service MITSUBISHI MONTERO 2000 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1039 of 1839

25-1

PROPELLER

SHAFT

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANT 2...............................SPECIAL TOOL 2............................

PROPELLER SHAFT 2.......................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1050 of 1839

26-1

FRONT AXLE

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANTS 5................................

SPECIAL TOOLS 5..........................

ON-VEHICLE SERVICE 10...................

Wheel Bearing Backlash Check 10..............

Front Axle Total Backlash Check 10.............

Front Axle Gear Oil Level Check 11.............

Differential Carrier Oil Seal Replacement 11......

Solenoid Valve Operation Check 12..............

FRONT HUB AND KNUCKLE ASSEMBLY 13.

DRIVE SHAFT 16...........................

INNER SHAFT, HOUSING TUBE 24..........

FREEWHEEL CLUTCH ASSEMBLY,

DIFFERENTIAL CARRIER 28.................

FREEWHEEL CLUTCH ASSEMBLY 31.......

DIFFERENTIAL CARRIER 34.................

SOLENOID VALVE, VACUUMPIPE, VACUUM

TANK 49....................................

FRONT DIFFERENTIAL MOUNT 51..........

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1053 of 1839

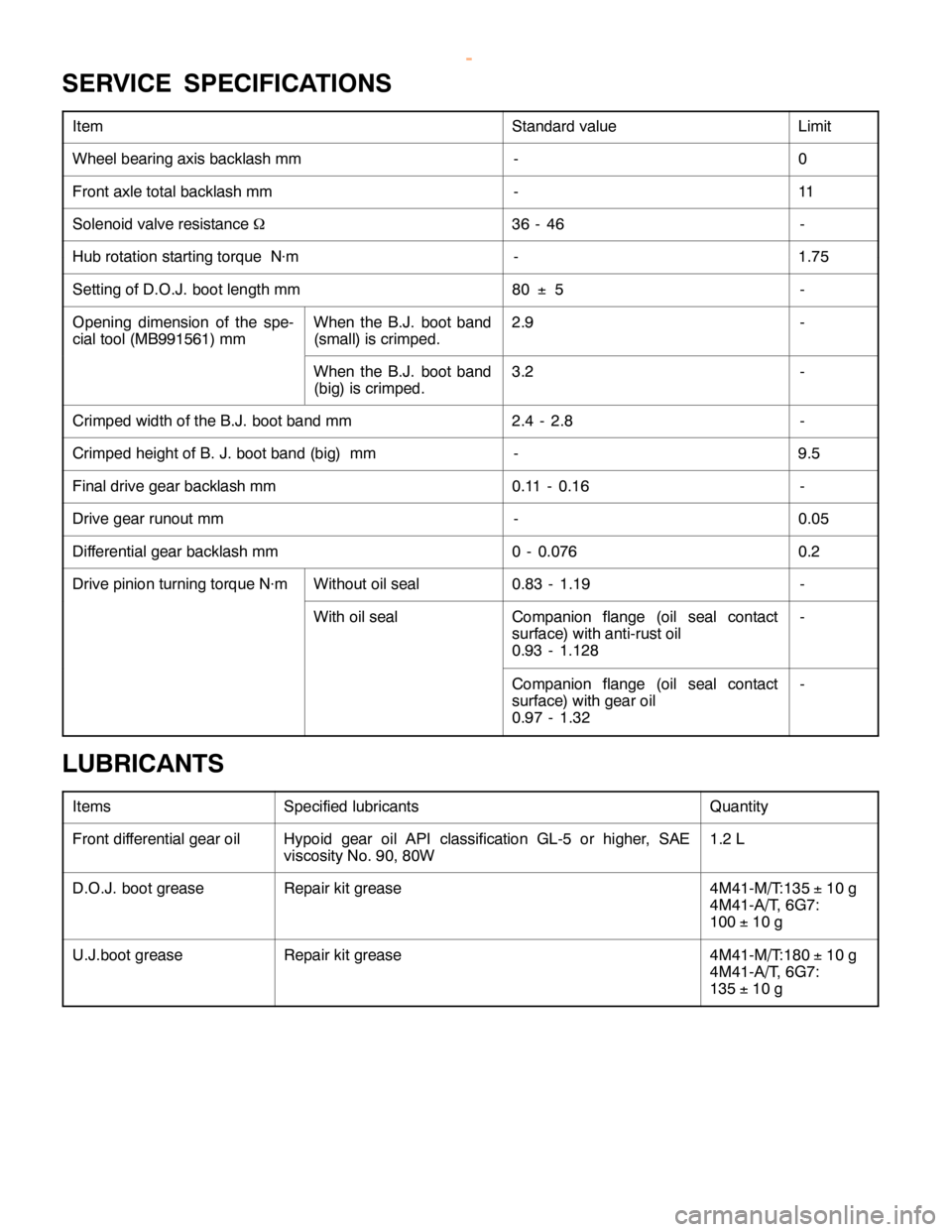

FRONT AXLE -Service Specifications/Lubricants26-4

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Wheel bearing axis backlash mm-0

Front axle total backlash mm-11

Solenoid valve resistanceW36 - 46-

Hub rotation starting torque N×m-1.75

Setting of D.O.J. boot length mm80±5-

Opening dimension of the spe-

cial tool (MB991561) mmWhen the B.J. boot band

(small) is crimped.2.9-

When the B.J. boot band

(big) is crimped.3.2-

Crimped width of the B.J. boot band mm2.4 - 2.8-

Crimped height of B. J. boot band (big) mm-9.5

Final drive gear backlash mm0.11 - 0.16-

Drive gear runout mm-0.05

Differential gear backlash mm0 - 0.0760.2

Drive pinion turning torque N×mWithout oil seal0.83 - 1.19-

With oil sealCompanion flange (oil seal contact

surface) with anti-rust oil

0.93 - 1.128-

Companion flange (oil seal contact

surface) with gear oil

0.97 - 1.32-

LUBRICANTS

ItemsSpecified lubricantsQuantity

Front differential gear oilHypoid gear oil API classification GL-5 or higher, SAE

viscosity No. 90, 80W1.2 L

D.O.J. boot greaseRepair kit grease4M41-M/T:135±10 g

4M41-A/T, 6G7:

100±10 g

U.J.boot greaseRepair kit grease4M41-M/T:180±10 g

4M41-A/T, 6G7:

135±10 g

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1103 of 1839

27-1

REAR AXLE

CONTENTS

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

SEALANTS 4................................

SPECIAL TOOLS 5...........................

ON-VEHICLE SERVICE 8.....................

Rear Axle Total Backlash Check 8................

Gear Oil Level Check 8.........................

Wheel Bearing Axial Play Check 8................Rear Differential Lock Detection Switch Check 9....

Rear Differential Lock System Air Leakage

Check 9.......................................

REAR HUB ASSEMBLY 10...................

KNUCKLE 13...............................

DRIVE SHAFT 14............................

REAR DIFFERENTIAL LOCK 20..............

DIFFERENTIAL CARRIER 23.................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1144 of 1839

31-1

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

TROUBLESHOOTING 3.......................ON-VEHICLE SERVICE 7.....................

Tyre Inflation Pressure Check 7.................

Tyre Wear Check 7............................

Wheel Runout Check 7.........................

WHEEL AND TYRE 7........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1145 of 1839

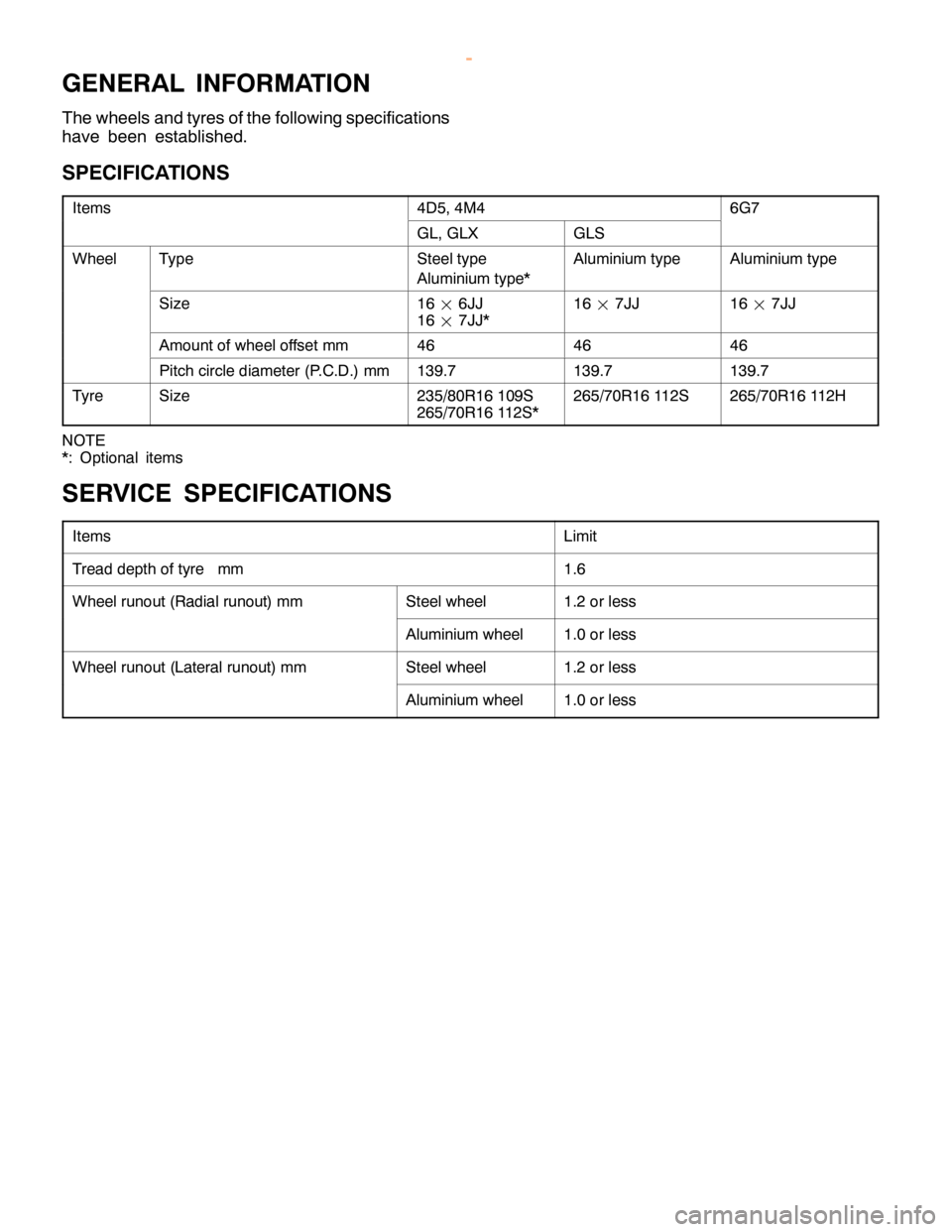

WHEEL AND TYRE -General Information/Service Specifications31-2

GENERAL INFORMATION

The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

Items4D5, 4M46G7

GL, GLXGLS

WheelTypeSteel type

Aluminium type*Aluminium typeAluminium type

Size16¢6JJ

16¢7JJ*16¢7JJ16¢7JJ

Amount of wheel offset mm464646

Pitch circle diameter (P.C.D.) mm139.7139.7139.7

TyreSize235/80R16 109S

265/70R16 112S*265/70R16 112S265/70R16 112H

NOTE

*: Optional items

SERVICE SPECIFICATIONS

ItemsLimit

Tread depth of tyre mm1.6

Wheel runout (Radial runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less

Wheel runout (Lateral runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1152 of 1839

Service Bulletins

Click on the applicable bookmark to select the Service Bulletin.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1170 of 1839

33A-1

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION 1..................

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......Ball Joint Dust Cover Check 6..................

UPPER ARM ASSEMBLY 7...................

SHOCK ABSORBER ASSEMBLY 10.........

LOWER ARM ASSEMBLY 13................

STABILIZER BAR 16........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1175 of 1839

FRONT SUSPENSION -On-vehicle Service33A-6

SIDE SLIP

Measure the side slip with a side slip tester.

Standard value: 0±

3mm

BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

lower arm assembly or stabilizer link.

NOTE

Cracks or damage of the dust cover may cause damage

of the ball joint.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk