relay MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 612 of 1839

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 625 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-15

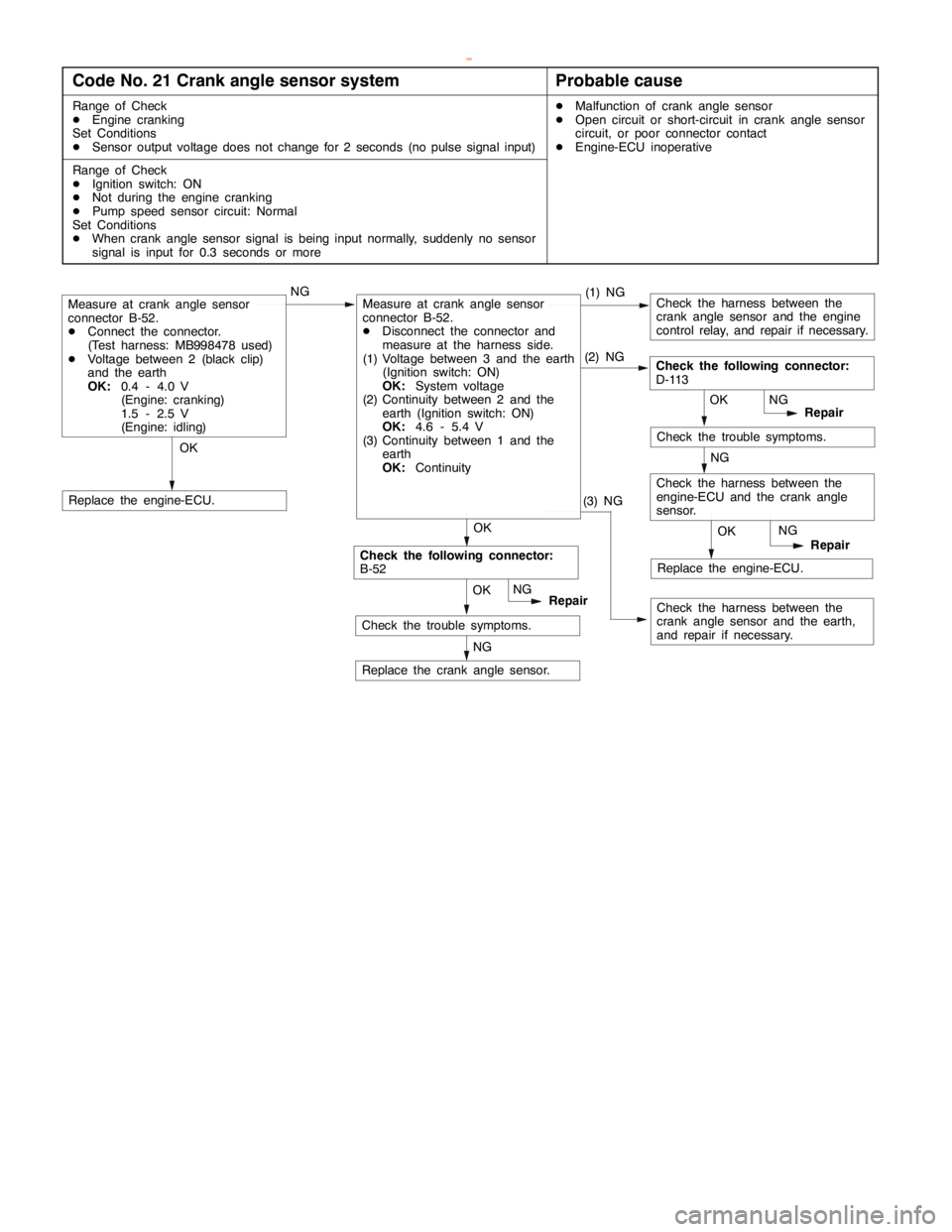

Code No. 21 Crank angle sensor systemProbable cause

Range of Check

DEngine cranking

Set Conditions

DSensor output voltage does not change for 2 seconds (no pulse signal input)DMalfunction of crank angle sensor

DOpen circuit or short-circuit in crank angle sensor

circuit, or poor connector contact

DEngine-ECU inoperative

Range of Check

DIgnition switch: ON

DNot during the engine cranking

DPump speed sensor circuit: Normal

Set Conditions

DWhen crank angle sensor signal is being input normally, suddenly no sensor

signal is input for 0.3 seconds or more

OK

Check the harness between the

crank angle sensor and the engine

control relay, and repair if necessary.

OKNG(1) NGMeasure at crank angle sensor

connector B-52.

DConnect the connector.

(Test harness: MB998478 used)

DVoltage between 2 (black clip)

and the earth

OK:0.4 - 4.0 V

(Engine: cranking)

1.5 - 2.5 V

(Engine: idling)

NG

Replace the crank angle sensor.

Replace the engine-ECU.

OKRepair

Check the following connector:

D-113

NG

OK

Repair NG

Check the harness between the

engine-ECU and the crank angle

sensor.NG

Check the trouble symptoms.

Replace the engine-ECU.

Check the harness between the

crank angle sensor and the earth,

and repair if necessary. OKRepair NG

Check the following connector:

B-52

Check the trouble symptoms.

Measure at crank angle sensor

connector B-52.

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 3 and the earth

(Ignition switch: ON)

OK:System voltage

(2) Continuity between 2 and the

earth (Ignition switch: ON)

OK:4.6 - 5.4 V

(3) Continuity between 1 and the

earth

OK:Continuity(2) NG

(3) NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 630 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-20

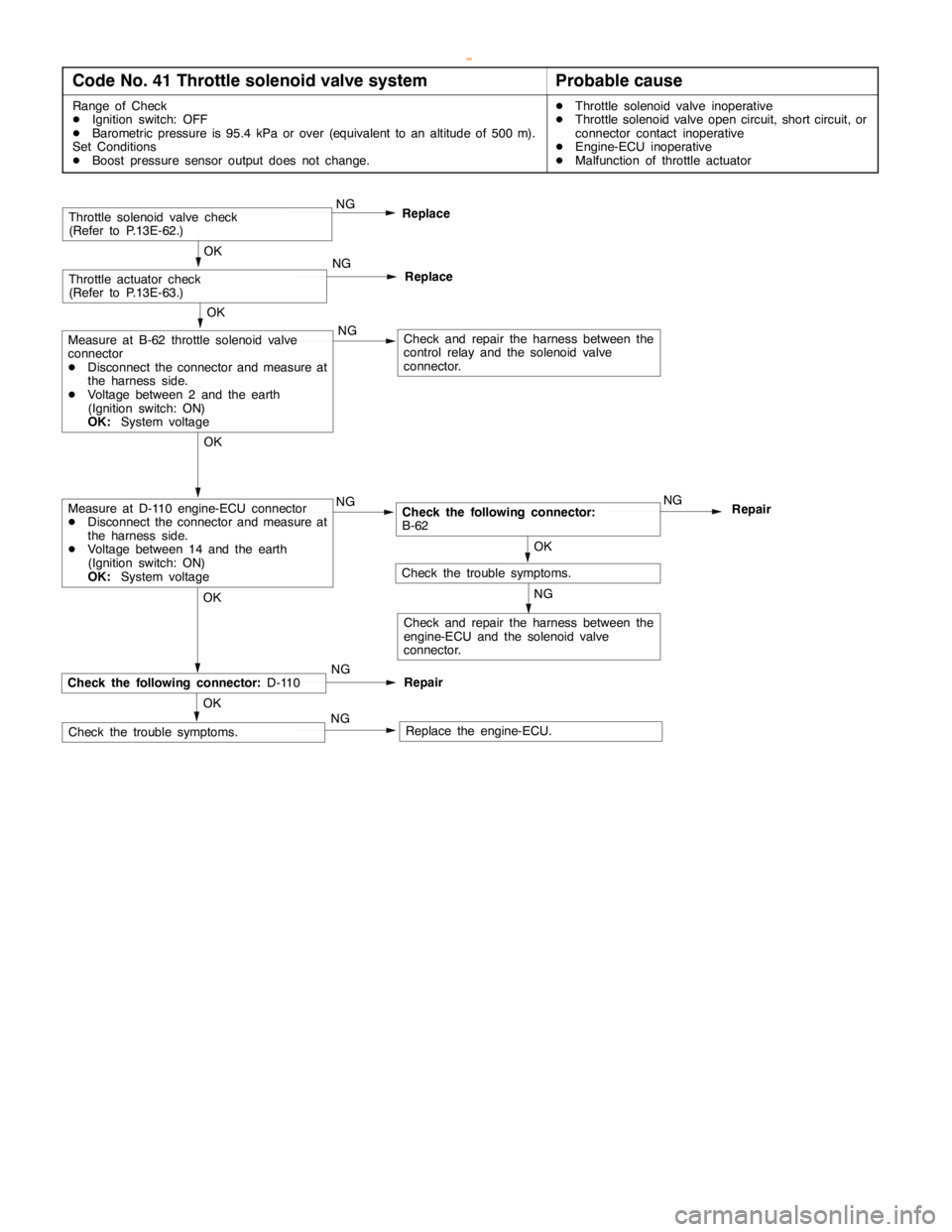

Code No. 41 Throttle solenoid valve systemProbable cause

Range of Check

DIgnition switch: OFF

DBarometric pressure is 95.4 kPa or over (equivalent to an altitude of 500 m).

Set Conditions

DBoost pressure sensor output does not change.DThrottle solenoid valve inoperative

DThrottle solenoid valve open circuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

DMalfunction of throttle actuator

Check and repair the harness between the

engine-ECU and the solenoid valve

connector.

NG

OK

Check the trouble symptoms.

OK

Check and repair the harness between the

control relay and the solenoid valve

connector. NG

OKMeasure at B-62 throttle solenoid valve

connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 2 and the earth

(Ignition switch: ON)

OK:System voltage

OK

Replace

Throttle actuator check

(Refer to P.13E-63.)NG

OK

Throttle solenoid valve check

(Refer to P.13E-62.)

Replace the engine-ECU. OK

RepairCheck the following connector:D-110

Check the trouble symptoms.NGReplace NG

Check the following connector:

B-62NG

RepairNGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 14 and the earth

(Ignition switch: ON)

OK:System voltage

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 631 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-21

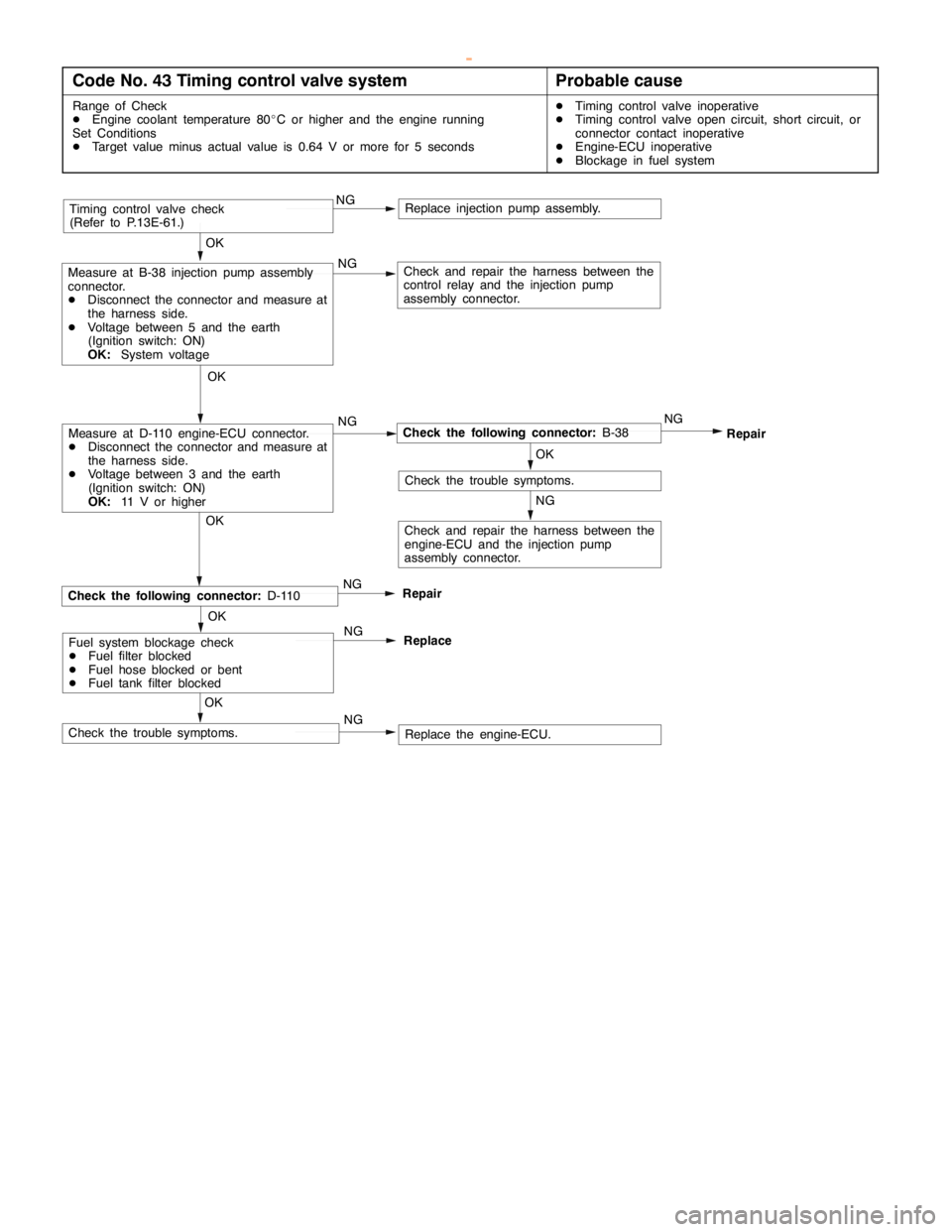

Code No. 43 Timing control valve systemProbable cause

Range of Check

DEngine coolant temperature 80_C or higher and the engine running

Set Conditions

DTarget value minus actual value is 0.64 V or more for 5 secondsDTiming control valve inoperative

DTiming control valve open circuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

DBlockage in fuel system

OK

OK

Check and repair the harness between the

control relay and the injection pump

assembly connector.

Timing control valve check

(Refer to P.13E-61.)

Replace the engine-ECU. OK

RepairCheck the following connector:D-110

Check the trouble symptoms.NG NG NG

Check the following connector:B-38NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:11 V or higherOK

Measure at B-38 injection pump assembly

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 5 and the earth

(Ignition switch: ON)

OK:System voltage

Replace injection pump assembly.

Check and repair the harness between the

engine-ECU and the injection pump

assembly connector.

Fuel system blockage check

DFuel filter blocked

DFuel hose blocked or bent

DFuel tank filter blockedOK

Replace NG

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 633 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-23

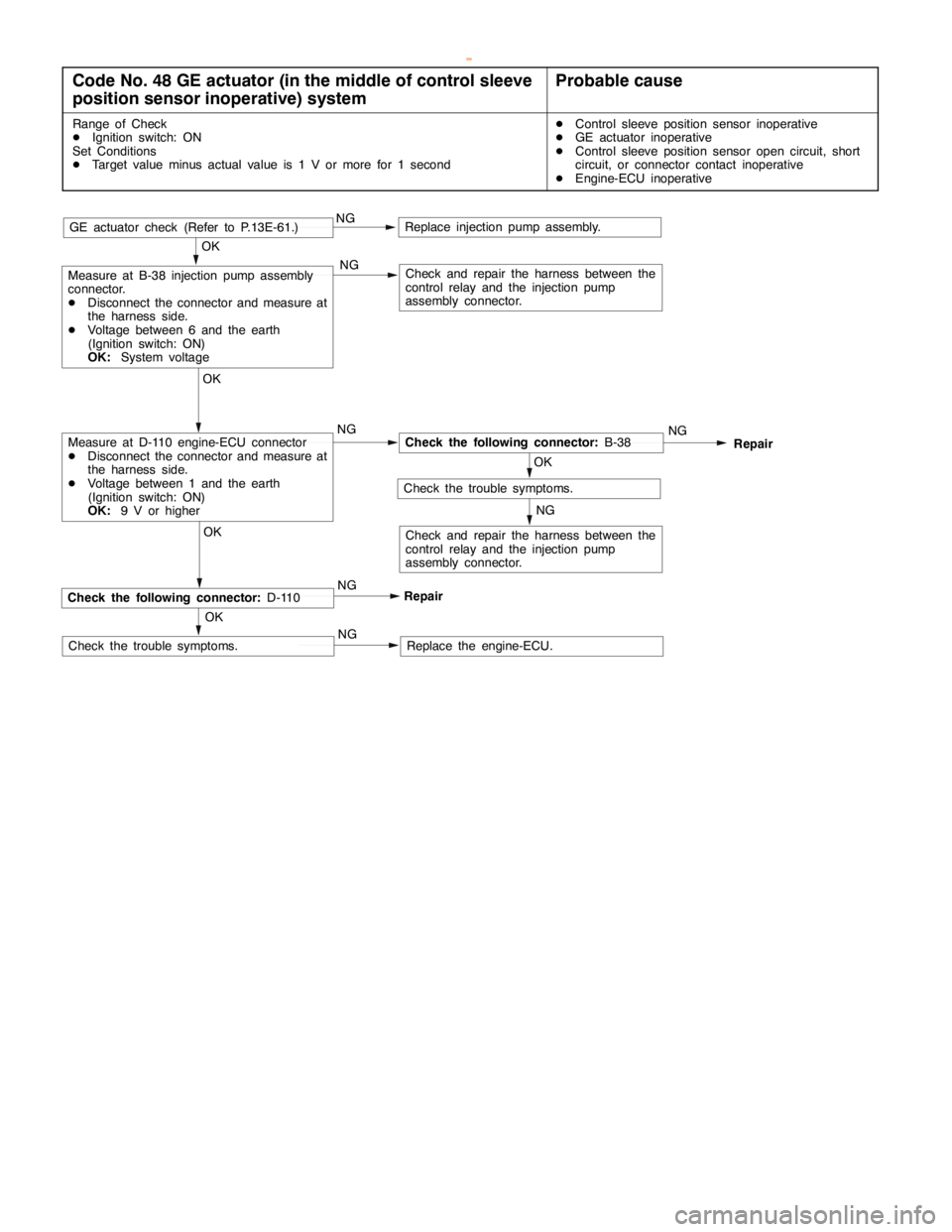

Code No. 48 GE actuator (in the middle of control sleeve

position sensor inoperative) systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DTarget value minus actual value is 1 V or more for 1 secondDControl sleeve position sensor inoperative

DGE actuator inoperative

DControl sleeve position sensor open circuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

OK

Check and repair the harness between the

control relay and the injection pump

assembly connector.

GE actuator check (Refer to P.13E-61.)

Replace the engine-ECU. OK

RepairCheck the following connector:D-110

Check the trouble symptoms.NGNG NG

Check the following connector:B-38NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:9 V or higherOK

Measure at B-38 injection pump assembly

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 6 and the earth

(Ignition switch: ON)

OK:System voltage

Replace injection pump assembly.

Check and repair the harness between the

control relay and the injection pump

assembly connector.

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 634 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-24

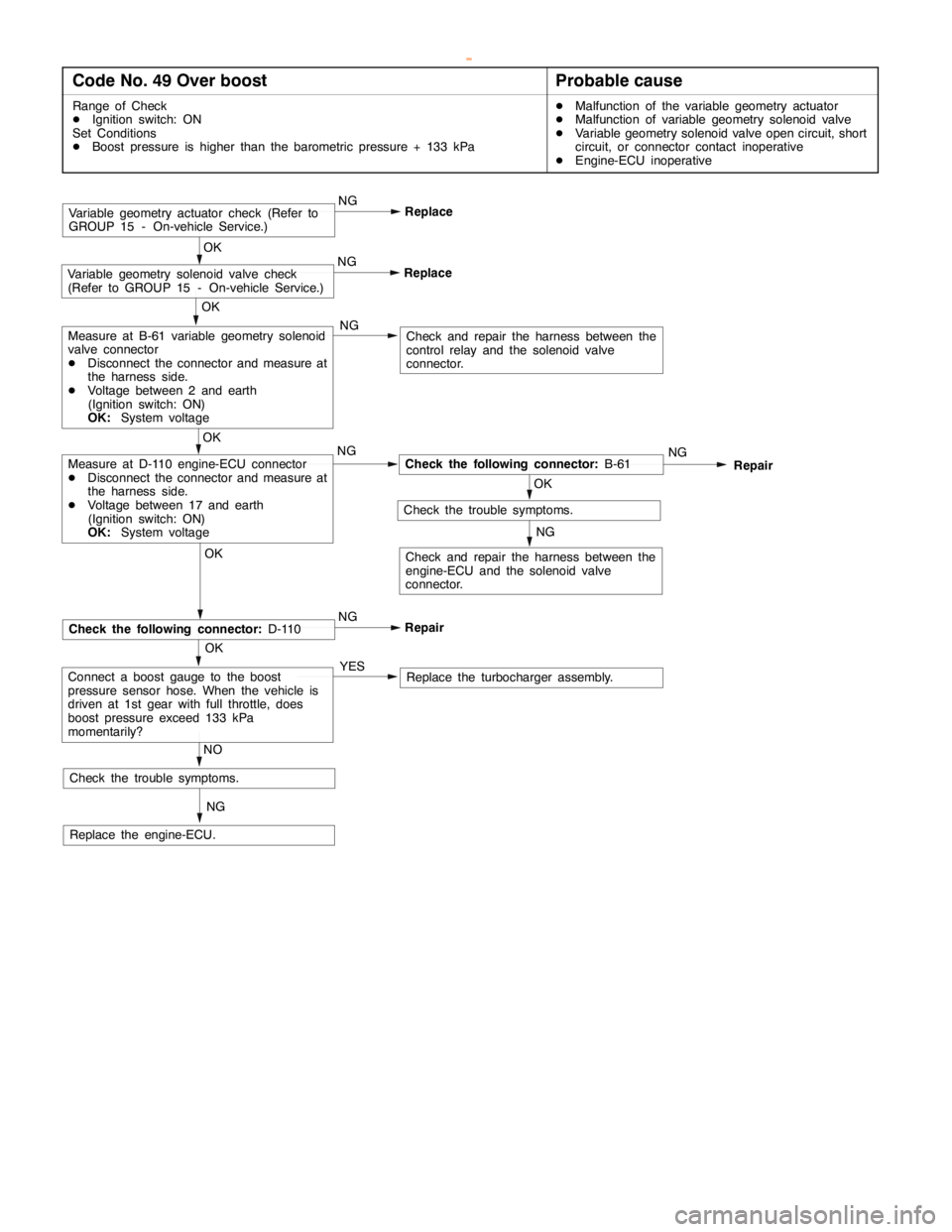

Code No. 49 Over boostProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DBoost pressure is higher than the barometric pressure + 133 kPaDMalfunction of the variable geometry actuator

DMalfunction of variable geometry solenoid valve

DVariable geometry solenoid valve open circuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OKOK

Check and repair the harness between the

control relay and the solenoid valve

connector.

Replace the engine-ECU.OK

ReplaceVariable geometry solenoid valve check

(Refer to GROUP 15 - On-vehicle Service.)

Check the trouble symptoms.NG

NG

Check the following connector:B-61NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 17 and earth

(Ignition switch: ON)

OK:System voltageOK

Measure at B-61 variable geometry solenoid

valve connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 2 and earth

(Ignition switch: ON)

OK:System voltage

Check and repair the harness between the

engine-ECU and the solenoid valve

connector.

ReplaceVariable geometry actuator check (Refer to

GROUP 15 - On-vehicle Service.)NG

OK

Repair

Check the following connector:D-110NG

NG

Replace the turbocharger assembly. YESConnect a boost gauge to the boost

pressure sensor hose. When the vehicle is

driven at 1st gear with full throttle, does

boost pressure exceed 133 kPa

momentarily?

NO

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 641 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-31

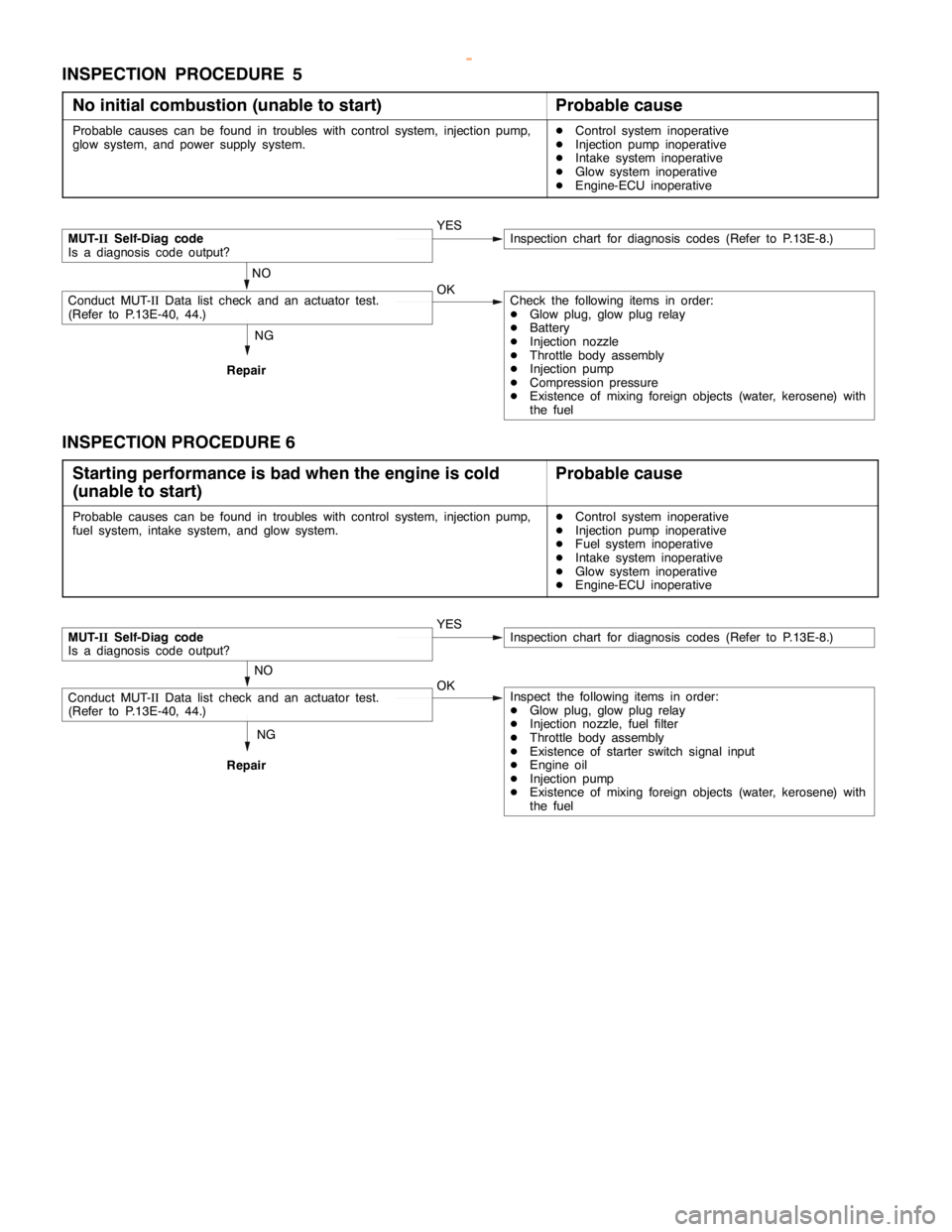

INSPECTION PROCEDURE 5

No initial combustion (unable to start)

Probable cause

Probable causes can be found in troubles with control system, injection pump,

glow system, and power supply system.DControl system inoperative

DInjection pump inoperative

DIntake system inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKCheck the following items in order:

DGlow plug, glow plug relay

DBattery

DInjection nozzle

DThrottle body assembly

DInjection pump

DCompression pressure

DExistence of mixing foreign objects (water, kerosene) with

the fuel

INSPECTION PROCEDURE 6

Starting performance is bad when the engine is cold

(unable to start)

Probable cause

Probable causes can be found in troubles with control system, injection pump,

fuel system, intake system, and glow system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DGlow plug, glow plug relay

DInjection nozzle, fuel filter

DThrottle body assembly

DExistence of starter switch signal input

DEngine oil

DInjection pump

DExistence of mixing foreign objects (water, kerosene) with

the fuel

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 643 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-33

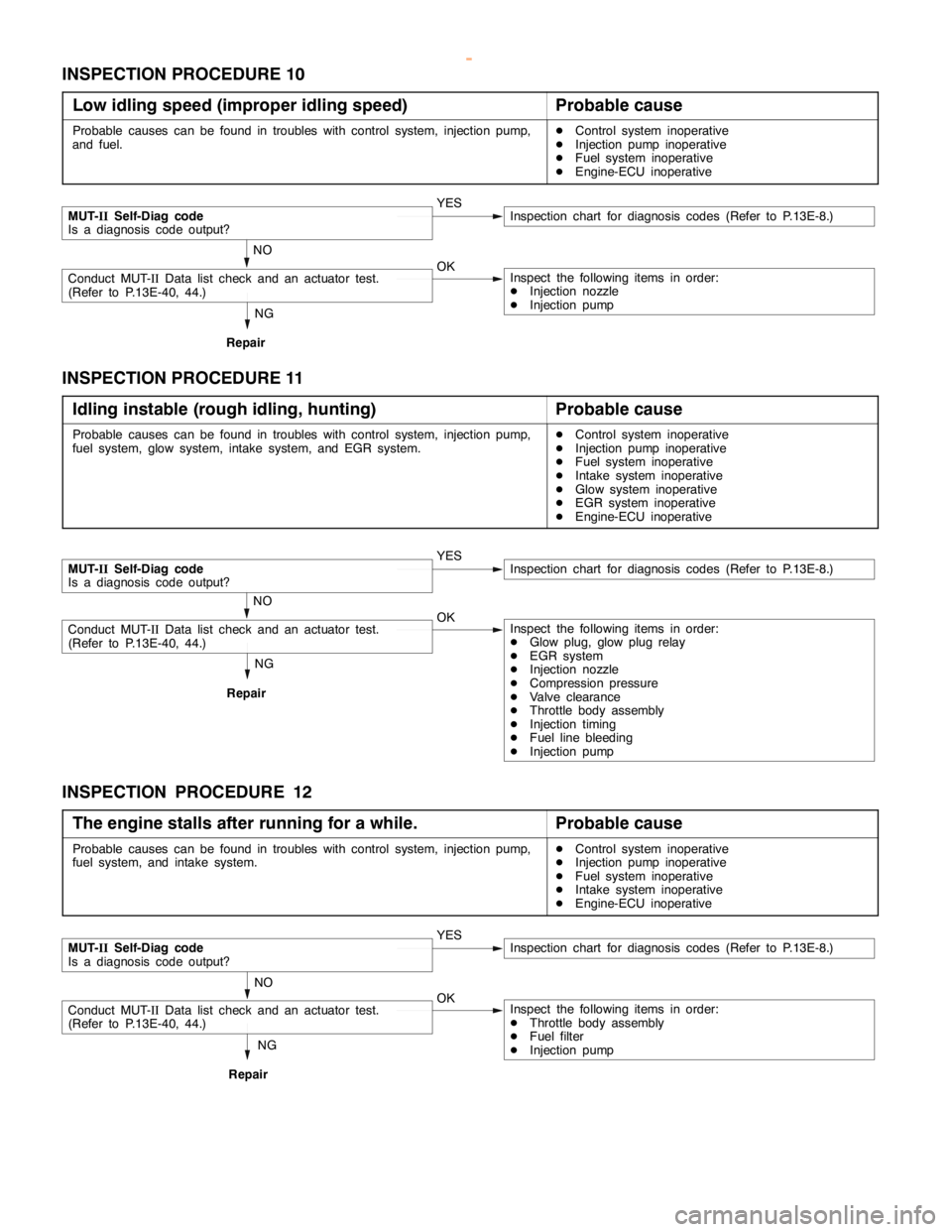

INSPECTION PROCEDURE 10

Low idling speed (improper idling speed)

Probable cause

Probable causes can be found in troubles with control system, injection pump,

and fuel.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DInjection nozzle

DInjection pump

INSPECTION PROCEDURE 11

Idling instable (rough idling, hunting)

Probable cause

Probable causes can be found in troubles with control system, injection pump,

fuel system, glow system, intake system, and EGR system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DGlow system inoperative

DEGR system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DGlow plug, glow plug relay

DEGR system

DInjection nozzle

DCompression pressure

DValve clearance

DThrottle body assembly

DInjection timing

DFuel line bleeding

DInjection pump

INSPECTION PROCEDURE 12

The engine stalls after running for a while.

Probable cause

Probable causes can be found in troubles with control system, injection pump,

fuel system, and intake system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DThrottle body assembly

DFuel filter

DInjection pump

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 645 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-35

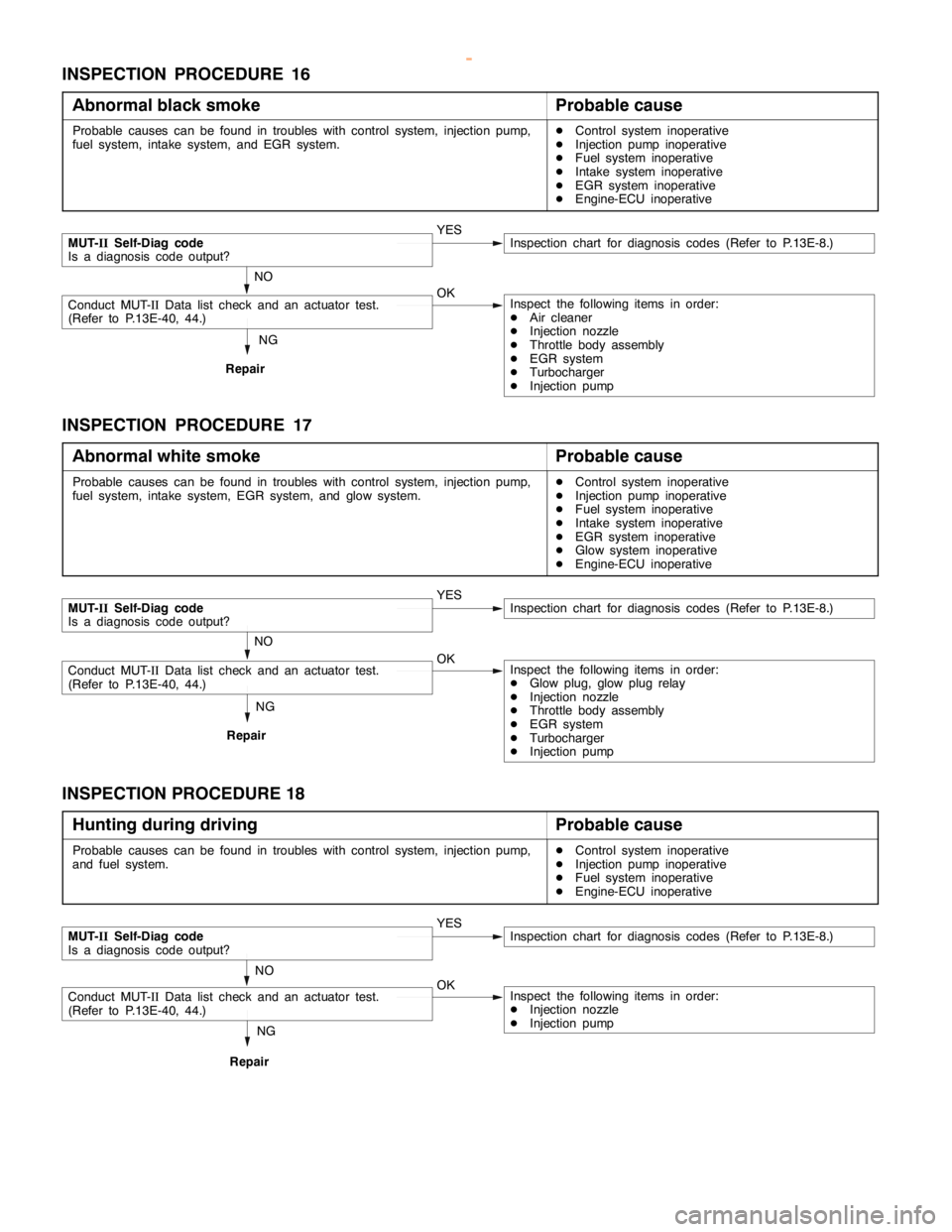

INSPECTION PROCEDURE 16

Abnormal black smoke

Probable cause

Probable causes can be found in troubles with control system, injection pump,

fuel system, intake system, and EGR system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEGR system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DAir cleaner

DInjection nozzle

DThrottle body assembly

DEGR system

DTurbocharger

DInjection pump

INSPECTION PROCEDURE 17

Abnormal white smoke

Probable cause

Probable causes can be found in troubles with control system, injection pump,

fuel system, intake system, EGR system, and glow system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEGR system inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DGlow plug, glow plug relay

DInjection nozzle

DThrottle body assembly

DEGR system

DTurbocharger

DInjection pump

INSPECTION PROCEDURE 18

Hunting during driving

Probable cause

Probable causes can be found in troubles with control system, injection pump,

and fuel system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13E-8.)

NO

Conduct MUT-IIData list check and an actuator test.

(Refer to P.13E-40, 44.)OKInspect the following items in order:

DInjection nozzle

DInjection pump

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 646 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-36

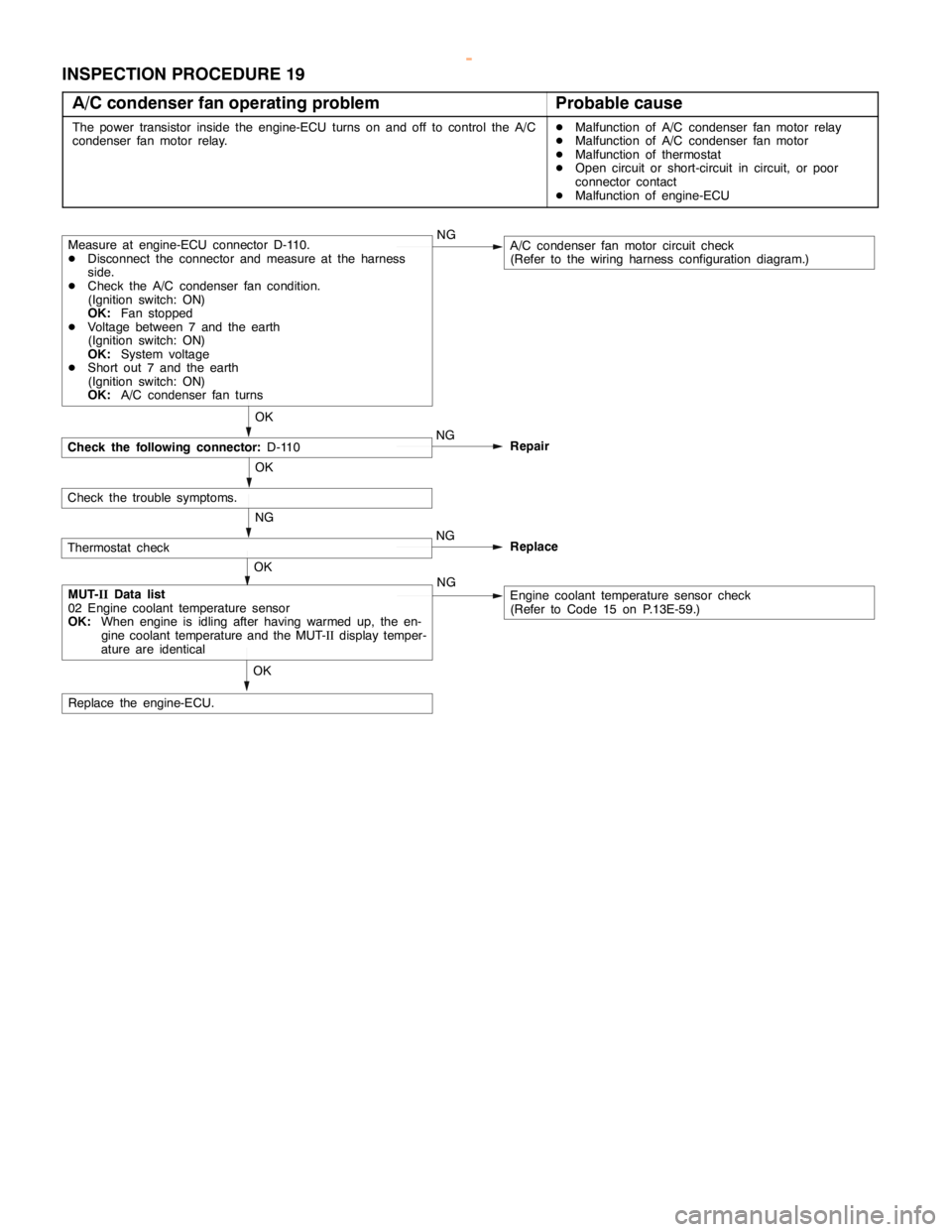

INSPECTION PROCEDURE 19

A/C condenser fan operating problem

Probable cause

The power transistor inside the engine-ECU turns on and off to control the A/C

condenser fan motor relay.DMalfunction of A/C condenser fan motor relay

DMalfunction of A/C condenser fan motor

DMalfunction of thermostat

DOpen circuit or short-circuit in circuit, or poor

connector contact

DMalfunction of engine-ECU

Check the following connector:D-110

OK

Measure at engine-ECU connector D-110.

DDisconnect the connector and measure at the harness

side.

DCheck the A/C condenser fan condition.

(Ignition switch: ON)

OK:Fan stopped

DVoltage between 7 and the earth

(Ignition switch: ON)

OK:System voltage

DShort out 7 and the earth

(Ignition switch: ON)

OK:A/C condenser fan turnsNGA/C condenser fan motor circuit check

(Refer to the wiring harness configuration diagram.)

OK

MUT-IIData list

02 Engine coolant temperature sensor

OK:When engine is idling after having warmed up, the en-

gine coolant temperature and the MUT-IIdisplay temper-

ature are identicalNGEngine coolant temperature sensor check

(Refer to Code 15 on P.13E-59.)

Check the trouble symptoms.OK

Replace the engine-ECU.NG

Repair

Thermostat checkNG

NGReplace

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk