service MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1189 of 1839

34-1

REAR

SUSPENSION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......

Ball Joint Dust Cover Check 5..................

UPPER ARM ASSEMBLY 6...................SHOCK ABSORBER/COIL SPRING/LOWER

ARM ASSEMBLY 9...........................

STABILIZER BAR 11.........................

TOE CONTROL ARM ASSEMBLY/TOE

CONTROL TOWER BAR 13..................

TRAILING ARM ASSEMBLY 16..............

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1205 of 1839

Service Bulletins

Click on the applicable bookmark to select the Service Bulletin.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1210 of 1839

35A-2

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 6..............................

SPECIAL TOOLS 6..........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 19...................

Brake Pedal Check and Adjustment 19..........

Hydraulic Brake Booster (HBB) Operation Check

HBB Check

HBB Motor Relay Continuity Check

Brake Booster Operating Test

Check Valve Operation Check

Load Sensing Spring Length Check and

Adjustment

Load Sensing Proportioning Valve Function

Test

Bleeding

Brake Fluid Level Sensor Check 30.............

Brake Booster Vacuum Switch Check

Disc Brake Pad Check and Replacement 31.....

Disc Brake Rotor Check 32.....................

Brake Disc Thickness Check 32.................

Brake Disc Run-out Check and Correction 33....

BRAKE PEDAL 34..........................

HYDRAULIC BRAKE BOOSTER (HBB)

HBB BUZZER

MASTER CYLINDER AND BRAKE

BOOSTER

Master Cylinder 43.............................

FRONT DISC BRAKE 44....................

REAR DISC BRAKE 49......................

LOAD SENSING PROPORTIONING

VALVE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1213 of 1839

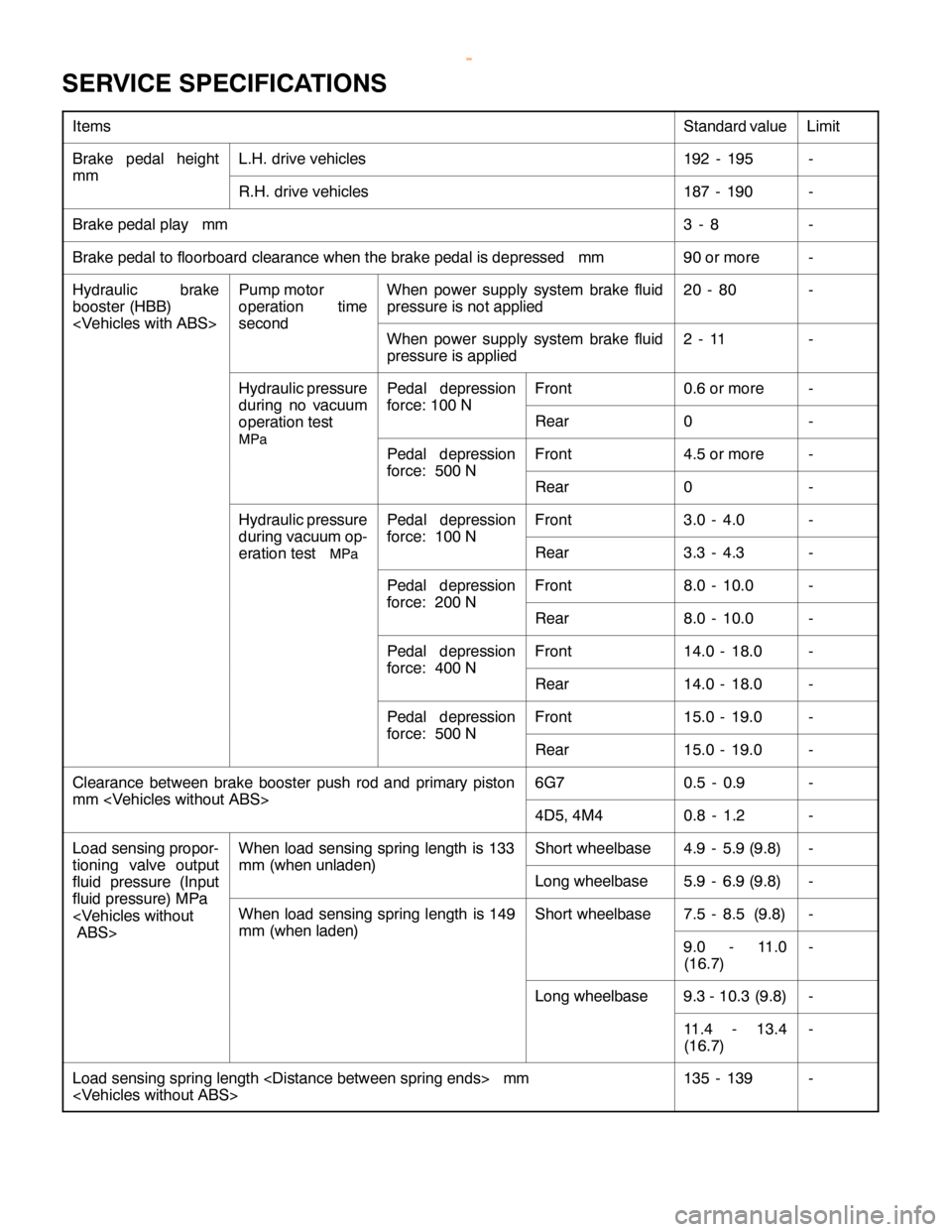

BASIC BRAKE SYSTEM -Service Specifications35A-5

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal heightL.H. drive vehicles192 - 195-

mm

R.H. drive vehicles187 - 190-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Hydraulic brake

booster (HBB)Pump motor

operation timeWhen power supply system brake fluid

pressure is not applied20 - 80-

When power supply system brake fluid

pressure is applied2-11-

Hydraulic pressurePedal depressionFront0.6 or more-

during no vacuum

operation testforce: 100 N

Rear0-

MPa

Pedal depressionFront4.5 or more-

force: 500 N

Rear0-

Hydraulic pressurePedal depressionFront3.0 - 4.0-

during vacuum op-

eration test

MPa

force: 100 N

Rear3.3 - 4.3-

Pedal depressionFront8.0 - 10.0-

force: 200 N

Rear8.0 - 10.0-

Pedal depressionFront14.0 - 18.0-

force: 400 N

Rear14.0 - 18.0-

Pedal depressionFront15.0 - 19.0-

force: 500 N

Rear15.0 - 19.0-

Clearance between brake booster push rod and primary piston6G70.5 - 0.9-

mm

4D5, 4M40.8 - 1.2-

Load sensing propor-When load sensing spring length is 133Short wheelbase4.9 - 5.9 (9.8)-

tioning valve output

fluid pressure (Inputmm (when unladen)

Long wheelbase5.9 - 6.9 (9.8)-

fluid pressure) MPa

9.0 - 11.0

(16.7)-

Long wheelbase9.3 - 10.3 (9.8)-

11.4 - 13.4

(16.7)-

Load sensing spring length

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1223 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-15

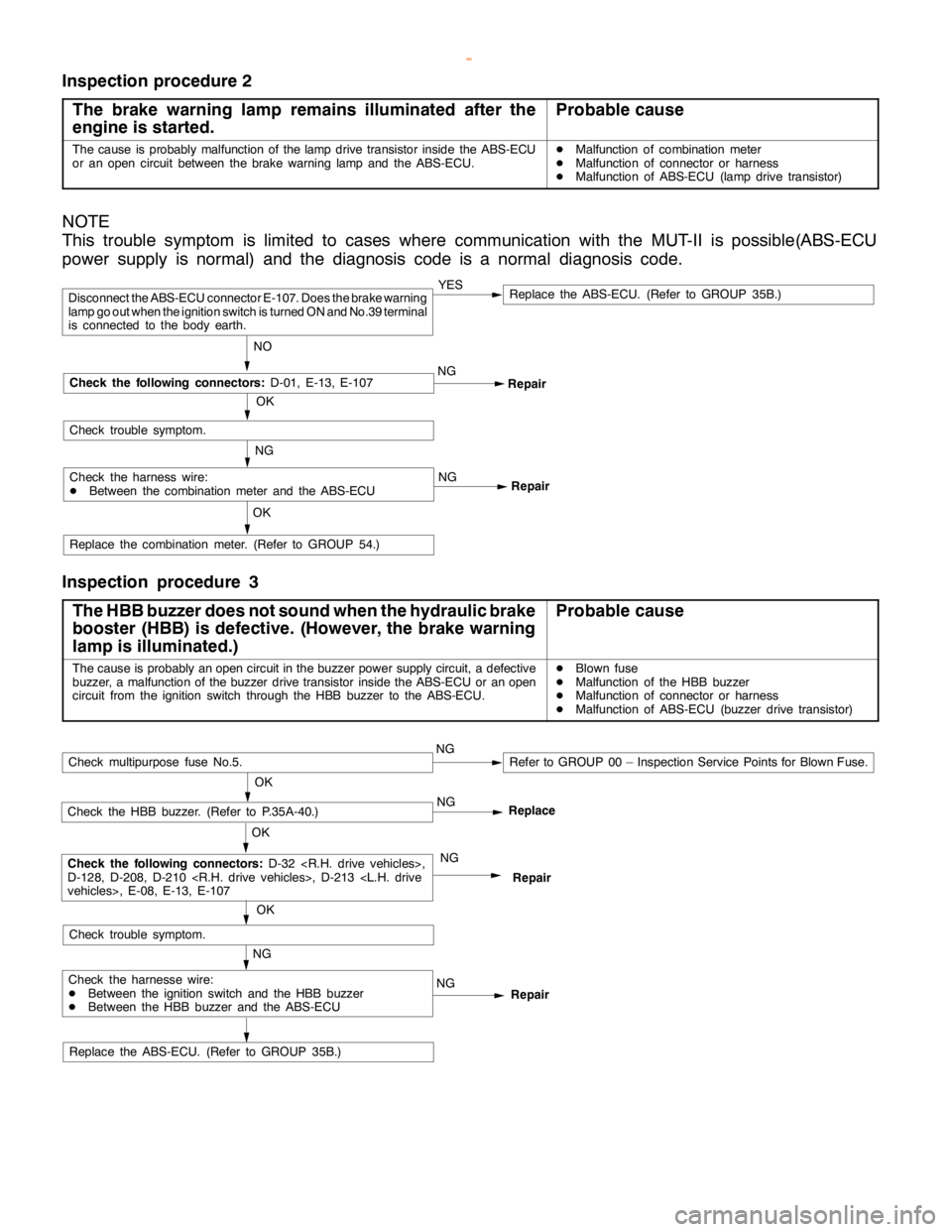

Inspection procedure 2

The brake warning lamp remains illuminated after the

engine is started.

Probable cause

The cause is probably malfunction of thelampdrive transistor inside the ABS-ECU

or an opencircuit between the brake warninglamp and theABS-ECU.DMalfunction of combination meter

DMalfunction of connector or harness

DMalfunction of ABS-ECU (lamp drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

Repair NG

Repair

Replace the combination meter. (Refer to GROUP 54.)

OK

YESReplace the ABS-ECU. (Refer to GROUP 35B.)

NO

Disconnect the ABS-ECU connector E-107. Does the brake warning

lamp go outwhen the ignition switch is turned ON and No.39 terminal

is connected to the body earth.

OK

Check the following connectors:

D-01, E-13, E-107

Check trouble symptom.

Check the harness wire:

DBetween the combination meter and the ABS-ECUNG

NG

Inspection procedure 3

The HBB buzzer does not sound when the hydraulic brake

booster (HBB) is defective. (However, thebrake warning

lamp is illuminated.)

Probable cause

The cause is probably anopencircuit in the buzzer power supply circuit, a defective

buzzer, a malfunction of the buzzer drive transistor inside the ABS-ECU or anopen

circuit from the ignition switch through the HBB buzzer to the ABS-ECU.DBlown fuse

DMalfunction of the HBB buzzer

DMalfunction of connector or harness

DMalfunction of ABS-ECU (buzzer drive transistor)

Replace the ABS-ECU. (Refer to GROUP 35B.)

Repair NG

Repair

NG

OK

Check the HBB buzzer. (Refer to P.35A-40.)

OK

Check the following connectors:

D-32

D-128, D-208, D-210

NG

OK

Check trouble symptom.

Check multipurpose fuse No.5.NGRefer to GROUP 00 – Inspection Service Points for Blown Fuse.

Check the harnesse wire:

DBetween the ignition switch and the HBB buzzer

DBetween the HBB buzzer and the ABS-ECUNGReplace

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1235 of 1839

BASIC BRAKE SYSTEM -On-vehicle ServiceBASIC BRAKE SYSTEM -On-vehicle Service35A-27

BLEEDING

Caution

Specified brake fluid: DOT3 or DOT4

1. Always use the specified brake fluid. Avoid using

a mixture of the specified brake fluid and other fluid.

2. Maintain the fluid reservoir level between the MIN

and MAX marks during the air bleeding.

3. Do not depress the brake pedal hard during the air

bleeding (normal air bleeding) to prevent the pump

motor from operating frequently.

4. After the air bleeding, check that the brake dragging

does not become stronger.

5. If the pedal is depressed with the reservoir cap

removed, the brake fluid may overflow. Do not depress

the brake pedal while the fluid is being added.

NORMAL AIR BLEEDING

After the front brake or the rear brake is removed and installed,

some fluid may remain in the hydraulic brake booster (HBB)

reservoir. In this case, bleed air from the brake caliper.

HBB SYSTEM AIR BLEEDING

If all the brake fluid inside the reservoir is drained due to

the removal and installation of the HBB, bleed air as follows:

Air bleeding from front brake system

1. Turn the ignition switch to the LOCK (OFF) position. Bleed

air from the front brake calipers (right and left) by pumping

the brake pedal.

Pump motor operation

2. Turn the ignition switch ON, and operate the pump motor.

If the pump motor is running free, supply the brake fluid

into the pump motor by depressing the brake pedal three

or four times.

Air bleeding from accumulator system

3. After the pump motor stopped, depress the brake pedal

three or four times with the ignition switch ON. Then

observe the brake fluid in the reservoir. If the brake fluid

looks whitish, wait for a few minutes until it becomes

clear.

4. Repeat step 3 until the brake fluid becomes clear.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1264 of 1839

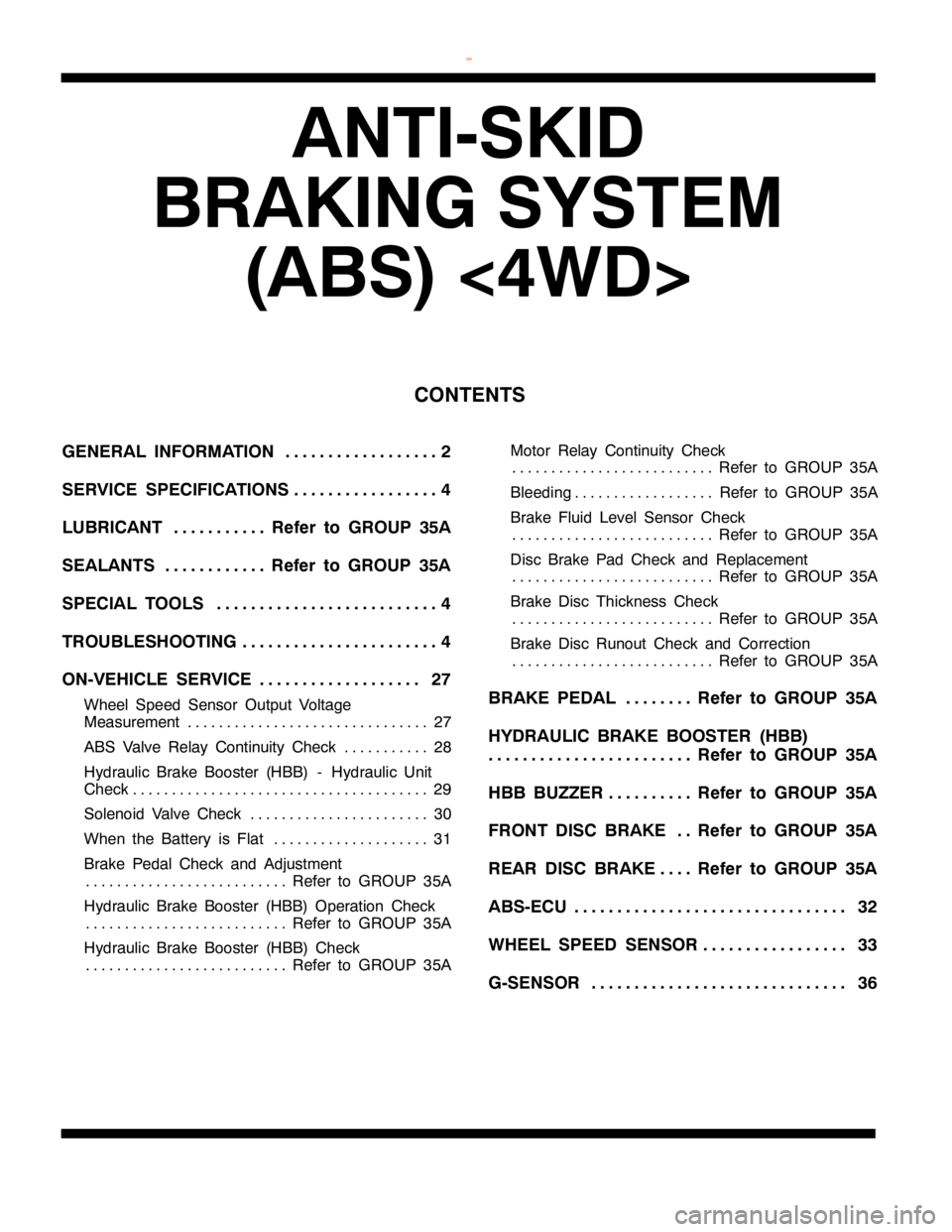

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANT Refer to GROUP 35A...........

SEALANTS Refer to GROUP 35A............

SPECIAL TOOLS 4..........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 27...................

Wheel Speed Sensor Output Voltage

Measurement 27...............................

ABS Valve Relay Continuity Check 28...........

Hydraulic Brake Booster (HBB) - Hydraulic Unit

Check 29......................................

Solenoid Valve Check 30.......................

When the Battery is Flat 31....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Operation Check

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Check

Refer to GROUP 35A ..........................Motor Relay Continuity Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and Replacement

Refer to GROUP 35A ..........................

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Runout Check and Correction

Refer to GROUP 35A ..........................BRAKE PEDAL Refer to GROUP 35A........

HYDRAULIC BRAKE BOOSTER (HBB)

Refer to GROUP 35A ........................

HBB BUZZER Refer to GROUP 35A..........

FRONT DISC BRAKE Refer to GROUP 35A..

REAR DISC BRAKE Refer to GROUP 35A....

ABS-ECU 32................................

WHEEL SPEED SENSOR 33.................

G-SENSOR 36..............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1271 of 1839

ABS <4WD> -TroubleshootingABS <4WD> -Troubleshooting35B-8

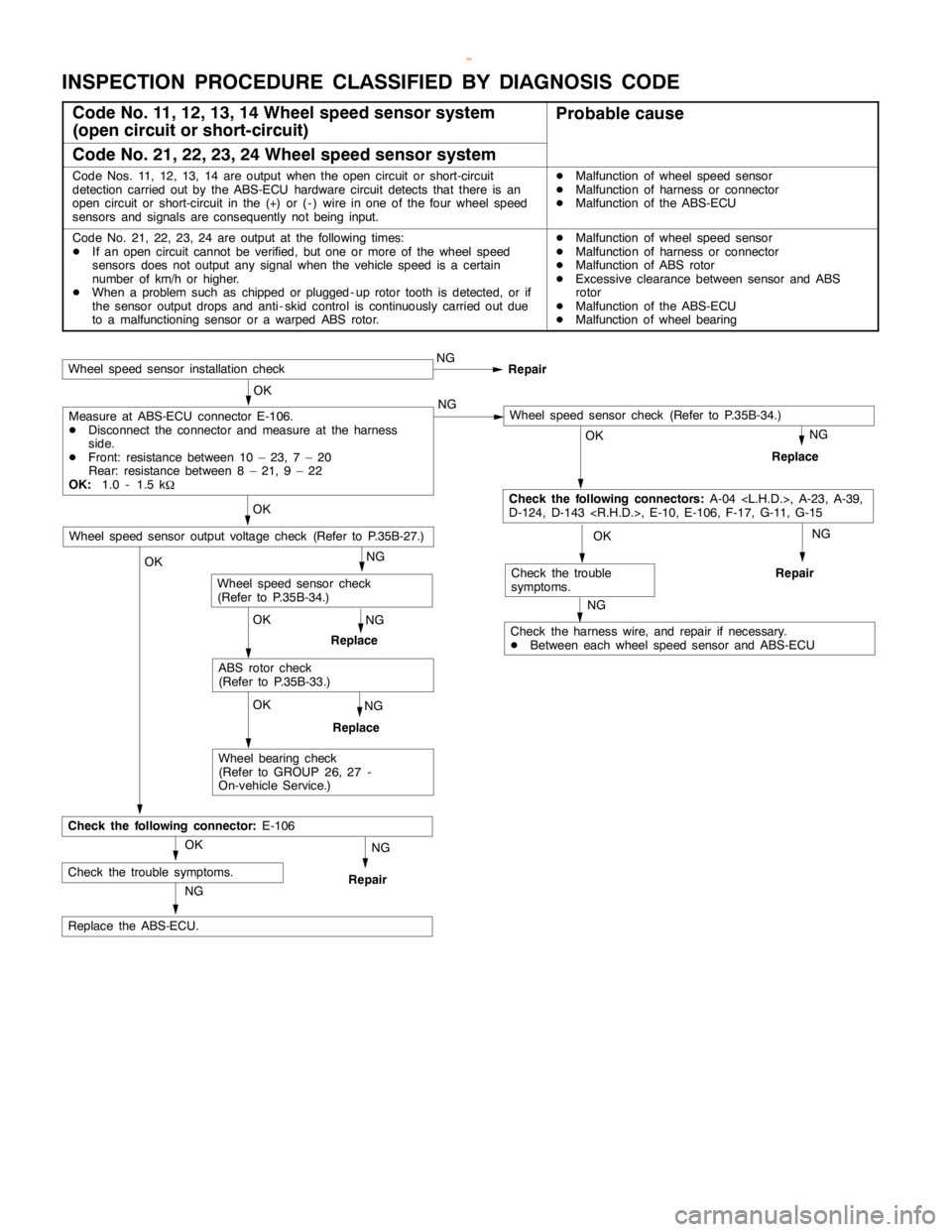

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No. 11, 12, 13, 14 Wheel speed sensor system

(open circuit or short-circuit)Probable cause

Code No. 21, 22, 23, 24 Wheel speed sensor system

Code Nos. 11, 12, 13, 14 are output when theopencircuit or short-circuit

detection carried out by the ABS-ECU hardware circuit detects that there is an

opencircuit or short-circuit in the (+) or ( - ) wire in one of the four wheel speed

sensors and signals are consequently notbeing input.DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of the ABS-ECU

Code No. 21, 22, 23, 24 are output at the following times:

DIf an opencircuit cannot be verified, but one or more of the wheel speed

sensors does not output any signal when the vehicle speed is a certain

number of km/h or higher.

DWhen a problem such as chipped orplugged - uprotor tooth is detected, or if

the sensor output drops and anti - skid control is continuously carried out due

to a malfunctioning sensor or a warped ABS rotor.DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of ABS rotor

DExcessive clearancebetween sensor and ABS

rotor

DMalfunction of the ABS-ECU

DMalfunction of wheel bearing

NG

NG

Replace the ABS-ECU.

NG

Repair

OK

Check the trouble symptoms.

OK

Check the following connector:E-106

OK

Wheel bearing check

(Refer to GROUP 26, 27 -

On-vehicle Service.)

NG

Replace

OK

ABS rotor check

(Refer to P.35B-33.)

NG

Replace

Wheel speed sensor check

(Refer to P.35B-34.)

OK

Wheel speed sensor output voltage check (Refer to P.35B-27.)

OK

Check the following connectors:A-04

D-124, D-143

Wheel speed sensor installation checkNG

Repair

OK

Measure at ABS-ECU connector E-106.

DDisconnect the connector and measure at the harness

side.

DFront: resistance between 10 – 23, 7 – 20

Rear: resistance between 8 – 21, 9 – 22

OK:1.0 - 1.5 k

WNG

NG

Replace

NG

Repair

OK

Check the trouble

symptoms.

NG

Check the harness wire, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU

Wheel speed sensor check (Refer to P.35B-34.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1272 of 1839

ABS <4WD> -Troubleshooting35B-9

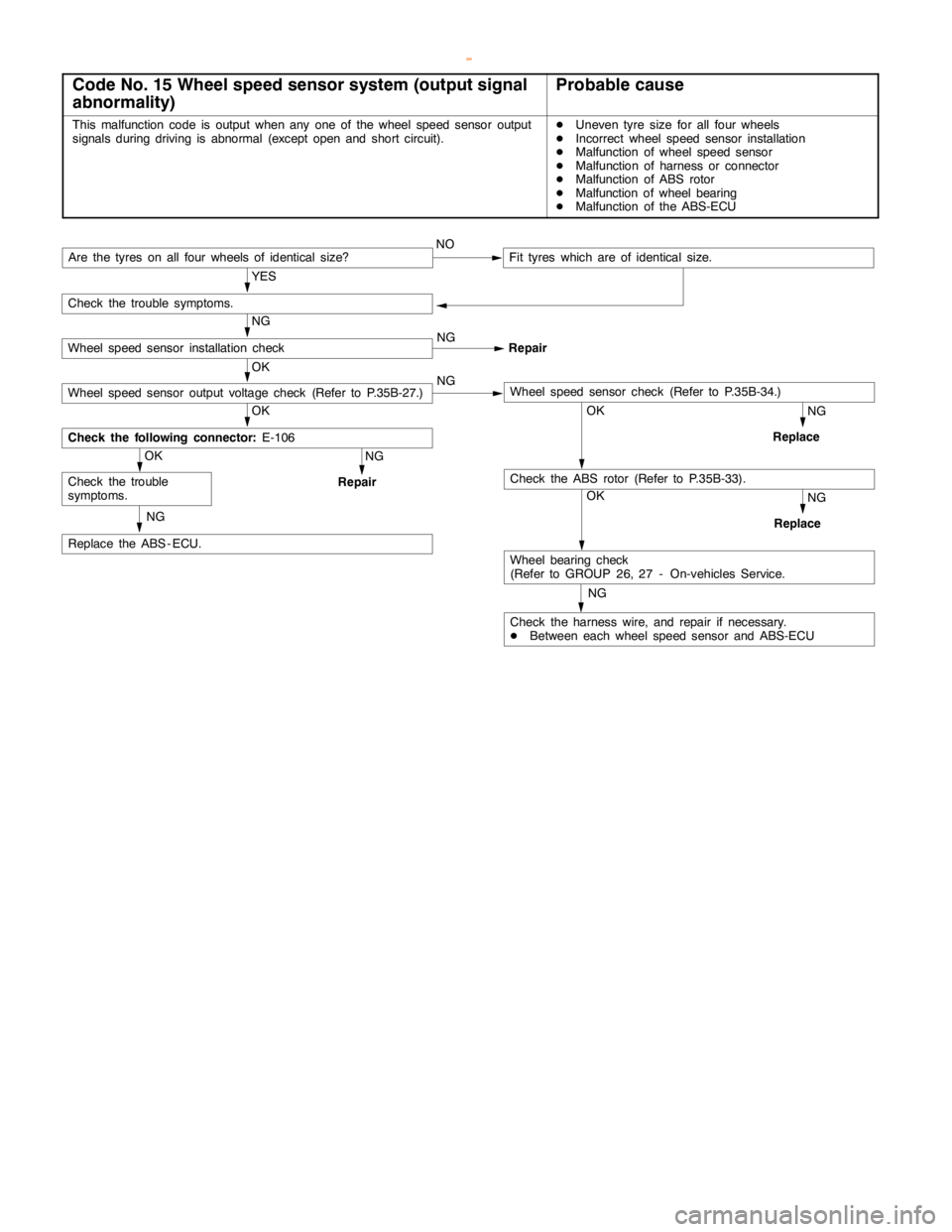

Code No. 15 Wheel speed sensor system (output signal

abnormality)Probable cause

This malfunction code is output when any one of the wheel speed sensor output

signals during driving is abnormal (exceptopen andshort circuit).DUneven tyre size for all four wheels

DIncorrect wheel speed sensor installation

DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of ABS rotor

DMalfunction of wheel bearing

DMalfunction of the ABS-ECU

NG

Check the harness wire, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU

OK

Wheel bearing check

(Refer to GROUP 26, 27 - On-vehicles Service.

NG

Replace

OKNG

Replace

NG

Replace the ABS - ECU.

OK

Check the trouble

symptoms.

NG

Repair

OK

Check the following connector:E-106

OK

Wheel speed sensor output voltage check (Refer to P.35B-27.)NGWheel speed sensor check (Refer to P.35B-34.)

NG

Wheel speed sensor installation checkNG

Repair

Are the tyres on all four wheels of identical size?NOFit tyres which are of identical size.

YES

Check the trouble symptoms.

Check the ABS rotor (Refer to P.35B-33).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1277 of 1839

ABS <4WD> -Troubleshooting35B-14

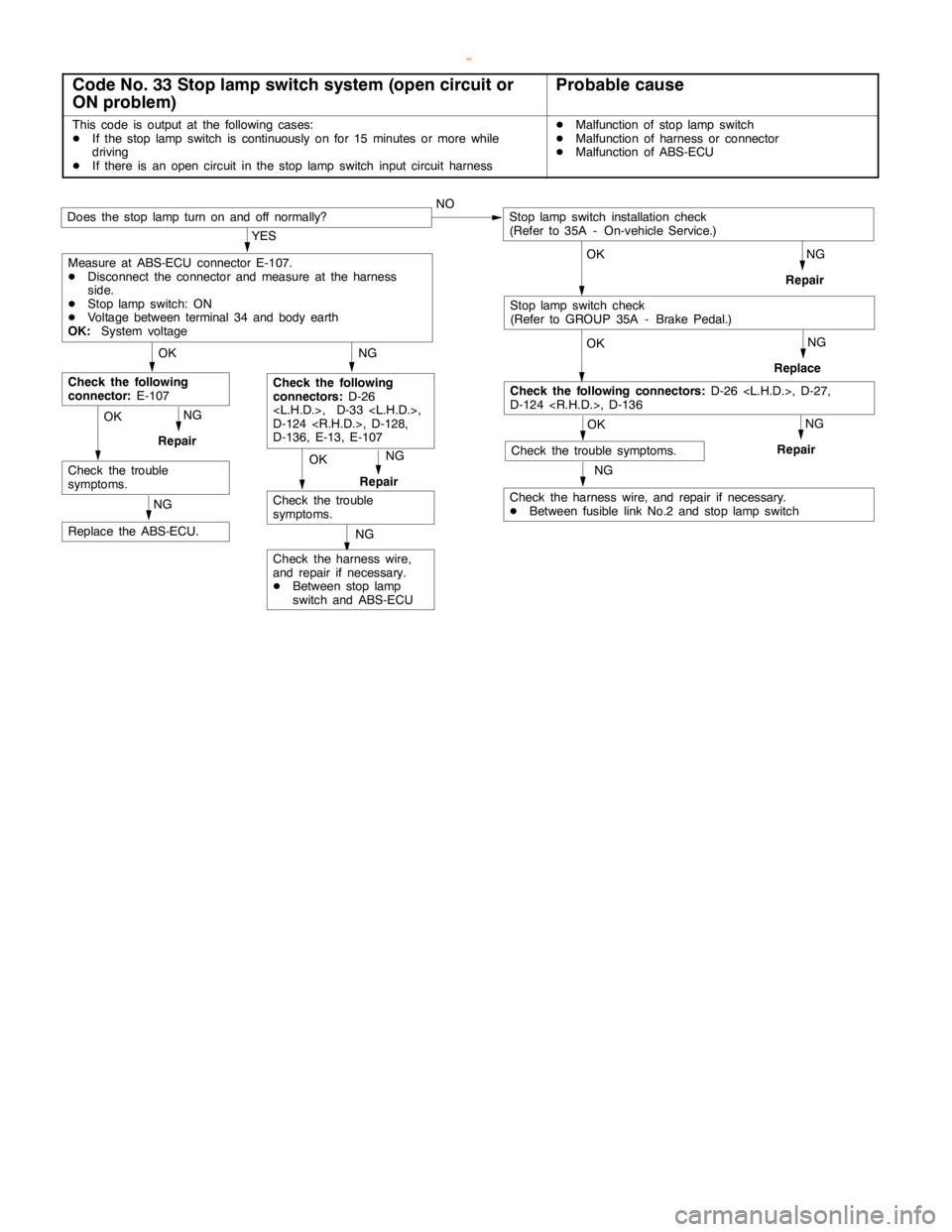

Code No. 33 Stop lamp switch system (open circuit or

ON problem)Probable cause

This code is output at the following cases:

DIf the stoplampswitch is continuously on for 15 minutes or more while

driving

DIf there is an opencircuit in the stoplampswitch input circuit harnessDMalfunction of stoplampswitch

DMalfunction of harness or connector

DMalfunction of ABS-ECU

OK

NG

Check the harness wire,

and repair if necessary.

DBetween stoplamp

switch and ABS-ECU

NG

Replace the ABS-ECU.

NG

Repair

Check the trouble

symptoms.NG

Repair

OK

Check the trouble

symptoms.

NG

Check the following

connectors:D-26

D-124

D-136, E-13, E-107

OK

Check the following

connector:E-107

NG

Check the harness wire, and repair if necessary.

DBetween fusible link No.2 and stoplampswitch

OK

OK

Check the following connectors:D-26

D-124

OK

Does the stoplampturn on and off normally?NO

NG

Repair

NG

Replace

NG

Repair

YES

Measure at ABS-ECU connector E-107.

DDisconnect the connector and measure at the harness

side.

DStoplampswitch: ON

DVoltage between terminal 34 and body earth

OK:System voltage

Stoplampswitch installation check

(Refer to 35A - On-vehicle Service.)

Check the trouble symptoms.

Stoplampswitch check

(Refer to GROUP 35A - Brake Pedal.)

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk