speed sensor MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1264 of 1839

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANT Refer to GROUP 35A...........

SEALANTS Refer to GROUP 35A............

SPECIAL TOOLS 4..........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 27...................

Wheel Speed Sensor Output Voltage

Measurement 27...............................

ABS Valve Relay Continuity Check 28...........

Hydraulic Brake Booster (HBB) - Hydraulic Unit

Check 29......................................

Solenoid Valve Check 30.......................

When the Battery is Flat 31....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Operation Check

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Check

Refer to GROUP 35A ..........................Motor Relay Continuity Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and Replacement

Refer to GROUP 35A ..........................

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Runout Check and Correction

Refer to GROUP 35A ..........................BRAKE PEDAL Refer to GROUP 35A........

HYDRAULIC BRAKE BOOSTER (HBB)

Refer to GROUP 35A ........................

HBB BUZZER Refer to GROUP 35A..........

FRONT DISC BRAKE Refer to GROUP 35A..

REAR DISC BRAKE Refer to GROUP 35A....

ABS-ECU 32................................

WHEEL SPEED SENSOR 33.................

G-SENSOR 36..............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1265 of 1839

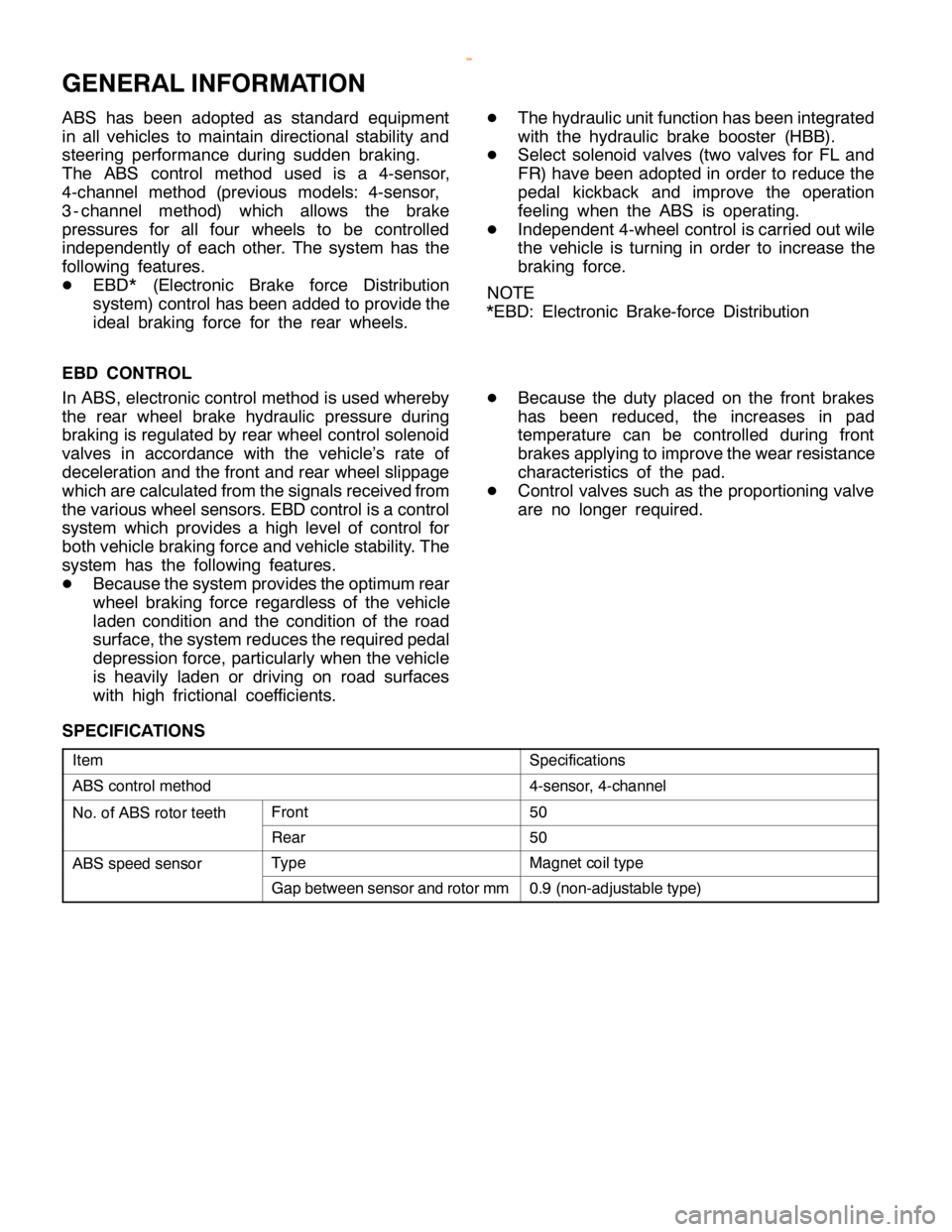

ABS <4WD> -General Information35B-2

GENERAL INFORMATION

ABS has been adopted as standard equipment

in all vehicles to maintain directional stability and

steering performance during sudden braking.

The ABS control method used is a 4-sensor,

4-channel method (previous models: 4-sensor,

3- channel method

)which allows the brake

pressures for all four wheels to be controlled

independently of each other. The system has the

following features.

DEBD

*(Electronic Brake force Distribution

system) control has been added to provide the

ideal braking force for the rear wheels.DThe hydraulic unit function has been integrated

with the hydraulic brake booster (HBB).

DSelect solenoid valves (two valves for FL and

FR) have been adopted in order to reduce the

pedal kickback and improve the operation

feeling when the ABS is operating.

DIndependent 4-wheel control is carried out wile

the vehicle is turning in order to increase the

braking force.

NOTE

*EBD: Electronic Brake-force Distribution

EBD CONTROL

In ABS, electronic control method is used whereby

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the signals received from

the various wheel sensors. EBD control is a control

system which provides a high level of control for

both vehicle braking force and vehicle stability. The

system has the following features.

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicle

laden condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled during front

brakes applying to improve the wear resistance

characteristics of the pad.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront50

Rear50

ABS speed sensorTypeMagnet coil type

Gap between sensor and rotor mm0.9 (non-adjustable type)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1270 of 1839

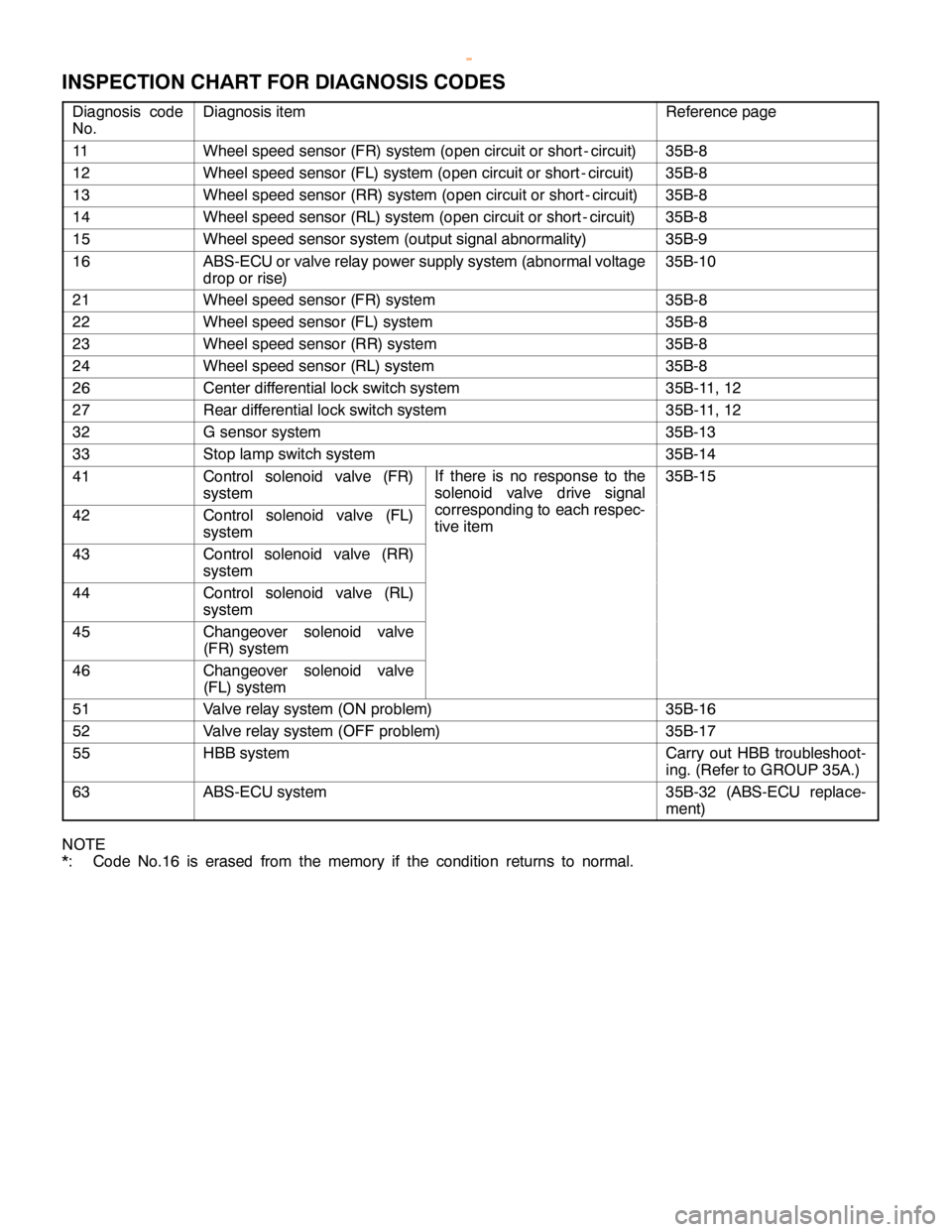

ABS <4WD> -Troubleshooting35B-7

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis code

No.Diagnosis itemReference page

11Wheel speed sensor (FR) system (open circuit or short - circuit)35B-8

12Wheel speed sensor (FL) system (open circuit or short - circuit)35B-8

13Wheel speed sensor (RR) system (open circuit or short - circuit)35B-8

14Wheel speed sensor (RL) system (open circuit or short - circuit)35B-8

15Wheel speed sensor system (output signal abnormality)35B-9

16ABS-ECU or valve relay power supply system (abnormal voltage

drop or rise)35B-10

21Wheel speed sensor (FR) system35B-8

22Wheel speed sensor (FL) system35B-8

23Wheel speed sensor (RR) system35B-8

24Wheel speed sensor (RL) system35B-8

26Center differential lock switch system35B-11, 12

27Rear differential lock switch system35B-11, 12

32G sensor system35B-13

33Stop lamp switch system35B-14

41Control solenoid valve (FR)

systemIf there is no response to the

solenoid valve drive signal35B-15

42Control solenoid valve (FL)

systemcorresponding to each respec-

tive item

43Control solenoid valve (RR)

system

44Control solenoid valve (RL)

system

45Changeover solenoid valve

(FR) system

46Changeover solenoid valve

(FL) system

51Valve relay system (ON problem)35B-16

52Valve relay system(OFFproblem)35B-17

55HBB systemCarry out HBB troubleshoot-

ing. (Refer to GROUP 35A.)

63ABS-ECU system35B-32 (ABS-ECU replace-

ment)

NOTE

*: Code No.16 is erased from the memory if the condition returns to normal.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1271 of 1839

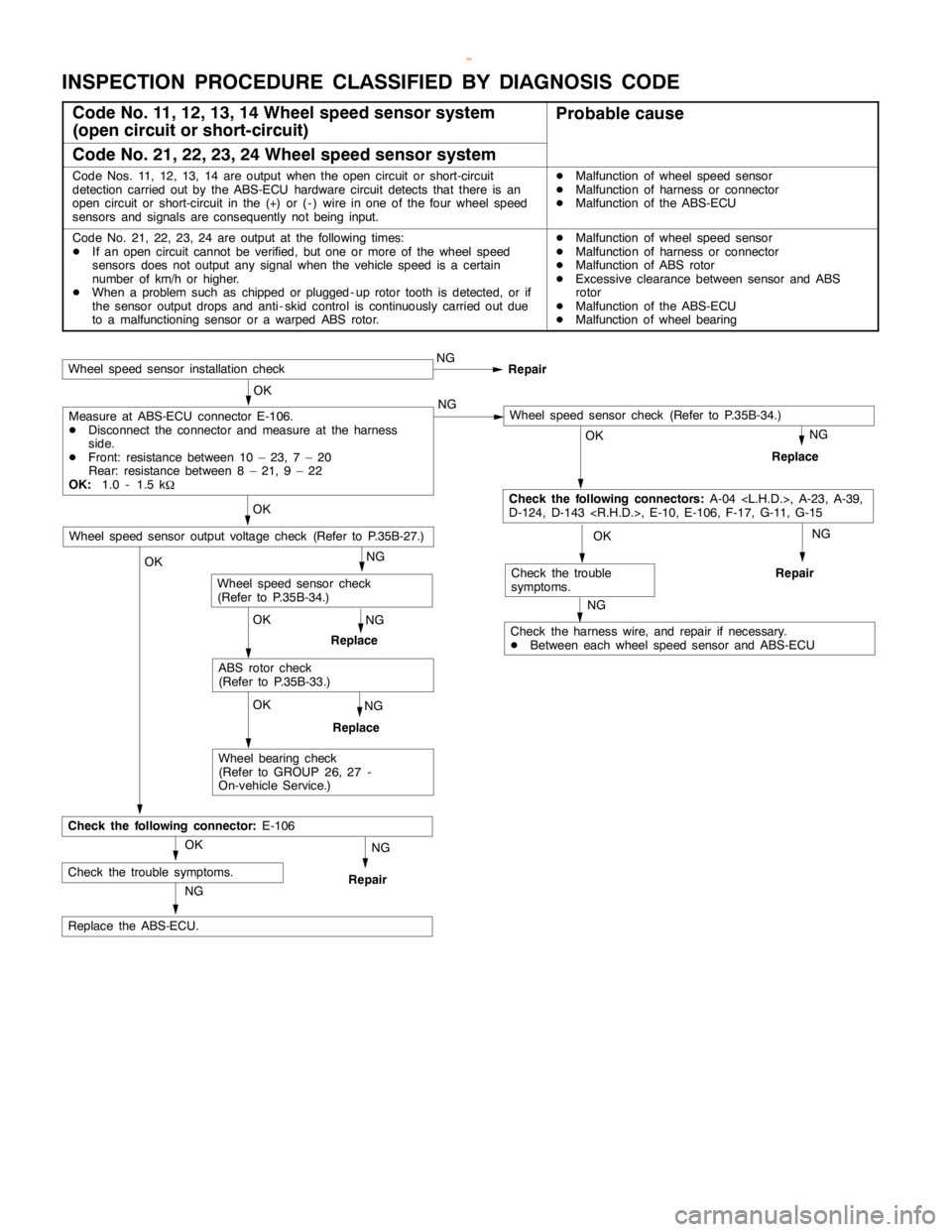

ABS <4WD> -TroubleshootingABS <4WD> -Troubleshooting35B-8

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No. 11, 12, 13, 14 Wheel speed sensor system

(open circuit or short-circuit)Probable cause

Code No. 21, 22, 23, 24 Wheel speed sensor system

Code Nos. 11, 12, 13, 14 are output when theopencircuit or short-circuit

detection carried out by the ABS-ECU hardware circuit detects that there is an

opencircuit or short-circuit in the (+) or ( - ) wire in one of the four wheel speed

sensors and signals are consequently notbeing input.DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of the ABS-ECU

Code No. 21, 22, 23, 24 are output at the following times:

DIf an opencircuit cannot be verified, but one or more of the wheel speed

sensors does not output any signal when the vehicle speed is a certain

number of km/h or higher.

DWhen a problem such as chipped orplugged - uprotor tooth is detected, or if

the sensor output drops and anti - skid control is continuously carried out due

to a malfunctioning sensor or a warped ABS rotor.DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of ABS rotor

DExcessive clearancebetween sensor and ABS

rotor

DMalfunction of the ABS-ECU

DMalfunction of wheel bearing

NG

NG

Replace the ABS-ECU.

NG

Repair

OK

Check the trouble symptoms.

OK

Check the following connector:E-106

OK

Wheel bearing check

(Refer to GROUP 26, 27 -

On-vehicle Service.)

NG

Replace

OK

ABS rotor check

(Refer to P.35B-33.)

NG

Replace

Wheel speed sensor check

(Refer to P.35B-34.)

OK

Wheel speed sensor output voltage check (Refer to P.35B-27.)

OK

Check the following connectors:A-04

D-124, D-143

Wheel speed sensor installation checkNG

Repair

OK

Measure at ABS-ECU connector E-106.

DDisconnect the connector and measure at the harness

side.

DFront: resistance between 10 – 23, 7 – 20

Rear: resistance between 8 – 21, 9 – 22

OK:1.0 - 1.5 k

WNG

NG

Replace

NG

Repair

OK

Check the trouble

symptoms.

NG

Check the harness wire, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU

Wheel speed sensor check (Refer to P.35B-34.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1272 of 1839

ABS <4WD> -Troubleshooting35B-9

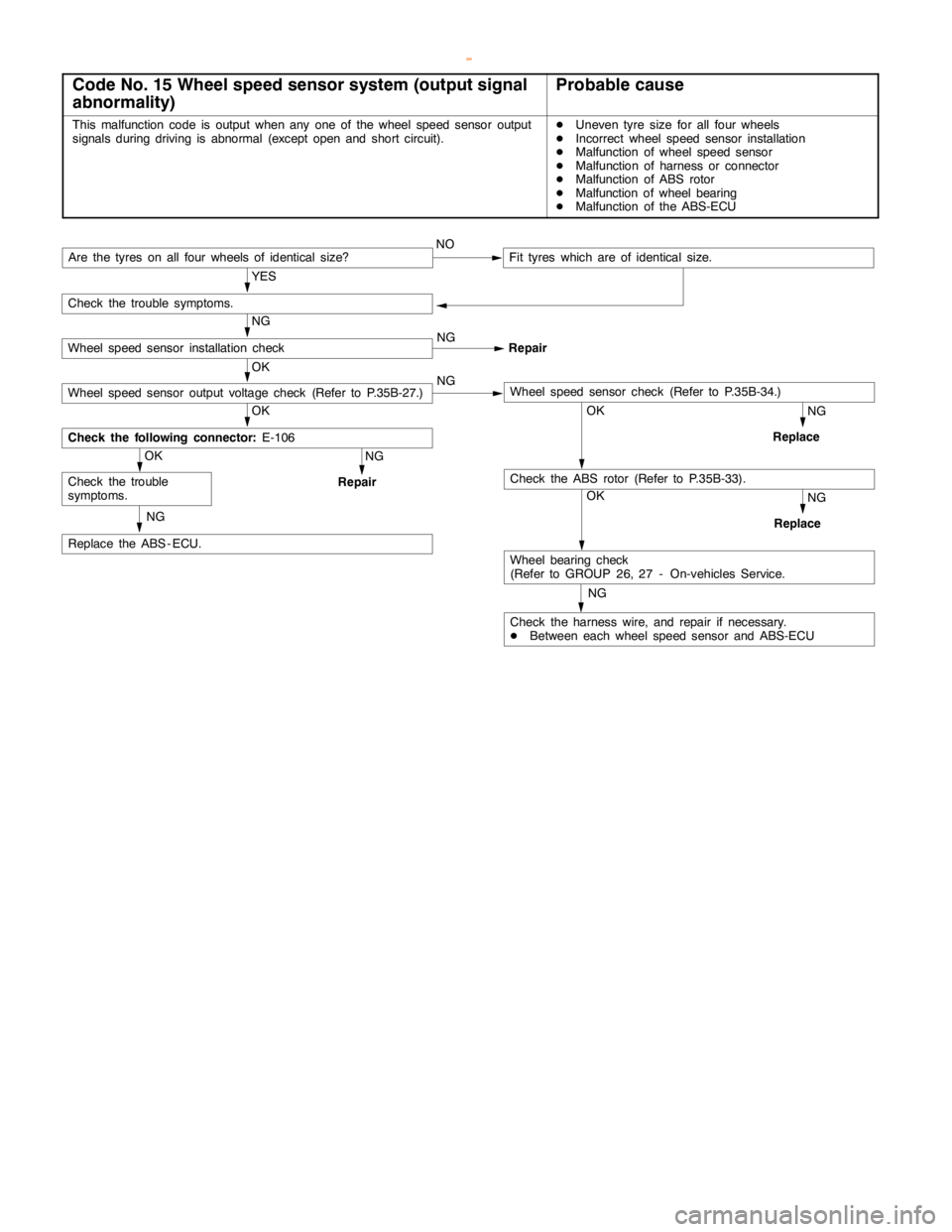

Code No. 15 Wheel speed sensor system (output signal

abnormality)Probable cause

This malfunction code is output when any one of the wheel speed sensor output

signals during driving is abnormal (exceptopen andshort circuit).DUneven tyre size for all four wheels

DIncorrect wheel speed sensor installation

DMalfunction of wheel speed sensor

DMalfunction of harness or connector

DMalfunction of ABS rotor

DMalfunction of wheel bearing

DMalfunction of the ABS-ECU

NG

Check the harness wire, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU

OK

Wheel bearing check

(Refer to GROUP 26, 27 - On-vehicles Service.

NG

Replace

OKNG

Replace

NG

Replace the ABS - ECU.

OK

Check the trouble

symptoms.

NG

Repair

OK

Check the following connector:E-106

OK

Wheel speed sensor output voltage check (Refer to P.35B-27.)NGWheel speed sensor check (Refer to P.35B-34.)

NG

Wheel speed sensor installation checkNG

Repair

Are the tyres on all four wheels of identical size?NOFit tyres which are of identical size.

YES

Check the trouble symptoms.

Check the ABS rotor (Refer to P.35B-33).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1284 of 1839

ABS <4WD> -Troubleshooting35B-21

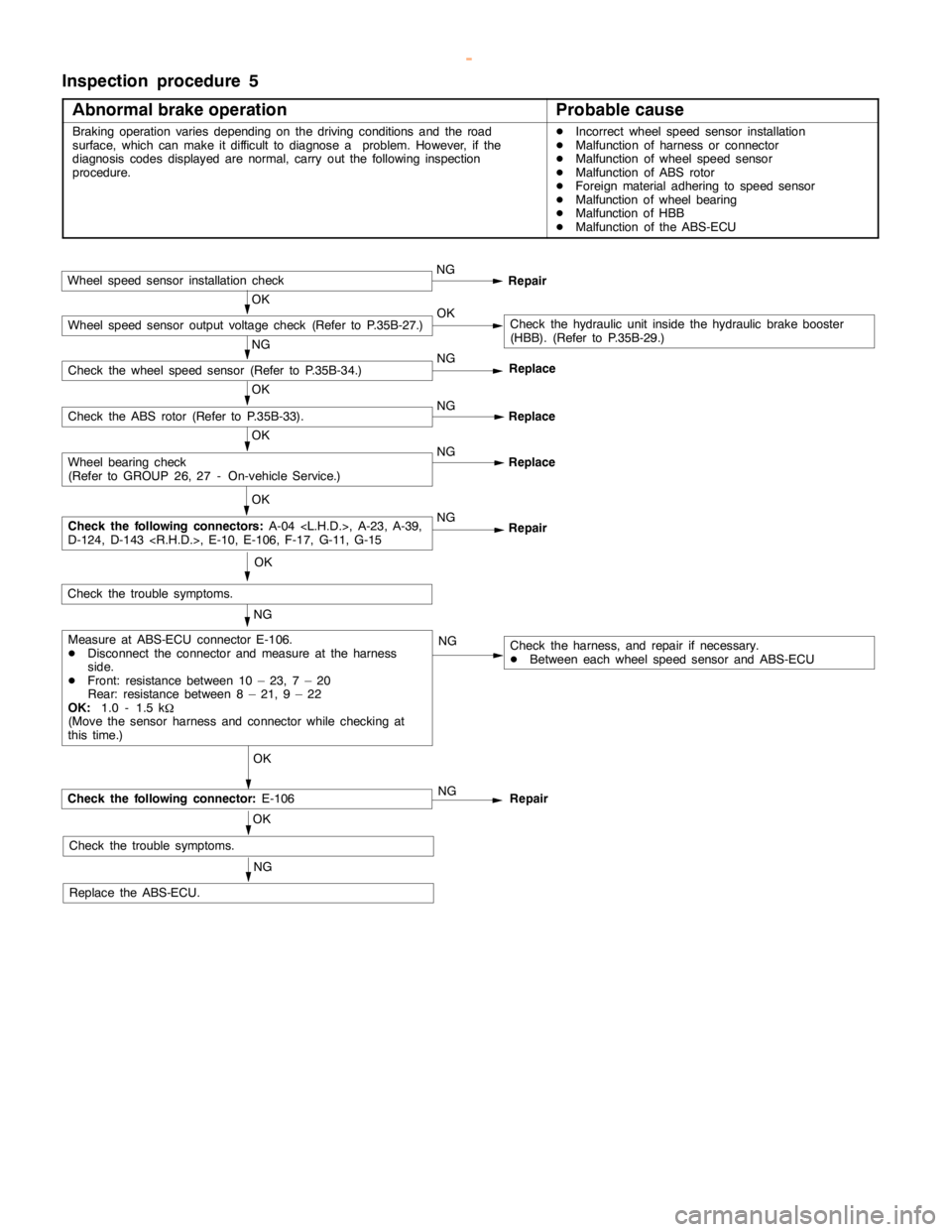

Inspection procedure 5

Abnormal brake operation

Probable cause

Braking operation variesdepending on the driving conditions and the road

surface, which can make it difficult to diagnose a problem. However, if the

diagnosis codes displayed are normal, carry out the following inspection

procedure.DIncorrect wheel speed sensor installation

DMalfunction of harness or connector

DMalfunction of wheel speed sensor

DMalfunction of ABS rotor

DForeign material adhering to speed sensor

DMalfunction of wheel bearing

DMalfunction of HBB

DMalfunction of the ABS-ECU

Wheel speed sensor installation checkNG

Repair

OKCheck the hydraulic unit inside the hydraulic brake booster

(HBB). (Refer to P.35B-29.)

NG

Check the wheel speed sensor (Refer to P.35B-34.)NG

OK

Check the ABS rotor (Refer to P.35B-33).NG

Replace

OK

NG

Replace

OK

NG

Repair

OK

NG

NG

OK

Check the following connector:E-106

OK

Check the trouble symptoms.

NG

Replace the ABS-ECU.NG

Repair

Check the harness, and repair if necessary.

DBetween each wheel speed sensor and ABS-ECU ReplaceMeasure at ABS-ECU connector E-106.

DDisconnect the connector and measure at the harness

side.

DFront: resistance between 10 – 23, 7 – 20

Rear: resistance between 8 – 21, 9 – 22

OK:1.0 - 1.5 k

W

(Move the sensor harness and connector while checking at

this time.)

Check the following connectors:A-04

D-124, D-143

Wheel bearing check

(Refer to GROUP 26, 27 - On-vehicle Service.)

Check the trouble symptoms.

Wheel speed sensor output voltage check (Refer to P.35B-27.)OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1285 of 1839

ABS <4WD> -Troubleshooting35B-22

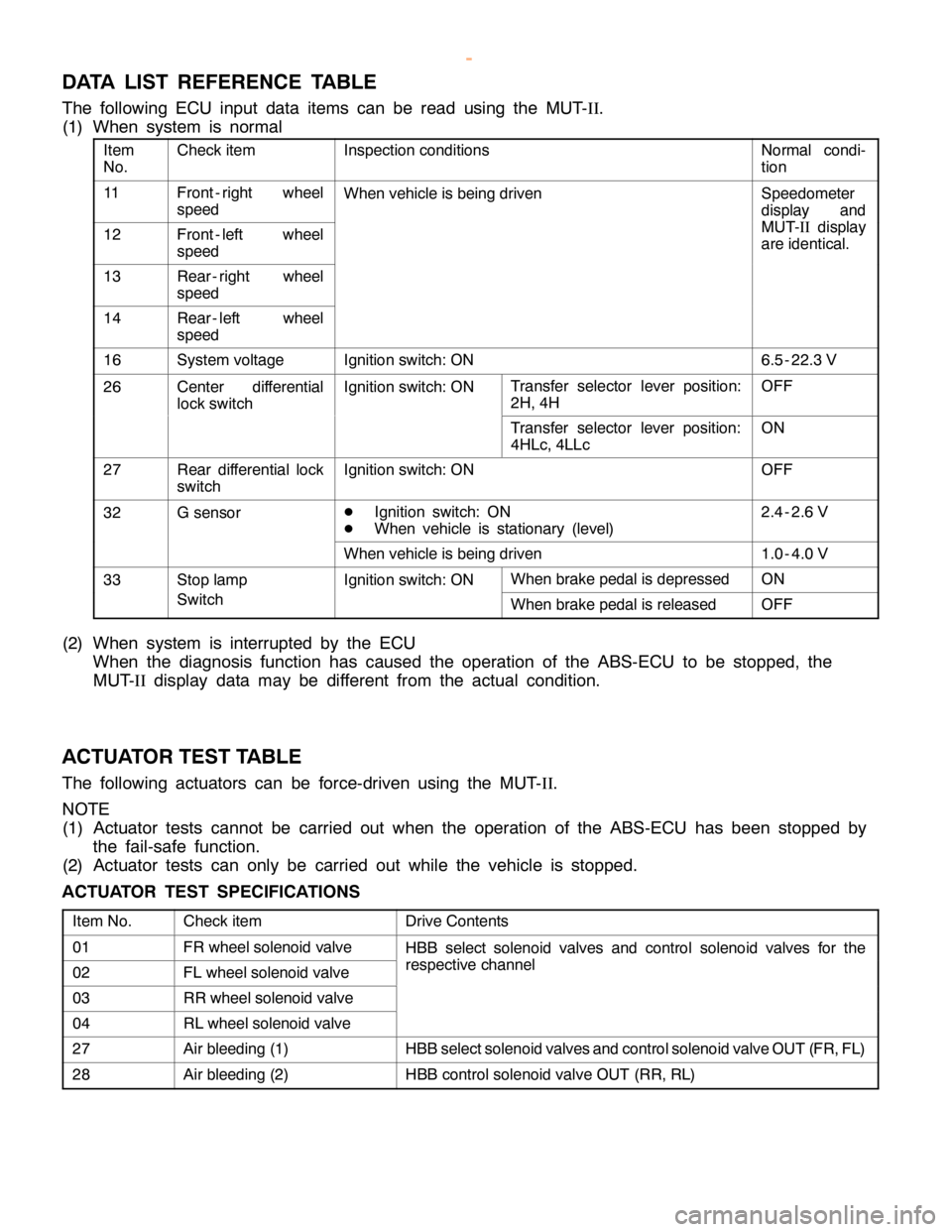

DATA LIST REFERENCE TABLE

The following ECU input data items can be read using the MUT-II

.

(1) When system is normal

Item

No.Check itemInspection conditionsNormal condi-

tion

11Front - right wheel

speedWhen vehicle is being drivenSpeedometer

display and

12Front - left wheel

speedMUT-IIdisplay

are identical.

13Rear - right wheel

speed

14Rear - left wheel

speed

16System voltageIgnition switch: ON6.5 - 22.3 V

26Center differential

lock switchIgnition switch: ONTransfer selector lever position:

2H, 4HOFF

Transfer selector lever position:

4HLc, 4LLcON

27Rear differential lock

switchIgnition switch: ONOFF

32G sensorD

Ignition switch: ON

D

When vehicle is stationary (level)2.4 - 2.6 V

When vehicle is being driven1.0 - 4.0 V

33Stop lampIgnition switch: ONWhen brake pedal is depressedON

SwitchWhen brake pedal is releasedOFF

(2) When system is interrupted by the ECU

When the diagnosis function has caused the operation of the ABS-ECU to be stopped, the

MUT-II

display data may be different from the actual condition.

ACTUATOR TEST TABLE

The following actuators can be force-driven using the MUT-II

.

NOTE

(1) Actuator tests cannot be carried out when the operation of the ABS-ECU has been stopped by

the fail-safe function.

(2) Actuator tests can only be carried out while the vehicle is stopped.

ACTUATOR TEST SPECIFICATIONS

Item No.Check itemDrive Contents

01FR wheel solenoid valveHBB select solenoid valves and control solenoid valves for the

02FL wheel solenoid valverespective channel

03RR wheel solenoid valve

04RL wheel solenoid valve

27Air bleeding (1)HBB select solenoid valves and control solenoid valve OUT (FR, FL)

28Air bleeding (2)HBB control solenoid valve OUT (RR, RL)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1562 of 1839

SRS -Post-collision Diagnosis52B-10

POST-COLLISION DIAGNOSIS

Check and service the vehicle after collision as follows

regardless of the operation of the pre-tensioner:

SRS-ECU MEMORY CHECK

The check procedure is the same as before.

REPAIR PROCEDURE

WHEN PRE-TENSIONER OPERATES IN A COLLISION.

1. Replace the following parts with new ones.

DSRS-ECU

DFront impact sensor

DSeat belt with pre-tensioner (Refer to P.52B-12.)

2. Check harnesses for binding, connectors for damage,

poor connections, and terminals for deformation.

UNDEPLOYED AIR BAGS IN LOW-SPEED COLLISION

Check the SRS-ECU and Front impact sensor and Seat belt

with pre-tensioner. If visible damage such as dents, cracks,

or deformation are found on the the SRS-ECU and Front

impact sensor and Seat belt with pre-tensioner, replace them

with new ones. Concerning parts removed for inspection,

replacement with new parts and cautions in working, refer

to INDIVIDUAL COMPONENT SERVICE.

SRS-ECU

The check procedure is the same as before.

Front impact sensor

The check procedure is the same as before.

Seat belt with pre-tensioner

1. Check the seat belt for damage or deformation.

2. Check the pre-tensioner for cracks or deformation.

3. Check that the unit is installed correctly to the vehicle

body.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1595 of 1839

CHASSIS ELECTRICAL-Combination Meter CHASSIS ELECTRICAL-Combination Meter54A-25

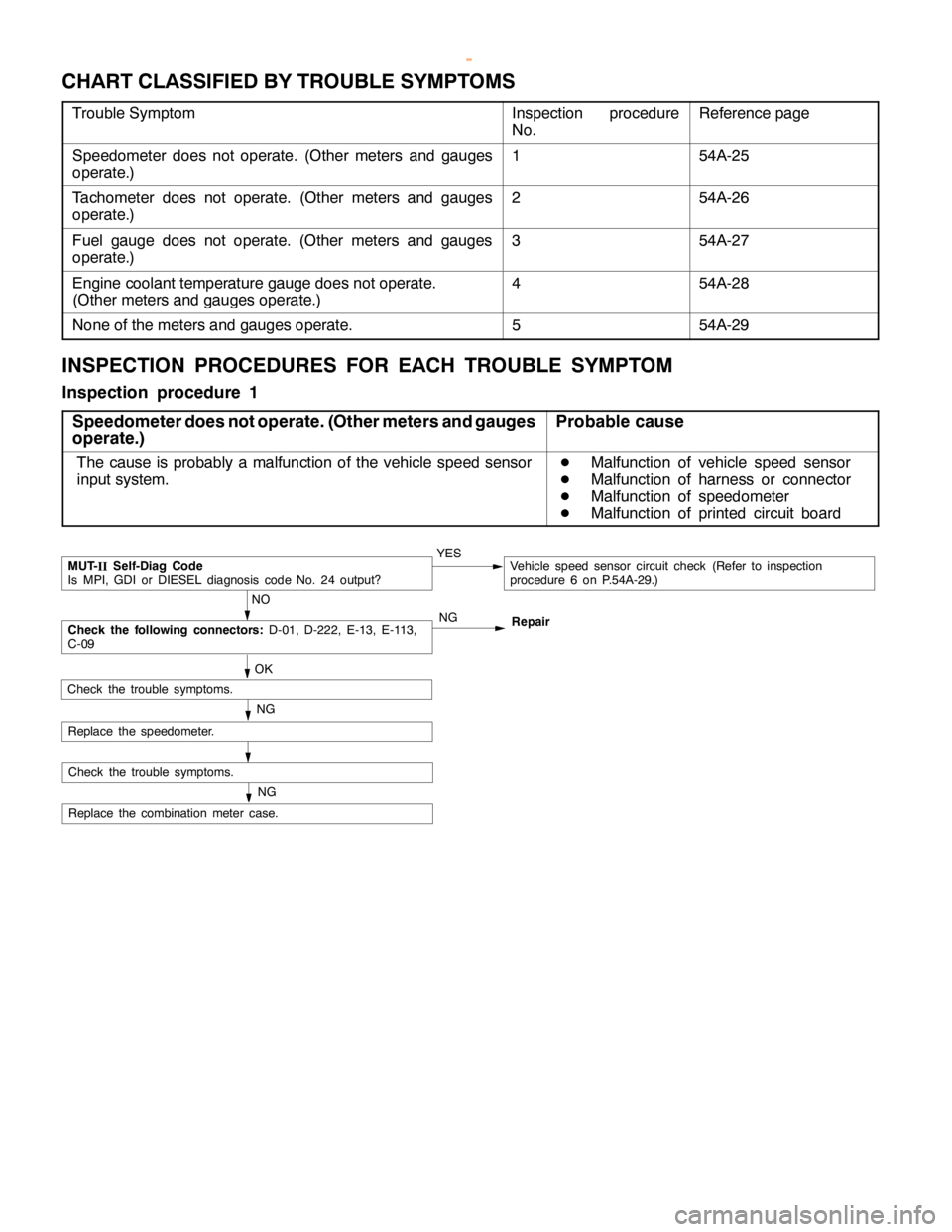

CHART CLASSIFIED BY TROUBLE SYMPTOMS

Trouble SymptomInspection procedure

No.Reference page

Speedometer does not operate. (Other meters and gauges

operate.)154A-25

Tachometer does not operate. (Other meters and gauges

operate.)254A-26

Fuel gauge does not operate. (Other meters and gauges

operate.)354A-27

Engine coolant temperature gauge does not operate.

(Other meters and gauges operate.)454A-28

None of the meters and gauges operate.554A-29

INSPECTION PROCEDURES FOR EACH TROUBLE SYMPTOM

Inspection procedure 1

Speedometer does not operate. (Other meters and gauges

operate.)

Probable cause

The cause is probably a malfunction of the vehicle speed sensor

input system.D

Malfunction of vehicle speed sensor

D

Malfunction of harness or connector

D

Malfunction of speedometer

D

Malfunction of printed circuit board

NO

MUT-

IISelf-Diag Code

Is MPI, GDI or DIESEL diagnosis code No. 24 output?YESVehicle speed sensor circuit check (Refer to inspection

procedure 6 on P.54A-29.)

OK

Replace the combination meter case.

NG

Check the trouble symptoms.

NGCheck the following connectors:D-01, D-222, E-13, E-113,

C-09Repair

NG

Check the trouble symptoms.

Replace the speedometer.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1599 of 1839

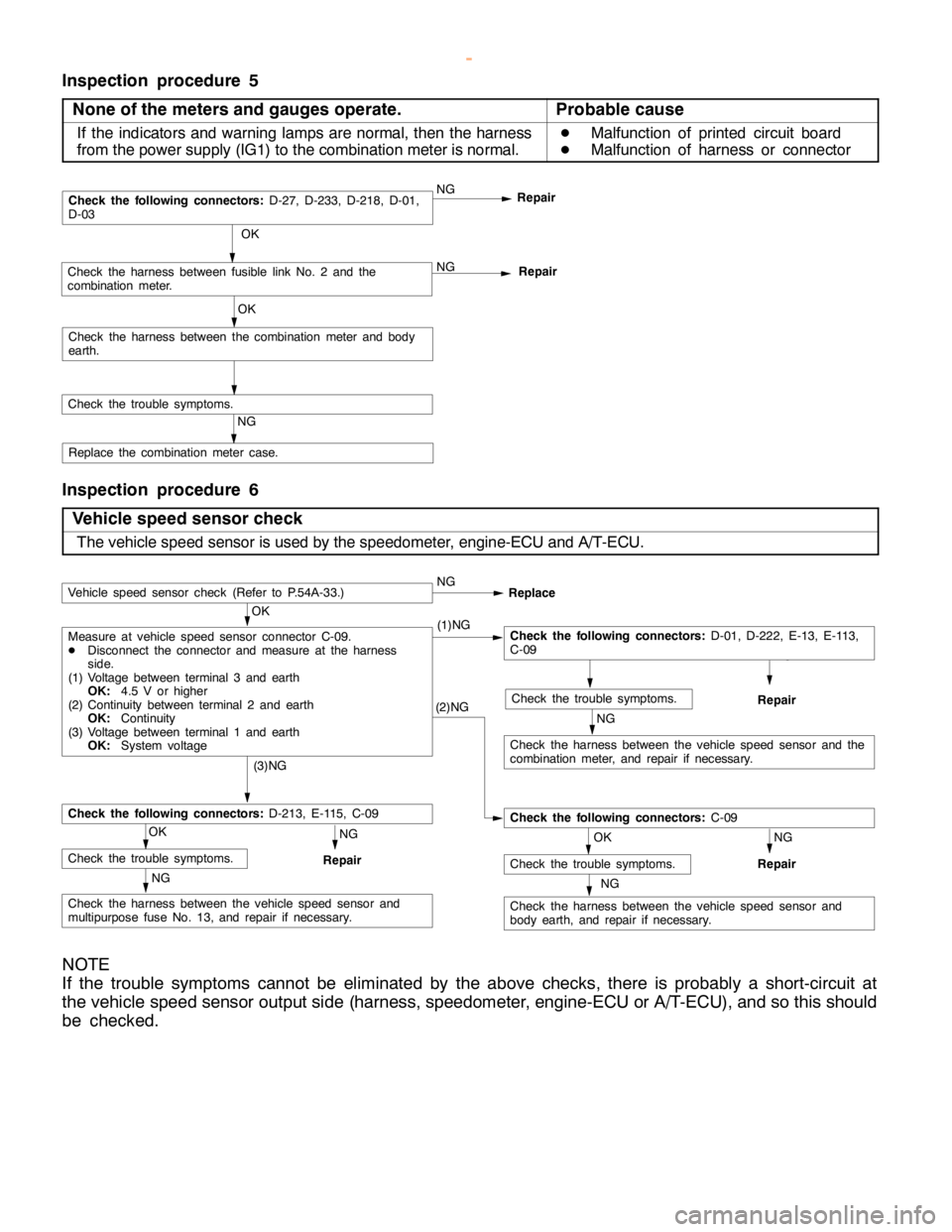

CHASSIS ELECTRICAL-Combination Meter54A-29

Inspection procedure 5

None of the meters and gauges operate.

Probable cause

If the indicators and warning lamps are normal, then the harness

from the power supply (IG1) to the combination meter is normal.D

Malfunction of printed circuit board

D

Malfunction of harness or connector

NGRepair NG

OK

Check the trouble symptoms.Repair

OK

Check the harness between the combination meter and body

earth.

Check the following connectors:D-27, D-233, D-218, D-01,

D-03

NG

Check the harness between fusible link No. 2 and the

combination meter.

Replace the combination meter case.

Inspection procedure 6

Vehicle speed sensor check

The vehicle speed sensor is used by the speedometer, engine-ECU and A/T-ECU.

NG

Check the harness between the vehicle speed sensor and

body earth, and repair if necessary.

RepairNG

OK

Check the trouble symptoms.NG

Check the harness between the vehicle speed sensor and

multipurpose fuse No. 13, and repair if necessary.

RepairNG

OK

Check the trouble symptoms.

Check the following connectors:D-213, E-115, C-09

(3)NG

(2)NG

Check the following connectors:C-09

NG

Check the harness between the vehicle speed sensor and the

combination meter, and repair if necessary.

RepairNG

OK

Check the trouble symptoms.

OK

Measure at vehicle speed sensor connector C-09.

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal 3 and earth

OK:4.5 V or higher

(2) Continuity between terminal 2 and earth

OK:Continuity

(3) Voltage between terminal 1 and earth

OK:System voltage(1)NGCheck the following connectors:D-01, D-222, E-13, E-113,

C-09

Vehicle speed sensor check (Refer to P.54A-33.)NG

Replace

NOTE

If the trouble symptoms cannot be eliminated by the above checks, there is probably a short-circuit at

the vehicle speed sensor output side (harness, speedometer, engine-ECU or A/T-ECU), and so this should

be checked.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk