Vacuum MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 59 of 284

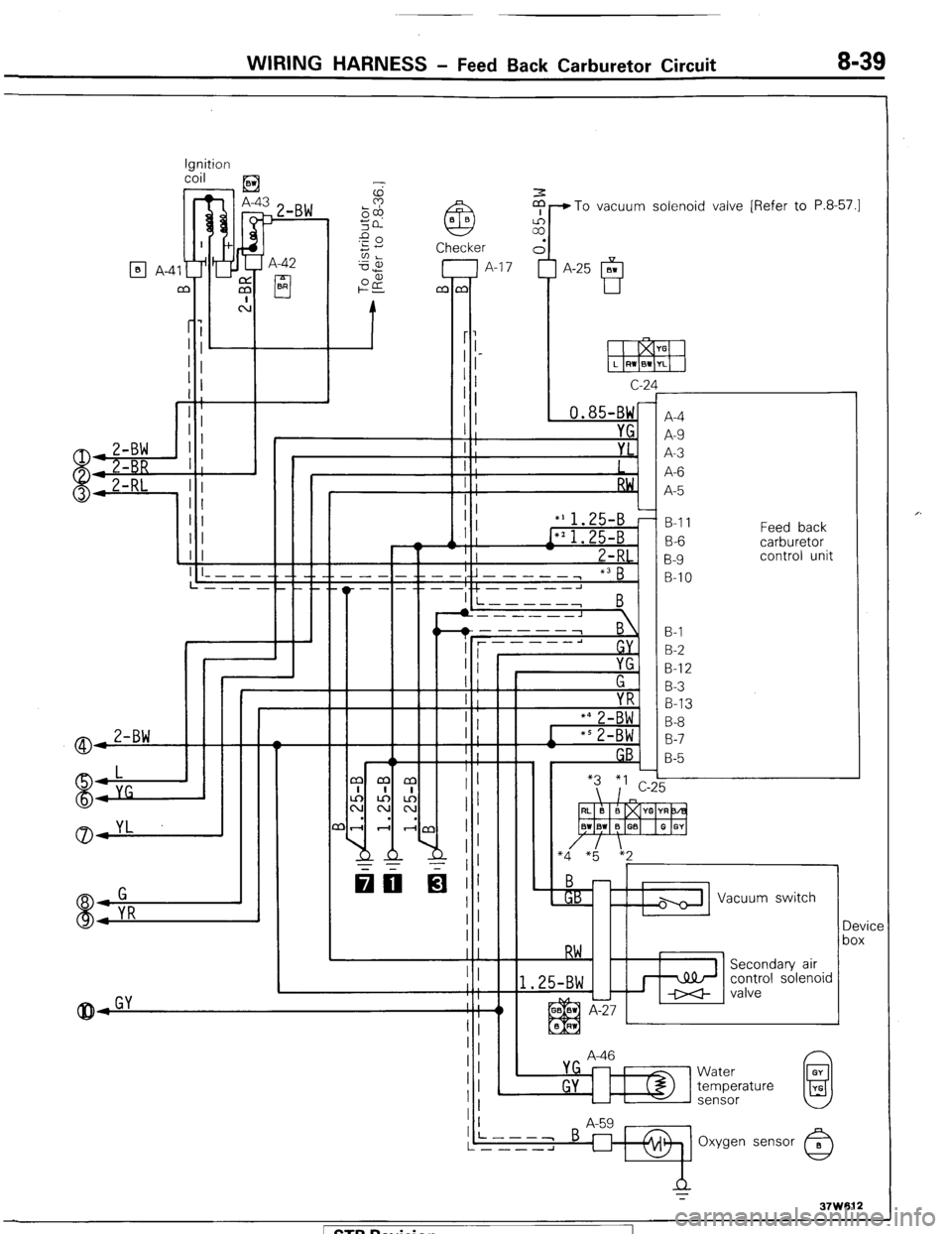

WIRING HARNESS - Feed Back Carburetor Circuit 8-39

Ignition

coil

) _ ,E3

$-To vacuum solenoid valve [Refer to P.8-57.1

7 A-42

cl BR

q A-4

c-2

, 0.85-BW

I YG

I ;

I : YL.

I

I ;

RW,

I :

‘A

f

r

A-4

A-9

A-3

A-6

A-5

B-l 1

B-6

B-9

B-IO Feed back

carburetor

control unit

I

II

II

(I I

1 I ! ! I I- - - - -. -_ __ __

L---- __._._

I +L----J I i-----,

B

B-l

B-2

B-l 2

B-3

B-13

B-8

B-7

B-5

A-46 Vacuum switch

Device

box

control solenoid

L

L

Water

temperature

sensor 1 STB Revision

Page 60 of 284

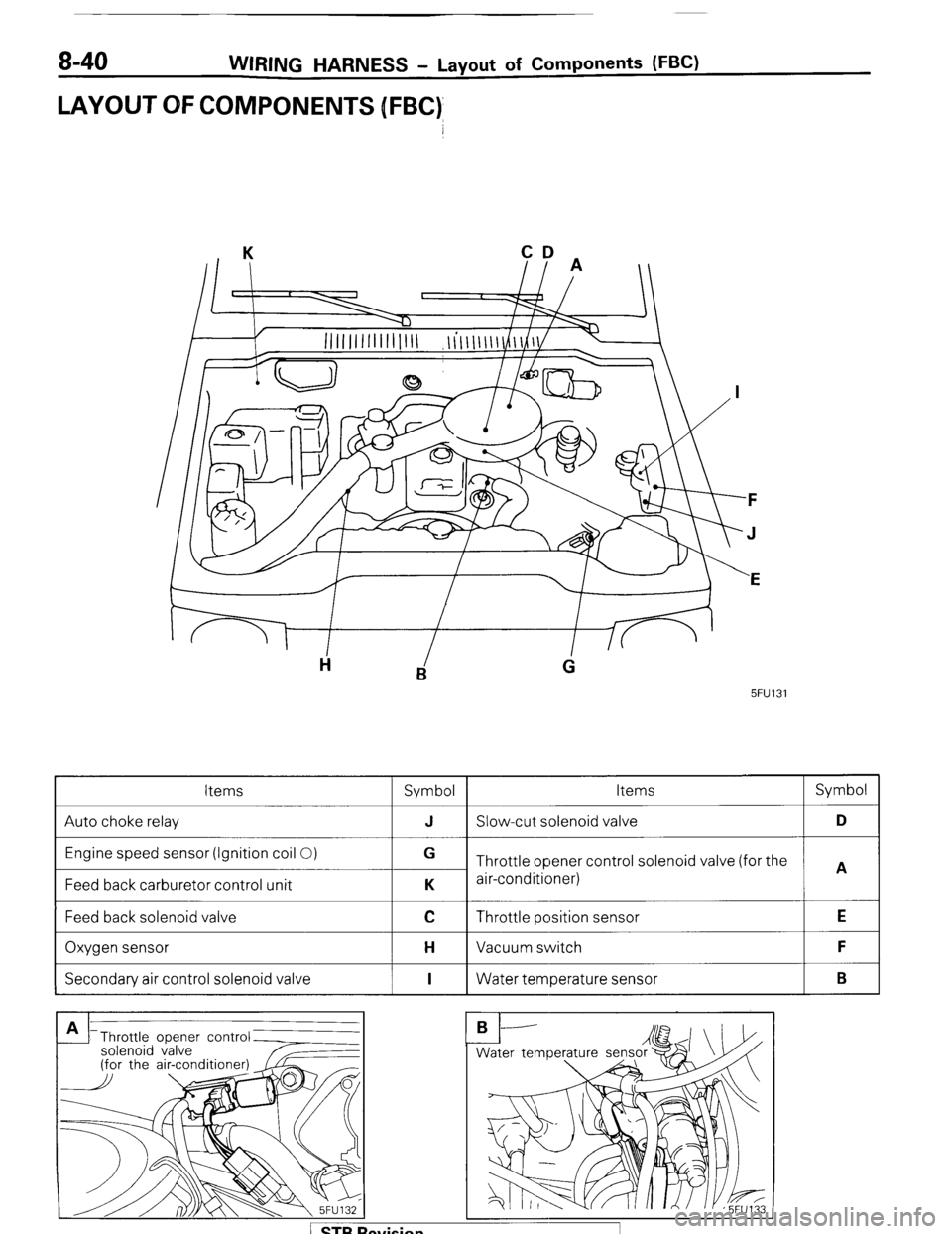

8-40 WIRING HARNESS - Layout of Components WC)

LAYOUT OFCOMPONENJS [FBC)

CD

II A

5FU131

Items

Symbol Items Symbol

Auto choke relay J Slow-cut solenoid valve D

Engine speed sensor (Ignition coil 0)

Feed back carburetor control unit G

Throttle opener control solenoid valve (for the

A

K air-conditioner)

Feed back solenoid valve

I

C Throttle position sensor

I E

Oxygen sensor

I H Vacuum switch

I F

Secondary air control solenoid valve

I I 1 Water temperature sensor

I B

Throttle opener contr

solenoid valve

Page 77 of 284

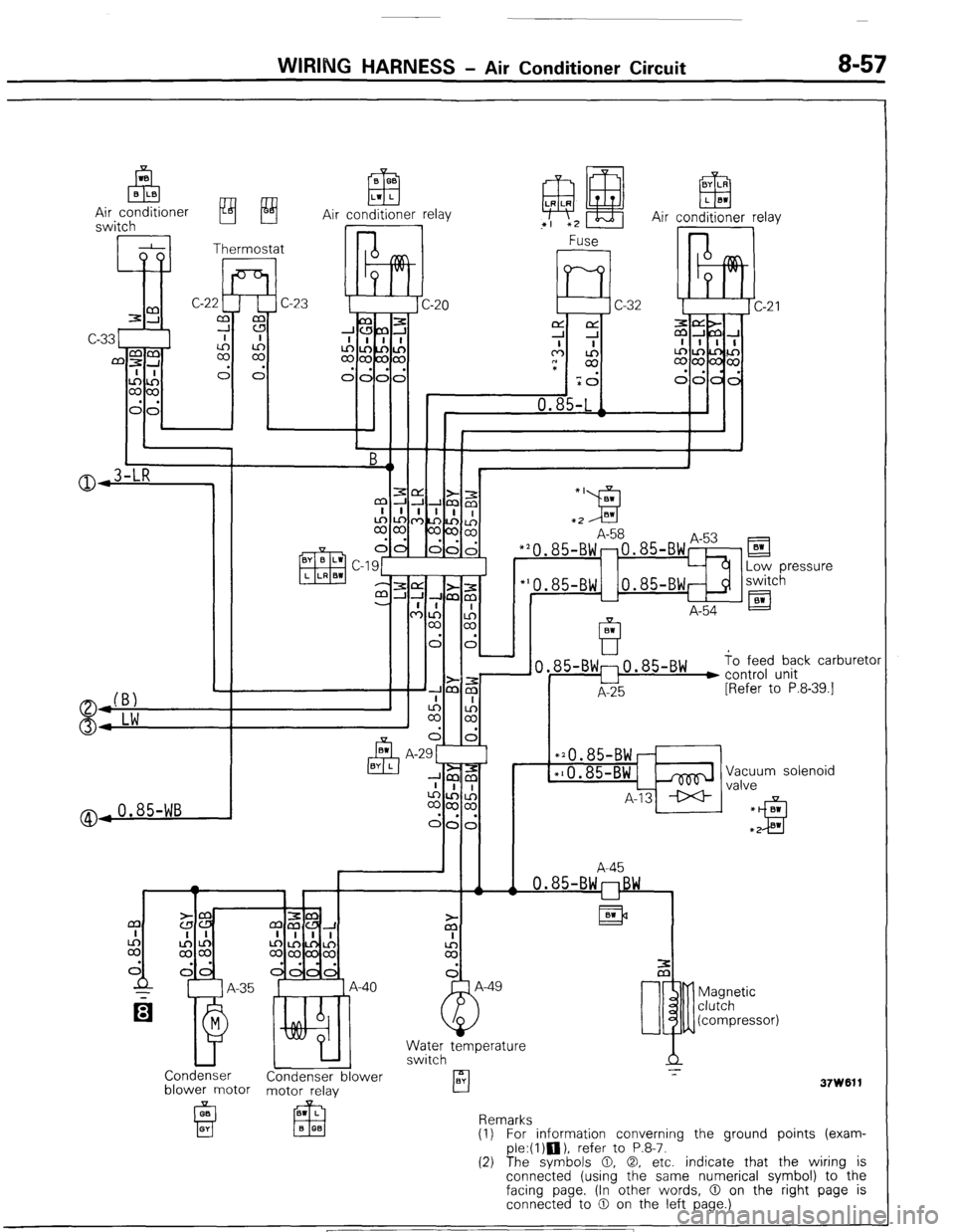

WIRING HARNESS - Air Conditioner Circuit 8-57

0

(Bl

0: Lw

@,0.85-WB B 0.3

ElFI Lvf L

Air conditioner relay I @ H ‘I *2 Air :on!$!er rela

85-Bw:o.85-Bw ) to feed back carburetor

u control unit

A-25 [Refer to P.8-39.1

l 20.85-BWr

l 10.85-BWL&

A-13 * Vacuum solenoid

valve

A-45

0.85-BWnBW

Is*la

Magnetic

clutch

(compressor)

U

Water temperature

switch

Condenser

Condenser blower -I-

BY

blower motor motor relay rl

37W611

Remarks

(1) For information converning the ground points (exam-

ple:(l)n), refer to P.8-7.

(2) The svmbols 0, 0, etc. indicate that the wiring is

connedted (using the same numerical symbol) to-the

facing page. (In other words, 0 on the right page is

connected to 0 on the left page.) ) STB Revision

Page 125 of 284

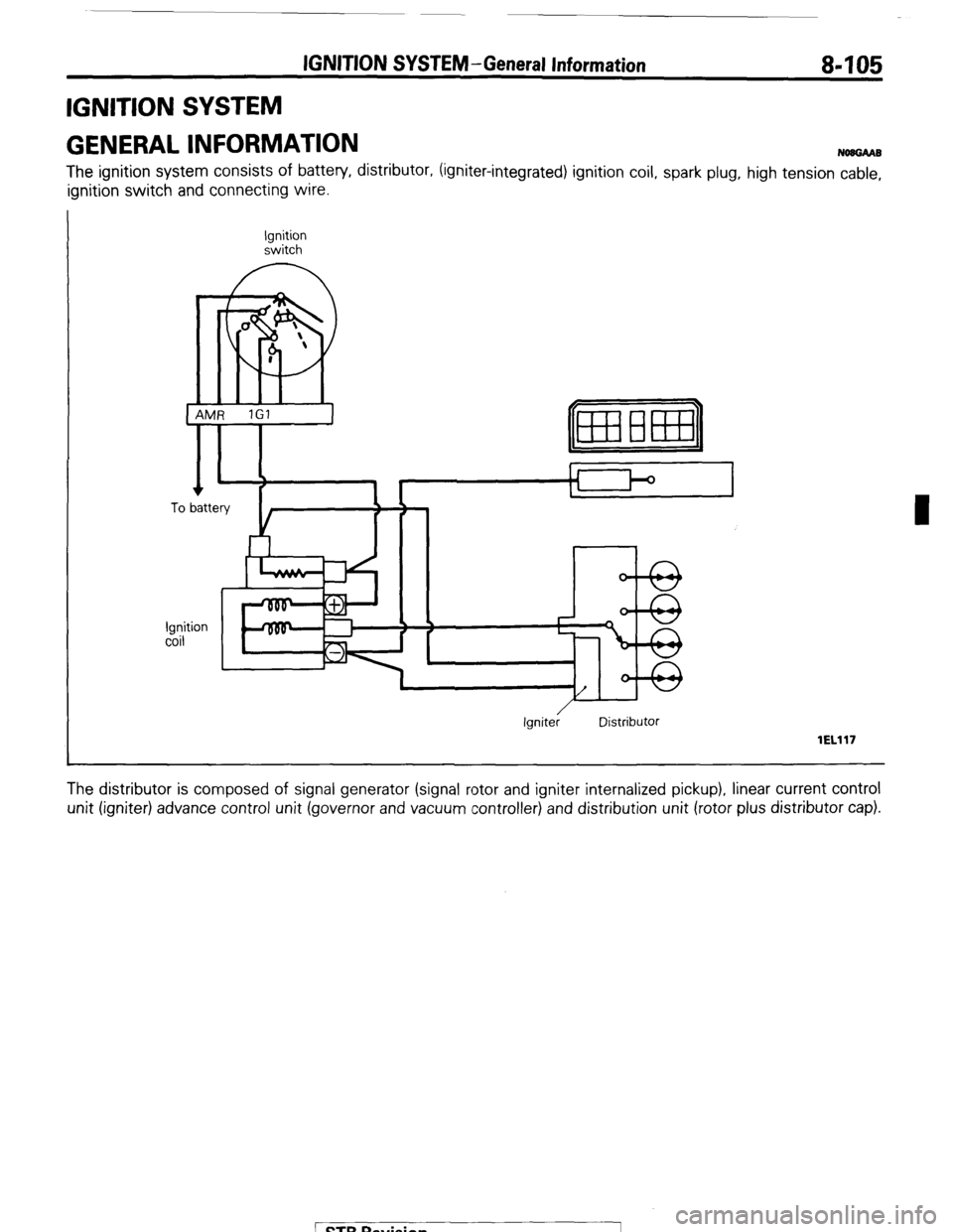

IGNITION SYSTEM -General Information 8-105

IGNITION SYSTEM

GENERAL INFORMATION

NOUGAAB

The ignition system consists of battery, distributor, (igniter-integrated) ignition coil, spark plug, high tension cable,

ignition switch and connecting wire.

Ignition

switch

0

m

I

1 AMR 1Gl

I

Ignition

coil

r

Ignite; Distributor

lEL117

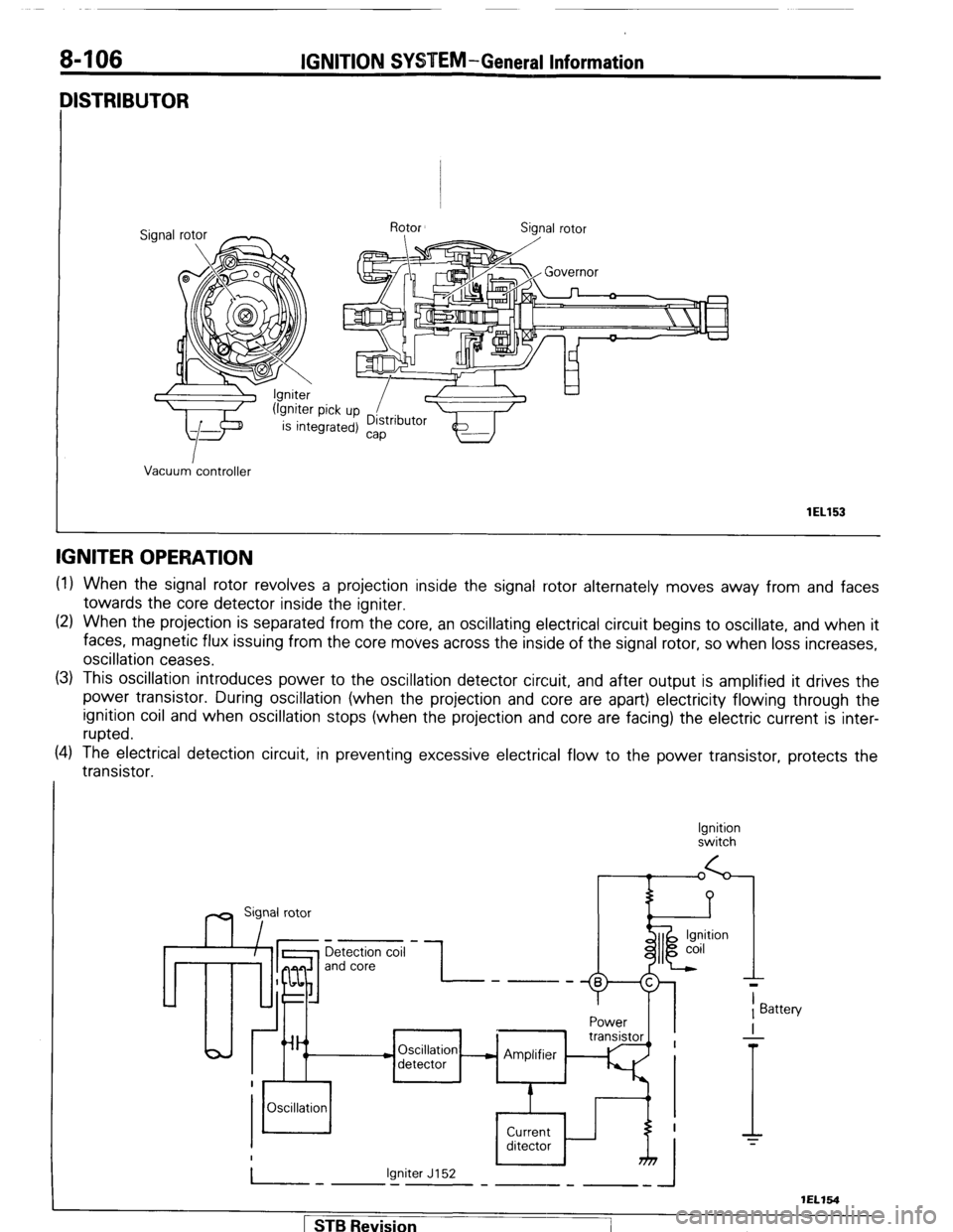

The distributor is composed of signal generator (signal rotor and igniter internalized pickup), linear current control

unit (igniter) advance control unit (governor and vacuum controller) and distribution unit (rotor plus distributor cap).

Page 126 of 284

IGNITION SYSTEM-General Information

IISTRIBUTOR

Vacuum controller

lEL153

IGNITER OPERATION

(1) When the signal rotor revolves a projection inside the signal rotor alternately moves away from and faces

towards the core detector inside the igniter.

(2) When the projection is separated from the core, an oscillating electrical circuit begins to oscillate, and when it

faces, magnetic flux issuing from the core moves across the inside of the signal rotor, so when loss increases,

oscillation ceases.

(3) This oscillation introduces power to the oscillation detector circuit, and after output is amplified it drives the

power transistor. During oscillation (when the projection and core are apart) electricity flowing through the

ignition coil and when oscillation stops (when the projection and core are facing) the electric current is inter-

rupted.

(4) The electrical detection circuit, in preventing excessive electrical flow to the power transistor, protects the

transistor.

Ignition

switch

m Sig,nal rotor

Detection coil

and core -I- ----

Power

Oscillation - Amplifier

detector

Oscillation

Current

ditector

Igniter J152

-.I-

T

1 Battery

I

-

T

1 STB Revision

-7

Page 128 of 284

8408 IGNITION SYSTEM - Specifications

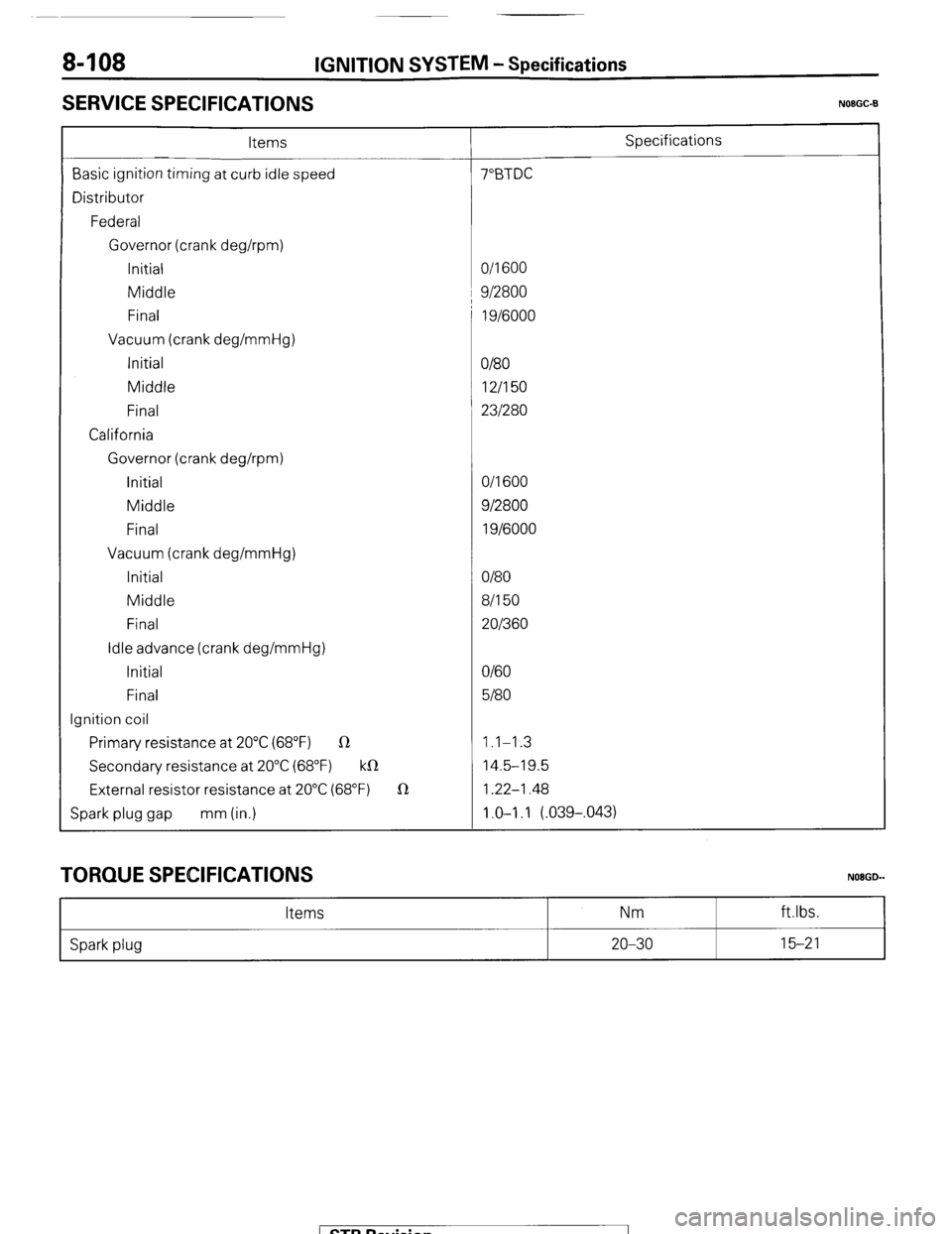

SERVICE SPECIFICATIONS

N08GC-B

Items Specifications

Basic ignition timing at curb idle speed 7”BTDC

Distributor

Federal

Governor (crank deghpm)

Initial O/l 600

Middle 1 9/2800

Final 1 g/6000

Vacuum (crank deg/mmHg)

Initial

O/80

Middle 12/I 50

Final 231280

California

Governor (crank deghpm)

initial O/l 600

Middle 912800

Final 1 g/6000

Vacuum (crank deg/mmHg)

Initial O/80

Middle 8/l 50

Final 201360

Idle advance (crank deg/mmHg)

Initial O/60

Final 5180

Ignition coil

Primary resistance at 20°C (68°F) R 1.1-1.3

Secondary resistance at 20°C (68°F) k0 14.5-19.5

External resistor resistance at 20°C (68°F) 1R 1.22-1.48

Spark plug gap mm (in.) 1.0-I .I (.039-,043)

TORQUE SPECIFICATIONS

Items Nm

NOBGD-

ft.lbs.

Spark plug 20-30 15-21

1 STB Revision

Page 131 of 284

IGNITION SYSTEM - Service Adjustment Procedures 8-111

SERVICE ADJUSTMENT PROCEDURES

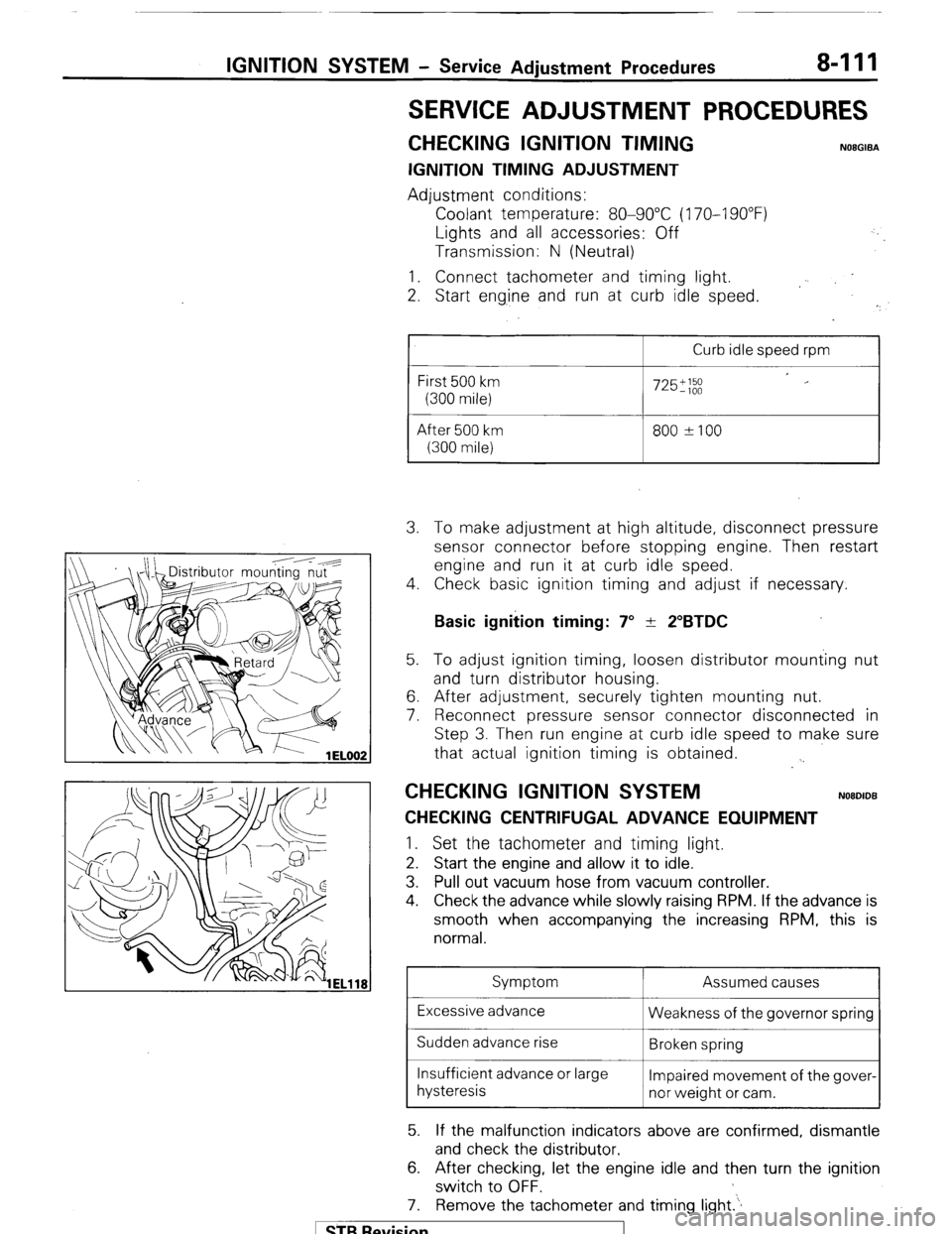

CHECKING IGNITION TIMING NOEGIBA

IGNITION TIMING ADJUSTMENT

Adjustment conditions:

Coolant temperature: 80-90°C (170-I 90°F)

Lights and all accessories: Off

Transmission: N (Neutral)

1. Connect tachometer and timing light.

2. Start eng.ine and run at curb idle speed.

I

Curb idle speed rpm

First 500 km

(300 mile)

After 500 km

(300 mile)

725';;;

800 ?I00 3. To make adjustment at high altitude, disconnect pressure

sensor connector before stopping engine. Then restart

engine and run it at curb idle speed.

4. Check basic ignition timing and adjust if necessary.

Basic ignition timing: 7” + 2”BTDC 5. To adjust ignition timing, loosen distributor mounting nut

and turn distributor housing.

6. After adjustment, securely tighten mounting nut.

7. Reconnect pressure sensor connector disconnected in

Step 3. Then run engine at curb idle speed to make sure

that actual ignition timing is obtained.

. .

CHECKING IGNITION SYSTEM NOBDIDB

CHECKING CENTRIFUGAL ADVANCE EQUIPMENT 1.

Set the tachometer and timing light.

2. Start the engine and allow it to idle.

3. Pull out vacuum hose from vacuum controller.

4. Check the advance while slowly raising RPM. If the advance is

smooth when accompanying the increasing RPM, this is

normal.

Symptom Assumed causes

Excessive advance

Weakness of the governor spring

Sudden advance rise

Broken spring

Insufficient advance or large

Impaired movement of the gover-

hysteresis

nor weight or cam.

5. If the malfunction indicators above are confirmed, dismantle

and check the distributor.

6. After checking, let the engine idle and then turn the ignition

switch to OFF.

7. Remove the tachometer and timing light.‘.

1 STB Revision

Page 132 of 284

8-112 IGNITION SYSTEM - Service Adjustment Procedures

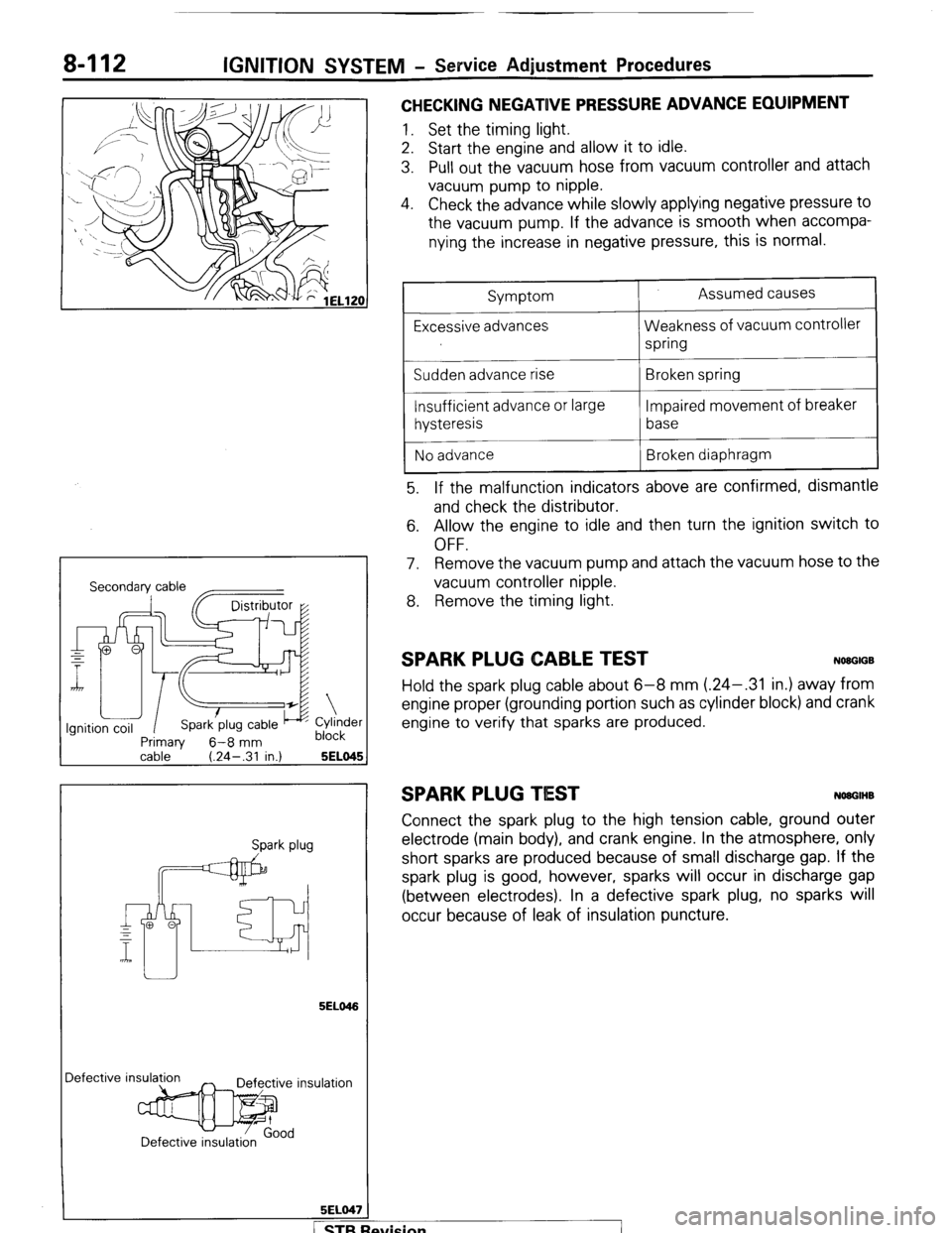

CHECKING NEGATIVE PRESSURE ADVANCE EQUIPMENT

1. Set the timing light.

2. Start the engine and allow it to idle.

3. Pull out the vacuum hose from vacuum controller and attach

vacuum pump to nipple.

4. Check the advance while slowly applying negative pressure to

the vacuum pump. If the advance is smooth when accompa-

nying the increase in negative pressure, this is normal.

Secondary cable

~~

Primaw 6-8 mm

Cylinder

block

cable ’ (.24-.31 in.) 5ELO45 1

Spark plug

5ELO46

Iefective insula

5ELO47

/

Symptom

Excessive advances

Sudden advance rise

Insufficient advance or large

hysteresis

No advance Assumed causes

Weakness of vacuum controller

spring

Broken spring

Impaired movement of breaker

base

Broken diaphragm

5. If the malfunction indicators above are confirmed, dismantle

and check the distributor.

6. Allow the engine to idle and then turn the ignition switch to

OFF.

7. Remove the vacuum pump and attach the vacuum hose to the

vacuum controller nipple.

8. Remove the timing light.

SPARK PLUG CABLE TEST NWGIGB

Hold the spark plug cable about 6-8 mm (.24-.31 in.) away from

engine proper (grounding portion such as cylinder block) and crank

engine to verify that sparks are produced.

SPARK PLUG TIEST NOUGIHB

Connect the spark plug to the high tension cable, ground outer

electrode (main body), and crank engine. In the atmosphere, only

short sparks are produced because of small discharge gap. If the

spark plug is good, however, sparks will occur in discharge gap

(between electrodes). In a defective spark plug, no sparks will

occur because of leak of insulation puncture.

fvision

I

Page 134 of 284

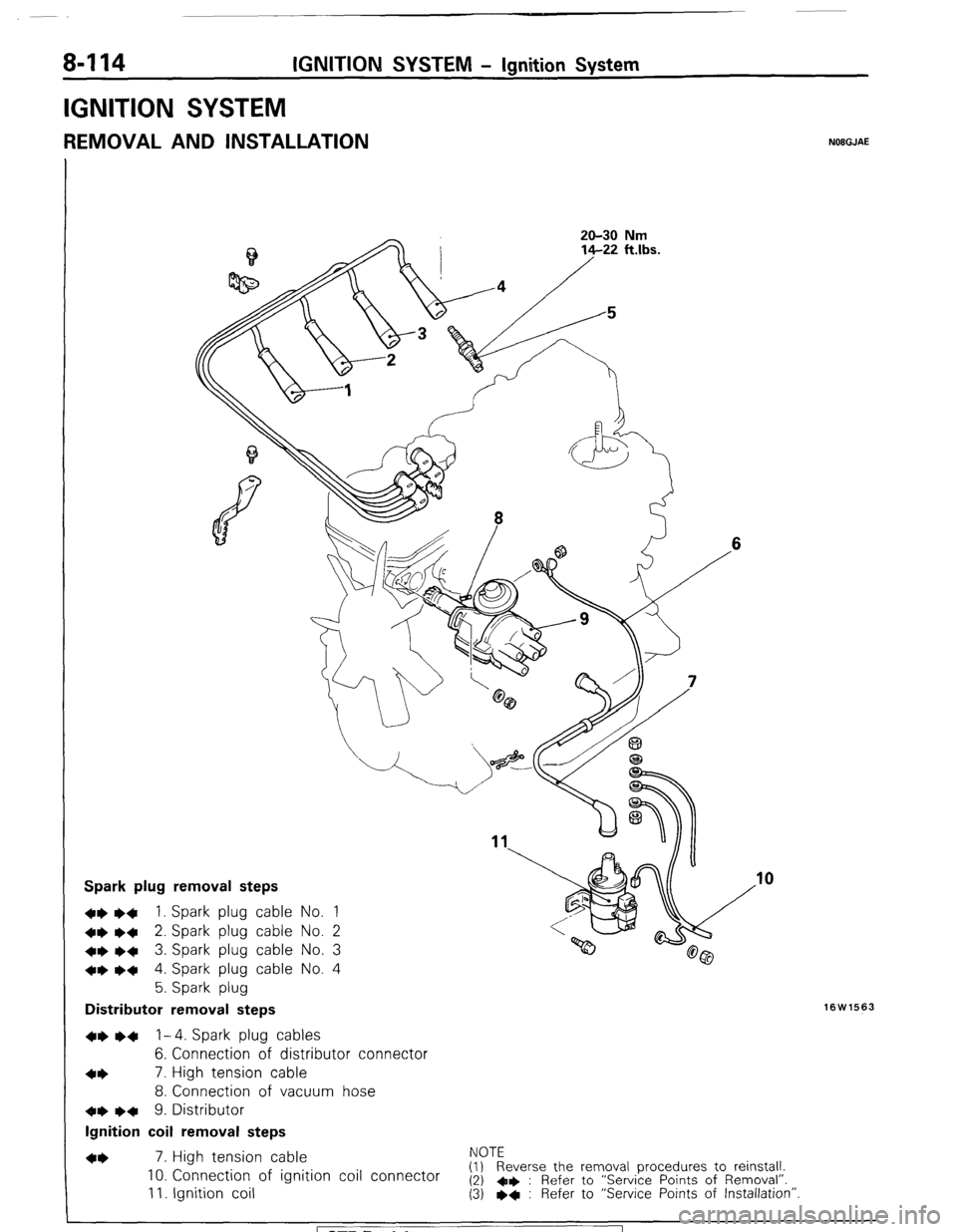

8-114 IGNITION SYSTEM - Ignition System

IGNITION SYSTEM

REMOVAL AND INSTALLATION NOEGJAE

20-30

Nm

Spark plug removal steps

+e l

+ 1. Spark plug cable No. 1

~~ ~~ 2. Spark plug cable No. 2

+e e+ 3. Spark plug cable No. 3

*e e+ 4. Spark plug cable No. 4

5. Spark plug

Distributor removal steps

16W1563

~~ l + 1-4. Spark plug cables

6. Connection of distributor connector

+* 7. High tension cable

8. Connection of vacuum hose

de l

q 9. Distributor

Ignition coil removal steps

7. High tension cable NOTE

10. Connection of ignition coil connector (1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”. 11. Ignition coil (3) l + : Refer to “Service Points of Installation”

I

1 STB Revision

Page 139 of 284

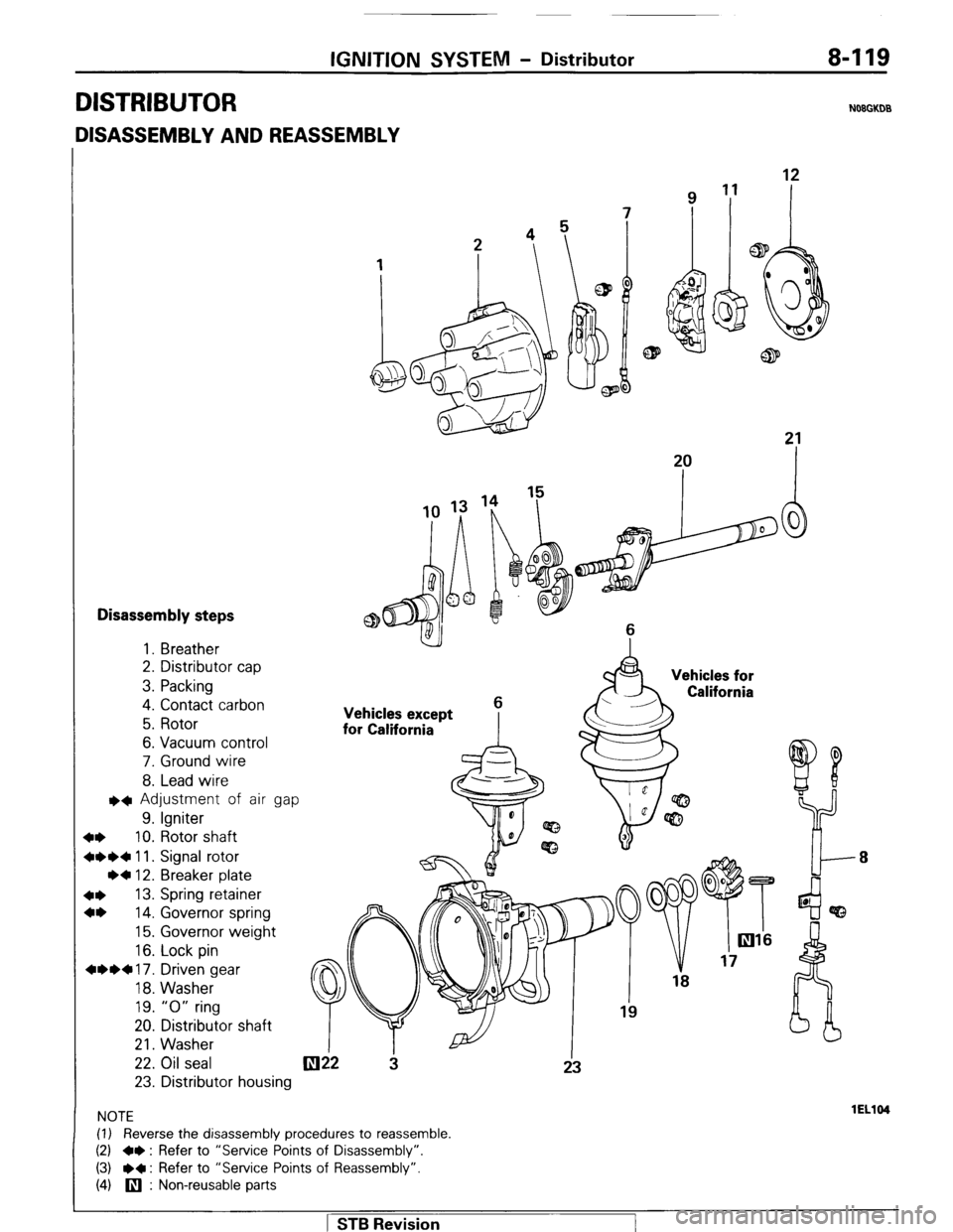

IGNITION SYSTEM - Distributor

DISTRIBUTOR

DISASSEMBLY AND REASSEMBLY

8-119

Disassembly steps

1. Breather

2. Distributor cap

3. Packing

4. Contact carbon

5. Rotor

6. Vacuum control

7. Ground wire

8. Lead wire

l + Adjustment of air gap

9. Igniter

4* 10. Rotor shaft

+*** 11. Signal rotor

l * 12. Breaker plate

4* 13. Spring retainer

4* 14. Governor spring

15. Governor weight

16. Lock pin

- Vehicles for

California

Vehicles except

for California

8

4**+ 17. Driven gear

18. Washer

19. “0” ring

20. Distributor shaft

21. Washer

22. Oil seal

23. Distributor housing

NOTE

(1) Reverse the disassembly procedures to reassemble.

(2) +e : Refer to “Service Points of Disassembly”.

(3) Hw: Refer to “Service Points of Reassembly”.

(4)

q : Non-reusable parts

lEL104 1 STB Revision