relay MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 528 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-37

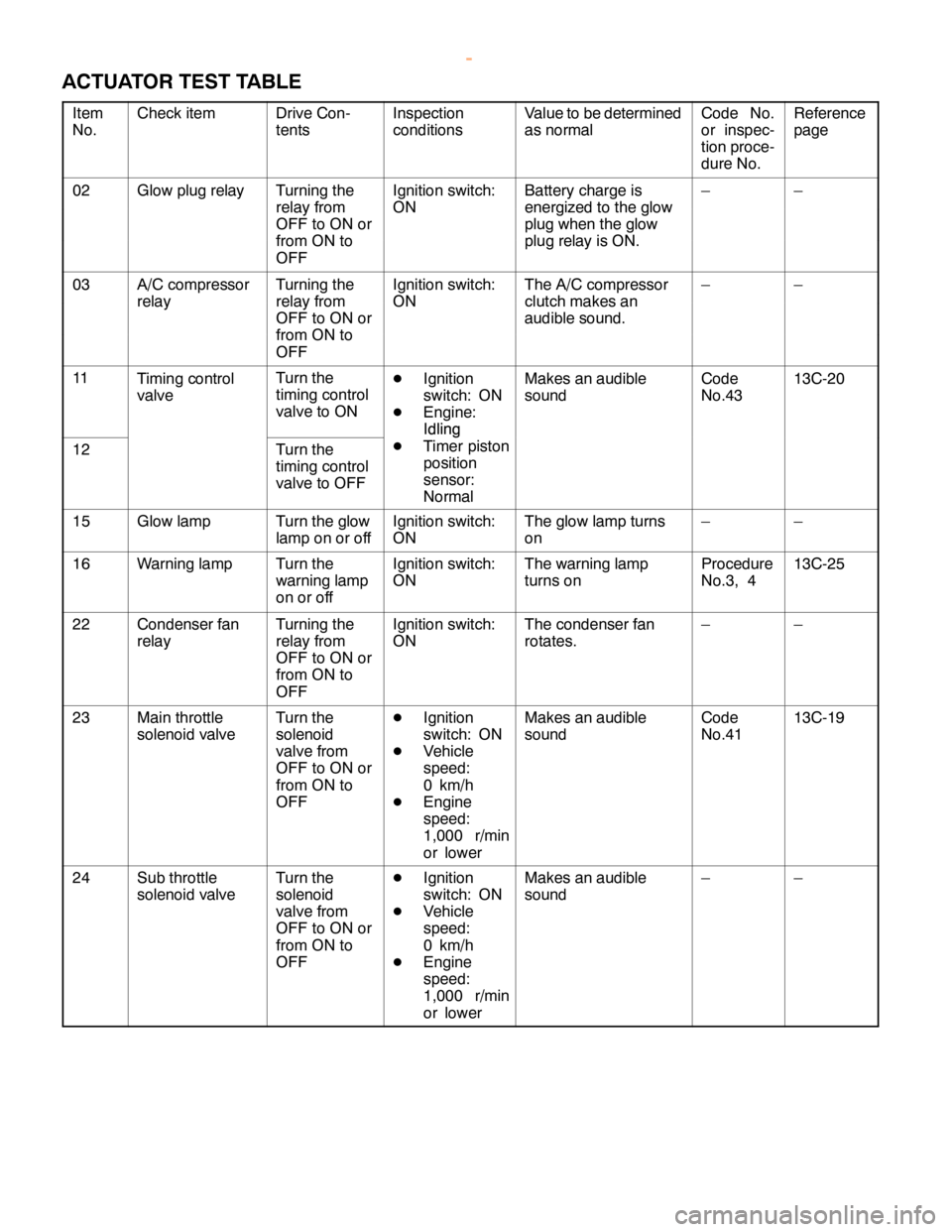

ACTUATOR TEST TABLE

Item

No.Check itemDrive Con-

tentsInspection

conditionsValue to be determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

02Glow plug relayTurning theIgnition switch:Battery charge is––

relay from

OFF to ON orONenergized to the glow

plug when the glow

from ON to

OFFplug relay is ON.

03A/C compressorTurning theIgnition switch:The A/C compressor––

relayrelay from

OFF to ON orONclutch makes an

audible sound.

from ON to

OFF

11Timing control

valveTurn the

timing control

valve to ONDIgnition

switch: ON

DEngine:

IdlingMakes an audible

soundCode

No.4313C-20

12Turn the

timing control

valve to OFF

Idling

DTimer piston

position

sensor:

Normal

15Glow lampTurn the glow

lamp on or offIgnition switch:

ONThe glow lamp turns

on––

16Warning lampTurn the

warning lamp

on or offIgnition switch:

ONThe warning lamp

turns onProcedure

No.3, 413C-25

22Condenser fan

relayTurning the

relay from

OFF to ON or

from ON to

OFFIgnition switch:

ONThe condenser fan

rotates.––

23Main throttle

solenoid valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

soundCode

No.4113C-19

24Sub throttle

solenoid valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

sound––

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 529 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-38

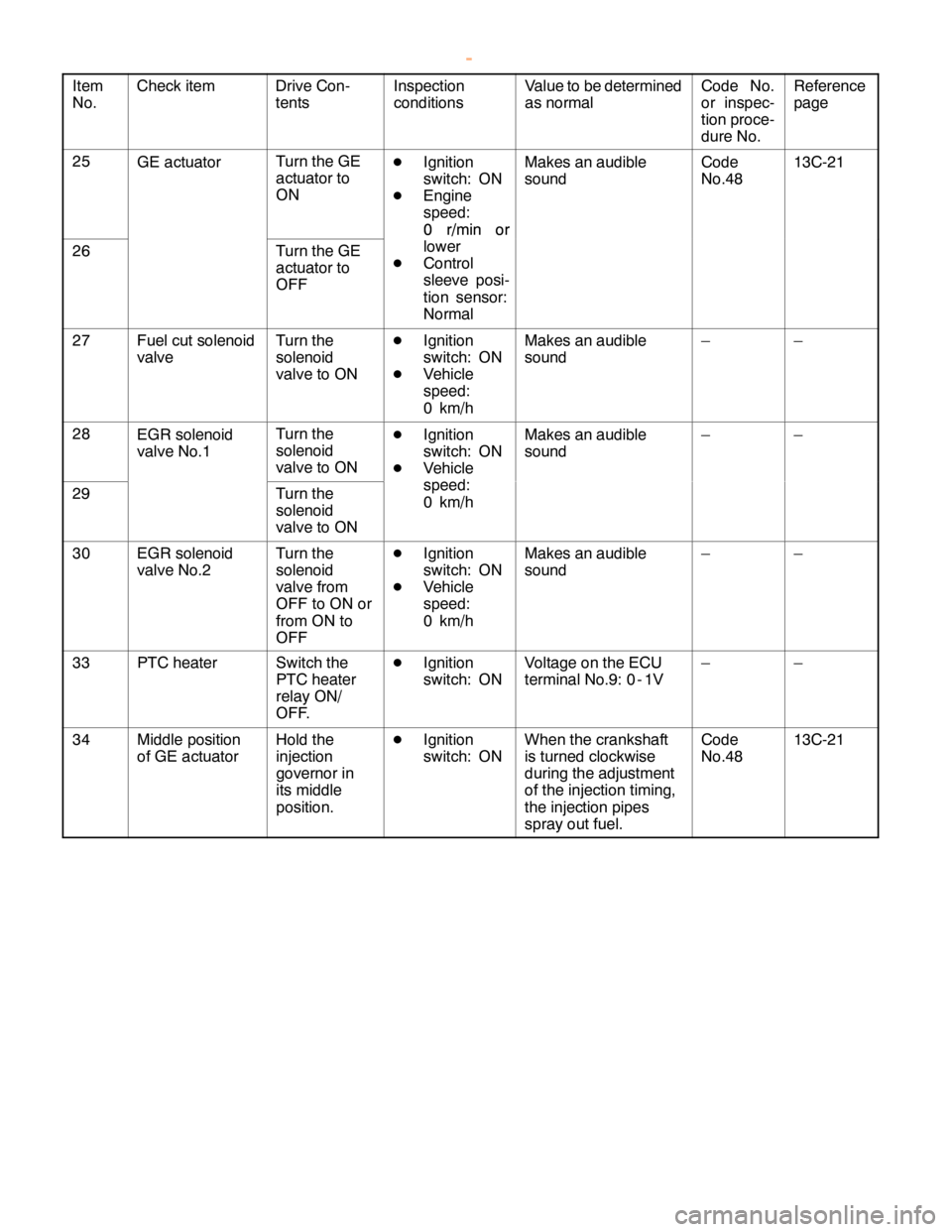

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be determined

as normal Inspection

conditions Drive Con-

tents Check item

25GE actuatorTurn the GE

actuator to

ONDIgnition

switch: ON

DEngine

speed:

0 r/min orMakes an audible

soundCode

No.4813C-21

26Turn the GE

actuator to

OFF

0 r/min or

lower

DControl

sleeve posi-

tion sensor:

Normal

27Fuel cut solenoid

valveTurn the

solenoid

valve to ONDIgnition

switch: ON

DVehicle

speed:

0 km/hMakes an audible

sound––

28EGR solenoid

valve No.1Turn the

solenoid

valve to ONDIgnition

switch: ON

DVehicleMakes an audible

sound––

29Turn the

solenoid

valve to ONspeed:

0 km/h

30EGR solenoid

valve No.2Turn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/hMakes an audible

sound––

33PTC heaterSwitch the

PTC heater

relay ON/

OFF.DIgnition

switch: ONVoltage on the ECU

terminal No.9: 0 - 1V––

34Middle position

of GE actuatorHold the

injection

governor in

its middle

position.DIgnition

switch: ONWhen the crankshaft

is turned clockwise

during the adjustment

of the injection timing,

the injection pipes

spray out fuel.Code

No.4813C-21

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 531 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-40

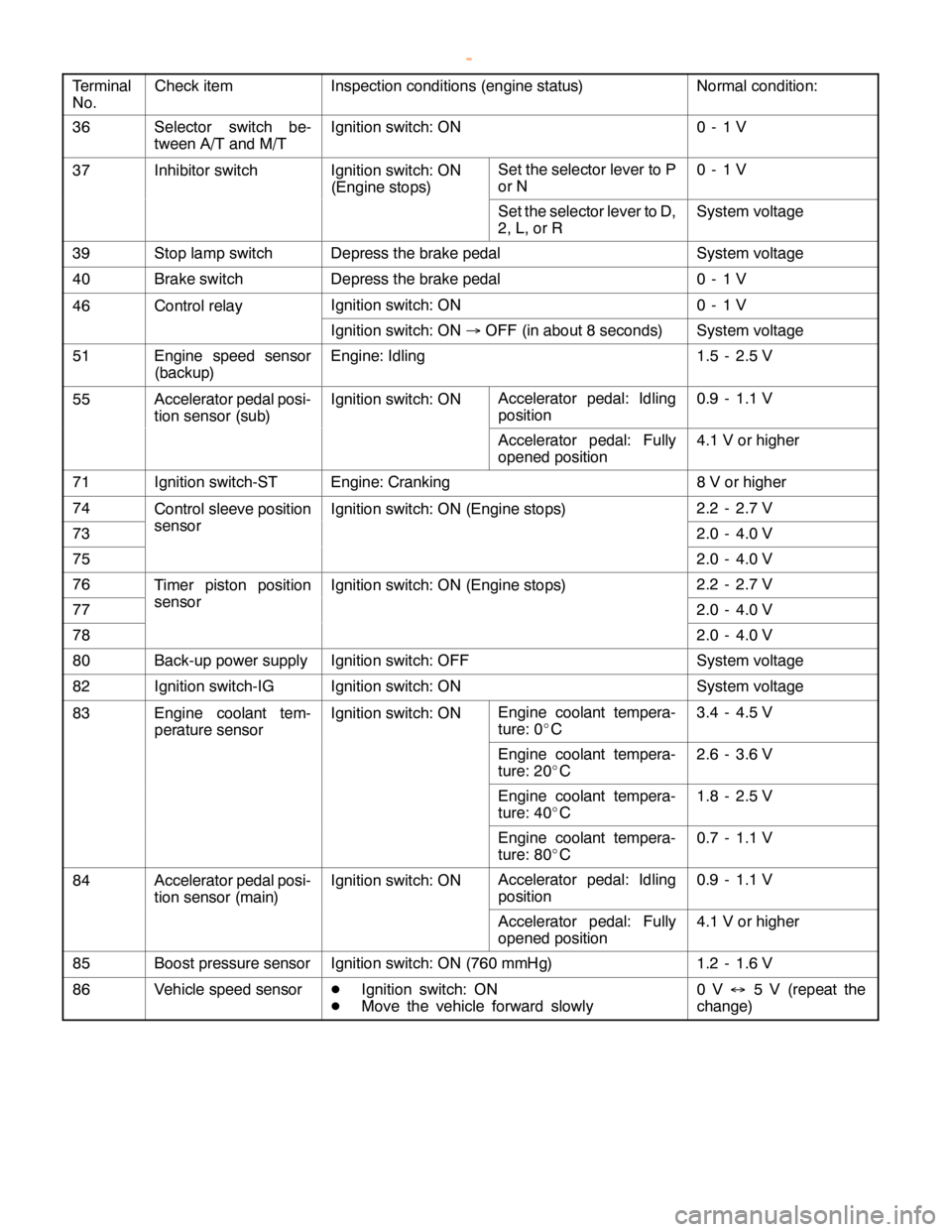

Terminal

No.Normal condition: Inspection conditions (engine status) Check item

36Selector switch be-

tween A/T and M/TIgnition switch: ON0-1V

37Inhibitor switchIgnition switch: ON

(Engine stops)Set the selector lever to P

or N0-1V

Set the selector lever to D,

2, L, or RSystem voltage

39Stop lamp switchDepress the brake pedalSystem voltage

40Brake switchDepress the brake pedal0-1V

46Control relayIgnition switch: ON0-1V

Ignition switch: ON®OFF (in about 8 seconds)System voltage

51Engine speed sensor

(backup)Engine: Idling1.5 - 2.5 V

55Accelerator pedal posi-

tion sensor (sub)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position4.1 V or higher

71Ignition switch-STEngine: Cranking8 V or higher

74Control sleeve positionIgnition switch: ON (Engine stops)2.2 - 2.7 V

73sensor2.0 - 4.0 V

752.0 - 4.0 V

76Timer piston positionIgnition switch: ON (Engine stops)2.2 - 2.7 V

77sensor2.0 - 4.0 V

782.0 - 4.0 V

80Back-up power supplyIgnition switch: OFFSystem voltage

82Ignition switch-IGIgnition switch: ONSystem voltage

83Engine coolant tem-

perature sensorIgnition switch: ONEngine coolant tempera-

ture: 0_C3.4 - 4.5 V

Engine coolant tempera-

ture: 20_C2.6 - 3.6 V

Engine coolant tempera-

ture: 40_C1.8 - 2.5 V

Engine coolant tempera-

ture: 80_C0.7 - 1.1 V

84Accelerator pedal posi-

tion sensor (main)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position4.1 V or higher

85Boost pressure sensorIgnition switch: ON (760 mmHg)1.2 - 1.6 V

86Vehicle speed sensorDIgnition switch: ON

DMove the vehicle forward slowly0V«5 V (repeat the

change)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 561 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-6

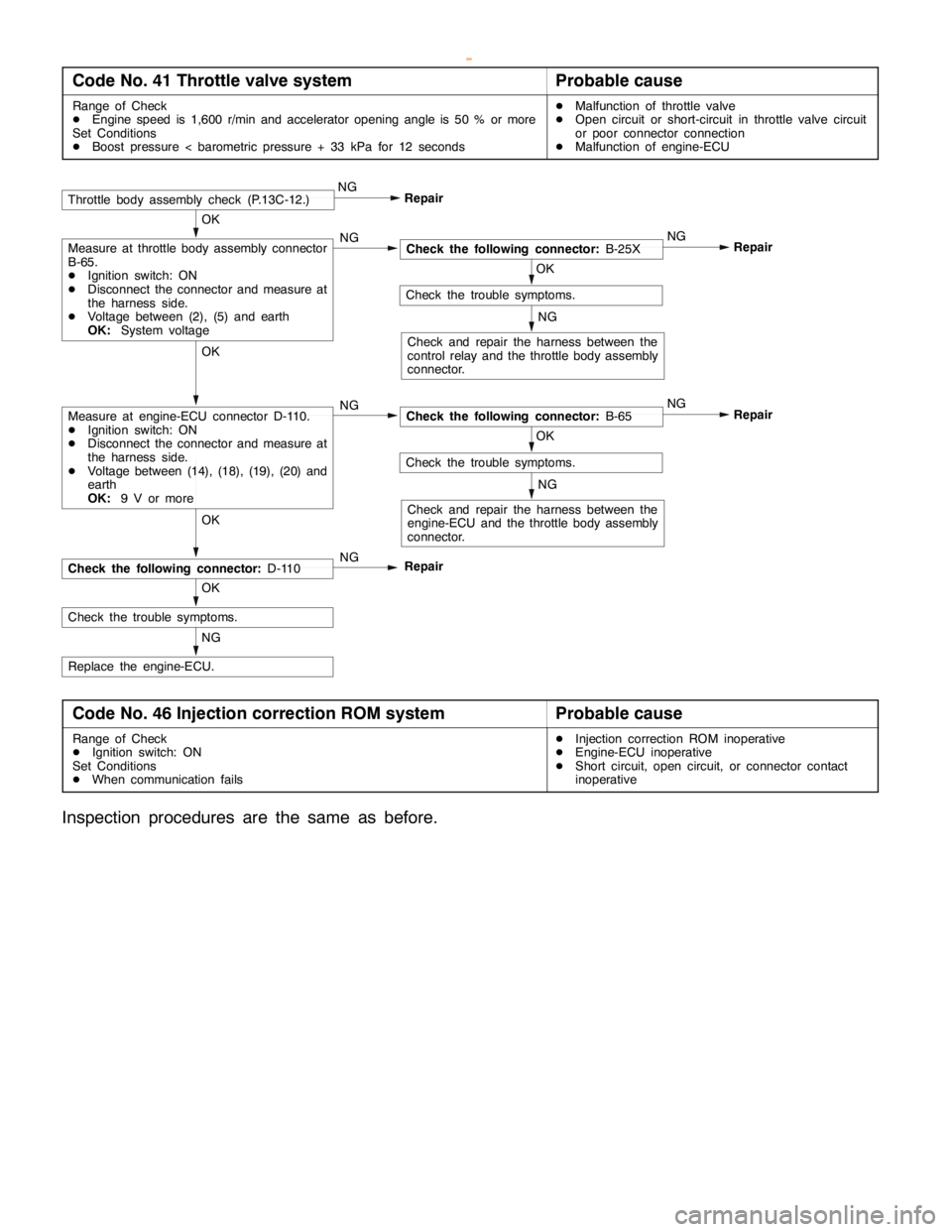

Code No. 41 Throttle valve systemProbable cause

Range of Check

DEngine speed is 1,600 r/min and accelerator opening angle is 50 % or more

Set Conditions

DBoost pressure < barometric pressure + 33 kPa for 12 secondsDMalfunction of throttle valve

DOpen circuit or short-circuit in throttle valve circuit

or poor connector connection

DMalfunction of engine-ECU

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

NG

Check the following connector:D-110

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

engine-ECU and the throttle body assembly

connector.

Repair NG

OK

Check the following connector:B-65 NG

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

control relay and the throttle body assembly

connector.

Repair NG

OK

Check the following connector:B-25X NGMeasure at throttle body assembly connector

B-65.

DIgnition switch: ON

DDisconnect the connector and measure at

the harness side.

DVoltage between (2), (5) and earth

OK:System voltage

RepairThrottle body assembly check (P.13C-12.)NG

Measure at engine-ECU connector D-110.

DIgnition switch: ON

DDisconnect the connector and measure at

the harness side.

DVoltage between (14), (18), (19), (20) and

earth

OK:9 V or more

Repair

Code No. 46 Injection correction ROM systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DWhen communication failsDInjection correction ROM inoperative

DEngine-ECU inoperative

DShort circuit, open circuit, or connector contact

inoperative

Inspection procedures are the same as before.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 562 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-7

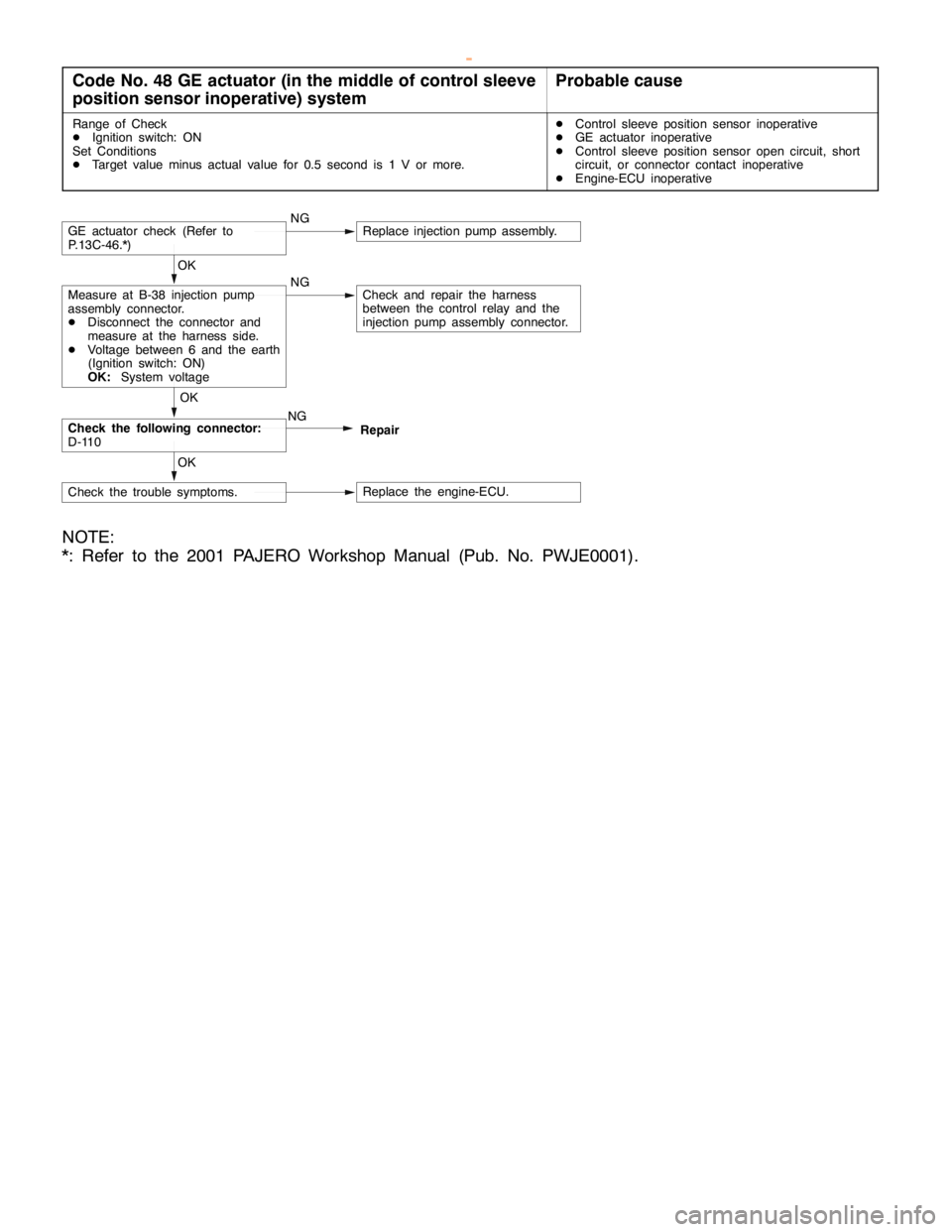

Code No. 48 GE actuator (in the middle of control sleeve

position sensor inoperative) systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DTarget value minus actual value for 0.5 second is 1 V or more.DControl sleeve position sensor inoperative

DGE actuator inoperative

DControl sleeve position sensor open circuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

NGGE actuator check (Refer to

P.13C-46.*)Replace injection pump assembly.

NGMeasure at B-38 injection pump

assembly connector.

DDisconnect the connector and

measure at the harness side.

DVoltage between 6 and the earth

(Ignition switch: ON)

OK:System voltageCheck and repair the harness

between the control relay and the

injection pump assembly connector. OK

Check the following connector:

D-110NG OK

Repair

Check the trouble symptoms.Replace the engine-ECU. OK

NOTE:

*: Refer to the 2001 PAJERO Workshop Manual (Pub. No. PWJE0001).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 563 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-8

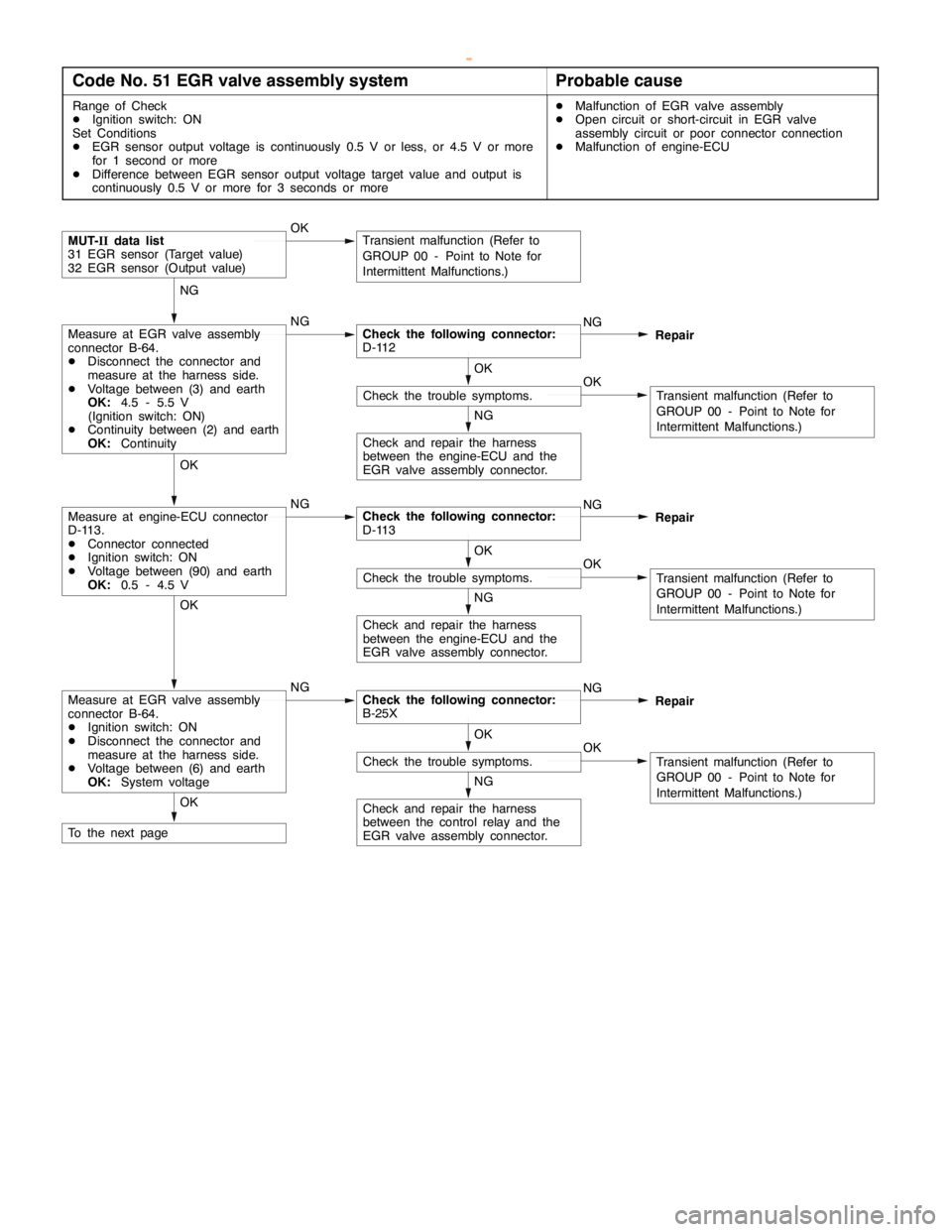

Code No. 51 EGR valve assembly systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DEGR sensor output voltage is continuously 0.5 V or less, or 4.5 V or more

for 1 second or more

DDifference between EGR sensor output voltage target value and output is

continuously 0.5 V or more for 3 seconds or moreDMalfunction of EGR valve assembly

DOpen circuit or short-circuit in EGR valve

assembly circuit or poor connector connection

DMalfunction of engine-ECU

Check and repair the harness

between the engine-ECU and the

EGR valve assembly connector.

NG

OKCheck the trouble symptoms.

OK

Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.)

NGMeasure at engine-ECU connector

D-113.

DConnector connected

DIgnition switch: ON

DVoltage between (90) and earth

OK:0.5 - 4.5 VCheck the following connector:

D-113NG

Repair OK

Check and repair the harness

between the engine-ECU and the

EGR valve assembly connector.

NG

OKCheck the trouble symptoms.

OK

Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.)

OKMUT-IIdata list

31 EGR sensor (Target value)

32 EGR sensor (Output value)Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.)

NGMeasure at EGR valve assembly

connector B-64.

DDisconnect the connector and

measure at the harness side.

DVoltage between (3) and earth

OK:4.5 - 5.5 V

(Ignition switch: ON)

DContinuity between (2) and earth

OK:ContinuityCheck the following connector:

D-112NG

Repair NG

To the next pageOK

Check and repair the harness

between the control relay and the

EGR valve assembly connector.

NG

OKCheck the trouble symptoms.

OK

Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.)

NGMeasure at EGR valve assembly

connector B-64.

DIgnition switch: ON

DDisconnect the connector and

measure at the harness side.

DVoltage between (6) and earth

OK:System voltageCheck the following connector:

B-25XNG

Repair OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 566 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-11

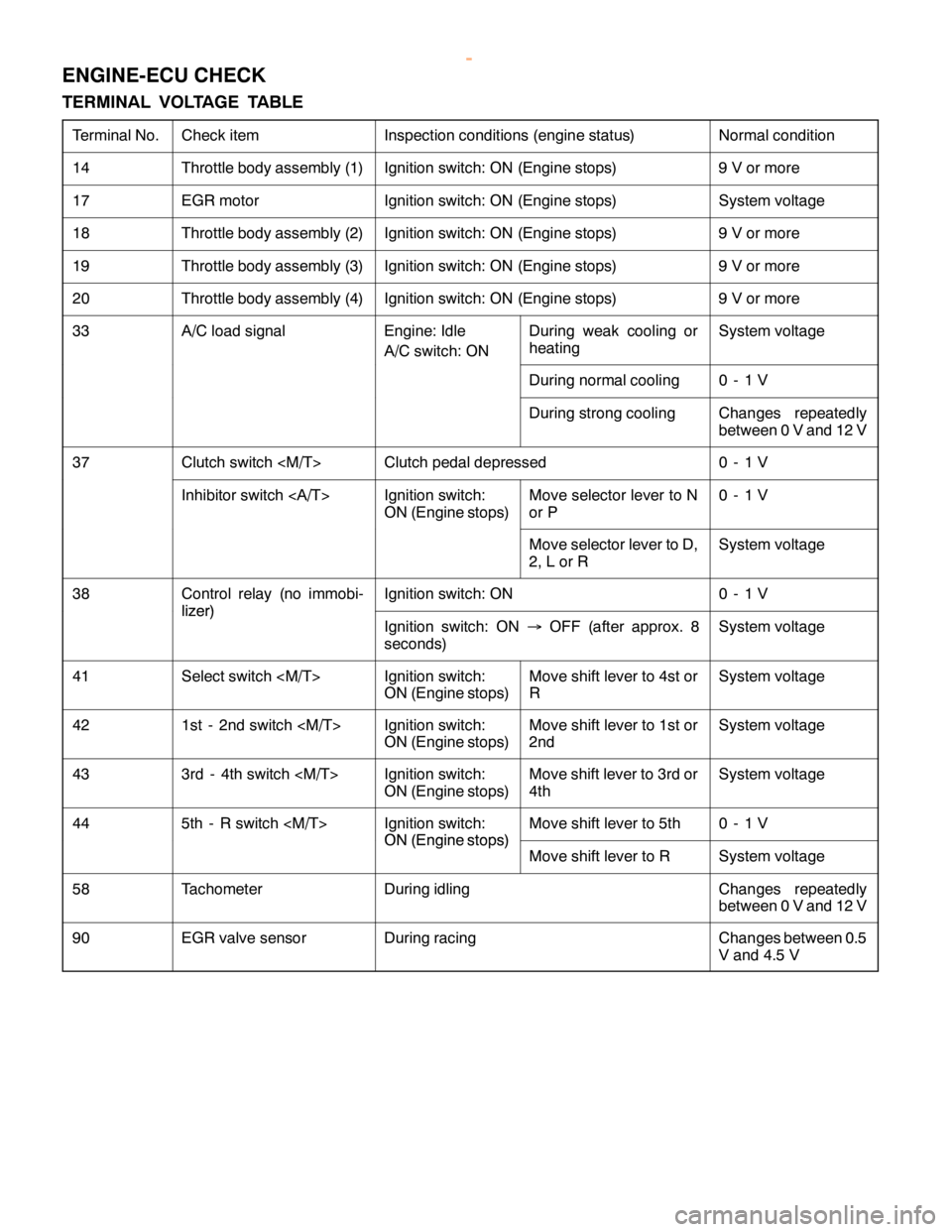

ENGINE-ECU CHECK

TERMINAL VOLTAGE TABLE

Terminal No.Check itemInspection conditions (engine status)Normal condition

14Throttle body assembly (1)Ignition switch: ON (Engine stops)9 V or more

17EGR motorIgnition switch: ON (Engine stops)System voltage

18Throttle body assembly (2)Ignition switch: ON (Engine stops)9 V or more

19Throttle body assembly (3)Ignition switch: ON (Engine stops)9 V or more

20Throttle body assembly (4)Ignition switch: ON (Engine stops)9 V or more

33A/C load signalEngine: Idle

A/C switch: ONDuring weak cooling or

heatingSystem voltage

During normal cooling0-1V

During strong coolingChanges repeatedly

between 0 V and 12 V

37Clutch switch

Inhibitor switch Ignition switch:

ON (Engine stops)Move selector lever to N

or P0-1V

Move selector lever to D,

2, L or RSystem voltage

38Control relay (no immobi-

lizer)

Ignition switch: ON0-1V

lizer)

Ignition switch: ON→OFF (after approx. 8

seconds)System voltage

41Select switch

ON (Engine stops)Move shift lever to 4st or

RSystem voltage

421st - 2nd switch

ON (Engine stops)Move shift lever to 1st or

2ndSystem voltage

433rd - 4th switch

ON (Engine stops)Move shift lever to 3rd or

4thSystem voltage

445th - R switch

ON(Enginestops)

Move shift lever to 5th0-1V

ON(Engine stops)

Move shift lever to RSystem voltage

58TachometerDuring idlingChanges repeatedly

between 0 V and 12 V

90EGR valve sensorDuring racingChanges between 0.5

V and 4.5 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 596 of 1839

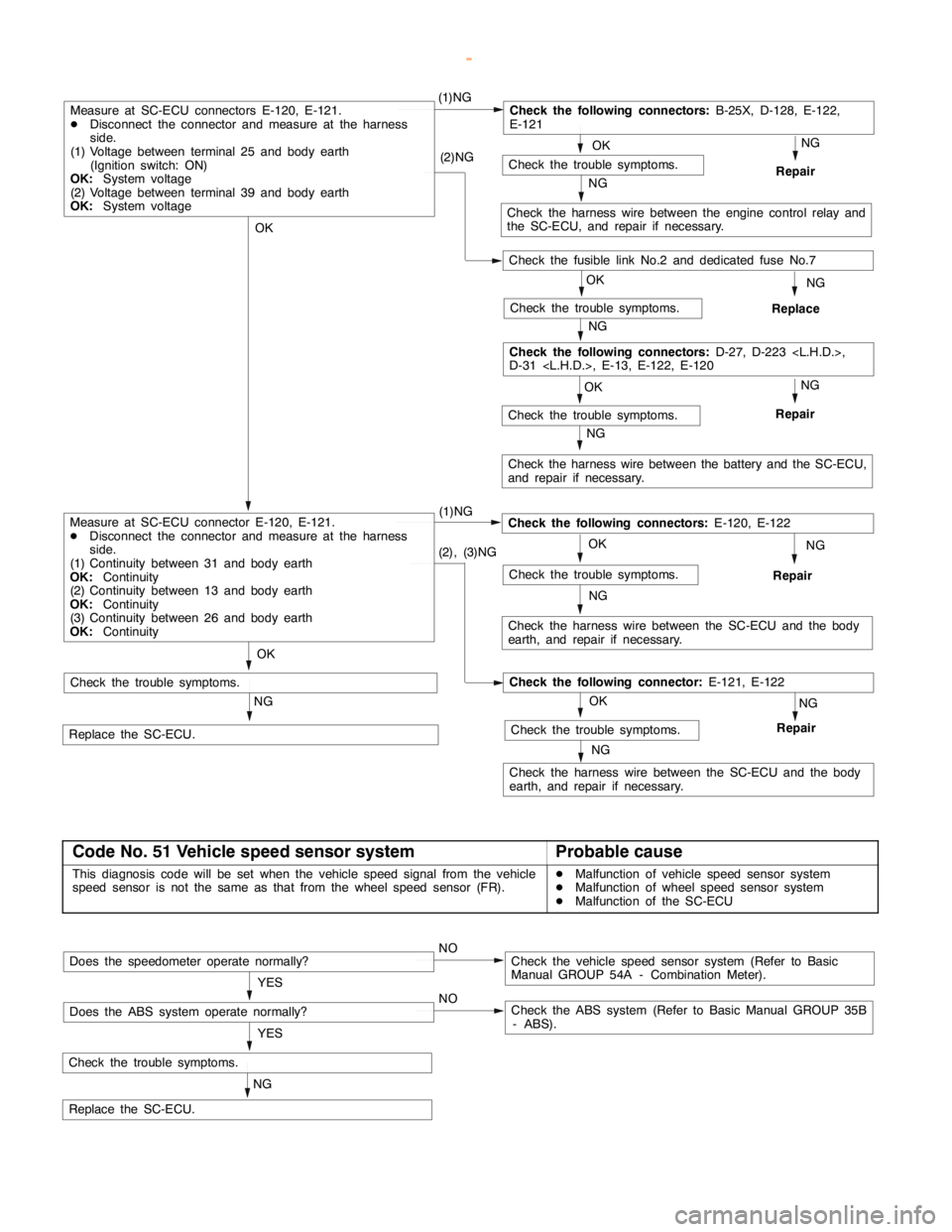

MITSUBISHI SC-Troubleshooting MITSUBISHI SC-Troubleshooting13E-7

OK

NG

Repair

OK

Check the trouble symptoms.

NG

OKNG

Repair

OK

(1)NGCheck the following connectors:

B-25X, D-128, E-122,

E-121

NG

Check the harness wire between the engine control relay and

the SC-ECU, and repair if necessary. (2)NG

OK

Check the trouble symptoms.

NG

Replace

NG

Check the harness wire between the battery and the SC-ECU,

and repair if necessary.

Check the following connectors:

D-27, D-223

D-31

Measure at SC-ECU connectors E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal 25 and body earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between terminal 39 and body earth

OK:

System voltage

NG (1)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

Repair

NG

Replace the SC-ECU.

Check the trouble symptoms.

Check the following connectors:

E-120, E-122

NG

(2), (3)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

OK

NG

Repair

NGCheck the trouble symptoms.

Check the following connector:

E-121, E-122

OK

Check the trouble symptoms.

Measure at SC-ECU connector E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Continuity between 31 and body earth

OK:

Continuity

(2) Continuity between 13 and body earth

OK:

Continuity

(3) Continuity between 26 and body earth

OK:

Continuity

Check the trouble symptoms.

Check the fusible link No.2 and dedicated fuse No.7

Code No. 51 Vehicle speed sensor systemProbable cause

This diagnosis code will be set when the vehicle speed signal from the vehicle

speed sensor is not the same as that from the wheel speed sensor (FR).DMalfunction of vehicle speed sensor system

DMalfunction of wheel speed sensor system

DMalfunction of the SC-ECU

NG

Check the trouble symptoms.

Replace the SC-ECU.YES

NOCheck the vehicle speed sensor system (Refer to Basic

Manual GROUP 54A - Combination Meter).Does the speedometer operate normally?

YES

NOCheck the ABS system (Refer to Basic Manual GROUP 35B

- ABS).Does the ABS system operate normally?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 602 of 1839

MITSUBISHI SC-Troubleshooting13E-13

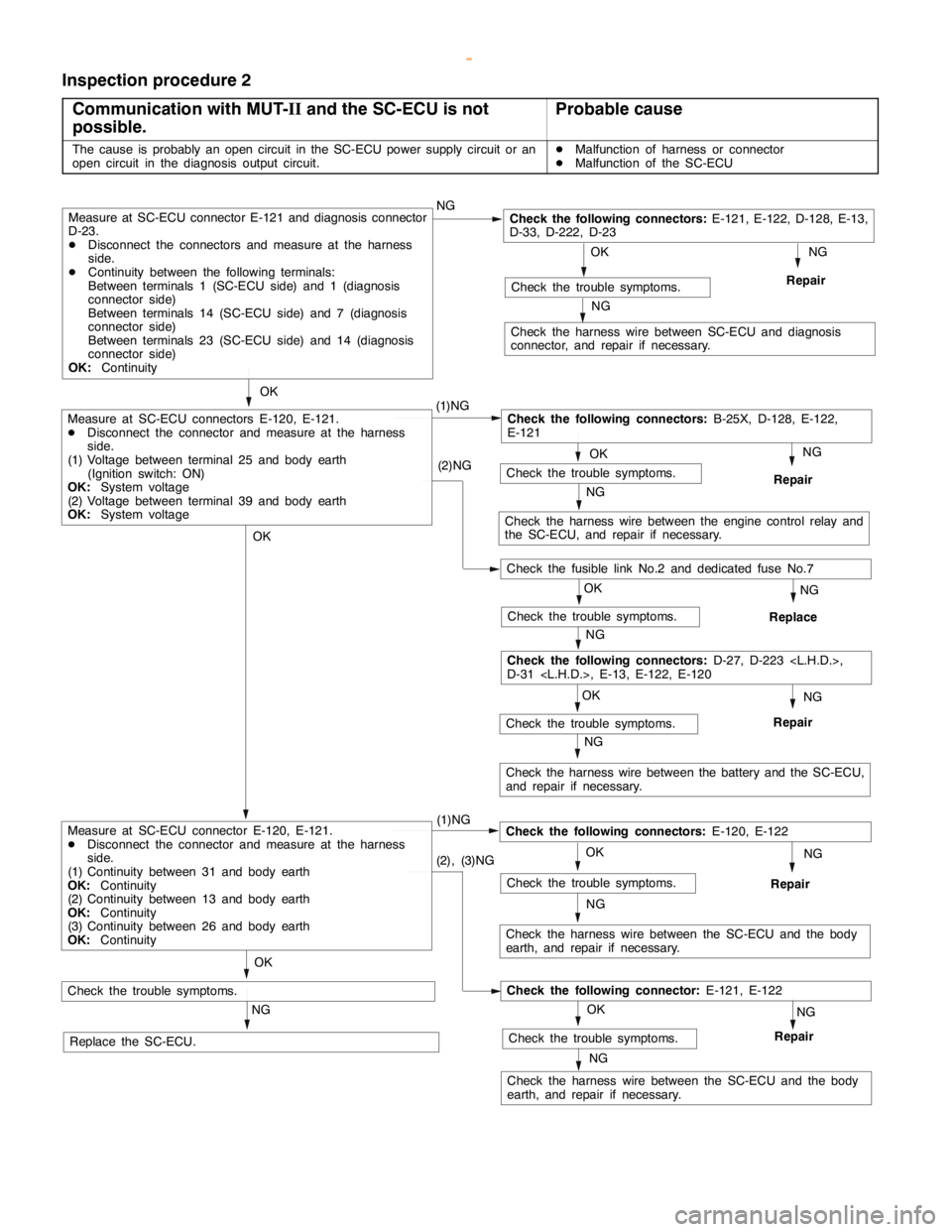

Inspection procedure 2

Communication with MUT-

IIand the SC-ECU is not

possible.

Probable cause

The cause is probably an open circuit in the SC-ECU power supply circuit or an

open circuit in the diagnosis output circuit.DMalfunction of harness or connector

DMalfunction of the SC-ECU

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between SC-ECU and diagnosis

connector, and repair if necessary.

OK

Measure at SC-ECU connector E-121 and diagnosis connector

D-23.

DDisconnect the connectors and measure at the harness

side.

DContinuity between the following terminals:

Between terminals 1 (SC-ECU side) and 1 (diagnosis

connector side)

Between terminals 14 (SC-ECU side) and 7 (diagnosis

connector side)

Between terminals 23 (SC-ECU side) and 14 (diagnosis

connector side)

OK:

ContinuityNGCheck the following connectors:

E-121, E-122, D-128, E-13,

D-33, D-222, D-23

OK

NG

Repair

OK

Check the trouble symptoms.

NG

OKNG

Repair

OK

(1)NGCheck the following connectors:

B-25X, D-128, E-122,

E-121

NG

Check the harness wire between the engine control relay and

the SC-ECU, and repair if necessary. (2)NG

OK

Check the trouble symptoms.

NG

Replace

NG

Check the harness wire between the battery and the SC-ECU,

and repair if necessary.

Check the following connectors:

D-27, D-223

D-31

Measure at SC-ECU connectors E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal 25 and body earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between terminal 39 and body earth

OK:

System voltage

NG (1)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

Repair

NG

Replace the SC-ECU.

Check the trouble symptoms.

Check the following connectors:

E-120, E-122

NG

(2), (3)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

OK

NG

Repair

NGCheck the trouble symptoms.

Check the following connector:

E-121, E-122

OK

Check the trouble symptoms.

Measure at SC-ECU connector E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Continuity between 31 and body earth

OK:

Continuity

(2) Continuity between 13 and body earth

OK:

Continuity

(3) Continuity between 26 and body earth

OK:

Continuity

Check the trouble symptoms.

Check the fusible link No.2 and dedicated fuse No.7

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 611 of 1839

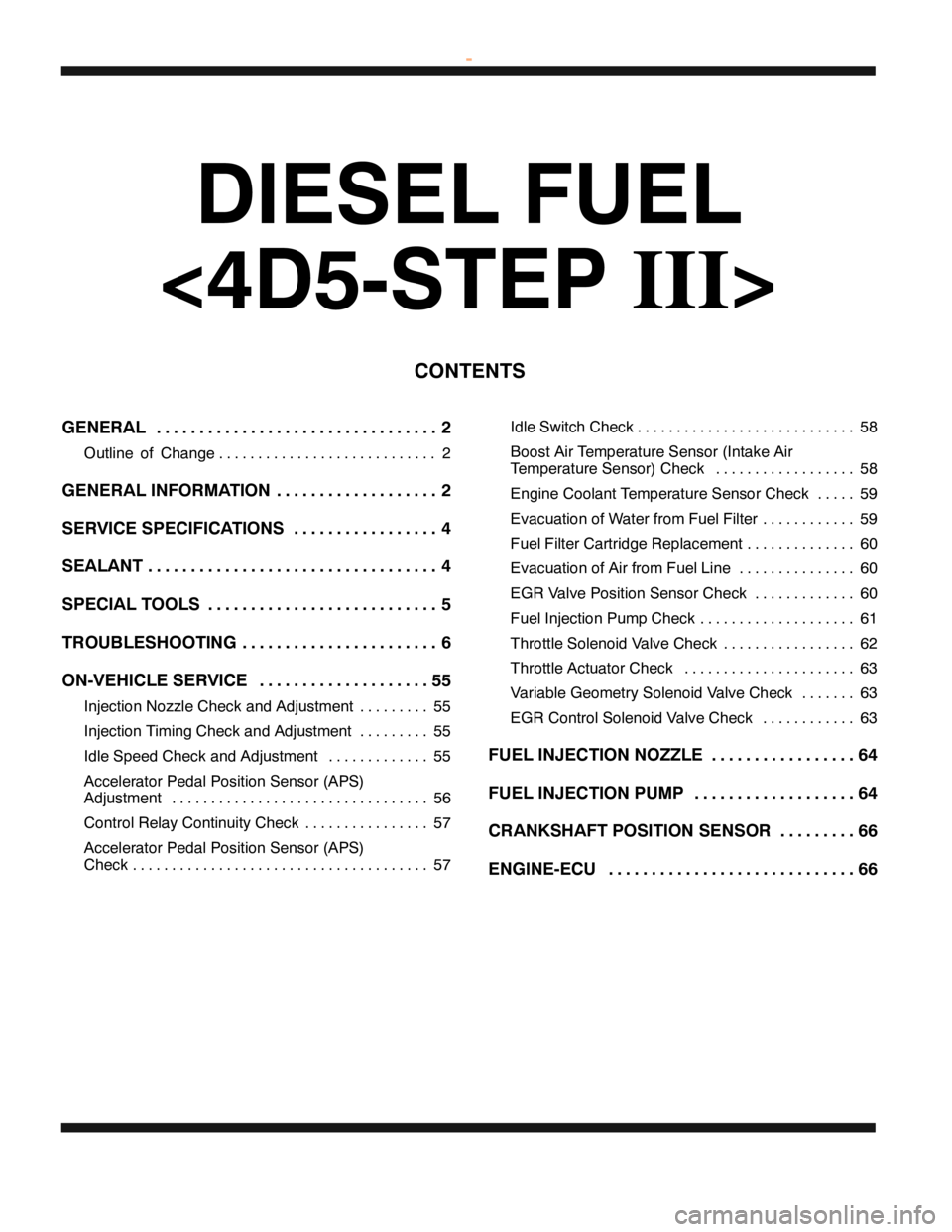

13E-1

DIESEL FUEL

<4D5-STEPIII

>

CONTENTS

GENERAL 2.................................

Outline of Change 2............................

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 4.................

SEALANT 4..................................

SPECIAL TOOLS 5...........................

TROUBLESHOOTING 6.......................

ON-VEHICLE SERVICE 55....................

Injection Nozzle Check and Adjustment 55.........

Injection Timing Check and Adjustment 55.........

Idle Speed Check and Adjustment 55.............

Accelerator Pedal Position Sensor (APS)

Adjustment 56.................................

Control Relay Continuity Check 57................

Accelerator Pedal Position Sensor (APS)

Check 57......................................Idle Switch Check 58............................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 58..................

Engine Coolant Temperature Sensor Check 59.....

Evacuation of Water from Fuel Filter 59............

Fuel Filter Cartridge Replacement 60..............

Evacuation of Air from Fuel Line 60...............

EGR Valve Position Sensor Check 60.............

Fuel Injection Pump Check 61....................

Throttle Solenoid Valve Check 62.................

Throttle Actuator Check 63......................

Variable Geometry Solenoid Valve Check 63.......

EGR Control Solenoid Valve Check 63............

FUEL INJECTION NOZZLE 64.................

FUEL INJECTION PUMP 64...................

CRANKSHAFT POSITION SENSOR 66.........

ENGINE-ECU 66.............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk