service MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1283 of 1839

ABS <4WD> -Troubleshooting35B-20

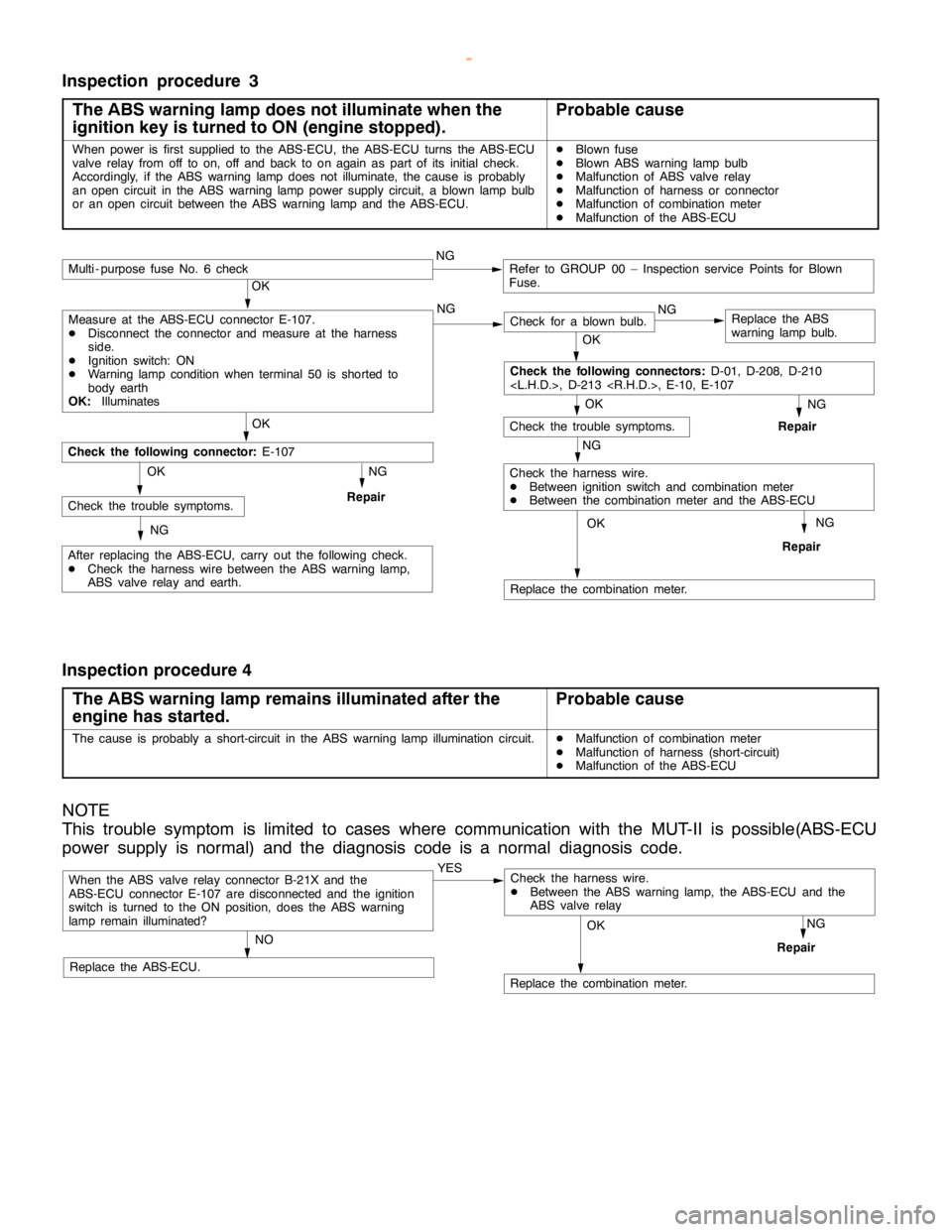

Inspection procedure 3

The ABS warning lamp does not illuminate when the

ignition key is turned to ON (engine stopped).

Probable cause

When power is first supplied to the ABS-ECU, the ABS-ECU turns the ABS-ECU

valve relay from off to on, off and back to onagain aspart of its initial check.

Accordingly, if the ABS warninglampdoes not illuminate, the cause is probably

an opencircuit in the ABS warninglamppower supply circuit, a blownlamp bulb

or an opencircuit between the ABS warninglamp and theABS-ECU.DBlown fuse

DBlown ABS warninglamp bulb

DMalfunction of ABS valve relay

DMalfunction of harness or connector

DMalfunction of combination meter

DMalfunction of the ABS-ECU

NG

Replace the combination meter.

NG

Repair

OK

NG

Check for a blown bulb.Replace the ABS

warning lamp bulb.

OK

NG

Repair

OK

Check the trouble symptoms.

Multi - purpose fuse No. 6 checkNGRefer to GROUP 00 – Inspection service Points for Blown

Fuse.

NG

Check the harness wire.

DBetween ignition switch and combination meter

DBetween the combination meter and the ABS-ECU

OK

OK

After replacing the ABS-ECU, carry out the following check.

DCheck the harness wire between the ABS warning lamp,

ABS valve relay and earth.

Check the following connector:E-107

NG

RepairCheck the trouble symptoms.OK

NG

Check the following connectors:D-01, D-208, D-210

Measure at the ABS-ECU connector E-107.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DWarning lamp conditionwhen terminal 50 is shorted to

body earth

OK:Illuminates

Inspection procedure 4

The ABS warning lamp remains illuminated after the

engine has started.

Probable cause

The cause is probably a short-circuit in the ABS warninglamp illuminationcircuit.DMalfunction of combination meter

DMalfunction of harness (short-circuit)

DMalfunction of the ABS-ECU

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

When the ABS valve relay connector B-21X and the

ABS-ECU connector E-107 are disconnected and the ignition

switch is turned to the ON position, does the ABS warning

lamp remain illuminated?YES

NO

Replace the ABS-ECU.

Replace the combination meter.

NG

Repair

OK

Check the harness wire.

DBetween the ABS warning lamp, the ABS-ECU and the

ABS valve relay

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1284 of 1839

ABS <4WD> -Troubleshooting35B-21

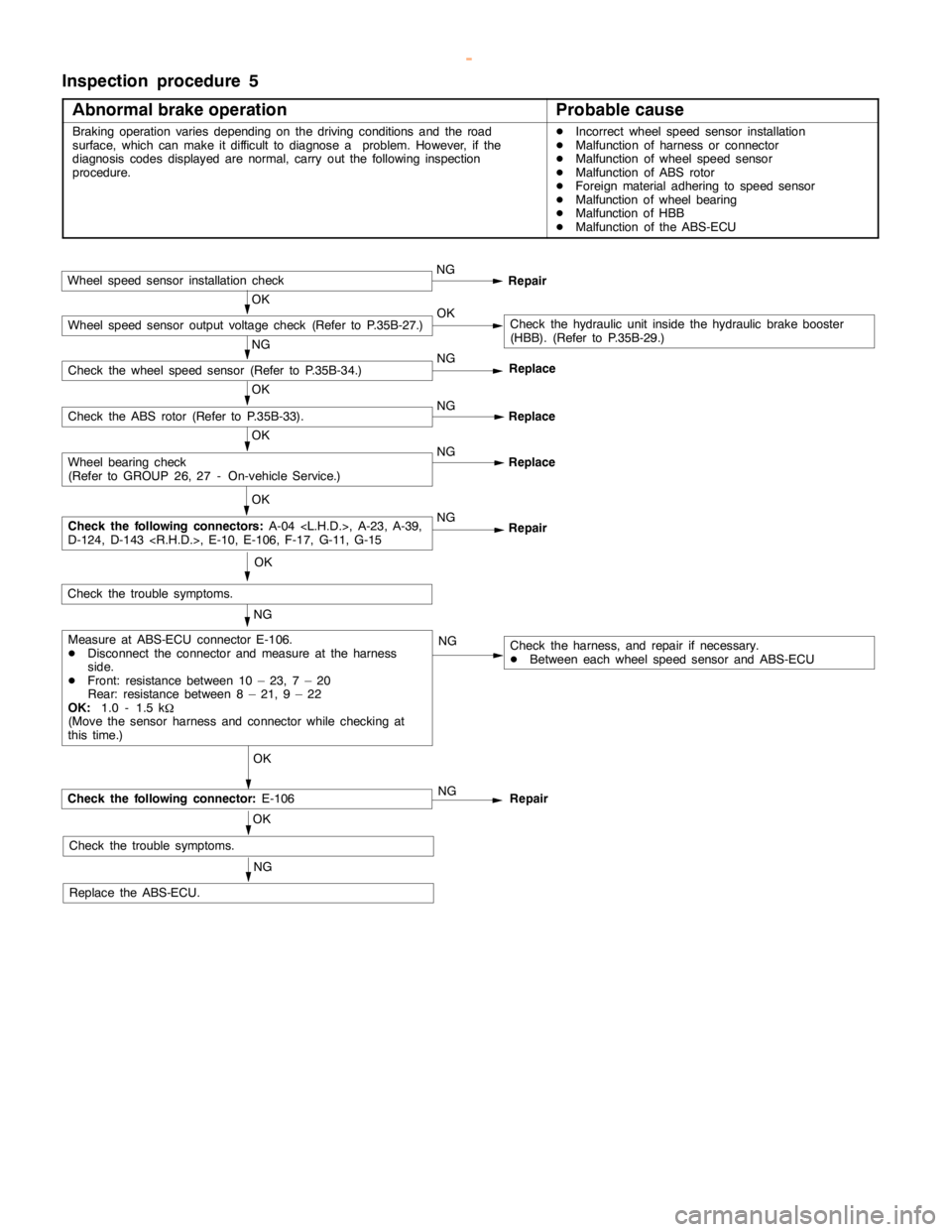

Inspection procedure 5

Abnormal brake operation

Probable cause

Braking operation variesdepending on the driving conditions and the road

surface, which can make it difficult to diagnose a problem. However, if the

diagnosis codes displayed are normal, carry out the following inspection

procedure.DIncorrect wheel speed sensor installation

DMalfunction of harness or connector

DMalfunction of wheel speed sensor

DMalfunction of ABS rotor

DForeign material adhering to speed sensor

DMalfunction of wheel bearing

DMalfunction of HBB

DMalfunction of the ABS-ECU

Wheel speed sensor installation checkNG

Repair

OKCheck the hydraulic unit inside the hydraulic brake booster

(HBB). (Refer to P.35B-29.)

NG

Check the wheel speed sensor (Refer to P.35B-34.)NG

OK

Check the ABS rotor (Refer to P.35B-33).NG

Replace

OK

NG

Replace

OK

NG

Repair

OK

NG

NG

OK

Check the following connector:E-106

OK

Check the trouble symptoms.

NG

Replace the ABS-ECU.NG

Repair

Check the harness, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU ReplaceMeasure at ABS-ECU connector E-106.

DDisconnect the connector and measure at the harness

side.

DFront: resistance between 10 – 23, 7 – 20

Rear: resistance between 8 – 21, 9 – 22

OK:1.0 - 1.5 k

W

(Move the sensor harness and connector while checking at

this time.)

Check the following connectors:A-04

D-124, D-143

Wheel bearing check

(Refer to GROUP 26, 27 - On-vehicle Service.)

Check the trouble symptoms.

Wheel speed sensor output voltage check (Refer to P.35B-27.)OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1294 of 1839

ABS <4WD> -On-vehicle Service35B-31

WHEN THE BATTERY IS FLAT

If the engine is started using a booster cable when the battery

is completely flat, and the vehicle is then driven without waiting

for the battery to be recharged, the engine may misfire and it

may not be possible to drive the vehicle. This is because the

ABS consumes a large amount of current when carrying out its

initial checks. If this happens, recharge the battery fully.

Caution

The vehicle posture will be unstable during braking, so

do not drive the vehicle with the ABS-ECU connector

disconnected or with the ABS not operating for any other

reason.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1301 of 1839

36-1

PARKING BRAKES

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANTS 2..............................

SEALANT 3..................................

ON-VEHICLE SERVICE 3.....................

Parking Brake Lever Stroke Check and

Adjustment 3..................................Parking Brake Switch Check 4..................

Lining Running-In 4............................

PARKING BRAKE LEVER 5..................

PARKING BRAKE CABLE 6..................

PARKING BRAKE DRUM 7...................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1310 of 1839

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 5..............................

SEALANT AND ADHESIVE 5.................

SPECIAL TOOLS 6..........................

ON-VEHICLE SERVICE 8.....................

Steering Wheel Free Play Check 8..............

Steering Angle Check 8........................

Tie Rod End Ball Joint Starting Torque Check 8..

Stationary Steering Effort Check 9...............

Steering Wheel Returnability Check 9............

Oil Pump Belt Tension Check <6G7,4D5> 9......Power Steering Fluid Level Check 10............

Power Steering Fluid Replacement 10...........

Power Steering System Bleeding 10.............

Oil Pump Pressure Test 11.....................

Power Steering Oil Pressure Switch Check

<6G7,4M4> 12.................................

Ball Joint Dust Cover Check 12.................

STEERING WHEEL AND SHAFT* 13.........

POWER STEERING GEAR BOX AND

LINKAGE 16................................

POWER STEERING OIL PUMP 30...........

POWER STEERING OIL HOSES 35..........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or maintenance) are

indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1314 of 1839

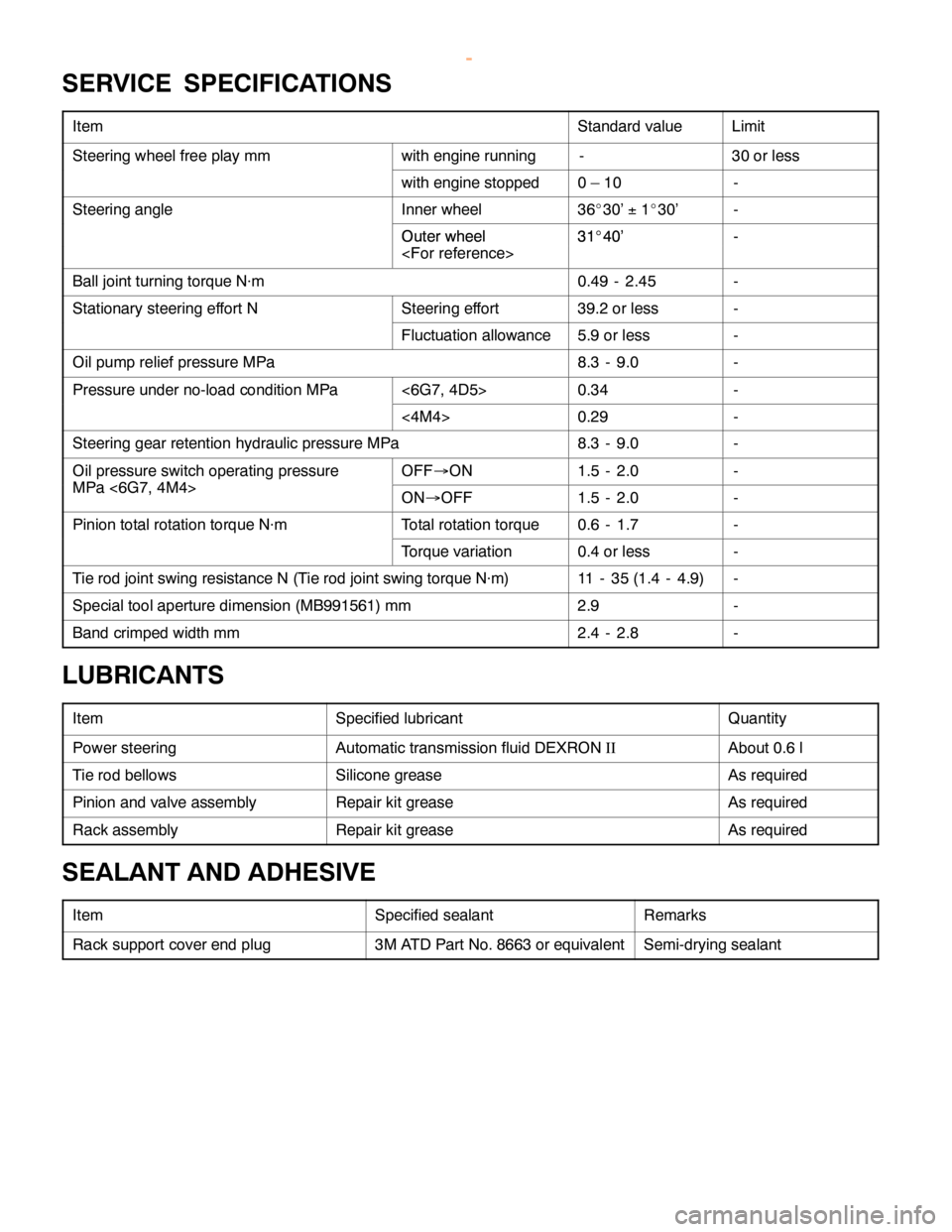

STEERING -Service Specifications/Lubricants/Sealant and Adhesive37A-5

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Steering wheel free play mmwith engine running-30 or less

with engine stopped0–10-

Steering angleInner wheel36_30’±1_30’-

Outer wheel31_40’-Outer wheel

Ball joint turning torque N×m0.49 - 2.45-

Stationary steering effort NSteering effort39.2 or less-

Fluctuation allowance5.9 or less-

Oil pump relief pressure MPa8.3 - 9.0-

Pressure under no-load condition MPa<6G7, 4D5>0.34-

<4M4>0.29-

Steering gear retention hydraulic pressure MPa8.3 - 9.0-

Oil pressure switch operating pressureOFF®ON1.5 - 2.0-

MPa <6G7, 4M4>ON®OFF1.5 - 2.0-

Pinion total rotation torque N×mTotal rotation torque0.6 - 1.7-

Torque variation0.4 or less-

Tie rod joint swing resistance N (Tie rod joint swing torque N×m)11 - 35 (1.4 - 4.9)-

Special tool aperture dimension (MB991561) mm2.9-

Band crimped width mm2.4 - 2.8-

LUBRICANTS

ItemSpecified lubricantQuantity

Power steeringAutomatic transmission fluid DEXRONIIAbout 0.6 l

Tie rod bellowsSilicone greaseAs required

Pinion and valve assemblyRepair kit greaseAs required

Rack assemblyRepair kit greaseAs required

SEALANT AND ADHESIVE

ItemSpecified sealantRemarks

Rack support cover end plug3M ATD Part No. 8663 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1353 of 1839

42-1

BODY

CONTENTS

HOOD3 ....................................

FENDER5 ..................................

FUEL FILLER DOOR6 .....................

WINDOW GLASS8 .........................

ADHESIVES 8.............................

SPECIAL TOOL 8.........................

WINDOW REPAIR 8.......................

WINDSHIELD 10..........................

QUARTER WINDOW GLASS 14...........

BACK DOOR GLASS 16..................

DOORS18 .................................

SERVICE SPECIFICATIONS 18............

SEALANT 18.............................

SPECIAL TOOLS 18......................

TROUBLESHOOTING 19..................ON-VEHICLE SERVICE 19................

Door Fit Adjustment 19.................

Door Window Glass Adjustment 19......

Defective Power Window Adjustment and

Replacement

20 .........................

Power Window Safety Mechanism Check 20..

Door Outside Handle Play Check 21.....

Power Window Operation Current

Check 21..............................

Circuit Breaker (Incorporated in the Power

Window Motor) Check 21...............

Door Inside Handle Play Check and

Adjustment 21..........................

DOOR ASSEMBLY 22.....................

DOOR TRIM AND WATERPROOF

FILM 24..................................

DOOR GLASS AND REGULATOR 30......

DOOR HANDLE AND LATCH 33..........

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP 36.....

BACK DOOR39 ...........................

SERVICE SPECIFICATION 39.............

SEALANT 39.............................

SPECIAL TOOL 39.......................

TROUBLESHOOTING 39..................

CONTINUED ON NEXT PAGE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1354 of 1839

42-2

ON-VEHICLE SERVICE 40................

Back Door Fit Adjustment 40............

Back Door Handle Play Check 40.......

BACK DOOR ASSEMBLY 41..............

BACK DOOR TRIM AND WATERPROOF

FILM 43..................................

BACK DOOR HANDLE AND LATCH 44....

KEYLESS ENTRY SYSTEM45 .............

TROUBLESHOOTING 45..................

ON-VEHICLE SERVICE 45.................

How to Replace a Battery of the

Transmitter 45..........................Encrypted Code Registration Method 45..

KEYLESS ENTRY SYSTEM 46............

SUNROOF47 ..............................

SERVICE SPECIFICATION 47.............

TROUBLESHOOTING 47..................

ON-VEHICLE SERVICE 47................

Water Test 47..........................

Sunroof Fit Adjustment 47...............

SUNROOF 48............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1408 of 1839

51-1

EXTERIOR

CONTENTS

FRONT BUMPER 3.......................

ADHESIVE 3..............................

SPECIAL TOOL 3.........................

FRONT BUMPER 4........................

REAR BUMPER 8........................

ROOF RAIL 11...........................

MOULDING 11...........................

ADHESIVE 11.............................

SPECIAL TOOL 11........................

MOULDING 12............................

GARNISH 16.............................

ADHESIVE 16............................

GARNISH 17.............................

MUDGUARD 19..........................

ADHESIVE 19............................

MUDGUARD 19...........................

REAR DEFLECTOR 21....................

SPECIAL TOOL 21.......................

REAR DEFLECTOR 21....................

SIDE STEP 22...........................

SIDE STEP 22............................

WINDSHIELD WIPER AND WASHER 23....

SERVICE SPECIFICATIONS 23............

TROUBLESHOOTING 23..................

WINDSHIELD WIPER AND WASHER 24...

REAR WIPER AND WASHER 28..........

REFERENCE VALUE 28..................

TROUBLESHOOTING 28..................

REAR WIPER AND WASHER 28..........

HEADLAMP WASHER 30.................

TROUBLESHOOTING 31..................

HEADLAMP WASHER 31.................

CONTINUED ON NEXT PAGE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1425 of 1839

EXTERIOR -Garnish51-18

REMOVAL SERVICE POINT

A

A"

SIDE SILL GARNISH REMOVAL

Remove by the same procedure as given in FRONT DOOR

MOULDING, FRONT WHEEL CUT MOULDING, REAR

WHEEL CUT MOULDING AND REAR DOOR MOULDING

REMOVAL. (Refer to P.51-14.)

INSTALLATION SERVICE POINT

"

AA

SIDE SILL GARNISH INSTALLATION

Install by the same procedure as given in FRONT DOOR

MOULDING, FRONT WHEEL CUT MOULDING, REAR

WHEEL CUT MOULDING AND REAR DOOR MOULDING

INSTALLATION. (Refer to P.51-14.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk