sensor MITSUBISHI LANCER IX 2006 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 125 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-19

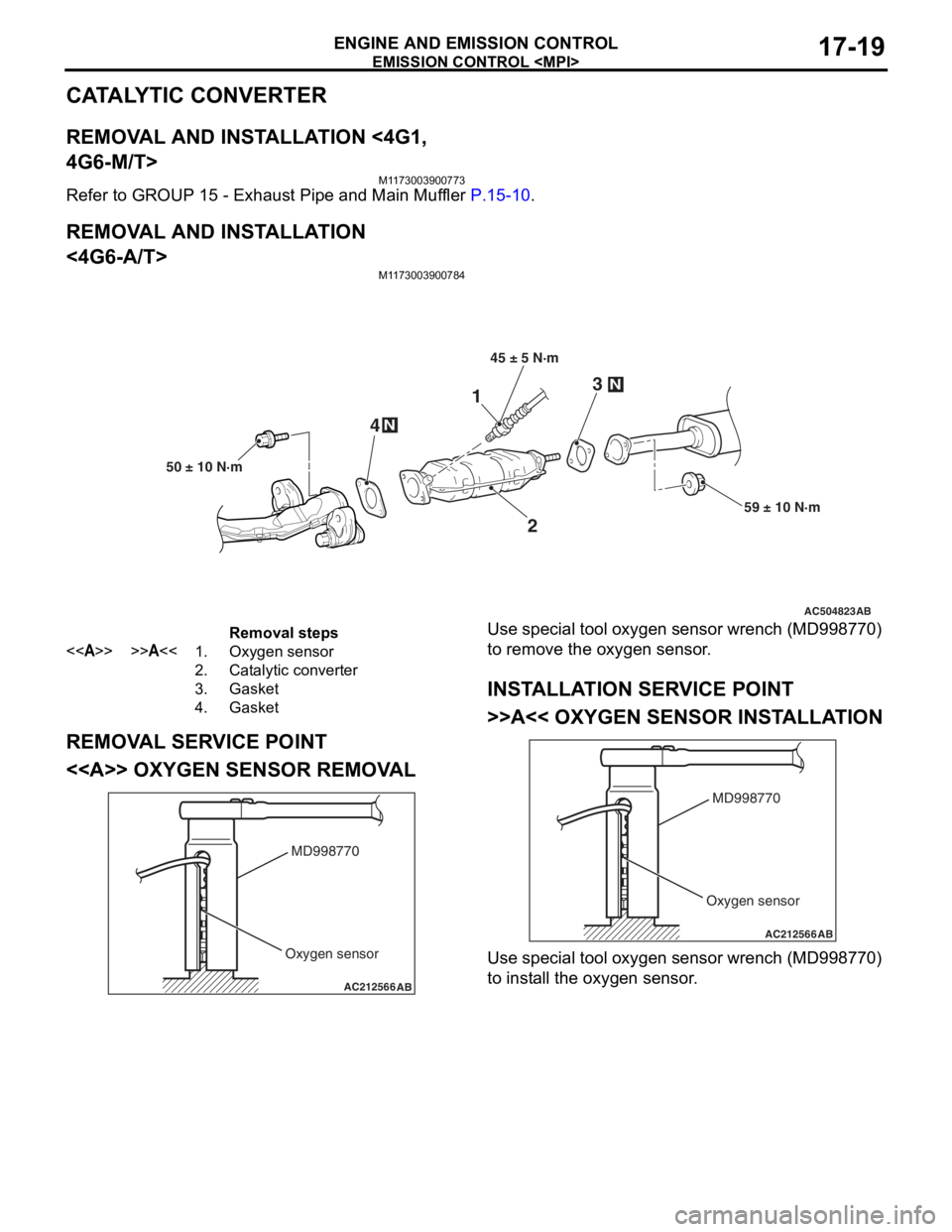

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION <4G1,

4G6-M/T>

M1173003900773

Refer to GROUP 15 - Exhaust Pipe and Main Muffler P.15-10.

REMOVAL AND INSTALLATION

<4G6-A/T>

M1173003900784

AC504823

2

3N

N4

59 ± 10 N·m

50 ± 10 N·m

1

45 ± 5 N·m

AB

Removal steps

<>>>A<<1.Oxygen sensor

2.Catalytic converter

3.Gasket

4.Gasket

REMOVA L SER V ICE POINT

<> OXYGEN SENSOR REMOV A L

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to remove

the oxyge n sen s or .

INSTALLA T ION SER VICE POINT

>>A<< OXYGEN SENSOR INST ALL A TION

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to inst

all the oxyge n sen s or .

Page 140 of 800

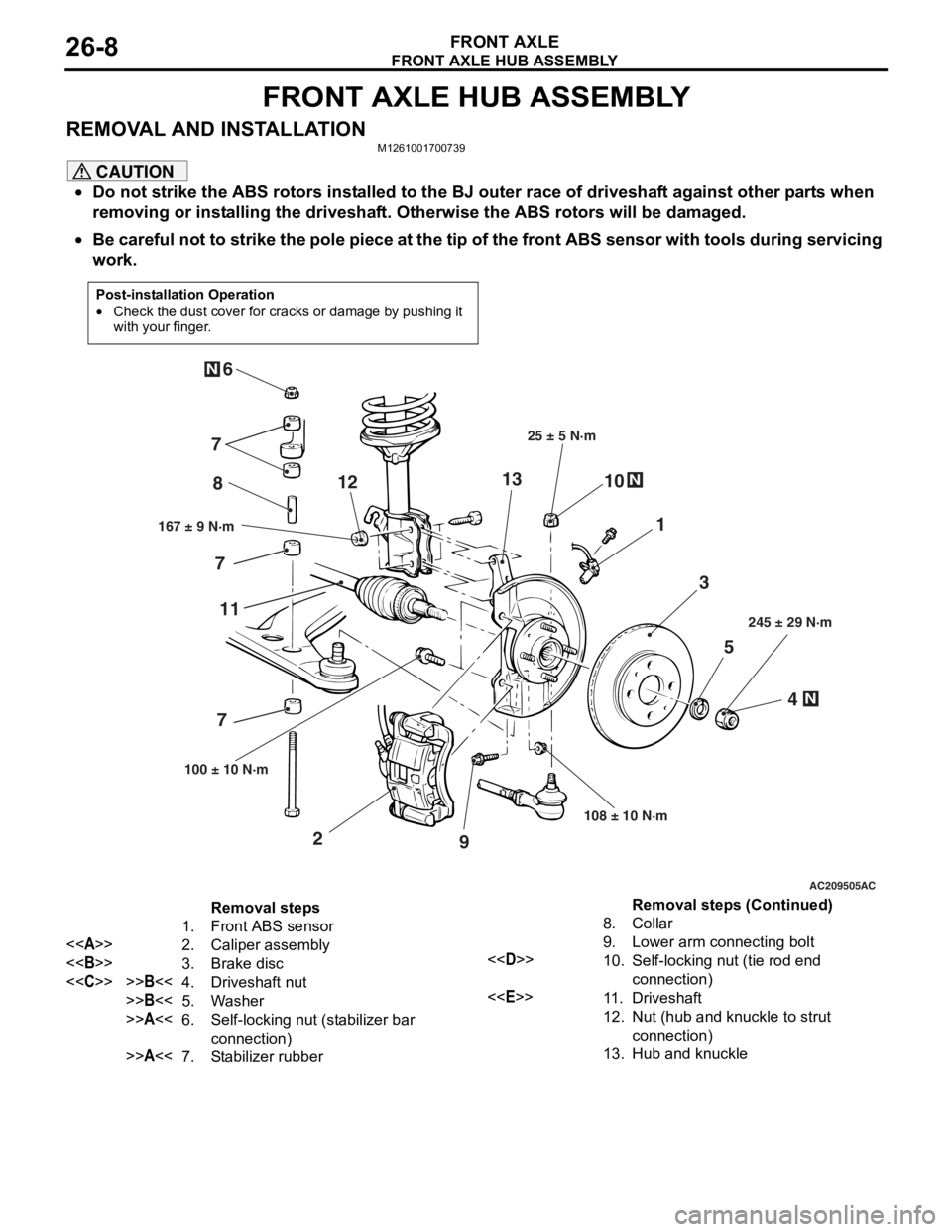

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-8

FRONT AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1261001700739

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of driveshaft against other parts when

removing or installing the driveshaft. Otherwise the ABS rotors will be damaged.

•

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

AC209505

N

N

N

5

4

3

1

8

10

9

2

7

6

167 ± 9 N·m 25 ± 5 N·m

108 ± 10 N·m 245 ± 29 N·m

100 ± 10 N·m

AC

7 7

11 12

13

Removal steps

1. Front ABS sensor

<> 2. Caliper assembly

<> 3. Brake disc

<

>>B<<5. Washer

>>A<<6.Self-locking nut (stabilizer bar

connection)

>>A<<7.Stabilizer rubber

8.Collar

9. Lower arm connecting bolt

<

connection)

<

12.Nut (hub and knuckle to strut

connection)

13.Hub and knuckle

Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Removal steps (Continued)

Page 146 of 800

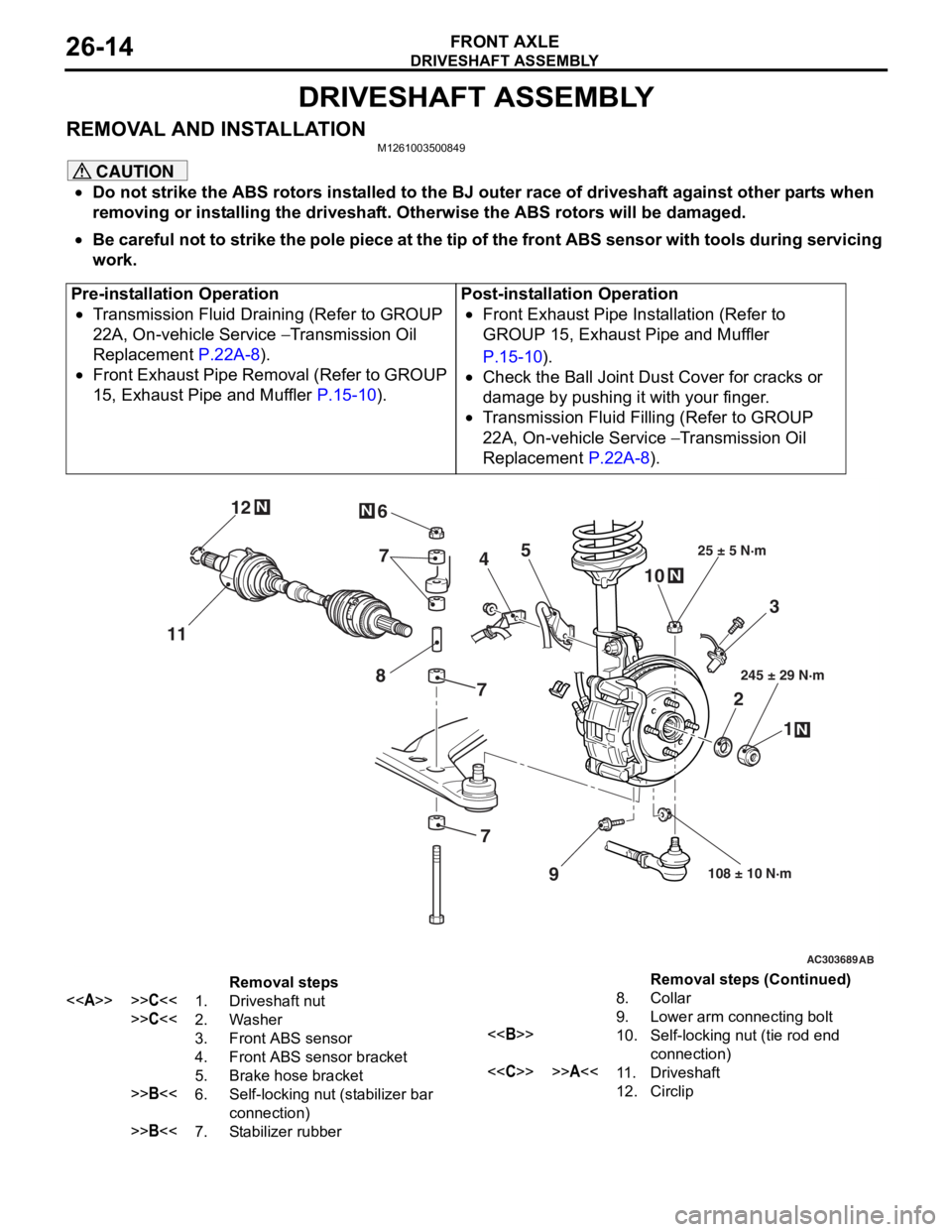

DRIVESHAFT ASSEMBLY

FRONT AXLE26-14

DRIVESHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500849

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of driveshaft against other parts when

removing or installing the driveshaft. Otherwise the ABS rotors will be damaged.

•

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service

− Transmission Oil

Replacement

P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler

P.15-10).

Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-10).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service

− Transmission Oil

Replacement

P.22A-8).

AC303689AB

9

N

N

NN

10

7

4

3

2 1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5

6

11 12

77

Removal steps

<>>>C<<1.Driveshaft nut

>>C<<2.Washer

3.Front ABS sensor

4.Front ABS sensor bracket

5.Brake hose bracket

>>B<<6.Self-locking nut (stabilizer bar

connection)

>>B<<7.Stabilizer rubber

8.Collar

9.Lower arm connecting bolt

<>10.Self-locking nut (tie rod end

connection)

<

12.Circlip

Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Removal steps (Continued)

Page 183 of 800

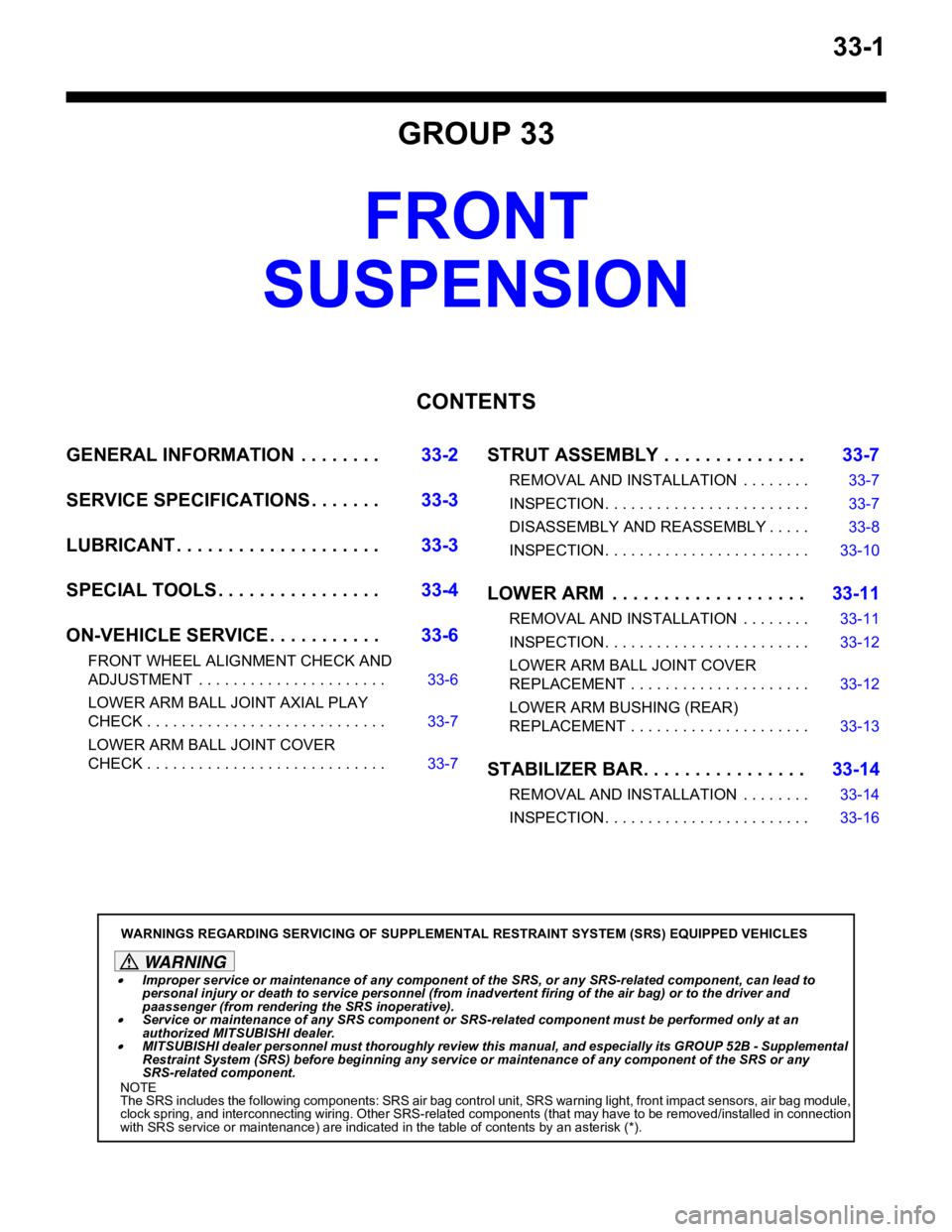

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATIO N . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-6

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-7

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR. . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 33-16

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

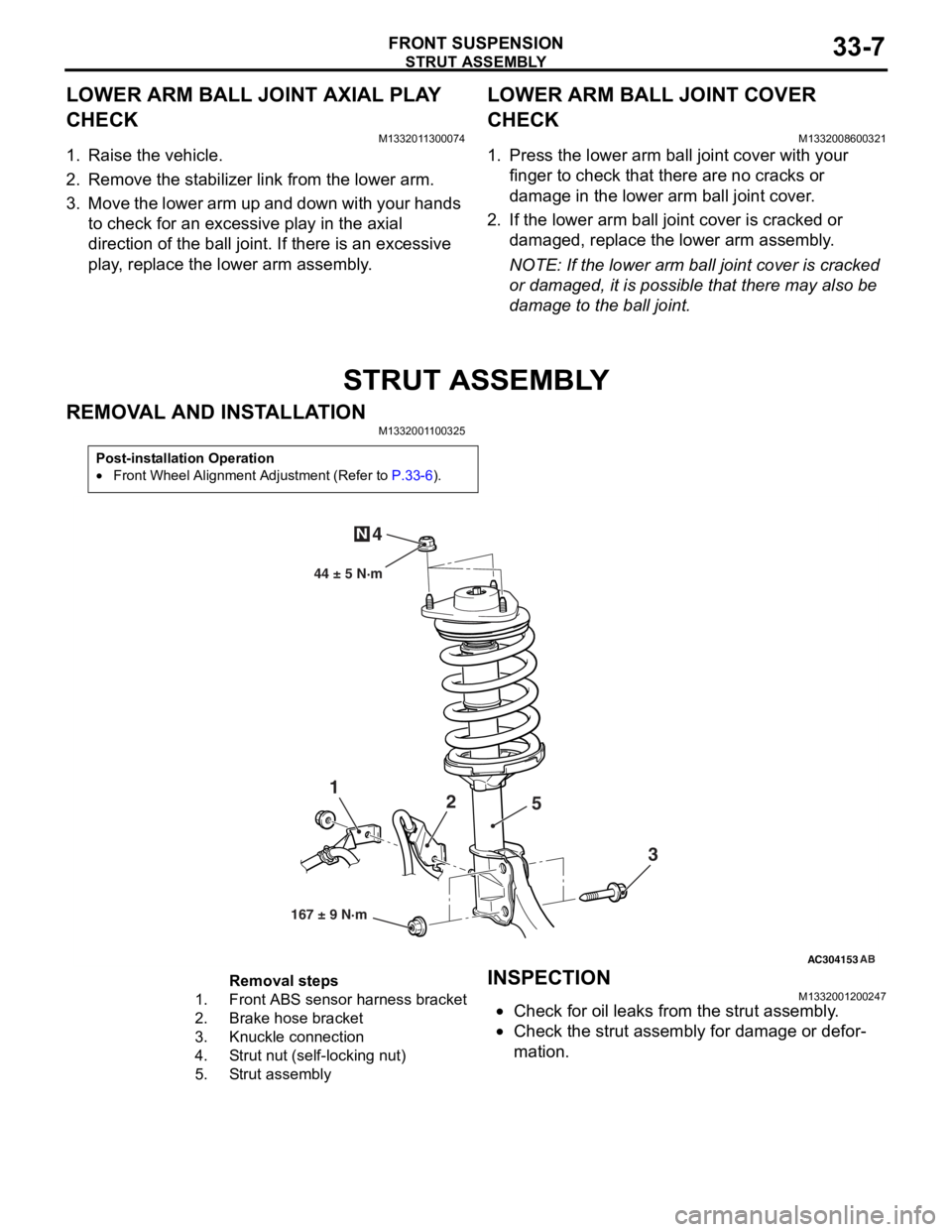

Page 189 of 800

STRUT ASSEMBLY

FRONT SUSPENSION33-7

LOWER ARM BALL JOINT AXIAL PLAY

CHECK

M1332011300074

1. Raise the vehicle.

2. Remove the stabilizer link from the lower arm.

3. Move the lower arm up and down with your hands to check for an excessive play in the axial

direction of the ball joint. If there is an excessive

play, replace the lower arm assembly.

LOWER ARM BALL JOINT COVER

CHECK

M1332008600321

1. Press the lower arm ball joint cover with your finger to check that there are no cracks or

damage in the lower arm ball joint cover.

2. If the lower arm ball joint cover is cracked or damaged, replace the lower arm assembly.

NOTE: If the lower arm ball joint cover is cracked

or damaged, it is possible that there may also be

damage to the ball joint.

STRUT ASSEMBLY

REMOVAL AND INSTALLATION

M1332001100325

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-6).

AC304153

44 ± 5 N·m

1 2

3

4

N

AB

167 ± 9 N·m

5

Removal steps

1.Front ABS sensor

harness bracket

2.Brake hose bracket

3.Knuckle connection

4.Strut nut (self-locking nut)

5.Strut assembly

INSPECTION

M13320012 0024 7

•Check for oil leaks fro m the stru t assemb ly .

•Check the stru t assemb ly for damage o r defor-

mation.

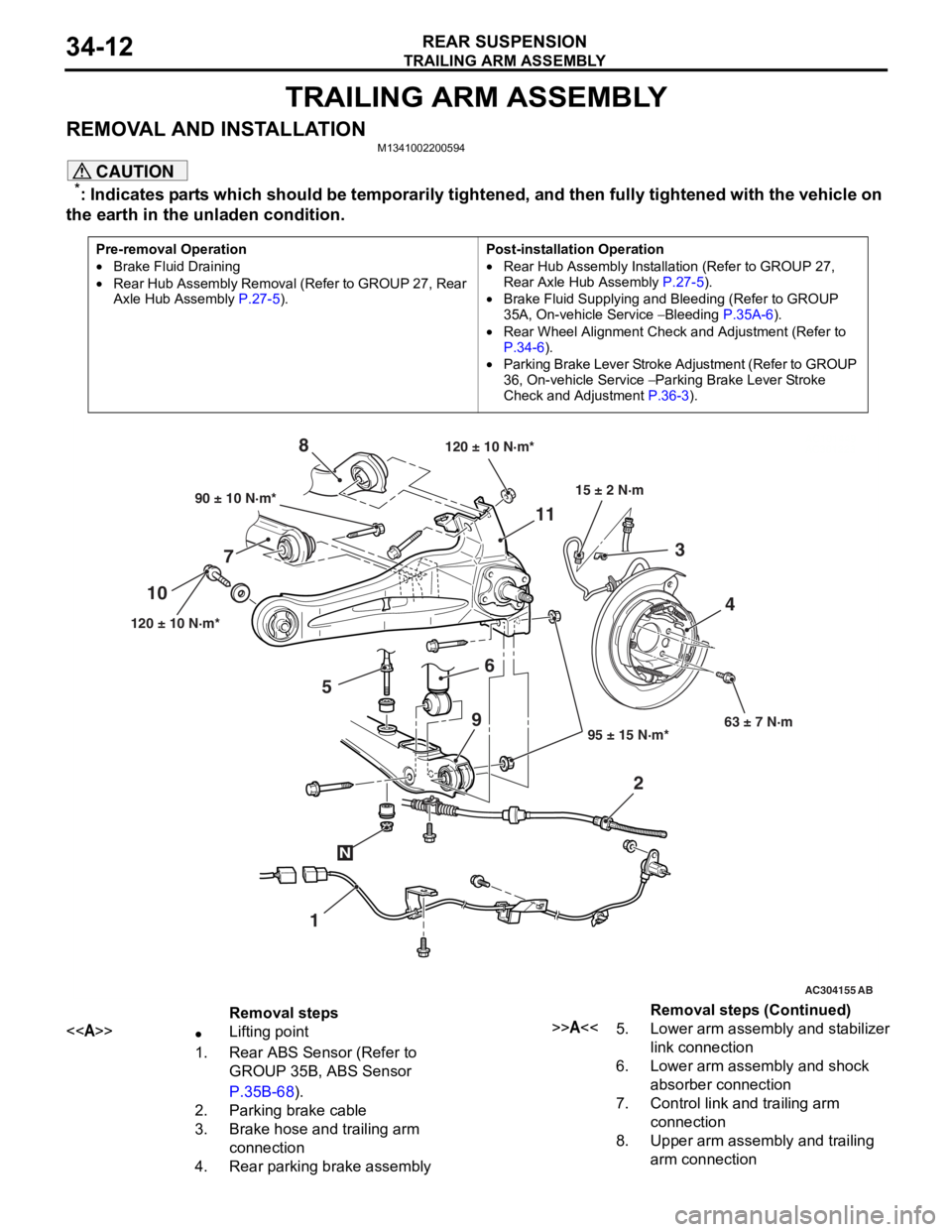

Page 210 of 800

TRAILING ARM ASSEMBLY

REAR SUSPENSION34-12

TRAILING ARM ASSEMBLY

REMOVAL AND INSTALLATIONM1341002200594

CAUTION

*: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle on

the earth in the unladen condition.

Pre-removal Operation

•Brake Fluid Draining

•Rear Hub Assembly Removal (Refer to GROUP 27, Rear

Axle Hub Assembly P.27-5).

Post-installation Operation

•Rear Hub Assembly Installation (Refer to GROUP 27,

Rear Axle Hub Assembly

P.27-5).

•Brake Fluid Supplying and Bleeding (Refer to GROUP

35A, On-vehicle Service

− Bleeding P.35A-6).

•Rear Wheel Alignment Check and Adjustment (Refer to

P.34-6).

•Parking Brake Lever Stroke Ad justment (Refer to GROUP

36, On-vehicle Service

− Parking Brake Lever Stroke

Check and Adjustment

P.36-3).

AC101449

AC301223

AC304155 AB

90 ± 10 N·m*

120 ± 10 N·m* 95 ± 15 N·m*63 ± 7 N·m

6

7 8

1

10

11

23

4

120 ± 10 N·m*

15 ± 2 N·m

N

9

5

Removal steps

<>•Lifting point

1.Rear ABS Sensor (Refer to

GROUP 35B, ABS Sensor

P.35B-68).

2.Parking brake cable

3.Brake hose and trailing arm

connection

4.Rear parking brake assembly

>>A<<5.Lower arm assembly and stabilizer

link connection

6.Lower arm assembly and shock

absorber connection

7.Control link and trailing arm

connection

8.Upper arm assembly and trailing

arm connection

Removal steps (Continued)

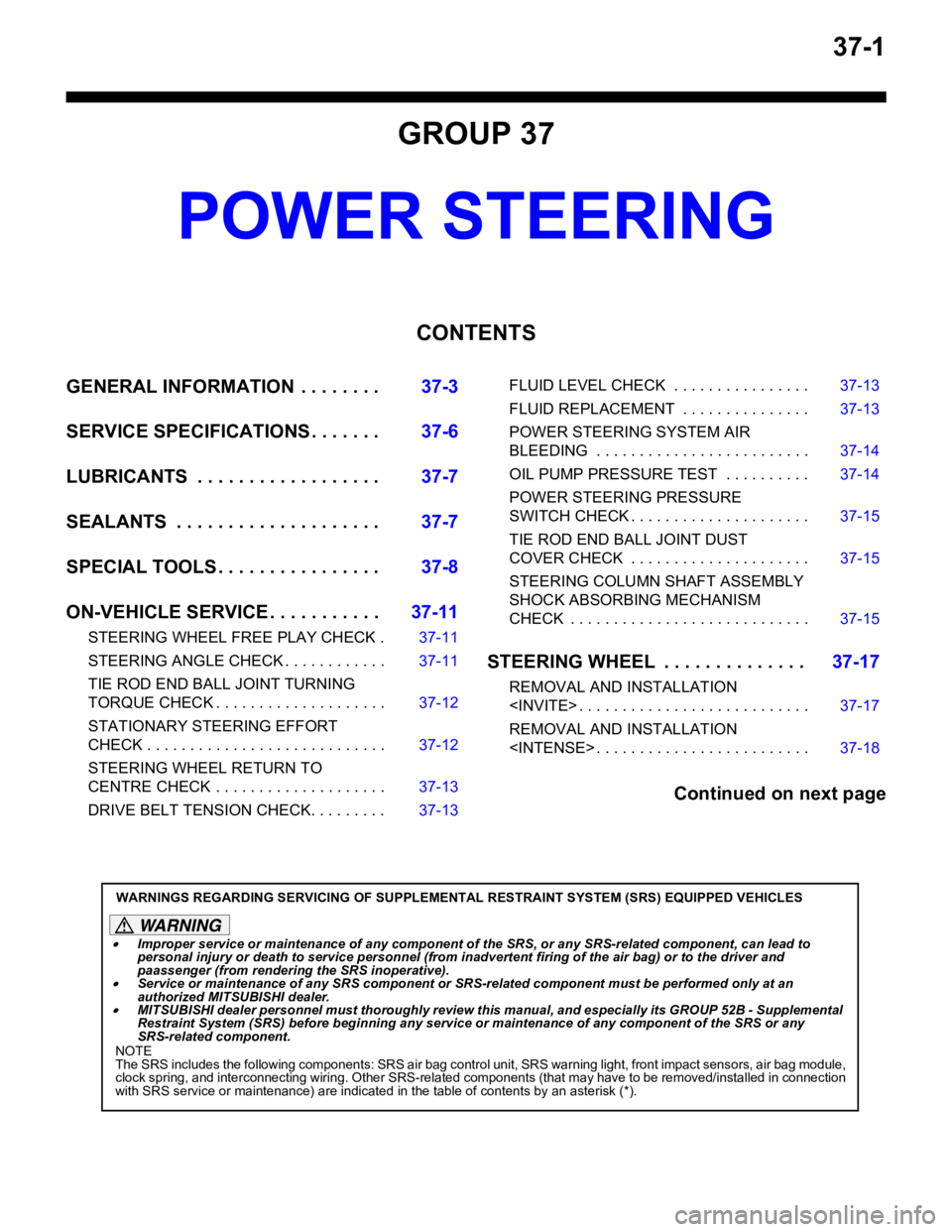

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 391 of 800

70-1

GROUP 70

COMPONENT

LOC ATIONS

CONTENTS

ECU . . . . . . . . . . . . . . . . . . . . . . . . . .70-2

RELAY . . . . . . . . . . . . . . . . . . . . . . . .70-5

SENSOR. . . . . . . . . . . . . . . . . . . . . . .70-6

FUSIBLE LINK AND FU SE . . . . . . . .70-11

EARTH CABLE . . . . . . . . . . . . . . . . .70-12

SOLENOID VALVE . . . . . . . . . . . . . . .70-13

DIODE . . . . . . . . . . . . . . . . . . . . . . . . .70-14

EARTH . . . . . . . . . . . . . . . . . . . . . . . .70-15

INSPECTION CONNECTOR AND

SPARE CONNECTOR . . . . . . . . . . . .70-19

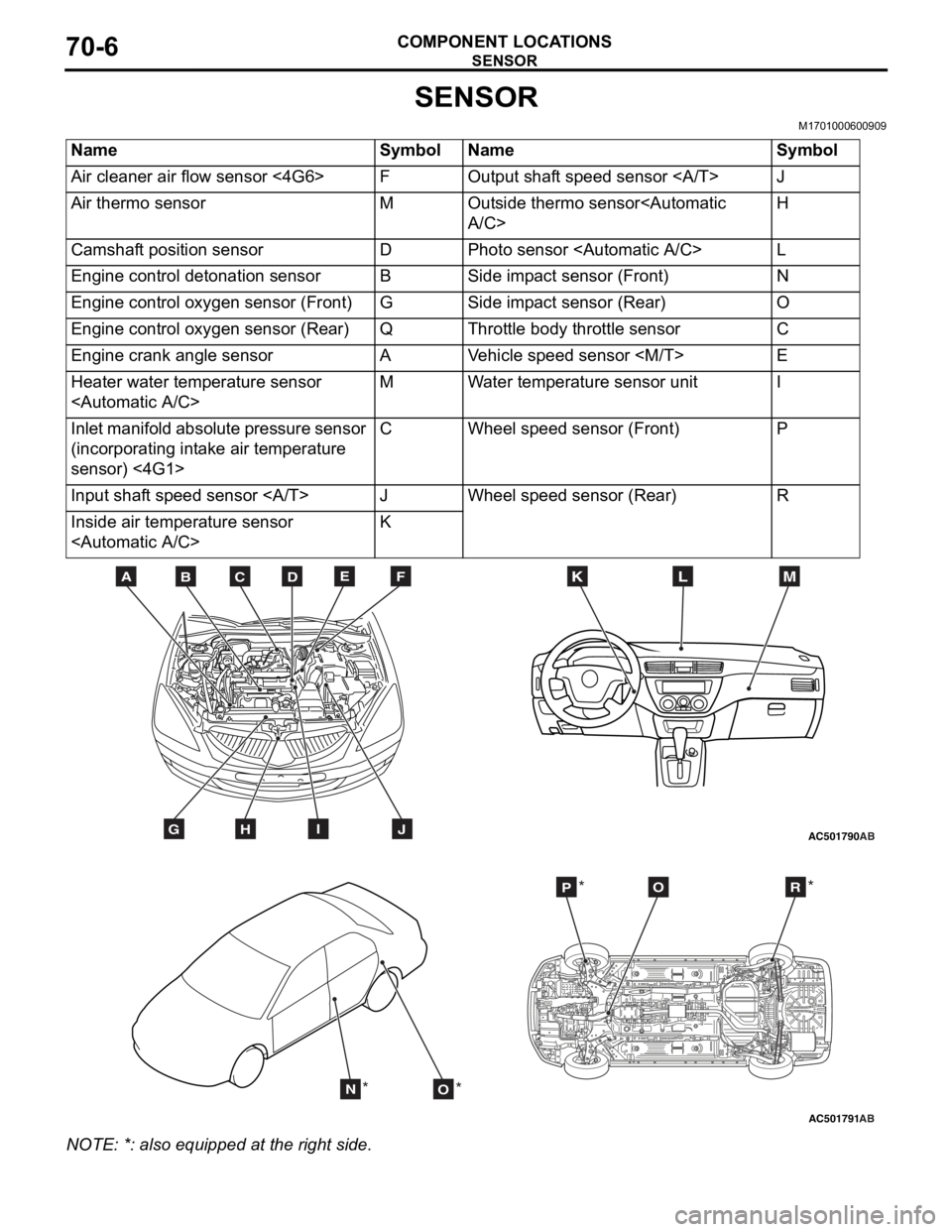

Page 396 of 800

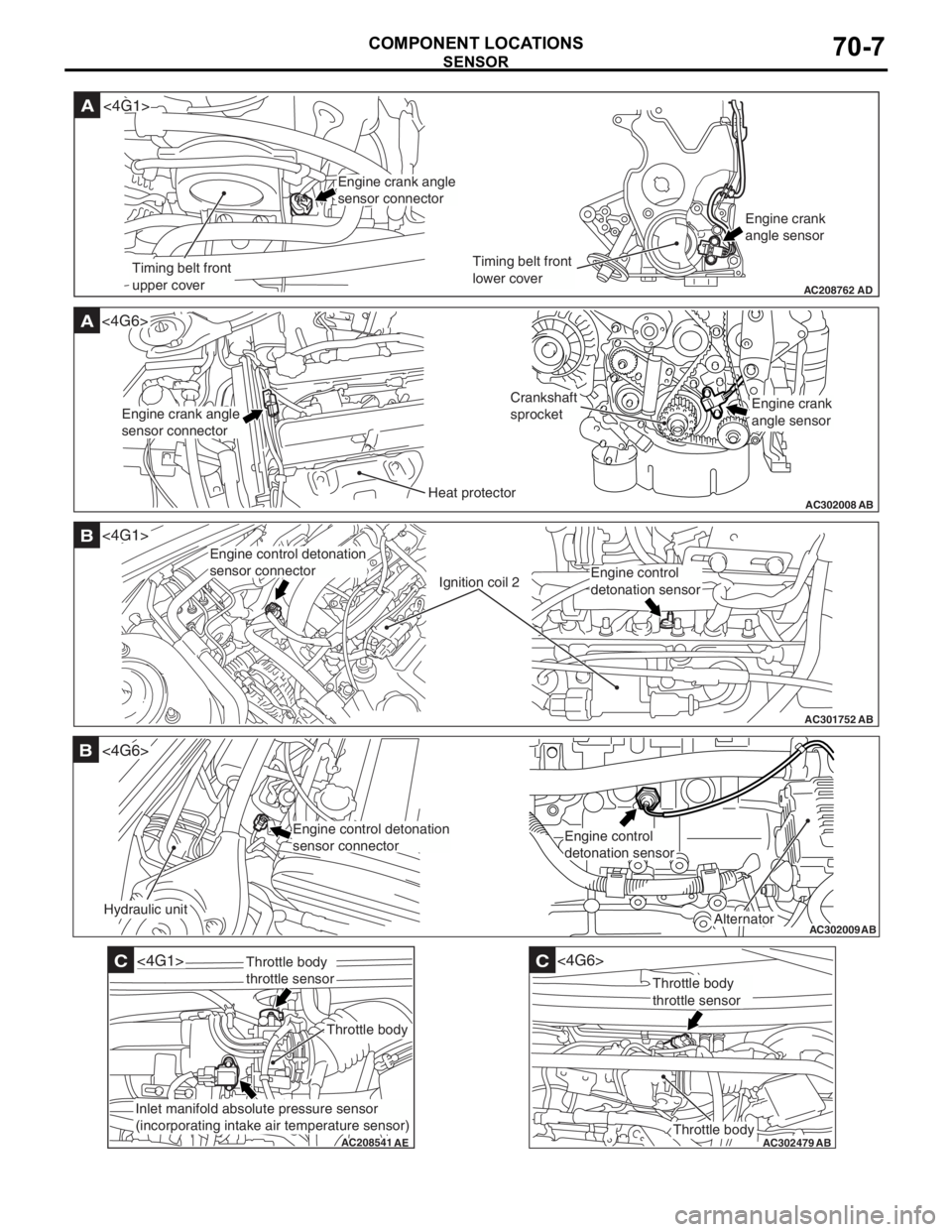

SENSOR

COMPONENT LOCATIONS70-6

SENSOR

M1701000600909

NameSymbolNameSymbol

Air cleaner air flow sensor <4G6>FOutput shaft speed sensor J

Air thermo sensorMOutside thermo sensor

Camshaft position sensorDPhoto sensor

Engine control detonation sensorBSide impact sensor (Front)N

Engine control oxygen sensor (Front)GSide impact sensor (Rear)O

Engine control oxygen sensor (Rear)QThrottle body throttle sensorC

Engine crank angle sensorAVehicle speed sensor

Heater water temperature sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature

sensor) <4G1>CWheel speed sensor (Front)P

Input shaft speed sensor JWheel speed sensor (Rear)R

Inside air temperature sensor

AC501790

BDCFEA

GHIJ

MKL

AB

AC501791AB

NO

POR

** *

*

NO

TE: *: also eq uipp ed at t he rig h t side.

Page 397 of 800

AC208762

A

AD

Timing belt front

upper coverTiming belt front

lower coverEngine crank

angle sensor

<4G1>

Engine crank angle

sensor connector

AC302008

A<4G6>

ABHeat protector

Crankshaft

sprocket

Engine crank angle

sensor connectorEngine crank

angle sensor

AC301752

B

AB

Ignition coil 2

<4G1>

Engine control detonation

sensor connector

Engine control

detonation sensor

AC302009

B

AB

Hydraulic unit

<4G6>

Alternator

Engine control detonation

sensor connectorEngine control

detonation sensor

AC208541

C

AE

<4G1>

Throttle body

Throttle body

throttle sensor

Inlet manifold absolute pressure sensor

(incorporating intake air temperature sensor)

AC302479

AB

C

Throttle body

<4G6>

Throttle body

throttle sensor

SENSOR

COMPONENT LOCA TIONS70-7