MITSUBISHI LANCER IX 2006 User Guide

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 11 of 800

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-5

5. Use the respective tool in the following table to remove the engine oil filter.

NumberSpecial tool

MD348631 <4G1>Oil filter wrench (MB991828) or

equivalent

MD365876 <4G1>

MD360935 <4G1>Oil filter wrench (MB991396) or

equivalent

MD136466 <4G6>Commercially- available tool

MD322508 <4G6>

MD356000 <4G6>Oil filter wrench (MB991610) or

equivalent

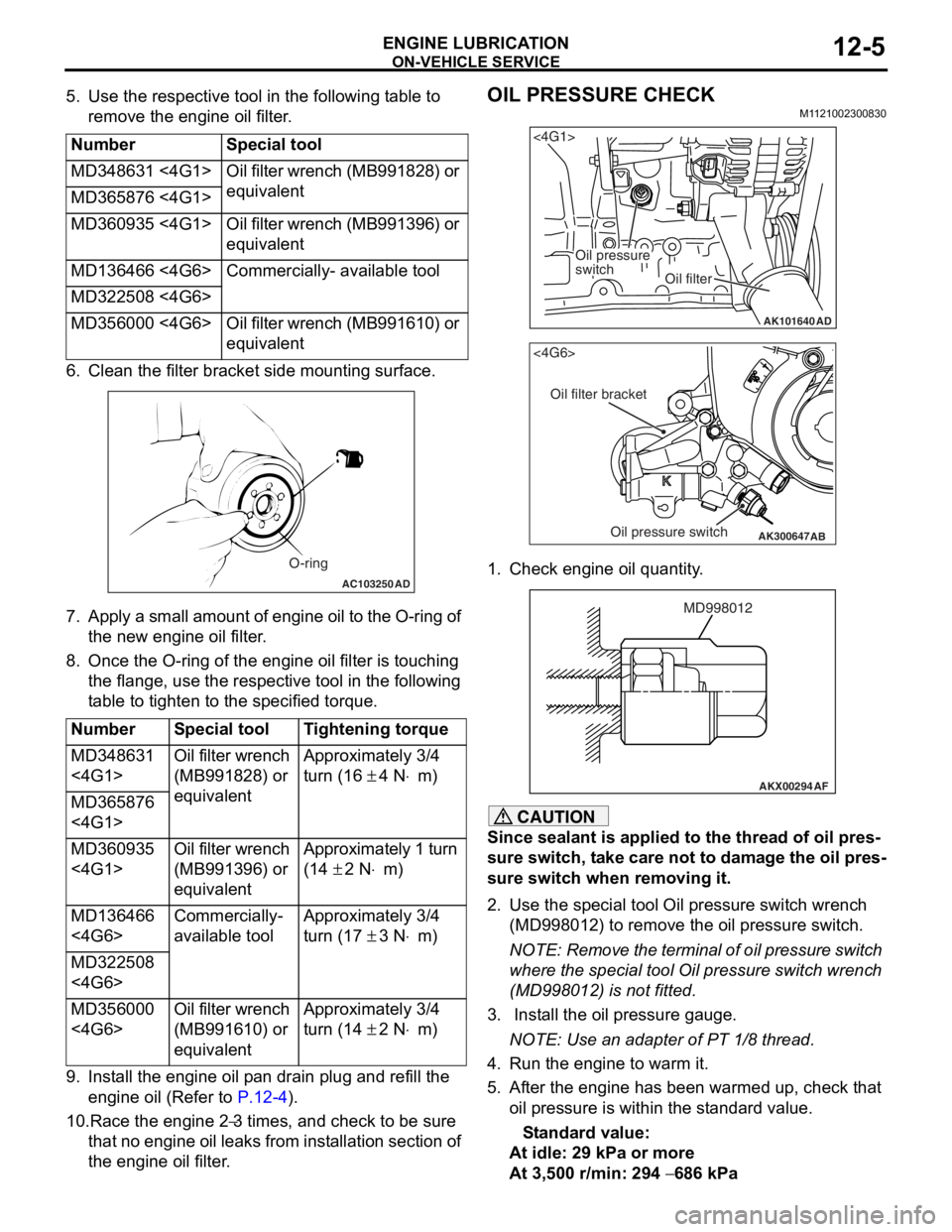

6. Cle an the filt er bracket side mou n ting surfa c e.

AC103250AD

O-ring

7.Ap ply a small a m ou nt o f en gine o i l to th e O-rin g of

th e new eng ine oil f ilte r .

8.Once the O-ring of the engine oil filter is tou c hing

th e flange, use the resp ective tool in the following

t able to tighten to the specified tor que.

NumberSpecial toolTightening torque

MD348631

<4G1>Oil filter wrench

(MB991828) or

equivalentApproximately 3/4

turn (16

± 4 N⋅m)

MD365876

<4G1>

MD360935

<4G1>Oil filter wrench

(MB991396) or

equivalentApproximately 1 turn

(14

± 2 N⋅m)

MD136466

<4G6>Commercially-

available toolApproximately 3/4

turn (17

± 3 N⋅m)

MD322508

<4G6>

MD356000

<4G6>Oil filter wrench

(MB991610) or

equivalentApproximately 3/4

turn (14

± 2 N⋅m)

9.In st all the en gine oil p a n drain plu g and refill the

en gine oil (Re f er to

P.12-4).

10.Race the en gine 2−3 times, and che ck to be sure

th

at n

o

en

gin

e

oil leaks fr om in st allation sectio n of

th

e engine oil filter

.

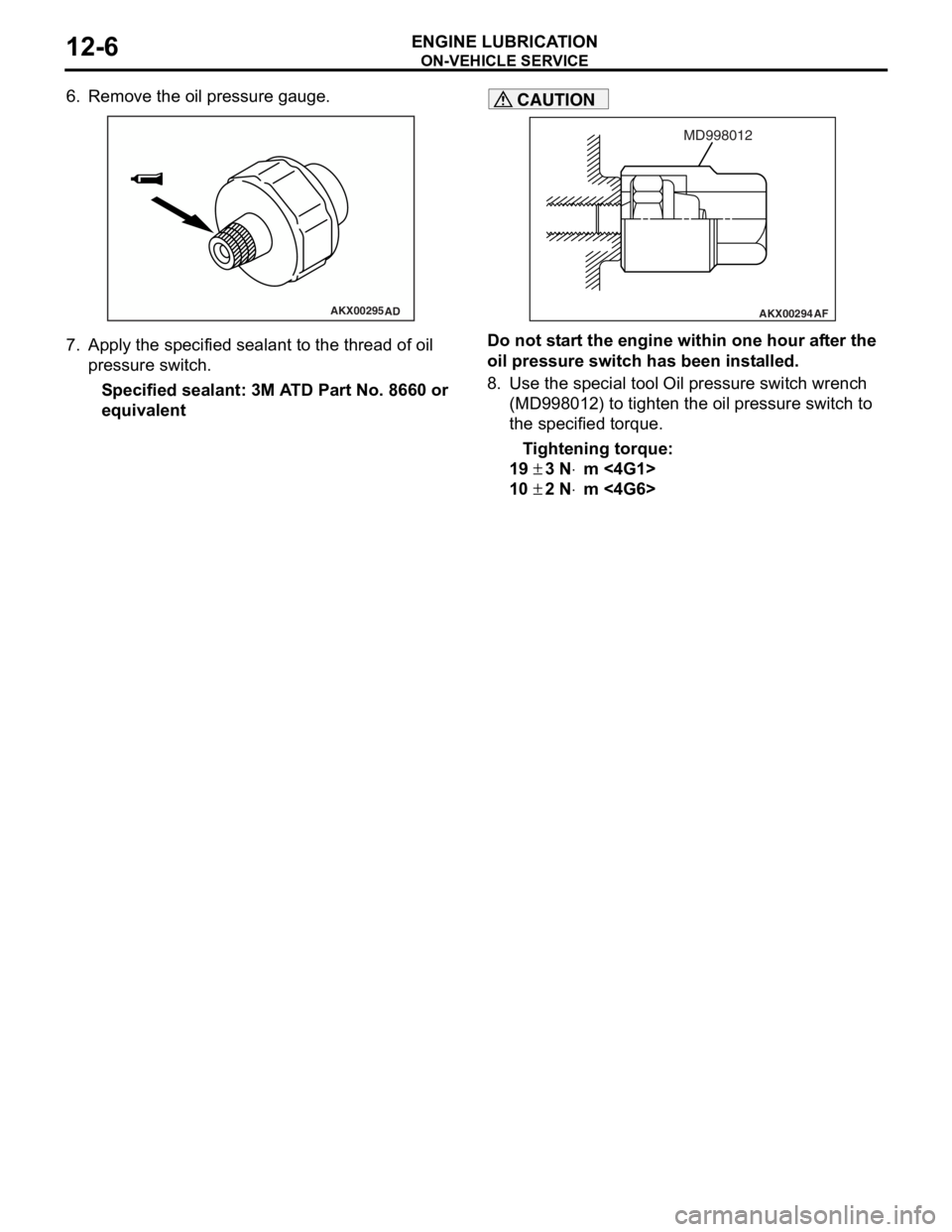

OIL PRESSURE CHECK

M1 121 0023 0083 0

AK101640

<4G1>

Oil pressure

switch

Oil filter

AD

AK300647

AB

<4G6>

Oil filter bracket

Oil pressure switch

1.Check e ngin e oil quan tity .

AKX00294

MD998012

AF

CAUTION

Since sealant is applied to the thread of oil pres-

sure switch, take care not to damage the oil pres-

sure switch when removing it.

2. Use the special tool Oil pressure switch wrench

(MD998012) to remove the oil pressure switch.

NOTE: Remove the terminal of oil pressure switch

where the special tool Oil pressure switch wrench

(MD998012) is not fitted.

3. Install the oil pressure gauge.

NOTE: Use an adapter of PT 1/8 thread.

4. Run the engine to warm it.

5. After the engine has been warmed up, check that oil pressure is within the standard value.

Standard value:

At idle: 29 kPa or more

At 3,500 r/min: 294 − 686 kPa

Page 12 of 800

ON-VEHICLE SERVICE

ENGINE LUBRICATION12-6

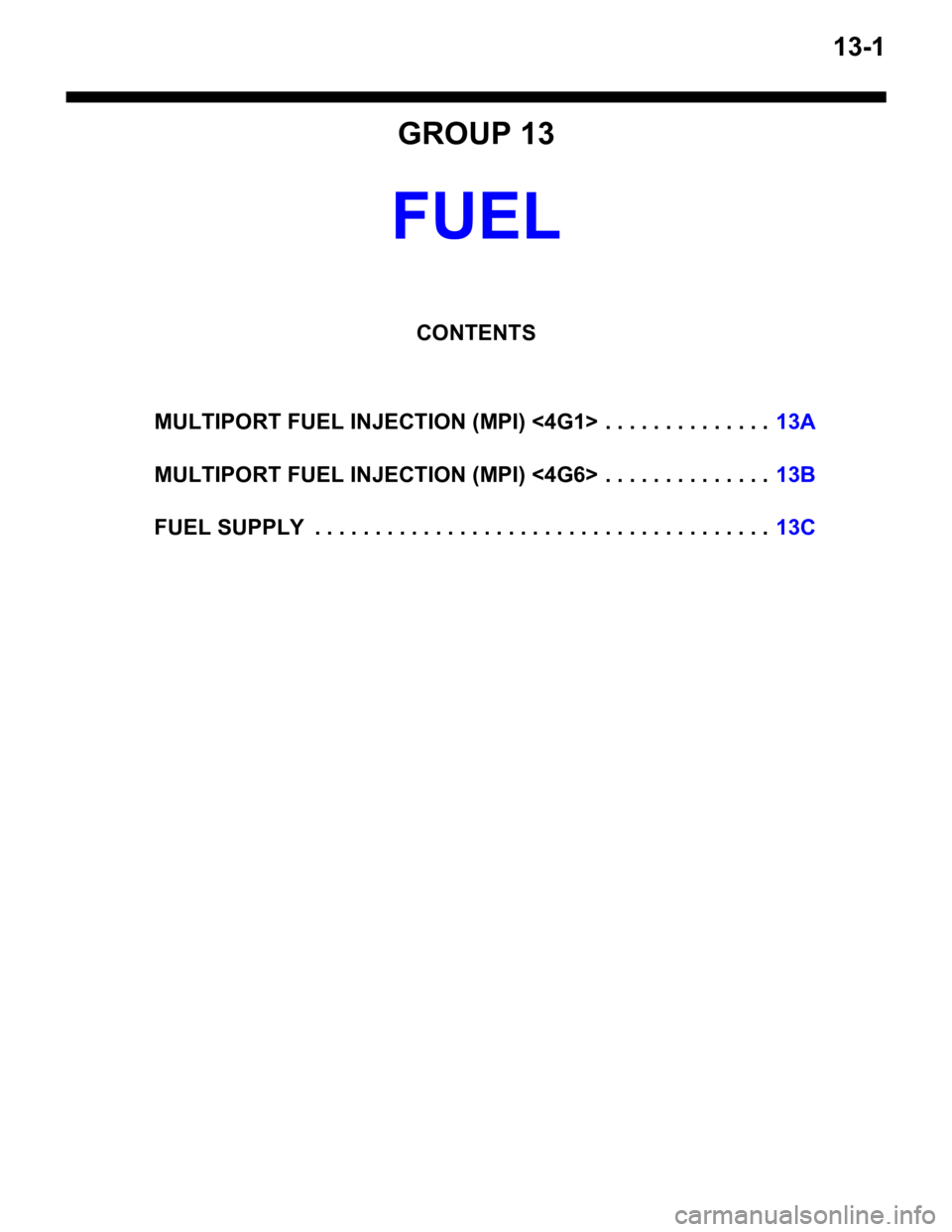

6. Remove the oil pressure gauge.

AKX00295AD

7.App l y t he sp ecified sealant to the thr ead of oil

pres sure sw itc h .

Specified sealan t: 3M A T D Part No. 8660 or

equival

ent

AKX00294

MD998012

AF

CAUTION

Do not start the engine within one hour after the

oil pressure switch has been installed.

8. Use the special tool Oil pressure switch wrench (MD998012) to tighten the oil pressure switch to

the specified torque.

Tightening torque:

19 ± 3 N⋅m <4G1>

10 ± 2 N⋅m <4G6>

Page 13 of 800

13-1

GROUP 13

FUEL

CONTENTS

MULTIPORT FUEL INJECTION (MPI) <4G1> . . . . . . . . . . . . . .13A

MULTIPORT FUEL INJECTION (MPI) <4G6> . . . . . . . . . . . . . .13B

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13C

Page 14 of 800

NOTES

Page 15 of 800

14-1

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . .14-2

SERVICE SPECIFICATIONS . . . . . . .14-2

LUBRICANT . . . . . . . . . . . . . . . . . . . .14-3

SEALANTS . . . . . . . . . . . . . . . . . . . .14-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .14-3

TROUBLESHOOTING . . . . . . . . . . . .14-5

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 14-5

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . . 14-6

ON-VEHICLE SERVICE . . . . . . . . . . .14-21

ENGINE COOLANT LEAK CHECK . . . . . . 14-21

RADIATOR CAP VALVE OPENING

PRESSURE CHECK . . . . . . . . . . . . . . . . . . 14-21

ENGINE COOLANT REPLACEMENT . . . . 14-21

CONCENTRATION MEASUREMENT . . . . 14-22

COOLING FAN MOTOR DRIVE

CONTROL UNIT CHECK . . . . . . . . . . . . . . 14-22

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-23

COOLING FAN MOTOR CHECK . . . . . . . . 14-24

THERMOSTAT . . . . . . . . . . . . . . . . . .14-24

REMOVAL AND INSTALLATION . . . . . . . . 14-24

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-26

WATER PUMP . . . . . . . . . . . . . . . . . .14-27

REMOVAL AND INSTALLATION <4G1> . . 14-27

REMOVAL AND INSTALLATION <4G6> . . 14-28

WATER HOSE AND WATER PIPE . .14-29

REMOVAL AND INSTALLATION <4G1> . . 14-29

REMOVAL AND INSTALLATION <4G6> . . 14-31

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-32

RADIATOR . . . . . . . . . . . . . . . . . . . . .14-33

REMOVAL AND INSTALLATION <4G1> . . 14-33

REMOVAL AND INSTALLATION <4G6> . . 14-35

Page 16 of 800

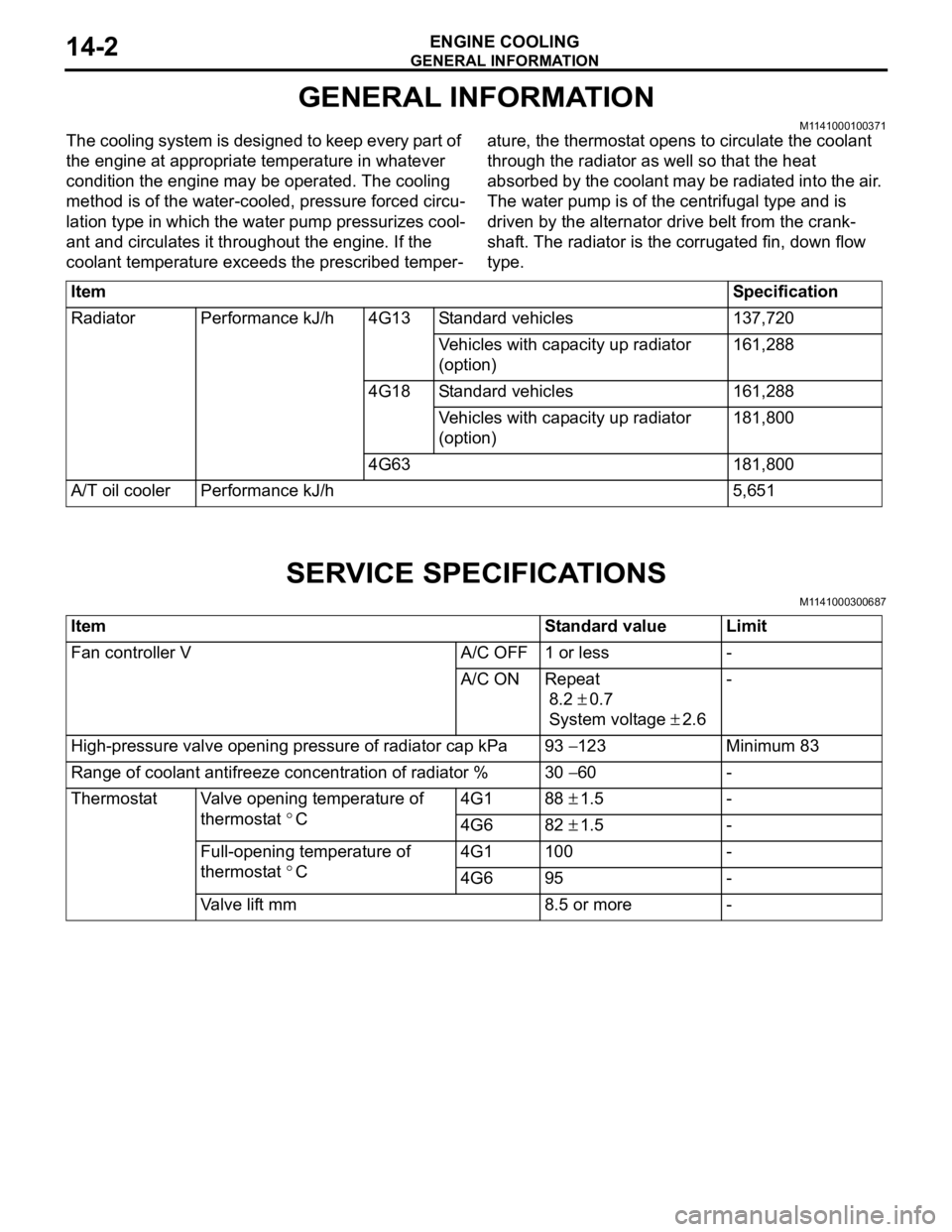

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATION

M1141000100371

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

-

lation type in which the water pump pressurizes cool-

ant and circulates it throughout the engine. If the

coolant temperature exceeds the prescribed temper

-

ature, the thermostat opens to circulate the coolant

through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

driven by the alternator drive belt from the crank

-

shaft. The radiator is the corrugated fin, down flow

type.

ItemSpecification

RadiatorPerformance kJ/h4G13Standard vehicles137,720

Vehicles with capacity up radiator

(option)161,288

4G18Standard vehicles161,288

Vehicles with capacity up radiator

(option)181,800

4G63181,800

A/T oil coolerPerformance kJ/h5,651

SERVICE SPECIFICATIONS

M1141000300687

ItemStandard valueLimit

Fan controller VA/C OFF1 or less-

A/C ONRepeat

8.2 ± 0.7

System voltage ± 2.6

-

High-pressure valve opening pressure of radiator cap kPa93 − 123Minimum 83

Range of coolant antifreeze concentration of radiator %30 − 60-

ThermostatValve opening temperature of

thermostat

°C

4G188 ± 1.5-

4G682 ± 1.5-

Full-opening temperature of

thermostat

°C

4G1100-

4G695-

Valve lift mm8.5 or more-

Page 17 of 800

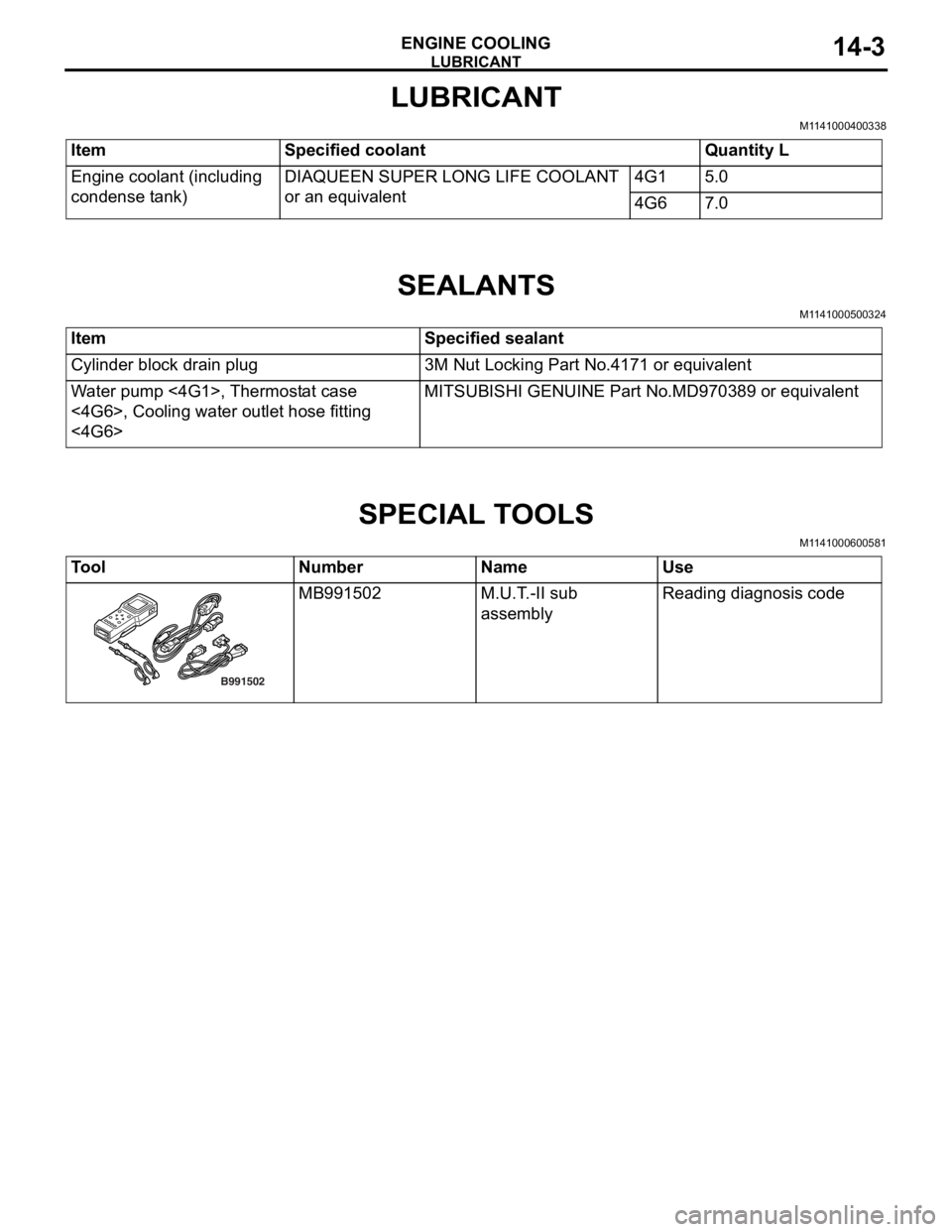

LUBRICANT

ENGINE COOLING14-3

LUBRICANT

M1141000400338

ItemSpecified coolantQuantity L

Engine coolant (including

condense tank)DIAQUEEN SUPER LONG LIFE COOLANT

or an equivalent4G15.0

4G67.0

SEALANTS

M1141000500324

ItemSpecified sealant

Cylinder block drain plug3M Nut Locking Part No.4171 or equivalent

Water pump <4G1>, Thermostat case

<4G6>, Cooling water outlet hose fitting

<4G6>MITSUBISHI GENUINE Part No.MD970389 or equivalent

SPECIAL TOOLS

M1141000600581

ToolNumberNameUse

B991502

MB991502M.U.T. -II sub

assemblyReading diagno sis co de

Page 18 of 800

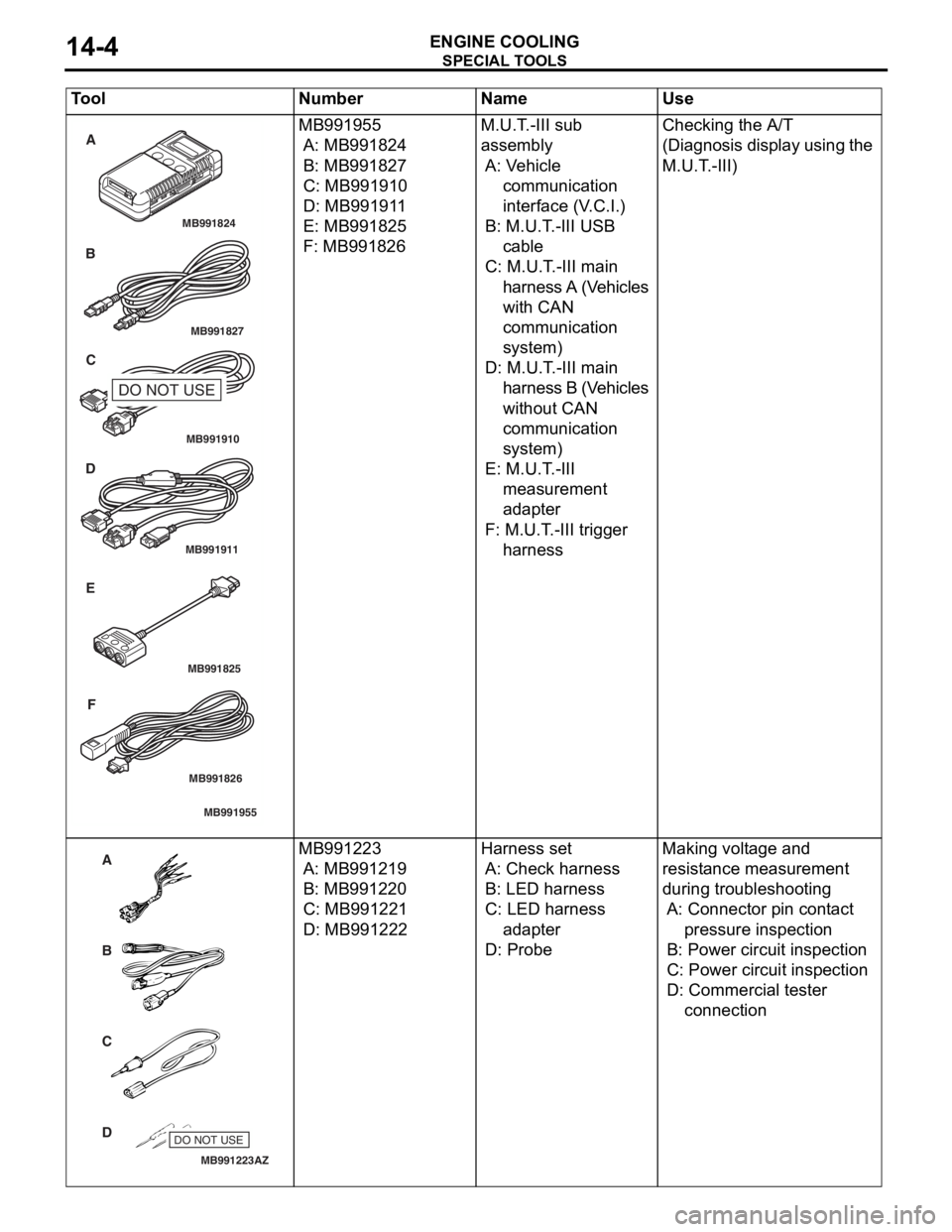

MB991910

MB991826MB991955

MB991911

MB991824

MB991827

MB991825

A

B C

D

E F

DO NOT USE

S PECIA L T O OLS

ENGINE COOLING14-4

MB991 955

A: MB9918 24

B: MB991827

C: MB99191 0

D: MB991911

E: MB991825

F: MB991 826

M.U.T. -III su b

assembly

A: Ve hicle

communication

interface (V .C.I.)

B: M.U.T. -III US B

cable

C: M.U.T . -III main

ha rn es s A (V e h i c le s

with CA N

communication

sy stem )

D: M.U.T. -III main

ha rn es s B (V e h i c le s

wit hout CAN

communication

sy stem )

E: M.U.T. -III

measureme n t

ad apter

F: M.U.T . -III trig ger

ha rness

Checkin g the A/T

(D

ia gn osis d i sp lay using t h e

M.U.

T . -III)

MB991223

A

D C

B

AZ

DO NOT USE

MB991 223

A: MB9912 19

B: MB991220

C: MB99122 1

D: MB991222

Harness se t

A: Check h a rnes s

B: LE D ha rness

C: LED ha rness

ad apter

D: Probe

Making vo lt age an d

resist

an ce measureme n t

during tro

uble s hoo ting

A: Connector pin cont act

pressure inspect i on

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

con nect i on

Tool Nu mber Na me Use

Page 19 of 800

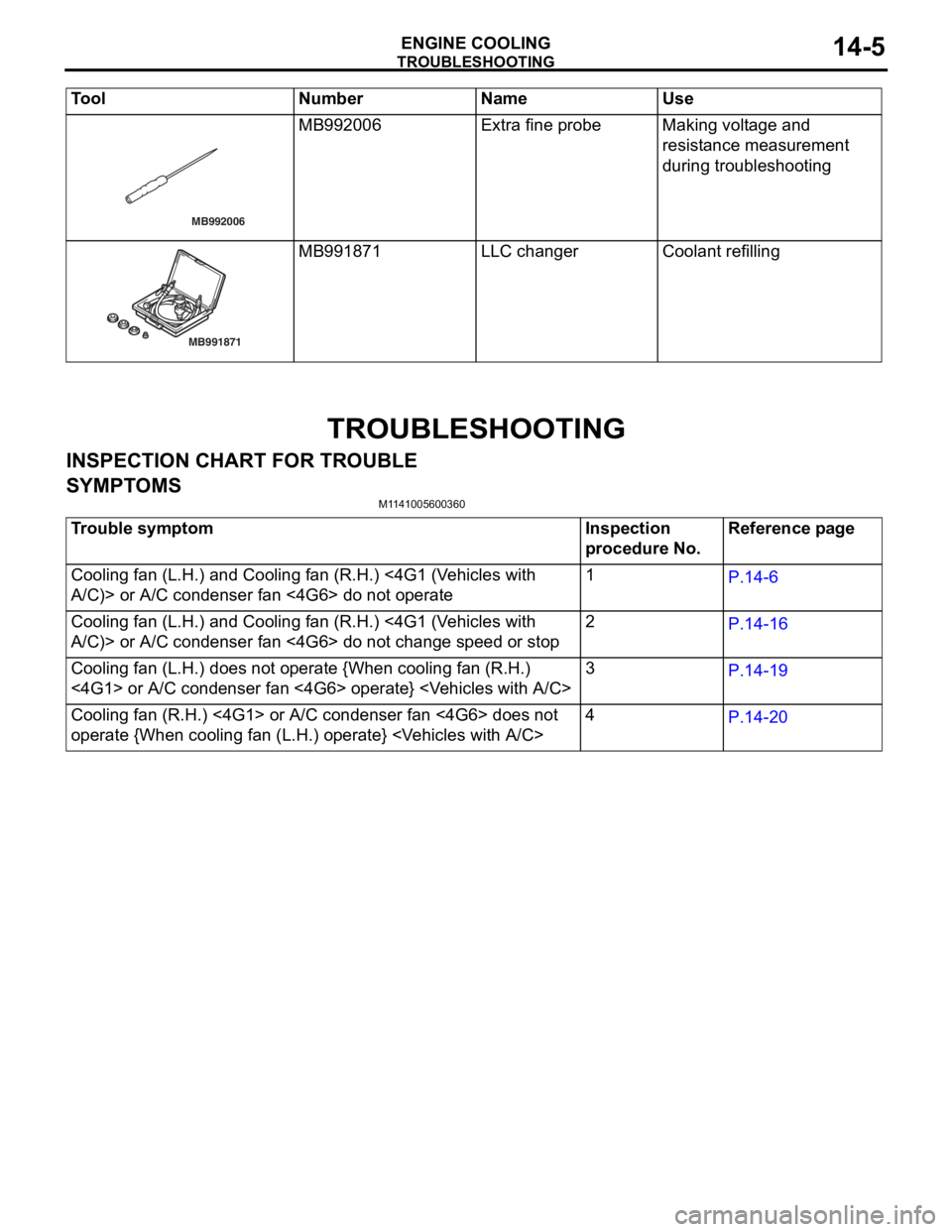

MB992006

TROUBLESHOOTING

ENGINE COOLING14-5

TROUBLESHOOTI N G

INSPECTION CHAR T FOR TROUBLE

SYMPT

O MS

M1141 0056 0036 0

Trouble symptomInspection

procedure No.Reference page

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not operate 1P.14-6

Cooling fan (L.H.) and Cooling fan (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan <4G6> do not change speed or stop2P.14-16

Cooling fan (L.H.) does not operate {When cooling fan (R.H.)

<4G1> or A/C condenser fan <4G6> operate}

Cooling fan (R.H.) <4G1> or A/C condenser fan <4G6> does not

operate {When cooling fan (L.H.) operate}

MB992006Extra fine pro b eMaking volt age an d

resist

an ce measureme n t

during tro

uble s hoo ting

MB991871

MB991871LLC cha ngerCoolant refilling

Tool Nu mber Na me Use

Page 20 of 800

TROUBLESHOOTING

ENGINE COOLING14-6

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS

INSPECTION PROCEDURE 1: Cooling Fan (L.H.) and Cooling Fan (R.H.) <4G1 (Vehicles with A/C)> or

A/C Condenser Fan <4G6> do not Operate

Wire colour code

B : Black LG : Light green

G : Green L : Blue

W : White Y : Yellow

SB : Sky blue BR : Brown

O : Orange GR : Gray

R : Red P : Pink V : Violet

FAN CONTROL

RELAY

A-09XENGINE CONTROL

RELAY

B-16X

AC303577

A-18-1

COOLING FAN

MOTOR (L.H.)

COOLING FAN

MOTOR (R.H.)

<4G1 (VEHICLES

WITH A/C>

OR

A/C CONDENSER

FAN MOTOR <4G6> A-18-2

A-18

COOLING FAN

MOTOR DRIVE

CONTROL UNIT 1 A-13

12 C-111

ENGINE-ECU

ENGINE-A/T-ECU

21 C-123

18 C-122

615 121179

810234

(MU802322)

(MU801824)

C-123

(MU803784)C-122

(MU802611)A-13

C-111 L

L 2

22 11

1B

L

2

3

4

B-W

FUSIBLE

LINK No.2

B3

1

R-Y

R-Y

8 A-13

11 C-111

615 121179

810234

(MU802611)

J/C (6)

C-12

C-134

R-Y

3328

A-13

C-111

Cooling Fan (L.H.) and Cooling Fan (R.H.) or A/C Condenser Fan Drive Circut

AB

CIRCUIT OPERA T ION

•The cooling fan motor drive contro l unit is pow-

ered from fusible link (2).

•The engine-ECU

water t

e mpe r ature sensor unit and the vehicle

speed sensor

senso

r to control the speed of the coo ling

fan

moto r (L.H.) and the cooling fa n mot o r (R.H.)

<4G1 (V

ehicles wit h A/C)> or A/C co ndenser fan

motor <4G6>.