relay MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

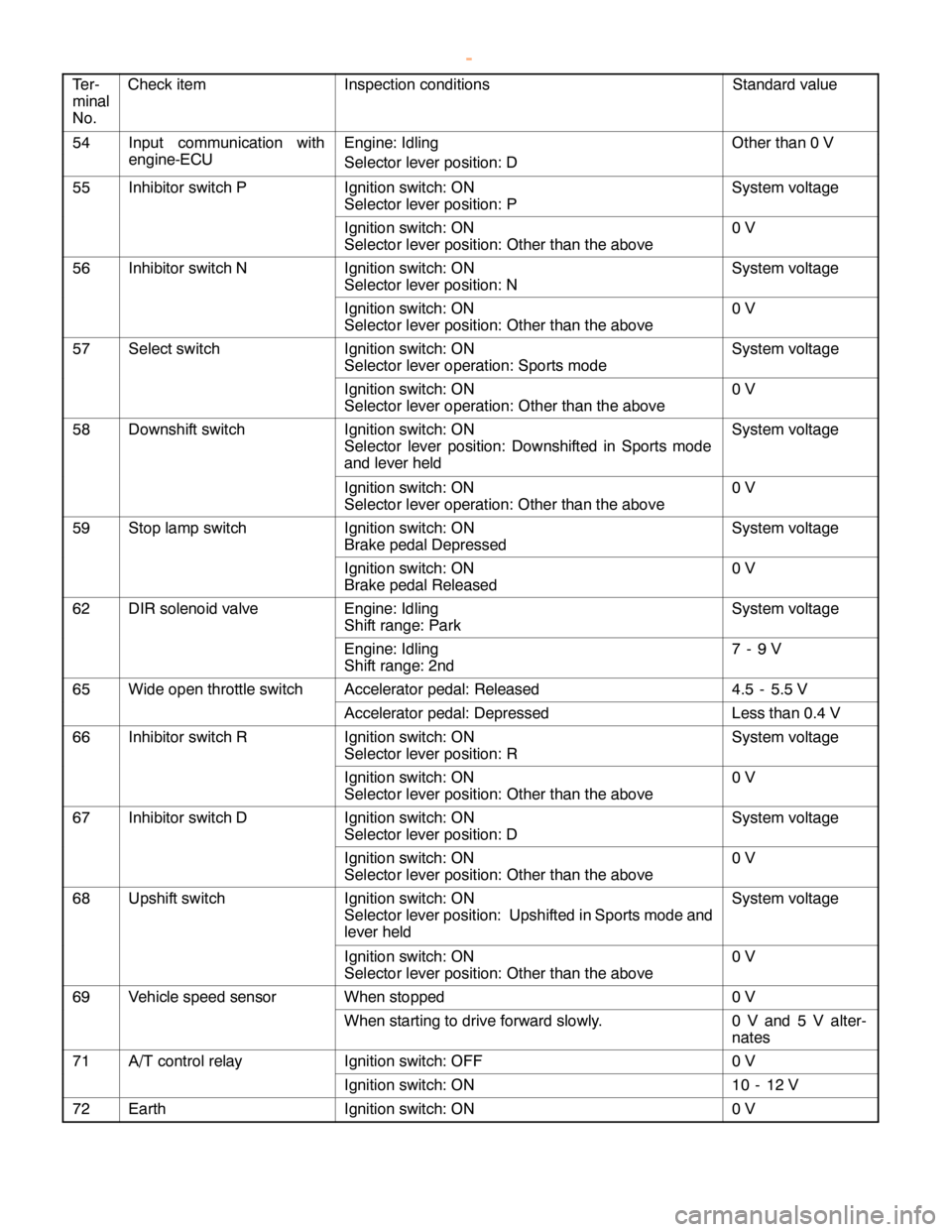

Page 969 of 1839

Page 973 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

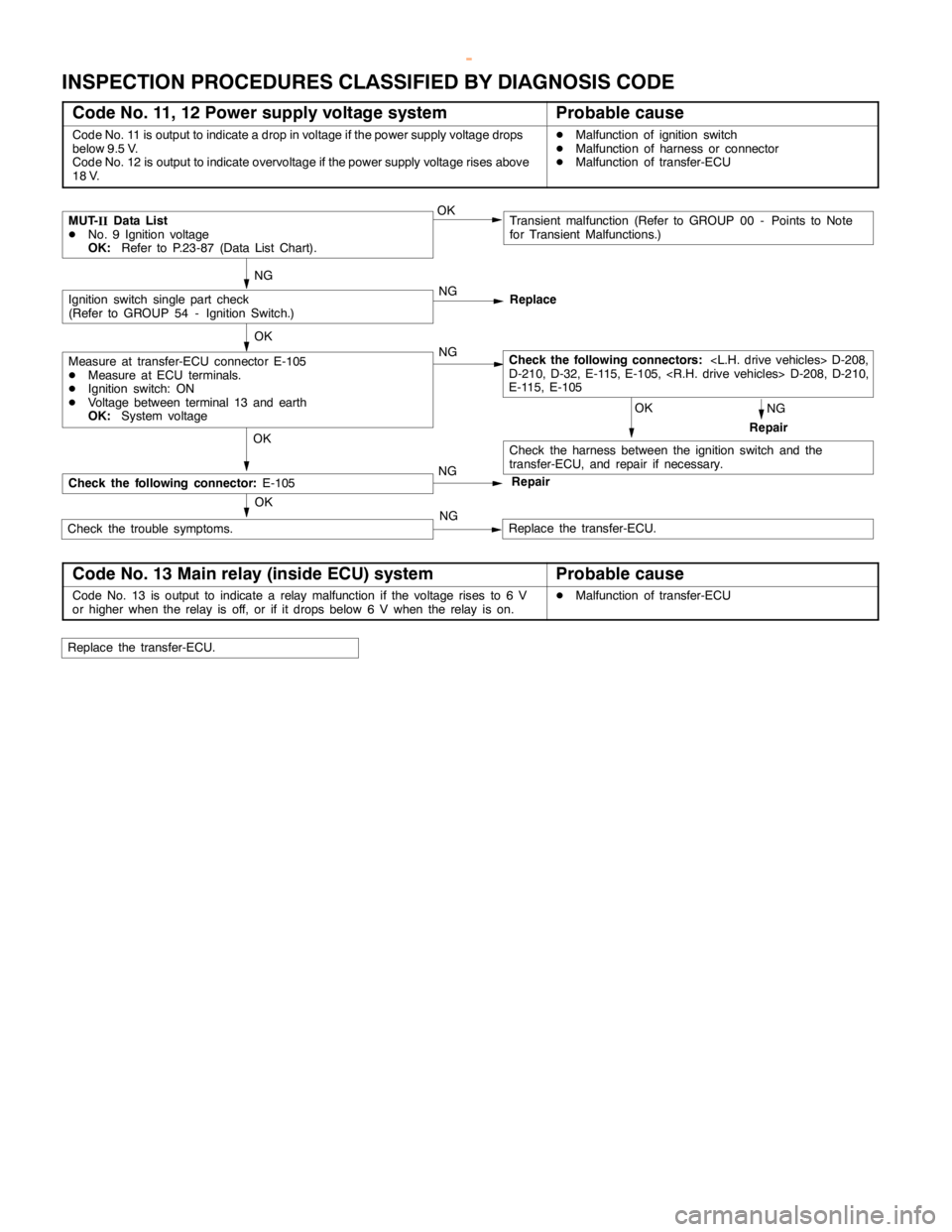

INSPECTION PROCEDURES CLASSIFIED BY DIAGNOSIS CODE

Code No. 11, 12 Power supply voltage systemProbable cause

Code No. 11 is output to indicate a drop in voltage if the power supply voltage drops

below 9.5 V.

Code No. 12 is output to indicate overvoltage if the power supply voltage rises above

18 V.DMalfunction of ignition switch

DMalfunction of harness or connector

DMalfunction of transfer-ECU

NG OK

OK

Repair NG

Replace

NG

Ignition switch single part check

(Refer to GROUP 54 - Ignition Switch.)

Check the following connectors:

D-210, D-32, E-115, E-105,

E-115, E-105

Repair

Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.)

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DIgnition switch: ON

DVoltage between terminal 13 and earth

OK:System voltage

Check the harness between the ignition switch and the

transfer-ECU, and repair if necessary.

OK

Replace the transfer-ECU. OKOK NG

NGCheck the trouble symptoms.

MUT-

IIData List

DNo. 9 Ignition voltage

OK:Refer to P.23-87 (Data List Chart).

NG

Check the following connector:E-105

Code No. 13 Main relay (inside ECU) systemProbable cause

Code No. 13 is output to indicate a relay malfunction if the voltage rises to 6 V

or higher when the relay is off, or if it drops below 6 V when the relay is on.DMalfunction of transfer-ECU

Replace the transfer-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

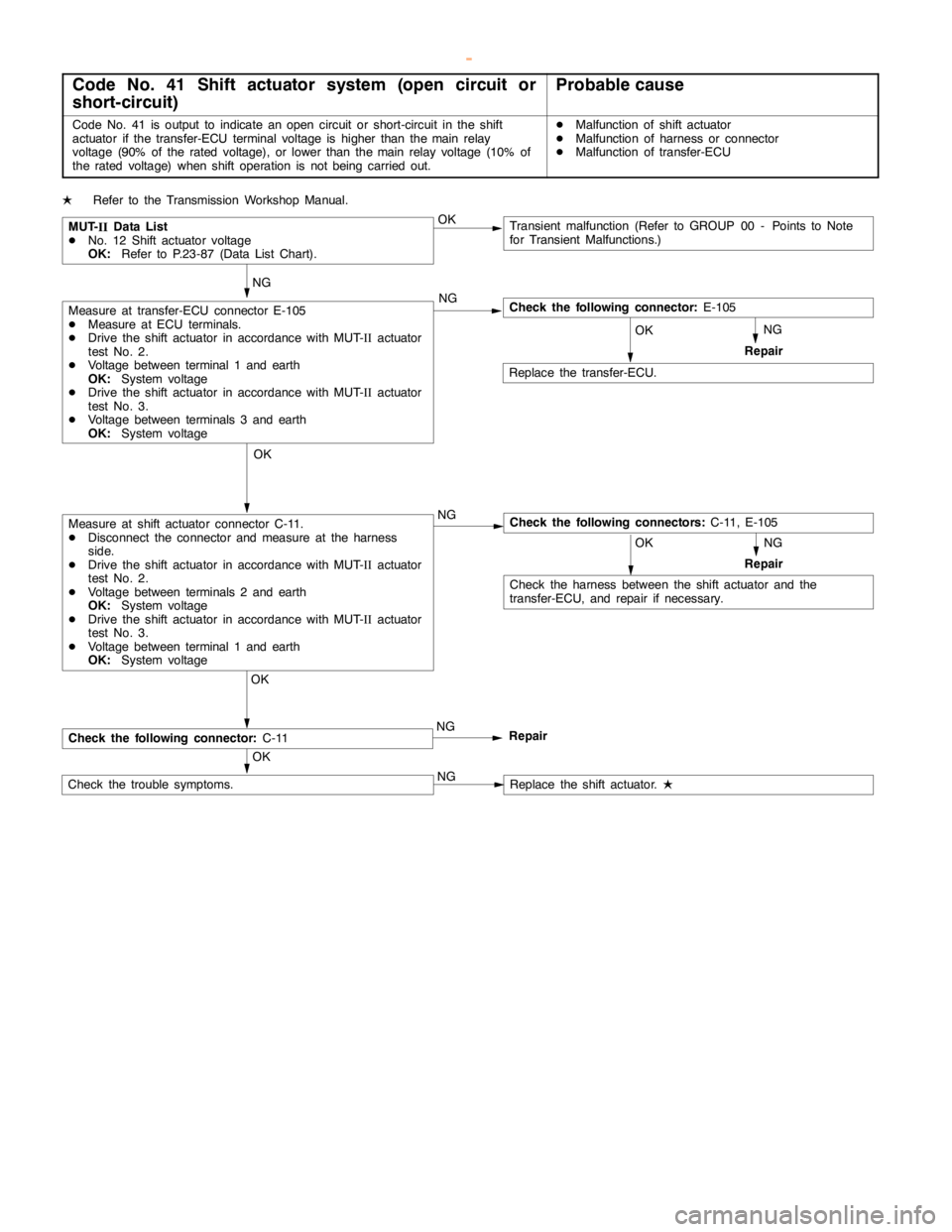

Page 985 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

Code No. 41 Shift actuator system (open circuit or

short-circuit)Probable cause

Code No. 41 is output to indicate anopencircuit or short-circuit in the shift

actuator if the transfer-ECU terminal voltage is higher than themainrelay

voltage (90% of the rated voltage), or lower than themainrelay voltage (10% of

the rated voltage) when shift operation is notbeingcarried out.DMalfunction of shift actuator

DMalfunction of harness or connector

DMalfunction of transfer-ECU

LRefer to the Transmission Workshop Manual.

NG

NG

NG

MUT-

IIData List

DNo. 12 Shift actuator voltage

OK:Refer to P.23-87 (Data List Chart).Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.) OK

OK NG

Check the harness between the shift actuator and the

transfer-ECU, and repair if necessary.Repair

OKOK

OK

OK

NG

NG

Replace the transfer-ECU.

Check the following connectors:C-11, E-105Measure at shift actuator connector C-11.

DDisconnect the connector and measure at the harness

side.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminals 2 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminal 1 and earth

OK:System voltage

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminal 1 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminals 3 and earth

OK:System voltage

Repair NG

Check the following connector:C-11Repair

Replace the shift actuator.

L

Check the following connector:E-105

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 986 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

Code No. 42 Shift actuator system (short-circuit)Probable cause

Code No. 43 Shift actuator system (open circuit)

Code No. 42 is output to indicate a short-circuit in the shift actuator if the shift

actuator current is +1 A greater than the target value while the actuator isbeing

driven.

Code No. 43 is output to indicate anopencircuit in the shift actuator if themain

relay voltage is lower than 6 V, or the shift actuator current is 0.1 A lower than

the actual value while the actuator isbeing driven.DMalfunction of shift actuator

DMalfunction of harness or connector

DMalfunction of transfer-ECU

LRefer to the Transmission Workshop Manual.

NG

NG

MUT-

IIData List

DNo. 10 Shift actuator voltage

OK:Refer to P.23-87 (Data List Chart).Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.) OK

OK NG

Check the harness between the shift actuator and the

transfer-ECU, and repair if necessary.Repair

Check the following connector:E-105

OK OK

NG

OK

OK

NG

NG

Check the trouble symptoms.

Replace the transfer-ECU.

Check the following connectors:C-11, E-105Measure at shift actuator connector C-11.

DDisconnect the connector and measure at the harness

side.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminals 2 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminal 1 and earth

OK:System voltage

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminal 1 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminals 3 and earth

OK:System voltage

Repair NG

Check the following connector:C-11Repair

Replace the shift actuator.

L

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 988 of 1839

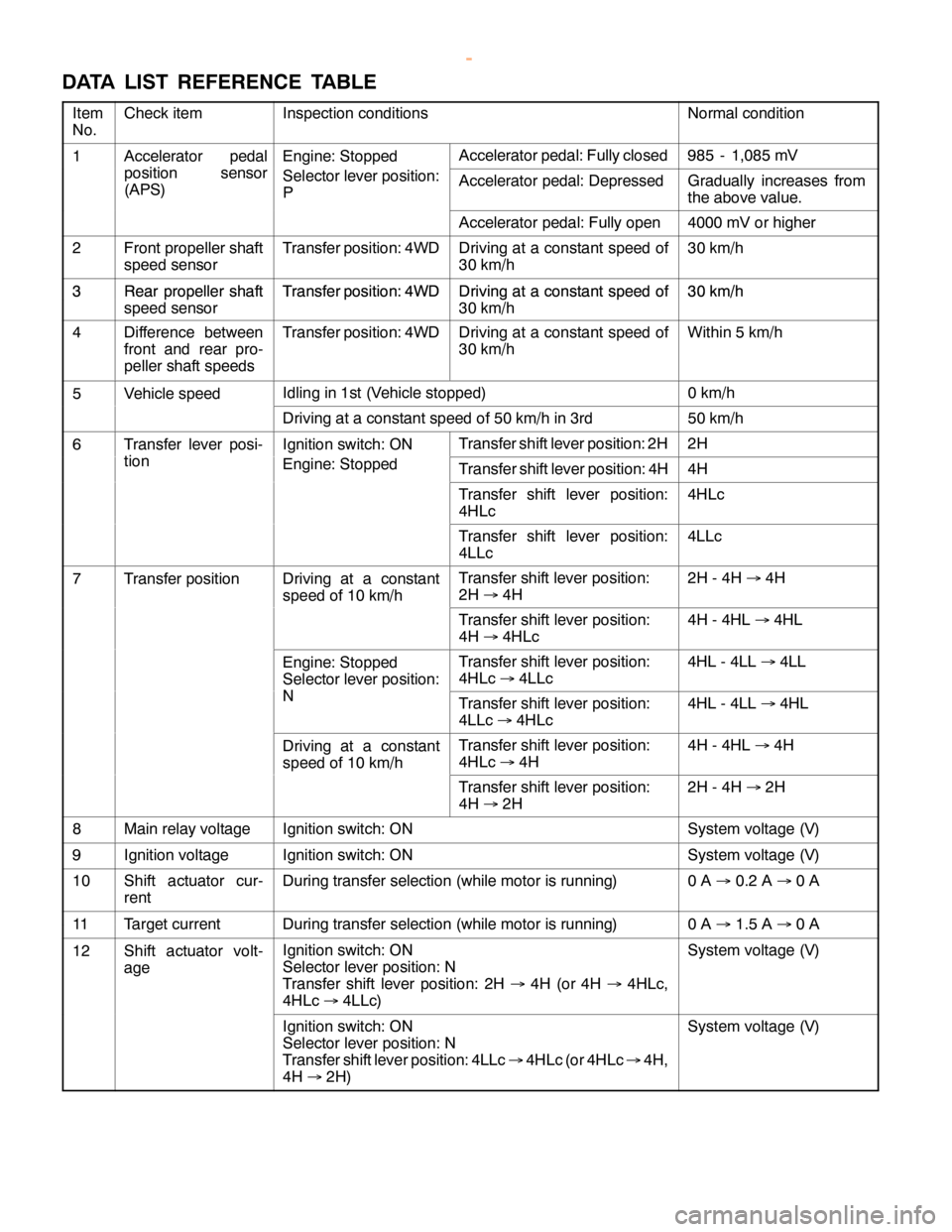

AUTOMATIC TRANSMISSION -Troubleshooting

DATA LIST REFERENCE TABLE

Item

No.Check itemInspection conditionsNormal condition

1Accelerator pedalEngine: StoppedAccelerator pedal: Fully closed985 - 1,085 mV

position sensor

(APS)Selector lever position:

PAccelerator pedal: DepressedGradually increases from

the above value.

Accelerator pedal: Fully open4000 mV or higher

2Front propeller shaft

speed sensorTransfer position: 4WDDriving at a constant speed of

30 km/h30 km/h

3Rear propeller shaftTransfer position: 4WDDriving at a constant speed of30 km/h3Rear propeller shaft

speed sensorTransfer position: 4WDDriving at a constant speed of

30 km/h30 km/h

4Difference between

front and rear pro-

peller shaft speedsTransfer position: 4WDDriving at a constant speed of

30 km/hWithin 5 km/h

5Vehicle speedIdling in 1st (Vehicle stopped)0 km/h

Driving at a constant speed of 50 km/h in 3rd50 km/h

6Transfer lever posi-Ignition switch: ONTransfer shift lever position: 2H2H

tionEngine: StoppedTransfer shift lever position: 4H4H

Transfer shift lever position:

4HLc4HLc

Transfer shift lever position:

4LLc4LLc

7Transfer positionDriving at a constant

speed of 10 km/hTransfer shift lever position:

2H®4H2H - 4H®4H

Transfer shift lever position:

4H®4HLc4H - 4HL®4HL

Engine: Stopped

Selector lever position:Transfer shift lever position:

4HLc®4LLc4HL - 4LL®4LL

NTransfer shift lever position:

4LLc®4HLc4HL - 4LL®4HL

Driving at a constant

speed of 10 km/hTransfer shift lever position:

4HLc®4H4H - 4HL®4H

Transfer shift lever position:

4H®2H2H - 4H®2H

8Main relay voltageIgnition switch: ONSystem voltage (V)

9Ignition voltageIgnition switch: ONSystem voltage (V)

10Shift actuator cur-

rentDuring transfer selection (while motor is running)0A®0.2 A®0A

11Target currentDuring transfer selection (while motor is running)0A®1.5 A®0A

12Shift actuator volt-

ageIgnition switch: ON

Selector lever position: N

Transfer shift lever position: 2H®4H (or 4H®4HLc,

4HLc®4LLc)System voltage (V)

Ignition switch: ON

Selector lever position: N

Transfer shift lever position: 4LLc®4HLc (or 4HLc®4H,

4H®2H)System voltage (V)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

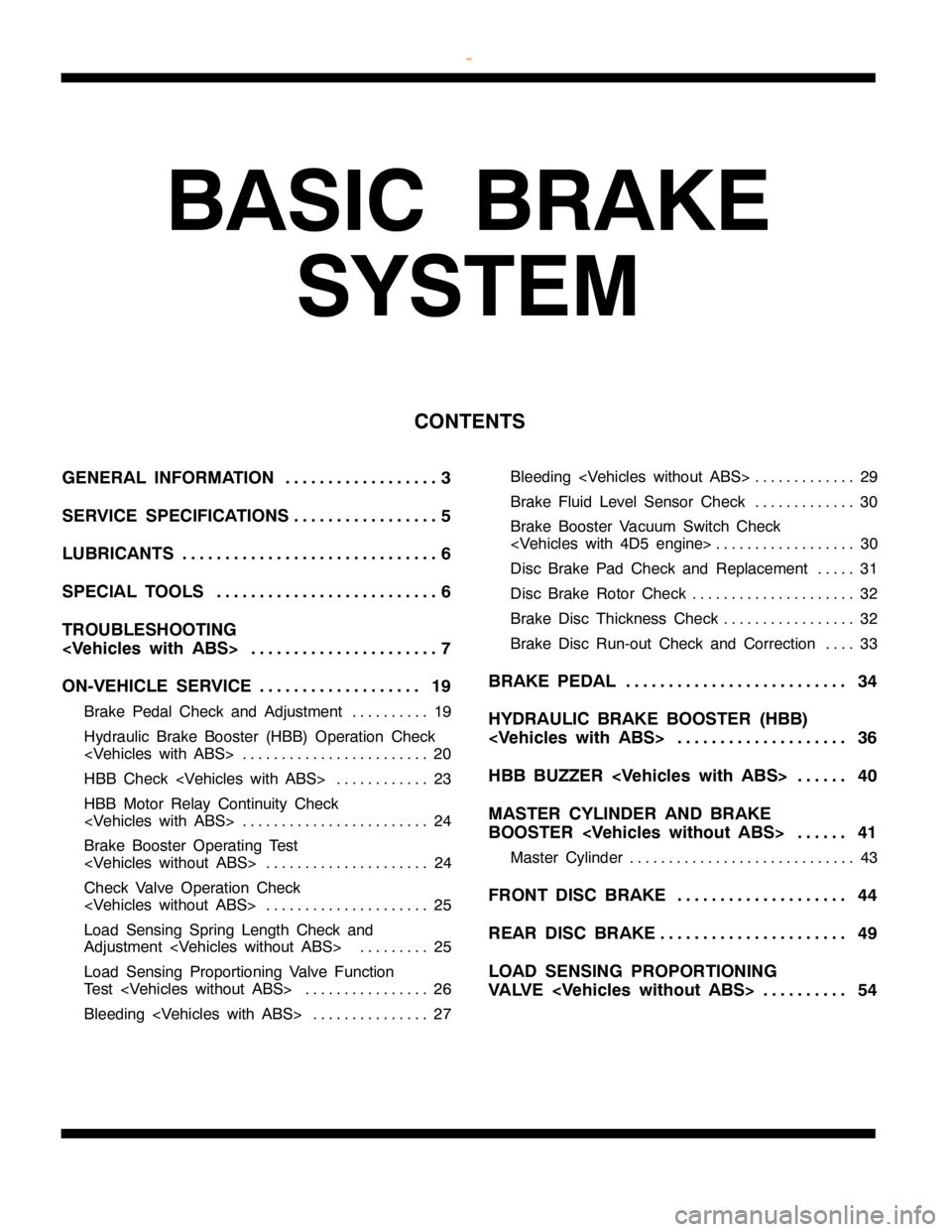

Page 1210 of 1839

35A-2

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 6..............................

SPECIAL TOOLS 6..........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 19...................

Brake Pedal Check and Adjustment 19..........

Hydraulic Brake Booster (HBB) Operation Check

HBB Check

HBB Motor Relay Continuity Check

Brake Booster Operating Test

Check Valve Operation Check

Load Sensing Spring Length Check and

Adjustment

Load Sensing Proportioning Valve Function

Test

Bleeding

Brake Fluid Level Sensor Check 30.............

Brake Booster Vacuum Switch Check

Disc Brake Pad Check and Replacement 31.....

Disc Brake Rotor Check 32.....................

Brake Disc Thickness Check 32.................

Brake Disc Run-out Check and Correction 33....

BRAKE PEDAL 34..........................

HYDRAULIC BRAKE BOOSTER (HBB)

HBB BUZZER

MASTER CYLINDER AND BRAKE

BOOSTER

Master Cylinder 43.............................

FRONT DISC BRAKE 44....................

REAR DISC BRAKE 49......................

LOAD SENSING PROPORTIONING

VALVE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1217 of 1839

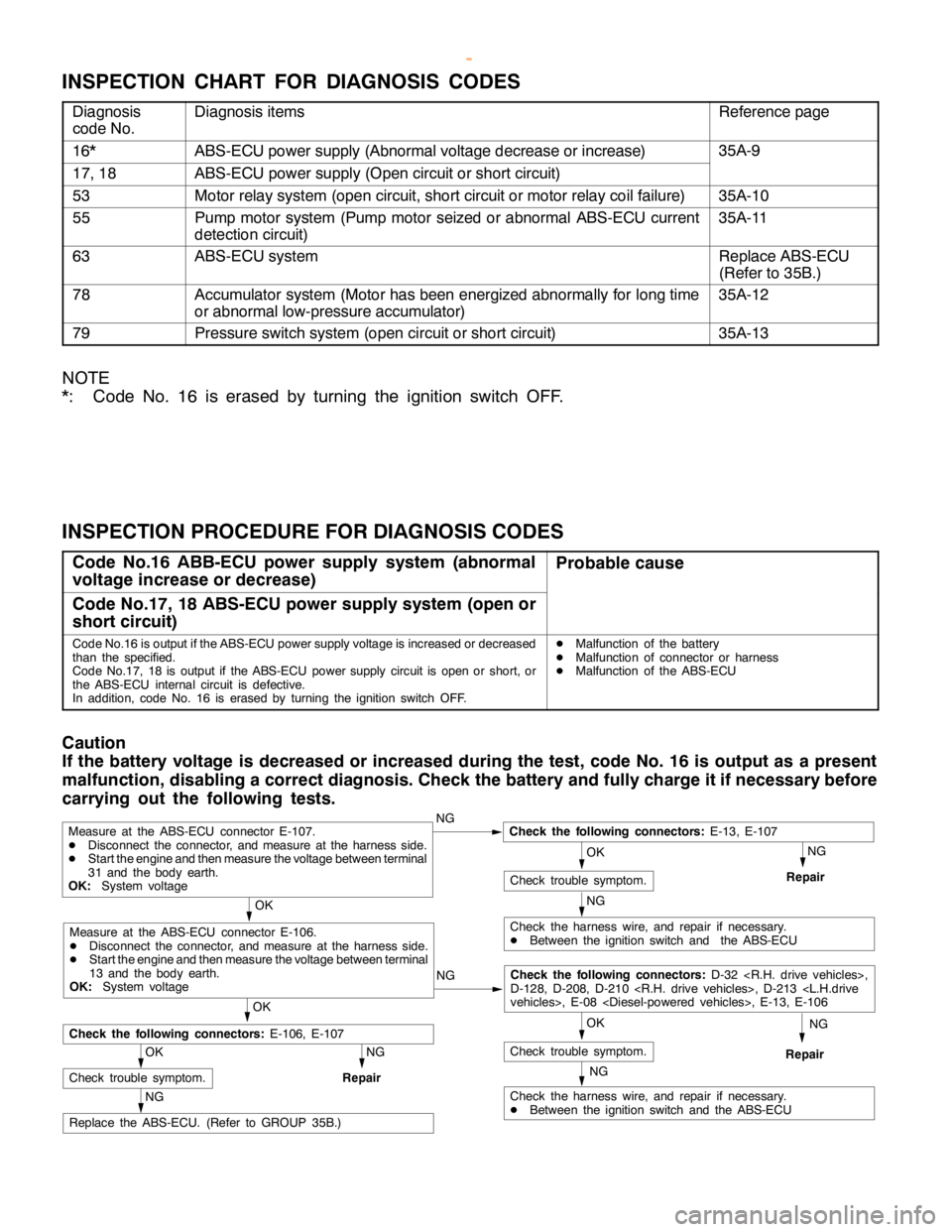

BASIC BRAKE SYSTEM -Troubleshooting35A-9

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

16*ABS-ECU power supply (Abnormal voltage decrease or increase)35A-9

17, 18ABS-ECU power supply (Open circuit or short circuit)

53Motor relay system (open circuit, short circuit or motor relay coil failure)35A-10

55Pump motor system (Pump motor seized or abnormal ABS-ECU current

detection circuit)35A-11

63ABS-ECU systemReplace ABS-ECU

(Refer to 35B.)

78Accumulator system (Motor has been energized abnormally for long time

or abnormal low-pressure accumulator)35A-12

79Pressure switch system (open circuit or short circuit)35A-13

NOTE

*: Code No. 16 is erased by turning the ignition switch OFF.

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.16 ABB-ECU power supply system (abnormal

voltage increase or decrease)Probable cause

Code No.17, 18 ABS-ECU power supply system (open or

short circuit)

Code No.16 is output if the ABS-ECU power supply voltage is increased or decreased

than the specified.

Code No.17, 18 is output if the ABS-ECU power supply circuit isopen orshort, or

the ABS-ECU internal circuit is defective.

In addition, code No. 16 is erased by turning the ignition switch OFF.DMalfunction of the battery

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

Caution

If the battery voltage is decreased or increased during the test, code No. 16 is output as a present

malfunction, disabling a correct diagnosis. Check the battery and fully charge it if necessary before

carrying out the following tests.

NG

NG

OK

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

OK

Check trouble symptom.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-107.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

31 and the body earth.

OK:System voltageNGCheck the following connectors:E-13, E-107

Repair

OK

Check the following connectors:E-106, E-107

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-106.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

13 and the body earth.

OK:System voltageNG

Check the following connectors:D-32

D-128, D-208, D-210

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

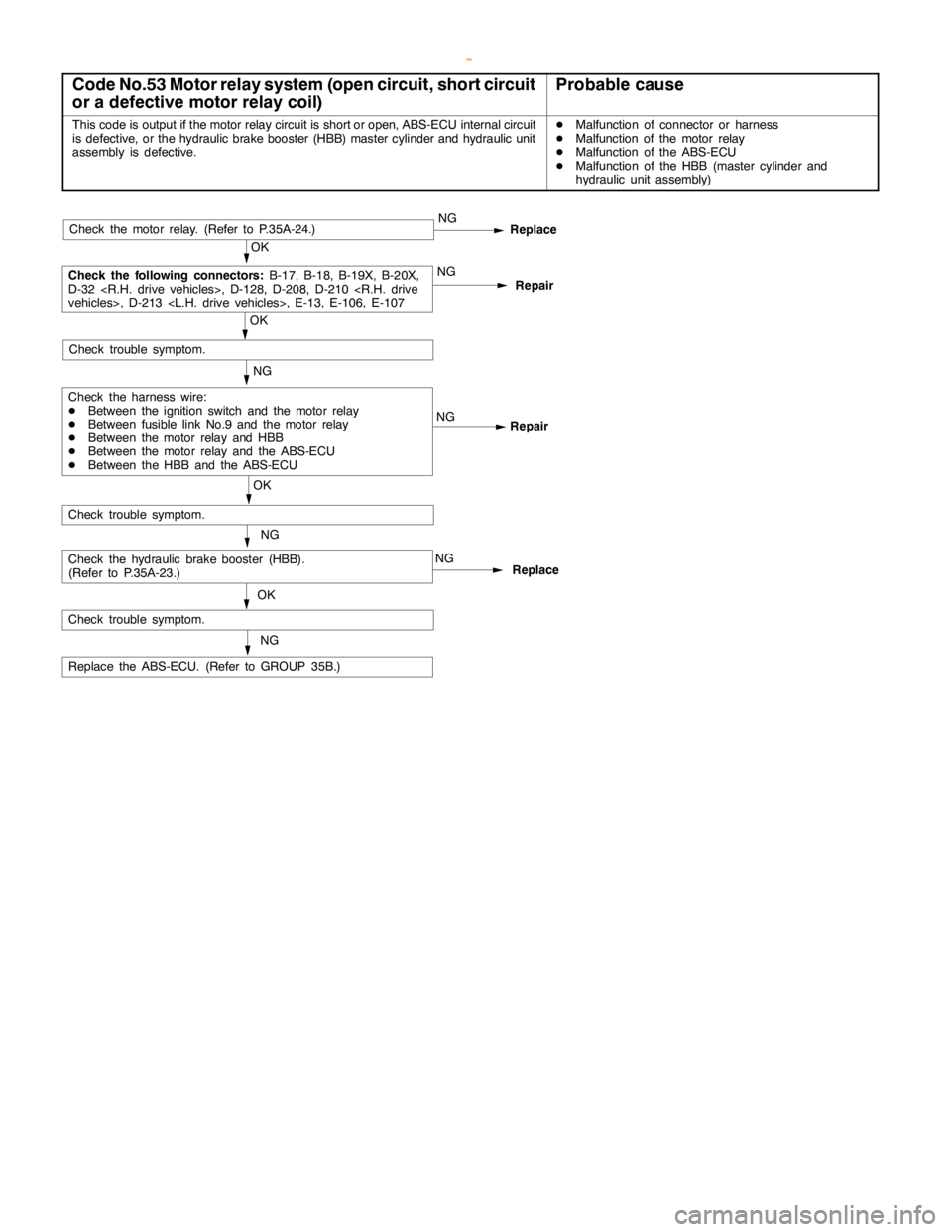

Page 1218 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-10

Code No.53 Motor relay system (open circuit, short circuit

or a defective motor relay coil)Probable cause

This code is output if the motor relay circuit is short or open, ABS-ECU internal circuit

is defective, or the hydraulic brake booster (HBB) master cylinder and hydraulic unit

assembly is defective.DMalfunction of connector or harness

DMalfunction of the motor relay

DMalfunction of the ABS-ECU

DMalfunction of the HBB (master cylinder and

hydraulic unit assembly)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

D-32

Check the harness wire:

DBetween the ignition switch and the motor relay

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the motor relay and the ABS-ECU

DBetween the HBB and the ABS-ECU

Check trouble symptom.

NG

NG

Replace

OK

Check the motor relay. (Refer to P.35A-24.)

Check the hydraulic brake booster (HBB).

(Refer to P.35A-23.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

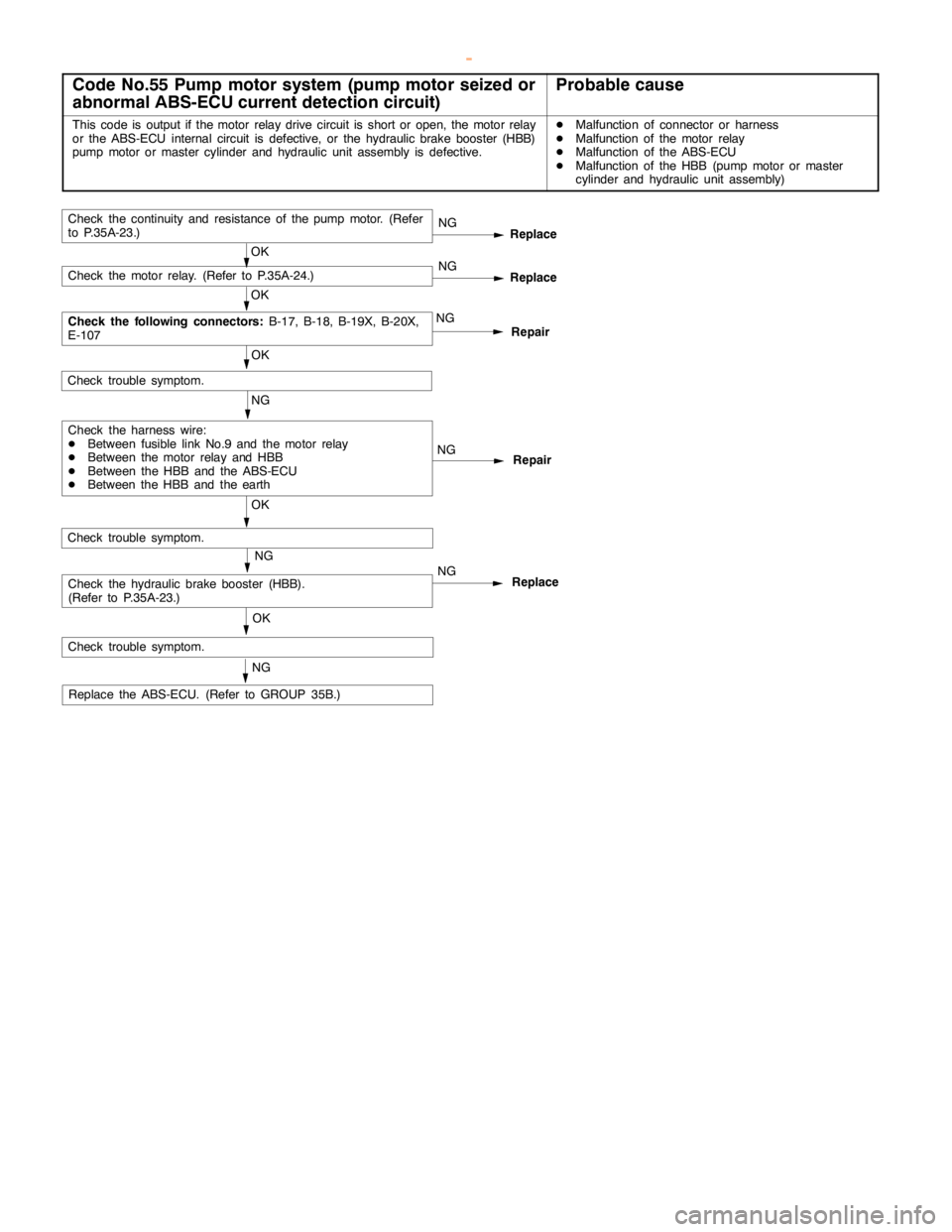

Page 1219 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-11

Code No.55 Pump motor system (pump motor seized or

abnormal ABS-ECU current detection circuit)Probable cause

This code is output if the motor relay drive circuit is short or open, the motor relay

or the ABS-ECU internal circuit is defective, or the hydraulic brake booster (HBB)

pump motor ormaster cylinder and hydraulic unit assembly is defective.DMalfunction of connector or harness

DMalfunction of the motor relay

DMalfunction of the ABS-ECU

DMalfunction of the HBB (pump motor or master

cylinder and hydraulic unit assembly)

NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

E-107

Check the harness wire:

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check the motor relay. (Refer to P.35A-24.)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

Check trouble symptom.

NG

OKCheck the hydraulic brake booster (HBB).

(Refer to P.35A-23.)Replace NG

Replace

OKCheck the continuity and resistance of thepump motor.(Refer

to P.35A-23.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1220 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-12

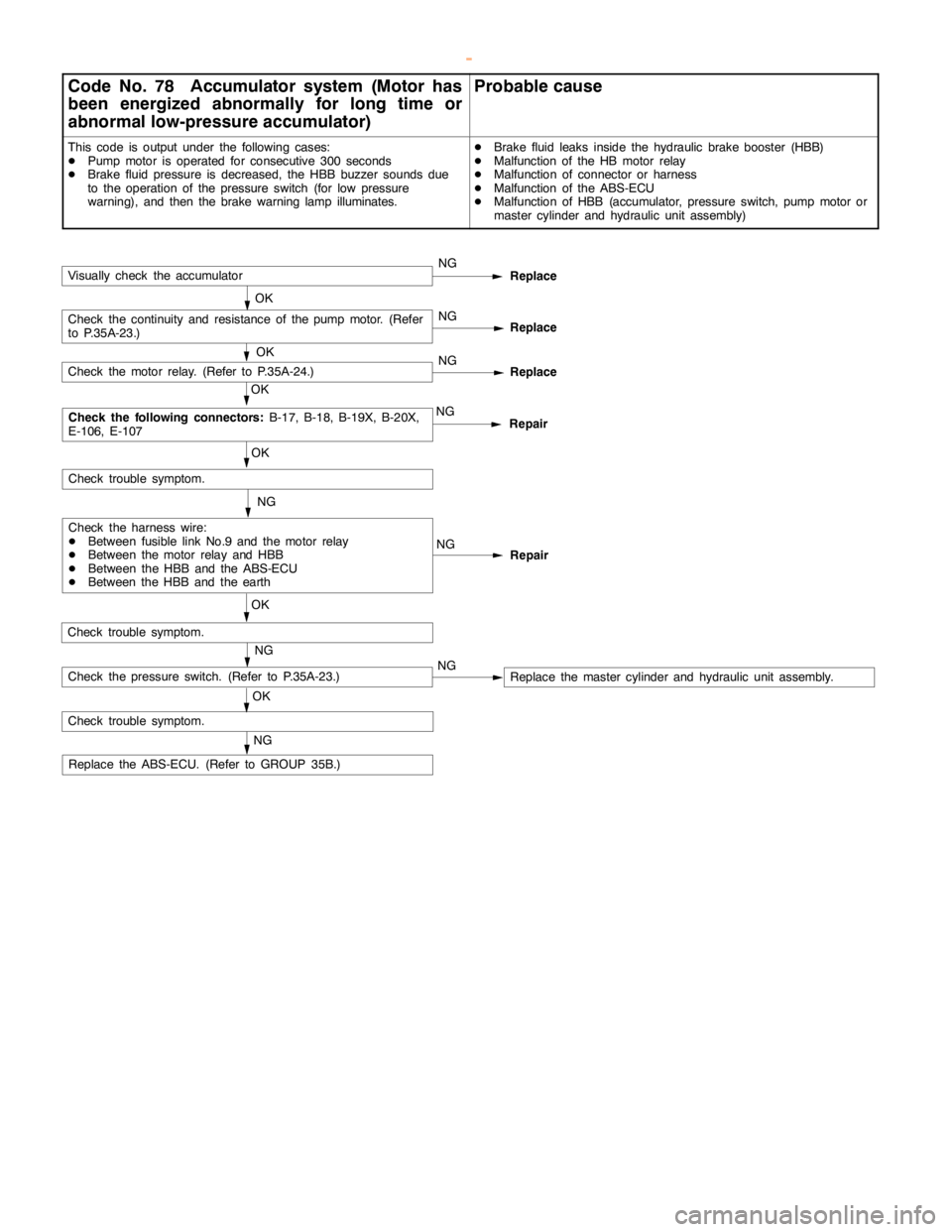

Code No. 78 Accumulator system (Motor has

been energized abnormally for long time or

abnormal low-pressure accumulator)Probable cause

This code is output under the following cases:

DPump motor is operated for consecutive 300 seconds

DBrake fluid pressure is decreased, the HBB buzzer sounds due

to the operation of the pressure switch (for low pressure

warning), and then the brake warninglamp illuminates.DBrake fluid leaks inside the hydraulic brake booster (HBB)

DMalfunction of the HB motor relay

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

DMalfunction of HBB (accumulator, pressure switch,pump motor or

master cylinder and hydraulic unit assembly)

NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

E-106, E-107

Check the harness wire:

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check the motor relay. (Refer to P.35A-24.)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

Check trouble symptom.

NG

OKCheck the pressure switch. (Refer to P.35A-23.)NG

Replace

OKCheck the continuity and resistance of thepump motor.(Refer

to P.35A-23.)NG

Replace

OKVisually check the accumulator

Replace the master cylinder and hydraulic unit assembly.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk