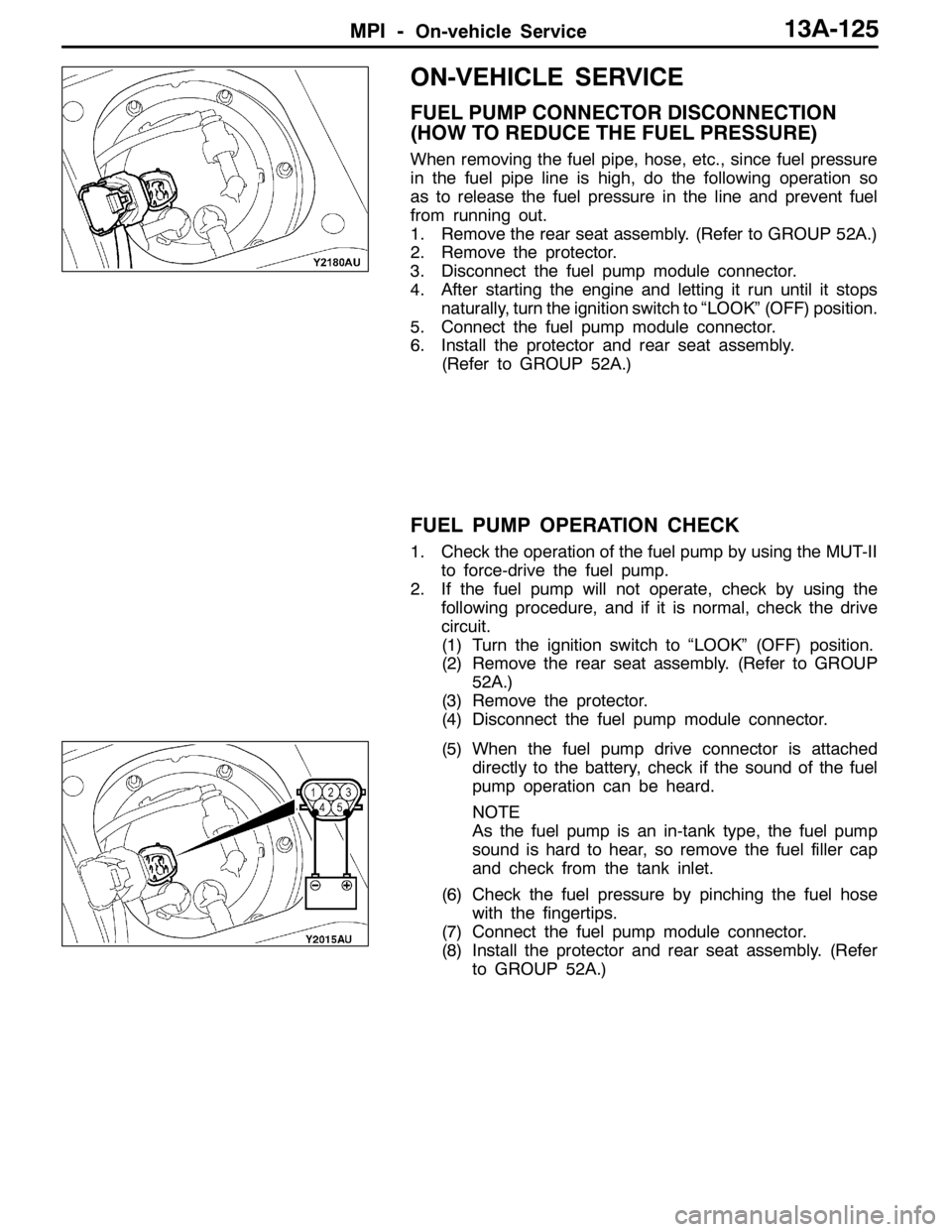

ON-VEHICLE SERVICE

FUEL PUMP CONNECTOR DISCONNECTION

(HOW TO REDUCE THE FUEL PRESSURE)

When removing the fuel pipe, hose, etc., since fuel pressure

in the fuel pipe line is high, do the following operation so

as to release the fuel pressure in the line and prevent fuel

from running out.

1. Remove the rear seat assembly. (Refer to GROUP 52A.)

2. Remove the protector.

3. Disconnect the fuel pump module connector.

4. After starting the engine and letting it run until it stops

naturally, turn the ignition switch to “LOOK” (OFF) position.

5. Connect the fuel pump module connector.

6. Install the protector and rear seat assembly.

(Refer to GROUP 52A.)

FUEL PUMP OPERATION CHECK

1. Check the operation of the fuel pump by using the MUT-II

to force-drive the fuel pump.

2. If the fuel pump will not operate, check by using the

following procedure, and if it is normal, check the drive

circuit.

(1) Turn the ignition switch to “LOOK” (OFF) position.

(2) Remove the rear seat assembly. (Refer to GROUP

52A.)

(3) Remove the protector.

(4) Disconnect the fuel pump module connector.

(5) When the fuel pump drive connector is attached

directly to the battery, check if the sound of the fuel

pump operation can be heard.

NOTE

As the fuel pump is an in-tank type, the fuel pump

sound is hard to hear, so remove the fuel filler cap

and check from the tank inlet.

(6) Check the fuel pressure by pinching the fuel hose

with the fingertips.

(7) Connect the fuel pump module connector.

(8) Install the protector and rear seat assembly. (Refer

to GROUP 52A.)

Page 658 of 1449

MPI -On-vehicle Service13A-126

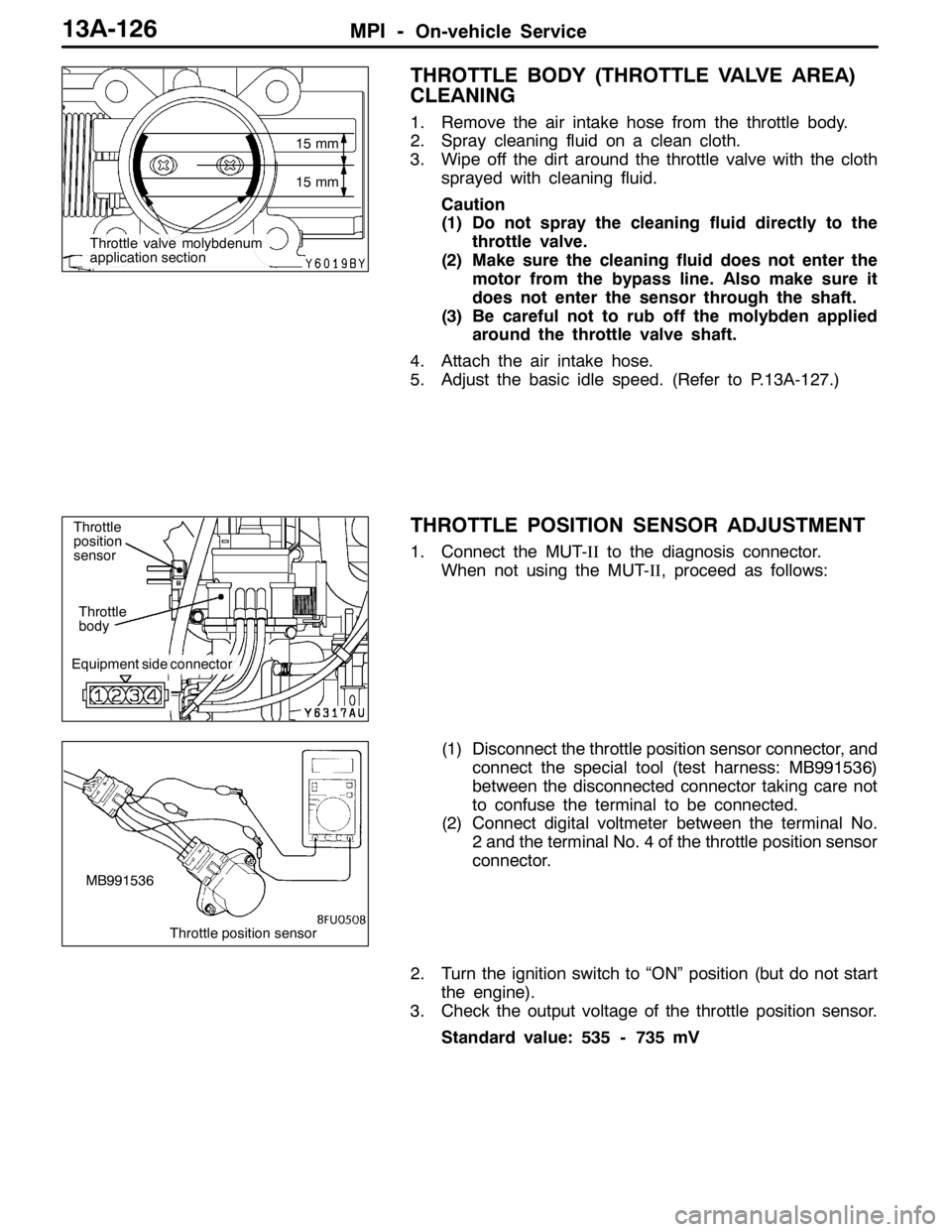

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

1. Remove the air intake hose from the throttle body.

2. Spray cleaning fluid on a clean cloth.

3. Wipe off the dirt around the throttle valve with the cloth

sprayed with cleaning fluid.

Caution

(1) Do not spray the cleaning fluid directly to the

throttle valve.

(2) Make sure the cleaning fluid does not enter the

motor from the bypass line. Also make sure it

does not enter the sensor through the shaft.

(3) Be careful not to rub off the molybden applied

around the throttle valve shaft.

4. Attach the air intake hose.

5. Adjust the basic idle speed. (Refer to P.13A-127.)

THROTTLE POSITION SENSOR ADJUSTMENT

1. Connect the MUT-IIto the diagnosis connector.

When not using the MUT-II, proceed as follows:

(1) Disconnect the throttle position sensor connector, and

connect the special tool (test harness: MB991536)

between the disconnected connector taking care not

to confuse the terminal to be connected.

(2) Connect digital voltmeter between the terminal No.

2 and the terminal No. 4 of the throttle position sensor

connector.

2. Turn the ignition switch to “ON” position (but do not start

the engine).

3. Check the output voltage of the throttle position sensor.

Standard value: 535 - 735 mV

Throttle valve molybdenum

application section15 mm

15 mm

Equipment side connectorThrottle

position

sensor

Throttle

body

MB991536

Throttle position sensor

Page 659 of 1449

MPI -On-vehicle Service13A-127

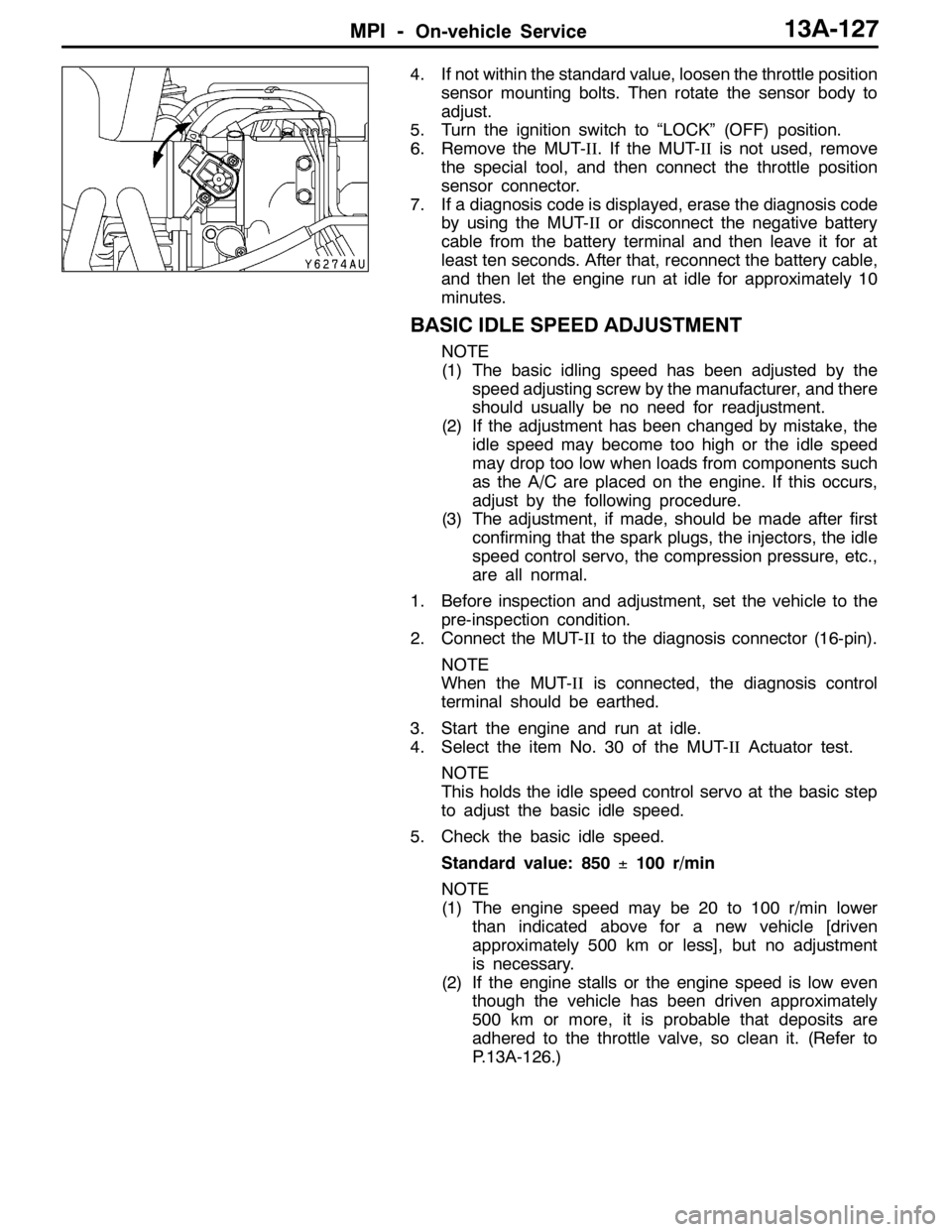

4. If not within the standard value, loosen the throttle position

sensor mounting bolts. Then rotate the sensor body to

adjust.

5. Turn the ignition switch to “LOCK” (OFF) position.

6. Remove the MUT-II. If the MUT-IIis not used, remove

the special tool, and then connect the throttle position

sensor connector.

7. If a diagnosis code is displayed, erase the diagnosis code

by using the MUT-IIor disconnect the negative battery

cable from the battery terminal and then leave it for at

least ten seconds. After that, reconnect the battery cable,

and then let the engine run at idle for approximately 10

minutes.

BASIC IDLE SPEED ADJUSTMENT

NOTE

(1) The basic idling speed has been adjusted by the

speed adjusting screw by the manufacturer, and there

should usually be no need for readjustment.

(2) If the adjustment has been changed by mistake, the

idle speed may become too high or the idle speed

may drop too low when loads from components such

as the A/C are placed on the engine. If this occurs,

adjust by the following procedure.

(3) The adjustment, if made, should be made after first

confirming that the spark plugs, the injectors, the idle

speed control servo, the compression pressure, etc.,

are all normal.

1. Before inspection and adjustment, set the vehicle to the

pre-inspection condition.

2. Connect the MUT-IIto the diagnosis connector (16-pin).

NOTE

When the MUT-IIis connected, the diagnosis control

terminal should be earthed.

3. Start the engine and run at idle.

4. Select the item No. 30 of the MUT-IIActuator test.

NOTE

This holds the idle speed control servo at the basic step

to adjust the basic idle speed.

5. Check the basic idle speed.

Standard value: 850±100 r/min

NOTE

(1) The engine speed may be 20 to 100 r/min lower

than indicated above for a new vehicle [driven

approximately 500 km or less], but no adjustment

is necessary.

(2) If the engine stalls or the engine speed is low even

though the vehicle has been driven approximately

500 km or more, it is probable that deposits are

adhered to the throttle valve, so clean it. (Refer to

P.13A-126.)

Page 660 of 1449

MPI -On-vehicle Service13A-128

6. If not within the standard value range, turn the speed

adjusting screw to make the necessary adjustment.

7. Press the MUT-IIclear key, and release the idle speed

control servo from the Actuator test mode.

NOTE

Unless the idle speed control servo is released, the

Actuator test mode will continue 27 minutes.

8. Turn the ignition switch to “LOCK” (OFF) position.

9. Disconnect the MUT-II.

10. Start the engine again and let it run at idle speed for

approximately 10 minutes; check that the idling condition

is normal.

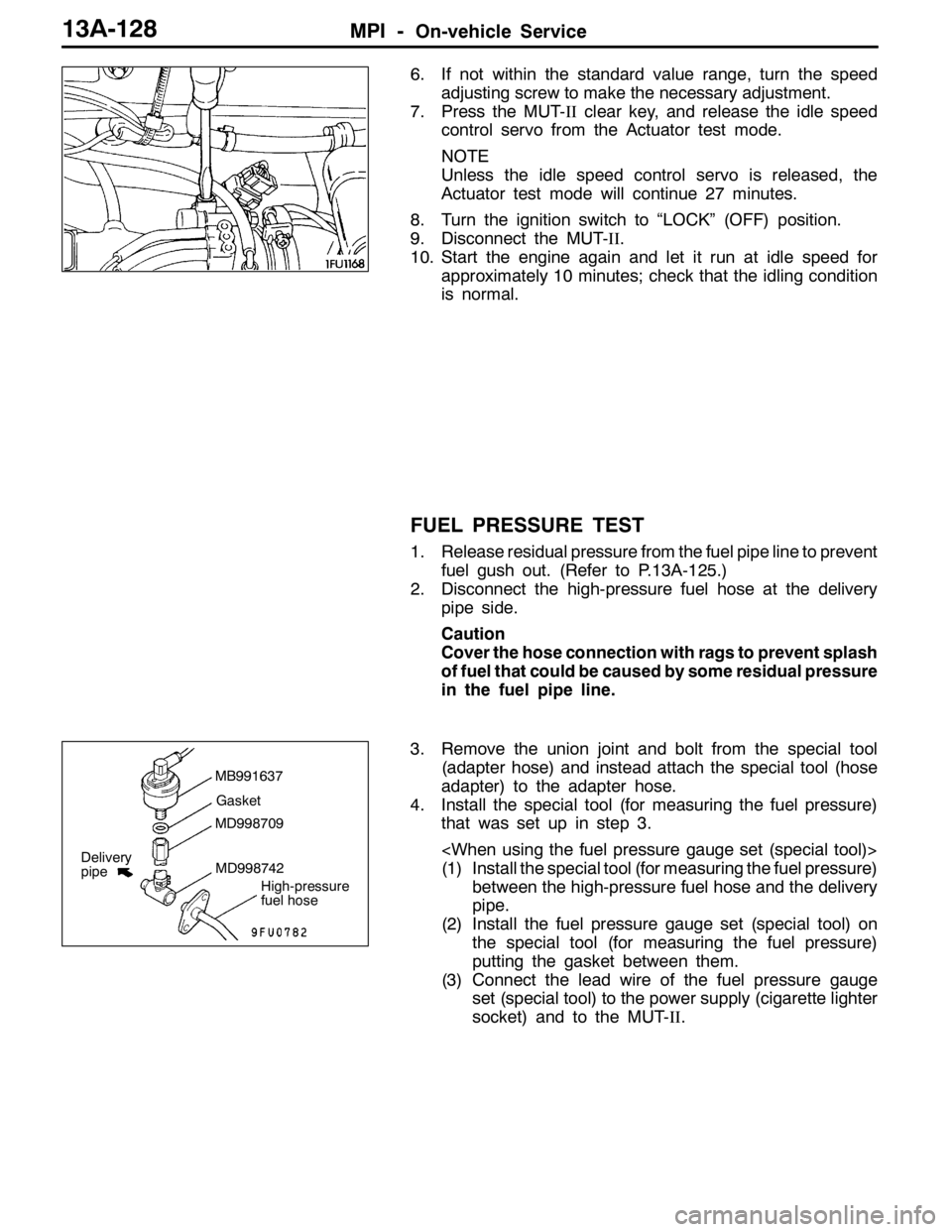

FUEL PRESSURE TEST

1. Release residual pressure from the fuel pipe line to prevent

fuel gush out. (Refer to P.13A-125.)

2. Disconnect the high-pressure fuel hose at the delivery

pipe side.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

3. Remove the union joint and bolt from the special tool

(adapter hose) and instead attach the special tool (hose

adapter) to the adapter hose.

4. Install the special tool (for measuring the fuel pressure)

that was set up in step 3.

(1) Install the special tool (for measuring the fuel pressure)

between the high-pressure fuel hose and the delivery

pipe.

(2) Install the fuel pressure gauge set (special tool) on

the special tool (for measuring the fuel pressure)

putting the gasket between them.

(3) Connect the lead wire of the fuel pressure gauge

set (special tool) to the power supply (cigarette lighter

socket) and to the MUT-II.

MB991637

Gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

Page 661 of 1449

MPI -On-vehicle Service13A-129

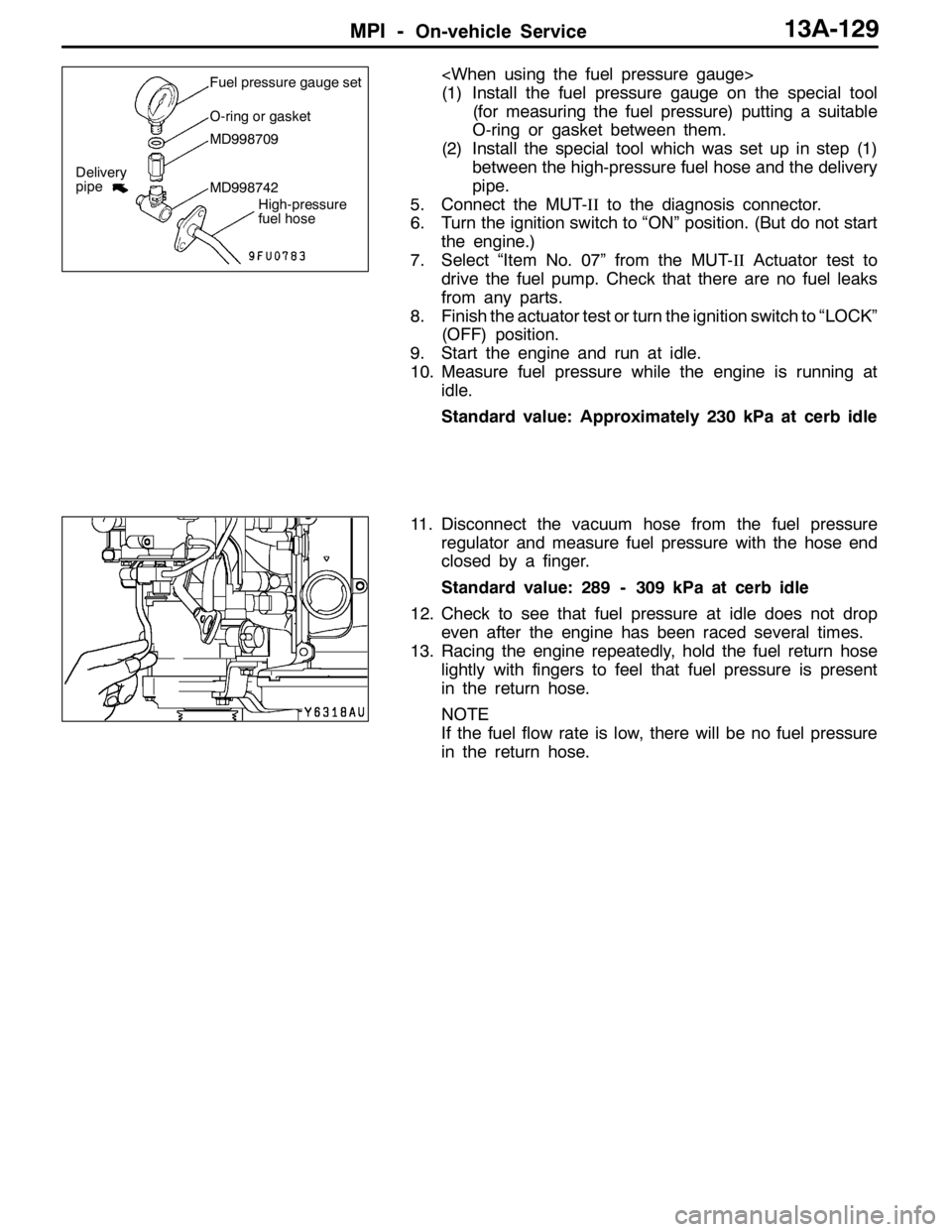

(1) Install the fuel pressure gauge on the special tool

(for measuring the fuel pressure) putting a suitable

O-ring or gasket between them.

(2) Install the special tool which was set up in step (1)

between the high-pressure fuel hose and the delivery

pipe.

5. Connect the MUT-IIto the diagnosis connector.

6. Turn the ignition switch to “ON” position. (But do not start

the engine.)

7. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump. Check that there are no fuel leaks

from any parts.

8. Finish the actuator test or turn the ignition switch to “LOCK”

(OFF) position.

9. Start the engine and run at idle.

10. Measure fuel pressure while the engine is running at

idle.

Standard value: Approximately 230 kPa at cerb idle

11. Disconnect the vacuum hose from the fuel pressure

regulator and measure fuel pressure with the hose end

closed by a finger.

Standard value: 289 - 309 kPa at cerb idle

12. Check to see that fuel pressure at idle does not drop

even after the engine has been raced several times.

13. Racing the engine repeatedly, hold the fuel return hose

lightly with fingers to feel that fuel pressure is present

in the return hose.

NOTE

If the fuel flow rate is low, there will be no fuel pressure

in the return hose.Fuel pressure gauge set

O-ring or gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe